#buy laser welding machine in India

Explore tagged Tumblr posts

Text

How to Optimize Materials with 20kW CNC Fiber Laser Cutting Machine

Using a 20kW CNC fiber laser cutting machine to optimize materials for optimal efficiency is important to producing accurate and superior outcomes. Operators will improve cutting efficiency and reduce problems like burrs and dross development by choosing the proper material qualities, like thickness, conductivity, and reflectivity. By ensuring that the laser energy is efficiently absorbed and used, optimizing the materials will result in higher cutting rates and lower manufacturing costs.

Improving the materials used for a 20kW CNC fiber laser cutting machine is important to raising the general effectiveness and caliber of the cutting operation. Through careful selection of materials consistent with their unique qualities and attributes, operators will minimize waste and mistakes while achieving excellent outcomes. To completely utilize the laser cutting machine's potential and lift industrial productivity as an entire, material optimization must be a top priority. By putting the recommendations and techniques covered in this article into practice, readers will surely be ready to increase the accuracy and efficiency of their laser-cutting procedures.

Choosing the Proper Materials

To get the simplest results from laser cutting, the proper materials must be used. Selecting materials for a 20kW CNC fiber laser cutting machine that will tolerate the laser beam's high power and intensity is crucial. Because they cut well and precisely, materials, including steel, aluminum, and chrome steel, are frequently utilized.

Due to differences in their composition and characteristics, many materials answer laser cutting in several ways. For instance, because they're more reflective than steel, metals like copper and brass have to be used at higher power levels. It is important to switch the facility, speed, and focus of the laser cutting device appropriately to ensure precise cuts and stop problems like burrs or material deformation.

Test cuts on sample materials should be performed to seek out the simplest settings for every sort of material to maximize the cutting process. Operators can attain greater cutting quality and efficiency by adjusting settings that are consistent with the fabric being utilized. Additionally, to ensure consistent performance while handling various materials, frequent calibration and adequate maintenance of the laser cutting equipment are necessary.

Optimizing Cutting Parameters

Optimizing cutting parameters, including power, focus, and speed, is important to maximizing cutting process efficiency. You'll improve the cut's overall quality, hamper production time, and increase cutting performance by tweaking these settings. Power governs the cutting action's intensity, speed decides how quickly the fabric is cut, and concentration manages the cut's accuracy. For best outcomes, these parameters with a CNC laser welding machine manufacturer in India must be adjusted by the actual needs of the fabric being processed.

Optimizing cutting parameters requires taking the type of fabric to be rigged into account. The qualities of various materials influence the simplest cutting conditions. For example, hard materials like metals can need higher power settings and slower speeds to make clean cuts. In contrast, softer materials like plastics might enjoy quicker speeds and lower power levels. Efficient cutting could also be achieved by modifying the cutting settings consistent with the hardness, thickness, and composition of the fabric.

It is impossible to overestimate the influence of varied cutting factors on the ultimate product's quality and overall effectiveness. Inaccurate settings can save time and money by causing problems like material deformation, uneven edges, or unfinished cuts. You'll maximize manufacturing productivity, reduce material waste, and acquire exact cuts by carefully adjusting cutting settings. To maximize productivity and uphold high standards for cutting quality, it's essential to periodically check and modify the cutting settings in accordance with the characteristics of the fabric and, therefore, the intended results.

Maximizing Efficiency and Minimizing Waste

To realize maximum production throughout the laser cutting process, efficiency must be optimized. Nesting software, which places pieces closer together to scale back material waste, is an efficient technique. A method to save lots of time and resources is to carefully organize the location of pieces on the fabric so that there's less scrap and more components produced from one sheet. You can easily have the option to buy a 6kw laser cutting machine.

If it's feasible, believe in automating the cutting process to extend efficiency even further. Automation guarantees uniform quality, expedites production, and lowers human error. Purchasing contemporary laser cutting equipment with cutting-edge features like material management systems and automatic nozzle changes will greatly increase productivity and efficiency.

In a 20kw CNC fiber Laser Cutting Machine, it's crucial to optimize material utilization and reduce waste, as well as maximize efficiency. You'll minimize waste and save production expenses by precisely estimating the quantity of fabric needed for every task and strategically scheduling cuts. A corporation will become more economical and sustainable by implementing a waste management system to collect and recycle unwanted resources.

Conclusion

Material optimization is a crucial aspect to think about if you would like your laser cutting operations to be optimized. Readers will maximize the performance of their 20kW CNC fiber laser cutting equipment by being consistent with the instructions provided in this blog article. Adopting material optimization improves final product quality, expedites manufacturing processes, and lowers operating expenses.

#buy laser welding machine in India#laser sheet cutting machine#20kw cnc fiber Laser Cutting Machine

0 notes

Text

Fiber Laser Cutting Machine Manufacturer in India

We are the best fiber laser cutting machine manufacturer in India, we give you a lot of metal laser cutting machine. As you are aware, industries are benefiting greatly from the one-by-one technological advancements that are occurring nowadays. The task is completed quickly and easily thanks to these technology, and the results are good as well. Currently, we’re talking about the metal sectors, which are leveraging these technologies to increase their output and generate a lot of money. As a result, we have offered you a high-quality laser cutting machine at a reasonable price. When compared to other products on the market, our laser fiber laser cutting machine is more affordable, has better quality, and is made with higher-quality components. We also use the most recent, cutting-edge technologies to ensure that our products last as long as possible. Additionally, all of our items are produced under the guidance of our professionals to prevent future problems.

Pusaan Automation Pvt. Ltd. is a brand-leading business in India, one that consistently earns the confidence of its customers and builds stronger bonds with them. When it comes to our sheet metal laser cutting machine price in India, it is reasonable and of high quality. We are the leading provider and manufacturer of fiber laser cutting machines in India and we supply the top models of laser machines for cutting sheet metal. Our powerful laser cutting machine provides a metal with a high-quality cutting surface. The quality of a product is rising thanks to this technology. Fiber laser machines are employed in numerous industries today, including the automotive, lighting, advertising, fitness equipment, and decoration industries. numerous metal businesses also use this laser cutting machine technology.

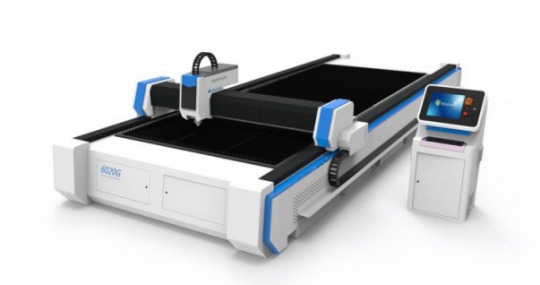

Open Type Fiber Laser Cutting Machine

This cutter’s metal body underwent a 600 ° C heat treatment and is kept cool for 24 hours in the chamber. When this is possible, a plano-milling machine and welded carbonic acid gas are used. High power and a twenty-year service life are therefore guaranteed. Maximum acceleration rate of 1.0G, repeated position precision of 0.05mm/1000mm, and maximum running speed of 100 M/min are all high class-leading and high-efficiency. A world first invention, easy integration, and contemporary design with the least amount of space required for a machine of the same level. Each and every feature, including the control arm, LED indication design, and stainless steel border, exudes excellent and supreme elegance.

