#Glass fiber reinforced thermoplastics

Explore tagged Tumblr posts

Text

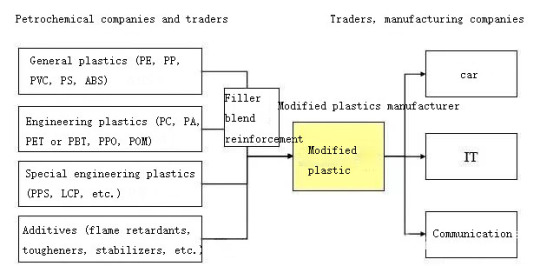

What are methods of plastic modification? What categories are there!

1. What is modified plastic? On the basis of general plastics and engineering plastics, through physical, chemical, mechanical and other methods, through filling, blending, reinforcement and other processing methods, performance of plastics is improved or functions are added, mechanical properties such as flame retardancy, strength, impact resistance, toughness of plastics are improved and…

View On WordPress

#Chemical modification#electronic appliances#Engineering plastic alloy#Engineering plasticization#engineering plastics#flame retardant#flame retardant color masterbatch#Flame retardant resin#Flame-retardant plastic products#Functional color masterbatch#Glass fiber reinforced thermoplastics#High performance of engineering plastics#modified plastic#Physical modification#Plastic alloy#plastic extender fillers#Plastic flame retardant#plastic materials#plastic modification#plastic modification technology#plastic products#polymer plastics#Reinforced and toughened resins#Reinforcement materials#reinforcing material#toughening agents

0 notes

Text

Plasticair Environmental: Leading Ventilation Fan Solutions

Plasticair Environmental specializes in high-performance air filtration solutions, including Horizontal Packed Bed, Fume Hood, Chrome, Vertical Packed Bed, Venturi scrubbers, and Mist Eliminators. Trusted by Plasticair Inc.

#plasticair#plasticair enviromental#Fiberglass-Reinforced Plastics (FRP)#Corrosion Resistance#Fiber Reinforced Plastics#Reinforced Thermoset Plastic (RTP)#Reinforced Thermoset Resin (RTR)#Glass-Reinforced Plastic (GRP)#Hand Lay-up Fabrication#Resin Transfer Molding#Corrosion Barrier Coating#Plasticair FRP Fans#Cost-Effective Solution#Industrial Applications#Quality Control in FRP#Resin Brand Importance#Durability of FRP#Thermoplastics vs. Thermosets#Fan Specifications#Acid Scrubbers#Alkaline Scrubbers#Odor Scrubbers#Odour Scrubbers#Chlorine Scrubbers#H2S Scrubbers#SO2 Scrubbers#Wet Scrubbers#Chemical Scrubbers#Fume hood scrubbers#Venturi scrubber

2 notes

·

View notes

Text

Fiberglass Recycling

Fiberglass is a type of composite that consists of a polymer material reinforced with glass fibers. Because of the nature of many composites, and the separation that recycling would entail, fiberglass is not often recycled and is considered to be difficult to recycle. This is particularly the case if thermoset polymers are used (as opposed to thermoplastic polymers), which cannot currently be recycled. Typically, when fiberglass is recycled, it is ground down before separation occurs between the plastic and glass components, and only the glass is often recycled. It should be noted that fiberglass is often made from recycled glass as a raw material to begin with. As the demand to recycle fiberglass increases, interest also grows in developing the infrastructure and policies needed to do so.

Sources/Further Reading: (Image source - ThePaGerS) (Composites World) (2022 article) (Wikipedia)

#Materials Science#Science#Glass#Composites#Fiberglass#Glass fibers#Recycling#Waste#2024Daily#WasteWednesday

20 notes

·

View notes

Text

TPO Waterproof Sheet Extrusion Line

Jwell company adopts the solid roll for combining multilayers, this new technology make the TPO sheet having a good function against wind uncovering.TPO waterproof sheet is a new type of waterproof product, which is produced with thermoplastic polyole-fin plus antioxygen and plastifier and so on, the middle layer is polyester fabric for reinforcement, the surface is laminated with textile fiber and aluminum foil. This kind of TPO waterproof sheet has the features of good weatherproof and suppleness. It is mainly used for house, tunnel, basement architecture and other waterproof fields. Used for different kinds of plastic material, such as PVC, TPO,etc.Being able to produce below sheets: Plastic roll sheet (model: H): without coating with inner reinforced material or outer material. Roll sheet with outer fiber (Model: L): coating with fiber or non-woven fabric. Inner reinforced roll sheet (Model: P): Inner layer coats with polyester mesh. Inner reinforced roll sheet (Model: G): Inner layer coats with glass fiber. Features of TPO waterproof coiled material 1. Ethylene propylene rubber and polypropylene are combined by advanced polymerization technology, which has both excellent weather resistance of ethylene propylene rubber and weldability of polypropylene. 2. The special formulation technology does not need to add any plasticizer that is easy to make the material brittle, does not produce the embrittlement of general hot welded coiled materials (such as PVC) due to the migration of plasticizer, and maintains the long-term waterproof function. 3. Excellent high and low temperature resistance. Like rubber materials, it still maintains flexibility at - 50 ℃ and mechanical strength at higher temperature. 4. Chemical resistance, acid, alkali, salt, animal oil, vegetable oil, lubricating oil corrosion, algae, mold and other microbial growth. 5. It has excellent root puncture resistance and can be used as root puncture resistant coiled material for planting roof. 6. Heat aging resistance and good dimensional stability. 7. The light colored surface dominated by white has smooth surface and high reflectivity, which has energy-saving effect 8. The lap joint is constructed by thermal welding, which can form a high-strength and reliable sealing waterproof layer. 9. The reinforced TPO waterproof coiled material is sandwiched with a layer of polyester fiber fabric in the middle, which provides the coiled material with high tensile performance, high tear strength, fatigue resistance and puncture resistance, and is more suitable for mechanically fixing the roof system. 10. The backing TPO waterproof coiled material is the fabric on the lower surface of the coiled material, which makes the coiled material easier to bond with the base layer. 11. Homogeneous TPO waterproof coiled material has good plasticity and can be processed into various shapes after heating to adapt to the practice of complex nodes Main technical specification Model SJP130/36-SJZ92/188-3400 JWP130/26+JWP130/26-2400 Product structure TPO+(Net)+TPO PVC+(Net)+PVC Products width 3200mm 2200mm Products thickness 0.8-3mm 0.5-3mm Extruder model SJP130/36-SJZ92/188 JWP130/26+JWP130/26 Capacity 1200kg/h 1500kg/h Read the full article

#Chinajwell#CompositeSheetExtrusionMachine#HDPE/PPT-GripSheetExtrusionMachine#HighPolymerCompositeWaterproofRollExtrusionLine#JwellExtrusionMachine#JwellMachinery#PEExtra-widthGeomembraneExtrusionMachine#Polymerwaterproofcoiledmaterialproductionline#PVCFloorLeatherExtrusionline#TPOWaterproofSheetExtrusionline#WaterproofRollExtrusionLine

2 notes

·

View notes

Text

Best Practices in Design for Manufacturing (DFM) for Plastic Parts

Design for Manufacturing (DFM) is a strategic engineering approach that simplifies and optimizes the manufacturing process right from the design stage. When applied to plastic part design, DFM ensures that products are easier, cost-effective, and efficient to manufacture without compromising on quality or performance.

In today's competitive market, the ability to address potential manufacturing challenges early in the design phase is a game-changer. From warping and sink marks to dimensional inaccuracies, DFM principles tackle these issues head-on, streamlining production, reducing costs, and maintaining product reliability.

