#Adhesion

Explore tagged Tumblr posts

Text

Anti-Icing Polar Bear Fur

Despite spending their lives in and around frigid water, snow, and ice, polar bears are rarely troubled by ice building up on their fur. This natural anti-icing property is one Inuits have long taken advantage of by using polar bear fur in hunting stools and sandals. In a new study, researchers looked at just how "icephobic" polar bear fur is and what properties make it so. (Image credit: H. Mager; research credit: J. Carolan et al.; via Physics World) Read the full article

126 notes

·

View notes

Text

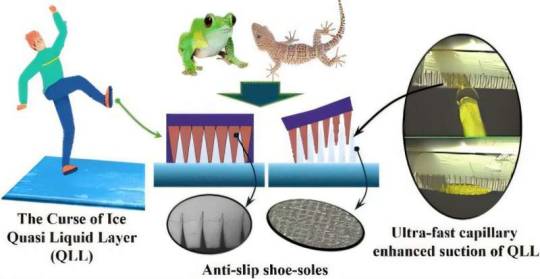

Animal footpads inspire a polymer that sticks to ice

A solution to injuries from slips and falls may be found underfoot—literally. The footpads of geckos have hydrophilic (water-loving) mechanisms that allow the little animals to easily move over moist, slick surfaces. Researchers have found that using silicone rubber enhanced with zirconia nanoparticles creates a gecko-inspired slip-resistant polymer. They say the material, which sticks to ice, could be incorporated into shoe soles to reduce injuries in humans. Their study is published in ACS Applied Materials & Interfaces. Slips and falls account for more than 38 million injuries and 684,000 deaths every year, according to the World Health Organization. And nearly half of these incidents happen on ice. Current anti-slip shoe soles rely on materials such as natural rubber that repel the layer of liquid water that sits atop the pavement on a rainy day.

Read more.

#Materials Science#Science#Polymers#Biomimicry#Surfaces#Ice#Silicone#Zirconia#Nanotechnology#Safety#Capillary action#Adhesion

17 notes

·

View notes

Text

Pelvic adhesions suck!!!! It hurts to move and sometimes even breathe.

What are adhesions? it's like endometriosis but it's scar tissue instead of uterine lining that sticks everything together. But unlike Endo, surgery won't help, in fact it can make it worse cuz it creates more scar tissue. 😭💔

#spoonie#chronic illness#chronically ill#chronic disease#chronic pain is a bitch#chronic pain#invisible illness#adhesion#pelvic pain#endometriosis#womens health#sexualhealth#no spoons#spoonie life#spoonie problems#spoonie support#spoonie shit#spoonie strong#spoonie stuff#but you dont look sick

6 notes

·

View notes

Text

2 notes

·

View notes

Text

a bit morbid but with the surge of adhesion, wouldn't you be able to remove all pressure acting on someone and boil them alive? if it only lets u add pressure, couldnt u just like, squash them? just add about 5 or so atmospheres in a small time frame. and boom. splat. or couldnt u rapidly decrease the pressure in their bodies, also squishing them?

anyway i can guess how the surges destroyed ashyn

4 notes

·

View notes

Text

Glue Mixer: Uniform Blending for Strong Adhesion – Enhance Plywood Quality

A glue mixer performs an important function in plywood production by ensuring consistent mixing of adhesives, leading to high bonding strength and high-quality boards. Being one of the top manufacturers of plywood machinery, we produce top-performance glue mixers that are aimed at precision, efficiency, and reliability.

Our high-end glue mixing machines maximize adhesive uniformity, minimizing wastage and plywood strength. For industrial production of plywood or small-scale businesses, our mixers ensure effortless application and improved adhesion.

Searching for a solid glue mixer to increase your manufacturing efficiency? Call DNH Engineers today and get to witness world-class plywood machine solutions!

Go and check out our website for more details: www.dnhengineers.com

0 notes

Photo

How Lizards Stick to Walls

1 note

·

View note

Text

#escalade#climbing#falaise#sports#environnement#climber#biodiversité#adhesion#licence#dons#soutien#partage

0 notes

Text

Is Water Wet? A Comprehensive Exploration

The question, "Is water wet?" might seem trivial, but it sparks curiosity and debate among scientists, philosophers, and everyday thinkers alike. This inquiry delves into the very nature of water and its properties, leading to a surprising exploration of science, perception, and semantics.

What Does It Mean to Be Wet?

To address whether water is wet, we first need to define "wetness." The term "wet" typically refers to a state where a liquid adheres to a surface, often making it slippery or damp. For instance:

Wetness in Daily Life: We describe a towel as wet when it has absorbed water, or skin as wet when water clings to it.

