#Epoxy Resin Manufacturing

Explore tagged Tumblr posts

Text

The Role of Glass Transition Temperature in Epoxy Molding Compounds

The Glass Transition Temperature (Tg) plays a pivotal role in determining the performance and durability of epoxy molding compounds. Tg refers to the temperature at which the polymer transitions from a rigid, glassy state to a more flexible, rubbery one. Understanding the impact of Tg on epoxy resin is crucial, particularly in high-temperature epoxy applications, as it directly influences the material's mechanical properties, thermal stability, and overall performance.

Epoxy Glass Transition Temperature and Its Significance

The Glass Transition Temperature in Epoxy is a defining factor in the epoxy resin molding process. As epoxy resins cure, their epoxy curing temperature influences how the resin bonds and behaves at different thermal conditions. If the Tg in epoxy resins is too low, the material may lose structural integrity when exposed to elevated temperatures. Conversely, a higher Tg results in improved thermal stability and makes the resin more resistant to heat and mechanical stress.

For industries relying on epoxy molding compounds, such as electronics and automotive, selecting the right epoxy resin performance can greatly affect product longevity and reliability. Understanding epoxy mold material properties and how they correlate with the Cure-Temperature-Glass-Transition can optimize the manufacturing process, ensuring that the final product meets the necessary performance criteria.

Optimizing Epoxy Tg for Better Results

In many applications, especially those involving high-performance environments, Epoxy Tg optimization is essential. Manufacturers can manipulate thermal properties of epoxy molding compounds to achieve the desired Tg, balancing flexibility and strength. The Impact of Tg on epoxy is especially evident in epoxy resin molding techniques, where fine-tuning the epoxy resin thermal stability allows for better control over product quality. The Tg and mechanical properties of epoxy are key to ensuring that the final molded parts exhibit durability and strength under varying conditions.

As an adhesive manufacturer in India, Kohesi Bond understands the critical importance of optimizing epoxy resin manufacturing process to deliver high-quality products. By mastering the control of epoxy bonding adhesive and its thermal properties, Kohesi Bond ensures superior performance across a wide range of applications.

For more information, visit Kohesi Bond's website!

#Epoxy Glass Transition Temperature#Glass Transition Temperature in Epoxy#Epoxy Molding Compounds#Epoxy Resin Performance#Epoxy Bonding Adhesive#Thermal Properties of Epoxy Molding Compounds#Epoxy Resin Thermal Stability#Epoxy Tg Optimization#Epoxy Resin Molding Techniques#Cure-Temperature-Glass-Transition#High-Temperature Epoxy Applications#Epoxy Tg and Mechanical Properties#Epoxy Resin Manufacturing Process#Impact of Tg on Epoxy#Epoxy Mold Material Properties#Adhesive Manufacturer in India#Epoxy Curing Temperature#Understanding Tg in Polymer Compounds#High-Performance Epoxy Applications#Epoxy Bonding Adhesive in India#Epoxy Resin Manufacturing

1 note

·

View note

Text

Insulator manufacturers | radiantenterprises

Radiant Enterprises is a leading manufacturer of custom-made support insulators, offering high-quality epoxy insulators for various applications. As one of the top customized epoxy insulator manufacturers in India, we specialize in cast resin post insulators and outdoor support insulators designed for durability and performance in demanding environments. Our precision-engineered solutions ensure superior electrical insulation and mechanical strength, making them ideal for power transmission and distribution systems. Trust us for reliable and customized insulation solutions tailored to your specific requirements.

#Custom made support insulator#Epoxy insulator#Customized epoxy insulator manufacturers in India#Cast resin post insulator#Outdoor support insulator#Insulator manufacturers#Pantograph insulator manufacturer in USA#United States of America#Pantograph insulator exporter in USA#Railway insulator#Customized powerrail epoxy insulator#Epoxy bushing#Traction convertor bushing#Low voltage bushings for traction convertor#Customized epoxy bushing manufacturers in India#Epoxy bushing manufacturers in India#USA

4 notes

·

View notes

Text

Medium voltage support insulator manufacturers in India | radiantenterprises

Elevate your electrical solutions with Radiant Enterprises, a top name among customised insulator manufacturers in India. Specializing in high-quality epoxy insulators, we cater to the specific needs of your projects with precision and expertise. As leading medium voltage support insulator manufacturers in India, we provide durable and reliable products that meet the highest industry standards.

