#energy Battery Industry

Explore tagged Tumblr posts

Text

🔋🌍 Battery Industry ESG Outlook: Unlocking Sustainable Growth 🔋🌍

Did you know that the global battery market is projected to expand at a compound annual growth rate (CAGR) of 14.1% from 2020 to 2027, reaching a value of US$ 108.4 billion? This growth is driven by the increasing demand for lithium-ion batteries, especially in the electric mobility sector. As the world gears up for a future with nearly 10 billion people by 2050, battery industry leaders are facing both challenges and opportunities.

One of the key challenges is addressing environmental, social, and governance (ESG) issues. Improper disposal of batteries contributes to pollution and negative health impacts. However, battery companies are stepping up their efforts, with some setting targets to reduce CO2 intensity and GHG emissions globally.

Notable companies in this sector include BYD Company Ltd., Duracell, Johnson Controls, LG Chem Ltd., and Samsung SDI Co. Ltd. These companies are at the forefront of developing sustainable technologies and business models.

To stay informed about industry developments, regulatory changes, and company actions, check out the Battery Industry ESG Study, Challenges, Issues & Risks Report by Grand View Research. It provides insights into ESG trends, challenges, and initiatives, helping investors and businesses make informed decisions for a greener and more sustainable future.

#Battery Industry ESG#Sustainable Growth#Lithium-Ion Batteries#Environmental Responsibility#energy Battery Industry#Battery Market

0 notes

Text

Basic Advantages of Prismatic Battery Modules

High energy density: prismatic battery modules can store more electricity at the same volume and weight, which means that electric vehicles can carry larger capacity battery packs and have longer driving range.

High space utilization: The cells of prismatic batteries are square in shape and can be arranged more closely together, reducing space waste and increasing the energy density of battery packs.

High safety: prismatic battery modules usually use aluminum shells, which have high strength and toughness, and can effectively prevent battery short circuits, leakage and other problems. At the same time, its strong sealing can effectively avoid aging and leakage at the seal, thereby improving the safety of the battery.

Long cycle life: prismatic battery modules have a long cycle life and can withstand multiple charge and discharge cycles while maintaining high performance stability, reducing the maintenance cost of electric vehicles.

Specific applications of prismatic battery modules in electric vehicles

As a power source: prismatic battery modules are the main power source of electric vehicles, providing electrical energy support for the vehicle and driving the vehicle. Its high energy density and long driving range enable electric vehicles to meet daily travel needs and even long-distance travel.

Building battery packs: In electric vehicles, multiple prismatic battery modules are combined into battery packs and installed at the bottom of the vehicle or other suitable locations. The battery pack is monitored and managed by the battery management system (BMS) to ensure the safe and efficient operation of the battery.

Optimizing vehicle performance: The high energy density and long cycle life of prismatic battery modules help improve the power performance and endurance performance of electric vehicles. At the same time, its lightweight design also helps to reduce the overall weight of the vehicle and improve the vehicle's energy efficiency and handling.

If you want to ask related questions or have any questions, please contact us:

mail: [email protected]

#peismaticbattery#batterymodule#battery pack#laserwelding#laser welding machine#aviation industry#energystorage#new energy#productionline#pouchbattery#cylindricalbattery#Huiyaolaser#YaoLaser#Huiyaolaserwelding#electric vehicles#customized#automationline#semi-automation line

2 notes

·

View notes

Text

What Percentage of Cars Sold in 2023 Were Electric?

The automotive industry has been rapidly shifting towards electric vehicles (EVs), driven by increasing environmental concerns, technological advancements, and government incentives. The year 2023 marked a significant milestone in this transition. This transition has raised the question: What Percentage of Cars Sold in 2023 Were Electric? Let’s dive into the data to understand the impact and…

View On WordPress

#automotive industry#automotive trends#battery production#battery technology#car manufacturing#car market trends#car sales 2023#charging infrastructure#charging networks#China EV market#Clean Energy#cobalt#consumer acceptance#electric cars#electric mobility#electric vehicles#environmental awareness#Environmental Impact#Europe EV market#EV adoption#EV incentives#EV maintenance#EV technology#EVs#Ford#future of cars#General Motors#global sales#Government Incentives#green alternatives

2 notes

·

View notes

Text

#good news#science#climate change#environmentalism#carbon capture#batteries#environment#innovation#industries#renewable energy#energy efficiency#electricity

8 notes

·

View notes

Text

Finding The Passionate And Best Solar Installers Melbourne

If you are looking for the best solar installation services for your home or business, look no further than our company, Green Edge Technologies. We have a team of highly skilled solar installers working day in and day out to ensure that all new installations are on time, meet all safety regulations, and provide customers with excellent value for money. We aim to provide our customers with the best possible solar installation services at a competitive price. We will work closely with you to ensure your needs are fulfilled, whether a small residential installation or a large commercial one. Contact us for more details about Best Solar Installers Melbourne.

