#Additive manufacturing

Explore tagged Tumblr posts

Text

Nanomanufacturing process slashes chip production costs by 99%

The current microelectronics manufacturing method is expensive, slow and energy and resource intensive. But a Northeastern University professor has patented a new process and printer that not only can manufacture advanced electronics and chips more efficiently and cheaply, it can make them at the nanoscale. "I thought that there must be an easier way to do this, there must be a cheaper way to do this," says Ahmed A. Busnaina, the William Lincoln Smith professor and a distinguished university professor at Northeastern University. "We started, basically, with very simple physical chemistry with a very simple approach." Busnaina runs the National Science Foundation Center for High-rate Nanomanufacturing at Northeastern University.

Read more.

#Materials Science#Science#Manufacturing#Materials processing#Electronics#Northeastern University#Nanotechnology#Additive manufacturing#3D printing

31 notes

·

View notes

Text

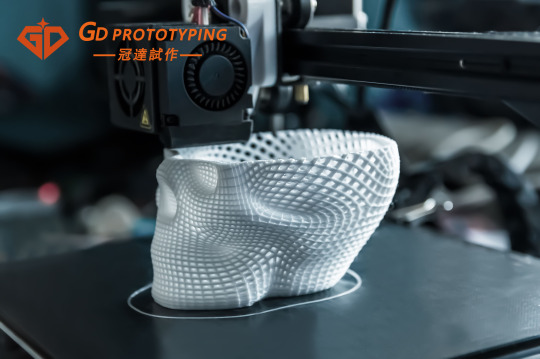

Top 8 Applications of 3D Printing in Medical Industry

3D printing technology, with its highly customizable, responsive and material-saving features, is triggering profound changes in the medical field. Especially in the application of medical models, 3D printing technology shows unparalleled advantages and potential.

Furthermore, 3D printing technology, as an emerging additive manufacturing technology, has made breakthroughs in its application in the medical field in recent years. The application of 3D printing technology in the medical field is becoming more and more widespread. Through the layer-by-layer stacking of digital models, a variety of medical devices, prosthetics, orthotics and other aids, and even human organs, can be accurately printed.

1.Surgical preview model

With 3D printing technology, doctors can create surgical preview models to help them simulate operations before surgery, improving accuracy and safety.

It is important for medical workers to conduct preoperative planning for risky and difficult procedures. In the previous surgical preview process, medical workers often need to obtain the patient's data through CT, magnetic resonance imaging (MRI) and other imaging equipment, and then the two-dimensional medical image using software to convert into realistic three-dimensional data. Today, medical workers can use devices such as 3D printers to print 3D models directly. In this way, it not only can assist the doctor to carry out accurate surgical planning, improve the success rate of surgery, but also to facilitate the communication and exchange between medical workers and patients on the surgical program plan.

2.Surgical guide

Surgical guides can help the surgeon to accurately position and operate during surgery, reducing surgical errors and improving surgical outcomes.

As an auxiliary surgical tool during surgery, surgical guides can help medical workers to accurately implement surgical programmes. Currently, the types of surgical guides have included joint guides, spinal guides, oral implant guides, etc. With the help of 3D printed surgical guides, firstly, the 3D scanning technology can produce three-dimensional data on the patient's affected area, which allows the doctor to obtain the most realistic information, so as to better plan the surgery. Secondly, while making up for the shortcomings of the traditional surgical guide manufacturing process, the size and shape of the guide can also be adjusted as needed.In this way, different patients can have a guide plate that meets their real needs.

3.Dental applications

3D printing technology is also widely used in the field of dentistry to print personalized trays, moulds, etc., to help patients have better dental treatment.

The application of 3D printing in the dental field mainly focuses on the design and production of metal teeth, invisible braces, etc. The emergence of cutting-edge technology of 3D printing creates more possibilities for those who need orthodontic treatment to achieve personalized and customized braces. At different stages of orthodontic treatment, orthodontists need different sets of braces. With the help of 3D printing to create multiple sets of braces needed for orthodontic treatment, it not only helps the healthy development of teeth, but also reduces the cost of braces production. The significance of these digital technologies is that they are gradually making it less necessary for doctors to make models, dentures, etc. by hand, and returning more of their efforts to the diagnosis of oral diseases and the performance of oral surgery itself.