We create industrial goods with the newest technologies and to the highest standards of luxury. 600 °C heat treatment, 24 hr. of oven cooling We employ high-quality components to ensure 20 years of operation without deformation. Auto collimator: to check the straightness of the guide rails and ensure each machine set’s precision. It features a database of expert cutting parameters, which means that different cutting parameters will be automatically applied for various sheet metal materials at various thicknesses, reducing the need for operator work. has excellent features implemented and uses servo motors that were originally imported. It has excellent MS 0.5–12mm (depending on material) cutting thickness. We offer top-notch Open Type Fiber laser cutting machine with cutting-edge features.

Exchange Table Type Fiber Laser Cutting Machine

Exchange Table Type Fiber Laser Cutting Machine: Buy Now! We give you a fantastic bargain and discount. Every detail is perfect, the suspension lamp style, the console has a chrome steel border, and we are producing industrial goods to meet the demands of high-end goods. Our exbelow shows the machine’s technical specs.perts provide the greatest electrical and driving systems. We only use parts of the highest calibre, and the table.

Sheet and Tube Fiber Laser Cutting Machine

Exchange Table Type Fiber Laser Cutting Machine: Buy Now! We give you a fantastic bargain and discount. Every detail is perfect, the suspension lamp style, the console has a chrome steel border, and we are producing industrial goods to meet the demands of high-end goods. Our exbelow shows the machine’s technical specs. It includes an upper and lower exchangeable table, which greatly reduces standby time. The drawer-type material collection device also allows for a wide variety of practical options, which significantly boosts the effectiveness of the entire five hundredth. It has a highly distinctive and contemporary style and is furnished with a companion interchangeable table. We included high-quality parts in the machine, giving you a wonderful experience and properly increasing your output.

Advantages of Fiber laser cutting Machine

There are several benefits to employing a fiber laser cutting machine. As you may be aware, there are numerous application domains that use this technology to increase production and expand their businesses quickly. The main benefits of a fiber laser cutting machine are five.

Boost in Cutting Speed– Fiber laser cutting machines have good cutting speeds, which enable them to do jobs fast and with the highest quality possible. A fiber-based laser can cut more quickly than a conventional laser while cutting a straight line that is 1 mm thick.

Superior Performance- You’ll discover that fiber lasers perform better than many of their competitors. Fibers offer a high-quality laser beam that may be tightly focused to attain incredibly high levels of accuracy and greater power density.

Cutting Reflective Material– The reflecting material is one of the key issues when utilising a conventional laser. There is a possibility that a laser reflector will strike the substance and cause damage. Because of this, cutting copper, brass, and aluminium with conventional lasers is uncommon. However, this reflective material issue is no longer a problem with fiber optic lasers, allowing cutting of these materials.

No Moving Parts- The absence of moving parts lowers running expenses and raises maintenance requirements. It is not essential to use a moving mirror to generate the required laser because light pulses are transmitted via fiber optic cabling. There is no material loss during cutting since only the cutting material makes contact with the laser.And provide a best finishing cut.

Higher Electrical Efficiency- Each time the fiber optic design is employed, power is saved, and because less energy is needed, the hardware’s lifespan is also increased. A laser cutter can handle any challenge. High powered lasers can be utilised on a very small region of material with hardly any distortion or warping.

Less Expensive- The cost of fiber laser cutting is perhaps its most beneficial advantage. The cost overhead for this method entails a little initial saving and a significant saving over the course of the laser’s lifetime. For one thing, unlike other laser technology, it does not need pricey optical mirrors. Furthermore, the focusing lens is sealed inside the cutting head rather than being exposed. As a result, unlike laser applications where damage and frequent replacement are required over the lifespan of fiber optics, concentrating lenses only need damage when maintained properly.

#best fiber laser cutting machine manufacturer in India#fiber laser cutting machine manufacturer in India#best fiber laser cutting machine in India#fiber laser cutting machine in India#fiber laser cutting machine

0 notes

Text

Metal fabrication Market | Trends and Growth Forecast to 2027

Key Highlights

Metal fabrication refers to the procedure of making structures and machines from various raw metal materials. This procedure comprises assembly, forming, machining, welding, burning, and cutting to produce a finished product. Metal fabrication is basically a value added procedure that involves making of structures, parts, and machines. In present times, the industry is highly cyclical and dynamic with its expansion depending on various end use sectors. The end use segments for the global metal fabrication market comprise energy, construction, aerospace, and automotive.

Changing demand of customers have made metal shops try for obtaining more profitability through diversification of customer base and make correct forecasts about the pattern of demands. Transparency Market Research has come up with an all-inclusive study on the global metal fabrication market, for the period 2019 to 2027. The report estimates that the global metal fabrication market is likely to grow at a rate of 3.5% CAGR.

Request a Sample-

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=11564

Rapid Industrialization to Drive Asia Pacific Market during the Assessment Tenure

Considering geographical segmentations, Asia Pacific is expected to account for a large share of the global metal fabrication market. Developing countries like Indonesia, China, and India are witnessing rapid growth in their economies and rapid industrialization. Economic progress and industrialization result in increased demand for various machines and metal structures, which is likely to trigger growth of the global metal fabrication market in the years to come.

Europe is estimated to emerge as another prominent region of the global metal fabrication market. Developed markets of western part of Europe such as the U.K., France, and Germany are likely to generate demand for metal fabrication technology, thanks to rapid development in the automation technology.

Request for covid19 impact analysis –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=11564

Integration of Automation to Offer Lucrative Opportunities for Growth

Various enterprise resource planning (ERP) technologies and software find increased utilization in the metal fabrication market in years to come. With the use of ERP technologies, the data becomes easily available and it speeds up the decision making process. Augmented utilization of computer-assisted technologies for manufacturing is assisting various market players to better their production capacity and operational efficiency. These technological progresses are expected to offer copious growth opportunities to the global metal fabrication market over the tenure of assessment, from 2019 to 2027.

The automobiles and aviation sectors make use of fabricated metal extensively and there is a constant rise in this trend, which is likely to trigger growth of the global metal fabrication market in years to come. However, the primary concern in relation to the fabrication equipment market is the fluctuation of price and availability of raw materials. These two factors are likely to impede growth of the global metal fabrication market in years to come.

Buy now-

https://www.transparencymarketresearch.com/checkout.php?rep_id=11564<ype=S

In addition, advancement made in the field of robotics and automation tools is likely to emerge as another factor for the expansion of the global metal fabrication market in years to come. At present, automation is utilized in the process of metal fabrication, which is to improve the efficiency of the operation and reduce the overall cost of labor in years to come. Furthermore, automation tools like laser saws help fabricators to produce metal parts that need to be cut precisely, thereby underscoring the significance of automation tools in the global metal fabrication market.

The Global Metal Fabrication Market has been segmented as presented below:

Metal Fabrication Market: Service

Metal Welding

Metal Machining

Metal Forming

Metal Shearing

Metal Cutting

Metal Rolling

Metal Folding

Metal Punching

Metal Stamping

Metal Fabrication Market: End-use Industry

Construction

Automotive

Aerospace

Manufacturing

Energy and Power

Electronics

Others (Including Consumer Products and Sports & Leisure)

Wax Market: Regional Analysis

North America

Europe

Asia Pacific

Middle East & Africa

Latin America

U.S.