This blog delves into the essential best practices for DFM in plastic part design. Whether you're an engineer, a designer, or a manufacturer, you'll find valuable insights and advanced strategies to elevate your design game. Here's what you can expect:

How Finite Element Analysis (FEA) predicts stress points to refine designs.

The role of sustainable materials and circular design in modern manufacturing.

How additive manufacturing (AM) enhances production workflows for better outcomes.

Get ready to explore innovative approaches and actionable insights that go beyond standard practices, giving you the edge in plastic part design.

Advanced Material Selection

Thermoplastics vs. Thermosetting Plastics

Selecting the right material is a fundamental step in DFM. Plastics are categorized into thermoplastics and thermosetting plastics:

Thermoplastics:

These plastics soften when heated and solidify when cooled, making them suitable for processes like injection molding and recycling. Examples include Polypropylene (PP), Polycarbonate (PC), and ABS. They are ideal for applications requiring flexibility and recyclability.

Thermosetting Plastics:

Once cured, these plastics become rigid and heat-resistant, making them excellent for high-stress applications. Examples include epoxies and phenolics.

Advanced Material Blends

To meet complex design requirements, advanced material blends offer enhanced properties:

Glass-Filled Nylon: Provides increased rigidity and durability.

UV-Resistant Polymers: Suitable for outdoor components.

Carbon Fiber-Reinforced Plastics: Achieve superior strength-to-weight ratios. Using custom blends helps optimize designs for specific applications, such as medical devices requiring both strength and biocompatibility.

Sustainable Materials

Eco-friendly material selection is vital for reducing the environmental impact of plastic production:

Biodegradable Plastics: Materials like PLA (Polylactic Acid) offer sustainability without compromising performance.

Recycled Polymers: Incorporating recycled materials reduces production waste and aligns with circular economy goals.

Circular Design Concepts: Ensures parts are designed for reuse and recyclability at the end of their lifecycle.

Material Properties and Applications

DFM optimizes material properties to meet specific part requirements:

Thermal Resistance: For parts exposed to high temperatures.

Chemical Resistance: Critical for medical or industrial applications.

Hygroscopic Behavior: Mitigating moisture absorption in materials like Nylon ensures dimensional stability.

Wall Thickness Optimization

Importance of Uniform Wall Thickness

Consistent wall thickness is a key factor in achieving defect-free plastic parts. It helps:

Improves Material Flow

Consistent wall thickness ensures smooth and uniform material flow during the injection molding process. This helps avoid disruptions, reduces the risk of incomplete filling, and enhances the overall quality of the part.

Minimizes Defects

Uniform walls help minimize common defects such as warping, sink marks, and voids. These issues often arise from uneven cooling or pressure variations, both of which are mitigated with consistent thickness.

Reduces Cycle Time

A uniform wall thickness allows for faster and more predictable cooling, which significantly reduces production cycle times. This efficiency accelerates manufacturing and enhances productivity.

Variable Wall Thickness

In complex designs where uniform thickness isn’t feasible, gradual transitions in wall thickness are essential. Key strategies include:

Avoiding sudden thickness changes to prevent material flow disruptions.

Using ribs and bosses to support structural integrity without adding unnecessary weight.

Advanced Simulations for Wall Thickness

Simulation tools improve wall thickness optimization:

Finite Element Analysis (FEA) helps identify stress concentration points.

Computational Fluid Dynamics (CFD) simulates plastic flow and cooling behaviors.

Draft Angles for Mold Release

Purpose of Draft Angles

Draft angles are critical for ensuring smooth mold release during injection molding. Properly designed draft angles prevent parts from sticking to the mold, reducing production downtime and mold wear.

Recommended Angles

The general recommendations include:

1° to 3°: For smooth surfaces.

3° to 5°: For textured surfaces to account for friction.

Micro-Feature Drafting

For intricate or micro-scale features, smaller draft angles (as low as 0.5°) may be required. These features often appear in:

Medical Device Prototypes

Intricate features with smaller draft angles, sometimes as low as 0.5°, are essential for medical device prototypes. These components often require precise micro-texturing to meet stringent design and performance standards.

Additive Manufacturing for Low-Volume Applications

In low-volume production, especially using additive manufacturing, small draft angles are tested to evaluate their efficiency. This approach is particularly useful for validating designs and ensuring manufacturability before scaling up.

Impact on Automated Assembly

Proper draft design enhances automation processes such as pick-and-place systems and robotic handling. It also ensures precision for operations like insert molding and overmolding.

Rib and Boss Design for Strength and Efficiency

Guidelines for Ribs

Ribs add structural support without increasing wall thickness. DFM best practices for rib design include:

Rib thickness: 60% of the adjacent wall thickness.

Gradual rib transitions to avoid sink marks.

Tapered rib design for better mold release.

Topology Optimization for Rib Placement

Using advanced design software, topology optimization identifies the most efficient rib placements. This reduces:

Overall part weight.

Material usage while maintaining strength.

Boss Design and Cooling Integration

Bosses provide locations for screws or fasteners. Effective boss design ensures:

Adequate wall support to prevent cracking.

Integration with cooling channels to improve heat dissipation during molding.

Undercuts and Complex Features

Challenges in Molding Undercuts

Undercuts add complexity to molds, increasing costs and production time. They often require side-actions, lifters, or collapsible cores for molding.

Solutions for Undercuts

To address undercuts:

Redesign to eliminate unnecessary undercut features.

Utilize collapsible cores or slides for complex designs.

3D-Printed Mold Inserts

For low-volume production or prototyping, 3D-printed mold inserts provide a flexible and cost-effective solution. They allow for:

Testing complex geometries before final production.

Reducing lead times and tooling costs.

Tolerances and Fits

Managing Tight Tolerances

Precision is critical in plastic part design, especially for:

Shrinkage compensation: Accounting for material contraction during cooling.

Managing hygroscopic materials like Nylon to maintain dimensional stability.

Statistical Tolerance Analysis

Using tools like Six Sigma and GD&T (Geometric Dimensioning and Tolerancing) ensures tight tolerances for high-quality production.

Surface Finish and Functional Texturing

Importance of Surface Finish

Surface finish impacts both functionality and aesthetics. Proper finishes:

Improve part appearance.

Enhance functional performance (e.g., reducing friction).

Laser Texturing for Precision

Laser technology offers precise surface texturing, enabling:

Functional designs like self-cleaning surfaces.

Custom finishes for improved medical device prototyping.

Gate and Runner System Design

Hot vs. Cold Runner Systems

Hot Runners: Reduce material waste and cycle time.

Cold Runners: More cost-effective for smaller production runs.

Sequential Valve Gating

This advanced gating technique prevents flow marks and ensures uniform part filling, especially for larger parts.

Assembly Considerations

Integrated Fasteners

Designing integrated fasteners, such as snap fits or living hinges, reduces assembly complexity and costs.

Design for Disassembly

Designing for easy disassembly aligns with sustainability goals, enabling recyclability and reducing waste.

Future Trends in DFM

As the manufacturing landscape evolves, new advancements in technology and materials are redefining how we approach Design for Manufacturing (DFM). These trends promise to further streamline processes, improve sustainability, and enhance product quality.

AI-Driven Design Automation

Artificial Intelligence (AI) is transforming DFM by enabling intelligent design optimization. AI tools analyze massive datasets to identify patterns, predict design flaws, and suggest improvements early in the design phase. Key benefits include:

Automated Design Adjustments: AI-powered software can automatically adjust dimensions, tolerances, and geometries for manufacturability.

