#Epoxy Insulators

Explore tagged Tumblr posts

Text

Low tension insulator for metros manufacturers in India | radiantenterprises

Radiant Enterprises is a trusted manufacturer of low tension insulators for metros in India, delivering reliable solutions to support urban transit systems. Our specialized low tension insulators for metros are designed to ensure safe and efficient operation with conductor rails, enhancing performance and durability in demanding metro environments. With a commitment to quality, we are a preferred choice for advanced low tension insulators across the rail industry.

Choose quality, choose reliability – partner with us for low tension insulator for metros projects.

#Low tension insulator for metros manufacturers in India#India#Australia#Low tension insulators#Brazil#Russia#Germany#Low tension insulators for metros#Conductor rails#Epoxy Insulators#Epoxy Bushings#Railway insulator#Railway Bushings#Business#Pantographs#Transformer#Electricals#Electricity

5 notes

·

View notes

Text

Revolutionising Electrical Systems – The Rise of Customised Epoxy Insulators

In the realm of electrical engineering and power distribution, innovation is the key to efficiency, reliability, and safety. One such groundbreaking development is the rise of customised epoxy insulators. Epoxy insulators are transforming the landscape of electrical systems, providing superior performance and durability. As epoxy insulators manufacturers in India continue to push the boundaries of technology, the benefits of these innovative products are becoming increasingly evident. This blog explores the revolutionary impact of customised epoxy insulators on electrical systems, highlighting their applications, advantages, and the leading manufacturers driving this transformation.

Understanding Epoxy Insulators

Epoxy insulators are a type of electrical insulator made from epoxy resin, a material known for its excellent electrical properties, mechanical strength, and resistance to environmental factors. These insulators are designed to withstand high voltage and harsh conditions, making them ideal for a wide range of applications in power distribution and electrical engineering.

Traditionally, electrical insulators have been made from materials such as porcelain and glass. However, epoxy insulators offer several advantages over these conventional materials, including higher mechanical strength, lighter weight, and better resistance to environmental degradation. This has led to a growing adoption of epoxy insulators in various sectors, from industrial power distribution to transportation systems.

The Advantages of Customised Epoxy Insulators

Customisation is a significant trend in the epoxy insulator market, allowing for tailored solutions that meet specific requirements and challenges. Here are some of the key advantages of customised epoxy insulators:

Enhanced Performance and Reliability

Customised epoxy insulators are designed to meet the unique demands of specific applications, ensuring optimal performance and reliability. By tailoring the design and composition of the insulator, manufacturers can enhance its electrical and mechanical properties, resulting in better performance under high voltage and extreme conditions.

Improved Durability and Longevity

Epoxy insulators are known for their durability and resistance to environmental factors such as moisture, chemicals, and UV radiation. Customisation further enhances these properties, ensuring that the insulators can withstand the rigours of their operating environments and provide long-lasting performance.

Cost-Effective Solutions

While the initial cost of customised epoxy insulators may be higher than standard insulators, their enhanced performance and longevity result in lower maintenance and replacement costs over time. This makes them a cost-effective solution for businesses looking to improve the reliability and efficiency of their electrical systems.

Flexibility in Design

The customisation process allows for flexibility in design, enabling manufacturers to create insulators that meet specific dimensional and performance requirements. This is particularly beneficial for applications with unique challenges or constraints, such as limited space or high-stress environments.

Environmental Benefits

Epoxy insulators are often more environmentally friendly than their traditional counterparts, as they require fewer resources to produce and have a longer lifespan. Customisation can further enhance these benefits by optimising the design for reduced material usage and improved energy efficiency.

Applications of Customised Epoxy Insulators

The versatility of customised epoxy insulators makes them suitable for a wide range of applications across various industries. Some of the key applications include:

Power Distribution and Transmission

In the power distribution and transmission sector, customised epoxy insulators are used in high-voltage applications to ensure the safe and efficient transfer of electricity. Their superior electrical properties and durability make them ideal for use in substations, transformers, and switchgear.

