#Engineering plastic alloy

Explore tagged Tumblr posts

Text

What are methods of plastic modification? What categories are there!

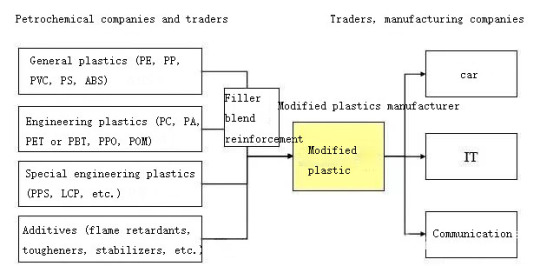

1. What is modified plastic? On the basis of general plastics and engineering plastics, through physical, chemical, mechanical and other methods, through filling, blending, reinforcement and other processing methods, performance of plastics is improved or functions are added, mechanical properties such as flame retardancy, strength, impact resistance, toughness of plastics are improved and…

View On WordPress

#Chemical modification#electronic appliances#Engineering plastic alloy#Engineering plasticization#engineering plastics#flame retardant#flame retardant color masterbatch#Flame retardant resin#Flame-retardant plastic products#Functional color masterbatch#Glass fiber reinforced thermoplastics#High performance of engineering plastics#modified plastic#Physical modification#Plastic alloy#plastic extender fillers#Plastic flame retardant#plastic materials#plastic modification#plastic modification technology#plastic products#polymer plastics#Reinforced and toughened resins#Reinforcement materials#reinforcing material#toughening agents

0 notes

Text

2.4Ghz 6 Channel 1:24 RC Excavator toy RC Engineering Car Alloy and plastic Excavator RTR For kids Christmas gift

Extra 2% off 80 Reviews405 orders US $17.30 US $24.72 30% off Store Discount: Buy 2 get 3% off US $4.00 off On orders over US $6.00 Control Channels: 6 Channels Movement Direction: Forward, backward, left, right Function:Turn frontward and backward, turn left and right. The arm rise and down. Simulation sound. Transmitter frequency:2.4G Control distance: About 30-50m Package…

View On WordPress

0 notes

Text

1958 Chevrolet Corvette

This 1958 Chevrolet Corvette underwent a pro-street-style metamorphosis between 2008 and 2011. It is endowed with a 383 cubic inch stroker V8 engine, harmonized with a TH350 three-speed automatic transmission, and a narrowed rear axle featuring a limited-slip differential. The rear suspension has been upgraded with a ladder-bar configuration, adjustable coilovers, and the addition of a lift-off hood. The body, painted a striking red with white coves, comes with a detachable hardtop. Inside, a roll cage has been installed along with a B&M Pro Stick shifter, a shift light, aftermarket gauges, and black Procar bucket seats. The enhancements also include dual Edelbrock carburetors, Hooker headers, side-exit exhaust pipes, 15” alloy wheels, and front disc brakes. Acquired by the current dealer in February 2024, this modified C1 Corvette is now part of the Coffee Walk Corvette Collection in Wylie, Texas, and is offered without reserve, complete with build records and a clean Pennsylvania title.

1958 Chevrolet Corvette

The fiberglass exterior is adorned in red with white coves and includes a removable hardtop and a lift-off hood with an integrated air scoop. A Stewart-Warner fuel-pressure gauge is mounted on the cowl, and the right-rear corner features a battery cutoff switch and external terminals. The gallery reveals cracks in the weatherstripping, pitted chrome, and paint imperfections.

1958 Chevrolet Corvette

Polished 15” alloy wheels are shod with 25.0×5.0” front and 29.5×11.5” rear Hoosier drag tires, installed in April 2024. A crossmember supports the rear suspension, which has been modified with ladder bars, a diagonal link, and adjustable coilovers. The braking system includes front disc brakes and rear drums.

1958 Chevrolet Corvette

The interior is equipped with a roll cage and Procar high-back bucket seats in black. Enhancements include a B&M Pro Stick shifter, an MSD shift light, rocker-switch controls, and fabricated metal door panels. The gallery displays flaking paint and wear on interior surfaces.

1958 Chevrolet Corvette

The three-spoke steering wheel is positioned in front of a 160-mph speedometer and auxiliary gauges. An AutoMeter pedestal tachometer is mounted atop the non-functional factory tachometer. Additional gauges for coolant temperature and oil pressure are located in the center console. The mechanical odometer is inoperative, and the total mileage remains unknown.

1958 Chevrolet Corvette

A Harwood plastic fuel cell is mounted in the trunk, which has been tubbed with fabricated aluminum panels to accommodate the rear wheels.

