#high-performance polymers

Explore tagged Tumblr posts

Text

Shaping Tomorrow: Insights into the Thermoplastic Polyester Engineering Resins Market

The thermoplastic polyester engineering resins market was USD 3,912.2 million in 2022, and it will touch USD 5,896.6 million, advancing at a 5.4% compound annual growth rate, by 2030. The growth of the industry is attributed to the increasing utilization of these resins for various nonstructural applications as they can be utilized without filters and are usually tougher and more ductile than…

View On WordPress

#advanced polymers#aerospace applications#automotive industry#engineering plastics#engineering resin market#high-performance polymers#Industrial applications#market growth#material innovation#plastic components#plastic industry#plastic materials#polymer engineering#resin manufacturing#sustainable materials#thermoplastic polyester engineering resins#thermoplastic properties#thermoplastic technology

0 notes

Text

Why Top Dispersing Agent Manufacturers Rely on AMPS Monomer for Advanced Industrial Applications

In the world of industrial chemistry, innovation drives efficiency and effectiveness. One such groundbreaking innovation is the widespread adoption of AMPS monomer—scientifically known as 2-acrylamido-2-methylpropane sulfonic acid—by leading dispersing agent manufacturers. This remarkable chemical compound has transformed the formulation of dispersing agents, offering unparalleled benefits across various industries. From water treatment to paints, coatings, and adhesives, AMPS chemical has proven itself indispensable in crafting advanced solutions for modern industrial challenges. For more information visit Why Top Dispersing Agent Manufacturers Rely on AMPS Monomer for Advanced Industrial Applications give tags

#“Dispersing Agent Manufacturers”#“AMPS Monomer”#“Advanced Industrial Applications”#“Industrial Chemicals”#“Polymer Chemistry”#“AMPS Applications”#“Chemical Dispersants”#“Industrial Additives”#“Dispersing Agents”#“Vinati Organics”#“Chemical Manufacturing”#“Polymer Industry”#“High-Performance Chemicals”

0 notes

Text

The Role of Glass Transition Temperature in Epoxy Molding Compounds

The Glass Transition Temperature (Tg) plays a pivotal role in determining the performance and durability of epoxy molding compounds. Tg refers to the temperature at which the polymer transitions from a rigid, glassy state to a more flexible, rubbery one. Understanding the impact of Tg on epoxy resin is crucial, particularly in high-temperature epoxy applications, as it directly influences the material's mechanical properties, thermal stability, and overall performance.

Epoxy Glass Transition Temperature and Its Significance

The Glass Transition Temperature in Epoxy is a defining factor in the epoxy resin molding process. As epoxy resins cure, their epoxy curing temperature influences how the resin bonds and behaves at different thermal conditions. If the Tg in epoxy resins is too low, the material may lose structural integrity when exposed to elevated temperatures. Conversely, a higher Tg results in improved thermal stability and makes the resin more resistant to heat and mechanical stress.

For industries relying on epoxy molding compounds, such as electronics and automotive, selecting the right epoxy resin performance can greatly affect product longevity and reliability. Understanding epoxy mold material properties and how they correlate with the Cure-Temperature-Glass-Transition can optimize the manufacturing process, ensuring that the final product meets the necessary performance criteria.

Optimizing Epoxy Tg for Better Results

In many applications, especially those involving high-performance environments, Epoxy Tg optimization is essential. Manufacturers can manipulate thermal properties of epoxy molding compounds to achieve the desired Tg, balancing flexibility and strength. The Impact of Tg on epoxy is especially evident in epoxy resin molding techniques, where fine-tuning the epoxy resin thermal stability allows for better control over product quality. The Tg and mechanical properties of epoxy are key to ensuring that the final molded parts exhibit durability and strength under varying conditions.

As an adhesive manufacturer in India, Kohesi Bond understands the critical importance of optimizing epoxy resin manufacturing process to deliver high-quality products. By mastering the control of epoxy bonding adhesive and its thermal properties, Kohesi Bond ensures superior performance across a wide range of applications.

For more information, visit Kohesi Bond's website!

