#3D Bioprinting Manufacturers

Explore tagged Tumblr posts

Text

3D Bioprinting Market Size, Share, Development Opportunities, Growth Outlook and Global Scope Analysis by Top Players

3D bioprinting is a groundbreaking technology that has the potential to revolutionize the field of medicine. It involves the use of 3D printing technology to create living tissues and organs that can be used for research, testing, and transplantation. The process begins with the creation of a digital 3D model of the desired tissue or organ, which is then fed into a bioprinter. The bioprinter then uses bioink, a substance made up of living cells, to print the tissue or organ layer by layer, creating a three-dimensional structure that mimics the natural tissues of the human body.

One of the major benefits of 3D bioprinting is the potential to address the shortage of organs available for transplant. Every year, thousands of people die waiting for a suitable organ donor. With 3D bioprinting, it may be possible to create personalized organs that are a perfect match for the recipient, reducing the risk of rejection and increasing the chances of a successful transplant. In addition to organ transplantation, 3D bioprinting has the potential to transform the field of regenerative medicine by providing a way to create customized tissue and bone grafts for patients.

Despite the many benefits of 3D bioprinting, there are still some challenges to be addressed. One of the biggest obstacles is the need for a reliable and safe source of bioink. While some progress has been made in developing bioinks that are suitable for use in bioprinters, there is still much research to be done to ensure that these substances are both safe and effective. In addition, the process of creating complex, multi-cellular structures is still in its early stages, and much work needs to be done to refine the technology and make it more efficient. Nonetheless, the potential benefits of 3D bioprinting make it an exciting field with enormous promise for the future of medicine.

Read more @ https://techinforite.blogspot.com/2023/02/3d-bioprinting-market-by-technology.html

#3D Bioprinting Trend#3D Bioprinting size#3D Bioprinting growth#3D Bioprinting#3D Bioprinting Industry#3D Bioprinting Price#3D Bioprinting Size#3D Bioprinting Share#3D Bioprinting Analysis#3D Bioprinting Forecast#3D Bioprinting Consumption#3D Bioprinting Sales#3D Bioprinting Segmentation#3D Bioprinting Manufacturers#3D Bioprinting Prospectus#3D Bioprinting Industry Trends#3D Bioprinting Growth#3D Bioprinting Trends#Global 3D Bioprinting Industry#Global 3D Bioprinting Trends#Global 3D Bioprinting Share#Global 3D Bioprinting Size

0 notes

Text

From 3D Printing to Bioprinting: The Future of Manufacturing

In recent years, the world of manufacturing has experienced significant transformations, with 3D printing and bioprinting technologies emerging as key drivers of change. These advanced manufacturing methods have the potential to revolutionize how products are created, impacting various industries and potentially reshaping the global supply chain. In this article, we will delve into the world of…

View On WordPress

#3D printing#additive manufacturing#bioprinting#decentralized production#future of manufacturing#on-demand manufacturing#personalized medicine#rapid prototyping#sustainability#tissue engineering

2 notes

·

View notes

Text

The Science Behind 3D Printing and Its Innovations

Introduction Alternative term for additive manufacturing: in this process, objects are conceptualized in another manner, changing how the objects are thought of by using 3D printing. One such technology is making creation from prototyping to final products more flexible and efficient. At TechtoIO, we deep dive into the science of 3D printing and the innovations that fuel this groundbreaking technology. Read to continue link

#Science Explained#Tags3D printed houses#3D printed prosthetics#3D printing applications#3D printing benefits#3D printing education#3D printing future#3D printing in automotive#3D printing in fashion#3D printing in healthcare#3D printing materials#3D printing prototyping#3D printing science#3D printing technology#additive manufacturing#aerospace 3D printing#bioprinting#construction 3D printing#custom 3D printing#innovations in 3D printing#Technology#Science#business tech#Adobe cloud#Trends#Nvidia Drive#Analysis#Tech news#Science updates#Digital advancements

1 note

·

View note

Text

3D Printing: From Prototypes to Organ Transplants

In the last decade, the landscape of manufacturing, medical science, and even the arts have been fundamentally transformed by the advent of 3D printing technology. Once a niche tool used for the creation of simple prototypes, 3D printing has burgeoned into a revolutionary force that stands at the forefront of innovation across numerous sectors. This article delves into the journey of 3D printing,…

View On WordPress

#3D ink#3D models#3D printed organs#3D printing#3D scanners#Additive manufacturing#Aerospace#Artificial organs#Automotive#Bioengineering#Bioink#Biomaterials#Bioprinting#Biotechnology#CAD#Cellular structures#Ceramics#Creative tech#Custom-made#customization#Dental devices#Design#Design thinking#Development#Digital fabrication#Digital manufacturing#Digital models#Disruptive tech#Donor organs#efficiency

1 note

·

View note

Text

The Art and Science of Biofabrication: Creating Life from Cells

Biofabrication Technology: Pioneering the Future of Medicine and Sustainability

Discover the transformative potential of biofabrication technology in healthcare and sustainability. Learn about applications, challenges, and future prospects in this comprehensive guide.