1958 Chevrolet Corvette

The 350ci V8 engine block, bored and stroked to 383ci, features four-bolt main bearings. The build includes forged pistons, ARP fasteners, a polished Edelbrock intake manifold, dual Edelbrock carburetors, an MSD ignition module, and Hooker long-tube headers that flow into side-exit exhaust pipes.

1958 Chevrolet Corvette

Power is transmitted to the rear wheels through a TH350 three-speed automatic transmission and a narrowed Dana 60 rear axle with a limited-slip differential.

1958 Chevrolet Corvette

142 notes

·

View notes

Note

Petition to let Styrofilm have nice things /silly

So oak won’t work for a desk… what about heavy metals or concrete or really strong plastic?

Or maybe he just needs flex tape /j

High-tensile steel with alloyed metals -- chromium, molybdenum, manganese, nickel, silicon, and vanadium -- has outstanding tension resistance and is usually used in structures and mechanical engineering applications.

These materials could potentially work for my case. However, they required large amounts of funds as high-tensile steel is expensive due to the complex manufacture method.

But, its benefits outweigh the cost. It only depends on the science department to distribute those funds.

22 notes

·

View notes

Note

have you any thoughts on soft body robots

Awesome username and yes absoloutely.

They break down into two major types:

Hollow, and membrane which form a kind of spectrum.

From hollow-types we begin with cloth-likes. This is your BMW Ginas, and your space-frames and monocoques (I love that word, it feels so good in the mouth to say).

Maestro, please:

youtube

Absurdly light, lithe, software defined, able to change shape in wild ways like some absurdist high fashion statement of skin and effect. Delicate like a bird. An olympic athlete without a wasted ounce of fat. A coathanger robot. Spartan. A puppet of cloth, metal and intention, like a scarecrow or a kite.

It would be brutal were it not potentially so fragile, for the impact forces are imparted entirely into the body's frame beneath which must deform to endure any crash or crumble the world speaks to those shapes. It is the butterfly, and the humming-bird of this branch of engineering. If you need a lifting body and you can some how distribute the fluttering forces across the surface with shape memory alloy stiffness in the cloth you have a self-definable prehensile wing. You have created the answer to almost every aerodynamic concern imaginable, forever.

And so, we go even further beyond in this metaphor.

We go to the true thoughts of softness now.

We find the ounce of fat we did not before. We find the blubber. The charm. The plush padding of privilage of our touch, of function and personality. The trembling doughy forms of gellatine flooding, filling those synthetic cloth or plastic or flexible metallic hulls.

The functional practicality here is simply beyond measure, and likely won't be understood in our lifetimes while we chase hardened hulls. Soft robots are dreamily suited to working with humans for we ourselves are largely soft robots of protein self-assembly systems, clumsily physics-enfolding some interpretation of our genetics through the pachinko machine of probability, space and time.

Looking upon the true soft robotics, we see thusly, a spectrum: gas and baloon like and perhaps even buoyant to float like a fairy -- to sloshing fluid to dense sticky gellatine, we find all the places of impact we need.

Bulbous, enduring, reflective of forces. A thing able to deal with the world and simply bounce, care free. Perhaps to tear, and spill, but always to knit and in bleeding become so much more than a body.

The factors of the structure deforming in ways no exoskeletal form is able to do so give dexterity simply unimaginable.

If the filling itself is prehensile perhaps like some bizzare synthetic echo of forms like those seen in molluscs, we run into a machine which isn't using tiny magnetic tubes to turn but an enormous mass which is structural and acting as a container perhaps for fuels in micro-pockets to prevent unwanted combustions or the spread of flames.

That is to say, the blubber energy dense like our own, powerful, like the non-beach-muscle bodies of non-magazines who achieve real work like mothers, brothers and beer-bellies and forms of joy of all in between.

This form is is fire-proof. It is shock resistant to a level no fragile ceramic metallic machine can really imagine.

And it is still lighter, than that metallic machine which by comparison now, is crystal, practically glass by comparison.

What else would you like to know?

I'm good for another round if you are.

9 notes

·

View notes

Text

Mayblade Day 4: Gender Swap

(I took liberty with my interpretation on this one. Since Kenny is the bladebreakers engineer, I wrote about a female engineer character instead…)

(The lovely Kiya belongs to @soclonely )

Whether it was the haphazardly organised appearance of her office or the way in which she glided through the room with single minded focus while chatting at a million words a minute, Steph could tell immediately that she liked Kiya.

“Once upon a time people made beyblades out of wood and plastic, but these days, with the development of three-d printing, you can make a beyblade out of almost anything if you put your mind to it.”

She tossed one of the beyblades in Steph’s direction, confident her reflexes would allow her to catch it - and they did, just … Turning the beyblade over in her hand, she inspected it closely.