Canada

France

Germany

Rest of Europe

China

India

Rest of Asia Pacific

GCC

South Africa

Rest of Middle East & Africa

Brazil

Argentina

Rest of Latin America

Companies in the Metal Fabrication market have increasingly shifted gears with wide application of digital technology across the continuum, from raw material sourcing to manufacturing to generation of final output, to warehousing to final distribution operations. Among the various affects, the market is witnessing new growth economics due to thinning of line between specialty and commodity businesses that are associated with the larger ecosystem. At the same time, new growth parameters are being vigorously being debated as industry stakeholders put greater emphasis on the circular economy processes.

More Trending Report-

https://www.prnewswire.com/news-releases/fluorochemicals-market-to-gather-traction-from-its-growing-prominence-in-water-repellent-fabrics-however-the-demand-for-fluorochemicals-in-the-automobile-sector-to-suffer-temporary-setback-due-to-covid-19-tmr-301269835.html

1 note

·

View note

Text

Preserving the Artisan-ship for an Ethical Fashion Industry

As slow fashion is getting more and more attention of the fashion conscious consumers, the number of people switching to exclusively handmade garments is growing. As a Fashion shopper, we are familiar with the term Handmade. This familiarity increases if you are part of the sustainable fashion community because in this circle, the tag represents more than just a higher price. It additionally stands for care, durability and a commitment to the environment.

So what does it mean for a piece of clothing to be handmade, rather than machine made? And in an age of exacting 3D printing, computer modeling, laser cutting, and ultrasonic welding, is one really more valuable than the other?

Symbolic of its name and exclusivity, handmade pieces are products made or created manually. As debated to machine made pieces, handmade items are products of artisanship and craftsmanship: The subtle art of working gently and slowly with one’s own hands. This way of producing is not only good for the designs and aesthetics but also to the environment. Slow fashion is one of the pillars of sustainable and ethical fashion as consumers are called on daily to buy more of handmade items rather than fast fashion products.

Due to the machine mass production and its consequent rock bottom prices, true artisanship in the fashion industry seems to be dying out. In most cases, true artisans are already well past their prime. As slow fashion is considered to be one of the bases of sustainable fashion, it is true to infer that artisanship is valuable to the future of fashion industry.

Artisanship implies that a brand is working directly with its makers to provide meaningful and sustainable work, preserving heritage craft traditions that would otherwise become obsolete, and compensating and treating its workers fairly. The amount of work that goes into embroidering and embellishing garments by hands in the fashion industry along with the level of consistency is incredible. It is important that efforts to rekindle its dying embers and develop its art should be consistent as well as deliberate. Put differently, we cannot afford to leave the mastery of this craft to chance. It should mean more to us than some product you stumble upon in an obscure village on a trip to some third world country or the other.

Belacci is a blend of Italian meticulous craftsmanship on Indian textures and fabrics cut to create a fineness style statement. Every piece of art in our collection is handcrafted in India keeping in mind the latest styles. We believe Ethical trade is never out of fashion. It takes a lot of sweat and time to produce clothes as many people are involved in this long process. It is our responsibility to make sure that every single one of them works under fair conditions. No matter if they are a cotton farmer, a sewer, a designer or a service provider - Team Belacci

Preserving and Nurturing the True Artisan-ship

If you are reading this blog post, we assume that you, too, care about preserving the art and craft of fashion design. We believe it is our job to prepare you for many aspects of the fashion world, including the type of couture methods.

The Economic Essence

A simple yet powerful step is to make sure that the handcrafted fashion products are economically viable. Buyers should actually demand for these products so that artisans can continue to produce them. If the profits they make from sales exceed their costs, then this would be an indication that their final products was worth more to the consumers than the factors of production that went into their creation. The sales income is the means to sustain the business. Any other profits they make are simply the means to expand their trade.

Business Training

The next step is to equip the new generation of artisans with modern business skills. Many ethical artisanal brands have sprung up in recent times but somehow, they only seem to be seen when an eco-lifestyle company launches in a developed country while selling products handmade. Teaching them modern business skills will enable the artisans and their families to explore these global opportunities for themselves and will enable them to build their crafts into world business brands.

Acknowledging the Traditions of Old Age Art

The ultimate step is to ensure that the coming generation appreciates the art. It is important to pass on to our children that artisanship isn’t synonymous with poverty and pity. The Akwete weaving for instance, has survived because from childhood, women are initiated into the intricacies of the art and use their skills creates sustainable livelihoods for themselves and their community. During holidays and after school hours, young girls literally learn at their mothers’ feet because the community recognizes this as the best way to preserve its heritage and empower the next generation of women.

Follow Belacci on Instagram - https://www.instagram.com/belacci.in/

While keeping in mind slow and ethical fashion, we need to be inspired by the Nobel pursuit of sustainable brands around the world promoting and preserving the art of handmade items and craftsmanship. We show our support for such endeavors in hand-loom textiles so that the local artisans can have a livelihood consisting of health care and basic needs.

#belacci#fashion#blogs#instagram#outfit#latest#sustainability#best lingerie brands best lingerie brands in India#Women clothing online

1 note

·

View note

Text

Significant Growth Foreseen by Laser Plastic Welding Market during 2025

Transparency Market Research delivers key insights for the laser plastic welding market in its published report, which includes global industry analysis, size, share, growth, trends, and forecast for 2020–2025. In terms of revenue, the global laser plastic welding market is projected to register a CAGR of 8.4% during the forecast period.

Consistent Demand from Automotive Industry to Bolster Market Growth

The amount of plastics used in the automotive industry is consistently rising, as it lowers the manufacturing cost and reduces the weight of vehicles. Manufacturers operating the automotive industry used laser plastic welding frequently to join interior and exterior plastic components, as it provides excellent joint quality and precise welding. Furthermore, strong joints formed with laser plastic welding with high precision and accuracy that do not affect the sensitive components close to the welding area, resulting into a high requirement of the laser plastic welding in the automotive industry. In addition, shifting inclination of consumers towards highly aesthetic automotive vehicles across continents is creating ample amount of opportunities for manufacturers. Besides this, the rising purchasing capability of an average person to buy vehicles is one of the vital factors fueling the expansion of the laser plastic welding market.

Get PDF brochure for Industrial Insights and business Intelligence @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=15332

Plastic to Metal Joining Welding Gaining Momentum in Global Market

Metallic industrial products are robust and ductile, and plastics are lightweight and easily formable. A variety of plastic and metallic products is used in industries frequently, owing to their significant properties. The importance of joining metal and plastic has witnessed a tremendous rise in recent years. There are various methods such as rivets, adhesives, and others to join these plastics and metals. However, the current trend of laser-assisted metal plastic joining (LAMP) is gaining traction across the globe, owing to its numerous applications such as short time joining, stable joint for a long time, easy automation, and no requirement of adhesives and rivets. Furthermore, the laser-assisted metal plastic joining (LAMP) method is applicable to join two dissimilar metals with a plastic intermediate sheet, to prevent local electric-physical corrosion in metals. The rising adoption of laser-assisted metal plastic joining (LAMP) method over the other conventional method to join metal and plastic product effectively is projected to boost the laser plastics welding market growth during the forecast period.