Faster Iteration Cycles: Machine learning algorithms reduce the time required for design revisions by predicting potential issues like stress points or material weaknesses.

Sustainable Plastic Innovations

The focus on environmental sustainability has pushed the boundaries of material science. Manufacturers are exploring innovative solutions to reduce waste and environmental impact:

Bio-based Plastics: Materials such as Polylactic Acid (PLA) and PHA are derived from renewable resources, offering biodegradability without compromising performance.

Recycled Plastics: Advanced sorting and recycling technologies are enabling high-quality recycled polymers for use in new designs, promoting a circular economy.

Integration of Additive Manufacturing (AM) for Complex Prototypes

Additive Manufacturing (AM), or 3D printing, continues to revolutionize prototyping and low-volume production. Its applications in DFM include:

Freedom of Design: AM enables the creation of intricate geometries, internal channels, and lightweight structures that are otherwise impossible with traditional manufacturing methods.

Rapid Prototyping: Engineers can produce prototypes within hours, test functionality, and iterate designs quickly.

Hybrid Manufacturing: Combining AM with traditional methods like injection molding allows for greater flexibility and cost-effectiveness. For example, 3D-printed mold inserts can be used for prototyping before committing to costly metal molds.

Enhanced Data-Driven DFM

Digital Twins: Digital twins—virtual replicas of physical products—are becoming central to optimizing manufacturing workflows. They allow real-time simulation and troubleshooting, ensuring smoother transitions from design to production.

IoT Integration: Sensors and IoT-enabled devices provide real-time feedback during manufacturing, helping refine designs for greater accuracy and efficiency.

The future of DFM is exciting, with these advancements poised to redefine efficiency, sustainability, and innovation across industries. Embracing these trends will ensure manufacturers stay competitive in an ever-evolving market.

Conclusion

Design for Manufacturing (DFM) is pivotal in creating cost-effective, high-quality, and reliable plastic parts. By implementing DFM principles early in the design phase, you can avoid common manufacturing challenges such as warping, sink marks, and dimensional inaccuracies while optimizing material use and production efficiency. From selecting the right materials to leveraging advanced technologies like AI, additive manufacturing, and sustainable practices, these strategies empower engineers and manufacturers to innovate while staying competitive in a rapidly evolving market.

At Aprios, we specialize in delivering end-to-end manufacturing solutions tailored to your needs. Our expertise in DFM for plastic part design ensures streamlined production, reduced costs, and superior product quality. Whether you're looking for advanced prototyping, material optimization, or scalable production processes, we’re here to help.

Explore how Aprios can take your project from concept to reality with our custom manufacturing services. We specialize in bringing your designs to life efficiently and sustainably, ensuring streamlined production and superior product quality. Contact us today to learn more about how we can support your manufacturing needs. Let Aprios help you transform your design vision into exceptional, manufacturable products.

#Custom Manufacturing Services#dfm services#design for manufacturing solutions#dfm development services#design for manufacturing services

1 note

·

View note

Text

3D Printing Materials Market Valued at USD 2,836.6 Million in 2025

Exploring the Dynamic World of 3D Printing Materials Market 2034

The world of 3D Printing Materials Market has come a long way since its inception, evolving from a niche technology to a mainstream manufacturing process. At the heart of this transformation is the ever-expanding universe of 3D printing materials. These materials are not just a means to an end; they are pivotal in defining what can be created, how it can be produced, and what industries can benefit from this cutting-edge technology. In this blog, we will delve into the key aspects of the 3D printing materials market, exploring the types, applications, and future trends shaping this exciting field.

Sample copy report:

https://wemarketresearch.com/reports/request-free-sample-pdf/3d-printing-materials-market/1338

Types of 3D Printing Materials

Thermoplastics: Thermoplastics are among the most widely used materials in 3D printing. They are known for their ease of use, affordability, and versatility. Popular thermoplastics include:

PLA (Polylactic Acid): Known for its eco-friendly nature and ease of printing, PLA is a favorite among hobbyists and beginners.

ABS (Acrylonitrile Butadiene Styrene): This material offers greater strength and durability, making it ideal for functional prototypes and end-use parts.

PETG (Polyethylene Terephthalate Glycol): Combining the ease of printing with durability, PETG is commonly used in applications requiring resistance to impact and moisture.

Resins: Resins are liquid materials that solidify under UV light and are used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) printers. They offer high resolution and detail, making them suitable for applications such as jewelry and dental products. Key types include:

Standard Resins: Ideal for detailed models and prototypes.

Tough Resins: Engineered for increased durability and impact resistance.

Flexible Resins: Designed to produce parts with rubber-like properties.

Metals: Metal 3D printing is used for high-performance applications in industries such as aerospace, automotive, and medical. Metal powders, such as titanium, aluminum, and stainless steel, are used in processes like SLM (Selective Laser Melting) and EBM (Electron Beam Melting). Metal 3D printing offers:

High Strength-to-Weight Ratio: Essential for aerospace and automotive components.

Complex Geometries: Allows for the creation of intricate designs that are difficult to achieve with traditional manufacturing methods.

Composites: Composite materials combine thermoplastics with reinforcing fibers, such as carbon fiber or glass fiber, to enhance strength and rigidity. These materials are used in applications where lightweight and high strength are critical, including in the automotive and sports equipment industries.

Innovations Driving the 3D Printing Materials Market

The 3D printing materials market is experiencing rapid innovation, driven by advancements in technology and changing industry needs. Here’s a closer look at some of the latest innovations that are transforming the landscape of 3D printing materials:

Nanomaterials: Nanotechnology is making waves in the 3D printing industry by enabling the creation of materials with enhanced properties at the nanoscale. Nanomaterials can improve strength, durability, and thermal resistance, making them ideal for high-performance applications. For example, incorporating nanoparticles into polymers can enhance their mechanical properties, leading to more robust and reliable printed parts.

Bio-inks and Bioprinting: Bioprinting is revolutionizing the medical and research fields by enabling the creation of living tissues and organs. Bio-inks, which are made from natural and synthetic biopolymers, are used in this process to print cellular structures. These materials can be tailored to support cell growth and tissue development, opening up new possibilities for regenerative medicine and personalized healthcare.

Applications of 3D Printing Materials Market

The versatility of 3D printing materials market has led to their adoption across various sectors:

Aerospace: Lightweight and durable materials are used to manufacture complex parts and components, reducing overall weight and fuel consumption.

Healthcare: Custom prosthetics, implants, and dental products are tailored to individual patients using biocompatible materials.

Automotive: 3D printing enables rapid prototyping and production of lightweight parts, enhancing vehicle performance and reducing time-to-market.

Consumer Goods: Customized products, from eyewear to home decor, benefit from the flexibility and personalization offered by 3D printing.

Future Trends in 3D Printing Materials Market

As the 3D printing industry continues to evolve, several trends are likely to shape the future of 3D printing materials:

Biodegradable and Sustainable Materials: There is a growing focus on developing eco-friendly materials that reduce environmental impact. Innovations in biodegradable plastics and recycling processes are set to make 3D printing more sustainable.

Advanced Metal Alloys: The development of new metal alloys with enhanced properties will open up new possibilities for high-performance applications in industries such as aerospace and defense.

Multi-Material Printing: Advances in multi-material printing technologies will allow for the creation of complex objects with varying properties in a single print, expanding the range of applications and functionalities.

Smart Materials: The integration of materials that respond to environmental changes (such as temperature or pressure) will lead to the development of "smart" products with adaptive capabilities.