Biofabrication technology, a cutting-edge field at the intersection of biology and manufacturing, holds immense promise for revolutionizing various industries, particularly healthcare and sustainability. This article delves into the intricacies of biofabrication, its applications, challenges, and the transformative impact it promises to deliver.

Introduction to Biofabrication Technology

Biofabrication refers to the use of advanced manufacturing techniques to fabricate biological constructs such as tissues, organs, and even entire organisms. Unlike traditional manufacturing methods, biofabrication utilizes living cells, biomaterials, and biologically active molecules to create functional tissues and structures.

Understanding Biofabrication Processes

Additive Manufacturing Techniques

One of the key methodologies employed in biofabrication is additive manufacturing, commonly known as 3D printing. This process allows for precise layer-by-layer deposition of biomaterials, enabling the creation of complex structures with unprecedented accuracy and resolution.

Biomaterials Used in Biofabrication

Various biomaterials are utilized in biofabrication, including hydrogels, polymers, and decellularized matrices. These materials provide the necessary scaffolding and support for cell growth and tissue formation.

Applications of Biofabrication Technology

Biofabrication holds tremendous potential across a multitude of applications:

Medical Field

In medicine, biofabrication enables the creation of patient-specific tissues and organs for transplantation, reducing the risk of rejection and addressing the global organ shortage crisis.

Tissue Engineering

Biofabricated tissues can be utilized for regenerative medicine applications, including wound healing, bone repair, and the development of artificial skin substitutes.

Drug Testing and Delivery

Biofabricated models allow for more accurate and efficient drug testing, minimizing the need for animal testing and accelerating the drug development process.

Challenges and Limitations

Despite its vast potential, biofabrication faces several challenges:

Regulatory Hurdles

Regulatory frameworks governing the use of biofabricated products are still evolving, posing challenges for widespread adoption and commercialization.

Scalability Issues

Scaling up biofabrication processes to meet the demands of mass production remains a significant hurdle, particularly for complex organs and tissues.

Future Prospects and Innovations

The future of biofabrication holds exciting possibilities:

Bioprinting Organs

Researchers are actively working on bioprinting complex organs such as hearts, kidneys, and livers, offering hope for patients awaiting organ transplants.

Personalized Medicine

Biofabrication enables the customization of medical treatments based on individual patient profiles, leading to more effective and personalized healthcare solutions.

Ethical Considerations in Biofabrication

Biofabrication raises important ethical questions:

Animal Testing

The use of animal-derived cells and tissues in biofabrication processes raises concerns about animal welfare and the ethical implications of such practices.

Intellectual Property Rights

Issues surrounding patenting and ownership of biofabricated products raise complex ethical and legal dilemmas, requiring careful consideration.

Impact of Biofabrication on Sustainability

Biofabrication also holds promise for promoting sustainability:

Reduction in Waste

By enabling the production of tissues and organs on demand, biofabrication reduces the need for animal experimentation and minimizes biomedical waste.

Environmental Benefits

Biofabricated products have the potential to reduce the environmental footprint of traditional manufacturing processes, contributing to a more sustainable future.

Case Studies in Biofabrication

Several companies are leading the charge in biofabrication:

Organovo

Organovo specializes in bioprinting human tissues for pharmaceutical research and therapeutic applications, paving the way for personalized medicine.

Modern Meadow

Modern Meadow focuses on biofabricating animal-free leather and meat products, offering sustainable alternatives to traditional animal-derived materials.

Collaborations and Partnerships

Collaboration between academia, industry, and government is critical for advancing biofabrication:

Academic Institutions

Universities and research institutions play a pivotal role in driving innovation and pushing the boundaries of biofabrication technology.

Industry Leaders

Partnerships with industry leaders facilitate the translation of research findings into practical applications and commercial products.

Investment Trends in Biofabrication

The biofabrication industry is witnessing significant investment:

Venture Capital Funding

Venture capital firms are pouring funds into biofabrication startups, recognizing the immense potential for disruptive innovation in healthcare and sustainability.