Lucrative Opportunities in Emerging Countries

Laser plastic welding systems and techniques are predominantly used in various key industries such as electrical & electronics, healthcare, automotive, and others. The demand for advanced laser plastic welding systems in these industries is consistently rising due to its ability to weld 3D and complex shapes. Prominent end-use industries such as healthcare and electrical & electronics have witnessed a healthy growth over the past 10 years, and this is anticipated to continue during the forecast period. Moreover, the market growth is not just in mature markets of North America and European countries, but also in fast-growing and developing countries such as China and India. Rapid penetration of healthcare and electronics industries in these countries is likely to create a positive impact on the demand for laser plastic welding machines in the upcoming years.

Key Players in Laser Plastics Welding Market

Prominent players operating in the global laser plastic welding market accounts for a substantial portion of the market share. Key players are adopting inorganic growth strategies to expand into new geographies. Recently, LPKF Laser & Electronics AG, one of the leading players operating in the laser plastic market has introduced PowerWeld 3D 8000 and laser plastic welding machine for mass production of small parts. Some of the leading players in the laser plastic welding market are TRUMPF GmbH + Co. KG, Han’s Laser Technology Industry Group Co., Nippon Avionics Co., Ltd., Jenoptik AG, Rofin Sinar Technologies Inc., Amada Miyachi Co. Ltd., Bielomatik Leuze GmbH + Co. KG, LPKF Laser & Electronics AG, DILAS Diodelaser GmbH, Leister Technologies AG and Dukane IAS LLC.

Purchase our Premium Research Report at: https://www.transparencymarketresearch.com/checkout.php?rep_id=15332<ype=S

Global Laser Plastic Welding Market Segmentation

Laser Plastic Welding Market, by System

Standalone System

Integrated

Laser Plastic Welding Market, by Method

Contour Welding

Quasi-Simultaneous

Simultaneous

Mask Welding

Radial Welding

Others

Laser Plastic Welding Market, by Laser

CO2 laser

Diode laserDio-Scan

Direct

Fiber Coupled

Multi-diode

Fibre laser

Nd:YAG Laser

Laser Plastic Welding Market, by Application

Component

Films

Laser Plastic Welding Market, by End-use Industry

Electrical & Electronics

Healthcare

Automotive

Consumer goods

Others

Explore Latest Reports by TMR:

Europe Plastic Packaging Market – https://www.prnewswire.com/news-releases/efforts-to-intensify-circular-plastic-economy-in-european-countries-underscores-growth-in-europe-plastic-packaging-market-valuation-projected-to-surpass-us-22-7-bn-by-2030—tmr-301293849.html

Reusable Water Bottles Market – https://www.prnewswire.com/news-releases/large-scale-programs-to-prevent-massive-environmental-degradation-related-to-single-use-plastics-to-bring-extensive-growth-opportunities-for-reusable-water-bottles-market-valuation-projected-to-touch-us-11-bn-by-2027-says-tmr-301288640.html

About Us

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

Contact

Rohit Bhisey

Transparency Market Research

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Blog: https://tmrblog.com/

Follow Us: Twitter | LinkedIn

0 notes

Text

Best mist collector manufacturers

With industrialisation, we have seen various modifications in the lifestyle of people, and it can include positive and negative as well. The technology enhancement has resulted in better comfort for us and environmental disturbance both. People are moving towards more environmentally friendly methods to decrease the ill effects of modernisation.

Mist collectors have the same purpose; they help minimise pollution and make a better working environment for everyone.

Mist collectors are industrial grade machines used to remove any pollutants from the air and help improve the air quality; they are commonly used in the metalworking industry. They work with the help of centrifugal technology wherein a drum is used to intercept unwanted particles, converted into large droplets and then finally being drained out of the machine.

When buying a mist collector, always look at the air quality standards you require, applications, size, specifications, power usage, installation options, and sound level considerations. You can always take help of an expert like Sphoorti India is a mist collector manufacturer guides you which machine will suit your industry the most.

It is essential for machining businesses that emit harmful gases to maintain indoor air quality. Therefore, mist collectors are used in various industries like:

Metalworking industry:

Mist collectors are used in these industries for extracting harmful oil and coolant mist. When the mists are exposed to high temperatures, they can convert into oil smoke, wherein the oil begins to burn before it is released into the air. The oil residue can also be deposited on the machine, and it can lead to decreased life of it and poses extreme effects on the health of the workers.

Commercial food production

Mist collectors are also used in various commercial food production industries to remove cooking odour, grease and mist. Hygiene is the primary factor in food industries, and mist collectors help maintain hygiene and a clean environment. The industries need to keep all the commercial food standards, which mist collectors much support.

Speciality applications:

Mist collectors help in extracting fumes during laser engraving, 3D printing, welding, wet scrubber exhaust and mobile applications.

Mist collectors play an essential role in maintaining a healthy environment for many industries. Therefore, it is also necessary to choose a manufacturer who can provide you with durable products that efficiently eliminate unnecessary fumes.

Mist collector is a leading mist collector manufacturer, helping its customers to make their industries pollution-free.

If you want more information or want to buy a mist collector, you can visit the following site:

http://mistcollectorindia.com/mist-collector/

0 notes

Photo

Do you know this? Neumatica is the best SPM machine manufacturers in India. Special Purpose Machine Manufacturers Bangalore they also provide gear shaft assembly with laser welding and also for automotive solutions.SPM presses are highly automated, precision action machines made to the specific requirements. If you are looking for this any then buy it from Neumatica with one touch

1 note

·

View note

Text

Metal Fabrication Market Global Industry Analysis Size, Share, Trends and Profitable Segments Breakdown and Detailed Analysis of Current and Future Industry Figures till 2027|Key Players O'Neal Manufacturing Services, Interplex Holdings Pte. Ltd., Komaspec, LancerFab Tech Pvt. Ltd.

Metal fabrication market will reach an estimated value while registering this growth at a rate of 3.20% for the forecast period of 2020 to 2027.The headway in robotics and computerization devices encourages the employment of robots and self-regulation instruments in metal fabrication. Presently, mechanization is practiced in metal fabrication to enhance productivity and more moderate operation expenses. The strengthening requirement for programmed production practices in the element fabrication business helps in manufacturing fabrication amenities reliable, as all hazardous operations such as welding and cutting are taken out by cyborgs. Apart from this, computerization devices such as laser saws make it more comfortable for fabricators to execute accurately cut alloy castings. The dearth of proficient employees and advancements in additive construction technologies may limit the metal fabrication industry. Accomplishing operational superiority as per business demands and focuses on emerging marketplaces offer possibilities for the metal fabrication market.

This metal fabrication market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on Data Bridge Market Research metal fabrication market contact us for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Global Metal Fabrication Market By Service (Metal Welding, Metal Machining, Metal Forming, Metal Shearing, Metal Cutting, Metal Folding, Metal Rolling, Metal Stamping and Metal Punching), End-Users (Construction, Automotive, Aerospace, Manufacturing, Energy & Power, Electronics, Others), Geography (North America, South America, Europe, Asia-Pacific, Middle East and Africa) – Industry Trends and Forecast to 2026 Metal fabrication market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to metal fabrication market.

Get a Sample Request on Metal fabrication market,@ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-metal-fabrication-market

Metal Fabrication Market Country Level Analysis:

Metal fabrication market is analyzed and market size, volume information is provided by country, type, process type and end user as referenced above.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

The countries covered in the market report are the U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and rest of South America as part of South America.

Asia-Pacific (APAC) secured a pre-eminent percentage of the metal fabrication market owing to comprehensive analysis and improvement ventures in China and India. Architecture and automotive are center divisions of the metal fabrication market in Asia, owing to the influential proximity of development and automotive firms.