Benefits of 3D Printing Materials Market Report:

Analyst Support: Get your query resolved by our expert analysts before and after purchasing the report.

Customer Satisfaction: Our expert team will assist with all your research needs and customize the report.

Inimitable Expertise: Analysts will provide deep insights into the reports.

Assured Quality: We focus on the quality and accuracy of the report.

Conclusion

The 3D printing materials market is a dynamic and rapidly evolving field, driven by continuous innovation and Technological Advancements. From thermoplastics and resins to metals and composites, the variety of materials available today provides limitless possibilities for creators and manufacturers alike. As we look to the future, emerging trends and new material developments promise to further revolutionize the industry, offering exciting opportunities for growth and transformation across various sectors. Whether you're a hobbyist, a designer, or an industry professional, staying informed about these advancements will be key to leveraging the full potential of 3D printing technology.

#3D Printing Materials Analysis#3D Printing Materials Demand#Market Insights 3D Printing#3D Printing Materials Future

0 notes

Text

Automotive Thermoplastic Polymer Composite Market: Lightweighting Solutions for the Future up to 2033

Market Definition

The automotive thermoplastic polymer composite market involves the use of advanced thermoplastic materials reinforced with fibers such as glass or carbon, engineered for automotive applications. These composites are lightweight, durable, and capable of withstanding high stresses, making them ideal for components like body panels, interiors, and structural reinforcements in vehicles. Their recyclability and design flexibility further enhance their appeal in modern automotive manufacturing.

To Know More @ https://www.globalinsightservices.com/reports/automotive-thermoplastic-polymer-composite-market

The automotive thermoplastic polymer composite market is anticipated to expand from $9.2 billion in 2023 to $16.8 billion by 2033, with a CAGR of 6.2%.

Market Outlook

The adoption of thermoplastic polymer composites in the automotive sector is driven by the industry’s focus on weight reduction, fuel efficiency, and compliance with stringent environmental regulations. Lightweight materials are crucial for enhancing vehicle performance while reducing emissions, making thermoplastic composites a preferred choice for automakers.

The increasing demand for electric vehicles (EVs) has further propelled the need for advanced lightweight materials to offset battery weight and optimize energy consumption. Thermoplastic polymer composites offer significant advantages, including faster processing times, superior impact resistance, and cost-effective manufacturing compared to traditional materials.

Challenges include the high cost of raw materials and the need for specialized manufacturing technologies, which can limit adoption among small-scale manufacturers. Additionally, concerns about the thermal and mechanical performance of certain thermoplastics under extreme conditions pose barriers. However, ongoing research and innovation in composite formulations and processing techniques are expected to overcome these challenges.

The growing integration of automation in composite manufacturing and the expansion of EV production present lucrative opportunities for market growth. As regulatory bodies emphasize sustainability, the recyclability of thermoplastic composites is likely to play a pivotal role in shaping market dynamics.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS26953

0 notes

Text

Composites Market: Analysis of Growth Drivers, Challenges, and Future Scope

The Composites Market has emerged as a key segment in global materials science, driven by increasing demand for lightweight, durable, and high-performance materials across diverse industries such as aerospace, automotive, construction, renewable energy, and consumer goods. Composites, made from fibers and resins, offer superior strength-to-weight ratios, corrosion resistance, and design flexibility, making them ideal for advanced applications.

Market Overview

The global composites market size was USD 99.91 billion in 2019 and is projected to reach USD 112.0 billion by 2027, exhibiting a CAGR of 6.88% during the forecast period. This growth is fueled by rising adoption in the aerospace and automotive sectors, innovations in renewable energy systems, and an increasing focus on sustainable materials.

Key Market Drivers

Lightweight Materials in Automotive and Aerospace

The growing demand for fuel efficiency and emission reduction has accelerated the adoption of lightweight composite materials in automotive and aerospace manufacturing.

Rising Use in Wind Energy

Wind turbines, particularly blades, rely on composite materials for their strength and weight-saving properties. The growth of renewable energy installations globally is a significant driver.

Infrastructure and Construction Applications

Composites are being increasingly used in construction for bridges, reinforcement, panels, and cladding due to their durability and resistance to environmental stressors.

Technological Advancements in Manufacturing

Innovations in production techniques such as 3D printing, automated fiber placement (AFP), and resin transfer molding (RTM) are enhancing the quality and cost-efficiency of composite manufacturing.

Focus on Sustainability

The development of bio-based and recyclable composites aligns with the growing push for environmentally sustainable materials.

Get a Free Sample PDF- https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/composites-market-102295

Market Segmentation

By Fiber Type

Glass Fiber Composites: Cost-effective and versatile, widely used in construction, automotive, and consumer goods.

Carbon Fiber Composites: High-strength, lightweight materials primarily used in aerospace, automotive, and sports applications.

Natural Fiber Composites: Emerging segment driven by sustainability trends and eco-friendly solutions.

By Resin Type

Thermoset Composites: Dominant due to their high strength and durability, used in aerospace and wind energy.

Thermoplastic Composites: Gaining traction for recyclability and faster processing times.

By End-Use Industry

Aerospace & Defense: The largest consumer of high-performance composites for structural applications.

Automotive: Increasing use for reducing vehicle weight and improving fuel efficiency.

Renewable Energy: Wind turbine blades and solar panel frames rely heavily on composites.

Construction & Infrastructure: Composites are used for corrosion-resistant and durable structures.

Consumer Goods: Sports equipment, electronics, and household products benefit from lightweight properties

By Region

North America: Leading market with significant aerospace and automotive production hubs.

Europe: Driven by stringent regulations promoting lightweight and energy-efficient materials.

Asia-Pacific: Fastest-growing region due to rising industrialization, construction, and manufacturing in China, India, and Japan.

Rest of the World: Moderate growth driven by infrastructure and renewable energy projects.

Key Challenges

High Production Costs

The cost of advanced fibers (e.g., carbon fiber) and specialized manufacturing techniques limits widespread adoption.

Recycling Limitations

Thermoset composites are difficult to recycle, posing challenges for sustainability.

Competition from Traditional Materials

Steel, aluminum, and other metals continue to compete with composites due to established infrastructure and lower costs.

Lack of Standardization

The absence of global standards for composite materials and processes can hinder market penetration.

Emerging Trends

Recyclable and Bio-Based Composites

Growing innovation in natural and bio-based resins is addressing sustainability challenges.

3D Printing and Additive Manufacturing

The integration of 3D printing technologies allows for customized and complex composite structures with reduced material waste.

Composites in Electric Vehicles (EVs)

The growing EV market is driving demand for lightweight composites in battery enclosures, body panels, and structural parts.

Advanced Composite Applications in Construction

Use of composites for bridge decks, reinforcing bars, and high-rise building panels is expanding.

Automated Manufacturing

Innovations in automation, including robotic systems for fiber placement and resin infusion, are increasing production efficiency.

Competitive Landscape

The composites market is characterized by intense competition, with key global players focusing on innovation, capacity expansion, and strategic partnerships. Notable companies include:

Toray Industries, Inc.

Hexcel Corporation

SGL Carbon SE

Owens Corning

Teijin Limited

Mitsubishi Chemical Holdings

Solvay S.A.

Huntsman Corporation

These players invest in research and development to create advanced, cost-effective, sustainable composite solutions.

Get More Info- https://www.fortunebusinessinsights.com/composites-market-102295

Future Outlook

The global composites market is poised for strong growth over the next decade, driven by increasing aerospace, automotive, renewable energy, and construction applications. The Asia-Pacific region is expected to dominate the market, while North America and Europe remain at the forefront of innovation and high-value applications. Sustainability and the adoption of advanced manufacturing technologies will play a critical role in shaping the market’s future.