#Epoxy Glass Transition Temperature#Glass Transition Temperature in Epoxy#Epoxy Molding Compounds#Epoxy Resin Performance#Epoxy Bonding Adhesive#Thermal Properties of Epoxy Molding Compounds#Epoxy Resin Thermal Stability#Epoxy Tg Optimization#Epoxy Resin Molding Techniques#Cure-Temperature-Glass-Transition#High-Temperature Epoxy Applications#Epoxy Tg and Mechanical Properties#Epoxy Resin Manufacturing Process#Impact of Tg on Epoxy#Epoxy Mold Material Properties#Adhesive Manufacturer in India#Epoxy Curing Temperature#Understanding Tg in Polymer Compounds#High-Performance Epoxy Applications#Epoxy Bonding Adhesive in India#Epoxy Resin Manufacturing

1 note

·

View note

Text

High-Performance Polymers Market Size, Share, Growth 2030

0 notes

Text

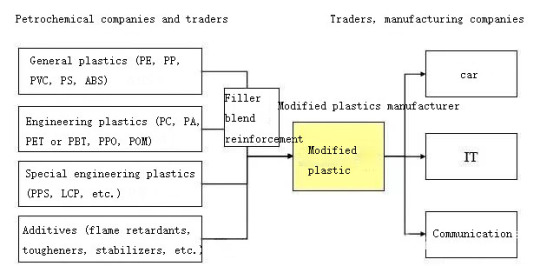

What are methods of plastic modification? What categories are there!

1. What is modified plastic? On the basis of general plastics and engineering plastics, through physical, chemical, mechanical and other methods, through filling, blending, reinforcement and other processing methods, performance of plastics is improved or functions are added, mechanical properties such as flame retardancy, strength, impact resistance, toughness of plastics are improved and…

View On WordPress

#Chemical modification#electronic appliances#Engineering plastic alloy#Engineering plasticization#engineering plastics#flame retardant#flame retardant color masterbatch#Flame retardant resin#Flame-retardant plastic products#Functional color masterbatch#Glass fiber reinforced thermoplastics#High performance of engineering plastics#modified plastic#Physical modification#Plastic alloy#plastic extender fillers#Plastic flame retardant#plastic materials#plastic modification#plastic modification technology#plastic products#polymer plastics#Reinforced and toughened resins#Reinforcement materials#reinforcing material#toughening agents

0 notes

Text

Experience the Difference with CERABOND 26: Where Quality Meets Simplicity in Floor Installation

Presenting CERABOND 26: the ultimate solution for hassle-free tile and stone installation on interior floors. This high-performance, ready-to-use polymer-based adhesive offers the following advantages:

Excellent adhesion properties

No soaking of tiles in water required

Single-component, ready-to-use material

No additional curing is needed

Great savings in labor, materials, and time

Extended open wet time for better workability

Suitable for various small format tiles and stones.

Experience the efficiency and convenience of CERABOND 26, revolutionizing your tile installation projects. Act now and elevate your interior floors to new levels of perfection!

E-mail us at: [email protected] or

contact us at 0984

#Experience the Difference with CERABOND 26: Where Quality Meets Simplicity in Floor Installation#Presenting CERABOND 26: the ultimate solution for hassle-free tile and stone installation on interior floors. This high-performance#ready-to-use polymer-based adhesive offers the following advantages:#Excellent adhesion properties#No soaking of tiles in water required#Single-component#ready-to-use material#No additional curing is needed#Great savings in labor#materials#and time#Extended open wet time for better workability#Suitable for various small format tiles and stones.#Experience the efficiency and convenience of CERABOND 26#revolutionizing your tile installation projects. Act now and elevate your interior floors to new levels of perfection!#E-mail us at: [email protected] or#contact us at 098404 80307#Cerachem#cerabond26#Constructionchemicals#Environmentalfriendly#innovation#Economical#WaterproofingAdvantages#Durability#Protection#BuildingMaterials#Tileadhesives#Jointfillers#Drymixmortars

0 notes

Text

Plastics underpin much of modern life—areas like medicine, technology, and food safety would be unrecognizable without plastics and their useful properties. However, the toughness of plastics, which is often desirable, also makes them a dangerous pollutant and difficult to recycle. The solution to this serious and growing problem is making plastics easier to recycle. In a study published in Chemical Science, researchers at Osaka University have found a way to make tough, high-performance polymers, the main component of plastics, that can be broken down easily and precisely into their component parts and recycled into materials that are like new.

Continue Reading.

137 notes

·

View notes

Text

New polymer design breaks the tradeoff between toughness and recyclability

Plastics underpin much of modern life—areas like medicine, technology, and food safety would be unrecognizable without plastics and their useful properties. However, the toughness of plastics, which is often desirable, also makes them a dangerous pollutant and difficult to recycle. The solution to this serious and growing problem is making plastics easier to recycle. In a study published in Chemical Science, researchers at Osaka University have found a way to make tough, high-performance polymers, the main component of plastics, that can be broken down easily and precisely into their component parts and recycled into materials that are like new. The main component of plastics are molecules called polymers, which are long chains of small repeating units called monomers. Current physical recycling simply reuses the polymers without breaking them down, and the recycled plastic is usually worse than the original.