Transportation Systems

One of the critical applications of epoxy insulators is in transportation systems, particularly in railways. Epoxy insulators for third rail systems are essential components that ensure the safe and reliable transmission of power to trains. These insulators need to withstand high voltage, mechanical stress, and environmental factors, making customisation crucial for optimal performance.

Industrial Applications

In industrial settings, customised epoxy insulators are used in a variety of applications, including machinery, equipment, and power distribution networks. Their ability to withstand harsh conditions and high voltage makes them ideal for use in manufacturing plants, chemical facilities, and other industrial environments.

Renewable Energy

The renewable energy sector also benefits from the use of customised epoxy insulators, particularly in wind and solar power systems. These insulators are designed to handle the unique challenges of renewable energy applications, such as exposure to harsh weather conditions and fluctuating power loads.

Leading Epoxy Insulators Manufacturers in India

India is home to several leading manufacturers of epoxy insulators, who are at the forefront of innovation and customisation in this field. Some of the top epoxy insulators manufacturers in India include:

Radiant Enterprises

Radiant Enterprises is a prominent name in the epoxy insulator market, known for its commitment to quality and innovation. The company offers a wide range of customised epoxy insulators for various applications, including power distribution, transportation, and industrial use. Radiant Enterprises' focus on research and development ensures that its products meet the highest standards of performance and reliability.

ABC Insulators

ABC Insulators is another leading manufacturer in India, specialising in the production of high-quality epoxy insulators. The company offers customised solutions to meet the specific needs of its clients, ensuring optimal performance and durability. ABC Insulators' state-of-the-art manufacturing facilities and experienced team make it a trusted partner for businesses across various industries.

XYZ Electricals

XYZ Electricals is a renowned name in the electrical insulator market, offering a wide range of epoxy insulators for different applications. The company's customised solutions are designed to meet the unique requirements of its clients, providing superior performance and reliability. XYZ Electricals' commitment to quality and innovation has made it a leading player in the Indian market.

The Future of Customised Epoxy Insulators

The future of customised epoxy insulators looks promising, with several trends and developments set to drive further innovation and growth in this field. Some of the key trends to watch include:

Advancements in Material Science

Ongoing research and development in material science are expected to lead to the creation of new epoxy resin formulations with enhanced properties. These advancements will further improve the performance and durability of customised epoxy insulators, making them even more effective for a wide range of applications.

Increased Focus on Sustainability

As businesses and industries place greater emphasis on sustainability, the demand for environmentally friendly insulators will continue to grow. Customised epoxy insulators, with their long lifespan and reduced environmental impact, are well-positioned to meet this demand. Manufacturers will likely focus on developing even more sustainable solutions in the future.

Integration with Smart Technologies

The integration of epoxy insulators with smart technologies, such as sensors and IoT devices, is another trend to watch. This integration will enable real-time monitoring and diagnostics, improving the reliability and efficiency of electrical systems. Customisation will play a crucial role in developing smart insulators that meet the specific needs of different applications.

Expansion into New Markets

The market for customised epoxy insulators is expected to expand into new regions and industries as awareness of their benefits grows. This expansion will create new opportunities for epoxy insulators manufacturers in India, driving further innovation and growth in the market.

Conclusion

Customised epoxy insulators are revolutionising electrical systems, offering superior performance, durability, and cost-effectiveness. As epoxy insulators manufacturers in India continue to innovate and push the boundaries of technology, the future looks bright for this transformative product. By leveraging the advantages of customised epoxy insulators, businesses across various industries can enhance the reliability and efficiency of their electrical systems, ensuring long-term success and sustainability.

#Epoxy insulator for third rail#Epoxy insulators#Epoxy Insulators manufacturers in India#Customised epoxy insulators manufacturers in India

4 notes

·

View notes

Text

Magnify Performance and Engineer Customization with Radiant

Transforming energy solutions with innovation, Radiant Enterprises proudly presents our bespoke Customised Insulator & Bushing offerings. Elevate your electrical setups with precision-crafted solutions tailored to your exact specifications, ensuring optimal performance and reliability.

