#Electroadhesion

Explore tagged Tumblr posts

Text

youtube

This Video is About Electroadhesion.

How would you stick a slice of banana to a sheet of copper? Until a few months ago, you couldn’t. But a new discovery called “hard-soft electroadhesion” enables chemists to stick almost any hydrogel to almost any metal, using nothing but an electric current. Join George as he tries to replicate electroadhesion in his basement and discovers what it has in common with superglue… and, surprisingly, water.

26 notes

·

View notes

Note

an unbreakable electroadhesion between slimegirls and lawyers

of course this cascades into a bunch of slimegirl lawyers electroadhering to each other and forming a singular giant blobgirl of litigation

20 notes

·

View notes

Photo

ESTAT introduces new linear electroadhesive brake for motion control

0 notes

Text

Gluing soft materials without glue

Science News from research organizations 1 2 Date: May 3, 2023 Source: American Chemical Society Summary: If you’re a fan of arts and crafts, you’re likely familiar with the messy, sticky, frustration-inducing nature of liquid glues. But researchers now have a brand-new way to weld squishy stuff together without the need for glue at all. They’ve demonstrated a universal, ‘electroadhesion’ technique that can adhere soft materials to each other just by running electricity through them. Share: advertisement FULL STORY If you’re a fan of arts and crafts, you’re likely familiar with the messy, sticky, frustration-inducing nature of liquid glues. But researchers reporting in ACS Applied Materials & Interfaces now have a brand-new way to weld squishy stuff together without the need for glue at all. They’ve demonstrated a universal, “electroadhesion” technique that can adhere soft materials to each other just by running electricity through them. There’s a glue out there for almost any situation, whether it involves plastic, fabric, wood or beyond. But things get a bit tricky when materials are soft and squishy, like tissues or engineered organs. Strategies including 3D-printing avoid glues altogether by fusing together an entire structure — such as an organ — all at once. But this can be slow and laborious, and require advanced technical equipment. Another alternative could be electroadhesion, in which an electric field is used to hold oppositely charged materials together, forming attachments between the materials’ components. This can involve chemical bonds, like ionic bonds, or more physical connections, like ensnaring polymer chains together. Plus, it works with little more than a household battery and pencil lead. Previously, Srinivasa Raghavan and colleagues showed that electroadhesion could reversibly hold a gel to a tissue without the need for sutures. But now, they wanted to see if the technique could work for any two materials, given that they had opposite charges, to precisely and reversibly hold them together. To explore the phenomenon, the team tested a gel in addition to three types of capsules made of alginate or chitosan — both naturally occurring polymers — that were either positively or negatively charged. When attached to graphite electrodes and exposed to a 10-V electric field for around 10 seconds, the oppositely charged materials stuck together. This bond was strong enough to withstand gravity, and evidence from previous experiments suggests it could last for years. By reversing the flow of electricity, however, the bond was easily broken. The team assembled chains and even 3D cubes out of individual, spherical capsules. The researchers also used electroadhesion to sort capsules by their charges, either by laying a charged gel on top of several capsules, or by touching them with a fingertip “robot” that adhered the capsules to themselves. The researchers say that this work demonstrates the universality of electroadhesion and could one day be used in robotics and tissue engineering. Video: https://youtu.be/QMSWC1Egn1A advertisement Story Source: Materials provided by American Chemical Society. Note: Content may be edited for style and length. Journal Reference: Leah K. Borden, Ankit Gargava, Uma J. Kokilepersaud, Srinivasa R. Raghavan. Universal Way to “Glue” Capsules and Gels into 3D Structures by Electroadhesion. ACS Applied Materials & Interfaces, 2023; 15 (13): 17070 DOI: 10.1021/acsami.2c20793 Cite This Page: American Chemical Society. “‘Gluing’ soft materials without glue.” ScienceDaily. ScienceDaily, 3 May 2023. . American Chemical Society. (2023, May 3). ‘Gluing’ soft materials without glue. ScienceDaily. Retrieved May 3, 2023 from https://ift.tt/QbWaZ5V American Chemical Society. “‘Gluing’ soft materials without glue.” ScienceDaily. https://ift.tt/QbWaZ5V (accessed May 3, 2023).