Read more.

#Materials Science#Science#Polymers#Toughness#Recycling#Strength of materials#Plastics#Osaka University

25 notes

·

View notes

Text

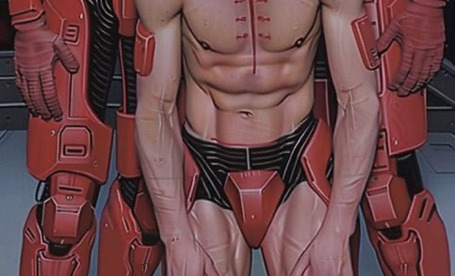

Standard Chastity/Underwear/Diaper Component of the Armor Suit

The Standard Chastity/Underwear/Diaper Component is an integral part of the advanced full-body armor suit worn by Cadets, Conscripts, Reservists and Intendurds in the Security Forces, Lifeguards, Paramedic Corps and Nursing Corps and training academies. This component is designed to ensure hygiene, control, and comfort for the wearer, whether used in conjunction with the full armor suit or as a standalone piece of equipment.

Design and Features

Material: Constructed from high-density, hypoallergenic synthetic fabrics, the component provides durability, flexibility, and breathability. The inner lining is coated with an antimicrobial layer to prevent infections and maintain cleanliness over extended periods.

Two-Chamber Design: The component features a specialized two-chamber design. One chamber securely encases the penis, while the other accommodates the scrotum, ensuring both are protected and kept in an optimal environment. This design helps in preventing chafing and maintaining hygiene, even during extended periods of use.

Chastity Mechanism: The chastity feature includes a secure, ergonomic cage designed to prevent unauthorized sexual activity. Made from lightweight, medical-grade polymers, it ensures comfort while maintaining strict control. The cage can be adjusted to fit various sizes and shapes, ensuring a snug but non-restrictive fit.

Waste Management: Integrated into the design is an advanced waste management system. This includes absorbent layers capable of handling urine and fecal matter, which are quickly wicked away to prevent discomfort and skin irritation. The component can be easily cleaned and sanitized, whether worn as part of the armor or independently.

Compatibility: The component seamlessly integrates with the full-body armor suit. Connection points allow for the automated removal and disposal of waste, managed by the suit’s internal systems. When worn independently, it functions efficiently, ensuring the wearer remains hygienic and comfortable.

Security and Monitoring: Equipped with biometric sensors, the component monitors the wearer’s physiological state, transmitting data to the suit’s central processing unit or an external monitoring system. This includes tracking hydration levels, waste excretion, arousal and other vital signs to ensure optimal health and performance.

Comfort and Fit: Designed for extended wear, the component features adjustable straps and a contoured design to prevent chafing and discomfort. The fit can be customized to each wearer, ensuring it remains secure without impeding movement or flexibility.

Usage and Maintenance

Usage: The Standard Chastity/Underwear/Diaper Component is designed for continuous use up to 7 days, with a standard operational period of 5 days. This duration ensures that cadets remain in peak condition during extended training exercises or deployments, without the need for frequent removal or maintenance.

Maintenance: Regular cleaning and sanitization are required to maintain its functionality and hygiene standards. The component can be detached from the suit and cleaned using standard military-grade cleaning agents. Replacement parts and servicing are available through authorized personnel and facilities.

The Standard Chastity/Underwear/Diaper Component exemplifies the blend of technological innovation and practical application, ensuring cadets maintain hygiene and comfort during their rigorous training and operational duties.

21 notes

·

View notes

Text

I’m a plumber. My father was a plumber, his father was a plumber, maybe his father was a plumber. We don’t know for sure. Grandpa was eaten by a tiger working at the zoo that one fateful afternoon, but this story isn’t about that. Where I work is a little company called Fel-Pro.

Maybe you’ve heard of Fel-Pro. You probably use their products. They’re one of the pre-eminent gasket manufacturers of the 21st century. Wherever there’s two tubes in your car that have to have a nice tight seal against each other, chances are Fel-Pro sells something to replace that seal. Are they as good as factory? Experts employed by Fel-Pro mumble and change the subject. Here’s the important thing: they have money, and some of that money goes to feed my kids by way of me fixing their office plumbing once in awhile.