4.Rehabilitation medical equipment

Through 3D printing technology, a variety of rehabilitation medical devices, such as prosthetics and orthotics, can be created to help patients regain function.

The real value of 3D printing for orthopaedic insoles, bionic hands, hearing aids and other rehabilitation devices is not only to achieve accurate customization, but also to allow accurate and efficient digital manufacturing technology to replace the traditional production methods, reducing the cost of individual customized rehabilitation medical devices and shortening the production cycle. 3D printing process is diversified, and there is a wide range of 3D printing materials. SLA light-curing 3D printing technology has the advantage of being able to provide the most efficient and cost-effective 3D printing technology. SLA light-curing 3D printing technology is widely used in rapid prototyping by the medical device industry due to its advantages of fast processing speed, high precision, good surface quality of photosensitive resin material moulding and moderate cost.

5.Medical Equipment Cases

3D printing technology can also be used to create a variety of medical devices, such as surgical instruments and medical equipment, to improve the personalization and accuracy of medical devices.

Take the example of 3D printing for mass customized production in the hearing aid shell industry. In the traditional way, injection moulds need to be made from a model of the patient's ear canal. The final shape of the hearing aid is obtained by drilling sound holes and manually processing the plastic product. If a mistake is made during the process, the mould needs to be recreated. The process of making a hearing aid using a 3D printer, on the other hand, begins with the design of a silicone mould or impression of the patient's ear canal, a step that is done using a 3D scanner. CAD software is then used to convert the scanned data into a design file that can be read by the 3D printer. The designer can then use the software to modify the 3D image and create the final product shape.

6.Precision replication and personalization

3D printing technology is able to accurately restore a patient's anatomy and produce full-size, high-fidelity medical models based on the patient's CT, MRI and other imaging data. These models not only have extremely high geometric accuracy and surface quality, but also reflect the unique physiological characteristics of the patient, providing doctors with real and reliable references.

7.Teaching and training

3D printed medical models also play an important role in medical education and training. By printing out models of various typical cases, medical students can perform practical operations in a simulated surgical environment to enhance their surgical skills and resilience. At the same time, these models can also be used as teaching tools to help students better understand human anatomy and disease principles.

8.Scientific research and experimentation

In the field of medical research, 3D printed medical models also have important applications. Researchers can use these models to conduct experimental studies such as drug screening and biomechanical testing to explore new treatment methods and technologies. In addition, by printing tissue or organ models with specific physiological functions, they can also provide strong support for research in cutting-edge fields such as organ transplantation and regenerative medicine.

In summary, 3D printing technology has a wide and far-reaching significance in the application of medical models. It not only improves the accuracy and efficiency of medical services, but also promotes the innovative development of medical education, research and clinical practice. With the continuous progress of technology and the expansion of application scope, we have reason to believe that 3D printing will play a more important role in the future medical field.

#3d printing#3d printing services#3d printed#additive manufacturing#3d print#medical device machining#medical 3d printing#3d printed parts#3d printing materials market#3d printing market share

4 notes

·

View notes

Text

Additive manufacturing for aerospace part.

Know more about additive manufacturing

#additive manufacturing#3d printing#aerospace#science#materials science and engineering#engineering#materials

6 notes

·

View notes

Text

Formnext is happening next week! 🌟 Curious about what to expect? Visit our Formnext Highlights Guide to warm up for the event.

