#Epoxy Bonding Adhesive

Explore tagged Tumblr posts

Text

The Role of Glass Transition Temperature in Epoxy Molding Compounds

The Glass Transition Temperature (Tg) plays a pivotal role in determining the performance and durability of epoxy molding compounds. Tg refers to the temperature at which the polymer transitions from a rigid, glassy state to a more flexible, rubbery one. Understanding the impact of Tg on epoxy resin is crucial, particularly in high-temperature epoxy applications, as it directly influences the material's mechanical properties, thermal stability, and overall performance.

Epoxy Glass Transition Temperature and Its Significance

The Glass Transition Temperature in Epoxy is a defining factor in the epoxy resin molding process. As epoxy resins cure, their epoxy curing temperature influences how the resin bonds and behaves at different thermal conditions. If the Tg in epoxy resins is too low, the material may lose structural integrity when exposed to elevated temperatures. Conversely, a higher Tg results in improved thermal stability and makes the resin more resistant to heat and mechanical stress.

For industries relying on epoxy molding compounds, such as electronics and automotive, selecting the right epoxy resin performance can greatly affect product longevity and reliability. Understanding epoxy mold material properties and how they correlate with the Cure-Temperature-Glass-Transition can optimize the manufacturing process, ensuring that the final product meets the necessary performance criteria.

Optimizing Epoxy Tg for Better Results

In many applications, especially those involving high-performance environments, Epoxy Tg optimization is essential. Manufacturers can manipulate thermal properties of epoxy molding compounds to achieve the desired Tg, balancing flexibility and strength. The Impact of Tg on epoxy is especially evident in epoxy resin molding techniques, where fine-tuning the epoxy resin thermal stability allows for better control over product quality. The Tg and mechanical properties of epoxy are key to ensuring that the final molded parts exhibit durability and strength under varying conditions.

As an adhesive manufacturer in India, Kohesi Bond understands the critical importance of optimizing epoxy resin manufacturing process to deliver high-quality products. By mastering the control of epoxy bonding adhesive and its thermal properties, Kohesi Bond ensures superior performance across a wide range of applications.

For more information, visit Kohesi Bond's website!

#Epoxy Glass Transition Temperature#Glass Transition Temperature in Epoxy#Epoxy Molding Compounds#Epoxy Resin Performance#Epoxy Bonding Adhesive#Thermal Properties of Epoxy Molding Compounds#Epoxy Resin Thermal Stability#Epoxy Tg Optimization#Epoxy Resin Molding Techniques#Cure-Temperature-Glass-Transition#High-Temperature Epoxy Applications#Epoxy Tg and Mechanical Properties#Epoxy Resin Manufacturing Process#Impact of Tg on Epoxy#Epoxy Mold Material Properties#Adhesive Manufacturer in India#Epoxy Curing Temperature#Understanding Tg in Polymer Compounds#High-Performance Epoxy Applications#Epoxy Bonding Adhesive in India#Epoxy Resin Manufacturing

1 note

·

View note

Text

Choosing the right adhesive for industrial applications is essential for project success. Learn about different adhesive types, key selection factors, and best practices to ensure efficiency and durability. Explore A-Gas Electronic Materials' expert advice and high-quality solutions.

#industrial adhesives#epoxy adhesives#polyurethane adhesives#acrylic adhesives#silicone adhesives#cyanoacrylate adhesives#material compatibility#bonding strength#curing time#adhesive application methods#health and safety in adhesives#A-Gas Electronic Materials#UK industrial adhesives#industrial bonding solutions

0 notes

Text

Bonding Excellence: Navigating Trends in the Epoxy Adhesive Market

Adhesives are essential products that are often overlooked. They’re noticed, until they fail. If your supports aren’t correctly fused, it could bring about disjointed parts, damaged equipment, and worn-out piping systems.

So, this blog has the ins and outs of epoxy adhesives, which can help you secure the pipe supports with confidence.