0 notes

Text

HAMR-E – Harvard Ambulatory Micro-Robot with Electroadhesion, by Sébastien D. de Rivaz et al (2018), Hansjörg Wyss Institute for Biologically Inspired Engineering, Harvard University. This tiny (1.48 gram) quadrupedal micro-robot can climb conductive surfaces using high-voltage to generate an electrostatic force between the foot pads and the surface. It was developed in conjunction with Rolls-Royce with the idea of inspecting the interior of jet engines without the expense of dismantling them.

64 notes

·

View notes

Text

'Electroadhesive' stamp picks up and puts down microscopic structures

‘Electroadhesive’ stamp picks up and puts down microscopic structures

[ad_1]

IMAGE: Optical image of a pattern of silicon dioxide particles, each 5 micrometers in diameter, and individually picked and placed using a new “electroadhesive ” stamp. view more

Credit: Sanha Kim and John Hart

If you were to pry open your smartphone, you would see an array of electronic chips and components laid out across a circuit board, like a miniature city. Each component…

View On WordPress

0 notes

Link

Researchers have created a micro-robot whose electroadhesive foot pads, inspired by the pads on a gecko's feet, allow it to climb on vertical and upside-down conductive surfaces, like the inside walls of a commercial jet engine. Groups of them could one day be used to inspect complicated machinery and detect safety issues sooner, while reducing

1 note

·

View note

Photo

The Gecko autonomous devices are wall climbing robots equipped with a spectrum of wall adhesion technologies to adapt to any potential vertical obstacle. Embedded in each of its 16 pads are electroadhesion generators, pneumatic (suction) machines, centrifugal (air blowing devices that can temporarily transform the Gecko into a flying robot), multiple microspines and a variety of sensors ranging from x-ray to ultrasound.. A wall may be slippery, rough, smooth or rocky but the Gecko will have no problem in traversing it. The tail component is removable and can be replaced with a variety of devices depending on its mission. The tail can be equipped with sensors that can assess a wall’s integrity, a paint blower or 3D printer that can change a building’s façade, or spying devices with exotic weaponry. March of Robots 2022: Day 26 – Wall Inspiration: Gecko #marchofrobots #marchofrobots2022 #createwithxencelabs #marchofrobots2025wall #marchofrobots2022day26 #art #artph #drawingchallenge #artchallenge #cartoonchallenge #drawing #digitaldrawing #illustration #illustrationartists #character #characterdesign #characterdrawing #robot #robotdesign #characterdrawing #drawingart #illustration #doodles #doodle @chocolatesoop #wall #lizard #gecko https://www.instagram.com/p/CbkD97lpb8N/?utm_medium=tumblr

#marchofrobots#marchofrobots2022#createwithxencelabs#marchofrobots2025wall#marchofrobots2022day26#art#artph#drawingchallenge#artchallenge#cartoonchallenge#drawing#digitaldrawing#illustration#illustrationartists#character#characterdesign#characterdrawing#robot#robotdesign#drawingart#doodles#doodle#wall#lizard#gecko