Now, it’s not all roses. My plumber and custodian buddies who work in other companies, they say that people mostly stay out of their way while they’re working. Maybe once in awhile, they’ll get a Super Dad who chats a bit about power tools, or asks some basic questions about their toilet at home, or doesn’t want to take responsibility for having left a cast-iron shit in the tank and then trying to cram it through the manifold using thirty pounds of toilet paper. The usual stuff, right?

At Fel-Pro, it’s different. These motherfuckers have opinions about plumbing, as you would expect from their careers. As soon as they hear even the smallest pinhole leak, the bathroom is filled wall-to-wall with engineers, trying to figure out if it’s a gasket interface issue. Once they realize it isn’t, they start discussing ways to make it a gasket issue.

Anything that leaks is caused by inferior gasketry, even if the pipe itself has split in the middle. They could solve that by making a sort of very long, pipe-shaped grommet gasket to replace the pipe entirely. Yeah, yeah. And then a bunch of these pencil-necks start climbing over top of me to take measurements with their Mitutoyo digital calipers, and video-chat with the toilet manufacturer’s engineers just to call them rookie-level chumps. All the while, the bathroom is slowly filling with water up to our waists, the water-shutoff valve having been removed years before to prevent these eggheads from being tempted to fuck with it.

As any professional would, I started ignoring them, but it turns out that showed up on my performance review. Everyone at Fel-Pro has to be vigilant against leaks, said my boss, a dour expression on his face. He thrust a diagram on how to apply the proper torque pattern to the wax seal of a toilet.

Don’t get me started on how angry they get when they see me using hardware-store silicone bathroom caulking to solve the problem. That’s not the ideal thermal interface, they moan, and start bringing out all kinds of high-zoot polymer compounds, emblazoned with safety warnings in Chinese. Those make the room spin pretty good, and sometimes they get worryingly hot on application, but I must admit they work a treat. One engineer brought me something he stole from a tour he took of NASA and told me to seal a leaking air conditioner drain with it. Well, mission accomplished, buddy: Jim, the custodian I share an office with, had to use a plasma cutter to remove it last week.

It’s gotten so bad that I’ve started only doing plumbing repairs in the middle of the night, when the engineers are likely to be at home, berating their spouses for daring to bring Scotch tape into their home.

176 notes

·

View notes

Text

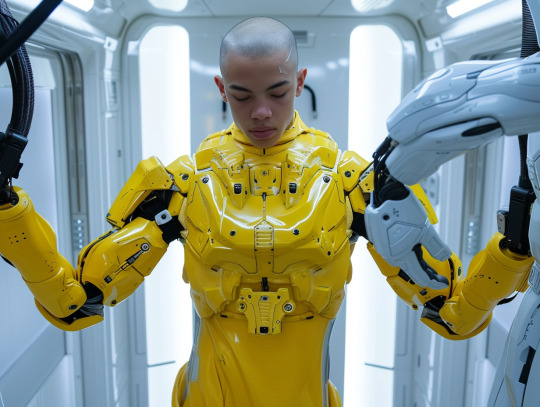

It's so easy to fall down the rabbit hole, they say. To get so comfortable with chipping chrome that you feel more at home in metal than meat.

You told yourself you were different- that you wouldn't get sucked in like the rest, that you could succeed with only the bare minimum, the personal link and the basic neural controller they chipped you with in high school.

Then something happened at the factory.

You were tired, dead on your feet after a 16 hour shift, and it only took a single moment of innatention for a malfunctioning belt to grab a stray thread on your gloves- they'd been fraying for ages now, but you couldn't afford new ones.

In the end, they say you'll live, but your record as nearly full 'ganic is broken, shattered by a shiny new prosthesis in place of your right arm. But, it's not all bad. Once you get used to it, it's actually pretty handy, stronger, steadier, and more precise than your hand of flesh, and after all, it's only one hand, right?

They fired you from your job at the factory. Cited poor performance, claimed the accident had nothing to do with it, but you know it's bullshit. It always is. Luckily, you weren't out of work too long. A guy you went to high school with says he could use you, says you won't have to do anything, just stand there with your new metal arm and an empty pistol and look tough. You believe him, after all, people have always been a little wary around you.

After a few more of those jobs, you've got more money than you've ever seen in your life. You're not rich, by any means, but for the first time in your short life, you don't have to choose between rent and food this week.

Eventually, one of the jobs goes sour. You don't even really remember how it happened, just that in-between one second and the next, people pulled out guns and started screaming, and for a split second, you truly believe that you will not see tomorrow.