“I’ve never seen a material like this.”

“You wouldn’t have,” Kiya told her. “I created it myself. That’s what Mr Dickenson hired me to do - design beyblades that can better withstand the demands of your bitbeast’s power. Do you have an idea of what kind of beyblade you want to make.”

Steph rifled through her bag. “I have some sketches…”

“Let me see,” Kiya said, snatching the sketchbook gently from Steph’s hands and beginning to rifle through it.

“You’ve switched out your weight disk?” Kiya mused, her words more of a statement than a question. “And in addition to a heavier weight disk you’ve gone for a winged attack ring - that’s good; the heavier weight disk will give the projections on the edge of your attack ring a higher impact.”

“That’s kinda what we’re going for,” Steph replied. She was amazed that Kiya had gotten all that information from a handful of, let’s face it, subpar sketches.

Kiya pondered this information, then snapped the notebook shit and walked over to the wall where she’d hung a periodic table of the elements.

“What element does your bitbeast wield?”

“Seraphina is a fire dragon.”

Kiya ran her finger over the elements on the table, hovering over the transitional elements until she settled on one in the middle of the table.

“Tungsten has the the highest melting point of any metal and low thermal expansion due to its strong metallic bonds,” she explained. “It should easily be able to withstand the heat of Seraphina’s attacks. But - tungsten is brittle, and quite frankly, difficult to work with.”

“Alloying small quantities of steel with it would counteract that,” Matt supplied. “And it won’t compromise its overall durability.”

Kiya frowned, looking annoyed at the interruption. “Ten points to captain obvious,” she muttered, reaching for the sketch book once again and a pen. She scribbled something into the margins of the page and handed it back to Steph.

“If you leave the designs with me, I can have the parts to you by the weekend.”

“That soon?” Steph exclaimed, unable to hide her surprise. “That’s only three days!” She was used to Kenny working fast, but even he couldn’t put an entire beyblade together in three days.

Kiya just shrugged. “Girl, find me some caffeine and I’ll have it done in two.”

11 notes

·

View notes

Text

Purdue University material engineers have created a patent-pending process to develop ultrahigh-strength aluminum alloys that are suitable for additive manufacturing because of their plastic deformability. Haiyan Wang and Xinghang Zhang lead a team that has introduced transition metals cobalt, iron, nickel and titanium into aluminum via nanoscale, laminated, deformable intermetallics. Wang is the Basil S. Turner Professor of Engineering and Zhang is a professor in Purdue's School of Materials Engineering. Anyu Shang, a materials engineering graduate student, completes the team. "Our work shows that the proper introduction of heterogenous microstructures and nanoscale medium-entropy intermetallics offers an alternative solution to design ultrastrong, deformable aluminum alloys via additive manufacturing," Zhang said. "These alloys improve upon traditional ones that are either ultrastrong or highly deformable, but not both."

Read more.

#Materials Science#Science#Aluminum#Alloys#Additive manufacturing#Strength of materials#Transition metals#Intermetallics#Purdue University

11 notes

·

View notes

Text

Not all Blackbirds featured such extensive amounts of plastic components. On the A-12 prototype, A-12T trainer, M-21, and YF-12A models, silicone-asbestos panels were replaced with A-110AT titanium alloy skin supported by hat-section stiffeners

The two tails were canted inward and mounted atop the aft end of each engine nacelle. Each tail consisted of a stub fin and a rudder. The stub fin was fixed in place, extending approximately 21 inches above the nacelle surface. It was constructed of titanium alloy machined parts, plate, formed members, and sheet. The stub fin contained rudder servos and housed each rudder pivot post. One full rudder, having no fixed vertical stabilizer, was mounted on each stub fin. Each rudder extended approximately 75 inches above the stub fin. The left and right rudders were identical and interchangeable. The A-12 prototype, A-12T trainer, M-21 motherships, and YF-12A had rudders

19

American Institute of Aeronautics and Astronautics

made from titanium alloy. All others incorporated rudders made largely of plastic materials. The metal rudders were built with a central structural box section and attached leading- and trailing-edge assemblies. Plastic rudders incorporated basic frame members of titanium alloy. Subordinate members, including some of the ribs, spars, and exterior surface panels were made of bonded silicone-asbestos reinforced plastic materials. The plastic rudders

Plastic rudders incorporated basic frame members of titanium alloy. Subordinate members, including some of the ribs, spars, and exterior surface panels were made of bonded silicone-asbestos reinforced plastic materials. The plastic rudders weighed approximately 500 pounds and the metal rudders weighed somewhat less.