4 notes

·

View notes

Text

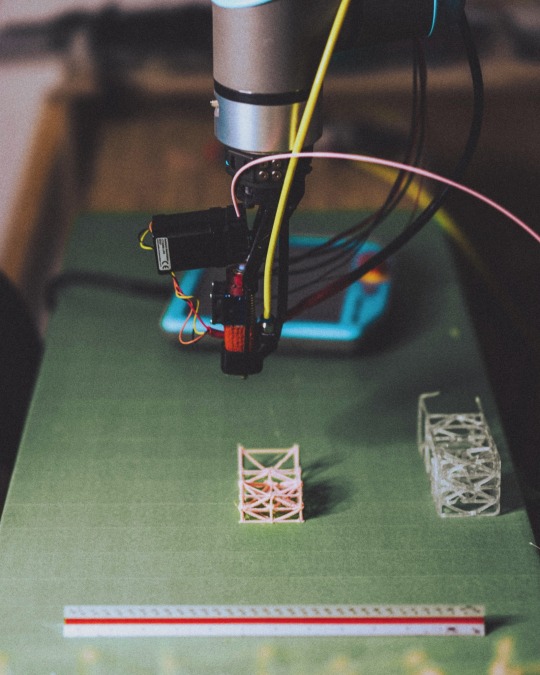

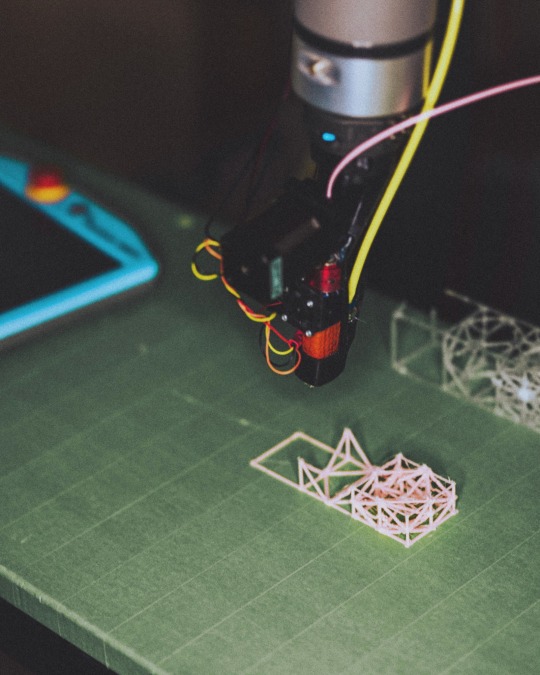

scene setup

#3d printing#digital fabrication#robotic fabrication#additive manufacturing#robots in architecture#3dprint

7 notes

·

View notes

Text

2 notes

·

View notes

Text

3D printing with Ceramic slurries

Did you know that 3D printing is becoming more accessible and affordable? While printing in various plastics or resin is relatively easy and inexpensive, printing in other materials can be more complex. There are printers available for metals and even concrete, but they tend to be much more expensive compared to their plastic counterparts. However, ceramic, as a material for 3D printing, has…

View On WordPress

12 notes

·

View notes

Text

From 3D Printing to Bioprinting: The Future of Manufacturing

In recent years, the world of manufacturing has experienced significant transformations, with 3D printing and bioprinting technologies emerging as key drivers of change. These advanced manufacturing methods have the potential to revolutionize how products are created, impacting various industries and potentially reshaping the global supply chain. In this article, we will delve into the world of…

View On WordPress

#3D printing#additive manufacturing#bioprinting#decentralized production#future of manufacturing#on-demand manufacturing#personalized medicine#rapid prototyping#sustainability#tissue engineering

2 notes

·

View notes

Text

Manufacturing Look: Energy-Efficient Strategies for a Greener Industry

As businesses worldwide are increasingly required to reduce their environmental footprint, achieving maximum productivity while minimizing energy consumption has become a key strategy for adopting sustainable practices. By effectively utilizing energy, industries can save significant amounts of money, reduce carbon dioxide emissions, and contribute to environmental preservation. This article explores some of the most common approaches to improving energy efficiency, along with their benefits and drawbacks.

The Importance of Energy Efficiency in Production

The manufacturing sector is among the most energy-intensive industries globally and is a major contributor to both energy consumption and greenhouse gas emissions. With the growing need to address climate change, manufacturers are being urged to reduce energy use while maintaining productivity and product quality. Implementing energy-efficient manufacturing processes provides two main benefits: it helps companies meet regulatory requirements by reducing energy consumption and offers a competitive advantage by cutting costs and enhancing their reputation.

Implementation of Energy Management Systems

One of the most effective strategies to boost energy efficiency is the adoption of Energy Management Systems (EnMS). EnMS involves a systematic approach to measuring, monitoring, and optimizing energy use in the production process. When combined with big data and real-time monitoring technologies, companies can track energy waste, evaluate progress, and make data-driven adjustments to eliminate inefficiencies.