1 note

·

View note

Text

You don't need glue to hold these materials together—just electricity

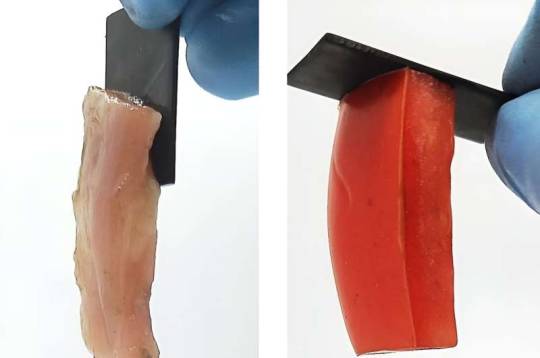

Is there a way to stick hard and soft materials together without any tape, glue or epoxy? A new study published in ACS Central Science shows that applying a small voltage to certain objects forms chemical bonds that securely link the objects together. Reversing the direction of electron flow easily separates the two materials. This electroadhesion effect could help create biohybrid robots, improve biomedical implants and enable new battery technologies. When an adhesive is used to attach two things, it binds the surfaces either through mechanical or electrostatic forces. But sometimes those attractions or bonds are difficult, if not impossible, to undo. As an alternative, reversible adhesion methods are being explored, including electroadhesion (EA). Though the term is used to describe a few different phenomena, one definition involves running an electric current through two materials causing them to stick together, thanks to attractions or chemical bonds. Previously, Srinivasa Raghavan and colleagues demonstrated that EA can hold soft, oppositely charged materials together, and even be used to build simple structures. This time, they wanted to see if EA could reversibly bind a hard material, such as graphite, to a soft material, such as animal tissue.

Read more.

12 notes

·

View notes

Photo

RT @WevolverApp: A micro-robot whose electroadhesive foot pads, origami ankle joints, and specially engineered walking gait allow it to climb on upside-down conductive surfaces, like the inside walls of a commercial jet engine. Full article: https://t.co/D10vCzgaBt Project by: Wyss Institute https://t.co/FfQxJOqsBy https://www.youtube.com/c/lifesang

0 notes

Photo

MIT Devises 'Electroadhesive Stamp' to Build Ultra-Complex Circuit Boards This ...https://bitprime.co/mit-devises-electroadhesive-stamp-to-build-ultra-complex-circuit-boards/?feed_id=10973&_unique_id=5da6d5a7dd6b7

0 notes

Text

‘Electroadhesive’ stamp picks up and puts down microscopic structures

New technique could enable assembly of circuit boards and displays with more minute components. ‘Electroadhesive’ stamp picks up and puts down microscopic structures syndicated from https://triviaqaweb.blogspot.com/

0 notes

Photo

Special series: the path untrodden part three⠀ ⠀ Follow along as Lyra Wanzer, S.B. ‘19, concentrating in mechanical engineering, builds an electroadhesive treaded robot for her senior capstone project⠀ ⠀ After many iterations on the tread design throughout the semester, Wanzer ultimately used a design with multiple layers. In our most recent update with Wanzer, she was working through different prototypes of the drive system alignment that connected the treads of her robot. In her final product, she has added end caps to prevent the wheels from sliding sideways and optimized the length of couplings between the wheels to secure the drive system. She made carbon fiber bushings, bearings to reduce friction between different parts of the car. She constructed the wheels of the robot from two layers of compliant foam. Wanzer tried both a concave and a convex tread and found that a convex tread worked best for her robot.⠀ ⠀ In the final stages of building her robot, Wanzer evaluated the total mass of the robot, the wheel torque, the voltages, and safety. She added a top plate to make the chassis, the base frame, rigid to protect the robot during testing. Then she studied the speed of the robot while it pulled a load of varying mass behind it to optimize her system. As the angle of the inclined surface increased, the speed of her robot decreased. Moving on a 30 degree incline, her robot was much faster than other existing electroadhesive robots.⠀ ⠀ In the future, she would like to see further work done in making the robot lighter and better able to hold a greater load. Wanzer intends to publish her work to share her design with the robotics community. Grateful for the mentorship she received from her lab, the course staff, and the @seasallabs , Wanzer speaks highly of the learning experience of the capstone project. Like her robot, she looks forward to exploring new ground and embarking on the next steps of her journey in robotics.⠀ #HarvardSEAS #LifeatSEAS #Harvard19 #student #robot #project (at Harvard John A. Paulson School of Engineering and Applied Sciences) https://www.instagram.com/p/Bx2HOL4H9tQ/?igshid=2x5thrsy6i95

0 notes

Text

“Electroadhesive” Stamp Picks up and Puts down Microscopic Structures

“Electroadhesive” Stamp Picks up and Puts down Microscopic Structures

If you were to pry open your smartphone, you would see an array of electronic chips and components laid out across a circuit board, like a miniature city. Each component might contain even smaller “chiplets,” some no wider than a human hair. These elements are often assembled with robotic grippers designed to pick up the components and place them down in precise configurations.