#4kw solar system#solar monitoring system#10kw solar#solar energy companies#15kw solar system price#solar panel installations near me#30kw solar system with battery#commercial and industrial solar#solar for business melbourne#best solar providers melbourne#20kw off grid solar system#solar power north melbourne#solar panel installations boxhil

2 notes

·

View notes

Text

A platform to expedite clean energy projects

New Post has been published on https://thedigitalinsider.com/a-platform-to-expedite-clean-energy-projects/

A platform to expedite clean energy projects

Businesses and developers often face a steep learning curve when installing clean energy technologies, such as solar installations and EV chargers. To get a fair deal, they need to navigate a complex bidding process that involves requesting proposals, evaluating bids, and ultimately contracting with a provider.

Now the startup Station A, founded by a pair of MIT alumni and their colleagues, is streamlining the process of deploying clean energy. The company has developed a marketplace for clean energy that helps real estate owners and businesses analyze properties to calculate returns on clean energy projects, create detailed project listings, collect and compare bids, and select a provider.

The platform helps real estate owners and businesses adopt clean energy technologies like solar panels, batteries, and EV chargers at the lowest possible prices, in places with the highest potential to reduce energy costs and emissions.

“We do a lot to make adopting clean energy simple,” explains Manos Saratsis MArch ’15, who co-founded Station A with Kevin Berkemeyer MBA ’14. “Imagine if you were trying to buy a plane ticket and your travel agent only used one carrier. It would be more expensive, and you couldn’t even get to some places. Our customers want to have multiple options and easily learn about the track record of whoever they’re working with.”

Station A has already partnered with some of the largest real estate companies in the country, some with thousands of properties, to reduce the carbon footprint of their buildings. The company is also working with grocery chains, warehouses, and other businesses to accelerate the clean energy transition.

“Our platform uses a lot of AI and machine learning to turn addresses into building footprints and to understand their electricity costs, available incentives, and where they can expect the highest ROI,” says Saratsis, who serves as Station A’s head of product. “This would normally require tens or hundreds of thousands of dollars’ worth of consulting time, and we can do it for next to no money very quickly.”

Building the foundation

As a graduate student in MIT’s Department of Architecture, Saratsis studied environmental design modeling, using data from sources like satellite imagery to understand how communities consume energy and to propose the most impactful potential clean energy solutions. He says classes with professors Christoph Reinhart and Kent Larsen were particularly eye-opening.

“My ability to build a thermal energy model and simulate electricity usage in a building started at MIT,” Saratsis says.

Berkemeyer served as president of the MIT Energy Club while at the MIT Sloan School of Management. He was also a research assistant at the MIT Energy Initiative as part of the Future of Solar report and a teacher’s assistant for course 15.366 (Climate and Energy Ventures). He says classes in entrepreneurship with professor of the practice Bill Aulet and in sustainability with Senior Lecturer Jason Jay were formative. Prior to his studies at MIT, Berkemeyer had extensive experience developing solar and storage projects and selling clean energy products to commercial customers. The eventual co-founders didn’t cross paths at MIT, but they ended up working together at the utility NRG Energy after graduation.

“As co-founders, we saw an opportunity to transform how businesses approach clean energy,” said Berkemeyer, who is now Station A’s CEO. “Station A was born out of a shared belief that data and transparency could unlock the full potential of clean energy technologies for everyone.”

At NRG, the founders built software to help identify decarbonization opportunities for customers without having to send analysts to the sites for in-person audits.

“If they worked with a big grocery chain or a big retailer, we would use proprietary analytics to evaluate that portfolio and come up with recommendations for things like solar projects, energy efficiency, and demand response that would yield positive returns within a year,” Saratsis explains.

The tools were a huge success within the company. In 2018, the pair, along with co-founders Jeremy Lucas and Sam Steyer, decided to spin out the technology into Station A.