Scientific Definition: Wetness is a sensory and physical condition caused by liquid molecules adhering to a surface.

From this definition, wetness involves a relationship between a liquid and a solid. But where does this leave water itself?

The Argument That Water Is Wet

Some argue that water is inherently wet because:

Water Can Transfer Wetness: Anything water touches becomes wet, leading to the inference that water must itself be wet.

Water Molecules Adhere to Each Other: Through a phenomenon called cohesion, water molecules are attracted to one another, forming hydrogen bonds. This interaction might be interpreted as water being "wet" to itself.

Common Usage: From a linguistic perspective, we often describe water as wet in casual conversation, suggesting that wetness and water are intertwined in our perception.

The Argument That Water Is Not Wet

On the other hand, many argue that water itself is not wet:

Wetness Is a Surface Phenomenon: Wetness arises only when water interacts with a solid. Water alone, without a solid surface to adhere to, cannot be wet.

Intrinsic vs. Relational Property: Wetness is not an inherent property of water but rather a description of the effect water has on other materials.

Scientific Clarification: Liquids like water are "liquid" by definition, but the term "wet" describes a state of interaction rather than a fundamental characteristic.

Scientific Insights Into the Nature of Water

To further explore, we can analyze water’s unique properties:

Cohesion and Adhesion: Water molecules bond with each other (cohesion) and with other surfaces (adhesion). These forces are what make materials wet when in contact with water.

Surface Tension: Water’s high surface tension allows it to bead up on surfaces, demonstrating its adhesive and cohesive properties.

Hydrophobic vs. Hydrophilic Surfaces: Whether a material gets wet depends on its interaction with water. For example:

Hydrophobic surfaces repel water (like rain on a waxed car).

Hydrophilic surfaces attract water, leading to a spread-out wet layer.

While these properties allow water to "make things wet," they do not inherently make water itself wet.

Philosophical Perspectives

The debate about water’s wetness also touches on deeper philosophical issues:

Perception of Wetness: Wetness is a sensory experience. Without the context of a surface or observer, can water be considered wet at all?

Semantic Relativity: The term "wet" may simply be a linguistic construct, with no absolute truth in its application to water.

Ontological Inquiry: Is wetness an essential quality of water, or is it only attributed through its interactions?

ALSO READ: How to Make Rose Water: The Ultimate DIY Guide

Experimental Observations

For a more practical approach, consider this experiment:

Submerge your hand in water. Your hand is wet because water adheres to your skin.

However, water molecules within the body of water are surrounded by other water molecules. There’s no solid surface for them to adhere to. Therefore, they lack the defining characteristic of wetness.

This suggests that water itself, in isolation, cannot be wet.

Conclusion

So, is water wet? The answer depends on how you define wetness:

If wetness describes the intrinsic property of a liquid, then water could be considered wet.

If wetness is strictly the result of interaction with a surface, water itself is not wet but makes other things wet.

This debate blends science, semantics, and philosophy, demonstrating how a seemingly simple question can lead to complex discussions. Whether you believe water is wet or not, this inquiry is a reminder of how the ordinary can inspire profound thought.

#Water#Science#Philosophy#IsWaterWet#Wetness#Nature#Cohesion#Adhesion#ScienceFacts#Physics#Curiosity#Debate#Exploration#HydrogenBonds#EducationalContent#ThoughtProvoking#SemanticDebate#WaterProperties#ScienceExplained#DeepQuestions

1 note

·

View note

Text

Making agriculture more resilient to climate change

New Post has been published on https://thedigitalinsider.com/making-agriculture-more-resilient-to-climate-change/

Making agriculture more resilient to climate change

As Earth’s temperature rises, agricultural practices will need to adapt. Droughts will likely become more frequent, and some land may no longer be arable. On top of that is the challenge of feeding an ever-growing population without expanding the production of fertilizer and other agrochemicals, which have a large carbon footprint that is contributing to the overall warming of the planet.

Researchers across MIT are taking on these agricultural challenges from a variety of angles, from engineering plants that sound an alarm when they’re under stress to making seeds more resilient to drought. These types of technologies, and more yet to be devised, will be essential to feed the world’s population as the climate changes.

“After water, the first thing we need is food. In terms of priority, there is water, food, and then everything else. As we are trying to find new strategies to support a world of 10 billion people, it will require us to invent new ways of making food,” says Benedetto Marelli, an associate professor of civil and environmental engineering at MIT.