In the end, nothing comes of it, just tensions running high and idiots with more iron than they can handle. But you can't stop the scene from running through your mind, can't stop thinking about how you almost didn't wake up. So, with shame in your heart, you find yourself at one of the underground clinics- the kind that sells chrome to those in the business of making others hurt.

At first? It was just some subdermal armor, an insurance policy in case things went nasty again. Then, after a botched job that leads to actual bullets flying, you get razor-sharp retractable polymer claws in your fingertips, so you'll never be unprotected again. Yet as you're strapped into the chair to lose a second arm, this time entirely by choice? You realize something. Every time you buy another piece of chrome, every time you sign away a little more meat and gain a little bit of metal, it gets a bit easier.

And worst of all? You can't find it in yourself to be afraid of that.

You feel confident, you feel powerful. Now, with your matching set of hot-rod red cyberarms, you're getting jobs as actual muscle now, working the door at clubs, working security for... less than reputable clients around town, and you're rolling in more scratch than you really know what to do with. So, when you bruise a collarbone lifting an armored car during a job, it only seems natural to chip shoulder replacements. After all, your arms were more than strong enough. It was the meat that was the problem. The meat has always been the problem.

You've been doing this for two years now, and tonight? You're ready for your first big score. A truck, loaded with enough money to set you up for the rest of your life (or maybe buy that FBC kit you've been catching yourself eyeing in the clinic's catalogue and two months of immunoblockers.) Over the past year, You've become more metal than meat, circulatory system abandoned for superior pumps, lungs forsaken for more efficient blood oxygenators, and limbs replaced and upgraded 10 times over, all in the pursuit of more.

You told yourself you were different- that you wouldn't get sucked in like the rest.

You were wrong.

10 notes

·

View notes

Text

The Auruk

Homeworld: Jallmina

Gravity: 36 m/s

Description

Jallmina is a colossal rocky planet which is tidally locked to small red dwarfs. The planet does not rotate relative to its star, instead the same area is always facing the sun with the planet having a distinct day side of perpetual light and a night side of ever present darkness. It is a world of amazing diversity with vast deserts, mysterious twilight forests, and night cloaked tundras. Despite the high gravity, organisms on Jallmina reach mythical size and make ready use of the planet’s abundance of natural resources to grow to immense size in its competitive and diverse ecosystems. While the Auruk’s impressive size and strength may be surprising to other species, on their world they are simply one of many giants and even still, they are dwarfed by the largest of beasts.

Average lifespan: 800 years

Age of adulthood: 60 years

Weight: 10-16 tons

Size: 13-15 feet tall, 40-45 feet long

Biology:

The Auruk are a people who possess immense size and strength even for their size. Their strong bones are made of magnetite and their polymer muscles give them impressive speed. Their twelve sturdy legs as well as the sides and top of their body have a thick shell which is usually dark purple in corporation while the softer parts of their body like their face and underbelly are pink. They have three compound eyes which allow them to see and perceive depth quite well. This enhanced depth perception is very useful as Auruk use their four 10-14 foot long oral tentacles to experience the world. Despite their thinness these possess high dexterity and strength and allow them to manipulate objects with precision while also being able to lift and throw vehicles should the need arise.

While their vision is good, Auruk usually rely on the smell to navigate the world as well as a hidden sense in their feet. Lacking external ears, auruk are deaf by traditional definition in a similar way to snakes and spiders. Instead, organs in their feet allow them to detect and produce infrasonic vibrations which travel through the ground like those utilized by elephants.

Communication

Auruk mainly communicate via infrasonic rumbles which they produce in rapid succession to make a morse code-esque language that can allow adults to communicate with each other up to 30 miles away without any technological aid. At closer ranges however, Auruk can also rhythmically strike the ground with their feet to produce noise. This is known as “far-speak” and “short-speak” with short speaking usually being used for communication at close ranges and is considered a more intimate thing which is better able to communicate nuances ideas.

When communicating with other species auruk almost always use sign language which they can easily perform their tentacles.

History

The ability to communicate over such long distances and share information made the auruk’s history much more peaceful and cooperative than those of other species. Being large and slow reproducing herbivores, conflict always resulted in losses that were simply not sustainable so the march of the Auruk’s civilization was slow and steady. Much of this progress was tempered by something the auruk didn’t understand at first. Jallmina has an odd distribution of natural resources, lacking large concentrations of accessible metal or fossil fuels.