Global Metal Fabrication Market Scope and Market Size:

On the basis of type, the metal fabrication market is segmented into iron, carbon steel, steel, stainless steel, cooper, and other.On the basis of process type, the metal fabrication market is segmented into metal welding, machining, metal forming, metal shearing, metal cutting, metal rolling, metal folding, metal punching, and metal stamping. On the basis of end user, the metal fabrication market is segmented into construction, automotive, manufacturing, energy and power, and electronics.

The major players covered in the metal fabrication market report are O'Neal Manufacturing Services, Interplex Holdings Pte. Ltd., Komaspec, LancerFab Tech Pvt. Ltd., BTD Manufacturing, Kapco Metal Stamping, Watson Engineering, Inc., Matcor-Matsu Group, STANDARD IRON & WIRE WORKS, INC., PA International, , Mayville Engineering Company, Inc., Aleris Corporation, Mazak Corporation, TRUMPF, DMG MORI., weMFG., R5 Metal Fabricators, Inc., N.W. Metal Fabricators, Inc. among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Get Table of Content on Request @ https://www.databridgemarketresearch.com/toc/?dbmr=global-metal-fabrication-market

Reasons for Buying this Metal Fabrication Market Report

Laser Capture Metal Fabrication Market, report aids in understanding the crucial product segments and their perspective.

Initial graphics and exemplified that a SWOT evaluation of large sections supplied from the Laser Capture Metal Fabrication Market industry.

Even the Laser Capture Metal Fabrication Market economy provides pin line evaluation of changing competition dynamics and retains you facing opponents.

This report provides a more rapid standpoint on various driving facets or controlling Medical Robotic System promote advantage.

This worldwide Locomotive report provides a pinpoint test for shifting dynamics that are competitive.

The key questions answered in this report:

What will be the Market Size and Growth Rate in the forecast year?

What is the Key Factors driving Laser Capture Metal Fabrication Market?

What are the Risks and Challenges in front of the market?

Who are the Key Vendors in Metal Fabrication Market?

What are the Trending Factors influencing the market shares?

What is the Key Outcomes of Porter’s five forces model

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-metal-fabrication-market

Browse Related Report:

Industrial Gases in Metals and Metal Fabrication Market

Silicon Metal Market

Sheet Metal Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Text

How to set up a manufacturing plant in India

How to set up a manufacturing plant in India

• Purchase of equipment

• Automated repetitive tasks

• Organize the production line

• Recruit and train a technically competent team

If you want to make manufacturing plant in India, learn the ins and outs of the industry first. The key is to answer the following questions:

What does the production look like?

What tools, machines are necessary?

What materials can you use? Where to get them and for how much?

How to price a job and where to find clients?

The answers to these questions can be found by getting to know the competition - checking their offer, analyzing the services.

Running a business alone is sometimes easier than working with a partner. When working with a partner - each decision must be joint and approved by both parties.

What if you have a completely different taste? What if your business partner is constipated and wants to get his way?

There are several solutions. You may split your responsibilities, but there will certainly be friction anyway. You can try to come to an agreement or… you just go your own way. For this not to happen, one thing is needed - "chemistry". If there is a positive spark between your partners and you speak the same language, you have a great chance for business success.

Purchase of equipment

You cannot provide manufacturing services without equipment, and purchasing such equipment requires capital. You can invest your own funds directly or seek capital from investors or a parent company. It is also possible to start small and buy for example a 3D printer , advertise your services and buy tools as you earn.

The tools are divided into materials and processes. The materials are of five main types:

• Wood

• Metal

• Plastic

• Circuits

• Textile

You will need to decide which material categories to consider, educate yourself on these categories and purchase the tools that match them. For example, if you want to provide services for electronic products, you will likely invest in micro-soldering stations, 3D printers for cases, and circuit manufacturing stations.

By carefully studying the devices you choose, you will be able to assess your performance realistically and safely and correct any inefficiencies. Visit factories, study workspace management and watch as many “How to make…” videos as possible. It cannot replace hands-on experience, but it is a good start.

Automated repetitive tasks

Automation isn't just about robots. To properly manage your micro-factory, you will seek to set up processes to automate administrative tasks and the paperwork generated, especially for programming, budgeting and making quotes. Having detailed assembly instructions in place and investing in skills training can save employees a lot of time and prevent communication errors.

For example, many service providers invest in automatic quoting, which ultimately saves them a lot of time and costs. Companies like Printelize offer software that does this relatively easily.

Organize the production line

Should you organize your production line by different process or by project?

• Organization by process translates into an organization of space around processes, such as 3D printing, welding or laser cutting. Each position relates to a separate process. Process planning allows you to stack multiple orders in the workflow, each involving a separate process at different times. But in this configuration, if an order starts to delay or overload the production line, it can have ripple effects.

• Organization by project results in the distribution of orders or projects between different lines. It increases flexibility and versatility and allows you to use downtime on one line to process excess from another line. The downside of organizing by project is that it requires more resources to invest production capacity in the long run, by limiting the number of lines you can afford.

Choosing your organizational mode is a balancing act and the final decision is yours alone. The optimum probably lies somewhere between these two distinct modes of organization. Your goal should be to put in place a structure that progresses in an orderly fashion and that is relevant to you. Many companies place quality assurance just before delivery, for example, or the welding operation just before sandblasting and painting.

Recruit and train a technically competent team

Invest in training all of your staff. Make sure everyone is knowledgeable and up to date with the latest technology knowledge. Also train your salespeople so that they know how to answer most technical questions and give specific values to customers. Make sure there are enough project managers to reduce stress and minimize errors. As your business grows, relying on them will be essential to avoid line congestion and other incidents.

When recruiting, manufacturing experience is a definite advantage to look for. If you work in an area where there are conventional factories, look for people who have worked there before. Also consider business schools, vocational high schools or other schools with good professionalization programs.

Look for the innovators. Those who work on the production lines need to be able to make decisions that will improve results and not just follow the instructions of their supervisors. These employees will probably end up knowing more than you do.

0 notes

Text

The Future of Laser Welding: Innovations and Trends in Indian Manufacturing

Laser welding is revolutionizing the manufacturing landscape in India, promising precision, efficiency, and a leap into the future. This blog post will uncover the latest innovations and trends in laser welding, demonstrating why this technology is essential for anyone looking to buy a laser welding machine in India or partner with a CNC laser welding machine manufacturer in India.

Introduction to Laser Welding

Laser welding uses a concentrated beam of light to join materials, often metals. Unlike traditional welding methods, laser welding offers unmatched precision and speed, making it ideal for complex manufacturing processes. This introduction aims to familiarize you with the basics and set the stage for exploring its future in India.

The Growth of Laser Welding in Indian Manufacturing

Manufacturing in India is booming, and with it, the demand for advanced technology. Laser welding is at the forefront, enabling manufacturers to enhance production capabilities and meet global standards. This section explores how laser welding is becoming integral to the manufacturing sector in India.

Why Choose Laser Welding

Laser welding stands out for several reasons:

Precision: Achieve cleaner, more accurate welds.

Speed: Faster welding process reduces production time.

Versatility suitable for various materials and thicknesses.

These attributes make it a go-to choice for industries seeking efficiency and quality.