The plastic pieces shaped like a pie and later rectangular shaped helped decrease the radar cross-section in the blackbirds to about 10 m. This was an important step and making the A-12 and later SR 71 stealthy. It’s also why they started painting the chines and around the Blackbirds black to cover up the shape of the panels.

Linda Sheffield Miller

@Habubrats71 via X

20 notes

·

View notes

Text

Why Settle for Less When You Can Have the Best?

At Virat Special Steel, we bring you top-notch quality in tools, die, and mould steel materials that go beyond expectations. Crafted with precision and engineered for excellence, our steel is a class apart, delivering durability, strength, and consistency to power your projects.

Virat Special Steels apart is not just its extensive product range, which includes everything from Die Steel to High-Speed Steels, but also its unwavering commitment to quality. By importing Tools & Die Steels from globally renowned manufacturers.

Virat Special Steels' mission goes beyond mere supply; it aims to support and enhance the tool and steel products industry by empowering businesses with high-quality materials that are crucial for their success.

The company's product list is a testament to its diverse offerings: - Die Steel (HH 370 - 410 BHN) (DIN-1.2714 / AISI L6) - Hot Work Steels (DIN 2343, 2344 / AISI H11, H13) - Plastic Mould Steels (DIN 2738, 2311, AISI P 20) - High Speed Steels (DIN 3243, 3343 / AISI M2, M35) - HCHCr (DIN 2379, 2080 / AISI D2, D3) - Alloy Steels, EN-Series, etc.

For more information visit Choose Virat Special Steel for unmatched quality that stands the test of time. Don’t compromise—opt for the best and elevate your work with steel that’s built to perform.

Experience the difference. Experience the best. Choose Virat Special Steel! https://www.viratsteels.com/

View more: https://www.youtube.com/watch?v=c4h5KqyzVd0&t=5s

youtube

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#tool steel#diesteel#db6 steel#h13steel#h11steel#din 2714#din 2344#din2738#din2343#Youtube

3 notes

·

View notes

Photo

Jensen Interceptor III Convertible

Jensen's striking replacement for the slant-eyed C-V8 first saw the light of day in 1966. It broke some of the firm's established traditions in that the design was outsourced - to Carrozzeria Touring - and the bodies were made of steel rather than glass-reinforced plastic. Power was initially supplied by a 6276cc Chrysler V8, driving through either a four-speed manual or three-speed TorqueFlite automatic transmission to an LSD-equipped Salisbury rear axle. The MKII model of 1969 brought revised frontal styling and ventilated disc brakes. Introduced at the October 1971 Earl's Court Motor Show, the Interceptor III was visually distinguished by cast headlight surrounds, GKN cast alloy wheels and a comprehensively revamped interior and was produced in four Series - G, H, J and S4. By May 1972 the engines on RHD cars had been increased in capacity to a whopping 7212cc. A total of some 6,408 Interceptors were produced between 1966 and 1976, however, just 505 of those were Convertibles.

One of 262 examples manufactured in 1975, chassis number 23111713 was supplied new to the United States of America in left-hand-drive configuration. Fitted with the aforementioned 6276cc Chrysler V8 engine allied to the three-speed TorqueFlite automatic transmission.

59 notes

·

View notes

Text

From Sci-Fi to Reality: The Potential for Real-Life Mecha Inspired by Gundam!

I've watched mecha anime, the seriesVoltes V,Robotech, Video Senshi Laserion. In fact the great experience is watching Gundam anime.

In recent years, advances in robotics, artificial intelligence, and engineering have brought the idea of real-life mecha closer to reality. Inspired by iconic series like Gundam, researchers and engineers are exploring the possibilities of creating large, human-piloted robots. While we may not have fully functional Gundams yet, the progress made so far is promising. Let's delve into the current developments and the potential future of real mecha.

It happened during 2018

In Japan, engineer Masaaki Nagumo always dreamed of climbing into his very own Mobile Suit Gundam mecha. As an adult, he finally made that dream a reality.

Photos below:Sakakibara Kikai

He created the 28-foot-tall, 7-tonne-heavy LW-Mononofu robot as a project for his employer, industrial machinery maker Sakakibara Kikai, in Japan’s Gunma Prefecture. The metal colossus took six years to finish, and is probably the world’s largest anime-inspired robot that you can actually ride in and control. It can move its arms and fingers, turn its upper body, and walk forward and backward at a snail-like speed of 1km/hour. As any respectable mecha, it also has a weapon – a metal gun that fires sponge balls at a speed of 87 mph.T

The LW Mononofu can be powered by both a 200-volt AC electricity source and a 24-volt DC battery. Its cockpit features levers, pedals and buttons that the rider can use to control the movements of the robot, as well as monitors showing live footage shot by cameras installed at five points on its gigantic body.

its only con is that it can't leave the hangar it was built in, because it is higher than the large door. It has to be dismantled to be taken out…

Despit this the enthuthiasts are determined to make the Giant mecha a real.