Whether it is unique designs or specialized materials, trust Radiant to deliver insulators and bushings that exceed expectations.

Connect with us at +91 82383 64067 or visit our website at: https://lnkd.in/d3CTJsXW to ignite innovation with our Customised Insulator and bushing solutions.

8 notes

·

View notes

Text

Epoxy floor paint company in Bangladesh - Firsttech BD

Best Commercial and Residential Flooring & Construction Chemicals Company In Bangladesh. FIRSTTECH started their service since 2009. This company has built a reputation based on quality products, economical solutions and efficiency services. FIRSTTECH is a Bangladesh based Industrial, commercial & Residential Flooring company. That deals in first Flooring sector Company in Bangladesh.

#Concrete Waterproofing#Floor Hardener#Decorative Flooring#Epoxy Flooring#Polyurethane Flooring#Heat Insulation

2 notes

·

View notes

Text

Electrical Cables Fireproof Coatings services in pune | Ugam Chemicals

For all your fireproofing and heat-resistant coating needs, look no further than Ugam Chemicals, the trusted supplier and manufacturer of high-quality protective coatings in Pune and across India. 🛡️🔥

Our Product Range:

🔹 Electrical Cables Fireproof Coatings suppliers in Pune: Protect your electrical systems with advanced fireproof coatings.

🔹 Flame Retardant Coatings manufacturer in Pune: High-performance coatings to minimize fire risks in industrial and commercial setups.

🔹 Fire Protective Epoxy Intumescent Coatings manufacturer in Pune: Enhance fire resistance for critical structures with durable epoxy solutions.

🔹 Fireproof Vermiculite Coating suppliers in Pune: Ideal for structural fireproofing needs. 🔸 Fireproof Vermiculite Coating services in India: Nationwide application services to ensure optimal fire safety.

Heat-Resistant and Thermal Insulation Paints:

✅ For 100°C: Trusted suppliers in Pune for medium-temperature applications. ✅ For 400°C: High-performance thermal insulation coatings for industrial usage. ✅ For 600°C (EPSI services in Pune): Perfect for extreme conditions in industrial environments. ✅ For 1200°C-WB: Specialized water-based coatings designed for ultra-high temperatures.

Elastomeric Heat Resistant Coatings

Our cutting-edge elastomeric coatings are ideal for a variety of surfaces, combining flexibility and thermal resistance to withstand harsh environments.

Why Choose Ugam Chemicals?

We are known for: ✔️ Top-notch quality products tailored for durability. ✔️ Expertise in fireproofing and heat-resistant coatings. ✔️ Reliable service with nationwide coverage. ✔️ On-time delivery for all your projects.

Whether you're looking for fireproof coatings for cables, heat-resistant paint for high temperatures, or thermal insulation solutions, Ugam Chemicals is your one-stop destination. Visit our website today to learn more! 🌟

📌 #FireproofCoatings #HeatResistantPaint #ThermalInsulationSolutions #UgamChemicals

#Electrical Cables Fireproof Coatings suppliers in pune#Flame Retardant Coatings manufacturer in pune#Fire Protective Epoxy Intumescent Coatings manufacturer in pune#fireproof vermiculite coating suppliers in pune#fireproof vermiculite coating services in india#Heat Resistant & Thermal Insulation Paint For 100 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 400 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 600 Deg C EPSI services in pune#Heat Resistant & Thermal Insulation Paint For 1200 Deg C- WB suppliers in pune#Elastomeric Heat Resistant Coatings suppliers in pune.

0 notes

Text

PU Insulation by Vertex Civil Solutions

Shield your building with Vertex Civil Solutions' top-notch PU insulation. Enjoy superior thermal performance, energy savings, and enhanced comfort. Our high-quality PU insulation is durable, versatile, and eco-friendly. Experience the difference with Vertex.

0 notes

Text

PVC Flooring: A Durable and Versatile Choice for Your Home (2023)

Introduction

PVC (polyvinyl chloride) flooring is a popular flooring option that is known for its durability, versatility, and cost-effectiveness. PVC flooring is made from a synthetic polymer and can be found in a wide range of designs and colors, making it a versatile option for different interior design styles. In this blog, we will explore the advantages of PVC flooring and why it is a great choice for your home.