What Is an Epoxy Adhesive?

From time-to-time epoxy adhesives are confused with bonding products like glue. However, they’re far more complex than most adhesives. These are often called structural adhesives These terms make their role clearer: They’re high-performance adhesives meant for applications calling for powerful bonding, such as aircraft, automobiles, aerospace technology, or heavy process piping systems.

Uses of Epoxy Adhesives Coming to process piping systems, the epoxy adhesives have a vital role to play. These systems frequently require to join unlike materials together, like composite pipe shoes and metal piping. Besides, adhesives need to hold structures together in heavy vibrations, high pressure, and corrosive environments.

An area where epoxy adhesives have advantage is when you’re including pipe supports like wear pads, pipe shoes, and Flat Plates. That’s since this mixture enables to install without welding.

Benefits of Epoxy Adhesives? • By safeguarding pipes or adding wear pads to the system, raw piping can be insulated. Suddenly, you’ve protected pipes from metal-on-metal contact deprived of the high cost of specialized labor. Also, by eliminating welding, you’ll be evading susceptible spots requiring special heat treatments. • These pipe supports can increase the life of the systems, need to be held together. These adhesives work pretty well since they are sturdy and can stand extreme environments. • An epoxy can also work as a sealant filling open gaps. This guards pipes and supports from corrosion.

Different Kinds of Epoxy Adhesives There are numerous epoxy adhesives, but they can be split into two one-component and two-component

One-Component Adhesives These more often than not come as a single paste. Though, the name can deceive a few. Though they come as only a single physical substance, they still require external elements to start the curing process. That means they require moisture, heat treatment, or special lighting for bonding.

Two-Component Adhesives These require you to blend two elements. When applied properly, the outcome is a powerful bond. Though, since two-part adhesives need mixing, there’s the likelihood for a human error.

What’s the Solution? If you desire to get the paybacks of a two-component adhesive without mixing the right ratio or getting it on the skin, use a static applicator. This loads onto a standard epoxy cartridge and brings a two-part epoxy in a flawless mixing ratio, saving the mess and guesswork that from time to time come with physically mixing two-component epoxies.

Due to the increasing demand for these adhesives in numerous industries, the total value of the epoxy adhesives will reach $13,484 million by 2030.

#epoxy adhesive#adhesive technology#market trends#industrial applications#construction industry#global market outlook#bonding solutions#market dynamics#epoxy resin#research and development#composite materials#market growth factors#aerospace applications

0 notes

Text

Strong and Durable: Exploring the Growth of the Epoxy Adhesive Market

Adhesives are essential products that are often overlooked. They’re noticed, until they fail. If your supports aren’t correctly fused, it could bring about disjointed parts, damaged equipment, and worn-out piping systems. So, this blog has the ins and outs of epoxy adhesives, which can help you secure the pipe supports with confidence. What Is an Epoxy Adhesive? From time-to-time epoxy…

View On WordPress

#Aerospace#Automotive#Bonding#Construction#Electronics#Epoxy Adhesive Market#Hardener#Industrial#Resin

0 notes

Text

How to paste wear resistant alumina ceramic sheet, it's time to reveal the answer!

Email: [email protected]

phone/whatsapp/telegram: +8615550321612

1 note

·

View note

Text

EPOXYSHİNE - DRAGON+ (3)

Epoxy floor coating is not just a practical choice for enhancing the durability of your flooring; it's also a stylish solution that can transform any space. Whether you're a homeowner looking to revamp your garage or a business owner seeking reliable commercial flooring solutions, understanding the benefits of epoxy will help you make informed decisions. As you search for "floor polishing near me," consider how an expertly applied epoxy coating can elevate your interiors while providing a long-lasting finish.

Epoxy Floor Coating

Epoxy floor coating is a highly durable and resilient flooring solution that has gained popularity in both residential and commercial spaces. This type of coating is made from a combination of resin and hardener, creating a strong bond when applied to existing concrete surfaces. The result is a seamless surface that can withstand heavy foot traffic, chemicals, and abrasions.