Trust Radiant Enterprises for innovative and customized insulator solutions designed to enhance the performance and safety of your electrical systems.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India#epoxy bushing#epoxy insulator#epoxy resin#electrical company#electrical engineering#electrical industry#fuse cutouts#smart grid sensor#rail insulator#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure#third rail#cable connector#innovative insulators#export quality

4 notes

·

View notes

Text

I'm all for my fellow merch makers making whatever decisions they want with what they produce. But I wish it were more widely known that a clear epoxy coat over acrylic pins and charms will yellow over time. ;;

#there are pros and cons to many things epoxy included!!#like if its a coat over the print then like. it can protect the print itself from getting scratched#and hell it just Looks Nice. the domed effect is very cool :)#when theres glitter in there too??? whoa mama#but yeah. the yellowing. granted it could take a few years for that to start#perhaps also depending on the manufacturer and the epoxy used#as well as sometimes the epoxy surface has like. a residual tackiness to it? (from my vograce experiences)#if you're slow to move merchandise like I am tho. it kinda makes stuff with epoxy feel like a ticking timebomb#unfortunately all my previous charms are epoxy domed bc i didn't know this at the time!! but I'm avoiding epoxy for my new pin sets#and won't be using it for charms again in the future. just as a personal preference.#like dont get me wrong. they'll be fine for a good long while#but i was going through my old charms bought from cons again the other day and even some of the ones from just two years ago#were yellowing 😞#grafftalk#delete later#also the same with clear epoxy resin in typical resin work. bc its the same stuff#but thats why a lot of resin crafts are best done with colour bc it usually hides the effects of the oxidation

17 notes

·

View notes

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

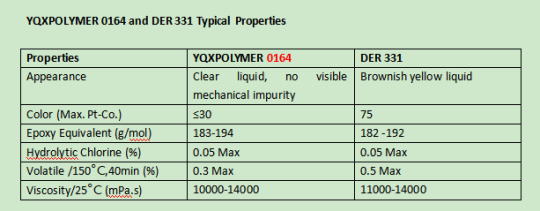

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

https://www.eporex.in/epoxy-resin-in-tamilnadu.php

#epoxy chemical manfacturer in tamilnadu#buy epoxy resin tamilnadu#epoxy resin Manufacturer tamilnadu#epoxy resin supplier tamilnadu

0 notes

Text

Discover the Versatility of Epoxy Resin Products for Your Projects- MB Epoxy

0 notes

Text

Clear Epoxy Resins That Deliver Flawless Finishes for Art and Decoration Projects

Johnberg Craft is committed to delivering high-quality epoxy products that meet the diverse needs of industries and individuals alike. Based in Ahmedabad, the company has earned a reputation for excellence through its innovative solutions, long-lasting products, and unwavering dedication to customer satisfaction. Whether you are looking for durable flooring solutions, crystal-clear resins, or top-tier grout for tiles, Johnberg Craft is your trusted partner.

The company specializes in offering products that enhance durability, design, and functionality. Their epoxy solutions are not only reliable but also eco-friendly, designed to support both aesthetic and industrial demands. With an emphasis on cutting-edge research and development, Johnberg Craft ensures that every product stands the test of time, providing clients with value for their investment.

Industrial Epoxy Flooring Built for Strength, Resistance and Polished Finishes

Renowned as a leading epoxy resin manufacturer in Ahmedabad, Johnberg Craft produces high-grade materials used in various applications, from art projects to large-scale industrial needs. Their products are celebrated for their superior finish, robust performance, and ease of use, making them a top choice across industries.