Durability and Longevity

One of the primary advantages of PVC flooring is its durability and longevity. Vinyl flooring is resistant to daily wear and tear, making it an excellent option for high-traffic areas. Additionally, PVC flooring is water-resistant, which means it can be used in areas prone to moisture, such as kitchens and bathrooms. PVC flooring also has a long lifespan, which makes it a cost-effective option in the long run.

Easy Maintenance

Another advantage of PVC flooring is its easy maintenance. Unlike other flooring options that require waxing or polishing, PVC flooring can be easily cleaned with a damp mop or mild cleaning solution. This makes it an excellent option for busy households or commercial spaces.

Comfortable and Quiet

Vinyl flooring is also known for its comfortable and quiet properties. It is soft and comfortable underfoot, making it a great option for areas where people stand for extended periods. Additionally, PVC vinyl flooring can absorb sound, making it an excellent choice for environments where noise reduction is necessary.

Marvel Vinyl's: PVC Vinyl Flooring

Conclusion

In conclusion, PVC flooring is a durable, versatile, and cost-effective option for your home or business. Its easy maintenance, comfortable and quiet properties, wide range of designs, eco-friendliness, and cost-effectiveness make it a great choice for any space. If you’re considering new flooring, PVC flooring is definitely worth considering. This article is republished and was originally published on www.marvelvinyls.com

#industrial pvc flooring#pvc insulation mat#pvcflooring#laminate flooring#epoxy flooring#renovation#living room

0 notes

Text

Recycling the unrecyclable: New method reclaims materials from epoxy resins and composites

Epoxy resins are coatings and adhesives used in a broad range of familiar applications, such as construction, engineering and manufacturing. However, they often present a challenge to recycle or dispose of responsibly. For the first time, a team of researchers, including those from the University of Tokyo, developed a method to efficiently reclaim materials from a range of epoxy products for reuse by using a novel solid catalyst. The work has been published in Nature Communications. There's a high chance you are surrounded by epoxy compounds as you read this. They are used in electronic devices due to their insulating properties; clothing such as shoes due to their binding properties and physical robustness; building construction for the same reason; and even in aircraft bodies and wind turbine blades for their ability to contain strong materials such as carbon fibers or glass fibers.

Read more.

#Materials Science#Science#Recycling#Epoxy#Resins#Composites#Adhesives#Catalysts#Materials processing#Fiber reinforcement#Fibers#University of Tokyo

27 notes

·

View notes

Text

i think no matter how much info about microplastics i read, i just cant grasp the severity of the situation. like my mind cant comprehend the fact that this new unbreakable material is everywhere, EVERYWHERE!! in food, toys, plants, animals, ground, organs, brains, in the air????? the fact that a compound that we dont know anything about and could be potentially detrimental to not only us but also the planet has so easily leaked into literally all there is and we cant do shit about it!!!

so now im wondering what will it be like in a few thousand, few hundred thousand years,, will the earth adapt? idk like organisms actually finding use for plastic, hell, actual plastic species being born. imagine cockroaches who have plastic exoskeletons that help them through difficult environments, plastic-laced fur being the norm for better insulation or a legit thinking humanoid made from plastic whose entire existence is a grim reminder, a premonition even, for what is to come, since history will always repeat itself

life built from plastic. human built from plastic. thought built from plastic. and subsequently a plastic god, worshipped by the plastic people for gifting them bodies made of glitter and epoxy resin. idk somebody should write a book about that

#a speculative biology book about plastic organisms would go so hard#imagine all tomorrows but everyone glitters in the sunlight like edward cullen#microplastics#speculative biology#speculative evolution