One of the major benefits of epoxy floor coating is its versatility. It can be customized in various colors and finishes, including high-gloss and matte textures. This means that property owners can choose a look that complements their interior design while still providing the durability they require. Additionally, the smooth finish of epoxy makes it easy to clean and maintain, which is particularly advantageous in commercial settings.

Furthermore, the installation process for epoxy floor coating is relatively quick, often completed within a few days. However, it’s essential to hire professionals who have the expertise and equipment to ensure a flawless application. The right team will properly prepare the surface, allowing for optimal adhesion and longevity of the coating.

Floor Polishing Near Me

When searching for floor polishing near me, it's essential to find a service that not only meets your expectations but also understands the unique needs of your flooring. Professional floor polishing can revitalize old surfaces, restoring their shine and luster while protecting them from future wear and tear.

Many local companies offer specialized services in floor polishing that cater to various materials, including hardwood, tile, and concrete. A quick search in your area will yield numerous options, allowing you to compare prices, services, and customer reviews to find the best fit for your needs.

Additionally, hiring professionals for floor polishing ensures that the job is done correctly and efficiently. They use advanced equipment and high-quality products that not only enhance the appearance of your floors but also extend their lifespan. So, don't hesitate to reac

Commercial Flooring Solutions

Commercial flooring solutions are essential for businesses seeking to enhance their aesthetic appeal while also ensuring durability and functionality. The choice of flooring can greatly influence the overall atmosphere of a commercial space, leading to improved employee morale and customer satisfaction.

Among the various options available, epoxy floor coatings stand out due to their seamless finish and resistance to heavy foot traffic. These coatings not only provide a sleek look but also protect the underlying surface from wear and tear, making them ideal for warehouses, retail spaces, and industrial environments.

Moreover, businesses often explore additional options such as vinyl flooring, carpet tiles, and laminate surfaces to meet specific needs. Each of these materials offers unique advantages, allowing business owners to choose the most suitable flooring solution that aligns with their operational demands and aesthetic preferences.

Metallic Epoxy Floor

A metallic epoxy floor offers a stunning visual appeal that enhances the aesthetic of any space. The reflective properties of the metallic pigments create a unique look, resulting in a three-dimensional effect that can mimic a variety of surfaces, such as water, marble, or even molten metal. This type of flooring is especially popular in modern homes, showrooms, and commercial spaces, providing an eye-catching yet durable surface.

One of the significant advantages of a metallic epoxy floor is its durability. This flooring solution is resistant to stains, chemicals, and impacts, making it ideal for high-traffic areas. Additionally, it is easy to clean and maintain, which means that business owners and homeowners can save time and resources. The seamless nature of epoxy flooring also contributes to a hygienic environment, especially in spaces like hospitals or laboratories.

Installing a metallic epoxy floor can be a customized process, allowing property owners to choose their preferred colors and patterns. Whether you’re looking for a sleek, industrial look or a vibrant, artistic finish, this flooring solution can be tailored to meet your unique vision. By consulting with professionals, you can ensure that your metallic epoxy floor is installed correctly and maximizes its longevity and beauty.

598 notes

·

View notes

Text

I'm extracting out (and updating) my current hypothesis about what happened with the Titan submersible from my extremely large commentary post (link to its current iteration: https://www.tumblr.com/jackalgirl/762730158416379904/only-one-1-day-behind-now-just-got-done-with?source=share -- I'm very much behind on watching and probably won't catch up until the weekend.

I've attached images, above, which I've taken from Dr. Kramer's presentation on behalf of the NTSB (link to original presentation here: https://media.defense.gov/2024/Sep/25/2003553505/-1/-1/0/CG-107%20NTSB%20TITAN%20MATERIAL%20ANALYSIS.PDF_REDACTED.PDF). Please note that the red circle and "Group 4" annotation on the slide labelled "Strain Gage Response" are from me (they're not in the original presentation).