It was not until their first explorations into paleontology that the auruk realized they were not the first sophonts on their word. Another species, commonly called “the first ones” lived on their world roughly 30 million years ago. They mined much of the planet’s resources and used most of its fossil fuels before dying out to war and climatic collapse. Knowledge of their existence and failings informed much of the slow progress of the Auruk who were unified as a people early on in their history. They knew to look before they lept and be wise to avoid the mistakes of their progenitors.

In the Galaxy

The Auruk are a somewhat enigmatic species who are generally rare beyond Jallmina and its close settlements. But over the course of their long lives, many auruk will travel the galaxy to see its wonders before returning home. They see cultures rise and fall, ideas and people stream past them. This tends to give them a longer term perspective which leads people to see them as wise individuals and traveling auruk are usually open to speak to others to share their ideas and learn from the world around them.

The Auruk’s size isn’t much of a barrier as in the known galaxy most public spaces are built to accommodate the largest species. This design is integral to most pact architecture as the auruk are the pact’s founding species, although now they are one of many.

#worldbuilding#specevo#scifi#scifiart#speculative biology#sci fi and fantasy#speculative evolution#speculative zoology

16 notes

·

View notes

Note

Your analysis is very informative and interesting!!!

I too am looking forward to seeing what the imola upgrades bring.

Correct me if I'm wrong but did ferrari not say they were going to upgrade the floor in miami? Did I hear wrong or plans changed or smth?

Also dis the track temperature in miami have a great impact on ferrari tyre performance? And will imola being colder bring issues like china?

I hope I don't come across as irritating i just really appreciate your takes😅

Hi anon! You're definitely not irritating! I love receiving asks and being able to discuss/rant about all kinds of f1 related stuff. You're very welcome here! And I'm sorry that my answer took a while :)

Floor in Miami:

Yes. After the team's struggles in China they made the decision to bring the floor early, hoping that it might solve their issues with tyre warming. However, a sprint weekend isn't ideal for bringing upgrades and the tyre data from the sim made Ferrari confident enough to revert to the original Imola plan.

Track temperature and tyre performance:

The reported issue in China was that the Ferrari drivers spent about 20 laps (of a 35/39 lap stint) trying to get heat into their hard tyres (track temperatures slightly below 30°c), but when they finally got them into the right window temperature wise they were worn down/past their peak and gave no real performance gains. The mediums were better, but not great.

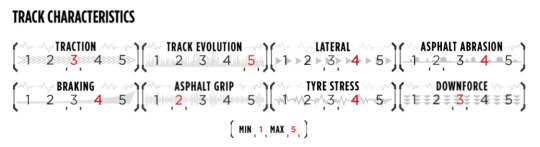

It's necessary here to make the difference clear between tyre degradation and tyre wear. Degradation is caused by the rubber gradually losing its grippy properties as the polymers break down or deform after continuous heat cycles, which makes them slower as they have less grip. Tyre wear can be better explained as damage or deterioration of the tyre itself. The wear is usually visible through graining or blistering. Degradation can often lead to tyre wear, as sliding and wheel spin caused by low grip will cause more deterioration.

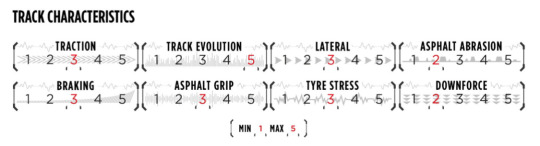

Shanghai is generally a track that is quite harsh on the tyres: asphalt abrasion is very high (a high level of abrasion tends to lead to higher tyre wear), as is the overall tyre stress, the braking and the lateral forces caused by the track layout. As a mouldy cherry on top, asphalt grip is very low, and even lower than usual because of the low temperatures.

This means tyres get worn down quite quickly, especially if they are cold like Ferrari's were. Most teams were therefore on a 2-3 stop strategy, with the only exception being Ferrari and Norris on a 1 stop

Track characteristics of Shanghai:

Miami however is much kinder on the tyres: asphalt abrasion is low, and stress, braking, lateral and grip are all at a medium level. With the high temperatures (track temperatures of 40-45°c) Ferrari had little problem getting the tyres into the right window. Miami was a 1 stop for almost everyone. So to answer part of your question, yes. Compared to China the temperatures and track characteristics of Miami did have a big positive impact on Ferrari's tyre performance (most obvious in qualifying), but at the same time none of the other teams were disadvantaged by it so Ferrari didn't gain anything beyond fixing their own issues.

