#automotive wheel industry

Explore tagged Tumblr posts

Text

The Automotive Wheel Industry: Trends and Insights

The automotive wheel industry is a critical segment of the broader automotive market, providing essential components that not only support vehicle movement but also contribute to safety, aesthetics, and performance. As the automotive landscape evolves, so too does the wheel industry, driven by technological advancements, changing consumer preferences, and global market dynamics. In this blog post, we’ll explore the key trends, challenges, and opportunities within the automotive wheel market based on the latest market research.

Market Overview

The Automotive Wheel Market is projected to reach a size of USD 37.94 billion in 2024 and is expected to grow to USD 51.97 billion by 2029, representing a CAGR of 6.5% during the forecast period from 2024 to 2029. This growth can be attributed to the increasing demand for vehicles, particularly in emerging markets, as well as the rise of electric and autonomous vehicles.

Key Trends Shaping the Automotive Wheel Industry

Shift to Lightweight Materials

As manufacturers seek to improve fuel efficiency and reduce emissions, the shift towards lightweight materials like aluminum and composite alloys has gained momentum. Lightweight wheels enhance vehicle performance by reducing overall weight, which is crucial for electric vehicles (EVs) aiming for extended range.

Customization and Aesthetics

Consumers are increasingly prioritizing personalization in their vehicle choices. Custom wheels—available in a variety of designs, finishes, and sizes—are in high demand. This trend is not only driven by individual tastes but also by the rise of social media platforms that showcase unique vehicle modifications.

Technological Advancements

The integration of advanced manufacturing technologies such as 3D printing and automated production processes is revolutionizing wheel design and production. These innovations enable manufacturers to create complex designs while reducing production costs and time.

Sustainability Initiatives

With growing environmental concerns, many companies are adopting sustainable practices. This includes using recycled materials, reducing waste in the manufacturing process, and developing eco-friendly coatings. Consumers are more likely to support brands that prioritize sustainability, making it a critical focus for the industry.

Smart Wheels and IoT Integration

The emergence of smart technologies in the automotive sector is influencing wheel design. Wheels equipped with sensors can monitor tire pressure, temperature, and overall condition, providing real-time data to enhance safety and performance. As the Internet of Things (IoT) continues to expand, expect more innovations in this area.

Challenges Facing the Automotive Wheel Market

Raw Material Prices

Fluctuations in the prices of raw materials, particularly aluminum and steel, pose a significant challenge for manufacturers. Price volatility can impact profit margins and overall production costs, leading to potential price increases for consumers.

Regulatory Compliance

Adhering to stringent regulations related to safety, emissions, and manufacturing processes can be complex and costly. Companies must remain agile to adapt to new regulations, especially as governments worldwide tighten standards to combat environmental issues.

Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains. Disruptions caused by geopolitical tensions, natural disasters, or pandemics can hinder production and delay deliveries, affecting the entire automotive market.

Opportunities in the Automotive Wheel Market

Emerging Markets

As developing economies grow, there is a rising demand for automobiles, presenting significant opportunities for wheel manufacturers. Companies that can establish a presence in these markets stand to benefit from increased sales and market share.

Electric Vehicle Growth

The shift towards electric vehicles is reshaping the automotive industry. As EVs become more prevalent, the need for specialized wheels designed to accommodate different weight distributions and performance characteristics will increase.

Collaborations and Partnerships

Forming strategic alliances with automakers, technology firms, and materials suppliers can enhance innovation and market reach. Collaborative efforts can lead to the development of cutting-edge products that meet evolving consumer demands.

Conclusion

The automotive wheel industry is on the cusp of transformation, driven by technological advancements, changing consumer preferences, and a focus on sustainability. As manufacturers navigate challenges such as raw material prices and regulatory compliance, opportunities abound in emerging markets and the electric vehicle sector. By staying attuned to these trends and adapting to the shifting landscape, businesses in the automotive wheel market can position themselves for success in the years to come. For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/automotive-wheel-market

#automotive wheel market#automotive wheel industry#automotive wheel market size#automotive wheel market share#automotive wheel market analysis#automotive wheel market report#automotive wheel market trends

0 notes

Text

🇺🇸 As we approach Chrysler's 100th anniversary, Frank B. Rhodes Jr., great-grandson of company founder Walter P. Chrysler, is raising concerns about the brand’s future and wants to take action to rescue it. In a recent open letter to “investors and workers,” Rhodes announced his plan to revitalize Chrysler and its related brands—Dodge, Ram, and Jeep—under new “American” ownership.

🚗 Stellantis, the current parent company of Chrysler, has come under criticism from Rhodes for its management of the brand, which he claims has been severely neglected. The Chrysler brand currently offers only one vehicle, the Pacifica minivan, while several promising concept cars, such as the Chrysler Airflow, were shelved before reaching production. Rhodes highlighted Stellantis’ focus on European brands like Citroën and Peugeot, arguing that Chrysler has been left behind.

💼 Rhodes, who has been a Chrysler ambassador for over 40 years, points to his family’s legacy and his own ownership of the final Chrysler 300C as reasons for his dedication to the brand. He submitted a 17-page proposal to Stellantis executives, inviting them to a confidential discussion on reviving Chrysler. His plan includes giving equity stakes to employees, echoing the worker-centered vision of his great-grandfather, who founded the company on principles of American ingenuity and innovation.