Conclusion

The composites market represents a transformative segment in materials science, offering unparalleled strength, flexibility, and sustainability for diverse industries. As demand for lightweight and high-performance materials continues to grow, composites will remain central to innovation in aerospace, automotive, and renewable energy sectors. Companies that embrace advancements in technology and sustainable solutions are well-positioned to capitalize on the market's expanding opportunities.

0 notes

Text

What Materials Enhance Temperature Resistance of Powder Coating Masking Tape

The application of powder coating masking tape has become increasingly popular in various industries, including automotive, aerospace, and manufacturing, due to its durability and superior finish. As demand for high-performance coatings grows, so does the need for effective masking solutions. This is where powder coating tape supplies play a critical role. Among these, powder coating high temp tape is particularly vital for ensuring clean edges and preventing contamination during the heating process. Understanding the materials that enhance the temperature resistance of these tapes is essential for selecting the best powder coating tape for specific applications.

The Importance of Temperature Resistance in Powder Coating

Temperature resistance is a fundamental characteristic for powder coating masking tape. The powder coating process typically involves applying a dry powder to a substrate and then curing it at high temperatures, ranging from 350°F to 450°F (approximately 177°C to 232°C). Standard masking tapes may not be able to withstand these temperatures, leading to adhesive failure, tape melting, or leaving residue on the finished product. Thus, materials that enhance temperature tolerance are crucial for ensuring that masking and strapping remain intact throughout the application process.

Key Materials That Enhance Temperature Resistance

Silicone Adhesives: Silicone-based adhesives are common in the formulation of powder coating high temp tape. These adhesives are specifically designed to withstand extreme temperatures, often up to 500°F (approximately 260°C). The inherent thermal stability of silicone allows it to maintain adhesion strength without breaking down or leaving a residue, making it an excellent choice for high-temperature powder coating processes.

Polyimide Film: Another material that provides exceptional temperature resistance is polyimide film, commonly known by the brand name Kapton. Polyimide films can withstand temperatures reaching 500°F (approximately 260°C) and are highly resistant to melting, making them suitable for masking applications in high-heat environments. Tapes made from polyimide films offer excellent insulation properties, which can protect sensitive areas during the curing process of powder coatings.

Glass Cloth Reinforcement: For applications requiring extreme heat resistance, tapes reinforced with glass cloth are an excellent option. The glass fibers enhance the tensile strength and thermal stability of the tape, allowing it to withstand intense heat without degrading. This type of tape is ideal for use in high-temperature environments where other tapes might fail. Powder coating tape supplies that incorporate glass cloth reinforcement provide additional durability and adherence to uneven surfaces, making them versatile in varying industrial applications.

High-Temperature Resistant Backing Materials: The backing material of the tape also contributes to its temperature resistance. Options like polyester or specialized thermoplastics have been developed to withstand high thermal exposure while maintaining physical integrity. These backing materials can work in conjunction with specialized adhesives to provide a tape that is both strong and heat-resistant.

Fluoropolymer Coatings: Tapes coated with fluoropolymer materials offer excellent heat resistance and low friction, making them ideal for applications where minimal adhesive residue is essential. Additionally, the fluoropolymer coating helps enhance the tape's resistance to chemicals and environmental stressors, further increasing its lifespan and performance in the powder coating arena.

Selecting the Best Powder Coating Tape

Choosing the best powder coating tape involves understanding the specific requirements of the application. Factors to consider include the maximum temperature the tape will encounter, the duration of exposure, and the surfaces being masked. Professionals should evaluate whether a silicone adhesive, polyimide film, glass fiber reinforcement, or fluoropolymer coating aligns best with their needs.

It's also important to consider the types of substrates being worked with during the powder coating process. Some tapes may adhere better to certain materials than others, affecting the final outcome of the coating. Understanding the adhesive properties and the interaction with the substrate can greatly influence the performance of the masking tape during high-temperature applications.

Importance of Quality and Compatibility

Quality plays a pivotal role when it comes to powder coating masking tape. High-quality materials ensure that the tape can withstand the rigors of the powder coating process without failing. Moreover, using compatible materials across the board—tapes, coatings, and substrates—ensures that the entire process remains efficient and yields high-quality results. For instance, using inferior tapes can lead to failures, resulting in higher costs due to rework and wasted materials.

Conclusion

Ultimately, the effectiveness of powder coating supplies significantly relies on the temperature resistance of the selected tapes. Materials such as silicone adhesives, polyimide films, glass cloth reinforcement, and specialized backing contribute greatly to the durability and functionality of powder coating high temp tape. As industries increasingly adopt powder coating, understanding these material properties becomes essential in order to select the right powder coating masking tape to ensure clean finishes and effective performance under high temperatures. By recognizing the importance of using the best powder coating tape, manufacturers can enhance their processes and deliver superior products.

0 notes

Text

Summary of 25 plastic reinforced modification formulas and 20 key points involved

There are many common plastic modification technologies, mainly reinforcement technologies, including fiber reinforcement, self-reinforcement, and molecular reinforcement; toughening technology; filling modification; blending and plastic alloy technology; flame retardant technology; nanocomposite technology; reaction grafting modification; aging resistance; functional modification, including…

View On WordPress

#Antistatic glass fiber reinforced PA6 impeller#Chopped glass fiber reinforced PP#Compatibilizer#Composite reinforced PP#Engineering plastic reinforced formula#Enhanced PF for chemical anti-corrosion pipelines#Epoxy fiberglass#Epoxy phenolic fiberglass#Flame retardant and antistatic reinforced PA6#Flame retardant glass fiber reinforced PA6 impeller#GF enhanced RJM-PU#Glass fiber reinforced PP#Glass fiber reinforced PVC#Glass fiber reinforced PVDC special-shaped components#High performance glass fiber reinforced PP#High strength unsaturated polyester board#Long glass fiber reinforced PA6#Mica reinforced PP#No. 771 unsaturated polyester fiberglass#plastic modification technologies#plastic reinforced modification formulas#PS coloring formula#thermoplastic reinforced formulations#Thermoset reinforced formulations#Transparent glass fiber reinforced PC#UHMWPE/carbon fiber composite materials#Wollastonite fiber-filled reinforced PP

0 notes

Text

Phone Cover for Ultimate Protection

In today's world, smartphones are essential tools in our daily lives. They connect us to the world, help us stay organized, and serve as a constant source of entertainment. With such an important role, protecting your phone is a priority. A phone cover for ultimate protection is a must-have accessory to safeguard your device from drops, scratches, and other potential damage.

A phone cover for ultimate protection not only shields your smartphone from external forces but also preserves its longevity. Phones are becoming more fragile with each new release, featuring glass backs, edge-to-edge screens, and slim profiles that are more prone to damage. Even minor accidents can lead to costly repairs, but investing in a protective phone cover can save you from these expensive fixes.

Why You Need a Phone Cover for Ultimate Protection

Accidents happen to everyone. Whether you drop your phone while walking, bump it against a hard surface, or just accidentally knock it off a table, a phone cover for ultimate protection is your first line of defense. Modern smartphones, especially high-end models, can be very costly to repair, and without protection, a single drop can mean cracked screens, broken frames, or worse.

A well-designed protective phone case absorbs impact, reducing the chances of severe damage. It provides a shock-absorbing layer between your phone and the hard surfaces it may come in contact with. By cushioning the blow from drops, bumps, and falls, the right phone cover for ultimate protection can prevent the worst outcomes, such as shattered screens or internal component damage.