If I'm reading this correctly (and I might not be), it looks like that at the time of the loud bang, there was a marked increase in strain at the sensor point in the axial (longitudinal, or along the forward/aft axis of the vehicle) direction, and a slightly smaller (but still marked) decrease in strain in the radial (around the right/left, or "starboard/port" as we would say in sailing, circumference of the vehicle).

The other two slides are Dr. Kramer's own visualizations: instead of plotting depth/strain over time as OceanGate had done, he simply focused on depth vs. strain. You can see the difference pre-"loud bang" (which happened on Dive 80) and post-. Instead of being a straight linear increase and decrease, now the gauge is slow to pick up the increase in strain during descent and quick to let it off on ascent.

So I suspect that in Dive 80, the "loud bang" was the sound of the hull delaminating into the three shells Dr. Kramer mentioned in his presentation (layer 1 into shell 1, layers 2/3 into shell 2, layers 4/5 into shell 3), with the most distinct and complete delamination between shell 1 and 2. at least two shells (layer 1 and layers 2-5), or possibly the three layers found in the debris (layer 1 as shell 1, layers 2/3 as shell 2, layers 3/4 as shell 3). I'm thinking that it could have been two shells at the point of the "loud bang" (layer 1 as shell 1, layers 2-5 as shell 2), and that the implosion itself caused layers 2-5 to separate into two distinct shells. But I believe that layer 1 definitely delaminated from the rest and the sound of this happening was the "loud bang".

This seems to make sense with respect to the strain gauge response: suddenly layer 1 is not being compressed by the other layers in the radial direction (less strain), and it's not being supported by the other layers in the axial direction as much, a direction in which the hull is acting like a bridge (it was only supported by the titanium rings at the end, so there would have been considerable stress in the middle since it was a straight line and not an arch, so more strain). I hypothesize that this delamination was most pronounced on the forward end of the hull.

What this tells me is that the strain gauges on layer 1, now separated from the rest of the hull's layers (at least in the forward area of the hull), would not have shown the same strain until the increased pressure (due to depth) had compressed the outer shell(s) enough to start affecting layer 1/shell 1.

I believe that the rubbing noted on shell 1 occurred because the outer two shells (possibly still laminated, so really just two shells at this point maybe) had more freedom to move and were, in fact, moving. This also weakened the epoxy bond between the shells and the forward ring.

On the final dive, the epoxy gave way. This allowed explosive saltwater intrusion into the interstices between the shells, popping them apart, Because the delamination was most pronounced in the forward part of the shell, the carbon fiber there for the most part simply shattered. Larger pieces remained intact in the aft direction. Parts of shell 3 did not delaminate at the adhesive part, but were simply cracked off by the forces being applied from the forward direction.

I'll come back and reassess this hypothesis when the hearings are over (or have reached a point where they have settled on a determination of what happened), and see how closely this allies with the conclusion they reach.

I would be curious to see if there would be any attempt to make a new hull (or at least a section, or "coupon") in the same way as Titan's hull, then put it under pressure and seeing if the layers would pop apart and if they do, what sounds it makes.

