#fiber laser welding machine

Explore tagged Tumblr posts

Text

A Continuous Fiber Laser Welding Machine's Functions

Metal materials like copper and aluminum can be welded with a continuous fiber laser welding machine. For welding stability, the fuselage uses a high-strength gantry bed structure design. With its higher photoelectric conversion efficiency, lower power consumption, and higher beam quality, the current advanced continuous laser is chosen as the light source.

Benefits of the fiber laser apparatus include its small size, convenient use, and compact structure. Welding equipment can be efficiently integrated with other equipment in the system thanks to its versatile laser output mode. High speed and precision are ensured by the highly responsive servo motor output, which works with the high-precision and high-strength screw linear module as the operating transmission mechanism.

In the field of new energy lithium battery PACK modules, this makes the laser welding machine an essential piece of equipment. With its outstanding beam quality, quick welding speed, and gorgeous, sturdy welding pool, the continuous fiber laser welding machine offers the ideal, stable, and effective welding solution for the lithium battery welding process.

Unlocking the Advantages: Your Guide to the Equipment's Benefits

Perfect welding: Easy adjustment, fine focusing, imported optical lenses, high-precision laser welding head.

High-quality fiber laser: Internationally recognized, with years of industrial application, a long lifespan, and no maintenance required.

Energy efficiency: Low power consumption, high electro-optic conversion efficiency, and excellent beam quality.

Adjustable power: A continuous 2000-watt (adjustable) pure fiber laser that can penetrate materials with depths ranging from 0.1-3 mm.

Precision control: A precise servo system ensures welding accuracy.

User-friendly interface: Easy-to-learn PC industrial computer with a welding CNC programming system.

Wide range capabilities: large surface stroke welding, a gantry frame motion structure, high machine tool precision, and a stable, long-lasting service life.

Enhanced functionality: Data-saving call functions, strong drawing and editing graphics capabilities, and compatibility with a range of input formats.

Exploring Equipment Indicators and Parameters: Key Features

This welding equipment offers a range of features that make it versatile and reliable for various applications:

Material Compatibility: Welds materials with thicknesses ranging from 0.5 mm to 2.0 mm, suitable for diverse projects.

Workspace Flexibility: Effective travel range spans 870 mm in the X-axis and 600 mm in object workpiece height.

Adjustable Welding Speed: Operates at speeds of up to 10 mm/s, ensuring welds meet specific requirements.

Power Options: Offers adjustable laser power levels, including 2 KW, 3 KW, and 6 KW.

Durability: Features an optical fiber working medium with a service life exceeding five years.

Material Versatility: Suitable for welding nickel strips, copper sheets, and aluminum rows.

Welding Modes: Offers both continuous and pulse modes for versatile welding processes.

Spot Welding Capabilities: Achieves contact surface melting depths ranging from 0.5 mm to 1 mm, ensuring strong welds with tensile strength exceeding material destructive strength.

Characteristics of the Equipment

This welding equipment offers advantageous features for a seamless and efficient welding experience:

Maintenance-Free Operation: Reduces downtime and maintenance costs.

Adjustable Parameters: Allows for easy modification of welding parameters, including motion speed.

Fault Alerts: Real-time fault alarm prompts for immediate issue resolution.

Flexible Operation: Offers automatic and manual operation modes, supporting arc and straight-line interpolation.

Laser Processing: Enables the creation of various plane graphics such as points, straight lines, circles, and squares.

Durable Components: Equipped with imported lenses in the welding field mirror to withstand high laser-generated temperatures.

User-Friendly System: Easy-to-learn operating system simplifies manual operation.

Smoke and Slag Control: Built-in air-blown wind knife ensures welding quality.

Cooling System: A water-cooled cycle in the welding head ensures stable welding effects.

Precision Mechanism: High-precision screw transmission and high-speed servo motors ensure accuracy and responsiveness.

Environmental Conditions

To ensure optimal performance and safety, adhere to these specifications for the operating environment:

Ambient Temperature: Operates effectively between 5°C and 35°C.

Humidity: Maintain relative humidity levels between 20% and 90% to prevent condensation and corrosion.

Air Source Pressure: Requires a compressed air source with a pressure range of 0.5 to 0.6 Mpa.

Power Supply Voltage: A stable voltage of 380V at 50Hz or 60Hz is required.

Total Power: Consumes ≤10KW of power to prevent electrical overloading.

Load-Bearing Capacity: The installation area must support up to 500 kg/m².

Grounding Type: Direct grounding ensures safety and minimizes electrical hazards.

Installation Environment: Requires a flat, vibration-free, and shock-free area for precise and stable operations.

Adhering to these specifications ensures reliable operation, extending the equipment’s service life while preventing potential issues related to environmental conditions.