As circuit…

View On WordPress

0 notes

Text

Packaging And Palletizing Robots

OnRobot only uses processors if they can present the required guarantees that they will implement appropriate technical and organisational security measures to adjust to personal data regulation. All processors should sign a processor agreement earlier than processing commences. According to the Cookie Act, OnRobot will need to have the person’s consent to use this software on the person’s gear https://palletizing.com/.

OnRobot s will document any personal information breach on an access-controlled drive. OnRobot safeguards the rights of information topics, together with the proper to entry, withdrawal of consent, rectification and erasure and will inform the info subjects of OnRobot’s processing of personal data. Data subjects are also entitled to attraction to the Danish Data Protection Agency.

Also, we deal with a really broad vary of panel kind-factor merchandise similar to glass sheets, show panels, handheld units, cell phones and tablets, composite sheets, and attire cloth. This video shows the Grabit panel gripper mounted on an articulated robotic selecting and placing boxes of laptop keyboards. Notice how the packing containers seem to defy gravity as they travel up the conveyor, which can be wrapped in the electroadhesion expertise. Technologies and methods aimed toward enhancing a packaging line’s reliability, production, security and sustainability.

Then the client permits OnRobot to make use of his knowledge for functions aside from communication, upcoming promotions, product updates or further information together with upcoming promotions, product updates and further news. The Personal Data Regulation allows you to deal with private data solely legally for the aim for which they have been collected. If you need to use data for purposes apart from the unique, you have to always have the consent of the registrant. All staff should be instructed in what to do with private data and tips on how to protect personal information.

<h2>Abb’s Expanded Product Range Set To Revolutionize Robotic Picking, Packing And Palletizing</h2>

USB flash drives, external exhausting disks, and so on. containing personal knowledge must be stored in a locked drawer or cabinet. Personal knowledge are erased securely in connection with phasing-out and restore of IT equipment.

Our extremely qualified service professionals and area service technicians can be found 24 hours a day, seven days per week, to provide assist for buyer needs as shortly and effectively as potential. Our fleet is numerous; from a small van, a van with a ramp, and greater supply autos to vehicles.

Those Eighties pictures of auto plant robots stay with us right now—long strains of huge metal arms, swinging jerkily, welding automobile frames in showers of sparks or becoming doorframes and automotive hoods. In 1921, Czechoslovakian Karel Capek wrote a play about an intelligent, artificially created particular person.

This permits us to supply our shoppers numerous options for his or her wants. In case of personal information breach, OnRobot will report the breach to the Danish Data Protection Agency as quickly as attainable and inside 72 hours. The report will outline the breach, the teams of persons affected and the influence the breach might have on these individuals and the way OnRobot has remedied or intends to treatment the breach. If the breach entails a high risk for the individuals about whom OnRobot processes personal data, OnRobot will also notify these persons.

The purpose of the coverage is to ensure and document that OnRobot protects private knowledge in accordance with the rules for processing of private data. The policy will also contribute to OnRobot offering details about its processing and use of registered private knowledge. Dual RG2 grippers with customizable fingertips make you twice as productive and help your robotic obtain most efficiency. Our machines from the IND-Pack 29 sequence can insert flat cardboard pad or cardboard tray with partitions beneath the containers.

Emerson is the place technology and engineering come together to create options for the benefit of our prospects, pushed without compromise for a world in motion. Protect against contaminants, leaks and tears with safe blister packaging options. Emerson offers superior testing systems that present in-line leak testing functionality to detect and reject leaks of modified environment from cases and trays that include damaged or faulty merchandise. Many major packaging traces are now not dedicated to a single product as SKUs increase, impacting line effectivity. To maximize the flexibility to vary over from one neck diameter to another and to fill either aseptic, CSD, or still products, Bickford’s doubled down on blow/fill technology.

<h3>Related Products</h3>

We have greater than 30 years of experience in plant engineering and supply turnkey solutions and methods configured to customer specs. Our business-main, excessive-velocity industrial robots embrace high-payload, prolonged-attain, extremely-maneuverable seven-axis and unique 15-axis twin-arm robots. More than 100 years of experience with driving of electric motors has led Yaskawa to develop merchandise which perfectly mix technical superiority with simple dealing with. Keeping your machines working effectively is crucial to your operation.