20 notes

·

View notes

Note

No carpets!? *horrified Bobert voice*

Not only are there no carpets—whether cut pile, Berber pile, sisal carpet, Saxony cut, plush carpet, texture cut, frieze cut, shag carpet, sculpted cut, cut-and-loop; whether made out of wool, cotton, silk, bamboo, jute, sisal, hemp, seagrass, coir, nylon, olefin, or polyester—there are no finished floors of any kind, linoleum, cement, whether fast setting, colored, fiber reinforced, self-leveling, mortar, high early-strength, sand mix, silica sand, plastic, hydraulic, or sheet vinyl, tile, cork tile, terrazo, rubber, epoxy, ceramic & stone, slate, aputitsiarvaq, or marble, whether white—Danby Imperial, Colorado Yule, or Carrarra—or black or green; or hardwood, whether overlay, strip flooring with alternate joints, or herringbone, inlaid, basket weave, Arenberg, Chantilly, or Versailles parquet; in fact no wood anywhere, whether redwood, treated western hemlock, yellow pine, cedar, wood-polymer, Engelmann spruce, pecan, southern magnolia, Colorado spruce, alpine fir, american beech, northern red oak, Canada Hemlock, red maple, sugar maple, eastern white pine, butternut hickory, shagbark hickory, american plane tree, eastern black walnut, ponderosa pine, white fir, northern catalpa, common bald cypress, american sweet gum, bur oak, California live oak, mahogany, Douglas fir, eastern cottonwood; nor any kind of a subfloor, sheathing, drywall, any kind of insulating material, polyicynene or other.

Picture that. In your Beetle-induced hypnotic visions.

#ask#house of leaves#most of this is quoted from house of leaves but i did have to write the carpet part myself#with the aid of a better homes and gardens article#for best results imagine this post appearing inside a blue square in the middle of a different post on your dashboard#during one of the tumblr updates where they broke the whole site

