#epoxy adhesive manufacturers

Explore tagged Tumblr posts

Text

Experience the Power of Aplicacer PU Flex

Designed for versatility, Aplicacer PU Flex offers unparalleled adhesive strength for a wide range of surfaces. Whether it's interior or exterior, dry or wet conditions, this multipurpose adhesive delivers superior performance every time. Say goodbye to challenges with its remarkable bonding ability on various substrates. Elevate your projects with Aplicacer PU Flex today! To know more about best waterproofing mineral mortars in india visit: https://capaindia.in/product/

#top tile adhesive brands in india#tile adhesive manufacturers#top building materials companies in india#best tile adhesive in india#tile adhesives for fixing natural stones#tile adhesives for vitrified tiles#high strength flooring mortars#block jointing mortar manufacturers in india#tile adhesive companies in india#floor repairs mortars in india#best waterproofing mineral mortars in india#elastomeric waterproofing coating#epoxy grouts in india#epoxy adhesive manufacturers#epoxy adhesives manufacturers#affordable waterproofing solutions#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system

0 notes

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

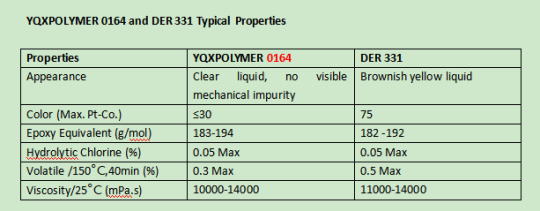

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

The Role of Glass Transition Temperature in Epoxy Molding Compounds

The Glass Transition Temperature (Tg) plays a pivotal role in determining the performance and durability of epoxy molding compounds. Tg refers to the temperature at which the polymer transitions from a rigid, glassy state to a more flexible, rubbery one. Understanding the impact of Tg on epoxy resin is crucial, particularly in high-temperature epoxy applications, as it directly influences the material's mechanical properties, thermal stability, and overall performance.

Epoxy Glass Transition Temperature and Its Significance

The Glass Transition Temperature in Epoxy is a defining factor in the epoxy resin molding process. As epoxy resins cure, their epoxy curing temperature influences how the resin bonds and behaves at different thermal conditions. If the Tg in epoxy resins is too low, the material may lose structural integrity when exposed to elevated temperatures. Conversely, a higher Tg results in improved thermal stability and makes the resin more resistant to heat and mechanical stress.

For industries relying on epoxy molding compounds, such as electronics and automotive, selecting the right epoxy resin performance can greatly affect product longevity and reliability. Understanding epoxy mold material properties and how they correlate with the Cure-Temperature-Glass-Transition can optimize the manufacturing process, ensuring that the final product meets the necessary performance criteria.

Optimizing Epoxy Tg for Better Results

In many applications, especially those involving high-performance environments, Epoxy Tg optimization is essential. Manufacturers can manipulate thermal properties of epoxy molding compounds to achieve the desired Tg, balancing flexibility and strength. The Impact of Tg on epoxy is especially evident in epoxy resin molding techniques, where fine-tuning the epoxy resin thermal stability allows for better control over product quality. The Tg and mechanical properties of epoxy are key to ensuring that the final molded parts exhibit durability and strength under varying conditions.

As an adhesive manufacturer in India, Kohesi Bond understands the critical importance of optimizing epoxy resin manufacturing process to deliver high-quality products. By mastering the control of epoxy bonding adhesive and its thermal properties, Kohesi Bond ensures superior performance across a wide range of applications.

For more information, visit Kohesi Bond's website!

#Epoxy Glass Transition Temperature#Glass Transition Temperature in Epoxy#Epoxy Molding Compounds#Epoxy Resin Performance#Epoxy Bonding Adhesive#Thermal Properties of Epoxy Molding Compounds#Epoxy Resin Thermal Stability#Epoxy Tg Optimization#Epoxy Resin Molding Techniques#Cure-Temperature-Glass-Transition#High-Temperature Epoxy Applications#Epoxy Tg and Mechanical Properties#Epoxy Resin Manufacturing Process#Impact of Tg on Epoxy#Epoxy Mold Material Properties#Adhesive Manufacturer in India#Epoxy Curing Temperature#Understanding Tg in Polymer Compounds#High-Performance Epoxy Applications#Epoxy Bonding Adhesive in India#Epoxy Resin Manufacturing

1 note

·

View note

Text

Addressing the Toughest Surface Damage Problems

Traditional repair methods are often not preferable when tackling significant surface wear and tear. These repairs, whether made by friction, impacts or corrosive elements, can be the reason for the failure of critical structures. Finding an advanced solution is important to deal with these extreme issues. High-performance repair options are essential to restore and maintain the durability of affected areas, and choosing the best epoxy manufacturer for this is crucial for achieving optimal results. Metal-filled epoxies are a strong solution to such problems and enhance the surface resilience to optimum.