Well, thanks to the japanese company called Tsubame Industry, that dream is nearly becoming reality. Well, if we can afford paying it, of course. The small Japanese startup recently showcased its newest product, dubbed ‘ARCHAX’, a pilotable robot inspired by Japanese mecha culture. Standing a whopping 4.5 meters tall and weighing around 3.5 tons, this real-life mecha is powered by a 300V battery and can switch from a standing mode to drivable mode, attaining a top speed of 10 kilometers per hour.

Nonetheless,if someone desires to undergo the thrilling journey with the ARCHAX, he has to pay an estimated 400 million yen ($2.75 million) for one.

It's name is inspired by that of the flying dinosaur Archeopteryx – was recently showcased in a series of videos posted by Tsubame Industry, and the Japanese startup announced that a working version will be presented at the Japan Mobility Show 2023 (formerly the Tokyo Motor Show) in November. As for when the mecha will hit the market, a Tsubame spokesperson said that it is expected to be available in about a year. However, considering the high price tag, the company is targeting wealthy foreign billionaires as potential clients.

Being made of iron and aluminum alloy, while the outer shell consists mainly of FRP (fiber-reinforced plastic). Although the head appears to feature a large camera, it is only for show. In reality, the pilot maneuvering the ARCHAX will have footage captured by 26 different cameras mounted all over the mecha fed into a number of monitors inside the cockpit. The control panel is reportedly similar to that of construction machinery, consisting of two joysticks, a number of pedals, and a touchscreen. Interestingly, the ARCHAX can also be remote-operated.

This mecha can move at a speed of 2 km/h, and in drive mode that speed is increased to 10 km/h. It’s not exactly soaring through the air like in video games, but it’s better than just standing still. It can tilt forward a maximum of 20 degrees in stand-up mode and 30 degrees in drive mode, to ensure that it doesn’t fall over. If these values are exceeded, the system shuts down to prevent serious accidents. The mecha is subject to risk assessment in accordance with the safety regulations of construction machinery and robots.His mechanical arms have 5 movable fingers, and it can grab a variety of things, still the weight of them is limited to 15 kilograms, for safety reasons. Trying to lift something heavy could cause the mecha to topple, putting the pilot at risk and damaging it.

Conclusion

The journey from science fiction to reality is a challenging but exciting path. While we may not see fully operational Gundams patrolling our cities in the immediate future, the advancements in robotics, AI, and engineering are bringing us closer to realizing the dream of real-life mecha. The fusion of technology and imagination continues to push the boundaries of what is possible, making the future of mecha an exhilarating topic to watch.

#sci fi#science fiction#mecha anime#Mobile Suit Gundam#機動戦士ガンダム#Kidō Senshi Gandamu#Tomino Yoshiyuki#富野 由悠季#Military science fiction#engineer Masaaki Nagumo#robots#real giant robots#ARCHAX mecha#Tsubame Industries#日本国#Japan is great#日本が大好きです#I love Japan#artificial intelligence#giant humanoid robots#technological advancements#日本は素晴らしい#LW-Mononofu#Sakakibara Kikai#サカキバラキカイ

2 notes

·

View notes

Text

Plastic Materials: Tall, Rich and Handsome in Engineering Plastics--Polycarbonate (PC)

I. Introduction to Engineering Plastics So-called engineering plastics are industrial plastics that can replace metals and be used as industrial parts or shell materials. Engineering plastics need to have excellent comprehensive performance. Compared with general plastics, they can meet higher requirements in mechanical properties, heat resistance, durability, corrosion resistance, etc. In…

View On WordPress

#crystalline plastics#engineering plastics#industrial parts#industrial plastics#injection molding#PA#PBT#PC#PC alloy#plastic products#POM#structural engineers