Features to Look for in a Phone Cover for Ultimate Protection

When choosing a phone cover for ultimate protection, it's essential to select one with the right features. Not all phone covers are created equal, and some offer more protection than others. Here are the key features to look for:

1. Shock Absorption

A phone cover for ultimate protection should have shock-absorbing qualities. Cases made from materials like TPU (thermoplastic polyurethane) and silicone are designed to absorb and disperse the energy from an impact. These materials are flexible, allowing them to absorb drops and provide cushioning to your phone, reducing the risk of internal damage. Cases with air cushions or reinforced corners provide additional impact protection.

2. Raised Edges

Protecting the screen and camera lens is crucial. Many high-quality phone covers for ultimate protection come with raised edges around the screen and camera. These raised edges help prevent direct contact with flat surfaces, reducing the risk of scratches, cracks, or damage to these vulnerable areas. A raised bezel keeps the phone’s screen off surfaces, offering added protection when placed face-down.

3. Durability and Material Quality

The materials used in a phone cover for ultimate protection play a significant role in the level of defense it provides. Harder materials like polycarbonate or carbon fiber can offer superior protection by acting as a rigid outer shell that resists scratches, dents, and cracks. Combined with softer materials like silicone or rubber, which offer shock absorption, a durable case gives the best of both worlds.

4. Water and Dust Resistance

Some phone covers for ultimate protection are designed to be waterproof or water-resistant. This added feature can protect your device from accidental spills, rain, or drops in water. Additionally, many cases have dust-resistant features, preventing dirt and debris from entering the device through ports, speakers, and other openings.

5. Full Coverage

A phone cover for ultimate protection should provide full coverage of your device. Look for cases that protect the back, sides, and front of the phone. Some cases come with built-in screen protectors or flip covers that shield the entire phone, offering an all-around protective solution. This kind of full coverage helps ensure that your device stays protected even in the most hazardous situations.

Types of Protective Phone Covers

Several types of phone covers for ultimate protection are available in the market, each designed for different needs:

1. Heavy-Duty Cases

These are the most robust types of phone covers, designed to withstand extreme conditions. Heavy-duty cases usually feature a multi-layer construction, combining hard outer shells and soft inner layers for maximum shock absorption. They are ideal for people who work in tough environments or for those prone to frequent drops.

2. Wallet Cases

Wallet cases not only offer ultimate protection but also provide storage for cards, cash, and IDs. These cases often feature a flip cover that offers full-screen protection and is perfect for individuals who like to carry fewer items. While wallet cases are bulkier, they provide excellent all-around protection and additional functionality.

3. Clear Protective Cases

Clear cases offer moderate protection while letting you showcase the design of your phone. These cases are made from durable materials like TPU or polycarbonate and are an excellent option for those who want protection without hiding the phone's aesthetic appeal. Some clear cases come with raised edges and reinforced corners for added security.

4. Rugged Cases

Rugged cases are a step up from heavy-duty cases, providing military-grade protection. These cases often meet military standards for drop resistance and offer additional features like reinforced bumpers, waterproofing, and dust-proofing. Rugged cases are perfect for outdoor enthusiasts or anyone who puts their phone through heavy use.

Conclusion

Investing in a phone cover for ultimate protection is one of the smartest decisions you can make to ensure the longevity and safety of your device. With various types of cases offering different features, you can find the perfect balance of durability, functionality, and design. Whether you prefer a sleek, slim case or a more rugged, heavy-duty option, a phone cover for ultimate protection will keep your phone safe from damage while maintaining its sleek appearance. Protect your investment and enjoy peace of mind knowing your phone is safe from drops, impacts, and accidents.

0 notes

Text

Wind Turbine Composite Materials Market - Forecast(2024 - 2030)

Wind Turbine Composite Materials Market Overview

Request Sample :

The government across the globe is also investing huge amounts in alternative energy sources such as solar and wind which is further supporting the market growth for composite materials. The increasing focus of governments on offshore wind energy installations is driving the market growth between 2021–2026. However, the high cost of carbon fiber and epoxy resin and recyclability issue of composites will likely hamper the market growth during the forecast period.

COVID-19 Impact

The COVID-19 pandemic has impacted the composite materials industry which has further impacted the wind turbine market. Due to the Covid-19, the manufacturing industry is impacted very badly that further impacted the wind turbine composite materials market. The slowdown in wind turbine installations and lack of raw material supplies, and workforce are impacting the market negatively. The covid-19 impacted every operation such as supply chain, production, sales, and others. However, the companies resumed their operation in 2021, which may positively impact the market.

Report Coverage

The report: “Wind Turbine Composite Materials Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Wind Turbine Composite Materials industry. By Fiber Type: Glass Fiber, Carbon Fiber, Aramid Fiber, and Basalt fiber By Resin Type: Thermoplastic [Polyethylene, Polystyrene, Polyamides, Nylon, Polypropylene, Others], and Thermoset [Epoxy, Polyester, Phenolic Polyamide, and Others] By Technology: Injection Molding, Compression Molding, Pultrusion, Filament Winding, and Layup By Application: Blades, Wind turbine Hub, Rotor, Tower, Nacelle, Cables, Blade Pitch Controller, Propellers, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Netherlands, Belgium, Spain, Denmark, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and Rest of the World (the Middle East and Africa)

Inquiry Before Buying :

Key Takeaways

The Asia Pacific region is expected to dominate the market and register the highest CAGR of 12.8% during the forecast period (2021–2026). The presence of leading chemical companies along with rapid growth in the personal care industry is propelling regional growth.

Epoxy resin is one of the widely used resins in wind turbine manufacturing. The segment is expected to register a high growth rate during the forecast period.

The growing installation of wind turbines in developing countries such as Brazil, Mexico, India, and China is creating a positive impact on the usage of wind turbine composite materials.

Figure: Asia Wind Turbine Composite Materials Market Revenue, 2020–2026 (US$ Billion)

For More Details on This Report — Request for Sample

Wind Turbine Composite Materials Market Segment Analysis: By Fiber Type

The glass fiber reinforced plastics segment accounted for the largest share of more than 55% in the wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Glass fiber offers various properties including high strength, high durability, weather-resistant, and lightweight have boosted its demand in numerous end-use industries. The easy availability and cost-effectiveness of glass fiber reinforced plastics are the key factors propelling the demand for glass fiber composites in wind turbine manufacturing. The carbon fiber segment will register a significant growth rate during the forecast period. Carbon fibers offer various properties such as low thermal expansion, high stiffness, high-temperature tolerance, and high chemical resistance among others.

Schedule A Call:

Wind Turbine Composite Materials Market Segment Analysis: By Resin Type

The thermoset segment accounted for the largest share of more than 70% in the Wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Thermoset composite is usually based on carbon, glass, and aramid fibers. Epoxy resin is the widely used thermoset type in wind turbine composite materials. Approximately 50% of European wind blades are manufactured from epoxy resin. These resins offer lightweight, and good adhesion compared to other resin types. Generally, they are combined with glass fibers and carbon fibers to manufacture wind blades. The thermoplastic segment is expected to register a significant growth rate during the forecast period. Thermoplastics are less expensive compared to thermoset resin types. They are easily weld-able, non-toxic in nature, and recyclable. These are some of the driving factors supporting the market growth between 2021–2026.