📉 Rhodes also expresses concern about the future of Dodge, which has focused heavily on electric vehicles (EVs) despite its core customer base being more interested in American muscle and performance cars. He argues that Stellantis’ push toward an all-electric lineup by 2028 for Chrysler is out of step with market trends, where hybrids are gaining popularity. The all-electric path, Rhodes warns, could be disastrous for the brand’s future.

🔧 Despite these challenges, Rhodes remains optimistic about the potential to rebuild Chrysler as a symbol of blue-collar luxury and innovation. He is calling for a return to American-designed and built products, and greater autonomy for Chrysler and Dodge within Stellantis. Rhodes’ ultimate goal is to rescue the brand from what he sees as poor management and ensure that Chrysler survives to celebrate its next century.

🚨 As Chrysler fans prepare for the 100th anniversary celebrations next summer, including a large event in Pennsylvania, Rhodes is urging action to prevent the brand from fading into obscurity. Without intervention, he warns, Chrysler’s future looks bleak.

#transatlantic torque#brits and yanks on wheels#companies#technology#brands#engineering#cars#tech#old cars#innovation#business and industry sectors#history#chrysler#dodge#Plymouth#walter chrysler#detroit#michigan#big three#Chrysler Motors#automotive#american auto#automobile#classic cars#car#made in usa#stellantis#fiat chrysler automobiles#american company#american car

13 notes

·

View notes

Link

DRIVE PILOT, the highly automated driving system from Mercedes-Benz, has won one of the most prestigious awards in the automotive industry: the Golden Steering Wheel 2024. The Auto Bild and Bild

#DRIVE PILOT#Golden Steering Wheel 2024#Mercedes-Benz#autonomous driving#highly automated driving#award ceremony#innovation#automotive industry#self-driving cars

0 notes

Text

Metalman Auto: Your Source for Precision Tubular Fabrication Services

Metalman Auto specializes in precise tubular fabrication services for various applications. We ensure flawless welding and finishing for superior results. Contact us for your tubular fabrication needs.

#automotive industry#automotive parts#automotive#electric vehicles#fabricationservices#car accessories#manufacturer#metal fabrication#metalman auto#oem manufacturing#tubular fabrication#metalman#automobiles#car parts#electric car parts manufacturer#components manufacturers#manufacturers#two wheels

1 note

·

View note

Text

https://introspectivemarketresearch.com/reports/automotive-brake-wheel-cylinder-market/

0 notes

Text

Automotive Aluminum Alloy Wheels Market 2024 to 2030 Updates, News, Key Players, Cumulative Annual Growth Rate

Global Automotive Aluminum Alloy Wheels Market research report published by Exactitude Constancy reveals the current outlook of the global and key regions from the following perspectives: Key players, countries, product types, and end industries. The report studies the top companies in the global market and divides the market into several parameters. This Automotive Aluminum Alloy Wheels Market research report pinpoints the industry's competitive landscape to understand the international competition. This report study explains the expected growth of the global market for the upcoming years from 2024 to 2030. This research report is accumulated based on static and dynamic perspectives on business.

The Automotive Aluminum Alloy Wheels Market is expected to grow at 3.6% CAGR from 2023 to 2030. It is expected to reach above USD 26.43 Billion by 2030 from USD 19.21 Billion in 2023.

Browse Complete Summary and Table of Content @ https://exactitudeconsultancy.com/ja/reports/27137/automotive-aluminum-alloy-wheels-market/

#Automotive Aluminum Alloy Wheels Industry#Automotive Aluminum Alloy Wheels Market 2024#Automotive Aluminum Alloy Wheels Market Analysis#Automotive Aluminum Alloy Wheels Market Research Report#Automotive Aluminum Alloy Wheels Market Demand#Automotive Aluminum Alloy Wheels Market Growth#Automotive Aluminum Alloy Wheels Market Insights#Automotive Aluminum Alloy Wheels Market Revenue#Automotive Aluminum Alloy Wheels Market Share#Automotive Aluminum Alloy Wheels Market Size#Automotive Aluminum Alloy Wheels Market Trends

0 notes

Text

youtube

#steelwheel#autowheel#wheelfactory#autorim#autodisc#rimfactory#Auto steel wheel#Steel wheel manufacturer#Auto wheel manufacturer#Steel wheel production#Automotive steel wheel#Car steel wheel#Steel rim manufacturer#Car wheel production#Automobile wheel maker#Steel wheel factory#Vehicle wheel manufacturer#Steel wheel supplier#Auto industry wheel#Car rim manufacturer#Steel wheel production company#Automotive wheel maker#Steel wheel assembly#Car wheel manufacturing#Auto steel rim#Wheel manufacturing plant#Steel wheel fabrication#Automotive rim producer#Car wheel factory#Steel wheel forging

0 notes

Text

X-by-Wire Systems

X-by-wire is an umbrella term used to describe electronically controlled systems in modern-day vehicles. These electronic systems often augment or replace traditional mechanical/hydraulic systems.

This technology makes use of electronic controls to activate brakes, steering, throttle or shift commands, instead of using cables or hydraulic pressure.

This helps in reducing the number of moving components, improving the efficiency of the system, faster response, and making the components less prone to wear and tear.