0 notes

Text

First chapter of Expiate

Crossposted to Ao3

Super Paper Mario, brotherly angst

~~~~~~~

It has to be a trick, some sleight of hand, some mischief perpetrated by that damned jester and his creepy mask.

They had fought before. They were brothers, of course they had fought. Rolling around at their father’s feet under a rickety kitchen table, vying for the single plastic wrench from their grungy, second-hand playset. Wrestling each other on a littered baseball field in Dyker Beach Park, old cigarette butts sticking to their clothes. And then there had been the infamous melee in the hallway of St. Ephram’s, lockers thundering with each impact as they threw each other about in a blind rage, the aftermath of Luigi being threatened with expulsion after the incident in religion class.

But now, all he can do is stare as his brother cackles wildly, leaping to the top of an eight-story-high robot, boasting of his spiritual bond with the towering head before jumping into the cockpit, letting loose a stream of scorching lasers. Mario can’t get his limbs to move, can’t form the commands in his brain that would lead him away from this awful scene. And he’s lost the plot somewhere, because now they’re back in space , Luigi’s monstrous creation giving chase to Peach and Squirps, who are hightailing it to the nearest asteroid cluster for cover.

His brother was working for Count Bleck. His brother was trying to end the world.

His brother was trying to kill him.

Mario laughs, his gut convulsing, again and again, each throb stronger than the last. It begins to hurt after a minute, but he can’t stop himself, bobbing up and down in the vast nothingness of space with each pained chortle.

The terrible discord echoes throughout the glass container fixed on his head, so much so he almost doesn’t hear the shriek as Brobot careens through the nearest nebula, gargantuan amber eyes emerging from starry destruction. Two dark vortices track a direct line his way, pools of malice and motor oil racing through a hazy curtain of glistening starlight and noxious ozone.

This is it, he thinks as the robot’s jaw unhinges, revealing a cavernous maw of angry geared teeth guarding a needle-pointed tongue curled in violent anticipation. The robot’s engines give a mighty roar, the backdraft pushing Mario’s bobbing trajectory in reverse before he feels the pull of a massive inhalation, Brobot sucking dust and asteroids and all kinds of space matter into its dark, alloyed throat. Mario’s survival instinct finally kicks into gear as he flails his limbs in every direction, searching for purchase, any anchor that will save him from being swallowed and digested by his brother’s murderous invention.

It’s too late, though, any hope of survival already halfway down the robot’s hungry gullet. He tries to remember the Prayer of Divine Mercy, one final supplication for forgiveness for both him and his brother, but the words won’t come. Brobot’s breath is searing down his neck when there’s a tug on his overalls, space flipping in all directions as Luigi shoots past him, leaving a trail of half-chewed, calescent detritus in his wake.

A meaty hand slaps the face of his helmet.

“Get your head in the game, Red!” Bowser hisses, claws digging into Mario’s upper arm. “This guy and his stupid robot mean business.”

This guy and his stupid robot are now trailing Peach and Squirps through a cluster of squarish mini-moons, jaw still unhooked as Brobot attempts to vacuum everything in its path, obliterating stars, comets, even small planets. It tries to devour Peach, who cuts a hard turn to the right, barely avoiding a fiery exhale, the hem of her skirt blistered and smoking as she clings to brave, little Squirps. Mario doesn’t know if it’s possible to be sick in space, if gravity would lock his disgust in his churning gut. He swallows down the acrid tang of bile, swearing to every saint he can name that whoever’s sick ploy this is, whoever had even a finger to do with what has become of his brother - he will tear them limb from limb while they scream for a mercy Mario will never allow.

It’s a close thing. The robot is good, the man driving it even better, the synthesis of expert engineering guided under a malevolent, deft hand. The three of them huddle under Peach’s impenetrable parasol, volleys of rocket fire bouncing off the shimmering pink fabric, again and again until even the seemingly inviolable shield begins to belch smoke. There’s a lull in the downpour of blaster fire, a small opening, so thin Mario thinks he may need Slim to fit through it. He doesn’t allow himself to think, launching upwards, using a protesting Bowser’s shell as leverage, catapulting himself right to the bulbous antenna of the robot. In quick succession, Mario deals it a thunderous blow, stomping with all his might as the orb finally cracks. He leaves Boomer behind for good measure, the little PIxl seeming to have grasped the gravity of the situation as he ignites with exceptional alacrity.

The resulting cataclysm sends shards of metal and wiring spraying in all directions, flowers of conflagration blossoming in quick time, a bouquet of iron-wrought carnage.