Innovations in Laser Welding Technology

The technology behind laser welding is continually evolving. Innovations include:

Fiber lasers offer higher efficiency and better control.

Hybrid Laser Welding: Combining laser welding with other methods for enhanced results.

Automation: Integrating AI and robotics for seamless operations.

These advancements are pushing the boundaries of what's possible in manufacturing.

Benefits for Indian Manufacturers

Adopting laser welding technology offers numerous benefits, including:

Cost Reduction: Lower operational costs due to faster production times.

Improved Quality: Higher consistency and fewer defects.

Environmental Impact: Reduced waste and energy consumption.

These benefits make a compelling case for investing in laser welding machines in India.

Key Markets for Laser Welding in India

Several industries are recognizing the advantages of laser welding.

Automotive: Precision welding of components enhances vehicle safety and performance.

Electronics: Miniaturization of parts requires extremely accurate welding.

Aerospace: High-strength, lightweight materials benefit from advanced welding techniques.

Understanding these markets can help businesses identify where laser welding can have the most significant impact.

Trends Shaping the Future of Laser Welding

Several trends are emerging in the world of laser welding:

Customization: Custom laser welding solutions tailored to specific industry needs.

Sustainability is becoming a priority.

Continual Innovation: Ongoing development of new technologies and applications.

Businesses may remain ahead of the curve by keeping an eye on these developments.

Choosing the Right Laser Welding Machine

When looking to buy laser welding machine in India, consider:

Machine Specifications: Ensure it meets your production requirements.

Manufacturer Reputation: Partner with a reliable CNC laser welding machine manufacturer in India.

Support and Training: Availability of technical support and operator training.

Making an informed choice can significantly impact your manufacturing efficiency and product quality.

Collaborating with CNC Laser Welding Machine Manufacturers

Working with experienced CNC laser welding machine manufacturer in India offers several advantages:

Expertise: Access to specialized knowledge and experience.

Customization: Machines tailored to your specific production needs.

After-Sales Support: Ongoing maintenance and troubleshooting support.

These collaborations can provide a significant edge in a competitive market.

Real-World Applications in Indian Industry

Laser Welding Machine is making waves across various sectors.

Jewelry: Precision welding for intricate designs.

Medical Devices: High-quality welds for critical components.

Machinery: Durable and precise welding for industrial machinery.

These applications showcase the versatility and importance of laser welding in modern manufacturing.

Overcoming Challenges with Laser Welding

Implementing laser welding technology isn't without challenges.

Initial Investment: High upfront costs can be a barrier.

Skill Gap: Requires trained operators and technicians.

Integration: Adapting existing production lines to incorporate new technology.

Addressing these challenges is crucial for successful adoption.

The Future of Laser Welding in India

The future looks bright for laser welding in India. Continued advancements in technology, coupled with increasing demand for high-quality manufacturing, will drive growth. By staying informed and adapting to new trends, businesses can harness the full potential of laser welding.

0 notes

Text

Metal Fabrication Market is likely to grow at a rate of 3.5% CAGR

Key Highlights

Metal fabrication refers to the procedure of making structures and machines from various raw metal materials. This procedure comprises assembly, forming, machining, welding, burning, and cutting to produce a finished product. Metal fabrication is basically a value added procedure that involves making of structures, parts, and machines. In present times, the industry is highly cyclical and dynamic with its expansion depending on various end use sectors. The end use segments for the global metal fabrication market comprise energy, construction, aerospace, and automotive.

Changing demand of customers have made metal shops try for obtaining more profitability through diversification of customer base and make correct forecasts about the pattern of demands. Transparency Market Research has come up with an all-inclusive study on the global metal fabrication market, for the period 2019 to 2027. The report estimates that the global metal fabrication market is likely to grow at a rate of 3.5% CAGR.

Request PDF Brochure –

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=11564

Rapid Industrialization to Drive Asia Pacific Market during the Assessment Tenure

Considering geographical segmentations, Asia Pacific is expected to account for a large share of the global metal fabrication market. Developing countries like Indonesia, China, and India are witnessing rapid growth in their economies and rapid industrialization. Economic progress and industrialization result in increased demand for various machines and metal structures, which is likely to trigger growth of the global metal fabrication market in the years to come.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=11564

Europe is estimated to emerge as another prominent region of the global metal fabrication market. Developed markets of western part of Europe such as the U.K., France, and Germany are likely to generate demand for metal fabrication technology, thanks to rapid development in the automation technology.

Buy Now :

https://www.transparencymarketresearch.com/checkout.php?rep_id=11564<ype=S

Integration of Automation to Offer Lucrative Opportunities for Growth

Various enterprise resource planning (ERP) technologies and software find increased utilization in the metal fabrication market in years to come. With the use of ERP technologies, the data becomes easily available and it speeds up the decision making process. Augmented utilization of computer-assisted technologies for manufacturing is assisting various market players to better their production capacity and operational efficiency. These technological progresses are expected to offer copious growth opportunities to the global metal fabrication market over the tenure of assessment, from 2019 to 2027.

The automobiles and aviation sectors make use of fabricated metal extensively and there is a constant rise in this trend, which is likely to trigger growth of the global metal fabrication market in years to come. However, the primary concern in relation to the fabrication equipment market is the fluctuation of price and availability of raw materials. These two factors are likely to impede growth of the global metal fabrication market in years to come.

Explore Transparency Market Research’s award-winning coverage of the global (Chemicals and Materials) Industry

https://www.prnewswire.com/news-releases/fumigation-products-market-volume-sales-set-to-surpass-1-million-tons-by-2027-amidst-adoption-of-digital-technologies-by-key-players-300997528.html

In addition, advancement made in the field of robotics and automation tools is likely to emerge as another factor for the expansion of the global metal fabrication market in years to come. At present, automation is utilized in the process of metal fabrication, which is to improve the efficiency of the operation and reduce the overall cost of labor in years to come. Furthermore, automation tools like laser saws help fabricators to produce metal parts that need to be cut precisely, thereby underscoring the significance of automation tools in the global metal fabrication market.

0 notes

Text

Metal fabrication market to reach valuation of ~us$ 23.05 BN by 2027: TRANSPARENCY MARKET RESEARCH

Key Highlights

Metal fabrication refers to the procedure of making structures and machines from various raw metal materials. This procedure comprises assembly, forming, machining, welding, burning, and cutting to produce a finished product. Metal fabrication is basically a value added procedure that involves making of structures, parts, and machines. In present times, the industry is highly cyclical and dynamic with its expansion depending on various end use sectors. The end use segments for the global metal fabrication market comprise energy, construction, aerospace, and automotive.

Changing demand of customers have made metal shops try for obtaining more profitability through diversification of customer base and make correct forecasts about the pattern of demands. Transparency Market Research has come up with an all-inclusive study on the global metal fabrication market, for the period 2019 to 2027. The report estimates that the global metal fabrication market is likely to grow at a rate of 3.5% CAGR.

Request a Sample-

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=11564

Rapid Industrialization to Drive Asia Pacific Market during the Assessment Tenure

Considering geographical segmentations, Asia Pacific is expected to account for a large share of the global metal fabrication market. Developing countries like Indonesia, China, and India are witnessing rapid growth in their economies and rapid industrialization. Economic progress and industrialization result in increased demand for various machines and metal structures, which is likely to trigger growth of the global metal fabrication market in the years to come.