The origin of these X-by-wire systems comes from the aerospace industry. Fly-by-wire is a proven technology, wherein all control systems, sensors and actuators are electronically connected.

The sensors measure the changes applied by the pilot, such as increasing throttle and controlling the yaw, pitch and roll movements of the aeroplane.

These sensor readings are interpreted by the control unit and corresponding commands are sent to the actuators to implement the changes in trajectory or speed.

However, applying this kind of system to road vehicles becomes complex, as there exist multiple dynamic objects in close proximity to every vehicle, and so, highly accurate, uninterrupted and quick responses are required.

Finally, the aerospace industry has comprehensively-trained individuals manning the aeroplanes, who will have better intuition while using this kind of a system as compared to the average driver on the road.

Pros and Cons of X-by-wire systems

The use of such electronic controls helps in reducing the number of moving components in the vehicle, and also contributes towards decreasing the total weight of the system, which is an integral step in increasing vehicular efficiency.

Additionally, electronic sensors can easily communicate with other active and passive safety features to ensure that special safety features such as electronic lane assistance, electronic stability control and adaptive cruise control can be easily integrated.

These systems also allow better control than mechanical systems, while also giving a faster response. Finally, X-by-wire technology allows automotive manufacturers to get a significant amount of flexibility in designing the systems, as electronic controls don’t demand the same space and positioning constraints as mechanical controls.

The major drawback is that the reliability of such X-by-wire systems is not entirely foolproof yet, which means that most electronic control systems still need mechanical backup.

Furthermore, the cost of implementing these systems is significantly higher due to the higher number of sensors and electromechanical actuators used.

There is also a risk of mobile phone signals interfering with electronic control systems and communication systems.

This interference needs to be prevented by properly isolating the spectrum of signal frequencies for different functions.

Because of these issues, X-by-wire systems have received a fair bit of backlash from most automotive regulatory committees.

Types of X-by-wire systems

1. Throttle-by-wire

A throttle-by-wire system uses pedal position and throttle position sensors, which operate in collaboration with the throttle pedal to control the amount of fuel entering the engine or current drawn by the motor.

A conventional throttle control system uses cables to actuate the throttle opening, which in turn governs the amount of fuel allowed to enter the engine.

In an electronic throttle control system, the pedal position sensor sends data about the extent of throttle actuation to the engine management system, which in turn calculates the amount of fuel required to fulfil the acceleration demands, and relays the information to the throttle actuator accordingly.

X-by-Wire Systems | Dorleco

Electronic Throttle Body | Source: Electronic Throttle Body

The throttle opening is thus controlled by the actuation of the pedal, i.e., if there is no signal coming from the pedal position sensor, the throttle is completely closed.

Most throttle-by-wire systems also take feedback from the throttle position sensor back to the engine management system to ensure the mitigation of any errors.

X-by-Wire Systems | Dorleco

Source: https://www.researchgate.net/figure/Schematic-of-the-electronic-throttle-control-system_fig1_262938429

In the above image, the ECU is responsible for sending the throttle actuation commands to the motor based on the data from the accelerator pedal sensor. It also takes input from the throttle position sensor to reduce the errors.

The pinion gear, intermediate gear and sector gear are responsible for the reduction from the motor actuation angle to the throttle opening angle.

2. Steer-by-wire

The steer-by-wire technology replaces the mechanical connection between the steering wheel and the steering mechanism seen in older vehicles. This system mainly consists of two major components – the steering wheel actuator, which is the feedback motor, and the steering rack actuator.

The steering wheel sensor measures the angle through which the driver has turned the steering wheel and transforms this into a digital signal to send to the steering rack actuator. The steering feedback motor provides haptic feedback that replicates the steering feel back to the driver.

X-by-Wire Systems | Dorleco

The steering rack actuator ensures the rack travel is in accordance with the signal received from the steering wheel sensor, which in turn ensures that the angle through which the wheels turn is in proportion with the steering input.

X-by-Wire Systems | Dorleco

Source: More freedom for steering: Steer-by-wire from ZF - ZF

One issue that is often encountered while using sensors and actuators in place of mechanical controls is the sensor noise. Any kind of unnecessary data being captured by the sensor can affect the fidelity of the sensors which can lead to hazardous scenarios.

Many developers overcome this challenge by using two different sensors at the same location to measure the same values, thus ensuring sensor redundancy. Sensors also need to be recalibrated throughout the life of the sensors based on their performance.

Future steer-by-wire technologies can also include adaptable settings based on the driver so that every driver gets to drive with customized comfort settings.

3. Brake-by-wire

Brake-by-wire actuates the brakes electronically in addition to the mechanical connection between the master cylinder and the brake callipers. There are two types of brake-by-wire systems – electrohydraulic system and electromechanical system.

In electrohydraulic systems, the actuation of brake callipers on each wheel is still hydraulic in nature, but the physical connection of these individual callipers to the master cylinder is replaced by an electronic one.

Pushing on the brake pedal activates a bunch of sensors, determining the amount of force to be imparted on the wheels based on the brake input, and actuating the callipers accordingly. Electromechanical systems, on the other hand, use electromechanical actuators to activate the callipers on each wheel.

The main issue with brake-by-wire systems is the complexity involved in the calibration of the hardware. The brake pedal position and the corresponding pressure exerted have a non-linear relationship. Furthermore, this calibration can vary based on vehicle size as well.

At the same time, brake-by-wire systems can easily be programmed to give varying outputs based on different driving conditions.

The pressure being applied can be altered on slippery surfaces or based on the suspension and steering parameters to improve the safety of the vehicle, unlike purely mechanical brakes.

X-by-Wire Systems | Dorleco

Source: Brake-By-Wire Systems Are More Connected Than You Think

Brake-by-wire is a technology that is seen as more safety-critical than throttle-by-wire systems, as it takes the physical connection between the driver and brakes out of the equation. In almost all vehicles, brakes are the most powerful system, since the rate of deceleration of the vehicle has to be higher than the rate of acceleration.

Any electronic failure or data loss can cause the brakes to malfunction, creating a life-threatening situation for the driver as well as the people nearby. However, hybrid approaches with electrohydraulic or electromechanical actuators help in designing fail-safes for the system.

Many systems also implement backup mechanical controls, which spring into action in case of power failure or sensor damage.

4. Shift-by-Wire

Shift-by-wire essentially eliminates the physical connection between the gear lever and the transmission and replaces it with electronic controls. This also takes away the need for the gear lever in the first place. There can simply be buttons, switches, paddle shifters, or the touchscreen settings on the infotainment unit, for shifting between park mode, reverse, neutral and drive.

This helps in decreasing the overall weight, complexity, and number of moving parts of the system.

The biggest advantage is the faster response of the gear shifts, as shift-by-wire systems can shift through gears as quickly as 50 milliseconds. With electronic shifters, you can also design foolproofs for deterring accidental shifts, thus improving the safety of the vehicle.

Errors in shifting between gears can also be mitigated using a shift-by-wire system. Error states can communicate with the ECU and relay information.

For example, if shifting to a higher gear is not conducive at the moment because of high torque load, or shifting to a lower gear is dangerous because of the risk of tire slippage, then these potentially hazardous situations can be avoided by this communication.

X-by-Wire Systems | Dorleco

Source: Shift by Wire

X-by-wire Development and Integration at Dorle Controls

With electronically-controlled systems in the automotive industry on the rise, X-by-wire is a concept that is set to become a fundamental aspect of the field. At Dorle Controls, we develop controls software for X-by-wire systems and test them on the target hardware to get an understanding of how they can be implemented in modern-day vehicles.

This includes designing an electronic throttle controller and testing the control logic on specific motors, implementing a steer-by-wire system on a test rig, and writing custom driver software controls for steering and throttle actuators.

Write to [email protected] to know how we can help you write control software specific to your requirements.

Read more on our website

#X-by-Wire Systems#Advanced Driver#Automatic Emergency Braking#automotive industry#mechanical connections#mechanical control#steering motor#steering wheel

0 notes

Text

Onwo products have been tested and confirmed to work in abrasive environments where conventional industrial lubricants have failed to lubricate. A whole spectrum of greases and oils are included in the performance plus products, which are made to withstand the harsh lubrication conditions seen in the steel, cement, mining, building, power, and automotive industries.

#petroleum lubricating oil#petroleum-based grease#automotive wheel bearing grease#industrial lubricant company#petroleum products#industrial oil suppliers#machinery grease#textile lubricants#onwo#rajpetro#raj petro

0 notes

Text

SupAlign's Quicktrak Laser Wheel Alignment Machines

SupAlign offers a range of Quicktrak laser wheel alignment machines suitable for any garage. From 2 wheel optical laser aligner gauges to 4 wheel laser alignment machines, their cost-effective but premium solutions provide accurate and efficient wheel alignment. With over 50 years of industry experience, their expert team is available to help you choose the best model for your needs. Contact them today for more information.

#SupAlign#Quicktrak#Wheel Alignment#Laser Aligners#Garage Equipment#Automotive Tools#Wheel Balancers#Ravaglioli#Expert Advice#Industry Experience

0 notes

Text

VW wouldn't locate kidnapped child because his mother didn't pay for find-my-car subscription

The masked car-thieves who stole a Volkswagen SUV in Lake County, IL didn’t know that there was a two-year-old child in the back seat — but that’s no excuse. A violent car-theft has the potential to hurt or kill people, after all.

If you’d like an essay-formatted version of this post to read or share, here’s a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2023/02/28/kinderwagen/#worst-timeline

Likewise, the VW execs who decided to nonconsensually track the location of every driver and sell that data to shady brokers — but to deny car owners access to that data unless they paid for a “find my car” subscription — didn’t foresee that their cheap, bumbling subcontractors would refuse the local sheriff’s pleas to locate the car with the kidnapped toddler.

And yet, here we are. Like most (all?) major car makers, Volkswagen has filled its vehicles with surveillance gear, and has a hot side-hustle as a funnel for the data-brokerage industry.

After the masked man jumped out of a stolen BMW and leapt into the VW SUV to steal it, the child’s mother — who had been occupied bringing her other child inside her home — tried to save her two year old, who was still in the back seat. The thief “battered” her and drove off. She called 911.

The local sheriff called Volkswagen and begged them to track the car. VW refused, citing the fact that the mother had not paid for the $150 find-my-car subscription after the free trial period expired. Eventually, VW relented and called back with the location data — but not until after the stolen car had been found and the child had been retrieved.

Now that this idiotic story is in the news, VW is appropriately contrite. An anonymous company spokesman blamed the incident on “a serious breach” of company policy and threw their subcontractor under the (micro)bus, blaming it on them.

This is truly the worst of all worlds: Volkswagen is a company that has internal capacity to build innovative IT systems. Once upon a time, they had the in-house tech talent to build the “cheat device” behind Dieselgate, the means by which they turned millions of diesel vehicles into rolling gas-chambers, emitting lethal quantities of NOX.

https://en.wikipedia.org/wiki/Volkswagen_emissions_scandal

But on the other hand, VW doesn’t have the internal capacity to operate Car-Net, it’s unimaginatively-named, $150/year location surveillance system. That gets subbed out to a contractor who can’t be relied on to locate a literal kidnapped child.

The IT adventures that car companies get up to give farce a bad name. Ferraris have “anti-tampering” kill-switches that immobilize cars if they suspect a third-party mechanic is working on them. When one of these tripped during a child-seat installation in an underground parking garage, the $500k car locked its transmission and refused to unlock it — and the car was so far underground that its cellular modem couldn’t receive the unlock code, permanently stranding it:

https://pluralistic.net/2020/10/15/expect-the-unexpected/#drm

BMW, meanwhile, is eagerly building out “innovations” like subscription steering-wheel heaters:

https://pluralistic.net/2020/07/02/big-river/#beemers

Big Car has loaded our rides up with so much surveillance gear that they were able to run scare ads opposing Massachusetts’s Right to Repair ballot initiative, warning Bay Staters that if third parties could access the data in their cars, it would lead to their literal murders:

https://pluralistic.net/2020/09/03/rip-david-graeber/#rolling-surveillance-platforms

In short: the automotive sector has filled our cars with surveillance gear, but that data is only reliably available to commercial data-brokers and hackers who breach Big Cars’ massive data repositories. Big Car has the IT capacity to fill our cars with cheat devices — but not the capacity to operate an efficient surveillance system to use in real emergencies. Big Car says that giving you control over your car will result in your murder — but when a child’s life is on the line, they can’t give you access to your own car’s location.

This Thu (Mar 2) I’ll be in Brussels for Antitrust, Regulation and the Political Economy, along with a who’s-who of European and US trustbusters. It’s livestreamed, and both in-person and virtual attendance are free. On Fri (Mar 3), I’ll be in Graz for the Elevate Festival.

Image: Cryteria (modified) https://commons.wikimedia.org/wiki/File:HAL9000.svg

CC BY 3.0 https://creativecommons.org/licenses/by/3.0/deed.en

—

Upsilon Andromedae (modified) https://www.flickr.com/photos/upsand/212946929/

CC BY 2.0 https://creativecommons.org/licenses/by/2.0/

[Image ID: A blue vintage VW beetle speeds down a highway; a crying baby is pressed against the back driver's-side window. In the sky overhead is the red glaring eye of HAL 9000 from 2001: A Space Odyssey, emblazoned with the VW logo. The eye is projecting a beam of red light that has enveloped the car.]

#pluralistic#worst timeline#parenting#car-net#automotive#stranger danger#commercial surveillance#surveillance#volkswagen#vw

2K notes

·

View notes

Text

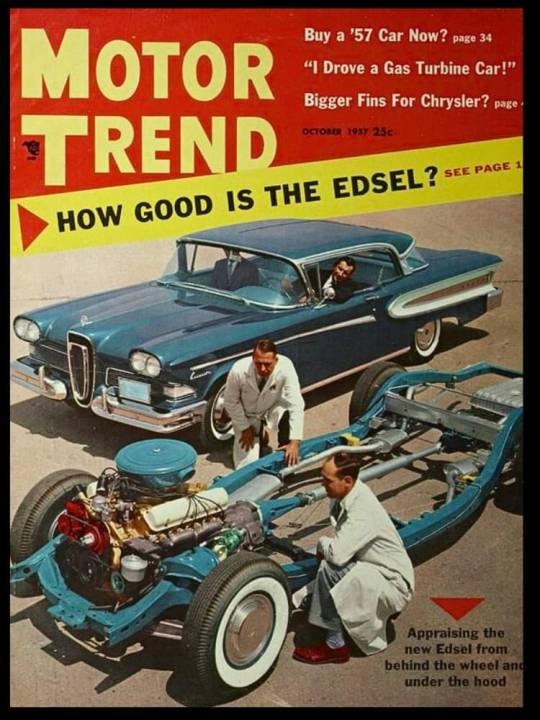

🇺🇲 On September 4, 1957, Ford Motor Company introduced the Edsel, a new division aimed at revolutionizing the market. Unlike Ford, Lincoln, or Mercury, the Edsel had its own identity with four models: the smaller Pacers and Rangers, and the larger Citations and Corsairs.

🚘 The Edsel became notorious for its failure. Launched during a booming economy, it was designed as a large, flashy car. But by the time it hit showrooms, the economy had shifted, and consumers wanted smaller, more efficient cars.

🤔 The Edsel’s unique design, including push-button gear shifting on the steering wheel, wasn’t well-received. Issues like a hood ornament that could fly off didn’t help its reputation. In its first year, Edsel sold just 64,000 cars, losing $250 million ($2.5 billion today).

💔 The Edsel brand was discontinued after the 1960 model year, marking one of the biggest flops in automotive history.

#brits and yanks on wheels#transatlantic torque#retro cars#brands#vehicle#cars#companies#old cars#american cars#automobile#ford edsel#edsel#ford motor co#ford#detroit#michigan#american auto#made in america#muscle car#old car#classic cars#car#classic car#luxury cars#business and industry sectors#lincoln#automotive#1950s cars#edsel ford#v8 engine

15 notes

·

View notes

Text

1949 Delahaye 175 S Saoutchik Roadster

Saoutchik was a cabinet maker when he moved to Paris from his home in Ukraine around 1900, but he didn’t take long to establish himself in the fledgling automotive coachbuilding industry and he showed a consistent flair over the next 50 years which puts him among the very elite of automotive designers.

His designs borrowed little from other designers, and along with names such as Figoni et Falaschi, Chapron, Franay and de Letourner et Marchand, Saoutchik was one of the foremost designers of exquisite Art Deco coachwork during the 20s and 30s.

Saoutchik was commissioned to produce the spectacular work-of-art by flamboyant English collector, Sir John Gaul. The design was based on the first post-war Delahaye chassis from a 175 S Roadster (chassis number 815023) producing 165 bhp from an engine much larger than the pre-war Delahayes ran – a 4,455 cc naturally aspirated overhead valve inline six cylinder engine with four-speed electro-mechanically actuated Cotal Preselector gearbox, Dubonnet coil spring front suspension, De Dion rear axle with semi-elliptic springs, and four-wheel hydraulic finned alloy drum brakes. The wheelbase was a whopping 116 inches.

The car was unveiled at the 1949 Paris Auto Show, and was exhibited at all the major European concours events that year, from Paris to Monte Carlo to San Remo, scooping the pool wherever it was exhibited. It won best-in-class in the Pebble Beach Concours d’Elegance in 2006 just a few months after a complete restoration. Just a few months later, the car was honored again, winning People’s Choice at theprestigious Amelia Island Concours d’ Elegance.

Having fulfilled its exhibition duties, it then passed through a succession of other flamboyant owners, including actress Diana Dors.

The final word on this stunning automobile goes to Ian Kelleher, President and Chief Operating Officer, RM Auctions

“Following the financial depression of World War II, there were few collectors with the means, flamboyance and flair to commission a car as exotic as this Saoutchik Roadster. Arguably the most desirable post-war, coachbuilt automobile of all time, it is truly a masterpiece of the coachbuilder’s art. Eye-catching and exotic, it is wonderful to drive and combines superlative styling on a chassis of competition quality.”

Courtesy of RM Auctions

89 notes

·

View notes

Text

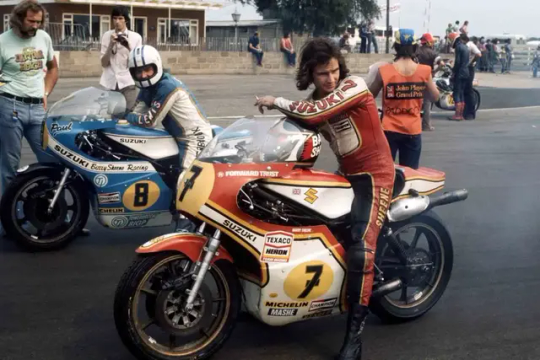

Osamu Suzuki

Suzuki chairman who over half a century grew the company into one of the world’s largest car and motorcycle manufacturers

Osamu Suzuki, who has died aged 94, was one of the global automotive industry’s longest serving leaders. A director since 1963 of Suzuki, the motorcycle and small car manufacturer based in Hamamatsu, Japan, he rose through the ranks to become in 1979 the firm’s president, a position he relinquished only in 2019 to ascend to the chairmanship. Latterly, as is customary with elder statemen of Japanese industry, he became an adviser, the title he still held at the time of his death.

When he first joined Suzuki, in 1958, it had been in the automobile business for only four years, building the tiny two-cylinder, air-cooled Suzulight car, in a country that was still finding its way as an industrial power. It had been founded in 1909 as a loom manufacturer, but the collapse of the cotton market in the early 1950s galvanised a move towards automotive endeavours.

Suzuki produced its first motorcycle – really a 36cc motorised pedal bike – in 1952 but 10 years later would notch up its first Isle of Man TT victory. In 1976, Barry Sheene won his first 500cc World Championship on a Suzuki RG500. The loom-making arm of the firm was separated from the automotive side in 1960 and, under Osamu, Suzuki expanded into the production of outboard motors, wheelchairs, all-terrain vehicles, and prefabricated housing.

He progressed conservatively to make Suzuki the largest small car producer in Japan, always with a keen eye on cost cutting, even on a shop-floor level: in one plant he famously had some of the light bulbs removed to save $40,000 on electricity.

Suzuki motorcycles arrived in the UK long before its cars, alongside Honda and others helping decimate the British motorcycle industry from the mid-60s onwards with dependable, easy to maintain two-wheeled machinery.

The now collectable Whizzkid Coupe and Jimny off-roader (sold in the UK as the Satana and Samurai) were relative latecomers to the Japanese car sales bonanza from 1979. The Suzuki Alto of the early 80s was the cheapest automatic car then available in the UK, priced at £4,000, while the 1985 Swift was the firm’s first four-cylinder “supermini” sized vehicle.

The Bedford Rascal – better known as the “Sooty van” in the TV puppet series Sooty and Sweep – was really a rebadged Suzuki Carry, or “kei” truck, built to conform to strict Japanese light commercial specifications. These Rascal/Carry trucks were a spin-off from a deal that Osamu Suzuki struck with General Motors in 1981 to sell its economy cars in North America with Chevrolet badges, in return for giving GM a 5% stake in the company.

Osamu would also preside in 2009 over a tie-up with VW that ended in a court battle, and latterly collaborated with Toyota on the design of self-driving cars.

From the late 60s, production of the small Fronte rear-engined cars ramped up under Osamu’s leadership but, unlike its rivals, Nissan, Toyota and Mazda, Suzuki did not give in to the temptation to move upmarket, preferring to use its resources to build satellite plants in emerging markets where its small runabout cars had most appeal.

Beginning in Thailand in 1967 – and followed by Indonesia, the Philippines, Australia and Pakistan in the 70s and 80s – Suzuki expanded its operations on the Pacific rim rather than tackle local rivals head on, although between 1967 and 1970 Japanese production rose substantially, based at four new locations.

In the early 80s Suzuki became the first Japanese manufacturer to establish a manufacturing outlet in India, where its new front-wheel drive Alto/Fronte broke the stranglehold of the outdated Hindustan ambassador (a locally built 1950s Morris Oxford), and the equally ancient Fiat 1100-based Premier Padmini to become the bestselling car in India. Osamu Suzuki made over 200 flights to India in an effort to get this historic deal done.

By the beginning of the 2000s Suzuki had 60 factories in 31 countries as sales rose tenfold to a value of $19bn.

The son of Toshiki and Matsuda Shunzo, and born in the city of Gero, Gifo Prefecture, in central Japan, Osamu graduated in law from Chuo University in Tokyo in 1953 and worked in the loans office of a local bank before joining Suzuki in 1958. Around the same time, he married Shoko Suzuki, the granddaughter of the company’s founder, and, as per local tradition when there is no male heir, adopted his wife’s family name.

Had Hirotaka Ono, the son-in-law he had been grooming to take his place, not died of cancer in 2007, Osamu would probably have enjoyed a much longer retirement. A keen golfer into his 90s, five years ago he handed the reigns of the company to his son Toshihiro, the eldest of his three children.

🔔 Osamu Suzuki, industrialist, born 30 January 1930; died 25 December 2024

Daily inspiration. Discover more photos at Just for Books…?

12 notes

·

View notes

Photo

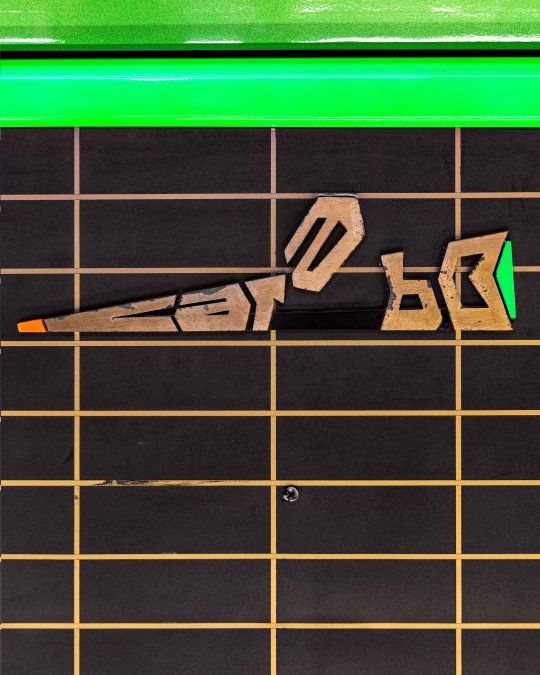

Alfa Romeo Carabo

The Carabo project was a collaborative effort between the Italian manufacturer and the Bertone styling house: a partnership which had previously borne fruits that included the 2000 Sportiva and BAT concept cars of the mid-1950s. The basis of the Carabo was a chassis numbered 75033.109 which was, more specifically, that of a 33 Stradale road car. Despite sharing mechanicals with the Tipo 33 race car and since being recognised as one of the most beautiful cars in history, Alfa had trouble finding owners for the Stradale due to its steep asking price of around $17,000. As a result, five of the Stradale chassis were passed to Italian carrozzerie: two to Pininfarina (used for the 33.2 and Cuneo concepts), one to Italdesign (which became the Iguana concept), and two to Bertone – the other being used as a basis for the 1976 Navajo concept.

The H-shaped tubular chassis supported an all-aluminium 1995cc engine which was designed by Carlo Chiti and, incidentally, was the first Alfa Romeo V8. The fuel-injected, longitudinally mounted motor used chain-driven camshafts and red-lined at 10,000rpm, despite being detuned to 230bhp from the Tipo race car’s 250-270bhp. This granted the Carabo a top speed of 160mph and the ability to dispatch the 0-62mph sprint in 5.5 seconds, with the power being sent to the rear wheels through a six-speed, syncromeshed, transaxle gearbox designed by Valerio Colotti.

Because of its underpinnings, designer Marcelo Gandini had the opportunity to create a car that would revolutionise the automotive industry for many years afterwards. The engine being mounted amidships allowed for a pointed front end, while the ground-hugging poise inherited from the Tipo race car meant the car was under a metre tall at its highest point. Combined with the squared-off rear end, these characteristics inspired countless wedge-shaped designs of the 70s and 80s, and also gave the car its name and colour: Carabo is derived from ‘Carabidae’, a family of ground-beetles with a distinctive green and gold colour.

The principle of the wedge-shaped profile was used to eliminate the high-speed aerodynamic lift troubles of the Lamborghini Miura, which Gandini had penned two years earlier. However, his innovative cerebration didn’t stop there: as well as having headlights hidden beneath active flaps, the Carabo was the first concept car with front-hinged wing doors, later used by Gandini when designing the Lamborghini Countach and since assuming the ‘Lamborghini doors’ meme. As well as inspiring the revolutionary raging bull, the Carabo clearly also lent styling cues to the Lancia Stratos Zero concept car, which in turn inspired the iconic Stratos HF. Unsurprisingly, the Carabo remained a one-off, but its revolutionary styling dramatically steered the automotive design industry onto a radically different path – one which produced some of the landmark cars of the 20th Century. Even those who can’t look favourably on its apparent aversion to curved surfaces should take a second to appreciate its legacy; after all, would an Aventador have quite the same drama without its ‘Carabo doors’?

#Alfa Romeo Carabo#BAT#33 Stradale#Navajo#Lamborghini Miura#Lamborghini Countach#Lancia Stratos Zero#Stratos HF#Aventador

242 notes

·

View notes

Text

“Teslas are the safest cars on the road, but most people don’t know that,” Tesla CEO Elon Musk wrote on X (formerly Twitter) last year. The superlative is typical of the billionaire, and the automaker itself, which boasts that its vehicles “are engineered to be the safest in the world.”

But while Tesla’s cars routinely receive top safety ratings, including from the National Highway Traffic Safety Administration, accident statistics show that the brand has the highest rate of accidents in which at least one car occupant is killed, according to a new report from the auto research firm iSeeCars.

More from Rolling Stone

Analyzing fatal collisions from 2017 to 2022 involving 2018 to 2022 car models, the group identified the Tesla Model S and Tesla Model Y as two of the most dangerous cars on the road by occupant fatality rate. Though models from Hyundai, Chevrolet, Mitsubishi, Porsche, and Honda occupied the top five spots on the list, the Tesla Model Y, a mid-size SUV, came in sixth, with a fatal accident rate 3.7 times higher than the average car, and 4.8 times higher than the average SUV. The Model S rate is double that of the average car.

Tesla did not immediately respond to a request for comment on the report.

The auto company had 5.6 fatal accidents per billion miles traveled by its vehicles, narrowly edging out Kia, with 5.5 per billion miles, as the brand with the overall highest rate of deadly accidents. This, the iSeeCars study notes, is “despite Tesla’s advanced driver-assist technology,” with features including so-called Autopilot and Full-Self Driving (FSD), which are meant to reduce human error. The former is a basic system including cruise control and automated lane-changing on freeways, while FSD allows a Tesla to “drive itself almost anywhere with minimal driver intervention,” per the company’s language. Both require the continued supervision of an attentive driver who can override the software.

Karl Brauer, an executive analyst with iSeeCars, said in the report that new cars overall are safer than they’ve ever been, and that most of the vehicle models on their lists “received excellent safety ratings, performing well in crash tests.” Therefore, he added, their elevated accident rates likely “reflect a combination of driver behavior and driving conditions.”

The study did not factor in the use of advanced systems such as Tesla Autopilot and FSD, but their shortcomings are well-documented, and Tesla accidents in which one of these features was engaged have triggered a wave of lawsuits, as well as regulatory scrutiny. Both NHTSA and the Department of Justice are investigating whether Tesla misled customers to believe that Autopilot and FSD is more dependable than it truly is. Critics say that drivers who assume their Tesla can operate safely and with total autonomy tend to become complacent or distracted — and then fail to take manual control when necessary.

This hasn’t stopped Musk from repeatedly promising, as he has for over a decade, that Tesla is close to a version of FSD which can safely operate without any human oversight. In October, he doubled down on this promise, unveiling a design for an autonomous two-seater “Robotaxi” (or “Cybercab”) without a steering wheel. He offered few specifics about how Tesla would be able to compete with companies that already have active fleets of autonomous taxis, like Google subsidiary Waymo, though he predicted the Tesla model would be in production before 2027, while acknowledging that he tends “to be a little optimistic with time frames.”

But for the moment, Tesla drivers are getting into fatal accidents with higher frequency than other drivers. Brauer commented that across the board in the automotive industry, improved safety features “are being countered by distracted driving and higher rates of speed, leading to rising accident and death rates in recent years.” No matter how well-made, a car can’t compensate for an irresponsible person in the driver’s seat.

#Tesla Has Highest Rate of Deadly Accidents Among Car Brands#Study Finds#tesla#leon fuckery#not a safe car#no to tesla#Analyzing fatal collisions from 2017 to 2022 involving 2018 to 2022 car models#the group identified the Tesla Model S and Tesla Model Y as two of the most dangerous cars on the road by occupant fatality rate.

3 notes

·

View notes