Read More: https://manufacturinglook.com/

#3d printing#additive manufacturing#energy-efficient manufacturing#industry 4.0#manufacturing look#quality control in manufacturing#reshoring trends#sustainable manufacturing

0 notes

Text

From roots to rugged circuits: Tree-inspired printing tech for flexible electronics

A printing technology, inspired by the resilience of tree root systems, is set to redefine the future of conformal electronics. This innovation addresses long-standing challenges related to the mechanical stability and resolution of circuits on irregular surfaces, particularly in smart robotics and advanced sensing systems. By improving both the durability and precision of electronic circuits, this new method promises to withstand extreme conditions—such as high temperatures and mechanical stress—thereby vastly expanding the potential applications and reliability of conformal electronics. Conformal electronics, which are crucial for applications like smart skins and robotics, have long struggled with significant mechanical and thermal vulnerabilities. Traditional printing methods often produce circuits that are prone to tearing, cracking, and other forms of damage, limiting their performance and dependability.

Read more.

#Materials Science#Science#Electronics#Flexible electronics#Circuits#Strength of materials#Biomimicry#Additive manufacturing

21 notes

·

View notes

Text

Feature story in leading newspaper on Lignik

Gamechanger 3D-printable biosynthetic material from CO2 for low-cost housing

Lignik can potentially remove billions of tons of CO2 from air

https://tribune.com.pk/story/2537139/lignik-a-solution-to-housing-issue

#australia#melbourne#pakistan#climate change#CCUS#co2#co2 emissions#housing#wastemanagement#affordability#climateactionnow#climate action#inventions#3d printing#additive manufacturing#biosynthesis#materials science

0 notes

Text

0 notes

Text

5 Common Tooling Challenges & How 3D Printing Solves Them 🚀

Struggling with tooling delays and high costs? Additive manufacturing eliminates these hurdles, making production faster, more efficient, and cost-effective. Discover the game-changing benefits! ✅ 80% Cost & Lead Time Savings – Injection molders using 3D-printed tooling. ✅ 300% Productivity Boost – Manufacturers optimizing jigs & fixtures. ✅ Faster EOAT Production – From weeks to overnight. Say goodbye to costly delays and hello to next-level efficiency with Stratasys 3D Printing! 🔗 Learn more: www.altem.com 📞 Contact us: +91 99009 59303

0 notes

Text

Some photos from the printing process

9 notes

·

View notes

Text

The AU project leverages the benefits of additive manufacturing , (AM), computational design and the use of composite materials to drive innovation in the medical and healthcare sector. By integrating these advanced technologies, AU aims to:

Optimize pressure distribution and comfort using personalized pressure mapping data.

Reduce weight, product size, and part count, enhancing ergonomics and usability.

Ensure more effective cooling and breathability.

Extend product longevity, performance, and customizability.

Introduce cutting-edge aesthetics to help combat stigma.

Improve sustainability by prioritizing additive over traditional subtractive manufacturing processes.

For more information, get in touch or check out our submission: 🔗 Link

#industrialdesign#product#composites#design#designer#rapidprototyping#3dprinting#additive manufacturing#cushion#computationaldesign

1 note

·

View note

Text

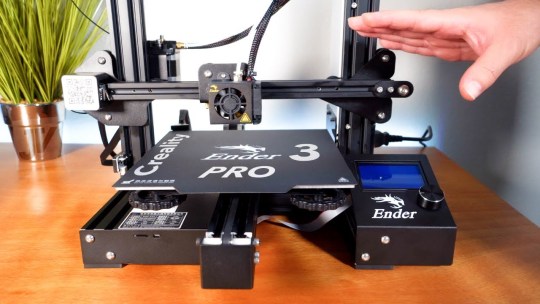

Mastering the Art of 3D Printing with Ender 3 Pro: Tackling Print Bed Adhesion Woes

So you got an Ender 3 pro? and you are having issues Embarking on a journey into the world of 3D printing can be an exciting yet challenging endeavour, especially when faced with print bed adhesion issues. If you find yourself grappling with stubborn prints sticking a bit too well, fear not. In this guide, we will delve into the nuances of optimizing your Ender 3 Pro, addressing common…

View On WordPress

4 notes

·

View notes