The elation of victory, the downward rush in the bloodstream, is quickly dispelled. Luigi won’t be emerging from that smoking wreckage unharmed, if he emerges at all. Mario’s heart bounds up his throat, threatening to push his Adam’s apple straight through his skin as he makes to rush towards the remains of the violent creation, which, along with the rest of them, have fallen back into the Whoa Zone, onto solid ground. He’s held back, both arms stuck in a firm grip on either side by Peach (whose wide eyes and tight lips tell him all he needs to know about her knowledge of the situation) and Bowser (who loudly opines that Mario has lost his damn mind).

Mario can only pray as the smoldering wreckage sends plumes of toxic clouds skyward, can only send entreaties up and down, left and right, into any direction or dimension he can think of that the man in the wreckage is not his brother, that it’s a lie, a mirage. He tells himself they’re back in the gaudy D-Dimension, that maniacal labyrinth of mirrors and deceit, but before he can convince himself of the lie, Mario sees something emerging from what was an amber iris, a peek of green and black. Luigi clambers out of the wreckage. He’s panting, dirty, his tunic and pants ripped and stained. Mario swears he sees a trickle of blood running down a now exposed forearm but Luigi wipes the sweat from his mouth with the back of his arm, giving them a feral smile as he boasts of future victories, allowing for one last verbal swipe at “Mr. Jumpsallthetime” before he opens a dimensional portal and disappears into nothingness.

Mario staggers towards the heap of crumpled metal, left ankle barking with the movement. There’s going to be an ugly trail of bruises come tomorrow, a haphazard map drawn up his left thigh all they way to his back. He pauses under what was once the robot’s mustache, hands going to his knees, catching a breath, then another and another and he can’t stop, in and out, in and out breathing was he always this aware of breathing why can’t he catch his breath he can’t breathe he can’t he can’t he can’t -

A soft hand finds the back of his neck, rubbing gently at the swollen, red skin, another wrapping around his waist, a familiar voice giving hushed instructions. Numbers, it sounds like. One, two, three, four, that’s right, Mario. Now exhale, one, two, three, four. Let’s do it again. One, two, three, four…

Color is the first to bleed back into his reality, the angular, neon scribbles of the Whoa Zone’s floor swirling in Mario’s vision. The rest of the world follows soon after - the stale odor of burnt metal an uneasy mix with the lingering chill of outer space. He shivers. Peach still has him half-wrapped in her soot-stained arms, the hem of her dress ragged and torn, tie-dyed in dark scorch marks. A quick glance across the way reveals a wide-eyed Bowser gaping in their direction and it’s almost funny, Bowser’s toothy gawking, if it weren’t so serious, the truth of their situation being shared in half-whispers between Tippi and Squirps. Questions about the “bad man,” the “creep,” the “evil guy who hurt me,” and it’s that last one that nearly sends Mario back into another spiral, that threatens to unravel his tenuous hold on reality. (His brother beat up a child ).

He focuses on the floor. On the rough denim bunched beneath his fingers. On Peach’s voice, scolding Tippi and Squirps into lowering their voices.

“Is Squirps okay?” Mario asks in an attempt to distract himself from his thoughts (Bad man. Creep. Evil guy. He can’t stop replaying the conversation, a sick, infinite loop woven in braids of guilt and horror. Luigi is the bad guy). Mario’s voice is ragged, hoarse and he’s yet to unlock his hands from his knees, yet to right himself from his bent-over position.

“He’ll be okay,” Peach answers, still rubbing circles on Mario’s back. “A little sore and a little scared,” she adds after a moment, breaking the massaging rhythm, inserting a rest that lasts a beat too long.

Peach clears her throat. When she speaks again, she almost sounds apologetic. “Maybe he didn’t mean to - “

Mario shoots to full height, ignoring the protests from his aching back, the electric trill shooting up from his battered ankle. He turns to Peach, making a show of patting at least some of the space matter from his overalls. He gives his cap a brief inspection, patting it down as well, sending a miniature plume of dust skyward before replacing it firmly on his head. “We need to move forward,” he says, voice still struggling against smoke-bruised vocal cords. “We can’t get distracted. There’s too much on the line,” he adds, gesturing at the swollen violet wound in the sky.

Peach’s mouth forms a thin line, her gaze searching Mario, reaching into his thoughts, a fine, taut line of shimmering gold. She says nothing, only giving Mario a shallow nod. She won’t push him on the issue. Not now. Not with so much at stake.

There will be time to grieve later.

It’s a somber processional to the dimensional portal.