Track characteristics of Miami:

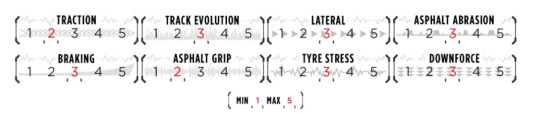

Imola is predicted to be colder than Miami but warmer than Shanghai at around 20-25°c air temperature, so I'd estimate the track temperatures to be somewhere around 30-35°c (but don't quote me on this lol). Even with the current version of the sf-24 this wouldn't be a repeat of China. While asphalt grip is the same, the asphalt abrasion, lateral forces, traction and tyre stress are all lower than Shanghai which will cause less tyre wear. The downforce of Imola is also a bit higher, which helps put more temperature into the tyres. The point I'm trying to make is that yes, temperature definitely matters, but what made China such a shit show was an unfortunate combination of temperature, track characteristics and bad setup choices by Ferrari. This is unlikely to happen in Imola.

But most importantly, Ferrari will be introducing their first upgrade package next race. Of course, this package isn't centered around the tyre heating issues as these were discovered while the development was already underway, but they've had many weeks now to either tweak it or to include upgrades that will target this issue. Regardless, the floor will most likely at the very least improve it, so I wouldn't be too worried about the temperatures at Imola! Hope this answers your question!

Track characteristics of Imola:

12 notes

·

View notes

Text

Mouse Anti Slip Grip Tape Compatible with Logitech G PRO X Superlight 2 DEX and Logitech G PRO 2 Lightspeed

✔ [UNRIVALED QUALITY] - Ultra-thin 0.5mm high-quality polymer material does not affect the touch feeling, superior water absorption performance. The new diamond texture design improves the friction coefficient. It will not slip even if your mouse strenuous move and improve the gaming experience.✨

✔ [PALM SWEAT ABSORPTION] - Comprehensive coverage, the new design of sweat absorption anti-slip tapes in the palm (free combination and paste according to your needs). Effectively improve your palm sweating troubles, keep your palm dry and improve comfort!If you are always sweating on your hands, buy it don't hesitate!❤

✔ [SPECIALLY CALIBATED SIZE] - Just size, specially designed for gaming mouse, pre-cut molded with high precision. The customization of our products are based on actual mouse to provide consumers with the best experience.🎉

✔ [EASY TO APPLY] - Self-Adhesive Design, the anti-slip tapes are all pre-cut. You just need to tear off and paste it simply when you use it, the American 3M adhesive is used to ensure strong adhesion and without residue after tearing off.🎊

3 notes

·

View notes

Text

Experience the Thrill with the Bohan MPX and TianGong TG F4 Electric Gel Blaster

Gel blasters have surged in popularity among enthusiasts seeking an adrenaline-pumping alternative to airsoft and paintball. If you’re looking for a game-changing gel blaster, the Bohan MPX and TianGong TG F4 Electric Gel Blaster are top contenders. These innovative models promise high performance, reliability, and a lot of fun for both seasoned players and newcomers.

Bohan MPX: Compact Powerhouse for Tactical Play The Bohan MPX stands out for its sleek design, lightweight build, and exceptional accuracy. Perfect for fast-paced tactical scenarios, this gel blaster delivers a seamless shooting experience. Its compact size ensures easy maneuverability in tight spaces, making it ideal for competitive matches.

What sets the Bohan MPX apart is its precision engineering. Its high-performance gearbox ensures consistent firing speeds, while the durable construction guarantees it can withstand intense gameplay. Whether you're defending a base or launching a surprise attack, the Bohan MPX will elevate your performance.

TianGong TG F4 Electric Gel Blaster – 220 FPS Semi & Full Auto Rifle For those who crave versatility and power, the TianGong TG F4 Electric Gel Blaster is a game-changer. With a firing velocity of 220 FPS (feet per second), this semi and full-auto rifle is built for domination on the field.

youtube

The TG F4 features an ergonomic design for maximum comfort during prolonged use. Its semi-auto mode is perfect for precise shots, while the full-auto setting lets you unleash rapid-fire excitement. The electric mechanism ensures a smooth and efficient firing cycle, minimizing downtime between shots.

Another highlight of the TG F4 is its rechargeable battery, offering extended playtime without compromising performance. Its durable polymer construction ensures it can endure the rigors of intense gameplay, making it a reliable choice for any skirmish.

Choose Your Ultimate Gel Blaster Whether you prefer the agility of the Bohan MPX or the raw power of the TianGong TG F4, both models deliver unparalleled performance. They’re perfect for casual backyard battles or high-stakes competitive events.

When choosing a gel blaster, consider your playstyle and priorities. If precision and mobility are key, the Bohan MPX is an excellent choice. For players who value power and versatility, the TianGong TG F4 will not disappoint.