Marelli is the director of one of the six missions of the recently launched Climate Project at MIT, which focus on research areas such as decarbonizing industry and building resilient cities. Marelli directs the Wild Cards mission, which aims to identify unconventional solutions that are high-risk and high-reward.

Drawing on expertise from a breadth of fields, MIT is well-positioned to tackle the challenges posed by climate change, Marelli says. “Bringing together our strengths across disciplines, including engineering, processing at scale, biological engineering, and infrastructure engineering, along with humanities, science, and economics, presents a great opportunity.”

Protecting seeds from drought

Marelli, who began his career as a biomedical engineer working on regenerative medicine, is now developing ways to boost crop yields by helping seeds to survive and germinate during drought conditions, or in soil that has been depleted of nutrients. To achieve that, he has devised seed coatings, based on silk and other polymers, that can envelop and nourish seeds during the critical germination process.

A new seed-coating process could facilitate agriculture on marginal arid lands by enabling the seeds to retain any available water.

In healthy soil, plants have access to nitrogen, phosphates, and other nutrients that they need, many of which are supplied by microbes that live in the soil. However, in soil that has suffered from drought or overfarming, these nutrients are lacking. Marelli’s idea was to coat the seeds with a polymer that can be embedded with plant-growth-promoting bacteria that “fix” nitrogen by absorbing it from the air and making it available to plants. The microbes can also make other necessary nutrients available to plants.

For the first generation of the seed coatings, he embedded these microbes in coatings made of silk — a material that he had previously shown can extend the shelf life of produce, meat, and other foods. In his lab at MIT, Marelli has shown that the seed coatings can help germinating plants survive drought, ultraviolet light exposure, and high salinity.

Now, working with researchers at the Mohammed VI Polytechnic University in Morocco, he is adapting the approach to crops native to Morocco, a country that has experienced six consecutive years of drought due a drop in rainfall linked to climate change.

For these studies, the researchers are using a biopolymer coating derived from food waste that can be easily obtained in Morocco, instead of silk.

“We’re working with local communities to extract the biopolymers, to try to have a process that works at scale so that we make materials that work in that specific environment.” Marelli says. “We may come up with an idea here at MIT within a high-resource environment, but then to work there, we need to talk with the local communities, with local stakeholders, and use their own ingenuity and try to match our solution with something that could actually be applied in the local environment.”

Microbes as fertilizers

Whether they are experiencing drought or not, crops grow much better when synthetic fertilizers are applied. Although it’s essential to most farms, applying fertilizer is expensive and has environmental consequences. Most of the world’s fertilizer is produced using the Haber-Bosch process, which converts nitrogen and hydrogen to ammonia at high temperatures and pressures. This energy intensive process accounts for about 1.5 percent of the world’s greenhouse gas emissions, and the transportation required to deliver it to farms around the world adds even more emissions.

Ariel Furst, the Paul M. Cook Career Development Assistant Professor of Chemical Engineering at MIT, is developing a microbial alternative to the Haber-Bosch process. Some farms have experimented with applying nitrogen-fixing bacteria directly to the roots of their crops, which has shown some success. However, the microbes are too delicate to be stored long-term or shipped anywhere, so they must be produced in a bioreactor on the farm.

MIT chemical engineers devised a metal-organic coating that protects bacterial cells from damage without impeding their growth or function.

To overcome those challenges, Furst has developed a way to coat the microbes with a protective shell that prevents them from being destroyed by heat or other stresses. The coating also protects microbes from damage caused by freeze-drying — a process that would make them easier to transport.

The coatings can vary in composition, but they all consist of two components. One is a metal such as iron, manganese, or zinc, and the other is a polyphenol — a type of plant-derived organic compound that includes tannins and other antioxidants. These two components self-assemble into a protective shell that encapsulates bacteria.

Play video

Mighty Microbes: The Power of Protective Polymers

Video: Chemistry Shorts

“These microbes would be delivered with the seeds, so it would remove the need for fertilizing mid-growing. It also reduces the cost and provides more autonomy to the farmers and decreases carbon emissions associated with agriculture,” Furst says. “We think it’ll be a way to make agriculture completely regenerative, so to bring back soil health while also boosting crop yields and the nutrient density of the crops.”

Furst has founded a company called Seia Bio, which is working on commercializing the coated microbes and has begun testing them on farms in Brazil. In her lab, Furst is also working on adapting the approach to coat microbes that can capture carbon dioxide from the atmosphere and turn it into limestone, which helps to raise the soil pH.