Addressing Cracks

Cracks in any surface can become the source of the most severe structural problems that directly influence the functionality and safety of the structure. Conventional patching methods usually do not give the required long-lasting result, especially in high-stress environments. Metal-filled epoxies, particularly metal patch and fill compound, offer a high-tech solution by creating a durable bond that effectively fills and seals cracks. Their composition guarantees that the repaired area will be able to bear the expected load and, thus, will not lose its strength over time.

Combating Corrosion

Corrosion can damage any metal surface by gradual degradation that may lead to its failure. Even in such cases, conventional coatings or treatments cannot adequately resist the continued corrosive attacks. In such cases, metal-filled epoxies are an effective solution that offers an efficient barrier against corrosive agents. Their advanced properties contribute to avoiding further damage and maintaining the full structural integrity of the metal component. By applying these epoxies, one can achieve a long-lasting shield against corrosion, extending the lifespan of critical assets.

Repairing Broken Parts

If the broken parts are not repaired correctly, they lead to costly downtime and disrupt operations. Most repair methods will fail to return these components to their original strength and functionality, does not prove reliable in such cases, and also will not restore durability. Metal-filled epoxies' ability to bond strongly with the damaged surfaces ensures an advanced repair that can handle the stresses much more effectively. This approach not only regains the part's functionality but also prevents future damage, providing a more reliable and durable solution.

About ITW Performance Polymers

ITW Performance Polymers specializes in advanced epoxy solutions, providing top-tier concrete epoxy adhesive, among other high-performance products. Their innovative technologies ensure exceptional durability and effectiveness in every application.

For more details, visit https://itwperformancepolymers.com/

Original Source: https://bit.ly/4dybYcQ

0 notes

Text

Global Tile Adhesives & Stone Adhesives Market Forecast to 2027: Cementitious and Epoxy Chemistries Drive Growth

The global tile & stone adhesives market size is projected to grow from USD 4.7 billion in 2022 to USD 7.0 billion by 2027, at a CAGR of 8.0%. Tile and stone adhesives are used to create a strong and durable bond between tile/stone and the tiling substrate. These adhesives are used to fix ceramic tiles, porcelain tiles, mosaics, marble, and granite to walls and floors in residential, commercial,…

View On WordPress

#adhesive stone wall tiles#Ceramic tile adhesives#Epoxy adhesives#Global Tile Adhesives & Stone Adhesives Industry#Global Tile Adhesives & Stone Adhesives Market#Grout sealers#marble tile adhesive#Mortar additives#natural stone adhesive#Natural stone adhesives#Polymer-modified adhesives#Stone Adhesives Market#stone tile adhesive#thinset for granite#tile & stone adhesives market#tile adhesive market#Tile Adhesives & Stone Adhesives Applications#Tile Adhesives & Stone Adhesives Ecosystem#Tile Adhesives & Stone Adhesives Industry#Tile Adhesives & Stone Adhesives Industry Forecast#Tile Adhesives & Stone Adhesives Manufacturers#Tile Adhesives & Stone Adhesives Market#Tile Adhesives & Stone Adhesives Producers#Tile Adhesives & Stone Adhesives Products#Tile Adhesives & Stone Adhesives Suppliers#Tile Adhesives & Stone Adhesives Technology#Tile Adhesives & Stone Adhesives Trends#Tile Adhesives Market#tile and stone adhesives market#wall stone adhesive

0 notes

Text

Recycling the unrecyclable: New method reclaims materials from epoxy resins and composites

Epoxy resins are coatings and adhesives used in a broad range of familiar applications, such as construction, engineering and manufacturing. However, they often present a challenge to recycle or dispose of responsibly. For the first time, a team of researchers, including those from the University of Tokyo, developed a method to efficiently reclaim materials from a range of epoxy products for reuse by using a novel solid catalyst. The work has been published in Nature Communications. There's a high chance you are surrounded by epoxy compounds as you read this. They are used in electronic devices due to their insulating properties; clothing such as shoes due to their binding properties and physical robustness; building construction for the same reason; and even in aircraft bodies and wind turbine blades for their ability to contain strong materials such as carbon fibers or glass fibers.

Read more.

#Materials Science#Science#Recycling#Epoxy#Resins#Composites#Adhesives#Catalysts#Materials processing#Fiber reinforcement#Fibers#University of Tokyo

27 notes

·

View notes

Text

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

Unique FAQs

Are synthetic resin adhesives suitable for outdoor applications?

How do synthetic resin adhesives compare to traditional adhesives?

What safety precautions should be taken when using synthetic resin adhesives?

Can synthetic resin adhesives be used underwater?

Are there eco-friendly alternatives to synthetic resin adhesives?

#synthetic resin adhesives#construction adhesives#acrylic adhesive#industrial adhesives#flooring installation#adhesive properties#durability#polyurethane adhesive

2 notes

·

View notes

Text

Dubai Adhesive Material Factory LLC

Welcome Dubai Adhesive Material Factory LLC to TradersFind! As a leading manufacturer in the construction industry, they offer specialized construction chemicals, adhesives, bitumen products, PU-based coatings, Epoxy coatings, cleaning chemicals, water treatment chemicals, and more.

Click here to explore their offerings on TradersFind- https://www.tradersfind.com/seller/dubai-adhesive-material-factory-llc

#dubaiadhesivematerial#construction#engineering#dubai#constructionmaterials#constructionchemicals#contractor#civilengineering#manufacturing#interiordesign#dubaiconstruction#building#architecture#propertydevelopment#b2bmarketing#businessnetworking#b2bportal#tradersfind#uae#uaebusiness#businessgrowth

2 notes

·

View notes

Text

How Synthetic Resin Adhesives Are Revolutionizing the Construction Industry

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

4 notes

·

View notes

Text

EPOXY FLOOR GRINDING WORKS

Manycon Saudi is one of the best Epoxy Floor Grinding Contractors in Saudi Arabia & all GCC & India

In Saudi Arabia, Manycon Contracting Company offers professional epoxy floor coating application services in addition to a variety of other concrete flooring services for clients throughout Qatar, Saudi Arabia and India. Our flooring services epoxy floor paint application, concrete polishing, shot blasting and concrete grinding, concrete stain application, flooring and adhesive removal.. Our epoxy floor coating and concrete flooring services are ideal for commercial buildings and industrial plants.

The following are some of the main types of buildings, which would benefit from our epoxy coating and floor finishing services.

Aircraft Hangars

Chemical Plants

Manufacturing Plants

Warehouses & Distribution Facilities

Laboratories

Hospitals

Commercial and Residential Garages

Showrooms

Commercial Kitchens

Office Buildings

Retail Spaces & Mall

Athletic Facilities

2 notes

·

View notes

Text

Speaking of ADHESIVES….

(As if anyone but me can find the discussion fascinating….)

The only glue which will NOT yellow, and will NOT be visible, given the transparency of alabaster - is a singular resin epoxy which can only be ordered from the manufacturer in the UK. I waded into their website in the spirit of bright good will, and was tortured for an hour trying to navigate my way through their crap website. A sizable box appears in front of the page you are trying to decipher - that asks “HI, CAN I HELP?”

No. No you cannot. I’d like to just read the description - and the box will NOT go away. When I stupidly succumbed to the BOX, and asked for help? (Do you even need to ask …?)

The torment continued as I tried to check out - and no matter how many times I inserted my information, the page de-populated as I hit “pay” - and it had to all be done again.

The 12th attempt held - I paid, and only then did I discover that two TINY bottles (think the size of superglue containers) @ £39 Fer fuck sake - and they charged me an additional £28 to SHIP IT TO MY UK POST ADDRESS.

Thieves, stoats, weasels and SCALLYWAGGS.

I wrote to them and told them what I thought of their stupid website, and demanded to know where they get off with that shipping amount - from a UK address to a UK address. Remarkably they relented, sent it by Royal Mail - and returned about 20 bucks.

And so…

Because no one can manufacture a tape with any amount of STICKY to it, I am unable to apply the resin epoxy to the breaks , and tape the seams to hold the mend in place. All tape just floats off and leaves me in tears.

So I came up with a CLEVER PLAN (just like Baldrick) - I used hot glue as a BANDAGE to hold the pieces together while the resin cures. Sure, it’s hideous, but a glob dries almost instantly, will pick off easily when it’s done - and here’s the final kick to the head…?

THE INSANELY EXPENSIVE RESIN ADHESIVE HAS A SEVEN-DAY-CURE-TIME.

Fuck me.

2 notes

·

View notes

Text

Unleash the Potential of Your Floors with IC PRECIFLOOR!

Engineered for durability and performance, IC PRECIFLOOR offers unmatched strength and resilience for all your flooring needs. With its high-strength formulation and easy application, achieve flawless results every time. Elevate your spaces with IC PRECIFLOOR and experience the difference! To know more about floor repairs mortars in India and high strength flooring mortars visit: https://capaindia.in/product/ic-precifloor/

#top building materials companies in india#tile adhesives for vitrified tiles#top tile adhesive brands in india#best tile adhesive in india#block jointing mortar manufacturers in india#high strength flooring mortars#tile adhesive companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#floor repairs mortars in india#best waterproofing mineral mortars in india#tile adhesive brands in india#tile and stone adhesive#cement based tile adhesive#affordable waterproofing solutions#aliphatic polyurethane waterproofing coating#epoxy resin adhesives manufacturers#epoxy grouts in india#epoxy adhesive manufacturers

0 notes

Text

High Toughness Epoxy Resin 9821A/B for Carbon Fiber High-pressure Gas Cylinders

launched 9821A/B high-toughness epoxy resin for winding molding. This product is a two-component epoxy resin system with the characteristics of moderate viscosity, long pot life and good operability. Its cast body has excellent mechanical properties, high elongation at break and good impact resistance.

9821A/B epoxy resin has excellent wettability to both carbon fiber and glass fiber, and is suitable for the production of high-toughness composite products wound with various types of fibers, such as carbon fiber high-pressure gas cylinders.

Carbon fiber composite high-pressure gas cylinders are made of carbon fiber materials and epoxy resin bodies through winding and high-temperature curing processes. Compared with metal gas cylinders, the carbon fiber material itself has better performance.

What are the advantages of high-pressure gas cylinders made of carbon fiber compared with metal gas cylinders?

Carbon fiber itself is lighter than aluminum, only about 1/4 of steel. Therefore, carbon fiber high-pressure gas cylinders weigh about 50% less than metal gas cylinders of the same volume, making them lighter to use.

The carbon fiber material itself has high strength and the compressive strength can reach more than 3000mpa, which can fully ensure the pressure stability of the carbon fiber high-pressure gas cylinder, making it safer and more reliable.

Carbon fiber high-pressure gas cylinders have excellent corrosion resistance and are resistant to acid, alkali, salt and atmospheric corrosion, making them safer to use.

During the processing of carbon fiber high-pressure gas cylinders, the carbon fiber winding process is mostly used. Under the action of tension, the carbon fiber bundles are impregnated with epoxy resin and continuously wrapped around the rotating mandrel, gradually forming a cylindrical structure. Most of the winding processes used are wet winding, in which the carbon fiber bundles are first processed in a specific dipping device, then directly wound onto the mandrel under tension control, and finally formed through curing and other processes.

The most commonly used wet winding method in the carbon fiber winding molding process has lower cost and good craftsmanship. Wet winding equipment mainly includes fiber frame, tension control equipment, dipping tank, spinning nozzle and rotating mandrel structure. The most advanced six-dimensional winding technology in the world can well control the fiber direction and realize the combination of hoop winding, spiral winding and plane winding. In actual production, a combination of helical winding and circumferential winding is often used. Circular winding can eliminate the hoop stress caused by the internal pressure of the gas cylinder, and helical winding can provide longitudinal stress and improve the overall performance of the gas cylinder.

The resin matrix of carbon fiber high-pressure gas cylinders not only needs to meet the mechanical strength and toughness requirements of the cylinder, but also because the matrix is prone to fatigue damage in a long-term inflation and deflation environment, a high-strength, fatigue-resistant resin system is needed to protect the cylinder service life. In addition to meeting the corresponding properties, the resin matrix used in wet winding molding is also required to have a lower initial viscosity at the operating temperature and a longer pot life at this temperature. Epoxy resin has the advantages of high bonding strength, small curing shrinkage, no small molecule volatiles, good process formability, heat resistance, good chemical stability, and low cost. It also has a large space for modification, is widely available in sources, is reasonably priced, and is suitable for wet winding process systems.

The resin in the composite material layer of high-pressure gas cylinders mainly uses epoxy resin. Epoxy resin is one of the commonly used thermosetting resin matrices in resin-based composite materials. It has the advantages of high bonding strength, small curing shrinkage, no small molecule volatiles, good process formability, heat resistance, good chemical stability, and low cost, and is widely used in fiber winding processes.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#epoxy adhesive#high toughness epoxy resin#carbon fiber#filament winding#filament winding process#carbon fiber winding#carbon fiber filament winding

0 notes

Text

Successful Applications of Ceramic Epoxy Adhesives in Various Industries

Ceramic epoxy adhesives are gaining prominence across multiple industries due to their exceptional strength, durability, and resistance to extreme conditions. These adhesives are engineered to bond ceramics and other materials, providing reliable solutions for demanding applications. Their unique properties make them ideal for high-performance environments, particularly in high-temperature applications.

In the aerospace sector, high temperature ceramic epoxy adhesives are used to assemble engine components and thermal protection systems. These adhesives withstand intense heat and mechanical stress, ensuring the structural integrity of critical components. As a result, they contribute significantly to the overall safety and efficiency of aerospace vehicles.

The automotive industry also benefits from the best ceramic epoxy adhesive for bonding parts that experience high stress and exposure to harsh conditions. Manufacturers utilize these adhesives to secure exhaust systems, engine components, and structural elements, enhancing vehicle performance and longevity. Their superior bonding capabilities help reduce the risk of failure, which is paramount in automotive applications.

Another significant application of ceramic epoxy adhesives is in the electronics industry. With the increasing demand for lightweight and durable materials, epoxy bonding adhesives are essential for assembling electronic components. These adhesives provide excellent insulation and thermal stability, making them suitable for circuit boards and other critical electronics, ensuring functionality even under extreme conditions.

In addition to these applications, the construction industry relies on high temperature ceramic adhesives for bonding tiles, stones, and other building materials. Their ability to withstand environmental factors, such as moisture and temperature fluctuations, makes them a preferred choice among builders and contractors.

As an adhesive manufacturer in India, Kohesi Bond offers a range of ceramic epoxy adhesives designed for diverse applications. Our products are formulated to meet the highest industry standards, ensuring reliability and performance. With our commitment to quality and innovation, we provide the right solutions for your adhesive needs, helping you achieve successful outcomes in your projects.

#Ceramic Epoxy Adhesive#High Temperature Adhesives#Industrial Adhesives#Epoxy Bonding#Adhesive Solutions#Aerospace Adhesives#Automotive Adhesives#Electronics Manufacturing#Construction Adhesives#Adhesive Manufacturer in India#High Performance Adhesives#Durable Bonding Solutions#Ceramic Adhesive Applications#Epoxy Adhesive Properties#Advanced Adhesives

1 note

·

View note

Text

Epoxy Manufacturer: What Skills Help Them Excel

Have you been searching for an experienced epoxy manufacturer? Several epoxy manufacturers are working in the industry These professionals can provide you with a variety of adhesive options. But how will you decide on an epoxy manufacturer that can truly help your business? There are a few skills and qualities that makeepoxy manufacturers excel. Let’s discuss.

Flexibility

One of the most important skills that epoxy manufacturers focus on is flexibility. This helps them cater to the changing requirements of the clients. The industries and warehouses will keep changing from time to time. So, epoxy manufacturers also have to keep up with these evolving changes. This helps them cater to the requirements of theclients perfectly.

Problem-solving

There are various problems that warehouses are facing. So, epoxy manufacturers need to keep up with these problems. If they do not know what problems various industries are struggling with, they will not have an understanding of what products to offer. So, epoxy manufacturers must have a problem-solving attitude. Whenever they come to know about an issue, they should quickly get started with the research and development process. This will help them manufacture and deliver the products quickly according to the problems.

Reliability

Epoxy manufacturers should also stay reliable at all times. The epoxy adhesive for metal products that they offer is being used in various sensitive settings. So, these products should be highly reliable. If the products are not of the best quality, the clients may not feel confident when using them. This is especially true when it comes to adhesives. Therefore, manufacturers should also know how to be reliable at all times.

Communication

Manufacturers should not just focus on manufacturing but also on effectively communicating with clients and other stakeholders.When they communicate clearly with the clients, they will give them great feedbackwhich will help them grow.

Apart from this, various other skills help manufacturers succeed. The right manufacturer will have effective management that manages everything seamlessly. So, the entire manufacturing process will be completed without any issues.

About ITW Performance Polymers:

ITW Performance Polymers is one of the most reliable companies that help you with concrete epoxy adhesive.

To learn more about epoxy adhesives, visithttps://itwperformancepolymers.com/

Original Source: https://bit.ly/3Yz5vui

0 notes

Text

Epoxy Floors in Oklahoma City: The Ultimate Flooring Solution

When it comes to durable, attractive, and long-lasting flooring options, epoxy floors in Oklahoma City are gaining popularity. Whether you're a homeowner looking to upgrade your garage or a business owner seeking a practical and aesthetically pleasing solution for your commercial space, epoxy flooring is a versatile choice that offers numerous benefits.

Epoxy Flooring Basics

Epoxy flooring is a type of surface coating that combines resin and hardener to create a strong, seamless, and highly resilient floor. It's a popular choice in various settings, from industrial facilities and warehouses to retail stores and homes. In Oklahoma City, epoxy floors are appreciated for their ability to withstand the city's variable weather conditions and heavy foot traffic.

Advantages of Epoxy Floors

Durability: Epoxy flooring is incredibly durable and can handle heavy loads without cracking or chipping. It can withstand the weight of vehicles, making it an ideal choice for garages and auto shops.

Easy Maintenance: Epoxy floors are effortless to clean and maintain. They are resistant to stains, chemicals, and moisture, making them perfect for areas prone to spills and accidents.

Aesthetically Pleasing: Epoxy floors are available in a wide range of colors and patterns, allowing you to customize your flooring to match your style and space. They can also be enhanced with decorative elements like flakes, metallic pigments, or quartz.

Longevity: When properly installed and maintained, epoxy floors can last for many years, making them a cost-effective investment.

Safety: Epoxy floors can be customized to include anti-slip additives, making them safer for areas where slip and fall accidents are a concern.

Applications of Epoxy Flooring in Oklahoma City

Residential Garages: Many homeowners in Oklahoma City are choosing epoxy flooring for their garages. It not only enhances the appearance of the space but also protects the concrete underneath from oil, grease, and other stains.

Commercial and Industrial Spaces: Epoxy flooring is a popular choice for commercial and industrial spaces in Oklahoma City. It can withstand heavy machinery, high foot traffic, and chemical exposure, making it suitable for manufacturing facilities, warehouses, and factories.

Retail Stores: Retailers appreciate the clean and polished look of epoxy floors, which can elevate the ambiance of their stores. The customizable design options allow for branding elements to be incorporated into the flooring.

Restaurants and Bars: Epoxy flooring's resistance to spills and easy cleaning make it a practical choice for the food and beverage industry. It also offers an opportunity for creative designs to enhance the dining experience.

Installation Process

Professional installation is crucial to achieving the full benefits of epoxy flooring. The process typically involves the following steps:

Surface Preparation: The existing concrete floor is thoroughly cleaned and prepared, which may include repairing cracks and imperfections.

Primer Application: A primer is applied to ensure proper adhesion between the epoxy coating and the concrete surface.

Epoxy Coating Application: The epoxy mixture is applied to the prepared surface, and it can be customized with various colors and patterns.

Additional Design Elements: If desired, decorative elements like flakes, metallic pigments, or quartz can be added during the epoxy application.

Topcoat Application: A clear topcoat is applied to provide additional protection and enhance the floor's shine.

Conclusion

Epoxy flooring installation offer a durable, attractive, and low-maintenance flooring solution for residential, commercial, and industrial spaces. With their customizable design options, resistance to stains and chemicals, and long lifespan, epoxy floors have become a top choice for those seeking a practical and aesthetically pleasing flooring solution in the vibrant city of Oklahoma. Whether you want to upgrade your garage or enhance your commercial space, epoxy flooring is a versatile option that can meet your needs and exceed your expectations.

https://mtcustomconcrete.com/epoxy/

2 notes

·

View notes