The company also excels as a crystal clear epoxy resin manufacturer, creating resins known for their glass-like transparency. These are ideal for applications requiring a flawless finish, such as decorative surfaces, jewellery, and tabletops.

For construction and tiling projects, Johnberg Craft provides the best epoxy grout for tiles in India. Perfect for achieving seamless finishes, this grout offers enhanced strength and resistance to stains, making it a reliable solution for both homes and commercial spaces.

Additionally, Johnberg Craft is a trusted provider of industrial epoxy flooring. These flooring options are designed to endure heavy traffic, resist chemicals, and maintain a polished appearance, making them suitable for warehouses, factories, and commercial spaces.

Johnberg Craft continues to be a market leader by combining innovation and quality. Reach out to their team today to explore their exceptional product range and find the perfect epoxy solution for your needs.

#industrial epoxy flooring#best epoxy grout for tiles in India#crystal clear epoxy resin manufacturer#epoxy resin manufacturer in Ahmedabad

0 notes

Text

Epoxy Resin: Driving Innovation and Industrial Growth in India

0 notes

Text

A company making wooden wind turbine blades has successfully tested a 50-meter-long prototype that’s set to debut soon in the Indian and European markets.

Last year, the German firm Voodin successfully demonstrated that their laminated-veneer timber blades could be fabricated, adapted, and installed at a lower cost than existing blades, while maintaining performance.

Now, Voodin has announced a partnership with the Indian wind company Senvion to supply its 4.2-megawatt turbines with these wooden blades for another trial run.

Wind power has accumulated more than a few demerit points for several shortfalls in the overall industry of this fossil-fuel alternative.

Some of these, such as the impact on bird life, are justified, but none more so than the fact that the turbine blades are impossible or nearly impossible to recycle, and that they need to be changed every 25 years.

Wind turbine blades are made from a mixture of glass and carbon fiber heated together with sticky epoxy resin, and these materials can’t be separated once combined, which means they go into landfills or are incinerated when they become too battered to safely operate.

GNN has reported that folks will occasionally find second-life value in these giant panels, for example in Denmark where they are turned into bike shelters. In another instance, they’re being used as pedestrian bridges.

But there are way more wind turbine blades being made every year than pedestrian bridges and bike shelters, making the overall environmental impact of wind power not all green.

“At the end of their lifecycle, most blades are buried in the ground or incinerated. This means that—at this pace—we will end up with 50 million tonnes of blade material waste by 2050,” Voodin Blade Technology’s CEO. Mr. Siekmann said recently. “With our solution, we want to help green energy truly become as green as possible.”

The last 15 years have seen rapid growth in another industry called mass timber. This state-of-the-art manufacturing technique sees panels of lumber heat-pressed, cross-laminated, and glued into a finished product that’s being used to make skyscrapers, airports, and more.

At the end of the day though, mass timber products are still wood, and can be recycled in a variety of ways.

“The blades are not only an innovative technological advancement but a significant leap toward sustainable wind production,” said Siekmann, adding that this isn’t a case of pay more to waste less; the blades cost around 20% less than carbon fiber.

Additionally, the added flexibility of wooden blades should allow for taller towers and longer blades, potentially boosting the output of turbine by accessing higher wind speeds.

Now partnered with Voodin, Senvion will begin feasibility analysis in the next few months, before official testing begins around 2027.

#good news#wind turbines#wind power#environmentalism#science#environment#fossil fuel alternatives#mass timber#recycling

11K notes

·

View notes

Text

🔧 Unlock the Power of FR-4 Epoxy Fiberglass Sheets! 🔧

Discover how FR-4 epoxy fiberglass sheets are revolutionizing industries with their exceptional electrical insulation and mechanical strength. From PCBs to industrial machinery, these materials are the backbone of modern engineering.

Explore our comprehensive guide to understand their applications and benefits.