11 notes

·

View notes

Text

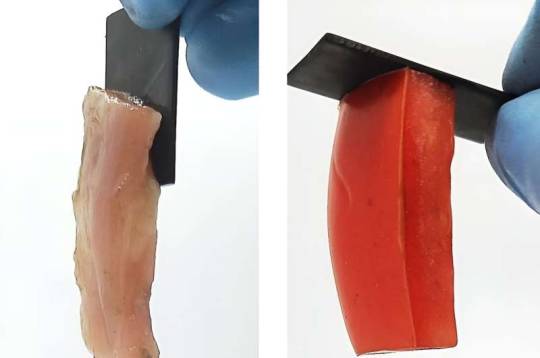

You don't need glue to hold these materials together—just electricity

Is there a way to stick hard and soft materials together without any tape, glue or epoxy? A new study published in ACS Central Science shows that applying a small voltage to certain objects forms chemical bonds that securely link the objects together. Reversing the direction of electron flow easily separates the two materials. This electroadhesion effect could help create biohybrid robots, improve biomedical implants and enable new battery technologies. When an adhesive is used to attach two things, it binds the surfaces either through mechanical or electrostatic forces. But sometimes those attractions or bonds are difficult, if not impossible, to undo. As an alternative, reversible adhesion methods are being explored, including electroadhesion (EA). Though the term is used to describe a few different phenomena, one definition involves running an electric current through two materials causing them to stick together, thanks to attractions or chemical bonds. Previously, Srinivasa Raghavan and colleagues demonstrated that EA can hold soft, oppositely charged materials together, and even be used to build simple structures. This time, they wanted to see if EA could reversibly bind a hard material, such as graphite, to a soft material, such as animal tissue.

Read more.

12 notes

·

View notes

Text

Ready to bond smarter? Visit us today to learn more and experience the adhesive revolution! Mr. JO Tecbond ASG

Mr. JO Tecbond - ASG: Smarter Adhesives for Stronger Bonds

Why settle for ordinary adhesives when you can experience extraordinary performance? Mr. JO Tecbond - ASG is the ultimate epoxy adhesive that combines strength, speed, and versatility at an unbeatable price.

Why Choose Mr. JO Tecbond - ASG?

✅ Stronger Bonds

Effortlessly adheres to stone, metal, and concrete, ensuring unmatched reliability.

✅ Fast Curing

Achieve results quickly, saving time on every project.

✅ Multipurpose

Perfect for crafting, repairs, and industrial applications alike.

✅ Solvent-Free Formula

Safe for you and the environment while delivering powerful results.

✅ Durable Results

Engineered to withstand the test of time across multiple surfaces.

Built for Makers and Trusted by Professionals !

Whether you’re a craftsman, artisan, or industrial expert, Mr. JO Tecbond - ASG is the adhesive you can count on:

- 🎨 Handicrafts: Precision and permanence for every masterpiece.

- ⚒️ Repairs: Reliable performance for tough fixes.

- 🏏Sports Goods: Tough bonds that endure the game.

Affordable Excellence

Mr. JO Tecbond - ASG delivers premium quality at just a fraction of the cost of other adhesives. It’s the smart choice for creating, repairing, and innovating.

"🔗 Stronger Bonds, Smarter Choices.

Meet Mr. JO Tecbond - ASG, the fast-curing, durable epoxy adhesive perfect for stone, metal, and concrete. Safer, versatile, and affordable!

👉 Explore Our Products: [www.jpoxypolymers.com/product/mr-jo-tecbond-asg]

Mr. JO Tecbond - ASG

2 notes

·

View notes

Text

【Feature Spotlight: Acrylic Card Case】

Hi all! It's K, your friendly editor from Kiyoai!

I'm sorry that the update has been temporarily stopped recently. In the first half of the year, my proprietor and I were immersed in the design and development of new products and spent a lot of time on things that had nothing to do with our work. Then, it’s summer.

Since May, we have released many acrylic card case products. During this time, we received a lot of comments asking "When will kiyoai's main business update?" We apologize for the inconvenience.

In the summer months, we feel hot and heavy when we use rosettes and it is easy to stain it. To this end, we have launched an acrylic card case that is convenient to carry in the summer as the main product. The massive update of the new Rosettes is expected to be released in September. Please stay tuned.

【 Table of Contents 】

Structure of acrylic card case

Disadvantages of decorations

Opportunity for the development of acrylic card case

Advantages and improvement of UV polyurethane

Structure of acrylic card case

Acrylic card cases are popular among young women because of their portability. In the early 20th century, the original role of the card box was to protect business cards and credit cards. In recent years, it has become a part of the decoration culture and has become a very distinctive product. Our acrylic card cases are in line with the current trend and are both designed and practical.