Final Thoughts

The continuous fiber laser welding machine represents a revolutionary step forward in welding technology. Its ability to deliver precise, efficient, and versatile welding solutions makes it an essential tool across industries, including automotive, aerospace, and renewable energy. By understanding its functions, benefits, and operational requirements, manufacturers can fully leverage this equipment to enhance productivity, reduce costs, and achieve superior product quality.

Investing in a continuous fiber laser welding machine is not just about adopting advanced technology—it's about future-proofing your manufacturing processes for the demands of tomorrow.

#Fiber Laser Welding Machine#Fiber Laser Welding Technology#High-Precision Welding Machines#Laser Welding for Copper and Aluminum#Industrial Laser Welding Equipment#Applications of Fiber Laser Welding#High-Strength Welding Equipment#Lithium Battery PACK Welding Solutions#Laser Welding for Automotive Manufacturing#Spot Welding vs. Continuous Laser Welding

0 notes

Text

Fiber Laser Welding Machine

Within the domain of present day fabricating, advancement is the driving drive behind advance. At the bleeding edge of this development is the momentous innovation of fiber laser welding machine. In this web journal post, we set out on a travel to reveal the boundless potential of fiber laser welding machines and their transformative affect on differing businesses.

Fiber laser welding machines epitomize exactness building at its finest. Utilizing progressed fiber optic innovation, these machines emanate a concentrated laser bar competent of unpredictably intertwining materials with unparalleled precision. Not at all like customary welding strategies, fiber laser welding minimizes warm mutilation, coming about in perfect welds with negligible affect on encompassing materials.

One of the foremost exceptional perspectives of fiber laser welding machines is their flexibility. From aviation components to therapeutic gadgets, these machines can consistently weld an cluster of materials, counting metals, combinations, and indeed different materials. This flexibility opens entryways to a horde of applications, engaging producers to thrust the boundaries of what's conceivable.

Speed and proficiency are too trademarks of fiber laser welding innovation. With lightning-fast handling speeds and fast bar conveyance, these machines can total welding assignments in a division of the time compared to conventional strategies. This quickened generation not as it were boosts effectiveness but moreover decreases costs, making fiber laser welding an alluring choice for forward-thinking producers.

Moreover, fiber laser welding machines exceed expectations in creating welds of extraordinary quality and quality. The exact control advertised by these machines guarantees steady comes about, indeed within the most requesting applications. Whether it's making complex components for car motors or creating fragile therapeutic inserts, fiber laser welding machines provide unmatched execution and unwavering quality.

Besides, the integration of mechanization and mechanical autonomy encourage upgrades the capabilities of fiber laser welding machines. Progressed control frameworks and automated arms streamline the welding process, expanding efficiency whereas minimizing human blunder. This marriage of innovation and mechanization moves fabricating into a unused time of proficiency and exactness.

As we see to long run, the potential of fiber laser welding machines knows no bounds. From opening unused conceivable outcomes in plan and building to revolutionizing whole businesses, these machines are reshaping the scene of cutting edge fabricating. With their unparalleled accuracy, speed, and flexibility, fiber laser welding machines are breaking boundaries and clearing the way for a future constrained as it were by creative ability.

1 note

·

View note

Text

How to choose metal Laser Welding Machines for metal industries?

Choosing the right metal laser welding machine for metal industries involves considering several key factors to ensure it meets your specific requirements and production needs.

Here’s a guide to help you make an informed decision:

1. Material Compatibility:

- Ensure the laser welding machine is suitable for the types of metals you work with. Different machines may be designed for specific materials, so choose one that accommodates the range of metals you commonly use.

2. Power and Pulse Duration:

- Consider the power and pulse duration of the laser source. Higher power allows for deeper penetration, while shorter pulse durations are suitable for delicate and precise welding. Select a machine with the appropriate power and pulse duration for your applications.

3. Welding Speed and Productivity:

- Evaluate the machine’s welding speed and overall productivity. Faster welding speeds can increase efficiency, but it’s essential to balance speed with the quality of the weld. Look for a machine that meets your production goals without compromising weld integrity.

4. Precision and Accuracy:

- Assess the precision and accuracy of the laser welding machine. This is crucial for applications that require fine details and tight tolerances. High precision is particularly important in industries like electronics or medical devices.

5. Ease of Use and Automation:

- Consider the user-friendliness of the machine. Look for features like intuitive controls, easy setup, and programming capabilities. Additionally, assess the potential for automation, as automated laser welding systems can enhance efficiency and consistency in production.

6. Cooling System:

- Laser welding generates heat, so an efficient cooling system is essential to maintain the machine’s performance and prevent overheating. Check the cooling capacity and whether the machine has built-in cooling mechanisms.

7. Maintenance and Serviceability:

- Evaluate the ease of maintenance and the availability of service and support. Choose a machine from a reputable manufacturer with a good track record for reliability and customer support.

8. Cost Considerations:

- Assess the initial cost as well as long-term operating costs, including consumables and maintenance. While it’s tempting to opt for the lowest upfront cost, consider the overall value and return on investment based on your production needs.