Europe is estimated to emerge as another prominent region of the global metal fabrication market. Developed markets of western part of Europe such as the U.K., France, and Germany are likely to generate demand for metal fabrication technology, thanks to rapid development in the automation technology.

Request for covid19 impact analysis –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=11564

Integration of Automation to Offer Lucrative Opportunities for Growth

Various enterprise resource planning (ERP) technologies and software find increased utilization in the metal fabrication market in years to come. With the use of ERP technologies, the data becomes easily available and it speeds up the decision making process. Augmented utilization of computer-assisted technologies for manufacturing is assisting various market players to better their production capacity and operational efficiency. These technological progresses are expected to offer copious growth opportunities to the global metal fabrication market over the tenure of assessment, from 2019 to 2027.

The automobiles and aviation sectors make use of fabricated metal extensively and there is a constant rise in this trend, which is likely to trigger growth of the global metal fabrication market in years to come. However, the primary concern in relation to the fabrication equipment market is the fluctuation of price and availability of raw materials. These two factors are likely to impede growth of the global metal fabrication market in years to come.

Buy now-

https://www.transparencymarketresearch.com/checkout.php?rep_id=11564<ype=S

In addition, advancement made in the field of robotics and automation tools is likely to emerge as another factor for the expansion of the global metal fabrication market in years to come. At present, automation is utilized in the process of metal fabrication, which is to improve the efficiency of the operation and reduce the overall cost of labor in years to come. Furthermore, automation tools like laser saws help fabricators to produce metal parts that need to be cut precisely, thereby underscoring the significance of automation tools in the global metal fabrication market.

The Global Metal Fabrication Market has been segmented as presented below:

Metal Fabrication Market: Service

Metal Welding

Metal Machining

Metal Forming

Metal Shearing

Metal Cutting

Metal Rolling

Metal Folding

Metal Punching

Metal Stamping

Metal Fabrication Market: End-use Industry

Construction

Automotive

Aerospace

Manufacturing

Energy and Power

Electronics

Others (Including Consumer Products and Sports & Leisure)

Wax Market: Regional Analysis

North America

Europe

Asia Pacific

Middle East & Africa

Latin America

U.S.

Canada

France

Germany

Rest of Europe

China

India

Rest of Asia Pacific

GCC

South Africa

Rest of Middle East & Africa

Brazil

Argentina

Rest of Latin America

Companies in the Metal Fabrication market have increasingly shifted gears with wide application of digital technology across the continuum, from raw material sourcing to manufacturing to generation of final output, to warehousing to final distribution operations. Among the various affects, the market is witnessing new growth economics due to thinning of line between specialty and commodity businesses that are associated with the larger ecosystem. At the same time, new growth parameters are being vigorously being debated as industry stakeholders put greater emphasis on the circular economy processes.

More Trending Report-

https://www.prnewswire.com/news-releases/players-in-wollastonite-powder-market-target-countries-with-booming-construction-industry-manufacturers-aim-at-new-formulations-to-score-over-substitutes-tmr-301288587.html

0 notes

Text

Gas Cutting Machine Market to Witness a Pronounce Growth During 2026

Market Overview

Gas cutting machine finds significant end-use industry applications for the processing of carbon and low alloy steels such as aerospace, automotive, steel processing industries and shipping among few others. The consumables and equipment for the welding processes are similar to this equipment, except the welding torch is replaced by the cutting torch which is incorporated with a high-pressure oxygen tube. Extensive range of applications that include grooving weld joint metal designs, making edges of metal sheets, cut rivets, risers, and many other are expected to drive the demands for these industrial instruments.

The equipment can be used to c ut metals in small sizes and shapes, which is rather cumbersome using other mechanical methods. Incorporation of multiple torches can be used to cut multiple number of metal profiles simultaneously. Moreover, some machining alternatives provide easy portability that find large applications for field operations. In conjunction with these characteristics, fast operations and relatively low-cost requirement in comparison to other mechanical procedures, gas cutting equipment market is expected to witness major traction over the next few years.

Request Sample Copy Of This Business Report: https://www.coherentmarketinsights.com/insight/request-sample/633

Market Dynamics

Global increase in the average per capita income over the past decade has led to increased consumer buying power. Increasing global air traffic, commercial and personal automotive, defense expenditure, scraping of old aircrafts and ships, and shipping, specifically in countries that include China, India, Indonesia, U.S., and Middle East countries among few others. Owing to these factors, multi-billion dollar end user industries such as automotive, aerospace & defense, metal processing and ship building are expected to witness significant demand growth. Requirement to meet these production demands, industries will invest in industrial process tools and equipment, which in turn will drive the demands for the gas cutting machine market.

Gas cutting equipment market growth is anticipated to be hindered by several technical limitations. These drawbacks include its usage limited to steel and cast iron materials, low dimensional tolerances, requirement of adequate flame control and proper ventilated spaces for its operations. Moreover, red hot slag and heat generated in the process also presents burn and fire hazards to the users and the industry. Advent 3D technology is featured with several advantages over the conventional technologies such as minimum material wastage, savings in terms of raw material costs, and high ROI, is anticipated to witness large adoption for industrial applications. Utilization of laser technology for its operations will present major challenge to the gas cutting machine market growth.

Get Request Customization Copy Of This Business Report: https://www.coherentmarketinsights.com/insight/request-customization/633

Key market participants in the industry include Kaltenbach Group, ESAB, Koike Aronson, Hornet Cutting Systems, Messer Cutting Systems, Ador Welding, Haco, Harris Products Group, Shangai Welding & Cutting Tool Works, SteelTailor, and Voortman Steel Machinery

About Coherent Market Insights:

Coherent Market Insights is a prominent market research and consulting firm offering action-ready syndicated research reports, custom market analysis, consulting services, and competitive analysis through various recommendations related to emerging market trends, technologies, and potential absolute dollar opportunity.

Contact Us:

Name: Mr. Raj Shah

Phone: US +12067016702 / UK +4402081334027

Email: [email protected]

Visit Our Blogs: https://blog.coherentmarketinsights.com

0 notes

Text

Laser Processing Market with COVID-19 Impact analysis by Laser Type (Solid Lasers, Liquid Lasers, Gas Lasers), Configuration (Fixed Beam, Moving Beam, Hybrid), Revenue (System Revenue, Laser Revenue), Application, End-user Industry, and Region - Global Forecast to 2025 published on

https://www.sandlerresearch.org/laser-processing-market-with-covid-19-impact-analysis-by-laser-type-solid-lasers-liquid-lasers-gas-lasers-configuration-fixed-beam-moving-beam-hybrid-revenue-system-revenue-laser-revenue.html

Laser Processing Market with COVID-19 Impact analysis by Laser Type (Solid Lasers, Liquid Lasers, Gas Lasers), Configuration (Fixed Beam, Moving Beam, Hybrid), Revenue (System Revenue, Laser Revenue), Application, End-user Industry, and Region - Global Forecast to 2025

“Laser processing market to grow at CAGR of 7.8% from 2020 to 2025”

The global laser processing market size is projected to grow from USD 4.0 billion in 2020 to USD 5.8 billion by 2025; it is projected to record a CAGR of 7.8%. The laser processing industry’s growth is driven mainly by the growing preference of end-user industries for laser-based material processing over traditional approaches, increasing demand for high-quality and genuine end-products, rising demand for miniaturization of microelectronic devices, and surging technological advancements in the medical sector. High deployment cost and lack of personnel with required technical expertise are expected to restrain the market’s growth.