9 notes

·

View notes

Text

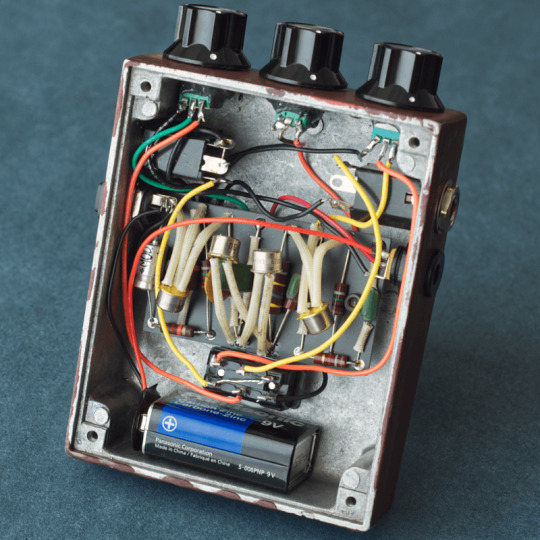

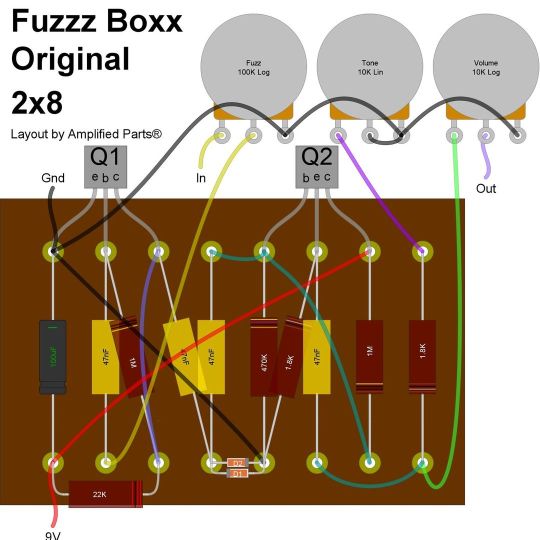

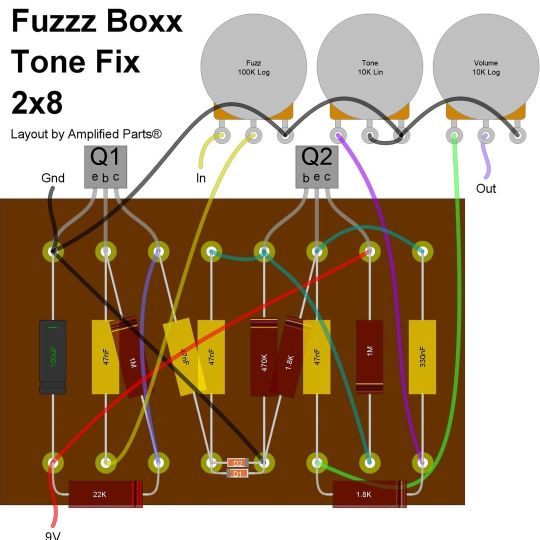

amplified parts - ZZ XXX

"... Sam Ash Fuzzz Boxx / Astro Astrotone Fuzz built on our wide spacing 2x8 pseudo eyelet board. The case is a hand-painted sloped YY enclosure, and the knobs are our newly-added P-K402 knobs, which are in the same style as the originals. There's a Lumberg power jack as well as a battery-power option which can be disconnected via the side rocker switch (P-H518). There were multiple transistor types used in the originals. This build uses silicon Fairchild TO-5s with a similar hfe range and the B-E junction of two TO-5 transistors for the clipping diodes. The insulation used on many of the leads is NOS, but it's very similar to our white old-style spaghetti sleeving, S-M436W. The last two photos are layouts for different build options. The first one, the "Tone Fix" option, adds an extra capacitor not found in the originals in order to squeeze a little more functionality out of the tone control, which is otherwise somewhat lackluster. The last photo is the original Fuzzz Boxx circuit. There is an added 100uF power supply stabilization cap in both layouts. Note that I used 9mm pots here to give the knobs wider spacing. Their 5mm bushings do not make it all the way through the thick walls of the YY enclosure, so they were epoxied in. 16mm Alpha pots have slightly longer bushing where that may not be a problem, but the knobs would have to be a little closer together."

cred: instagram.com/amplifiedparts; amplifiedparts.com/pedal-guides/build-project-fuzzz-boxx;

#amplifiedparts#sam ash fuzzz boxx#astrotone fuzz#diy projects#diy tutorial#ZZ XXX#eyelet board#enclosures

31 notes

·

View notes

Text

Cable termination insulator manufacturers in India | radiantenterprises

Radiant Enterprises is a premier cable termination insulator manufacturer in India, specializing in high-quality, customized solutions for reliable electrical connections. Our range includes durable cable termination insulators, customized epoxy termination plugs, and insulated plugs for symmetrical T-connectors, all crafted for superior performance. We also provide customized insulated termination pieces to meet unique specifications, ensuring safety and efficiency in various power applications.

Choose Radiant Enterprises for reliable, innovative, and customized solutions in the realm of cable termination insulators.

#Cable termination insulator manufacturers in India#Cable termination insulators#Customized epoxy termination plugs#Insulated plugs for symmetrical T-connectors#Brazil#India#Customized insulated termination pieces#Germany#Australia#Russia#Epoxy Insulators#Epoxy Bushings#Railway Insulators#Railway Bushings

5 notes

·

View notes

Text

5 Applications of PVC Foam Core across Industries & For Various Projects

PVC foam core is a material that's used in construction, electrical wiring, and even plumbing. It's lighter than standard foam boards but just as strong and durable, so it can be used to insulate pipes and ducts or build trusses. The PVC foam core has many applications that you may not have imagined before reading this article.

Pipe insulation

PVC foam core is used to insulate pipes, and it's a great option for most situations. In addition to being an excellent insulator, PVC foam core is easy to install and inexpensive.

Construction trusses

PVC foam core is used in trusses to help support the roof. Trusses are building structure that uses metal or wood to form triangles that span across an entire room, forming a grid. Trusses can be made in many different shapes and sizes depending on their purpose, but they all have at least one thing in common: they're designed to support the weight above them, whether it's from another part of the structure or from people walking around below them (like you).