“It can help change the pH of soil to stabilize it, while also being a way to effectively perform direct air capture of CO2,” she says. “Right now, farmers may truck in limestone to change the pH of soil, and so you’re creating a lot of emissions to bring something in that microbes can do on their own.”

Distress sensors for plants

Several years ago, Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT, began to explore the idea of using plants themselves as sensors that could reveal when they’re in distress. When plants experience drought, attack by pests, or other kinds of stress, they produce hormones and other signaling molecules to defend themselves.

Strano, whose lab specializes in developing tiny sensors for a variety of molecules, wondered if such sensors could be deployed inside plants to pick up those distress signals. To create their sensors, Strano’s lab takes advantage of the special properties of single-walled carbon nanotubes, which emit fluorescent light. By wrapping the tubes with different types of polymers, the sensors can be tuned to detect specific targets, giving off a fluorescent signal when the target is present.

For use in plants, Strano and his colleagues created sensors that could detect signaling molecules such as salicylic acid and hydrogen peroxide. They then showed that these sensors could be inserted into the underside of plant leaves, without harming the plants. Once embedded in the mesophyll of the leaves, the sensors can pick up a variety of signals, which can be read with an infrared camera.

Sensors that detect plant signaling molecules can reveal when crops are experiencing too much light or heat, or attack from insects or microbes.

These sensors can reveal, in real-time, whether a plant is experiencing a variety of stresses. Until now, there hasn’t been a way to get that information fast enough for farmers to act on it.

“What we’re trying to do is make tools that get information into the hands of farmers very quickly, fast enough for them to make adaptive decisions that can increase yield,” Strano says. “We’re in the middle of a revolution of really understanding the way in which plants internally communicate and communicate with other plants.”

This kind of sensing could be deployed in fields, where it could help farmers respond more quickly to drought and other stresses, or in greenhouses, vertical farms, and other types of indoor farms that use technology to grow crops in a controlled environment.

Much of Strano’s work in this area has been conducted with the support of the U.S. Department of Agriculture (USDA) and as part of the Disruptive and Sustainable Technologies for Agricultural Precision (DiSTAP) program at the Singapore-MIT Alliance for Research and Technology (SMART), and sensors have been deployed in tests in crops at a controlled environment farm in Singapore called Growy.

“The same basic kinds of tools can help detect problems in open field agriculture or in controlled environment agriculture,” Strano says. “They both suffer from the same problem, which is that the farmers get information too late to prevent yield loss.”

Reducing pesticide use

Pesticides represent another huge financial expense for farmers: Worldwide, farmers spend about $60 billion per year on pesticides. Much of this pesticide ends up accumulating in water and soil, where it can harm many species, including humans. But, without using pesticides, farmers may lose more than half of their crops.

Kripa Varanasi, an MIT professor of mechanical engineering, is working on tools that can help farmers measure how much pesticide is reaching their plants, as well as technologies that can help pesticides adhere to plants more efficiently, reducing the amount that runs off into soil and water.

Varanasi, whose research focuses on interactions between liquid droplets and surfaces, began to think about applying his work to agriculture more than a decade ago, after attending a conference at the USDA. There, he was inspired to begin developing ways to improve the efficiency of pesticide application by optimizing the interactions that occur at leaf surfaces.

“Billions of drops of pesticide are being sprayed on every acre of crop, and only a small fraction is ultimately reaching and staying on target. This seemed to me like a problem that we could help to solve,” he says.

Varanasi and his students began exploring strategies to make drops of pesticide stick to leaves better, instead of bouncing off. They found that if they added polymers with positive and negative charges, the oppositely charged droplets would form a hydrophilic (water-attracting) coating on the leaf surface, which helps the next droplets applied to stick to the leaf.

Graduate student Maher Damak (left) and associate professor of mechanical engineering Kripa K. Varanasi, have found a way to drastically cut down on the amount of pesticide liquid that bounces off plants.

Later, they developed an easier-to-use technology in which a surfactant is added to the pesticide before spraying. When this mixture is sprayed through a special nozzle, it forms tiny droplets that are “cloaked” in surfactant. The surfactant helps the droplets to stick to the leaves within a few milliseconds, without bouncing off.

In 2020, Varanasi and Vishnu Jayaprakash SM ’19, PhD ’22 founded a company called AgZen to commercialize their technologies and get them into the hands of farmers. They incorporated their ideas for improving pesticide adhesion into a product called EnhanceCoverage.