The four acrylic card sets that are expected to be released in June use uv resin solution to fix the decorations. This is a very popular decoration method, there are epoxy resin decoration, polyester glue decoration, sealing decoration and other styles.

Disadvantages of decorations

Each decoration method has its charm, but there are also some disadvantages. For example, making a card box with craft glue is not only three-dimensional and beautiful, but also simple to make. But in the production process it is difficult to modify, easy to stain and can not be cleaned.

Decal decorations are easy to make and can be easily modified. But small items fall off easily and the stickers themselves look cheap.

Epoxy resin has a sense of transparency and can hold small items well. However, it needs to be fully applied to the surface of the card and requires 24 hours of natural drying. In addition, epoxy resin will turn yellow in about 1 year and lose transparency.

Opportunity for the development of acrylic card case

My proprietor and I talked about this one day while getting our nails done at Ikebukuro's nail salon. The manicurist in charge said, "Clear nail polish? Fast drying, transparent, no yellowing, but the difficulty is low viscosity. "

At this time, other staff brought UV lamps. The president stared at the lamp and asked, "Have you tried UV antioxidant solution?" . "What's that?" When I asked him, he told me, "It's a clear, sticky adhesive that hardens after five minutes of UV light." In this way, the first card case made of UV polyurethane was born.

Advantages and improvement of UV polyurethane

Advantages of UV polyurethane solution compared to previous painting methods.

① It is no longer necessary to apply comprehensively to the surface of the card. There is no need to apply adhesive except for the bonding part, and the card surface will not yellow.

② The hardened UV anti-ultraviolet liquid is very firm, even if it is rubbed hard, small decorative items will not fall off.

③ The melting point of UV resin liquid is 80 degrees, and it will not melt even in the summer heat.

In the second wave of the shell design, the thickness of the inner inch was increased from 2mm to 3.3mm, which can accommodate acrylic. In addition, the second cartridge cartridge is changed to magnetic type, which is convenient to open the storage, and also reduces the wear of the acrylic card surface. (The second one is in production)

Summary ✨

This time, we introduce Kiyoai acrylic card box! Please be sure to try out the new acrylic card case. Then, enjoy the fashion on a hot summer day with suitable lightweight decorative items! Finally, the big update to kiyoai is also scheduled to start in September, so stay tuned. ♪

2 notes

·

View notes

Text

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

Unique FAQs

Are synthetic resin adhesives suitable for outdoor applications?

How do synthetic resin adhesives compare to traditional adhesives?

What safety precautions should be taken when using synthetic resin adhesives?

Can synthetic resin adhesives be used underwater?

Are there eco-friendly alternatives to synthetic resin adhesives?

#synthetic resin adhesives#construction adhesives#acrylic adhesive#industrial adhesives#flooring installation#adhesive properties#durability#polyurethane adhesive

2 notes

·

View notes

Text

Industrial Rubber-to-Metal Bonding: How Epoxy Adhesives Ensure Durability

In the heart of countless machines and structures lie silent partnerships – bonds between rubber and metal that keep things running smoothly. This critical connection, known as rubber-to-metal bonding, plays a vital role in applications ranging from automotive engine mounts to construction expansion joints. Here's where epoxy bonding adhesives from Kohesi Bond, a leading adhesive manufacturer in India, step in to ensure exceptional durability.

Traditional methods of rubber to metal bonding often involved mechanical fasteners. While seemingly secure, these can introduce stress points and compromise the overall flexibility of the joint. Epoxy bonding adhesives offer a superior solution.