Trusses are used primarily in construction projects where there isn't enough room for conventional beams or columns--for example, if you're building an apartment complex with many floors above ground level yet only one stairwell leading up from street level (or no stairwell at all), trusses are perfect!

Air conditioning ducts

PVC foam core can be used in air conditioning ducts to insulate and reduce noise. It's also used as an insulating layer in HVAC systems. The foam core provides thermal insulation, sound absorption and fire resistance for the ducts.

Underground piping

PVC foam core is a lightweight and strong material that's easy to work with, as it can be cut and shaped. It also has excellent joining properties, which make it ideal for underground piping. The durability of PVC foam core allows you to use less material than other types of pipe insulation. This makes it cost effective as well as non-toxic!

Electrical conduits

Electrical conduits are used to carry electrical wiring in a building or structure. They can be installed in walls, floors, and ceilings. PVC foam core is an ideal material for this application because it provides excellent fire resistance while being easy to install with standard tools. In addition, it's inexpensive compared with other insulating materials such as fiberglass batts or mineral wool boards--and since you don't need any special tools or skills to work with PVC foam core (just some common hand tools), its cost savings potential is substantial over time!

PVC foam core can be used in many different ways

PVC foam core is a lightweight, rigid material that can be easily cut and glued into place. It's often used to create signs, store products or protect sensitive documents. This versatile material has many applications in both the commercial and residential realms.

PVC foam core, like PU tooling boards, is easy to transport because it's lightweight and can be rolled up into manageable sizes for transport by hand or vehicle. The low thermal conductivity of PVC foam core makes it ideal for use as insulation in homes where energy efficiency is important; because there are no gaps between layers of material like those found in other insulations such as fiberglass batting or polystyrene beads (Styrofoam), heat doesn't pass through as easily which saves money on heating bills over time!

Conclusion:

PVC foam core is a great material for many different applications. It can be used in construction, electrical wiring and even pipe insulation. The versatility of PVC foam core makes it an excellent choice when choosing an insulating material for your next project! When you are looking for PVC foam core, or other industrial application product, like an epoxy tooling board, or else, ensure that you source your supply from a reliable and quality name.

2 notes

·

View notes

Text

Elevate Your Electrical Systems with Radiant Enterprises – Premier Epoxy Insulator Manufacturers in India

Discover excellence in insulation solutions with Radiant Enterprises, the leading Epoxy Insulator manufacturer and exporter in India. Our commitment to quality extends to customized solutions, making us the preferred choice for tailored Epoxy Insulators that meet the unique needs of diverse industries. Trust Radiant Enterprises for superior craftsmanship, reliability, and innovation in every customised Epoxy Insulator manufacturer in India. Your electrical systems deserve the best, choose Radiant for unmatched quality and performance. With a legacy of precision engineering and a global footprint, we are dedicated to providing Epoxy Insulators that set the industry standard for durability and efficiency.

Partner with us for cutting-edge solutions that power a sustainable and connected future.

#Epoxy Insulator#Epoxy Insulators Manufacturers in India#Customised Epoxy Insulators Manufacturers in India#Epoxy Insulator Manufacturers in India#electrical company#electrical engineering#electrical industry#exportquality#innovativeinsulators#India

7 notes

·

View notes

Text

Best Commercial and Residential Flooring & Construction Chemicals Company In Bangladesh - FIRSTTECH BD.

#Concrete Waterproofing#Floor Hardener#Decorative Flooring#Epoxy Flooring#Polyurethane Flooring#Heat Insulation

1 note

·

View note

Text

#Electrical Cables Fireproof Coatings suppliers in pune#Flame Retardant Coatings manufacturer in pune#Fire Protective Epoxy Intumescent Coatings manufacturer in pune#fireproof vermiculite coating suppliers in pune#fireproof vermiculite coating services in india#Heat Resistant & Thermal Insulation Paint For 100 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 400 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 600 Deg C EPSI services in pune#Heat Resistant & Thermal Insulation Paint For 1200 Deg C- WB suppliers in pune#Elastomeric Heat Resistant Coatings suppliers in pune.

0 notes