#fr43#fr4#fiberglass#epoxy resin#engineering#pcb#industrial design#customsolutions#technology#innovation#manufacturing#materials#electronics

0 notes

Text

How Custom Epoxy Insulators Reduce Downtime in Electrical Systems

In today's fast-paced industrial world, even a few minutes of electrical system downtime can translate into substantial financial losses. Whether it is in power transmission, distribution, or industrial automation, the reliability and stability of electrical components play a crucial role. One of the unsung heroes in this landscape is the epoxy insulator — particularly those that are custom-made for specific system requirements.

At Radiant Enterprises, we specialize in high-quality insulators that are engineered to minimize failure risks and ensure continuous operation. This article explores how custom epoxy insulators significantly reduce downtime in electrical systems, improve overall performance, and offer long-term cost savings.

What Are Epoxy Insulators?

An epoxy insulator is a type of electrical insulation component made from high-grade epoxy resin, often reinforced with glass fibre. These insulators are known for their excellent electrical, mechanical, and thermal properties. Because of their robustness and reliability, epoxy insulators are extensively used in switchgear, transformers, circuit breakers, and other high-voltage and medium-voltage applications.

Unlike porcelain or ceramic insulators, epoxy insulators offer better performance in compact spaces and harsh environments. Their ability to withstand high mechanical stress, temperature variations, and environmental factors makes them an ideal choice for modern electrical infrastructure.

The Value of Custom-Made Support Insulators

Not all electrical systems are created equal. They often differ in configuration, voltage ratings, and environmental exposure. That is where custom made support insulators come into play.

Custom epoxy insulators are tailored to meet the specific mechanical and electrical requirements of your system. These insulators are designed to align perfectly with the physical constraints and performance needs of a given setup. This level of customization ensures a better fit, easier installation, and optimized function — all of which directly contribute to reducing downtime.

For example, in outdoor substations where high moisture and pollution levels are common, using a custom outdoor support insulator with enhanced tracking and erosion resistance can prevent flashovers and failures, which in turn keeps your system running smoothly.

Benefits of Custom Epoxy Insulators in Reducing Downtime

1. Enhanced Mechanical Strength

Custom epoxy insulators can be designed to meet specific load-bearing requirements. This is particularly important in environments where insulators must support heavy conductors or be mounted in positions that experience vibration or mechanical stress. A poorly designed insulator may crack under pressure, leading to system failures. A custom made support insulator, on the other hand, can be engineered with reinforced resin systems to handle extreme loads, reducing the risk of breakdowns.

2. Optimized Thermal Performance

Epoxy resin insulators offer excellent thermal resistance. However, in applications involving high current or elevated ambient temperatures, a standard insulator might degrade over time. A customized epoxy insulator manufacturer in India like Radiant Enterprises can create insulators with specific thermal ratings and formulations that maintain integrity even under prolonged high-temperature exposure. This leads to a longer lifespan and fewer unexpected shutdowns.

3. Improved Dielectric Properties

By customizing the composition and design, cast resin post insulators can be made to exhibit superior dielectric strength. This minimizes the risk of partial discharge or electrical arcing, both of which are common causes of equipment failure and subsequent downtime. Customization also allows for the inclusion of features like embedded electrodes or shielding to manage field stress, thereby boosting operational reliability.

4. Resistance to Environmental Stressors

Outdoor environments expose insulators to UV radiation, moisture, dust, and pollutants. A custom outdoor support insulator can be treated with special coatings or additives that resist these stressors, preventing surface degradation and flashover incidents. This customization ensures consistent performance regardless of weather conditions, reducing the need for frequent maintenance or unexpected repairs.

5. Faster Installation and Maintenance

A custom made support insulator is typically designed for easy integration into your existing setup. This means faster installation with fewer adjustments, and in many cases, plug-and-play compatibility. When maintenance is required, modular or standardized custom designs can facilitate quick replacement, further minimizing system downtime.

youtube

Applications Where Custom Epoxy Insulators Make a Difference

Power Generation and Distribution

Power plants and substations rely on cast resin post insulators to ensure safe and efficient energy flow. Custom insulators reduce arcing and withstand high fault currents, making them indispensable for preventing system disruptions.