During the testing for this product, they realized that there weren’t any good ways to measure how many of the droplets were staying on the plant. That led them to develop a product known as RealCoverage, which is based on machine vision. It can be attached to any pesticide sprayer and offer real-time feedback on what percentage of the pesticide droplets are sticking to and staying on every leaf.

RealCoverage was used on 65,000 acres of farmland across the United States in 2024, from soybeans in Iowa to cotton in Georgia. Farmers who used the product were able to reduce their pesticide use by 30 to 50 percent, by using the data to optimize delivery and, in some cases, even change what chemicals were sprayed.

He hopes that the EnhanceCoverage product, which is expected to become available in 2025, will help farmers further reduce their pesticide use.

“Our mission here is to help farmers with savings while helping them achieve better yields. We have found a way to do all this while also reducing waste and the amount of chemicals that we put into our atmosphere and into our soils and into our water,” Varanasi says. “This is the MIT approach: to figure out what are the real issues and how to come up with solutions. Now we have a tool and I hope that it’s deployed everywhere and everyone gets the benefit from it.”

#000#2024#Accounts#adhesion#agriculture#air#ammonia#approach#atmosphere#Bacteria#billion#Biological engineering#biopolymers#Brazil#Building#Capture#carbon#Carbon dioxide#carbon emissions#carbon footprint#carbon nanotubes#career#career development#Cells#challenge#change#chemical#Chemical engineering#chemicals#chemistry

0 notes

Text

Unsticking in Jumps

Soft materials tend to be sticky, and once they're adhered to a surface, they're often harder to remove than they were to attach -- think of Scotch tape stuck to a desk. This difficulty separating sticky things -- known as adhesion hysteresis -- has been attributed to various causes, like energy lost to viscoelasticity or age-related chemical bonding. But a new study shows that both those explanations are unnecessary. (Image and research credit: A. Sanner et al.; via Physics World) Read the full article

71 notes

·

View notes

Text

Is Tribology Approaching Its Golden Age? Grand Challenges in Engineering Education and Tribological Research

Valentin L. Popov* Technische Universität Berlin, Berlin, Germany In spite of its obvious importance, the subject of tribology has relatively low visibility in the engineering community and among the general public. The author’s hypothesis is that this problem is at least partly due to the poor “availability” of tribology. In other words, there are practically no simple methods or concepts…

View On WordPress

#adhesion#boundary element method#contact mechanics#磨损#elastohydrodynamics#lubrication#third body#tribochemistry#wear#接触力学#润滑

0 notes

Text

LE PEUPLE JAPONAIS SE RÉVOLTE ET REJETTE L'ADHÉSION DU JAPON À L'ACCORD MONDIAL DE L'OMS SUR LES PANDÉMIES !!

AUCUN PEUPLE NE VEUT DE L'OMS !!

Le Japon se révolte

Le Japon rejette l'Organisation Mondiale de la Santé ! Des milliers de Japonais se rassemblent pour protester contre l'adhésion du Japon à l'accord mondial de l'OMS sur les pandémies. Il semble que les Japonais ne veuillent pas que des mondialistes psychotiques non élus exigent des vaccins, des masques et des fermetures...

PARTAGEZ !! DIFFUSEZ !! INFORMEZ !!

THE JAPANESE PEOPLE REVOLT AND REJECT JAPAN'S ACCESSION TO THE WHO GLOBAL PANDEMIC AGREEMENT!!!

NO PEOPLE WANT THE WHO!!

Japan revolts

Japan rejects the World Health Organization! Thousands of Japanese gather to protest Japan's accession to the WHO's global agreement on pandemics. It seems the Japanese don't want unelected psychotic globalists demanding vaccines, masks and closures...

SHARE!! SPREAD THE WORD! INFORM !!

#japon#japan#OMS#WHO#adhesion#people#peuple#population#japonais#japanese#agrrement#accord#mondialiste#globalist

1 note

·

View note

Text

electing to believe this is what griddlehark looks like to everyone else

#like i could go into my thoughts on bodymodification in domincus and how i think#light eyes/non-brown eyes are infinitely more common now#despite the fact there still seems to be adhesion to the relative norm (natural eye colors#yellow eyes being both unique to the populace of canaan house and unique enough that#gids lineage can be determined via#DESPITE the fact that while theoretically it would be a superficial change#john seems to have inadvertently changed his own genetics to do it? making it something a necromancer Could Do?#idk. whatever#the locked tomb#thoughts from the stars#1k#2k#3k#shout out to my first post to hit#4k#5k#sighs#6k

7K notes

·

View notes

Text

Turns out there's a whole-ass way to stick things together that nobody noticed until now?

0 notes