#electrochemical

Explore tagged Tumblr posts

Text

The discharge process will not appear electrolyte stratification, the high current discharge performance is better ❗

The rated capacity of C20 in small-size battery is usually less than 38Ah ❗

Small-size batteries are mainly used in small power scenarios ❗

The practical battery selection is more complex, welcome to leave message, our experts will provide you with effective power solutions!

About small-size batteries, 3 basic insights you should know! 👀

#SmallSizeBattery#BatteryTheory#Electrochemical#BatteryLife#BatteryCategory#DidYouKnow#SmallSizeBatteries#BatteryInsights#ElectrolyteStratification#HighCurrentDischarge#RatedCapacity#SmallPowerScenarios#BatterySelection#PowerSolutions#BatteryExperts#EffectivePower

3 notes

·

View notes

Text

So heavily rusted was this metal bollard on a concrete jetty jutting out into the sea for about thirty feet that it almost resembled ancient teakwood!!! one had a hard time recognizing it for the metallic structure it in fact was..

The jetty was undergoing repair at the time I visited it, but one wonders at the faith of future boats who choose to use this rusted hulk as an anchoring point!!!.

Nothing brings out the crippling corrosive power of salt spray than do these stark images of corrosion gone absolutely amuck.

Dawis Beach, near Digos City, Mindanao, The Philippines, January 26, 2024.

#metal#corrosion#salt spray#teakwood#rust#bollard#jetty#anchorage#philippines#mindanao#electrochemical#seashore#beach#wharf#iron#steel

1 note

·

View note

Text

STONYLAB Glass Sealed Electrolytic Cell with PTFE Lid for Electrochemistry

Price as low as $348.83 USD

Portable Sealed Electrolytic Cell are used for electrochemical reactions, experiments, and tests

Capacity: 10 ml

This kit includes 10 ml glass cell, PTFE stopper and sleeve and 2 electrode holders

The top inlet port design helps to inject material without opening the lid; Side hose can be used to fill in gas or connect to vacuum pump

Warranty: StonyLab 1-year limited warranty; if received damaged, please contact us immediately; we will solve it until satisfied

Products also shown in pictures:

Mini magnetic stirrer

Tubular Electrolytic Cell Reaction Bracket

DC Power Supply

Find our full electrochemistry collection at

#StonyLab#stonylabstore#LabSupplies#stonylabproduct#electrochemistry#electrolyticcell#electrochemical#electrode#electrolyzer

0 notes

Text

brain empty skills doodling WAHOO

#disco elysium#they are like my go-to skills to draw minus half light lol#de volition#de electrochemistry#de drama#de skills#sunnysidedoodles#sunnysidedisco#described#suggestive text#cw body horror#<- jic im not sure but electrochem and drama kind of look freaky dfgdhd#if theres any other things i should tag this as lemme know#also GOODNIGHT (it is morning)

4K notes

·

View notes

Text

Atomic-scale probing of short-range order and its impact on electrochemical properties in cation-disordered oxide cathodes

Material synthesis The cathodes designated as Li1.2Ti0.4Mn0.4O2.0 (LTMO) and Li1.2Ti0.2Mn0.6O1.8F0.2 (LTMOF) were prepared through a conventional solid-state reaction process. Starting materials such as Li2CO3 (sourced from Alfa Aesar with an ACS purity of at least 99%), Mn2O3 (with a purity of 99.9% from Alfa Aesar), TiO2 (99.9% pure, Alfa Aesar), and LiF (Alfa Aesar, with a purity of 99.99%)…

View On WordPress

#Atomicscale#cathodes#cationdisordered#electrochemical#Impact#order#Oxide#Probing#Properties#shortrange

0 notes

Text

Don’t Think (Too) Much — inspired by this comic

#like omg hes so cute what should i say#electrochem say FUCK HIM RN#logic say just say yes holy shit its not that hard#kim kitsuragi#harry du bois#art#comic#disco elysium#waw#azlysium

1K notes

·

View notes

Text

8 December 2024

I discovered peach tea thanks to a friend and I've been obsessed with it - I love it so much I drink it almost every day and I'm not much of a tea person.

Study-wise there's nothing new: I spent this weekend with potentiometry (what a huge chapter 😭) and I hope the test on Tuesday won't deck me

#only two tests on electrochem left though!#i almost made it woooo#mine#op#studyblr#chemblr#chemistry

233 notes

·

View notes

Text

Siffrin plays Disco Elysium AU: Featuring backseat gamer Loop.

#in stars and time#ISAT#Siffrin#Loop#disco elysium#digital art#When I first thought of a crossover I went from 1) 'ISAT Disco AU but Loop is all of the skills'#To: 2) 'Loop is in the mindspace alongside the skills#To my magnum opus: 3)'Loop is sitting next to Siffrin backseat gaming him the whole time.'#Loop beat Disco Elysium ages ago and repeated it to the point they know all the vision quests and dialogue variables.#Siffrin just started playing and Loop keeps ruining the fun by using their meta-game knowledge to try and help.#Also let's be real. Siffrin's stats are 100% completely focused into motorics and nothing else.#If we can't Savoir Faire ourselves of this situation - we will explode. Endurance? Call my insurance instead.#Thinking skills? None. Emotional intelligence and morale? A failed social interaction canonically feels like death to them.#I might have bumped Phys up but...Siffrin's Electrochem stat is like -10. And Pain Threshold is emotional durability too.#Unused part of this joke is that I set their signature skill to Drama.#Both these games made my brain melt so now I get to combine them! I have that power!#This joke made me laugh the entire 3 hours I sat down and drew it and that is what creation should be about.

423 notes

·

View notes

Text

MIT engineers make converting CO2 into useful products more practical

New Post has been published on https://thedigitalinsider.com/mit-engineers-make-converting-co2-into-useful-products-more-practical/

MIT engineers make converting CO2 into useful products more practical

As the world struggles to reduce greenhouse gas emissions, researchers are seeking practical, economical ways to capture carbon dioxide and convert it into useful products, such as transportation fuels, chemical feedstocks, or even building materials. But so far, such attempts have struggled to reach economic viability.

New research by engineers at MIT could lead to rapid improvements in a variety of electrochemical systems that are under development to convert carbon dioxide into a valuable commodity. The team developed a new design for the electrodes used in these systems, which increases the efficiency of the conversion process.

The findings are reported today in the journal Nature Communications, in a paper by MIT doctoral student Simon Rufer, professor of mechanical engineering Kripa Varanasi, and three others.

“The CO2 problem is a big challenge for our times, and we are using all kinds of levers to solve and address this problem,” Varanasi says. It will be essential to find practical ways of removing the gas, he says, either from sources such as power plant emissions, or straight out of the air or the oceans. But then, once the CO2 has been removed, it has to go somewhere.

A wide variety of systems have been developed for converting that captured gas into a useful chemical product, Varanasi says. “It’s not that we can’t do it — we can do it. But the question is how can we make this efficient? How can we make this cost-effective?”

In the new study, the team focused on the electrochemical conversion of CO2 to ethylene, a widely used chemical that can be made into a variety of plastics as well as fuels, and which today is made from petroleum. But the approach they developed could also be applied to producing other high-value chemical products as well, including methane, methanol, carbon monoxide, and others, the researchers say.

Currently, ethylene sells for about $1,000 per ton, so the goal is to be able to meet or beat that price. The electrochemical process that converts CO2 into ethylene involves a water-based solution and a catalyst material, which come into contact along with an electric current in a device called a gas diffusion electrode.

There are two competing characteristics of the gas diffusion electrode materials that affect their performance: They must be good electrical conductors so that the current that drives the process doesn’t get wasted through resistance heating, but they must also be “hydrophobic,” or water repelling, so the water-based electrolyte solution doesn’t leak through and interfere with the reactions taking place at the electrode surface.

Unfortunately, it’s a tradeoff. Improving the conductivity reduces the hydrophobicity, and vice versa. Varanasi and his team set out to see if they could find a way around that conflict, and after many months of trying, they did just that.

The solution, devised by Rufer and Varanasi, is elegant in its simplicity. They used a plastic material, PTFE (essentially Teflon), that has been known to have good hydrophobic properties. However, PTFE’s lack of conductivity means that electrons must travel through a very thin catalyst layer, leading to significant voltage drop with distance. To overcome this limitation, the researchers wove a series of conductive copper wires through the very thin sheet of the PTFE.

“This work really addressed this challenge, as we can now get both conductivity and hydrophobicity,” Varanasi says.

Research on potential carbon conversion systems tends to be done on very small, lab-scale samples, typically less than 1-inch (2.5-centimeter) squares. To demonstrate the potential for scaling up, Varanasi’s team produced a sheet 10 times larger in area and demonstrated its effective performance.

To get to that point, they had to do some basic tests that had apparently never been done before, running tests under identical conditions but using electrodes of different sizes to analyze the relationship between conductivity and electrode size. They found that conductivity dropped off dramatically with size, which would mean much more energy, and thus cost, would be needed to drive the reaction.

“That’s exactly what we would expect, but it was something that nobody had really dedicatedly investigated before,” Rufer says. In addition, the larger sizes produced more unwanted chemical byproducts besides the intended ethylene.

Real-world industrial applications would require electrodes that are perhaps 100 times larger than the lab versions, so adding the conductive wires will be necessary for making such systems practical, the researchers say. They also developed a model which captures the spatial variability in voltage and product distribution on electrodes due to ohmic losses. The model along with the experimental data they collected enabled them to calculate the optimal spacing for conductive wires to counteract the drop off in conductivity.

In effect, by weaving the wire through the material, the material is divided into smaller subsections determined by the spacing of the wires. “We split it into a bunch of little subsegments, each of which is effectively a smaller electrode,” Rufer says. “And as we’ve seen, small electrodes can work really well.”

Because the copper wire is so much more conductive than the PTFE material, it acts as a kind of superhighway for electrons passing through, bridging the areas where they are confined to the substrate and face greater resistance.

To demonstrate that their system is robust, the researchers ran a test electrode for 75 hours continuously, with little change in performance. Overall, Rufer says, their system “is the first PTFE-based electrode which has gone beyond the lab scale on the order of 5 centimeters or smaller. It’s the first work that has progressed into a much larger scale and has done so without sacrificing efficiency.”

The weaving process for incorporating the wire can be easily integrated into existing manufacturing processes, even in a large-scale roll-to-roll process, he adds.

“Our approach is very powerful because it doesn’t have anything to do with the actual catalyst being used,” Rufer says. “You can sew this micrometric copper wire into any gas diffusion electrode you want, independent of catalyst morphology or chemistry. So, this approach can be used to scale anybody’s electrode.”

“Given that we will need to process gigatons of CO2 annually to combat the CO2 challenge, we really need to think about solutions that can scale,” Varanasi says. “Starting with this mindset enables us to identify critical bottlenecks and develop innovative approaches that can make a meaningful impact in solving the problem. Our hierarchically conductive electrode is a result of such thinking.”

The research team included MIT graduate students Michael Nitzsche and Sanjay Garimella, as well as Jack Lake PhD ’23. The work was supported by Shell, through the MIT Energy Initiative.

#000#air#applications#approach#Building#Capture#carbon#Carbon dioxide#catalyst#challenge#change#chemical#chemistry#climate#CO2#communications#conductors#Conflict#data#Design#development#diffusion#economic#efficiency#electrochemical#electrode#electrodes#electrolyte#electrons#Emissions

0 notes

Text

"You said you can read minds, yes?" The question was emphasised by the tilt of a head, neutral expression flat on crystalline face. "You've mentioned it's pretty overwhelming, you can't control what you hear?" "Yes, yes, and no... not really..." Came Ra'ad's reply, his attention diverted to focus on the corner where wall meets ceiling. Reviewing the biopsychology notes Chio had on amperi, a frown shifts his jaw just enough to be noticed. "If it's not too much to ask," Chio shifts, eyes flicking over his own handwriting to focus in Ra'ad's general direction; he's met by a brief flick of eye contact, "Could you tell me what I'm thinking of now?"

Haha magics and mutants au Ra'ad gets diagnosed as a psychic :P let's hope this neurodivergent old man gets the ability to stop having unwanted voices broadcasting in his head :)c

and a coloured Chio my beautiful therapist 😌

#ra'ad#chio#oc#ben 10 oc#ben 10#fanart#sometimes i want to make entire comics but then i get exhausted so i never finish them#i tried to do that to this one too- a little 2 page comic#but like... the abandoned comics are also 2 parters (and they all involve a petrosapien this is unrelated :p)#so i thought 'well you may not be the ficiest of ramble writers but you do ramble pretty good' and maybe i wrote extra context for the comi#hah- welcome to the stage my coloured chio therapist of the andromeda 5 (and maybe others too lmao) this is just a solo ra'ad session#plus some xenobiology headcanons too- referencing another post i made#a petrosapien's is split between electrical and chemical (the electrical nervous system is quartz compression)#the chemical nervous system is akin to cerebral fluid and operates more on neural plasticity than a pre-wired system#amperi have an electrochemical nervous system but it's like intensified#(this comic is totally not setting up for something *grins*)

53 notes

·

View notes

Text

#everything can be a romcom trope if your volition-electrochem combo is high enough#disco elysium#de#my harry is lowkey crazy... went a little overboard with minmaxing

113 notes

·

View notes

Text

And they were roommates

#disco elysium#volition#electrochemistry#I love how everyone draws volition as a short king#had to improv from electrochemical#thats a gem on his leg btw

23 notes

·

View notes

Text

DRAMA³ - Topsy turvy, sweetly dreaming...

DRAMA² - Toss and turning in a frantic state of disbelief...

DRAMA¹ - The crowd goes wild with applause!

DRAMA - ... Over absolutely nothing.

---

The sillies <2

#my art#artists on tumblr#disco elysium#the skills disco elysium#drama disco elysium#Drama de#The skills de#skilltober#Not pictured is Drama⁴ which is a mouth on the back of their head#*I* personally don't know much about that guy. I hear Scio (Drama¹) hates him though -Electrochem

25 notes

·

View notes

Note

Your tags in my notes give me life every time 🙏🙏thank you so much!

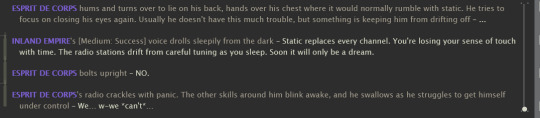

I would love to hear your thoughts on what might happen to Esprit post-RCM!! And yeah poor electrochem... I think it was meant for the little daily dopamine highs of life, the good food and new experiences and cute cats, but it's been hijacked by addiction into something best ignored :((

!! YESS omg of course, you make such good art AND writing i have gotta pay my respects!! hgkjh delighted to see your DE fanworks always :3 <33

!! HELL YES I WOULD LOVE TO SHARE, and its so cool to have that echem mention because it's a really good parallel: YES!! Electrochemistry is made to take care of general mesolimbic system reports and for lil everyday happy dopamine moments, little treats and smiles from kim hkjhg but it gets fucked up by addiction because HOLY SHIT life is AWFUL and DEPRESSING and surely drugs and alcohol will save us!! :')

AND SIMILARLY!! i think Esprit De Corps (literally Group Spirit or team spirit) is originally meant to be a skill of Community and Belonging, but gets fucked up by the RCM!! more under cut because this is LONG hgkjh

in my headcanons, Esprit is the youngest skill to form, but it wasn't as late as the RCM. Originally, I think that Esprit was made for the kinship Harry felt for the The Fifteenth Indotribe. Harry and seven other kids, running together as a group of friends causing trouble, this was Harry's first sense of belonging somewhere. Pretty low level and not as psychically linked, just happy to feel connected to people. When the indotribe eventually fell apart, Esprit was left fractured and dormant for a while as Harry drifted from having a sense of community. Esprit for real, at this point in time, Esprit is a ghost of a fury, low level and barely tangible.

(The thing holding them together was their attachment to the other skills, because at least they're still part of a group that way, even if Harry wasn't. Friends with Empathy, a part of the psyches, one of the 24 skills. If Esprit lacked those bonds with the other furies, its likely they would have faded entirely.)

Then Harry became a gym teacher, and Esprit returns as Esprit L'école (School Spirit :3) which helps him communicate with school staff, faculty and students. And Harry cares about this new community dearly. Deeply tender at heart, Harry loves the kids in his classes and finds camaraderie with his coworkers and wants the best for this school. Not just the best gym teacher, he's one of the best teachers in general. He puts his everything into this school, and Esprit L'école thrives in this new environment for several years.

Then they meet Dora, and shit gets fucked!! Dora convinces Harry to join the RCM, and Esprit fractures further. Unlike the Fifteenth Indotribe or the Grand Couron High School, this isn't something he finds community in. I mean, they think they do at first. The RCM is meant to help the community, right? Surely working here will bolster Esprit? But y'know how it goes, RCM culture is harsh and immoral and corrupted at its heart, for the scarce good they can do, there is so, so much bad for the community and god Esprit is hurting.

...but this is for Dora, and trying to put a bandage on a dying relationship, so Esprit De Corps forces it. Forces themselves to lean hard into the kinship with cops and to fit into police culture and conform to RCM standards, forces himself to be The Cop Skill. All of the skills at this point are going into overdrive as well, Volition tries to focus on hard work in hopes that it will pay off in the long run, Empathy tries to make himself smaller so he's not in the way, Echem is RUNNING OUT OF DOPAMINE and oh hey, this speed shit makes us a better cop, I'll take it!! dear god, the RCM is fucking over ALL THE SKILLS, everyone is struggling at this point.

And Dora leaves. Harry suffers, and so do the skills, and trying to distract from it, they just launch themselves HARDER into the RCM shit. nothing else to live for, to do, throw all reluctance to the wind, work yourself to the brink of death. 18 total years of service, 216 cases, above 90% of officers in the entire RCM, a Lieutenant Double-Yefreitor. Renowned and accomplished; this is not the community Esprit De Corps loves, but it is the one he's entrenched in, and nothing, not even amnesia, can detach him from this.

Until they quit.

honestly ive seen like! a few fics where harry quits the RCM, and always thought, "oh hey nice acab :] ...HEY WAIT WHAT'S ESPRIT DOING." so i made a fic, because a LOT of my fics are focused on the skills side of things. the humans are no longer my priority, i am a skills lover and my fucking god i gotta make my own food around here [gestures at several in-progress pasta bakes and cake batters and salad ingredients because EVERYTHING IS WIPS]

there was a first concept that was just like "DOES ESPRIT JUST DISAPPEAR???" which would have been TRAGIC and i could've made a whole cool thing about it but im alrEADY WORKING ON SEVERAL MULTI-CHAPTERS HKJHG and that's not how skills work in my canon <3

so my fic is a oneshot called "Who Are You, If Not..." because when you've made your whole life one thing and that thing gets taken away from you, who do you become? and its not very plot heavy, it's just a late-night conversation between the psyche skills.

here's a snippet from while i was working on the coding hkgjh

(since i write a lot of skills, i have this style where i put all skill actions in the [check] color and leave dialogue in white, which is a little restrictive to work with but i like how it turns out <33)

to lose a group you attached yourself to, even if they were bad for you, even if everything about it sucked. but you keep checking in, you keep instinctively going back because at least it was something. ough... i think it's scary for them, yknow? he's losing touch with what he based his existence around, and he knows its for the better, but it's... complicated hkjgh

ANYWAY THOSE ARE MY ESPRIT THOUGHTS HKJHG <33 thank you for reading if you did!! i LOVE the concept of esprit being more than just the cop skill, he's the skill of community to me!! hkjhg yay :]

#volta transmissions#inland drabbles#task: Who Are You If Not#HGKJH THANK YOU FOR THE ASK AND THE OPPORTUNITY TO RAMBLE!!!!#electrochem is tragic and one of my favorites for real hgkjh and i loveee esprit very dearly <3 psyches are my second fave skillset fr#(motorics comes first i love all the motorics hkjfh)#my god i could talk about any of the skills forever probably hkjgh

13 notes

·

View notes

Text

who are you in this haunted house story?

the dark entity.

you’re not from here. you don’t need what they need. their fear is so…. trivial. they are small, so very small compared to you. they eat and walk and cry and laugh. you just watch. it’s fascinating, really, their little rituals and their meaningless concerns. sometimes, you envy their small joys or even their modest pain. they don’t know what it is to wait in the dark, unfeeling, as time passes over you as eternal as the sea. but my, how you are glad to have guests again. you see, over your many years, you've become aware of a secret: fear tastes sweet.

tagged by: @sortilegii (thanks so much for the tag :D)

tagging: @sifonie, @greenleads, @volucerrubidus, @masquenoire, and anyone else who might like to complete this quiz!

#IT WAS PROBABLY NOTHING BUT IT FELT LIKE THE WORLD: musings.#rp memes.#well... damn JSJSJ they're really calling out blamore with this one huh 💀 LMAO nooo but i think it is really interesting that i got this-#result. not because blamore is actually a dark entity but because i have a feeling it is sometimes seen as more of a force of nature-#than anything else (ex. a human being for one) and this is something that has crossed into blamore's own behavior as it now tends to-#dehumanize itself unfortunately ): but i mean... and not to say that it's good to do so OFC but it hasn't felt like it was human-#ever since it got transformed especially thanks to all of the weird electrochemical signals that it's plants send it.#yeah - so that is to say that blamore's plants actually DO communicate with him in their own way and it's bizarre and something-#that it still hasn't gotten fully used to because it's not like they're talking to him you know? it's like something tactile-#/ something he can physically feel and so it's hard for it to determine what they're even trying to tell blamore sometimes#but yeah! there's just a little bit more of a lore drop for y'all haha

7 notes

·

View notes