Railways and Transportation

Electrified rail networks, especially high-speed systems, require outdoor support insulators that can handle dynamic loads and vibrations. Customization allows the design to meet the specific needs of traction and auxiliary power systems.

Renewable Energy Systems

Solar and wind installations often face harsh environmental conditions. Customized epoxy insulator manufacturers in India like Radiant Enterprises offer insulators that can operate reliably in saline, humid, or dusty environments without performance loss.

Industrial Automation and Switchgear

In automation panels and switchgear, space constraints are a major challenge. Custom epoxy insulators are compact and can be molded to fit snugly into tight spaces while still meeting the necessary voltage and mechanical specifications.

Why Choose Radiant Enterprises?

Radiant Enterprises is one of the leading customized epoxy insulator manufacturers in India, known for our focus on quality, performance, and client-specific solutions. Here is what sets us apart:

Tailored Solutions: Every insulator is custom-engineered based on your technical drawings or system requirements.

High-Grade Materials: We use premium epoxy resins and fillers to ensure durability and high performance.

In-House Testing: All insulators undergo rigorous mechanical, thermal, and electrical testing before dispatch.

Wide Application Range: From cast resin post insulators to outdoor support insulators, we cater to diverse industries.

With decades of experience and a dedicated R&D team, we ensure that each product contributes to your system’s uptime, efficiency, and safety.

Conclusion

The impact of custom epoxy insulators on reducing downtime in electrical systems cannot be overstated. From enhanced mechanical strength and thermal performance to superior environmental resistance, the benefits are clear. When sourced from reputed customized epoxy insulator manufacturers in India like Radiant Enterprises, these components offer unmatched reliability and longevity.

Investing in custom made support insulators, whether it is for cast resin post insulator needs or robust outdoor support insulator applications, is a proactive step toward building a more resilient and efficient electrical infrastructure.

Let Radiant Enterprises be your trusted partner in creating customized insulator solutions that not only meet but exceed your expectations. Contact us today to learn more about our product offerings and how we can help optimize your systems for uninterrupted performance.

#Custom made support insulator#Epoxy insulator#Customized epoxy insulator manufacturers in India#Cast resin post insulator#Outdoor support insulator#United States of America#USA#Youtube

5 notes

·

View notes

Text

Customised epoxy insulators manufacturers in India | radiantenterprises

Radiant Enterprises is a leading name among epoxy insulators manufacturers in India, specializing in high-quality insulation solutions for various industrial applications. Our expertise in producing customized epoxy insulators ensures that we can meet the unique needs of your projects with precision and reliability. We take pride in being a premier provider of epoxy insulators for third rail systems, delivering products that enhance safety and performance. Our advanced manufacturing processes and stringent quality control make us a trusted choice for durable and efficient epoxy insulators. Choose Radiant Enterprises for superior epoxy insulators tailored to your specific requirements.

Contact us today to discover how our customized solutions can benefit your operations.

#Epoxy insulators#Epoxy Insulators manufacturers in India#Customised epoxy insulators manufacturers in India#Epoxy insulator for third rail#Epoxy bushing#25 kv Epoxy bushing manufacturer in India#Epoxy bushing manufacturer in India#Railway insulator#Railway roof feedthrough 25 kV bushing#Customized conductor rail insulator#Cycloaliphatic epoxy resin#Europe#India#Railway#Third rail#locomotive#tram#bullet train

4 notes

·

View notes

Text

PCB Manufacturing Process: All You Need to Know

Creating a printed circuit board (PCB) is a systematic process that begins with meticulous design and material selection, crucial for ensuring functionality and durability. The initial steps involve the application of a thin layer of copper over a substrate material, typically a fiberglass substrate reinforced with epoxy resin and glass fiber, which provides the necessary rigidity and electrical insulation. This copper layer is then patterned to form conductive areas that will eventually carry electrical signals.

The layout design process utilizes advanced CAD software for precision, ensuring that the conductive paths and component placement areas are accurately defined. Once the design is finalized, it's transferred onto the PCB using photo reactive chemicals and UV exposure, a process known as outer layer imaging. This method allows for the precise alignment of layers and the creation of intricate circuit patterns.