The founders started by working with energy companies but soon shifted their focus to real estate owners with huge portfolios and large businesses with long-term leasing contracts. Many customers have hundreds or even thousands of addresses to evaluate. Using just the addresses, Station A can provide detailed financial return estimates for clean energy investments.

In 2020, the company widened its focus from selling access to its analytics to creating a marketplace for clean energy transactions, helping businesses run the competitive bidding process for clean energy projects. After a project is installed, Station A can also evaluate whether it’s achieving its expected performance and track financial returns.

“When I talk to people outside the industry, they’re like, ‘Wait, this doesn’t exist already?’” Saratsis says. “It’s kind of crazy, but the industry is still very nascent, and no one’s been able to figure out a way to run the bidding process transparently and at scale.”

From the campus to the world

Today, about 2,500 clean energy developers are active on Station A’s platform. A number of large real estate investment trusts also use its services, in addition to businesses like HP, Nestle, and Goldman Sachs. If Station A were a developer, Saratsis says it would now rank in the top 10 in terms of annual solar deployments.

The founders credit their time at MIT with helping them scale.

“A lot of these relationships originated within the MIT network, whether through folks we met at Sloan or through engagement with MIT,” Saratsis says. “So much of this business is about reputation, and we’ve established a really good reputation.”

Since its founding, Station A has also been sponsoring classes at the Sustainability Lab at MIT, where Saratsis conducted research as a student. As they work to grow Station A’s offerings, the founders say they use the skills they gained as students every day.

“Everything we do around building analysis is inspired in some ways by the stuff that I did when I was at MIT,” Saratsis says.

“Station A is just getting started,” Berkemeyer says. “Clean energy adoption isn’t just about technology — it’s about making the process seamless and accessible. That’s what drives us every day, and we’re excited to lead this transformation.”

#adoption#agent#ai#Alumni/ae#Analysis#Analytics#approach#architecture#Artificial Intelligence#batteries#Born#Building#buildings#Business#carbon#carbon footprint#CEO#classes#clean energy#Cleaner industry#climate#Companies#consulting#course#data#deal#decarbonization#deploying#Design#Developer

0 notes

Text

Electric vehicles (EVs) are transforming transportation with promises of sustainability and reduced emissions. However, widespread adoption faces challenges like improving battery technology, building charging infrastructure, addressing range limitations, and managing power grid demands.

At M.Kumaraswamy College of Engineering (MKCE), students tackle these issues through hands-on projects, focusing on advancing batteries, expanding charging networks, optimizing vehicle efficiency, and lowering production costs. Emerging trends like autonomous EVs, ultra-fast charging, and renewable energy integration are explored, ensuring students contribute meaningfully to the EV revolution.

By blending innovation with practical training, MKCE equips future engineers to drive sustainable transportation and shape a greener world. For more interesting information click here..

#private college#best engineering college in karur#mkce college#best engineering college#engineering college in karur#mkce#libary#engineering college#top 10 colleges in tn#mkce.ac.in#mkce Electric Vehicles (EVs)#mkce Battery Technology#mkce Sustainable Transportation#mkce EV Charging Infrastructure#mkce management#mkce Range Anxiety#mkce Solid-State Batteries#mkce Vehicle-to-Grid (V2G)#mkce Smart Charging#mkce EV Production Costs#mkce Battery Recycling#mkce Autonomous Electric Vehicles#mkce Energy-Efficient Vehicles#mkce EV Battery Life#Smart Grids#EV Industry Trends#Electric Drivetrains#Sustainable Manufacturing#Electric Ride-Sharing#Charging Network Expansion

0 notes

Text

Discover the perfect power solution for your industrial needs with Goodenough Energy's Industrial UPS and Battery Energy Storage Systems (BESS). Designed to provide uninterrupted power supply, these advanced systems ensure operational reliability, reduce downtime, and enhance energy efficiency. Whether managing critical infrastructure or optimizing energy usage, our Industrial UPS and BESS solutions deliver sustainable, scalable, and dependable energy for your business."

0 notes

Text

Understanding the Surging Demand for Secondary Batteries

The Rise of Rechargeable Batteries The past decade has seen a tremendous rise in the use of rechargeable batteries across various industries and applications. As devices become more portable and powered by electricity, the demand for batteries that can be repeatedly charged has grown exponentially. Secondary batteries, also known as rechargeable batteries, offer the key advantage of being reusable as opposed to single-use primary batteries. This eco-friendly and cost-saving attribute has made secondary batteries a vital part of our increasingly digital world. Lithium-Ion Dominates the Market The lithium-ion Secondary battery is currently the most widely used rechargeable battery chemistry. First commercialized in the early 1990s, lithium-ion batteries quickly came to dominate the portable electronics market due to their high energy density, lack of memory effect, and slow self-discharge rate when not in use. Devices such as laptops, smartphones, power tools, and electric vehicles almost universally use lithium-ion battery packs. Major battery manufacturers like LG Chem, Panasonic, and CATL produce billions of lithium-ion battery cells each year to meet the massive worldwide demand. Experts forecast that lithium-ion will maintain its market leadership for the foreseeable future unless cheaper and higher-performing alternatives emerge. Rise of Renewable Energy Storage Another key driver for the secondary battery industry has been the expansion of renewable energy sources such as solar and wind farms. As these intermittent power generation methods have grown in scale and importance, large-format battery energy storage systems are increasingly being deployed to store excess renewable energy for times when the sun isn't shining or the wind isn't blowing. Lithium-ion remains the technology of choice for utility-scale batteries, though other chemistries like lead-acid are also used. As more countries and states aim to transition to net-zero emissions, battery storage will grow in strategic importance to balance renewable energy on the grid. Electric Vehicles Spur Battery Manufacturing Perhaps no other industry holds as much promise to disrupt battery demand patterns as electric vehicles. With automakers committing to electrified lineups and countries proposing bans on new internal combustion engines, EVs are expected to constitute half of new vehicle sales worldwide by 2040 according to some estimates. The batteries needed to power these millions of EVs will need to be produced at an unprecedented scale. While most current EV models use lithium-ion packs, continued advances in chemistries like lithium iron phosphate, sodium-ion, and solid-state could see new battery types emerge for automotive applications seeking lower costs and faster charging. Either way, the EV boom will be a game changer for both vehicle and battery manufacturing industries.

Get more insights on, Secondary Battery

For Deeper Insights, Find the Report in the Language that You want.

Japanese

About Author:

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Coherent Market Insights#Rechargeable Battery Industry#Rising Electric Vehicle Adoption#Growth of Consumer Electronics Sector#Renewable Energy Adoption

0 notes

Text

The Role of Automation in Laser Welding Machines for Batteries

Automated laser welding machines for batteries are at the forefront of modern manufacturing. These cutting-edge machines have revolutionized the welding process, enabling precision, speed, and reliability in battery assembly. Let's delve into the industry aspects of these remarkable tools.

Industry Applications

Powering the Future with Laser Precision:

1. Electric Vehicle (EV) Industry: The EV sector relies heavily on automated laser welding machines for battery pack assembly. These machines ensure the integrity and safety of high-capacity lithium-ion battery packs that power electric cars.

2. Energy Storage Industry: In the energy storage sector, these machines are indispensable for creating robust battery modules used in renewable energy solutions, ensuring the efficient storage of green energy.

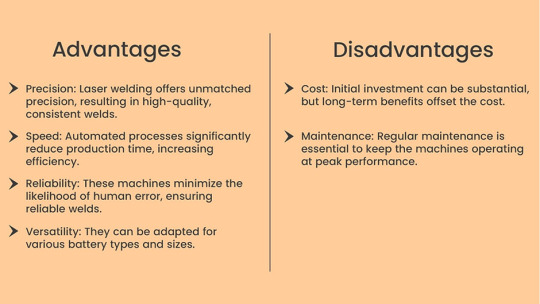

Advantages and Disadvantages

The Pros and Cons of Automated Laser Welding Machines:

Advantages:

Precision: Laser welding offers unmatched precision, producing high-quality, consistent welds.

Speed: Automated processes significantly reduce production time, increasing efficiency.

Reliability: These machines minimize the likelihood of human error, ensuring reliable welds.

Versatility: They can be adapted for various battery types and sizes.

Disadvantages:

Cost: Initial investment can be substantial, but long-term benefits offset the cost.

Maintenance: Regular maintenance is essential to keep the machines operating at peak performance.

How to Use Automated Laser Welding Machines for Batteries?

Operating these machines involves the following steps:

Material Preparation: Ensure the battery components are clean and properly aligned.

Machine Setup: Configure laser parameters such as power, pulse duration, and focal point.

Welding: Activate the machine to perform automated laser welding, creating precise welds.

Quality Check: Inspect welds for quality, ensuring they meet industry standards.

Customization

Automation in laser welding machines allows for flexibility and customization:

Parameter Adjustment: Tailor laser settings for specific materials and applications.

Integration: Seamlessly integrate the machine into automated production lines for maximum efficiency.

Software Enhancements: Customize the control software to meet your unique requirements.

What Makes It Different?

Why Opt for Automated Laser Welding?

High Productivity: These machines offer unparalleled productivity and repeatability.

Reduced Labor Costs: Automation decreases the need for manual labor.

Quality Assurance: Automated processes minimize the risk of defects.

The Need in the EV and Energy Storage Industry

Automated laser welding machines are indispensable in these burgeoning industries:

EV Battery Packs: They ensure the safety and reliability of lithium-ion battery packs, a core component of electric vehicles.

Energy Storage Solutions: These machines contribute to the efficient storage and distribution of renewable energy, fostering sustainability.

Conclusion

Automation in laser welding machines for batteries is transforming the manufacturing landscape. Its precision, speed, and reliability are pivotal in the growth of the EV and energy storage sectors. As we march towards a sustainable future, these machines will continue to play a central role in creating high-quality battery systems.

#battery pack assembly#laser welding#laser welding equipment#laser welding machines#laser welding machines in India#lithium ion batteries#lithium ion battery packs#EV battery packs#energy storage solutions#automated laser welding#automated laser welding machine#electric vehicle industry#energy storage industry#energy storage system

0 notes

Text

Energy: Department of Energy Selects Argonne to Lead National Energy Storage Hub

The U.S. Department of Energy selects Argonne to lead a groundbreaking energy storage hub, advancing next-gen battery technology.

The U.S. Department of Energy has appointed Argonne National Laboratory to spearhead the Energy Storage Research Alliance (ESRA), a significant initiative aimed at advancing battery technology and energy storage innovation. This national energy storage hub will unite nearly 50 leading researchers from three national laboratories and 12 universities, including top institutions like Columbia…

#Argonne#batteries#Bitcoin#breakthroughs#DOE#electrochemical#energy#energy security#Energy Storage#ESRA#funding#industry#innovation#manufacturing#materials chemistry#national labs#research hub#transportation#universities

1 note

·

View note

Text

Unlocking Growth in the Battery Coating Market: A Path to Innovation and Sustainability

The Rapid Evolution of Battery Coatings

As the global demand for cleaner energy and sustainable technologies escalates, the battery coating market has emerged as a pivotal enabler of next-generation energy solutions. Battery coatings, essential for enhancing the performance, longevity, and safety of energy storage systems, are increasingly in demand across industries such as electric vehicles (EVs), consumer electronics, and renewable energy.

From ensuring the durability of lithium-ion batteries to improving thermal management and conductivity, advanced coatings are revolutionizing the way energy storage systems function. These coatings help mitigate key challenges such as overheating, degradation, and electrolyte leakage, making them critical in scaling up battery applications in modern industries.

The surge in electric vehicle (EV) adoption has further catalyzed innovation in the battery coating space. Governments and corporations globally are setting ambitious goals for net-zero emissions, driving demand for innovative, efficient, and safe battery technologies. In this context, the battery coating market is not just evolving; it is transforming industries.

Opportunities and Challenges in the Battery Coating Market

The global battery coating market is poised for exponential growth. According to MarketsandMarkets, the market is projected to expand from USD 604.7 million in 2024 to USD 1,613.6 million by 2030, registering a CAGR of 17.8% during the forecast period. Let’s explore the key factors driving this growth and the challenges the industry faces.

Market Drivers

Surge in EV and Hybrid Vehicle ProductionThe proliferation of Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), Hybrid Electric Vehicles (HEVs), and Fuel Cell Electric Vehicles (FCEVs) has created a robust demand for advanced battery technologies. As the EV market continues to flourish, the need for high-performance coatings that ensure safety and enhance energy efficiency is skyrocketing.

Expanding Consumer Electronics and Renewable Energy StorageThe rapid growth of consumer electronics and renewable energy projects has increased the emphasis on battery reliability and efficiency. Coatings that enhance conductivity, reduce resistance, and prevent degradation are key to meeting the demands of these industries.

Market Restraints

High Costs of Advanced TechnologiesThe implementation of cutting-edge battery coating solutions comes with a steep price tag, often making it a barrier for companies aiming to adopt these technologies. This challenge calls for cost-effective innovations without compromising quality and performance.

Opportunities

Innovations in Battery MaterialsTechnological advancements in materials science are creating unprecedented opportunities for the battery coating market. From nanotechnology-based coatings to solid-state innovations, these breakthroughs promise safer, longer-lasting, and more efficient batteries. Companies investing in R&D have the potential to redefine industry standards.

Challenges

Preference for Solid ElectrolytesAs the industry increasingly transitions to solid-state batteries, which rely on solid electrolytes, the demand for traditional liquid-electrolyte-based coatings is facing competition. Adapting coating technologies to suit solid-state systems is critical for sustained growth.

Industry Players Shaping the Market

Several key players are at the forefront of innovation in the battery coating market, driving growth and shaping industry trends. These include:

Arkema (France)

Solvay (Belgium)

Asahi Kasei Corporation (Japan)

PPG Industries, Inc. (US)

SK Innovation Co. Ltd. (South Korea)

Mitsubishi Paper Mills, Ltd. (Japan)

Tanaka Chemical Corporation (Japan)

Targray (Canada)

These companies are investing heavily in research and development to create cutting-edge coating technologies that address industry challenges while capitalizing on opportunities.

For More Insights Download PDF Brochure :

The battery coating market is a dynamic space where innovation meets necessity. As industries pivot toward sustainability, battery coatings will continue to play a critical role in enabling high-performance energy storage systems. Companies and decision-makers investing in advanced coating solutions today are poised to lead the energy transition tomorrow. Whether you are an executive exploring sustainable solutions or a professional seeking cutting-edge technologies, now is the time to align your strategies with the evolving trends of the battery coating market.

#Battery Coating Market#Advanced Battery Technology#Electric Vehicles#Energy Storage Solutions#Sustainable Innovation#Battery Materials#EV Industry Trends

0 notes

Text

What Are Plug-and-Play BESS Solutions, and Why Are They Game-Changers for Industry?

In most industries and commerce businesses today, energy reliability and efficiency are key factors in operations. That is where Plug-and-Play Battery Energy Storage Solutions (BESS), a completely new school of energy storage, comes into the picture. These systems are generally basic, modular, and effective, with the intention of achieving maximal organizational exploitation of energy resources and the least power outages and charges.

What may be understood as plug-and-play BESS solutions?

Standard BESSs are fully integrated battery power stations that are easily embedded in energy networks without requiring complicated adjustments. In contrast to more conventional practices of BESS, which can be comparatively intricate to integrate and set up, plug-and-play systems are factory-built, pre-integrated, and tested, allowing employing businesses to connect and implement them without introducing significant technical knowledge or time to configure.

These systems keep power in reserve and discharge it when there is a high demand; it is therefore inexpensive and stable power system. They can be used alongside renewable energy that includes solar and wind power making them ideal for use in industries that are focused on sustainability.

Why Are Plug-and-Play BESS Solutions Game-Changers for Industry?

1. Ease of Deployment

The plug-and-play nature of these solutions eliminates extensive installation processes. These pre-configured systems can be directly connected to the existing power network, reducing the time to deploy and labour costs significantly. Therefore, they are the most viable option for industries requiring quick energy solutions.

2. Scalability and Flexibility

Plug-and-play BESS solutions are modular. Such arrangements can be scaled up or down according to the business' energy demands. Plugging small into a business's energy requirements creates an opportunity to begin small and enlarge as the energy demands come. This can be done without the need to overhaul the energy storage system.

3. Improved Energy Efficiency

By storing energy during off-peak hours and providing it for high-demand periods, plug-and-play BESS systems optimize the energy cost of industries. This avoids utilities only during peak hours but helps to decrease utility bills, thereby making the business less reliant on the grid during peak times and thus providing a high degree of energy resilience.

4. Renewable Energy Integration

As industries move towards cleaner energy sources, plug-and-play BESS solutions play a pivotal role in bridging the gap between intermittent renewable energy supply and constant demand. These systems store energy generated from solar or wind sources, ensuring a steady power supply even when renewable generation fluctuates.

5. Increased Power Resilience

Power outages can be expensive to industries. Production halts and loss of revenues are inevitable when power supply is interrupted. The plug-and-play BESS system stands as a backup source for power supply in case of grid failure. This reliability is particularly critical to manufacturing, healthcare, and data center-based companies.

6. Lower Total Cost of Ownership

With minimal installation and maintenance requirements, these plug-and-play BESS solutions truly offer a lot of cost-effectiveness in energy storage. Their long lifetime and energy savings enhance the ability to better contain the total cost of ownership in businesses.

Conclusion

The plug-and-play BESS solutions are transforming the way industries manage and utilize energy. Their deployment ease, scalability, and capability of integrating renewable sources make it a game-changing innovation in energy storage. These solutions will not only make business energy consumption more efficient but also contribute to a better future as they bring abundance to our civilization.

#Plug-and-Play BESS Solutions#Industrial Energy Storage#Commercial Battery Storage#Scalable Energy Solutions#Renewable Energy Integration#Energy Efficiency for Industries#Cost-Effective Energy Storage

1 note

·

View note

Text

What is the Average EV Range in 2024?

As we move into 2024, electric vehicles (EVs) are no longer just for early adopters. They’re becoming a common sight on the roads, thanks to advancements in battery technology that have boosted their range. The average EV today can go anywhere between 300 to 400 kilometers (186 to 248 miles) on a single charge, with some premium models going well beyond that.

High-Range EVs in India

In India, we’re seeing some exciting developments in the EV space, with both upcoming and current models pushing the limits of range:

BYD eMAX 7: Set to launch in October 2024, it’s expected to offer a range of around 500 kilometers.

Mercedes-Benz EQS: This luxury option tops the charts with an impressive 770 kilometers of range.

Tata Avinya: Coming in 2026, it's expected to provide about 500 kilometers of range, catering to the demand for long-range EVs.

Hyundai Ioniq 6: Expected to offer a range of up to 614 kilometers, showing Hyundai’s commitment to electric mobility.

With these impressive ranges, managing charging stations becomes more important. That’s where tools like Tecell’s charging management software come in handy. Tecell makes it easy to manage charging stations, providing access to EV drivers with flexible pricing models. Whether you’re a small business or a large enterprise, Tecell’s software can scale to your needs. Plus, their free tier makes it accessible to smaller companies, and the roaming feature offers cost-effective options for EV drivers and charge point operators alike.

#2024 EVs#Aerodynamics#automotive industry#battery life#battery technology#charging infrastructure#charging stations#Clean Energy#consumer demand#Eco-Friendly#electric mobility#electric power#electric vehicles#emissions#energy density#energy management#energy storage#Environmental Impact#EV adoption#EV efficiency#EV Market#EV range#EV trends#fast-charging#Ford Mustang Mach-E#future of mobility#government policies#green technology#innovation#lightweight materials

1 note

·

View note

Text

0 notes

Text

Designing tiny filters to solve big problems

New Post has been published on https://thedigitalinsider.com/designing-tiny-filters-to-solve-big-problems/

Designing tiny filters to solve big problems

For many industrial processes, the typical way to separate gases, liquids, or ions is with heat, using slight differences in boiling points to purify mixtures. These thermal processes account for roughly 10 percent of the energy use in the United States.

MIT chemical engineer Zachary Smith wants to reduce costs and carbon footprints by replacing these energy-intensive processes with highly efficient filters that can separate gases, liquids, and ions at room temperature.

In his lab at MIT, Smith is designing membranes with tiny pores that can filter tiny molecules based on their size. These membranes could be useful for purifying biogas, capturing carbon dioxide from power plant emissions, or generating hydrogen fuel.

“We’re taking materials that have unique capabilities for separating molecules and ions with precision, and applying them to applications where the current processes are not efficient, and where there’s an enormous carbon footprint,” says Smith, an associate professor of chemical engineering.

Smith and several former students have founded a company called Osmoses that is working toward developing these materials for large-scale use in gas purification. Removing the need for high temperatures in these widespread industrial processes could have a significant impact on energy consumption, potentially reducing it by as much as 90 percent.

“I would love to see a world where we could eliminate thermal separations, and where heat is no longer a problem in creating the things that we need and producing the energy that we need,” Smith says.

Hooked on research

As a high school student, Smith was drawn to engineering but didn’t have many engineering role models. Both of his parents were physicians, and they always encouraged him to work hard in school.

“I grew up without knowing many engineers, and certainly no chemical engineers. But I knew that I really liked seeing how the world worked. I was always fascinated by chemistry and seeing how mathematics helped to explain this area of science,” recalls Smith, who grew up near Harrisburg, Pennsylvania. “Chemical engineering seemed to have all those things built into it, but I really had no idea what it was.”

At Penn State University, Smith worked with a professor named Henry “Hank” Foley on a research project designing carbon-based materials to create a “molecular sieve” for gas separation. Through a time-consuming and iterative layering process, he created a sieve that could purify oxygen and nitrogen from air.

“I kept adding more and more coatings of a special material that I could subsequently carbonize, and eventually I started to get selectivity. In the end, I had made a membrane that could sieve molecules that only differed by 0.18 angstrom in size,” he says. “I got hooked on research at that point, and that’s what led me to do more things in the area of membranes.”

After graduating from college in 2008, Smith pursued graduate studies in chemical engineering at the University of Texas at Austin. There, he continued developing membranes for gas separation, this time using a different class of materials — polymers. By controlling polymer structure, he was able to create films with pores that filter out specific molecules, such as carbon dioxide or other gases.

“Polymers are a type of material that you can actually form into big devices that can integrate into world-class chemical plants. So, it was exciting to see that there was a scalable class of materials that could have a real impact on addressing questions related to CO2 and other energy-efficient separations,” Smith says.

After finishing his PhD, he decided he wanted to learn more chemistry, which led him to a postdoctoral fellowship at the University of California at Berkeley.

“I wanted to learn how to make my own molecules and materials. I wanted to run my own reactions and do it in a more systematic way,” he says.

At Berkeley, he learned how make compounds called metal-organic frameworks (MOFs) — cage-like molecules that have potential applications in gas separation and many other fields. He also realized that while he enjoyed chemistry, he was definitely a chemical engineer at heart.

“I learned a ton when I was there, but I also learned a lot about myself,” he says. “As much as I love chemistry, work with chemists, and advise chemists in my own group, I’m definitely a chemical engineer, really focused on the process and application.”

Solving global problems

While interviewing for faculty jobs, Smith found himself drawn to MIT because of the mindset of the people he met.

“I began to realize not only how talented the faculty and the students were, but the way they thought was very different than other places I had been,” he says. “It wasn’t just about doing something that would move their field a little bit forward. They were actually creating new fields. There was something inspirational about the type of people that ended up at MIT who wanted to solve global problems.”

In his lab at MIT, Smith is now tackling some of those global problems, including water purification, critical element recovery, renewable energy, battery development, and carbon sequestration.

In a close collaboration with Yan Xia, a professor at Stanford University, Smith recently developed gas separation membranes that incorporate a novel type of polymer known as “ladder polymers,” which are currently being scaled for deployment at his startup. Historically, using polymers for gas separation has been limited by a tradeoff between permeability and selectivity — that is, membranes that permit a faster flow of gases through the membrane tend to be less selective, allowing impurities to get through.

Using ladder polymers, which consist of double strands connected by rung-like bonds, the researchers were able to create gas separation membranes that are both highly permeable and very selective. The boost in permeability — a 100- to 1,000-fold improvement over earlier materials — could enable membranes to replace some of the high-energy techniques now used to separate gases, Smith says.

“This allows you to envision large-scale industrial problems solved with miniaturized devices,” he says. “If you can really shrink down the system, then the solutions we’re developing in the lab could easily be applied to big industries like the chemicals industry.”

These developments and others have been part of a number of advancements made by collaborators, students, postdocs, and researchers who are part of Smith’s team.

“I have a great research team of talented and hard-working students and postdocs, and I get to teach on topics that have been instrumental in my own professional career,” Smith says. “MIT has been a playground to explore and learn new things. I am excited for what my team will discover next, and grateful for an opportunity to help solve many important global problems.”

#000#air#applications#battery#biogas#boiling#california#carbon#Carbon dioxide#carbon footprint#Carbon sequestration#career#chemical#Chemical engineering#chemicals#chemistry#Cleaner industry#climate change#CO2#coatings#Collaboration#college#deployment#development#Developments#devices#double#Emissions#energy#energy consumption

0 notes