Gear up, hit the field, and let the adventure begin!

2 notes

·

View notes

Text

Key Design Considerations for Pantograph Support Insulators in High-Speed Rail Systems

In the realm of high-speed rail systems, every component plays a crucial role in ensuring safe and efficient operations. Among these components, pantograph support insulators stand out as critical elements that facilitate the seamless transmission of power from overhead lines to the train's electrical system. As a leading pantograph insulator manufacturer in India, Radiant Enterprises recognizes the importance of meticulous design considerations in crafting reliable and durable insulators. In this blog post, we'll explore the key design considerations essential for pantograph support insulators in 25 KV high-speed rail systems, shedding light on Radiant Enterprises' commitment to excellence in manufacturing.

Understanding Pantograph Support Insulators

Pantograph support insulators are integral components of the overhead electrification system in high-speed rail networks. These insulators provide electrical isolation and mechanical support for the pantograph, which is the apparatus mounted on the train's roof responsible for collecting electricity from the overhead wires (catenary). In 25 KV high-speed rail systems, where trains operate at exceptionally high speeds, the performance and reliability of pantograph support insulators are paramount.

Design Considerations for Pantograph Support Insulators

Material Selection: The choice of materials significantly influences the performance and longevity of pantograph support insulators. At Radiant Enterprises, we utilize high-quality, durable materials such as silicone rubber or composite polymers that exhibit excellent electrical insulation properties, mechanical strength, and resistance to environmental factors such as UV radiation, pollution, and temperature variations.

2. Electrical Insulation: Ensuring reliable electrical insulation is paramount to prevent electrical arcing and ensure the safe transmission of power. Our pantograph support insulators are engineered to withstand high voltage levels (25 KV) and exhibit low electrical conductivity to minimize power losses and mitigate the risk of electrical faults.

3. Mechanical Strength: Pantograph support insulators are subjected to mechanical stresses induced by the pantograph's movement and external forces such as wind loads and vibrations. Therefore, our insulators undergo rigorous mechanical testing to ensure they can withstand these forces without deformation or failure, ensuring uninterrupted operation and minimal maintenance requirements.

4. Corrosion Resistance: In outdoor environments exposed to moisture, pollution, and corrosive agents, corrosion resistance is essential to maintain the structural integrity of pantograph support insulators over their operational lifespan. Our insulators are engineered with corrosion-resistant materials and undergo surface treatments to enhance their resistance to rust and degradation, ensuring long-term reliability and performance.

5. Dimensional Accuracy: Precision engineering is critical to ensure proper fit and alignment of pantograph support insulators with the overhead wires and the train's pantograph. Our insulators are manufactured with tight tolerances and undergo strict quality control measures to guarantee dimensional accuracy and compatibility with the rail infrastructure, minimizing installation challenges and optimizing performance.

6. UV Stability: Exposure to ultraviolet (UV) radiation can degrade insulator materials over time, compromising their electrical and mechanical properties. Therefore, our pantograph support insulators are formulated with UV-stabilized materials that withstand prolonged exposure to sunlight without degradation, ensuring reliable performance and longevity in outdoor applications.

Radiant Enterprises: Your Trusted Pantograph Insulator Manufacturer in India

As a leading manufacturer of pantograph support insulators in India, Radiant Enterprises is committed to delivering superior quality products that meet the stringent requirements of high-speed rail systems. Our state-of-the-art manufacturing facilities, coupled with a team of experienced engineers and quality assurance experts, enable us to design and produce pantograph insulators that excel in performance, reliability, and durability.

Conclusion

In the dynamic world of high-speed rail systems, the reliability and performance of pantograph support insulators are critical for ensuring safe and efficient operations. By adhering to meticulous design considerations such as material selection, electrical insulation, mechanical strength, corrosion resistance, dimensional accuracy, and UV stability, manufacturers like Radiant Enterprises can deliver pantograph insulators that meet the demanding requirements of 25 KV high-speed rail systems. As a trusted pantograph insulator manufacturer in India, Radiant Enterprises is committed to providing innovative solutions that contribute to the advancement of railway electrification technology and the seamless operation of high-speed rail networks.

#Customised epoxy insulators manufacturer in India#Pantograph insulator manufacturer in India#25 KV pantograph support insulators manufacturers in India#25 KV roof busbar support insulator manufacturers in India#Solid third rail insulator#Customized Powerrail Epoxy Insulators#Epoxy Insulators#Epoxy insulator manufacturers in India

7 notes

·

View notes