After the design transfer, the excess copper is removed through a careful etching process, leaving behind the copper traces that form the circuitry. The PCB then undergoes a laminating process to apply a solder mask, a protective layer that covers the entire board while exposing the areas where components will be soldered. This solder mask application is crucial for preventing short circuits and ensuring the longevity of the PCB.

Following the application of the solder mask, a silkscreen printing process adds labels and markings to the PCB, aiding in component placement and board identification. The final step in the fabrication processes involves applying a surface finish, such as tin plating, to protect the exposed copper and ensure a reliable soldering surface. Other surface finishes like HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) are also used depending on the application requirements.

Throughout the PCB manufacturing process, precision is maintained through the use of technologies like CNC machines for accurate drilling of holes that will accommodate electronic components. Each part of the PCB fabrication process, from the initial design to the final surface finish, is critical to enhancing the PCB's electrical performance and longevity.

The final stages of assembly involve the placement of components onto the PCB, often by a contract manufacturer specializing in PCB assembly. This is followed by soldering, which can be done through various methods, to securely attach the components to the board.

Rigorous electrical tests are conducted to validate the PCB's performance, ensuring that it meets stringent quality standards before integration into electronic devices. These tests verify the integrity of the conductive paths, the correct orientation of components, and the overall functionality of the PCB.

This holistic approach underscores the importance of meticulous craftsmanship and thorough quality assurance in producing reliable PCBs that power our modern gadgets effectively. Each step, from the initial plating process to the final surface finishing, contributes to enhancing the PCB's electrical performance and longevity, making it a vital component in the electronics industry.

To read more please visit:

Reachemical chemicals

16479857177

600 Matheson Blvd W Unit 5, Mississauga, Ontario ,ON L5R 4C1.

#thin layer of copper#plating process#excess copper#laminating process#tin plating#fabrication processes#substrate material#exposed copper#solder mask application#circuit board manufacturing process#conductive areas#surface finish#layer alignment#outer layer imaging#parts of the pcb fabrication process#epoxy resin and glass fiber#contract manufacturer#outer layers#electrical tests#photo reactive chemicals

0 notes

Text

Trusted Epoxy Resin Manufacturers for Industrial-Scale Applications

Looking for trusted epoxy resin manufacturers for industrial applications? MB Enterprises delivers high-quality epoxy resin solutions ideal for large-scale use across construction, flooring, electronics, and marine industries. Our products are engineered for excellent strength, chemical resistance, and long-term durability.

As leading epoxy resin manufacturers, we ensure consistent quality, bulk availability, and customized options to suit specific industrial requirements. With advanced production facilities and a commitment to timely delivery, MB Enterprises is the go-to source for reliable epoxy resin. Whether you need materials for heavy-duty flooring or high-performance coatings, we offer dependable solutions designed to meet the demands of large-scale operations. Get in touch with MB Enterprises today for premium epoxy resin tailored to your needs.

#Epoxy Resin Manufacturers#Epoxy Resin Manufacturers in India#resin manufacturers#Epoxy resin suppliers in India#epoxy resin#resin epoxy#liquid epoxy#epoxy chemical

0 notes

Text

SLES Manufacturers in India - Bansal Trading Company

Sodium Lauryl Ether Sulfate (SLES) is an essential surfactant widely used in personal care and cleaning products due to its excellent foaming properties, mildness, and effectiveness in removing dirt and oil. As the demand for SLES continues to rise, Bansal Trading Company stands out as a leading manufacturer in India, known for its commitment to quality, innovation, and sustainability. This blog explores the contributions and strengths of Bansal Trading Company in the Sles Manufacturers In India.

#SLES Manufacturers in India#iron oxide suppliers in delhi#vegacid 1880 suppliers in india#trichloroethylene suppliers in india#epoxy resin suppliers india#customize ecommerce development company#niacinamide distributors in india#top chemical distributors in india#stearic acid suppliers in delhi

0 notes