Tippi is already waiting at the threshold, wings flittering in impatience, Squirps curled in on himself on the ground beneath her. Mario trails Peach and Bowser, who exchange hushed words, Bowser throwing an occasional wide-eyed glance in Mario’s direction.

“Did that green jerk land a solid hit or something?” he hears Bowser mutter. “Is that why Red’s acting so weird?”

Peach shakes her head. “He’s fine,” she lies. “He has to be.”

#hello there#writing#the eternal struggle#mario#luigi#mr l#spm#angst#my usual#i'm actually witing!#consistently!#this hasn't happened in forever!#meaning it's time to resurrect the star war wips#okay now it's time to hit the gym#l-ater! tumblr!

47 notes

·

View notes

Text

Haynes 188 Sheet Suppliers in India

Haynes 188 Sheet in Mumbai, Haynes 188 Sheet Importers in Mumbai, Haynes 188 Sheet Suppliers in Mumbai, Haynes 188 Sheet Exporters in Mumbai, Haynes 188 Sheet Stockists in Mumbai.

HAYNES 188 Sheets is a cobalt-nickel-chromium-tungsten alloy that may be readily fabricated for aerospace and commercial gas turbine engine applications, including combustion cans, flame holders, liners, transition ducts, and afterburner parts. HAYNES 188 Coils is generally found in hot sections of engines in burner cans, ducting and afterburner components. In recent years, Udimet 188 Coils has been eclipsed by Alloy 230 for many applications due to improved properties. Udimet 188 Plates has good forming characteristics and is capable of being forged, hot worked or cold worked, although it does work-harden very rapidly so frequent intermediate annealing treatments are recommend for complex forming operations. Buy Alloy 188 Plates at reasonable price from us.

What are Haynes 188 Plates?

Haynes 188 Plate is a cobalt-based alloy that is composed of nickel, chromium, tungsten, and molybdenum, along with other elements. It is known for its excellent high-temperature strength, resistance to corrosion and oxidation, and good weldability.

What are the properties of Haynes 188 plates?

Haynes 188 plates have excellent high-temperature strength, good oxidation resistance, and good resistance to corrosion and erosion. They also have good weldability and formability, making them suitable for a wide range of industrial applications.

What are the applications of Haynes 188 plates?

Haynes 188 plates are commonly used in high-temperature applications, such as gas turbine components, exhaust systems, and heat exchangers. They are also used in chemical processing, power generation, and aerospace applications.Specifications:AMS 5608 / AMS 5609Standard:AMS, AMS and APISpecialize:Shim Sheet, Perforated Sheet, B. Q. Profile.Size:0.5 MM TO 200 MM THICK IN 1000 MM TO 2500 MM WIDTH & 2500 MM TO 12500 MM LENGTHForm:Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange)Finish:Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)Hardness:Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.Grade:Haynes 188 (UNS R30188)

Haynes 188 Plates Equivalent Grades

STANDARDWERKSTOFF NR.UNSHaynes 188–R30188

188 Haynes Plates Chemical Composition :

GradeCMnpSSiCrNiCoBFeLaWHaynes 18805-151.25 max020 max.015 max20-.5021.0 -23.020.0 -24.0Bal.015 max3.0 max03-1513.0 -15.0

Special Products

Haynes 188 Sheet

Alloy 188 Sheet

Conicro 4023 Sheet

2.4683 Sheet

Uns R30188 Sheet

Cobalt Alloy Haynes 188 Sheet

AMS 5772 Sheet

Cobalt Nickel 188 Sheet

Stellite 188 Sheet

Haynes 25 Sheet

L605 Sheet

Udimet L605 Sheet

Stellite 25 Sheet

UNS R30605 Sheet

2.4964 Sheet

AMS 5537 Sheet

Ams 5759 Sheet

HS25 Sheet

Cocr20w15ni Sheet

Cobalt Alloy Haynes 25 Sheet

Cobalt L605 Sheet

Inconel X750 Sheet

X750 Sheet

Haynes X750 Sheet

Nicrofer 7016 Sheet

Udimet X750 Sheet

Pyromet X750 Sheet

Superimphy 750 Sheet

2.4669 Sheet

UNS N07750 Sheet

Nickel Alloy X750 Sheet

NiCr15Fe7TiAl Sheet

Nickelvac X750 Sheet

AMS 5699 Sheet

Alloy X750 Sheet

Nimonic C263 Sheet

Nickel Alloy C263 Sheet

UNS N07263 Sheet

Haynes 263 Sheet

2.4650 Sheet

NiCo20Cr20MoTi Sheet

AMS 5872 Sheet

Hastelloy C263 Sheet

Nicrofer 5120 Coti Sheet

Nicrofer 5120 Coti Round Bar

Inconel 945 Round

Inconel 945 Bar

UNS N09945 Round

Inconel 945X Round

2 notes

·

View notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

Compact yet robust, cartridge heaters are indispensable in various industries for their remarkable compactness and unparalleled power. Their cylindrical design, housing a high-resistance wire within a metal sheath, ensures concentrated and precise heating. From plastic moulding to aerospace engineering, these miniature yet mighty cartridge heaters find their place in diverse applications, providing uniform heat distribution with exceptional precision. Understanding their anatomy reveals efficient components like the nickel-chromium alloy wire, swiftly transferring heat to the surrounding material. Factors like watt density, sheath material, and operational temperature significantly influence their performance and suitability for specific tasks.

#CartridgeHeaters#IndustrialHeating#PrecisionHeating#CompactPower#EfficientTechnology#VersatileHeaters#IndustrialApplications#HeatingSolutions#RobustPerformance#OptimalEfficiency

2 notes

·

View notes