9. Safety Features:

- Ensure the laser welding machine complies with safety standards and incorporates necessary safety features. This includes features like enclosures, interlocks, and proper ventilation to protect operators from laser radiation and other potential hazards.

10. Supplier Reputation:

- Choose a reputable and reliable supplier or manufacturer. Look for reviews, testimonials, and the company’s track record in delivering quality laser welding machines. A reliable supplier can provide ongoing support and ensure that you get the most out of your investment.

By carefully considering these factors, you can select a metal laser welding machine that aligns with your specific requirements and contributes to the success of your metal industry operations.

0 notes

Text

Interested parties plus WhatsApp:+86 19975134656

0 notes

Link

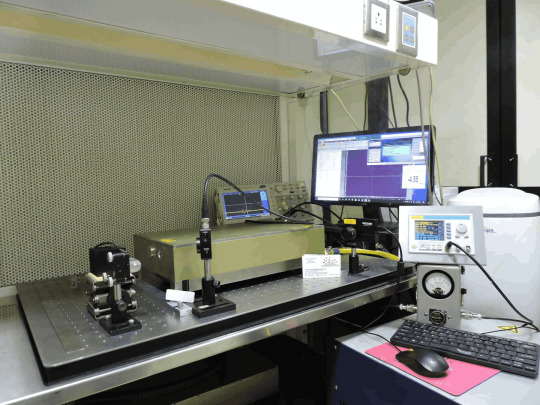

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion MegaWatt Lasers QPC Lasers Amplitude Lasers (Continuum), PhotoScribe Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

Intelligent Robotic Cutting Machines !

Robotic cutting technology has transformed manufacturing, bringing unrivaled precision, efficiency and quality control to the process of cutting and trimming raw materials. Cutting a sample for a customer during a recent live demonstration highlights the huge potential for innovation and new ways of manufacturing with Intelligent Cutting.

The intelligent robot, with its advanced cutting tools and 3D scanning capabilities, was able to complete the complex cutting process with ease and accuracy. The main demonstration of the robot's flexibility and high precision showed the customer how it can adapt to a wide range of materials and handle a variety of cutting jobs, fully cutting everything from tubes and square plates to a wide range of irregular metal materials.

The robots have partners such as Fanuc, ABB, and Exton, and real-time monitoring and analysis software is one of the standout features. With these tools, the user can track and control the entire cutting process from start to finish and make adjustments as needed for optimal cut quality and maximum work efficiency.

Overall, this demonstration showcased the incredible versatility, precision, and efficiency of robotic cutting technology in manufacturing. We believe this technology has great potential to reduce waste, improve quality and increase production, leading to more sustainable, innovative and profitable businesses.

#laser cutting machine#intelligent robot#robotic laser cutting#robotic welding#robotic cleaning#robotic laser cutting machine#fiber laser cutting#intelligent robot fiber laser cutting machine

0 notes

Text

How to Choose India's Top Manufacturers of Robotic Welding Machines

The modern industrial environment demands automation, efficiency, and precision more than ever. Robotic welding robots, which offer unmatched accuracy and speed in welding processes, have completely changed the manufacturing industry. Selecting the best robotic welding machine manufacturers in India is essential for companies trying to stay competitive. The most important things to take into account when choosing the ideal manufacturer for your requirements are covered in this article.

Recognizing the Value of Robotic Welding

Modern production relies heavily on robotic welding equipment, especially in industries like heavy machinery, aerospace, and automotive. By automating tedious operations, these devices improve worker safety, provide uniform weld quality, and cut down on material waste. The number of firms providing robotic welding solutions is growing along with the demand for these products. But not every manufacturer offers the same caliber of innovation, service, and quality.

Important Things to Think About When Selecting a Manufacturer

1. Credibility and Background

A manufacturer's experience and reputation are important determinants of its dependability. Reputable manufacturers with a track record of success are more likely to offer dependable after-sales support and top-notch equipment. Examine case studies, testimonials, and reviews from customers to determine the manufacturer's reputation in the market.

For example, Weldarc India has established a strong name in the Indian market thanks to its state-of-the-art fiber laser cutting machines. With years of experience and a wide range of products, companies like these frequently have the know-how to customize robotic welding systems to meet the demands of particular industries.

2. Innovation in Technology

With ongoing developments in automation, artificial intelligence, and precision welding methods, the field of robotic welding is expanding quickly. Research and development (R&D)-focused manufacturers are more likely to present creative solutions that can boost your manufacturing efficiency.

Seek out suppliers of robotic welding equipment with the newest technology available, such as real-time monitoring, adaptive control systems, and smooth connection with other automation systems. This technical advantage may completely alter the way that businesses compete in the marketplace.

3. Customization Abilities

When it comes to welding operations, every business has different needs. A one-size-fits-all strategy might not work. Prominent producers provide customization choices so that robotic welding robots can be customized to meet certain requirements. Modifiable features like software integration, specific welding heads, and machine size adjustments guarantee that the machine will work flawlessly as part of your production line.

Weldarc India, for instance, demonstrates their capacity to meet a variety of industrial needs by not only manufacturing fiber laser cutting machines but also providing a range of welding goods. It is important to have this flexibility when choosing a manufacturer.

4. After-Sale Assistance and Maintenance

Investing heavily in a robotic welding system requires constant support to keep it operating properly. Take into account the post-purchase services offered by the manufacturer, such as installation, training, upkeep, and repair. Reducing downtime and sustaining productivity can be greatly aided by having a readily available supply of spare parts and a customer support team that responds quickly.

It is better to engage with manufacturers who have a significant presence in India, such as those who provide extensive service networks. This local presence guarantees that you won't have to wait a long time to receive the assistance you require.

5. Economy of Cost

Even if it plays a big role, cost shouldn't be the only thing taken into account. Sometimes the best value isn't necessarily found in the cheapest alternative. Rather, concentrate on the machine's total cost-effectiveness, taking into account aspects like durability, energy efficiency, and the possibility of long-term savings through lower maintenance and higher output.

Examine the total cost of ownership for various manufacturers, accounting for the machine's anticipated lifespan, running expenses, and original investment. If a somewhat greater initial cost results in cheaper operating costs and a longer equipment life, then it might be justified.

6. Adherence to Industry Standards

Robotic welding equipment has to abide by strict industry norms and guidelines, especially when it comes to quality and safety. Verify that the manufacturer satisfies all applicable regulatory standards, including ISO certifications. This compliance protects the safety of your operations in addition to the machine's quality.

Long-term investment protection is ensured by manufacturers who adhere to the most recent industry standards and are more likely to produce machines that satisfy present and future regulatory needs.

Know more: Fiber Laser Cutting Machine manufacturer

The Function of Manufacturers of Fiber Laser Cutting Equipment in Robotic Welding

In modern manufacturing, robotic welding is frequently combined with fiber laser cutting technologies. Prominent producers such as Weldarc India provide a complete solution for your production demands by offering both robotic welding systems and fiber laser cutting machines. Higher precision and efficiency may be achieved by combining these technologies, thus it's critical to take into account suppliers who have experience in both fields.

In summary

Selecting the best robotic welding machine manufacturer in India necessitates carefully weighing several criteria, including reputation, cost-effectiveness, industry standards compliance, technical innovation, customization possibilities, and after-sales support. Manufacturers with experience in cutting and welding technologies, such as Weldarc India, provide a dependable choice for companies wishing to improve their manufacturing capacities.

You can be sure that the manufacturer you choose will not only satisfy your present requirements but also foster your future expansion and creativity in the cutthroat manufacturing market by concentrating on these important factors.

#Robotic Welding Machine Manufacturers India#Fiber Laser Cutting Machine manufacturer#welding products manufacturer in India#Welding Machine manufacturer in India#robotic welding systems#welding automation#industrial welding machines#laser welding machines#automated welding solutions#welding technology in India

0 notes

Text

How to Optimize Materials with 20kW CNC Fiber Laser Cutting Machine

Using a 20kW CNC fiber laser cutting machine to optimize materials for optimal efficiency is important to producing accurate and superior outcomes. Operators will improve cutting efficiency and reduce problems like burrs and dross development by choosing the proper material qualities, like thickness, conductivity, and reflectivity. By ensuring that the laser energy is efficiently absorbed and used, optimizing the materials will result in higher cutting rates and lower manufacturing costs.

Improving the materials used for a 20kW CNC fiber laser cutting machine is important to raising the general effectiveness and caliber of the cutting operation. Through careful selection of materials consistent with their unique qualities and attributes, operators will minimize waste and mistakes while achieving excellent outcomes. To completely utilize the laser cutting machine's potential and lift industrial productivity as an entire, material optimization must be a top priority. By putting the recommendations and techniques covered in this article into practice, readers will surely be ready to increase the accuracy and efficiency of their laser-cutting procedures.

Choosing the Proper Materials

To get the simplest results from laser cutting, the proper materials must be used. Selecting materials for a 20kW CNC fiber laser cutting machine that will tolerate the laser beam's high power and intensity is crucial. Because they cut well and precisely, materials, including steel, aluminum, and chrome steel, are frequently utilized.

Due to differences in their composition and characteristics, many materials answer laser cutting in several ways. For instance, because they're more reflective than steel, metals like copper and brass have to be used at higher power levels. It is important to switch the facility, speed, and focus of the laser cutting device appropriately to ensure precise cuts and stop problems like burrs or material deformation.

Test cuts on sample materials should be performed to seek out the simplest settings for every sort of material to maximize the cutting process. Operators can attain greater cutting quality and efficiency by adjusting settings that are consistent with the fabric being utilized. Additionally, to ensure consistent performance while handling various materials, frequent calibration and adequate maintenance of the laser cutting equipment are necessary.

Optimizing Cutting Parameters

Optimizing cutting parameters, including power, focus, and speed, is important to maximizing cutting process efficiency. You'll improve the cut's overall quality, hamper production time, and increase cutting performance by tweaking these settings. Power governs the cutting action's intensity, speed decides how quickly the fabric is cut, and concentration manages the cut's accuracy. For best outcomes, these parameters with a CNC laser welding machine manufacturer in India must be adjusted by the actual needs of the fabric being processed.

Optimizing cutting parameters requires taking the type of fabric to be rigged into account. The qualities of various materials influence the simplest cutting conditions. For example, hard materials like metals can need higher power settings and slower speeds to make clean cuts. In contrast, softer materials like plastics might enjoy quicker speeds and lower power levels. Efficient cutting could also be achieved by modifying the cutting settings consistent with the hardness, thickness, and composition of the fabric.

It is impossible to overestimate the influence of varied cutting factors on the ultimate product's quality and overall effectiveness. Inaccurate settings can save time and money by causing problems like material deformation, uneven edges, or unfinished cuts. You'll maximize manufacturing productivity, reduce material waste, and acquire exact cuts by carefully adjusting cutting settings. To maximize productivity and uphold high standards for cutting quality, it's essential to periodically check and modify the cutting settings in accordance with the characteristics of the fabric and, therefore, the intended results.

Maximizing Efficiency and Minimizing Waste

To realize maximum production throughout the laser cutting process, efficiency must be optimized. Nesting software, which places pieces closer together to scale back material waste, is an efficient technique. A method to save lots of time and resources is to carefully organize the location of pieces on the fabric so that there's less scrap and more components produced from one sheet. You can easily have the option to buy a 6kw laser cutting machine.

If it's feasible, believe in automating the cutting process to extend efficiency even further. Automation guarantees uniform quality, expedites production, and lowers human error. Purchasing contemporary laser cutting equipment with cutting-edge features like material management systems and automatic nozzle changes will greatly increase productivity and efficiency.

In a 20kw CNC fiber Laser Cutting Machine, it's crucial to optimize material utilization and reduce waste, as well as maximize efficiency. You'll minimize waste and save production expenses by precisely estimating the quantity of fabric needed for every task and strategically scheduling cuts. A corporation will become more economical and sustainable by implementing a waste management system to collect and recycle unwanted resources.

Conclusion

Material optimization is a crucial aspect to think about if you would like your laser cutting operations to be optimized. Readers will maximize the performance of their 20kW CNC fiber laser cutting equipment by being consistent with the instructions provided in this blog article. Adopting material optimization improves final product quality, expedites manufacturing processes, and lowers operating expenses.

#buy laser welding machine in India#laser sheet cutting machine#20kw cnc fiber Laser Cutting Machine

0 notes

Text

Custom-made welding Machines by Leading Fiber Laser Manufacturer

Weldarc India stands as the leading fiber laser cutting machine manufacturer in India, specializing in custom-made welding machines designed to meet unique industrial requirements. Our advanced technology and precision engineering ensure high-quality, efficient solutions tailored to your specific needs. Focusing on innovation and customer satisfaction, we provide durable and reliable machines that enhance productivity and performance. Partner with Weldarc India for customized welding solutions that set new standards in the industry, ensuring your business stays ahead in the competitive market. Experience excellence with our custom manufacturing services.

#Fiber Laser Cutting Machine#Custom Welding Machines#Welding Machine Manufacturer#Industrial Welding Solutions#Welding Equipment India#Welding Automation#Laser Cutting Technology#Bespoke Welding Machines#Precision Engineering#Weldarc India

0 notes

Text

fiber laser welding machine manufacturer in pune

Welcome to Angel India, your premier destination for advanced fiber laser welding solutions in Pune. As a pioneering fiber laser welding machine manufacturer in Pune, we specialize in delivering cutting-edge technology that ensures precision, efficiency, and reliability in every weld.

At Angel India, we leverage our years of expertise and state-of-the-art facilities to cater to diverse industrial needs. Whether you require high-speed welding for automotive components or intricate welding for electronics, our fiber laser machines are designed to meet the most demanding requirements. Our commitment to innovation drives us to constantly refine and enhance our products, ensuring they exceed industry standards.

0 notes

Text

https://ceslasermachine.com/

A fiber laser cutting machine is a high-accuracy tool used for cutting different kinds of materials such as metals, plastics, and composites. It uses a fiber laser, which produces a laser beam with high power density through optical fibers. This beam is focused on the material to be cut, resulting in rapid heating, melting, and vaporization, allowing for accurate and efficient cutting with little thermal distortion.

#ces laser marking machine#automatic laser welding machine manufacturers#ces machine ahmedabad#ces laser machine#Fiber Laser Cutting Machine#automatic laser welding machine#double laser cuttin#laser welding machine manufacturers#double laser cutting machine exporter#single pallet laser cutting machine manufacturer

0 notes

Text

Environmental Benefits of Laser Welding Machines in Indian Manufacturing

In recent years, the manufacturing landscape in India has seen significant advancements. One of the most notable innovations is the adoption of laser welding machines. These machines are not only efficient but also environmentally friendly. In this blog, we will explore the environmental benefits of laser welding machines in India and why they matter for the future of manufacturing.

1. Reduced Energy Consumption

Laser welding equipment is designed to be energy efficient. They use a focused beam of light to join materials, requiring significantly less energy than traditional welding methods like MIG and TIG. This reduced energy consumption leads to lower operational costs and a smaller carbon footprint for manufacturers. In a world where energy conservation is crucial, this advantage must be noticed.

2. Minimal Material Waste

One of the standout features of laser welding machines is their precision. The focused laser beam creates accurate welds, which minimizes the amount of material wasted during the process. Traditional welding methods often require filler materials, leading to more waste and higher material consumption. By reducing waste, laser welding machines in India contribute to resource efficiency and support sustainable manufacturing practices.

3. Lower Emissions

Laser welding equipment produces far fewer emissions compared to conventional welding techniques. Traditional methods often involve the use of gases and fluxes that can release harmful pollutants into the atmosphere. In contrast, laser welding is a cleaner process, emitting significantly lower levels of harmful gases. This reduction in emissions is vital for improving air quality and protecting the environment.

4. Enhanced Safety

Safety is a critical concern in manufacturing. Laser welding machines operate with less risk of accidents compared to traditional methods that involve open flames or high electrical currents. This not only protects workers but also reduces the potential for hazardous emissions. A safer work environment is essential for promoting sustainable practices in manufacturing.

5. Versatility Across Materials

Laser welding machines in India can handle a wide range of materials, including metals and plastics. This versatility allows manufacturers to optimize processes and reduce the need for multiple machines. By streamlining operations, companies can further decrease their environmental impact while maintaining high-quality standards.

6. Contribution to Sustainability Goals

As industries strive to meet sustainability goals, adopting laser welding equipment can be a significant step forward. The combination of reduced energy consumption, minimal waste, and lower emissions aligns with the objectives of many manufacturers aiming for eco-friendly practices. By investing in laser welding, companies can enhance their reputation as environmentally responsible businesses.

Conclusion

The environmental benefits of laser welding machines are clear. They offer reduced energy consumption, minimal material waste, and lower emissions, all while providing a safer and more versatile manufacturing solution. As Indian industries continue to evolve, embracing laser welding machines in India can lead to a more sustainable future. By prioritizing eco-friendly practices, manufacturers can contribute to a healthier planet while also improving their operational efficiency.

For those interested in expanding their capabilities, partnering with a reputable battery manufacturing equipment supplier in India can help integrate advanced technologies like laser welding into their operations. This collaboration can further enhance productivity and sustainability in the manufacturing sector.

#laser welding machine#laser welding machines in India#laser welding equipment#fiber laser welding machine#battery manufacturing equipment#battery manufacturing equipment supplier#lithium ion battery manufacturing equipment#lithium ion battery manufacturing equipment supplier

0 notes

Text

Fiber Laser Welding Machines

As industries continue to push the boundaries of innovation, the demand for advanced manufacturing technologies has never been greater. One such technology that has gained significant traction is the fiber laser welding machines. Known for its precision and efficiency, fiber laser welding is reshaping how industries approach welding tasks, offering a host of benefits that traditional methods cannot match.

What Sets Fiber Laser Welding Machines Apart?

Fiber laser welding machines utilize a fiber optic laser to produce a high-intensity beam capable of welding materials with extreme precision. Unlike conventional welding techniques that rely on heat from an electric arc or gas flame, fiber laser welding directs energy precisely where it’s needed, resulting in cleaner, stronger welds.

Key Advantages of Fiber Laser Welding Machines

Exceptional Speed and Accuracy

Fiber laser welding machines are incredibly fast, completing welds in a fraction of the time compared to traditional methods. This speed does not come at the expense of accuracy; the laser’s precision ensures that even the most intricate welds are executed flawlessly, making it ideal for high-precision industries. Enhanced Material Compatibility

These machines are versatile enough to weld a wide array of materials, including various metals and alloys. Whether you’re working with stainless steel, aluminum, copper, or titanium, fiber laser welding can handle the job with ease, offering strong, durable welds that meet industry standards.

Reduced Thermal Distortion

One of the significant challenges in welding is managing heat distortion, which can compromise the integrity of the materials being welded. Fiber laser welding minimizes this risk by focusing heat on a very narrow area, reducing the thermal distortion and preserving the original properties of the materials. Eco-Friendly Welding Solution

Fiber laser welding is an environmentally friendly option due to its energy efficiency and reduced need for consumables like welding rods or gases. The process itself generates minimal waste, contributing to more sustainable manufacturing practices.

Ease of Automation

The adaptability of fiber laser welding machines makes them perfect for automated production lines. Their ability to be integrated with robotic systems allows for continuous, high-speed production with minimal human intervention, leading to lower labor costs and increased throughput.

Diverse Applications Across Industries

Fiber laser welding machines are revolutionizing various sectors by providing reliable and efficient welding solutions:

Aerospace: Critical for welding high-strength, lightweight components that require precise joints.

Automotive: Used extensively for welding car parts, including batteries, sensors, and structural components, where strength and durability are paramount.

Electronics: Essential for micro-welding tasks, such as assembling circuit boards, connectors, and other delicate components.

Jewelry: Provides the fine control needed for intricate designs and delicate metalwork.

Innovations on the Horizon

The future of fiber laser welding is bright, with ongoing research and development focusing on further enhancing this technology:

Hybrid Welding Systems: Combining fiber laser welding with other welding techniques to achieve superior results for specialized applications.

Real-Time Process Monitoring: Advanced sensors and AI-driven systems that provide real-time feedback during the welding process, ensuring perfect welds every time.

Portable Fiber Laser Welding Machines: Development of compact, portable units for on-site welding in remote or challenging environments.

Conclusion

Fiber laser welding machines represent a significant leap forward in welding technology, offering unmatched precision, speed, and versatility. As industries continue to demand higher standards of quality and efficiency, fiber laser welding will undoubtedly play a crucial role in meeting these expectations.

By investing in fiber laser welding technology, manufacturers can ensure they remain at the forefront of innovation, delivering superior products while optimizing production processes. The future of welding is here, and it’s powered by fiber lasers.

0 notes

Video

youtube

fiber laser welding handheld machine for stainless steel wires

0 notes

Text

Intelligent Robotic Cutting Machines

Robotic cutting technology has transformed manufacturing, bringing unrivaled precision, efficiency and quality control to the process of cutting and trimming raw materials. Cutting a sample for a customer during a recent live demonstration highlights the huge potential for innovation and new ways of manufacturing with Intelligent Cutting.

The intelligent robot, with its advanced cutting tools and 3D scanning capabilities, was able to complete the complex cutting process with ease and accuracy. The main demonstration of the robot's flexibility and high precision showed the customer how it can adapt to a wide range of materials and handle a variety of cutting jobs, fully cutting everything from tubes and square plates to a wide range of irregular metal materials.

The robots have partners such as Fanuc, ABB, and Exton, and real-time monitoring and analysis software is one of the standout features. With these tools, the user can track and control the entire cutting process from start to finish and make adjustments as needed for optimal cut quality and maximum work efficiency.

Overall, this demonstration showcased the incredible versatility, precision, and efficiency of robotic cutting technology in manufacturing. We believe this technology has great potential to reduce waste, improve quality and increase production, leading to more sustainable, innovative and profitable businesses.

#laser cutting machine#intelligent robot#robotic laser cutting#robotic welding#robotic cleaning#robotic laser cutting machine#fiber laser cutting#intelligent robot fiber laser cutting machine

0 notes

Text

A Review of the Best Robotic Welding Machine Manufacturers in India

In the rapidly evolving manufacturing landscape, robotic welding machines have emerged as a critical component for industries aiming to enhance productivity, precision, and safety. As automation continues to drive the future of welding, several companies in India have positioned themselves as leaders in developing and manufacturing robotic welding systems. This review delves into India's top robotic welding machine manufacturers India, offering insights into their offerings, innovations, and contributions to the industry.

The Rise of Robotic Welding in India

Robotic welding machines, also known as automated welding systems, are revolutionizing the manufacturing sector by enabling consistent and high-quality welds with minimal human intervention. These machines are equipped with advanced robotics technology, allowing them to perform complex welding tasks with precision and speed. The demand for robotic welding systems in India has surged, driven by the need for efficiency, reduced labor costs, and enhanced safety in industrial operations.

Key Factors to Consider When Choosing a Robotic Welding Machine Manufacturer

Before diving into the list of top manufacturers, it's essential to understand the key factors that set these companies apart:

Technology and Innovation: The best manufacturers invest heavily in research and development to stay at the forefront of technological advancements. This includes incorporating AI, machine learning, and IoT into their robotic welding systems.

Product Range: A diverse product portfolio indicates a manufacturer's ability to cater to various industries and welding needs, from automotive to heavy machinery.

Customization and Flexibility: Leading manufacturers offer customizable solutions that can be tailored to specific production requirements, ensuring optimal performance and integration into existing workflows.

After-Sales Support and Service: Robust after-sales support, including training, maintenance, and spare parts availability, is crucial for ensuring the long-term success of robotic welding systems.

Top Robotic Welding Machine Manufacturers in India

1. Weldarc India

Weldarc India has established itself as a prominent player in the Indian welding industry, particularly in the realm of fiber laser cutting and welding machines. Their robotic welding machines are known for their precision, reliability, and adaptability to various industrial applications. Weldarc India combines cutting-edge technology with extensive industry experience, making them a preferred choice for businesses looking to invest in high-quality robotic welding systems.

Key Highlights:

Innovative Technology: Weldarc India integrates the latest advancements in robotics and automation, ensuring their machines deliver exceptional performance and efficiency.

Customization: The company offers tailored solutions to meet the specific needs of its clients, ensuring seamless integration into existing production lines.

Comprehensive Support: Weldarc India provides extensive after-sales support, including training, maintenance, and rapid spare parts delivery, ensuring minimal downtime for their clients.

2. ABB India

ABB is a global leader in robotics and automation, and its Indian subsidiary is no exception. ABB India offers a wide range of robotic welding systems designed to meet the diverse needs of industries across the country. Their solutions are characterized by high precision, flexibility, and ease of use.

Key Highlights:

Advanced Robotics: ABB's robotic welding machines are equipped with state-of-the-art technology, including AI and machine learning capabilities, for enhanced performance.

Industry Versatility: ABB serves a wide range of industries, from automotive to aerospace, with solutions that are adaptable to various welding applications.

Global Expertise: Leveraging ABB's global expertise, the Indian subsidiary provides world-class robotic welding systems tailored to the local market.

3. Fanuc India

Fanuc is another global giant in the field of robotics and automation, with a strong presence in India. Fanuc India's robotic welding machines are renowned for their reliability, speed, and precision, making them a top choice for industries seeking to optimize their welding processes.

Key Highlights:

High-Speed Operations: Fanuc's robotic welding systems are designed for high-speed, high-volume production environments, ensuring maximum efficiency.

Precision Welding: With advanced control systems, Fanuc's machines deliver consistent and accurate welds, even in complex applications.

Comprehensive Solutions: Fanuc offers a full range of robotic welding solutions, from standalone machines to fully integrated systems, catering to various industry needs.

4. Kuka Robotics India

Kuka Robotics is a global leader in industrial robotics, and their Indian division offers a wide range of robotic welding machines that are widely used in automotive and general manufacturing sectors. Kuka's systems are known for their versatility, allowing them to handle a broad spectrum of welding tasks with ease.

Key Highlights:

Versatile Solutions: Kuka's robotic welding machines can be customized to suit various applications, from simple spot welding to complex seam welding.

Robust Design: Built to withstand harsh industrial environments, Kuka's machines are durable and reliable, ensuring long-term operation.

Integrated Automation: Kuka offers fully integrated robotic welding solutions that streamline production processes, enhancing overall productivity.

5. Yaskawa India

Yaskawa is a well-known name in the robotics industry, with a significant presence in the Indian market. Yaskawa India's robotic welding machines are designed to deliver high-quality welds with minimal supervision, making them ideal for industries aiming to increase automation.

Key Highlights:

Precision and Control: Yaskawa's machines offer precise control over welding parameters, ensuring consistent results across different welding tasks.

User-Friendly Interface: Yaskawa's systems are designed with ease of use in mind, featuring intuitive interfaces that simplify operation and programming.

Comprehensive Support: Yaskawa India provides extensive support services, including training, maintenance, and technical assistance, ensuring that clients get the most out of their robotic welding systems.

Read more: Fiber Laser Cutting Machine manufacturer

The Future of Robotic Welding in India

As industries continue to embrace automation, the demand for robotic welding machines in India is expected to grow exponentially. Manufacturers like Weldarc India, ABB, Fanuc, Kuka, and Yaskawa are leading the charge, offering cutting-edge solutions that cater to the evolving needs of the market. These companies are not only advancing the capabilities of robotic welding systems but also driving innovation in related fields, such as fiber laser cutting and laser welding machines.

The future of robotic welding in India looks promising, with continuous advancements in technology and increasing adoption across various sectors. Businesses looking to stay competitive in this dynamic environment should consider partnering with one of these top manufacturers to leverage the benefits of robotic welding systems.

Conclusion

Selecting the right robotic welding machine manufacturer is crucial for businesses aiming to enhance their production capabilities and maintain a competitive edge. The manufacturers listed in this review, including Weldarc India, have proven their expertise and commitment to delivering high-quality, reliable, and innovative robotic welding systems. By choosing a trusted partner, companies can ensure they are equipped with the best technology to meet their welding needs and drive future growth.

Weldarc India stands out not only for its advanced robotic welding solutions but also for its dedication to customer satisfaction through customized solutions and comprehensive support. As a leader in the industry, Weldarc India continues to set the standard for excellence in robotic welding machine manufacturing in India.

#Robotic Welding Machine Manufacturers India#Robotic Welding Machine#robotic welding systems#welding products manufacturer in India#Fiber Laser Cutting Machine manufacturer#Welding Machine manufacturer in India#Laser welding machine manufacturers in India#top robotic welding manufacturers#automated welding systems#best welding machine brands India#welding industry India#industrial robotics India

0 notes