Wind Turbine Composite Materials Market Segment Analysis: By Technology

The Layup segment accounted for the largest share of more than 33% in the wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Layup is the most common method used for the production of composites. The method is involved in placing layers of composite fiber in a structured order by using a matrix of resin and hardener. This method is widely used for the production of wind blades.

Wind Turbine Composite Materials Market Segment Analysis: By Application

The blades segment accounted for the largest market share of more than 55% of the market in 2020 and is estimated to grow significantly during the forecast period. Turbine blades serve as the most important composite-based part of wind turbines. The growing demand for wind energy is driving manufacturers to develop large wind blades for the high production of wind energy. For the development of large blades, a huge quantity of composite materials is used. Glass fibers and carbon fibers are used for the manufacturing of wind blades.

Wind Turbine Composite Materials Market Segment Analysis — By Geography

The Asia Pacific region held the largest share of more than 45% in the Wind Turbine Composite Materials market in 2020, owing to the rapid growth in the installation of wind turbines. The presence of developing nations such as China and India is driving the market growth. The presence of leading wind turbine manufacturers including Suzlon Energy Limited, and AVIC Huiteng Windpower Equipment Co., Ltd are supporting the region’s growth during the forecast period. The increasing investments by key developers for manufacturing efficient wind turbines are also boosting the market growth during the forecast period. According to the data published by Global Wind Energy Council (GWEC), China installed about 52 gigawatts of new wind power capacity in 2020.

Buy Now :

Wind Turbine Composite Materials Market Drivers

Rising Demand for Renewable Energy Sources

Wind energy is one of the fastest-growing renewable energies globally. Wind power is a clean energy source, and its usage is on the rise worldwide. The U.S. wind energy occupies approximately 38% of total renewable energy produced in 2019. According to the IRENA’s data, wind energy generation is increased from 7.5GW in 1997 to 564GW by 2018. Some ongoing and under-construction wind projects in the U.S. include Traverse Wind Energy Center, Aviator Wind Project, Goodnight Wind Energy Project, Alle-Catt Wind Farm, and Vineyard Wind I among others. According to the Ministry of New and Renewable Energy (MNRE), India has the fourth-highest wind installed capacity in the world with a total installed capacity of 39.25 GW (as of 31st March 2021) and has generated around 60.149 billion Units during 2020–2021. According to the European Commission, the total installed wind energy capacity in Europe reached 210GW and is estimated to reach 350GW, supplying up to 24% of electricity demand

Wind Turbine Composite Materials Market Challenges

Recyclability Issue of Composites

Composite materials are preferred for wind applications because of their durability and superior strength. Proper waste disposal and recycling at the end of the useful life of composite materials are necessary. Many current and future waste management and environmental legislation are making strict regulations on engineering materials to be properly recovered and recycled. The complex material compositions and the cross-linked nature of thermoset resins are making it difficult for recyclability. However, the use of polymers that can be recycled when used with carbon and other niche fibers reduces the composite non-recyclable. This has become a major issue as the landfills are filling up at a faster pace along with the need for going green due to global warming. Biological attack on composite materials may consist of fungal growth or marine fouling

Wind Turbine Composite Materials Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Wind Turbine Composite Materials market. Major players include:

TPI Composites, Inc.

MFG Wind

LM Wind Power

Gamesa Corporation Technology

Vestas Wind Systems A/S

Suzlon Energy Limited

Siemens AG

AVIC Huiteng Windpower Equipment Co., Ltd.

AREVA and others.

Acquisitions/Technology Launches

In May 2021, Hexcel launched a range of HexPly® surface finishing prepregs and semi- prepregs for wind turbine blades and automotive and marine applications.

Relevant Reports

Composite Materials Market — Forecast(2021–2026) Report Code: CMR 0010

High-Temperature Composite Materials Market — Forecast(2021–2026) Report Code: CMR 10087

For more Chemicals and Materials Market reports, please click here

#WindTurbine#CompositeMaterials#RenewableEnergy#SustainableTech#GreenEnergy#MaterialInnovation#CleanEnergySolutions

0 notes

Text

Bulk Molding Compound: An Engineered Thermoplastic Composites Material

Bulk molding compound, commonly known as BMC, is an engineered thermoplastic composites material predominantly used in compression and injection molding applications. It consists of fiber reinforcement, typically short glass fibers, embedded in a non-crosslinked thermosetting polymer matrix. The polymer matrix is typically made from unsaturated polyester or vinyl ester resin.

Bulk molding compound, commonly known as BMC, is an engineered thermoplastic composites material predominantly used in compression and injection molding applications. It consists of fiber reinforcement, typically short glass fibers, embedded in a non-crosslinked thermosetting polymer matrix. The polymer matrix is typically made from unsaturated polyester or vinyl ester resin.

Get More Insights On Bulk Molding Compound (BMC) https://www.exoltech.us/blogs/246973/Bulk-Molding-Compound-An-Engineered-Thermoplastic-Composites-Material

0 notes

Text

3D Printing Materials Market Analysis, Trends and Dynamic Demand by Forecast 2024 to 2033

Exploring the Dynamic World of 3D Printing Materials Market

The world of 3D Printing Materials Market has come a long way since its inception, evolving from a niche technology to a mainstream manufacturing process. At the heart of this transformation is the ever-expanding universe of 3D printing materials. These materials are not just a means to an end; they are pivotal in defining what can be created, how it can be produced, and what industries can benefit from this cutting-edge technology. In this blog, we will delve into the key aspects of the 3D printing materials market, exploring the types, applications, and future trends shaping this exciting field.

Sample copy report:

https://wemarketresearch.com/reports/request-free-sample-pdf/3d-printing-materials-market/1338

Types of 3D Printing Materials

Thermoplastics: Thermoplastics are among the most widely used materials in 3D printing. They are known for their ease of use, affordability, and versatility. Popular thermoplastics include:

PLA (Polylactic Acid): Known for its eco-friendly nature and ease of printing, PLA is a favorite among hobbyists and beginners.

ABS (Acrylonitrile Butadiene Styrene): This material offers greater strength and durability, making it ideal for functional prototypes and end-use parts.

PETG (Polyethylene Terephthalate Glycol): Combining the ease of printing with durability, PETG is commonly used in applications requiring resistance to impact and moisture.

Resins: Resins are liquid materials that solidify under UV light and are used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) printers. They offer high resolution and detail, making them suitable for applications such as jewelry and dental products. Key types include:

Standard Resins: Ideal for detailed models and prototypes.

Tough Resins: Engineered for increased durability and impact resistance.

Flexible Resins: Designed to produce parts with rubber-like properties.

Metals: Metal 3D printing is used for high-performance applications in industries such as aerospace, automotive, and medical. Metal powders, such as titanium, aluminum, and stainless steel, are used in processes like SLM (Selective Laser Melting) and EBM (Electron Beam Melting). Metal 3D printing offers:

High Strength-to-Weight Ratio: Essential for aerospace and automotive components.

Complex Geometries: Allows for the creation of intricate designs that are difficult to achieve with traditional manufacturing methods.

Composites: Composite materials combine thermoplastics with reinforcing fibers, such as carbon fiber or glass fiber, to enhance strength and rigidity. These materials are used in applications where lightweight and high strength are critical, including in the automotive and sports equipment industries.

Innovations Driving the 3D Printing Materials Market

The 3D printing materials market is experiencing rapid innovation, driven by advancements in technology and changing industry needs. Here’s a closer look at some of the latest innovations that are transforming the landscape of 3D printing materials:

Nanomaterials: Nanotechnology is making waves in the 3D printing industry by enabling the creation of materials with enhanced properties at the nanoscale. Nanomaterials can improve strength, durability, and thermal resistance, making them ideal for high-performance applications. For example, incorporating nanoparticles into polymers can enhance their mechanical properties, leading to more robust and reliable printed parts.