“Machine tools end-user industry to hold largest share of laser processing market by 2025”

The machine tools end-user industry segment is projected to hold the largest share of the laser processing market during the forecast period. Lasers play an integral role in general machine construction, mainly in cutting and welding purposes. Lasers help achieve clean-cut edges and reliable weld seams, especially in the field of sheet metal and tube processing. For instance, lasers are used in the production of tubes and other components that are cut or welded. This has opened numerous application areas for lasers in the machine tools industry.

“Solid lasers to hold largest share of laser processing market by 2025”

The solid lasers segment is projected to hold the largest share of the laser processing market during the forecast period. Solid lasers prevent the wastage of materials in the active medium and produce both continuous and pulsed output with high efficiency. These lasers have numerous applications, such as drilling holes in metals, endoscopy in medical, and targeting in military.

“Hybrid configuration segment to hold largest share of laser processing market by 2025”

The hybrid configuration segment is projected to hold the largest share of the laser processing market during the forecast period. A hybrid system is more efficient than the moving beam system as it provides a constant beam delivery path length and allows a comparatively simpler beam delivery system. This is due to the presence of a movable table and a movable head in the hybrid system.

“System revenue segment to hold larger share in laser processing market by 2025”

The system revenue segment is projected to hold a larger share of the laser processing market during the forecast period. System revenue covers the revenue generated from the sales of several types of laser processing systems, such as systems for marking & engraving, welding & brazing, cutting & scribing, drilling, cladding & coating, annealing, material removal, and other multi-function laser processing systems.

“Cutting application segment to hold largest share of laser processing market by 2025”

The cutting application segment is projected to hold the largest share of the laser processing market during the forecast period. The need for high-powered lasers for cutting of metals and non-metals is increasing worldwide. Lasers have also gained considerable traction in low-power applications, such as plastics cutting and paper cutting, in recent years. In the microelectronics industry, lasers have proven to be an economical method of cutting wafers to deliver high-quality products.

“APAC to be largest laser processing market by 2025”

Asia Pacific (APAC) is projected to hold the largest share of the global laser processing market during the forecast period. The major countries contributing to the laser processing industry in APAC include China, Japan, South Korea, and India. APAC has been ahead in terms of the adoption of laser processing solutions as compared with other regions. High population density, rise in R&D investments in technologies, and growth of the manufacturing and electronics sectors are expected to drive the growth of the laser processing market in the region.

Breakdown of Profiles of Primary Participants:

By Company: Tier 1 – 25%, Tier 2 – 40%, and Tier 3 – 35%

By Designation: C-level Executives – 35%, Directors – 25%, and Others* – 40%

By Region: North America – 45%, Europe – 20%, APAC – 25%, and RoW** – 10%

*Others include VPs, sales, marketing, and product managers.

**RoW includes South America and Middle East & Africa.

Major Players Profiled:

Coherent (US)

Trumpf (Germany)

Han’s Laser (China)

IPG Photonics (US)

Jenoptik (Germany)

Lumentum (US)

Gravotech (France)

LaserStar (US)

Lumibird (France)

Epilog Laser (US)

Research Coverage

This report offers detailed insights into the laser processing market, which is segmented based on laser type into solid lasers, gas lasers, liquid lasers, and others. Based on revenue, the market is segmented into laser revenue and system revenue. Based on application, the market is segmented into cutting, welding, drilling, marking & engraving, microprocessing, advanced processing, and others. Based on configuration, the market is segmented into fixed beam, moving beam, and hybrid. Based on end-user industry, the market is segmented into machine tools, microelectronics, automotive, medical & life sciences, aerospace & defense, architecture, and others. The study also forecasts the size of the market based on four regions—North America, Europe, Asia Pacific (APAC), and RoW.

Reasons to Buy the Report

The report would help market leaders/new entrants in the following ways:

It segments the laser processing market comprehensively and provides the closest approximations of the overall and segment-based market sizes across different laser types, revenue types, configurations, applications, end-user industries, and regions.

The report would help stakeholders understand the pulse of the market and provide them with information on key drivers, restraints, challenges, and opportunities for the growth of the market.

This report would help stakeholders understand their competitors better and gain more insights to enhance their market position. The competitive landscape section includes the competitive analysis of top players, as well as strategies such as product launches & developments, mergers and acquisitions, partnerships, and contracts adopted by major market players.

0 notes

Text

Asia-Pacific Collaborative Robot Market – Industry Trends and Forecast to 2026

Asia-Pacific Collaborative Robot Market By Component (Hardware, Software), By Safety Method (Power and Force Limiting, Safety Rated Monitored Stop, Speed and Separation Monitoring, Hand Guiding), By Solution (Camera Based 3D Space Monitoring System, Safe Gripping, Safety laser scanner, Safety Light Curtain), By Payload Capacity (Less than 5kg, 5Kg to 10Kg, above 10 kg), By Application (Packaging, Pick and Place / Drop, Assembly, Machine Tending, Material Handling, Lab Analysis, Quality Testing, Test and Inspection, Gluing and Welding, Molding Operation, Polishing, Others), By End User (Automotive, Electrical and Electronics, Metals and Machining, Plastic and Polymers, Aerospace and Defense, Food and Beverages, Furniture and Equipment, Pharmaceuticals, Entertainment, Cosmetics, Others), Countries (Japan, China, South Korea, India, Australia, Singapore, Thailand, Malaysia, Indonesia, Philippines and Rest of Asia-Pacific) – Industry Trends and Forecast to 2026

A collaborative robot is capable of performing multiple tasks, as assisted by the humans. In contrast, autonomous robots are built to perform same task repeatedly and work independently. Collaborative robots have additional features, such as safety monitored stop, hand guiding, speed & separation monitoring, and power & force limiting. There are various types of collaborative robots that are used in industries like safety monitored stop is used to stop the functioning of robot when the safety zone violates; hand guiding is used for path teaching and detection of applied forces; speed & separation monitoring is used for operations requiring frequent worker presence, and power & force limiting is used for the direct collaboration with workers. Collaborative robots are being used in multiple verticals, which include supply chain management, manufacturing, and healthcare. Few force limited robot models are Universal Robots UR3, UR5, UR10, Rethink Robotics Baxter, Sawyer, KUKA LBR iiwa, ABB Yumi, Fanuc CR-35iA, and F&P Robotics among other robots.

Asia-Pacific collaborative robot market is projected to register a highest CAGR in the forecast period of 2019 to 2026.

Request-a-sample@https://www.databridgemarketresearch.com/request-a-sample/?dbmr=asia-pacific-collaborative-robot-market

Segmentation: Asia-Pacific Collaborative Robot Market

Asia-Pacific collaborative robot market is segmented into six notable segments which are component, solution, safety method, payload capacity, application and end user.

· On the basis of component, the market is segmented into hardware and software.

· On the basis of solution, the market is segmented into safety light curtain, safety laser scanner, camera based 3D space monitoring system, and safe gripping.

· On the basis of safety method, the market is segmented into speed and separation monitoring, power and force limiting, safety-rated monitored stop, and hand guiding.

· On the basis of payload capacity, the market is segmented into up to 5kg, 5Kg to 10Kg, and above 15Kg.