The Power of Epoxy Bonding Adhesives

Kohesi Bond's high-performance epoxy bonding adhesives are specifically formulated for rubber to metal bonding. These adhesives boast several key advantages:

Exceptional Strength: Epoxy adhesives create a strong, uniform bond between rubber and metal, eliminating the risk of weak points associated with mechanical fasteners. This translates to superior resistance to stress, vibration, and shock – crucial factors for industrial applications.

Enhanced Flexibility: Unlike rigid fasteners, epoxy adhesives retain a degree of flexibility. This allows the bonded components to move slightly without compromising the joint's integrity, ensuring smooth operation and reduced wear on other parts.

Durability in Harsh Environments: Kohesi Bond's epoxy bonding adhesives are formulated to withstand a variety of harsh environments. They exhibit excellent resistance to extreme temperatures, chemicals, and weathering, making them ideal for demanding industrial applications.

Improved Design Freedom: Epoxy adhesives enable the creation of complex shapes and geometries that wouldn't be possible with mechanical fasteners. This allows for more efficient and innovative designs in rubber to metal bonding applications.

Choosing the Right Epoxy Adhesive for Rubber to Metal Bonding

At Kohesi Bond, we understand that every application has unique requirements. That's why we offer a range of epoxy bonding adhesives specifically designed for rubber to metal bonding. Our team of experts can help you select the right adhesive based on factors like the type of rubber, the operating environment, and the desired bond strength.

Conclusion

By utilizing high-performance epoxy bonding adhesives from Kohesi Bond, you can ensure exceptional durability and performance in your rubber to metal bonding applications. With their superior strength, flexibility, and environmental resistance, these adhesives offer a reliable and versatile solution for a wide range of industrial needs.

Explore the possibilities of Kohesi Bond's epoxy bonding adhesives for your next rubber to metal bonding project. Visit our website!

#Epoxy Bonding Adhesive#Rubber to Metal Bonding#Rubber to Metal Adhesive#Adhesive for Rubber to Metal#Industrial Bonding Solutions#Epoxy Adhesive for Rubber#High-Strength Adhesives#Durable Rubber Metal Bonding#Industrial Epoxy Adhesives#Adhesive Manufacturer in India

1 note

·

View note

Note

i kind of....i kind of want to know what the other boys are as types of glue now. please bestow your wisdom 🎤

😭😂

i got u

Alexei - Craft glue: "This water-based glue has zero to low toxicity, which makes it safe for use by both kids and adults."

Brooklyn - Glue stick: "It dries rapidly after application and is quite user-friendly both in terms of handling and cleaning."

Leo - Super glue: "At its core, super glue is a cyanoacrylate adhesive known for its quick adhesion and ability to form super strong bonds with a clean, dry finish."

Milo - Epoxy: "They are a viable option for household repairs as they can hold up in extreme conditions"

Rory - Hot glue: "Hot glue is referred to those adhesives that are available in a solidified form and must be heated before use."

Tobias - Glue dots: "These sticky dots can be conveniently put anywhere, and the best part is that they are removable"

26 notes

·

View notes

Text

FFXIV Amaurotine mask in the works along with some grimoires. I tried out using epoxy with some kydex pieces to make swappable clips for the headband. Seems to work pretty great! I always kinda hated having visible rivets on my masks since I kinda had less faith in adhesives so I went with a mechanical bond with rivets. Put a decent amount of pull on the clips and they definitely feel rock solid. And didn't annoy my face when test fitting it on myself. It'll fit even better when I add the foam padding.

6 notes

·

View notes

Text

How Synthetic Resin Adhesives Are Revolutionizing the Construction Industry

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

4 notes

·

View notes

Text

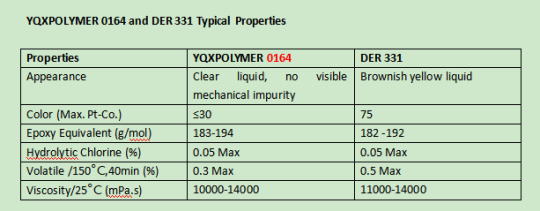

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes