#laser welding

Explore tagged Tumblr posts

Text

youtube

#lasermachine#laser welding machine#welding services#laser welding#metal laser welding#welding#Youtube

2 notes

·

View notes

Link

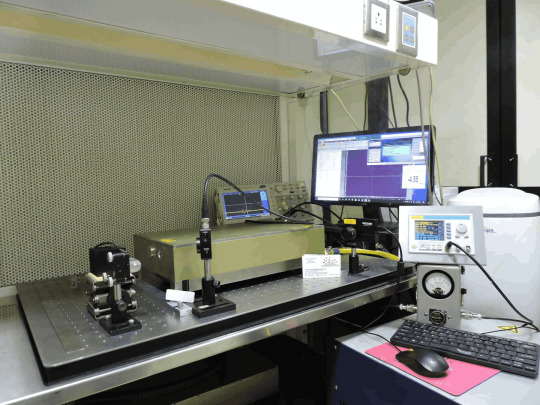

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion MegaWatt Lasers QPC Lasers Amplitude Lasers (Continuum), PhotoScribe Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

Advantages of Battery Laser Welding Machines in the Manufacturing Industry

In the fast-evolving landscape of battery production, manufacturers are constantly seeking advanced technologies to enhance efficiency, precision, and cost-effectiveness. Battery laser welding machines have emerged as a revolutionary solution, offering a wide array of benefits that cater to the demands of modern energy storage systems. This article explores the advantages of employing battery laser welding machines in manufacturing, highlighting their role in revolutionizing battery production processes.

Unparalleled Precision

Precision is a crucial factor in battery production, where even the tiniest defect can significantly impact performance and safety. Battery laser welding machines provide unparalleled precision, thanks to the focused and concentrated laser beam. This allows for excellent and accurate welds, ensuring the integrity of delicate battery components, such as thin foils and electrodes. As a result, manufacturers can consistently produce high-quality batteries with minimal defects, improving overall reliability and customer satisfaction.

Enhanced Efficiency

Efficiency is a key driver in any manufacturing process, and battery laser welding machines excel in this regard. Their high welding speeds and rapid heat input minimize production cycle times, enabling faster throughput and increased productivity. Additionally, the non-contact nature of laser welding eliminates the need for consumables, reducing downtime for material changes and reducing overall maintenance costs. This efficiency translates into greater output, making laser welding an indispensable technology in meeting the rising global demand for energy storage solutions.

Reduced Production Costs

In the competitive manufacturing landscape, cost optimization is a paramount concern. Battery laser welding machines contribute to cost reduction in multiple ways. Firstly, their precision minimizes material wastage, resulting in fewer rejected components and lower scrap rates. Secondly, the high automation potential of laser welding allows for streamlined workflows, reducing the need for manual labour and associated labour costs. Furthermore, the speed and accuracy of laser welding led to fewer rework cycles, saving time and resources. Over time, these cost-cutting benefits make battery laser welding a financially viable option for large-scale production.

Versatility in Battery Design

Battery designs have become increasingly intricate to cater to diverse applications, from portable electronics to electric vehicles and renewable energy storage. Battery laser welding machines offer unparalleled versatility in welding complex geometries and dissimilar materials. They can handle a wide range of battery cell formats, from cylindrical and prismatic to pouch cells, facilitating the production of custom battery packs tailored to specific applications. This adaptability grants manufacturers the flexibility to stay at the forefront of innovation and adapt to rapidly evolving market demands.

Minimal Heat-Affected Zones

Traditional welding techniques can introduce significant heat into the weld area, potentially causing thermal stress and affecting battery performance and longevity. In contrast, batterylaser welding machines generate minimal heat-affected zones (HAZ) due to their focused and precise energy delivery. This characteristic reduces the risk of damage to temperature-sensitive battery components and preserves the material properties, ensuring the highest level of performance and safety.

Improved Safety Standards

Battery safety is of utmost importance, especially in high-energy applications like electric vehicles and energy storage systems. Battery laser welding machines play a vital role in enhancing safety standards by producing strong and reliable welds. The integrity of laser-welded joints reduces the risk of battery leakages, ensuring that batteries can withstand challenging operating conditions without compromising safety.

Environmental Friendliness

In today's environmentally conscious world, sustainable manufacturing practices are a priority. Battery laser welding machines contribute to eco-friendly production processes in several ways. Their high efficiency and precision result in less material waste, reducing the environmental impact of manufacturing. Additionally, the non-contact nature of laser welding means no fumes or harmful byproducts are emitted during the welding process, creating a cleaner working environment and contributing to a greener manufacturing facility.

Conclusion

The advantages of battery laser welding machines in the manufacturing industry are undeniable. Their precision, efficiency, and ability to reduce production costs make them a game-changer in battery production processes. As energy storage technology continues to advance, battery laser welding machines will play a pivotal role in shaping the future of battery manufacturing, enabling the development of safer, more efficient, and environmentally friendly energy storage solutions. With ongoing research and development, these machines will certainly continue to evolve, empowering manufacturers to meet the growing demands of the global energy landscape.

#Advanced Manufacturing#Battery Manufacturing#Electric Vehicles#Energy Storage#Industrial Automation#Laser Welding#Manufacturing Innovation#Precision Engineering#Renewable Energy#Sustainable Manufacturing

0 notes

Text

Fiber laser handheld welding machine installation tutorial shared!

0 notes

Text

Elevate Your Welding Precision with Bare Metal Laser's State-of-the-Art Laser Welding Machine

Experience unparalleled welding precision and efficiency with Bare Metal Laser's advanced laser welding machine. Our cutting-edge technology offers superior weld quality, increased productivity, and cost-effectiveness for your welding projects. Revolutionize your welding process with precision and speed like never before. Visit BareMetalLaser today to explore how our innovative laser welding machine can transform your welding operations and take your craftsmanship to the next level.

1 note

·

View note

Text

How to choose metal Laser Welding Machines for metal industries?

Choosing the right metal laser welding machine for metal industries involves considering several key factors to ensure it meets your specific requirements and production needs.

Here’s a guide to help you make an informed decision:

1. Material Compatibility:

- Ensure the laser welding machine is suitable for the types of metals you work with. Different machines may be designed for specific materials, so choose one that accommodates the range of metals you commonly use.

2. Power and Pulse Duration:

- Consider the power and pulse duration of the laser source. Higher power allows for deeper penetration, while shorter pulse durations are suitable for delicate and precise welding. Select a machine with the appropriate power and pulse duration for your applications.

3. Welding Speed and Productivity:

- Evaluate the machine’s welding speed and overall productivity. Faster welding speeds can increase efficiency, but it’s essential to balance speed with the quality of the weld. Look for a machine that meets your production goals without compromising weld integrity.

4. Precision and Accuracy:

- Assess the precision and accuracy of the laser welding machine. This is crucial for applications that require fine details and tight tolerances. High precision is particularly important in industries like electronics or medical devices.

5. Ease of Use and Automation:

- Consider the user-friendliness of the machine. Look for features like intuitive controls, easy setup, and programming capabilities. Additionally, assess the potential for automation, as automated laser welding systems can enhance efficiency and consistency in production.

6. Cooling System:

- Laser welding generates heat, so an efficient cooling system is essential to maintain the machine’s performance and prevent overheating. Check the cooling capacity and whether the machine has built-in cooling mechanisms.

7. Maintenance and Serviceability:

- Evaluate the ease of maintenance and the availability of service and support. Choose a machine from a reputable manufacturer with a good track record for reliability and customer support.

8. Cost Considerations:

- Assess the initial cost as well as long-term operating costs, including consumables and maintenance. While it’s tempting to opt for the lowest upfront cost, consider the overall value and return on investment based on your production needs.

9. Safety Features:

- Ensure the laser welding machine complies with safety standards and incorporates necessary safety features. This includes features like enclosures, interlocks, and proper ventilation to protect operators from laser radiation and other potential hazards.

10. Supplier Reputation:

- Choose a reputable and reliable supplier or manufacturer. Look for reviews, testimonials, and the company’s track record in delivering quality laser welding machines. A reliable supplier can provide ongoing support and ensure that you get the most out of your investment.

By carefully considering these factors, you can select a metal laser welding machine that aligns with your specific requirements and contributes to the success of your metal industry operations.

0 notes

Text

Beyond the Torch: Unveiling the Hidden World of Welders and Their Metal Mastery

Crafting Excellence in Williamsport:

Williamsport, PA, is not merely a location for Iron Associates Inc.; it's the essence of our craftsmanship. Rooted in this dynamic community, our skilled welders shape metal into masterpieces that grace the local landscape. From industrial wonders shaping the cityscape to bespoke creations enhancing the character of Williamsport's homes, Iron Associates is an integral part of the city's aesthetic evolution.

Our commitment to Williamsport extends beyond the sparks illuminating our workshops; a pledge to excellence defines each weld. The city's spirit echoes in our work, making Iron Associates a trusted name in the community for welding services near me. As we explore the intricate tapestry of Williamsport, we invite you to witness the precision and artistry that set our welding services apart.

Unveiling the Hidden Artistry:

At Iron Associates, we transcend the commonplace perception of welding, uncovering a hidden world of artistry. The Welder, our signature service, is a canvas for our craftsmen to weave creativity into every weld. It's not just about joining metals; it's about sculpting them into expressions of beauty and strength. This hidden artistry is unveiled in every project, reflecting a commitment to mastery that goes beyond the torch.

In this hidden world, precision is paramount. Iron Associates combines state-of-the-art technology with the seasoned expertise of our craftsmen to ensure that every project, from intricate metal artwork to industrial fabrication, is executed with unmatched precision. The Welder is more than a service; it's an invitation to witness the transformative potential of metal mastery.

Meeting Your Vision, Every Weld at a Time:

At Iron Associates, we understand that welding is a journey of realization and transformation. Whether you're an artist envisioning a metal sculpture, a homeowner with a custom ironwork project, or an industrial entity requiring top-notch fabrication, we are here to bring your vision to life.

As you navigate the world of welding services near me, consider Iron Associates Inc. as your beacon of creativity and precision. We are not just welders but craftsmen unveiling the hidden potential within metal. Our commitment to excellence, innovative approach, and unwavering precision make us the go-to choice for all your welding needs. Explore the secret world beyond the torch with Iron Associates Inc. and witness your projects come to life in ways you never imagined.

Discover the extraordinary world of metal mastery with Iron Associates Inc. – your trusted choice for welding services near me. Embrace the hidden artistry that lies beyond the torch, and let your projects become a masterpiece in the hands of our skilled craftsmen.

Iron Associates Inc.

3010 Lycoming Creek Rd, Williamsport, PA 17701, United States

(877) 751 7893

#welding#welder#welding supply near me#welding shops near me#welding supplies near me#stick welding#welding machine#welding near me#laser welding

1 note

·

View note

Text

Summary of 19 plastic connection methods!

Plastics are widely used in daily chemical packaging, medical equipment, automobiles and in daily products. This article makes a brief introduction to these plastic connection technologies. Content is for reference of friends who are engaged in product structure design: 1 Adhesive connection Adhesive connection refers to technology of connecting surfaces of homogeneous or heterogeneous objects…

View On WordPress

#automotive plastic parts#Design of Injection Mold#Hot plate welding#hot riveting#Hot-air riveting#injection mold#injection molding decoration technology#Insert molding#Laser welding#molded products#Molded thread forming#molding#molding technology#Multiple Part Molding#plastic connection methods#plastic connection technologies#plastic parts#plastic products#Pressure fit#Product structure design#Solvent connection#two-color injection molding#ultrasonic plastic welding#ultrasonic riveting#Ultrasonic welding#Vibration welding

0 notes

Text

SLTL's Cutting-Edge Laser Welding and Marking Solutions Take Center Stage at India International EV Show 2023 – Chennai

CHENNAI, 26th-28th May, 2023 - SLTL Group, a pioneering technology company with a rich history of innovation, is thrilled to announce its participation in the India International EV Show in Chennai. The event, scheduled to take place from 26-28 May, 2023, is a platform where industry leaders and enthusiasts gather to explore the latest advancements in electric vehicles (EVs). SLTL Group will be showcasing its cutting-edge laser welding and marking solutions specifically designed for the automobile industry.

#manufacturing#laser welding#lasermarking#India International EV Show#lasertechnology#electric vehicles#automobile#laser solutions

0 notes

Text

Our laser welding machine leaves a very precise, and damages free welding quality over the statue.

1 note

·

View note

Video

tumblr

Laser Marking on Glass Bottle video from C. And C. Laser Engineering Whatsapp/Mobile: +91-9833105515.

Laser Marking on Glass Bottle - The above video shows Laser marking on glass Bottle using a nano-second UV laser.

Glass or Glass Bottle can only be marked with UV Laser. IR (1064 nm) laser gets reflected from the glass. UV laser (355 nm) and DUV (266 nm) get absorbed easily by the glass and hence are the ideal source for marking on Glass or Glass Bottle. In the video shown above, the glass bottle has been laser marked with a 355 nm 5 W UV laser with a Galvo-based marking system having a laser marking field of 100 X 100 sq. mm., using a rotary. Green (532 nm) laser and CO2 (10.6 µm) would fracture & crack the glass.

C. And C. Laser Engineering is popular for its job work services in laser marking, laser welding, laser cutting, and micro-machining.

#laser marking#laser marking job work#laser marking services#laser marking on glass#glass laser marking#laser welding#laser cutting

2 notes

·

View notes

Text

The Role of Automation in Laser Welding Machines for Batteries

Automated laser welding machines for batteries are at the forefront of modern manufacturing. These cutting-edge machines have revolutionized the welding process, enabling precision, speed, and reliability in battery assembly. Let's delve into the industry aspects of these remarkable tools.

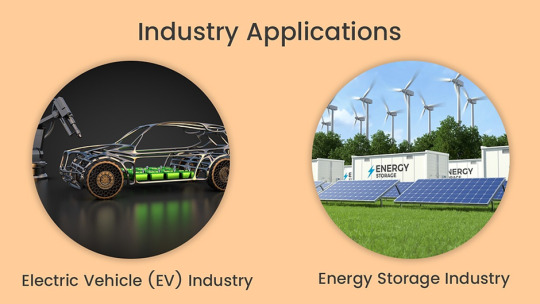

Industry Applications

Powering the Future with Laser Precision:

1. Electric Vehicle (EV) Industry: The EV sector relies heavily on automated laser welding machines for battery pack assembly. These machines ensure the integrity and safety of high-capacity lithium-ion battery packs that power electric cars.

2. Energy Storage Industry: In the energy storage sector, these machines are indispensable for creating robust battery modules used in renewable energy solutions, ensuring the efficient storage of green energy.

Advantages and Disadvantages

The Pros and Cons of Automated Laser Welding Machines:

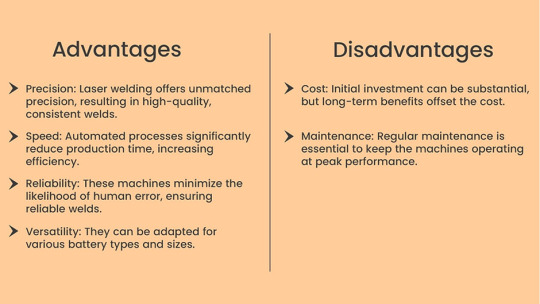

Advantages:

Precision: Laser welding offers unmatched precision, producing high-quality, consistent welds.

Speed: Automated processes significantly reduce production time, increasing efficiency.

Reliability: These machines minimize the likelihood of human error, ensuring reliable welds.

Versatility: They can be adapted for various battery types and sizes.

Disadvantages:

Cost: Initial investment can be substantial, but long-term benefits offset the cost.

Maintenance: Regular maintenance is essential to keep the machines operating at peak performance.

How to Use Automated Laser Welding Machines for Batteries?

Operating these machines involves the following steps:

Material Preparation: Ensure the battery components are clean and properly aligned.

Machine Setup: Configure laser parameters such as power, pulse duration, and focal point.

Welding: Activate the machine to perform automated laser welding, creating precise welds.

Quality Check: Inspect welds for quality, ensuring they meet industry standards.

Customization

Automation in laser welding machines allows for flexibility and customization:

Parameter Adjustment: Tailor laser settings for specific materials and applications.

Integration: Seamlessly integrate the machine into automated production lines for maximum efficiency.

Software Enhancements: Customize the control software to meet your unique requirements.

What Makes It Different?

Why Opt for Automated Laser Welding?

High Productivity: These machines offer unparalleled productivity and repeatability.

Reduced Labor Costs: Automation decreases the need for manual labor.

Quality Assurance: Automated processes minimize the risk of defects.

The Need in the EV and Energy Storage Industry

Automated laser welding machines are indispensable in these burgeoning industries:

EV Battery Packs: They ensure the safety and reliability of lithium-ion battery packs, a core component of electric vehicles.

Energy Storage Solutions: These machines contribute to the efficient storage and distribution of renewable energy, fostering sustainability.

Conclusion

Automation in laser welding machines for batteries is transforming the manufacturing landscape. Its precision, speed, and reliability are pivotal in the growth of the EV and energy storage sectors. As we march towards a sustainable future, these machines will continue to play a central role in creating high-quality battery systems.

#battery pack assembly#laser welding#laser welding equipment#laser welding machines#laser welding machines in India#lithium ion batteries#lithium ion battery packs#EV battery packs#energy storage solutions#automated laser welding#automated laser welding machine#electric vehicle industry#energy storage industry#energy storage system

0 notes

Text

Handheld laser welding live !

Live demonstrations of the Handheld Laser Welding and Cutting Machine showcase the impressive versatility of modern laser technology. This portable machine offers unmatched flexibility and precision, allowing workers to easily reach and manipulate hard-to-reach areas of material.

The fiber laser beam emitted by the machine is so intense that it creates an extremely hot spot on any surface it touches, allowing it to effortlessly cut through materials as diverse as aluminum, stainless steel and copper. This machine also offers great control, allowing the welder to adjust the amount of power according to the material being welded. This results in clean and accurate cuts with little to no discoloration or warping of the edges.

The machine's welding capabilities are equally impressive, providing precise and strong bonds without the need for external adhesives such as glues or staples. The welded adhesive is so strong and durable that it can withstand even the toughest pressure tests.

All in all, the Handheld Laser Welder and Cutter is a stunning demonstration of the power and efficiency of modern laser technology. Its ability to cut and weld different materials with precision and ease makes it a must-have tool for any modern industrial project. This technology is rapidly evolving, and it's easy to see that handheld laser machines are blazing a trail for the future when it comes to flexibility and precision.#Laser Welder #Handheld Laser Welder #Fiber Welding #Laser Welding #Handheld Welding

0 notes

Text

87 notes

·

View notes

Text

Affordable Handheld Metal Laser Welding Machine for Sale

A metal laser welding machine, also known as a laser welder or laser welding system, is a specialized equipment used for precise and efficient welding of metal components. It utilizes laser technology to generate a highly concentrated and intense laser beam that melts and fuses metal materials together.

Handheld Metal Laser Welding Machine

Handheld metal laser welding machines are designed to be lightweight and portable, allowing for easy transportation and maneuverability. They typically have a compact size and ergonomic design, enabling operators to access and weld difficult-to-reach areas or perform welding tasks in different locations.

Handheld metal laser welding machines offer the advantages of mobility, accessibility, and versatility in metal welding applications. They provide a convenient solution for on-site repairs, small-scale production, or situations where traditional fixed-position laser welding machines may not be feasible.

Welding head

The laser is eventually fired from the welding head and applied to the material.It consists of nozzle,scale tube, protective glass,focusing lens, reflector,motor,collimator,wire feeding bracket, switch button, waterways,QBH protective sleeve and so on. Nozzle and protective lens are wearing parts. And when workers’ welding, auxiliary gas is often needed to avoid material producing gas that could react with air and to avoid residue and aerosol entering the welding head to damage the components.So we need to prepare extra nozzles and protective lens. How laser welding works?The laser is generated by laser source and is transported to welding head, then it is collected and reflected by reflector and is focused by focusing lens to reach the nozzle and finally fired to the material, after all this happens, the user could conduct welding conveniently and flexibly.

When considering a handheld metal laser welding machine, factors to consider include laser power, portability features, battery life (if applicable), cooling system, ease of use, and the specific welding requirements of your application.

Main body

Displayer is a window for interaction between user and machine. The screen of displayer is touch screen, its functions are machine parameter adjustment and language conversion. Control board equals to computer mainframe. And wire feeder is designed to melt the wire into the welding joint during material processing when the welding joint width over 5 mm.

Water chiller is used to cool laser source and welding head and could only be filled with distilled water and purified water in summer and with antifreeze in winter. And the volume of liquids contained is 15L, the replacement period of liquids is 2-3 months.

Metal Laser Welding Machine for Sale

Ranging from entry-level handheld laser welding guns to automatic laser welding systems with CNC controller, as well as professional 3D laser welding robot. All types of laser beam welders available in IGOLDEN with powers of 1000W, 2000W and 3000W for machinists.

Three-in-one laser welder

The advanced version of laser welder is the three-in-one laser welder, as its name suggests, it has multifunctions of of welding, cleaning and cutting. Its welding function is the same as that of a normal laser welder. And it could be easily to changed into the cutting pattern by the change of nozzle, when it is converted into the pattern of cutting, it could only cut some extra and useless pieces of the material edges with less precision and worse effect than normal fiber laser cutters. If it is applied in cleaning, cleaning head and special focusing lens for laser cleaner should be installed. It is easy and convenient in operation and alteration of patterns.

Metal Laser Welding Machine Features

Laser Source:

Metal laser welding machines use a laser source, typically a solid-state laser, to generate the laser beam. Common types of lasers used include fiber lasers, Nd:YAG lasers, and disk lasers. These lasers provide high power and excellent beam quality for precise and controlled welding.

Welding Process:

Metal laser welding involves focusing the laser beam onto the joint or area to be welded. The laser beam rapidly heats and melts the metal surfaces, creating a localized molten pool. Upon cooling, the molten metal solidifies, resulting in a strong and durable weld joint. The process can be performed in continuous wave (CW) mode or pulsed mode, depending on the application requirements.

Non-contact Welding:

Laser welding is a non-contact welding process, meaning the laser beam does not physically touch the workpiece. This eliminates the need for mechanical force or contact between the welding tool and the material, reducing the risk of contamination or damage to the welded parts.

Materials:

Metal laser welding machines can be used to weld a wide range of metals and alloys, including stainless steel, carbon steel, aluminum, titanium, copper, brass, and various other alloys. They are particularly effective for welding thin sheets or components with high precision and minimal distortion.

Speed and Efficiency:

Laser welding is a fast and efficient welding method. The concentrated energy of the laser beam results in rapid heating and cooling rates, allowing for high welding speeds. This contributes to increased productivity and reduced production time compared to traditional welding techniques.

Precision and Control:

Metal laser welding machines offer high precision and control over the welding process. The laser beam can be accurately focused and directed to the desired welding area, allowing for precise positioning and control of the heat input. This enables the welding of intricate or complex geometries with minimal damage to the surrounding material.

Versatility:

Metal laser welding machines are versatile and can be used for various welding applications. They can perform spot welding, seam welding, overlap welding, and even 3D welding of complex components. Laser welding can also be combined with other processes, such as laser cutting or laser marking, to create integrated manufacturing solutions.

Automation and Integration:

Metal laser welding machines can be integrated into automated production lines or robotic systems for increased productivity and consistency. They can be equipped with vision systems and sensors to aid in precise positioning and quality control.

Metal Laser Welding Machine Advantages

The laser welder has varieties of advantages and they will be explained in detail. Laser welder could be used in a wide range , it works well no matter in outdoor or from long distance. And the machine can be used flexibly and conveniently in various working occasions. Besides, there are many welding methods offered for users to choose, stitch welding, butt welding, vertical welding, flat fillet weld, inside corner weld and outside corner weld, and it has free switching of welding and cutting, users only need to change a welding nozzle to a cutting nozzle. The welding effect is good because of small heat affected zone, hard to deform and blacken, welding deeply, full melting, compact and firm structure, high weld strength.

There is no need to polish welding joint for it adopts continuous welding, the surface of welded part is smooth and well-done with no perlage and few subsequent polishing procedure. Little consumable material needed in welding process to save the costs of material. This machine is equipped with safety alarms. The nozzle works only when it touches metals and automatically stops outputting laser once the working parts moved from the platform, and the tact switch has the function of temperature sensing. Therefore, this machine has a high safety level. Last but not the least, laser welder is labor-saving for it could be operated by workers who only have short-term training. In a nutshell, the laser-welder is friendly to both owner and user with advantages of time saving, labor saving and cost saving.

How does laser welding work?

Welding by laser beam is basically very simple: Two precisely cut sheets are held together. The laser melts the edges of the sheet metal. The melt flows into each other – and the joint is complete.

Quality assurance in laser beam welding

Laser beam welding is a non-contact joining process. It is always carried out automatically. Modern laser beam welding systems are equipped with an integrated measuring system, which independently checks the dimensions of the manufactured component. This makes these systems particularly precise, which is the basis for guaranteeing constant quality.

Costs for a laser beam welding system

The costs are still the biggest disadvantage of these innovative processes. It depends strongly on what and which material is to be processed with the laser welding system. Even simple micro systems used, for example, for engraving wedding rings can cost several thousand euros. Brand-new high-performance plants rarely cost less than 100,000 euros, rather more. These expenses are offset by excellent manufacturing quality and high productivity. In fact, laser welding is usually carried out at a much higher speed than conventional electric or inert gas welding processes.

What speed is possible with laser welding?

In addition to precision and low heat input, the working speed is one of the outstanding properties of laser welding. Under ideal conditions, a long, straight endless seam can be welded at a speed of up to 60 m/minute. Since the intensity of the laser beam can be varied, the impact of the material used is less decisive for the working speed of a laser welding system. Even thick sheets can be precisely joined in a matter of seconds.

Types of laser welding

Laser welding is a versatile, low cost way of achieving high quality spot welds for different materials and thicknesses. It results across a wide range of materials. There are three common types, including CO2, YAG and fiber laser welders. There are high-power welders for large-format and thick sheets, and low-power welders for small-size parts. There are welders for metals and non-metallic materials such as plastics and ceramics.

Different methods can be classified as follows:

• Welds between slices. Including butt welds, end welds, center penetration fusion welds, and center perforation fusion welds.

• Wire and wire welds. Including wire-to-wire butt welds, cross welds, parallel lap welds, and T-type welds.

• Welds of metal wires and block components. It can successfully realize the connection between the metal wire and the block element, and the size of the block element can be arbitrary. Attention should be paid to the geometric dimensions of the wire-like components during welding.

• Welds of different metals. Welds different types of metals must solve the range of weldability parameters. The welding between different materials is only possible with certain material combinations.

0 notes

Text

Deformable mirror technology takes laser welding and 3D printing to new heights

Yongcui Mi has developed a new technology that enables real-time shaping and control of laser beams for laser welding and directed energy deposition using laser and wire. The innovation is based on the same mirror technology used in advanced telescopes for astronomy. In a few years, this new technology could lead to more efficient and reliable ways of using high-power lasers for welding and directed energy deposition with laser and wire. The manufacturing industry could benefit from new opportunities to build more robust processes that meet stringent quality standards. "We are the first to use deformable mirror technology for this application. The mirror optics can handle multi-kilowatt laser power, and with the help of computer vision and AI, the laser beam can be shaped in real time to adapt to variations in joint gaps," explains Yongcui, a newly minted Ph.D. in Production technology from University West.

Read more.

9 notes

·

View notes