#3D scanners

Explore tagged Tumblr posts

Text

Progress: Radius

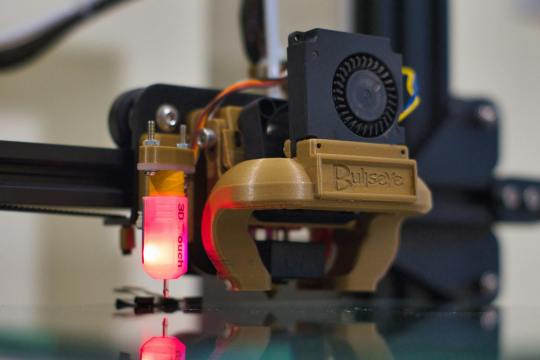

On Monday, we took part in a workshop where we explored different interesting tools. We used a laser cutter to cut and engrave materials and scanned objects to make digital 3D models. Although we didn’t use the 3D printers, we had a look at how they work. Besides that, we learned about other cool tools and techniques for making and designing things. The workshop gave us a good introduction to modern technology for creating and building.

3 notes

·

View notes

Photo

(via Global 3D Scanners Market | Trends and Outlook 2024-2030)

0 notes

Text

TINH HÀ - ĐẠI LÝ ỦY QUYỀN MÁY ĐO SCAN 3D FARO TẠI VIỆT NAM

Phân phối chính hãng các dòng máy đo quét laser 3D FARO.

Cung cấp dịch vụ đo quét 3D bằng máy FAROARM.

Xem thêm các dòng máy đo FARO tại: https://tinhha.com.vn/may-do-3d-faro/

Liên hệ chúng tôi để được hỗ trợ nhiều hơn: Công ty TNHH Thương Mại Dịch Vụ Tinh Hà ∘ Hotline: 024 6668 9888 – 0945 275 870 ∘ Email: [email protected] ∘ Website: https://tinhha.com.vn/

0 notes

Text

Sheet Metal Forming: Enhancing Precision with 3D Scanning and Reverse Engineering

Reverse Engineering

Sheet metal forming is a vital manufacturing process used to create metal components for industries such as automotive, aerospace, and heavy machinery. This process involves shaping metal sheets into various forms using techniques like bending, stamping, and drawing. While traditional methods are still widely used, the integration of 3D scanning and reverse engineering technologies has revolutionized sheet metal forming, making it more efficient and precise than ever before.

How 3D Scanning is Transforming Sheet Metal Forming

One of the main challenges in sheet metal forming is ensuring that the final product meets exact design specifications. In traditional setups, this requires manual inspections and measuring, which can be time-consuming and prone to human error. 3D scanning has changed this landscape by enabling manufacturers to capture detailed and accurate 3D models of metal components. These models allow for precise analysis and ensure that parts are produced to exact measurements.

With high-precision 3D metrology, manufacturers can significantly reduce material wastage, minimize errors, and streamline the overall production process. This not only improves efficiency but also cuts down on costs related to rework and rejected parts.

Reverse Engineering in Sheet Metal Forming

Reverse engineering is another critical tool that complements 3D scanning in sheet metal forming. It allows manufacturers to recreate or modify existing parts when original designs or documentation are unavailable. Using reverse engineering, companies can scan a physical part, analyze its geometry, and generate digital models that can be used for redesign or reproduction.

This process is particularly useful when working with legacy equipment or when making design improvements to existing parts. Reverse engineering enables manufacturers to optimize designs for better performance, durability, and ease of production. Additionally, it plays a crucial role in quality control and inspection services, ensuring that every piece of metalwork aligns with the required standards.

Benefits of 3D Scanning and Reverse Engineering in Metal Forming

The integration of 3D scanning and reverse engineering into the sheet metal forming process offers numerous advantages:

Accuracy: Both technologies ensure high precision, reducing errors and improving product quality.

Cost Efficiency: Faster inspections and reduced material waste lower production costs.

Speed: Digital models from 3D scanners accelerate the prototyping and production process.

Quality Control: Inspection using 3D data allows for comprehensive analysis, ensuring that all parts conform to design specifications.

Future of Sheet Metal Forming

As manufacturing technologies continue to advance, 3D scanning, reverse engineering, and related digital tools will play an even more significant role in shaping the future of sheet metal forming. The ability to produce accurate, high-quality parts with minimal error will become an industry standard, ensuring that manufacturers stay competitive in an increasingly digital world.

By leveraging 3D scanning, reverse engineering, and other advanced technologies, businesses can improve the efficiency and accuracy of their sheet metal forming operations, leading to enhanced production processes and better end products.

0 notes

Text

instagram

ma deuxième passion

0 notes

Text

In my painting studio

#art contemporain#contemporary art#blender#3d#scans#3d scanners#artists on tumblr#artist studio#roses#gloomcore

0 notes

Text

【 We are opening a workshop! 】

0 notes

Text

Now the full work available for minting at our.zora

Sҽɾҽʂ Cσɳҽƈƚα - An experimental audiovisual piece by Flavia Goa and L3V1AT4

Exploring the intersection between the organic and the technological, this audiovisual work is an immersive journey through sound and visual landscapes that dialogue with philosopher Donna Haraway's ideas about imaginary terrestrial futures.

The soundtrack, developed by Flavia Goa, is based on the spatiality of a sublime and neutral world, using organic sounds mixed with guitar melodies with personalized tuning. These sound elements were meticulously selected to evoke the harmonious coexistence between nature and technology. The visuals, created by L3V1AT4 through creative programming in TouchDesigner, result from a series of codes that generate each frame and moment of the audiovisual narrative. Using photogrammetry techniques to scan plants and flowers, the captured 3D models are animated and respond dynamically to the nuances of the soundtrack, illustrating the ongoing conversation between machines and living beings. Images and recordings of natural landscapes are later distorted by filters developed in TouchDesigner, projecting a deep connection and dialectic between the natural and the artificial.

This piece is part of the 𝐒.𝐄.𝐄.𝐃. 𝐙𝐎𝐑𝐀 𝐂𝐎𝐋𝐋𝐄𝐂𝐓𝐈𝐕𝐄 𝐃𝐑𝐎𝐏 𝐕2.𝟎

#work#artist on tumblr#artists on tumblr#l3v1at4#graphic art#graphics#works#edits#graphic design#visuals#computer generated image#generative#generative visuals#generative art#touchdesigner#creative coding#creative programming#multimedia#multimedia art#3d artwork#3d art#3d#animation#art#3d photo#3d scan#3d scanners#photogrametry#donna haraway#organic

0 notes

Text

3D Printing: From Prototypes to Organ Transplants

In the last decade, the landscape of manufacturing, medical science, and even the arts have been fundamentally transformed by the advent of 3D printing technology. Once a niche tool used for the creation of simple prototypes, 3D printing has burgeoned into a revolutionary force that stands at the forefront of innovation across numerous sectors. This article delves into the journey of 3D printing,…

View On WordPress

#3D ink#3D models#3D printed organs#3D printing#3D scanners#Additive manufacturing#Aerospace#Artificial organs#Automotive#Bioengineering#Bioink#Biomaterials#Bioprinting#Biotechnology#CAD#Cellular structures#Ceramics#Creative tech#Custom-made#customization#Dental devices#Design#Design thinking#Development#Digital fabrication#Digital manufacturing#Digital models#Disruptive tech#Donor organs#efficiency

1 note

·

View note

Text

3D Printers & DIY Black Friday Deals 2024

This year, companies are warming up for BFCM as early as October! What used to be a weekend event has now stretched even longer. Want to know what to expect? Read and compare with previous years' BFCM deals.

0 notes

Text

Weird Science (1985)

#weird science#scifi movies#funny#fantasy#bride of frankenstein#dream girl#nerd#geeky#barbie doll#scifi fantasy#computers#80s movies#1980s#dream woman#gifs#gifset#modem#scanner#electronics#3d animation

2K notes

·

View notes

Text

How many of them are sitting at the bottom of the ocean?

#3d workers island#3dwiscr#tony domenico#2024#oil pastel#fanart#portfolio#traditional art#the warping due to plastic wrap was a happy accident from trying to protect my scanner glass from the pastel#but i think it really makes the piece#highly recommend 3d workers island. tony has done it again

603 notes

·

View notes

Text

En China hay un negocio en que puedes ir a escanearte en 3D y te hacen un muñeco hiperrealista de ti mismo:

100 notes

·

View notes

Text

Is your project ready for the next level? 🚀 With our premium 3D scanning services, from rapid prototyping to reverse engineering, we help you see what’s beneath the surface. Get it right, the first time. #tripleinfotech #3dscanning #3dscanner #reverseengineering

📞 Call us: +91 78 99899008 🌐 Visit us: tripleinfotech.com

0 notes

Text

RINSED HERALD and a poem about electronic rot

#art#collage#collage art#poem#poetry#scanner#scanner art#3ds#RINSED HERALD#picross 3d doesn't always require the top screen so i literally just covered it with painters tape

6 notes

·

View notes

Text

Sketchbook pages finally got my hands on a printer/scanner and it's been amazing so fun so fun <3

#my art#art#sketch#sketchbook#traditional art#traditional sketch#drawing#anatomy#anatomy practice#practice#art practice#cubes#3d#gel pen#so cool so cool#scanner#printer

10 notes

·

View notes