Bio-inks and Bioprinting: Bioprinting is revolutionizing the medical and research fields by enabling the creation of living tissues and organs. Bio-inks, which are made from natural and synthetic biopolymers, are used in this process to print cellular structures. These materials can be tailored to support cell growth and tissue development, opening up new possibilities for regenerative medicine and personalized healthcare.

Applications of 3D Printing Materials Market

The versatility of 3D printing materials market has led to their adoption across various sectors:

Aerospace: Lightweight and durable materials are used to manufacture complex parts and components, reducing overall weight and fuel consumption.

Healthcare: Custom prosthetics, implants, and dental products are tailored to individual patients using biocompatible materials.

Automotive: 3D printing enables rapid prototyping and production of lightweight parts, enhancing vehicle performance and reducing time-to-market.

Consumer Goods: Customized products, from eyewear to home decor, benefit from the flexibility and personalization offered by 3D printing.

Future Trends in 3D Printing Materials Market

As the 3D printing industry continues to evolve, several trends are likely to shape the future of 3D printing materials:

Biodegradable and Sustainable Materials: There is a growing focus on developing eco-friendly materials that reduce environmental impact. Innovations in biodegradable plastics and recycling processes are set to make 3D printing more sustainable.

Advanced Metal Alloys: The development of new metal alloys with enhanced properties will open up new possibilities for high-performance applications in industries such as aerospace and defense.

Multi-Material Printing: Advances in multi-material printing technologies will allow for the creation of complex objects with varying properties in a single print, expanding the range of applications and functionalities.

Smart Materials: The integration of materials that respond to environmental changes (such as temperature or pressure) will lead to the development of "smart" products with adaptive capabilities.

Benefits of 3D Printing Materials Market Report:

Analyst Support: Get your query resolved by our expert analysts before and after purchasing the report.

Customer Satisfaction: Our expert team will assist with all your research needs and customize the report.

Inimitable Expertise: Analysts will provide deep insights into the reports.

Assured Quality: We focus on the quality and accuracy of the report.

Conclusion

The 3D printing materials market is a dynamic and rapidly evolving field, driven by continuous innovation and technological advancements. From thermoplastics and resins to metals and composites, the variety of materials available today provides limitless possibilities for creators and manufacturers alike. As we look to the future, emerging trends and new material developments promise to further revolutionize the industry, offering exciting opportunities for growth and transformation across various sectors. Whether you're a hobbyist, a designer, or an industry professional, staying informed about these advancements will be key to leveraging the full potential of 3D printing technology.

#3D Printing Materials Market Demand#3D Printing Materials Market Scope#3D Printing Materials Market Analysis#3D Printing Materials Market Trend

0 notes

Text

Polycarbonate Composites Market: Lightweight and Durable Innovations Driving Industrial Use up to 2033

The Polycarbonate Composites Market focuses on materials created by combining polycarbonate (PC) resin with reinforcing agents such as glass fibers, carbon fibers, or other fillers. These composites are well-known for their excellent impact resistance, high strength-to-weight ratio, optical clarity, and flame-retardant properties. The versatility of polycarbonate composites makes them widely used in applications across automotive, electronics, aerospace, construction, and healthcare industries.

To Know More @ https://www.globalinsightservices.com/reports/polycarbonate-composites-market

The polycarbonate composites market is anticipated to expand from $2.1 billion in 2023 to $4.3 billion by 2033, achieving a CAGR of 7.4%.

Market Outlook The Polycarbonate Composites Market is experiencing strong growth due to the increasing demand for lightweight yet durable materials in key industries. The automotive sector, in particular, is a significant driver, as manufacturers are seeking materials that reduce vehicle weight to improve fuel efficiency and meet stringent emission standards. Polycarbonate composites are becoming a preferred choice for automotive components such as headlamp lenses, interior parts, and glazing solutions due to their exceptional strength and lightweight characteristics.

In the electronics and electrical industry, the demand for polycarbonate composites is also surging. The materials’ excellent electrical insulation properties and high heat resistance make them suitable for producing enclosures, connectors, and electronic device casings. The growth of the consumer electronics market and the rising adoption of smart devices are contributing to increased usage of polycarbonate composites in this sector.

Aerospace and defense industries are turning to polycarbonate composites for applications that require high performance and safety, such as aircraft interiors, cockpit canopies, and ballistic-grade materials. The aerospace sector’s focus on weight reduction for fuel efficiency and enhanced durability further drives the demand for polycarbonate composites. Additionally, the construction industry is leveraging these materials for glazing applications and structural components where impact resistance and transparency are essential.

The market is witnessing innovations in composite manufacturing processes, such as the development of thermoplastic composites that offer advantages in recyclability and faster production cycles. Advancements in nanotechnology and surface modification techniques are also enhancing the properties of polycarbonate composites, expanding their application range and performance capabilities.

Environmental sustainability is a growing trend in the Polycarbonate Composites Market. Companies are investing in research and development to produce eco-friendly composites using bio-based polycarbonates and recycled materials. The push for sustainable materials aligns with global efforts to reduce plastic waste and promote the circular economy.

Asia-Pacific is expected to dominate the Polycarbonate Composites Market, driven by rapid industrialization, urbanization, and growing automotive and electronics manufacturing. Countries like China, Japan, and South Korea are leading in both production and consumption of polycarbonate composites. North America and Europe are also key markets, with strong demand from the automotive and aerospace sectors.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS32456

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request For Report Customization @ https://www.globalinsightservices.com/request-customization/GIS32456

Market Segmentation

In 2023, the Polycarbonate Composites Market demonstrated robust performance, with a market volume of 600 million metric tons and projections to reach 900 million metric tons by 2033. The automotive sector dominates the market share at 45%, driven by the industry’s demand for lightweight and durable materials. The electronics segment follows with a 30% share, benefiting from the increasing use of polycarbonate composites in consumer electronics. The construction segment holds a 25% share, supported by the material’s strength and versatility. Key players such as Covestro AG, SABIC, and Teijin Limited maintain substantial market presence, influencing sector dynamics.

Competitive pressures and regulatory frameworks significantly impact the Polycarbonate Composites Market. Companies are investing in sustainable production methods to comply with stringent environmental regulations. The EU’s Green Deal and similar policies worldwide are pushing for eco-friendly manufacturing processes. Future projections indicate a 10% annual increase in R&D expenditure, targeting innovations in recycling and material efficiency. The market outlook remains optimistic, with growth driven by advancements in composite technology and expanding applications across various industries. However, challenges such as fluctuating raw material prices and the need for technological advancements persist, necessitating strategic collaborations and investments in cutting-edge technologies.

Major Players

SABIC Innovative Plastics

Covestro

Teijin Limited

Mitsubishi Chemical Corporation

Chi Mei Corporation

LG Chem

Trinseo

Lotte Chemical

Asahi Kasei Corporation

Idemitsu Kosan

RTP Company

Plazit Polygal

PolyOne Corporation

Ensinger

Bayer MaterialScience

A. Schulman

SABIC

Sumitomo Chemical

Toray Industries

Mitsui Chemicals

Request For Discounted Pricing @ https://www.globalinsightservices.com/request-special-pricing/GIS32456

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

For In-Depth Competitive Analysis, Buy Now @ https://www.globalinsightservices.com/checkout/single_user/GIS32456

About Us

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

0 notes

Text

0 notes