Jakobsens tapped honey in the identical room as they packed and palletized, and this resulted in a loud manufacturing. In addition, part of the method was manual and the aim was to protect the employees from stressful and monotonous duties. New fully automatic palletizing resolution for honey producer Jakobsens A/S with 3 palletizing stations, switch cart and foil wrapping.

<ul><li>Recently one of many firm’s customers changed their integration philosophy from a number of strains feeding into one massive robotic palletizing cell to at least one small palletizing cell per line.</li><li>While the form and the mental images of robots change over time, one true constant seems to remain.</li><li>Innovative Handling (-materialhandling.com), an integrator for Fanuc Robotics (), specializes in palletizing.</li><li>Those pictures may be a lingering distortion of at present’s robotic realities.</li><li>As Capek envisioned, robots are extremely capable, by no means tiring workers.</li></ul>

The KR QUANTEC PA is even capable of stack a number of pallets to a great peak with the utmost precision. They can be used to stack a number of pallets to an excellent peak effortlessly. Palletizing robots from KUKA stack the heaviest masses with the utmost precision – and have minimal space and upkeep requirements. All models have a specially designed robotic arm, the PC-based mostly KR C4 robot controller and the KUKA smartPAD educate pendant.

Achieve the pliability needed to satisfy market demand while sustaining production and high quality standards. Get more of your merchandise to market with secure shipments and robust packaging that protects against injury throughout transport and delivery.

<h2>Automatic Grading Solutions For Pelagic Fish</h2>

Personal information for employees are erased 5 years after employment has ended, and private information about applicants are erased after six months. OnRobot doesn't use the personal data for functions aside from those listed. OnRobot doesn't gather more personal data than needed to satisfy the aim. The private knowledge should be provided to ensure that OnRobot to enter into employment, buyer and provider contracts. The document offers an overview of the processing for which OnRobot is accountable.

On The company’s intranet or similar closed group, the principles in the E-information protection directive do not apply. Upon receipt of a enterprise card from a buyer you have his consent. If you write his data you want his signature on this paper to have a formal requirement for consent if you want to use his info.

Sixty years after Capek coined the term, automakers around the globe started making major investments in industrial robots. D. G. Yuengling and Son Brewery, Pottsville, PA, is America’s oldest brewery, with continuous operations since 1829.

Collaborative robots are price-efficient, protected, and flexible to deploy. Collaborative robots - or cobots - are making automation easier than ever, even for small and mid-sized companies. Beside the progressive know-how and excessive product high quality our popularity can also be constructed on sure qualities and values, one of the important of which is integrity.

By submitting your request, you give consent to the processing and storage of your personal information. At AMF, the proof of our success is when our clients rise to the top. AMF is the one full baking solutions provider with areas all through North America and the world. We assist bakeries reduce their dangers and stay online with native service and support across the globe.

<h3>Conveyor Belts For Food Industry</h3>

Joe Frinzi, operations and high quality supervisor, describes the upgrading of the Pottsville facility’s depalletizing and palletizing system. They provide a large assortment of standard, natural and fair commerce honeys as well as agave syrup. We consider we have got the options we had been looking for and the applied system drives passable. Of course there have been, and nonetheless are, some 'bumps' alongside the way in which, but they have all been resolved sensibly and in acceptable reaction time.

<h3>Packaging / Palletising</h3>

We might want to contact you concerning future occasions and products together with Packaging Digest, please uncheck this field if you do not want to receive these updates. Become one with the more than 13,000 world packaging professionals sharing news, ideas, and — yes! “A single robot on a observe is significantly decrease in value than two robots, two grippers, two controllers, two security techniques, and two of every little thing,” he provides. “Electroadhesion pressure is a function of the fabric we’re gripping and the surface space that we’re contacting,” explains Duncheon. “Boxes, cartons and instances lend themselves very properly to electroadhesion.

Sweet palletizing specialist in Serbia Sunoko makes use of the KR QUANTEC PA to stack sacks of sugar. KR QUANTEC PA stacks animal litter The KR QUANTEC PA palletizes as much as forty tonnes of animal litter per shift at CERTECH. Find out how that relieves the burden on staff during palletizing operations.

0 notes