Government Grants

Government agencies are also supporting biofabrication research through grants and funding opportunities, further fueling industry growth.

Educational Initiatives in Biofabrication

Educational programs are essential for nurturing the next generation of biofabrication experts:

Training Programs

Specialized training programs and courses equip students and professionals with the skills and knowledge needed to excel in the field of biofabrication.

Research Opportunities

Research institutions offer diverse opportunities for conducting groundbreaking research in biofabrication, driving innovation and discovery.

Global Adoption and Market Growth

Biofabrication is gaining traction worldwide:

Regions Leading in Biofabrication

Countries like the United States, Japan, and Germany are at the forefront of biofabrication research and innovation.

Market Size and Growth Projections

The global biofabrication market is poised for exponential growth, driven by increasing demand for personalized healthcare solutions and sustainable manufacturing practices.

Public Perception and Awareness

Public perception plays a crucial role in shaping the future of biofabrication:

Media Representation

Accurate and balanced media coverage is essential for fostering understanding and acceptance of biofabrication technology among the general public.

Public Acceptance

Building trust and transparency around biofabrication processes is essential for gaining public acceptance and overcoming skepticism.

Conclusion

In conclusion, biofabrication technology represents a paradigm shift in medicine and manufacturing, offering unprecedented opportunities for improving healthcare outcomes and promoting sustainability. Despite the challenges and ethical considerations, the future of biofabrication is bright, driven by innovation, collaboration, and a shared commitment to advancing human health and environmental stewardship.

FAQs on Biofabrication Technology

What is biofabrication technology?

How does biofabrication differ from traditional manufacturing methods?

What are the main applications of biofabrication?

What challenges does biofabrication face in terms of regulation and scalability?

How can biofabrication contribute to sustainability efforts?

#Biofabrication technology#3D bioprinting#Tissue engineering#Regenerative medicine#Sustainable manufacturing#Additive manufacturing#Personalized healthcare#Organ transplantation#Ethical considerations#Venture capital investment

0 notes

Text

Print wide range of biocompatible biomaterials with BIOX6 The BIO X6 is designed as an open source system, ensuring compatibility with a diverse array of biomaterials. The revolutionary BIO X6 elevates bioprinting to new heights. It is designed to enable an increased level of complexity without any added difficulty to researchers.

Know More: https://altem.com/bio-x6/

For more information, mail us at [email protected]

0 notes

Text

The Bright Future of Bioengineering

In the ever-evolving landscape of healthcare, the future lies in the hands of innovative breakthroughs and advancements derived from ongoing research. One pivotal aspect of this transformative journey is in the realm of bioengineering. This field seamlessly integrates engineering principles into the intricate tapestry of biological systems and biomedical technologies. From groundbreaking medical…

View On WordPress

0 notes

Text

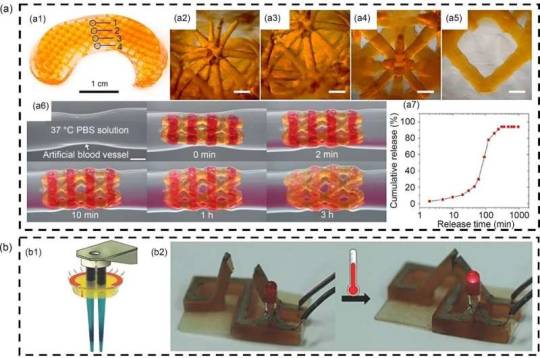

From lab to life: 3D bioprinting unveils new horizons in biomedical applications

With the development of intelligent biomedical engineering, the application of three-dimensional (3D) printing technology has become increasingly widespread. However, existing 3D printing technologies mainly focus on inorganic or polymer materials, limiting their applications in biocompatibility and biodegradability. Due to these challenges, there is a need for in-depth research on biocompatible and functional materials. This review, conducted by institutions such as China University of Petroleum (East China), Zhejiang University, and Tel Aviv University, was published in Bio-Design and Manufacturing, on 29 April 2024. The research team explored the combination of peptide self-assembly technology with 3D printing for developing complex biological structures and organs. This breakthrough lays the foundation for future biomedical applications. The study provides an in-depth analysis of recent progress in 3D bioprinting in Israel, focusing on scientific studies on printable components, soft devices, and tissue engineering. It highlights the potential of peptide self-assembly technology as a bioinspired ink for constructing complex 3D structures.

Read more.

11 notes

·

View notes

Text

Biotechnology Market- Trends Shaping the Future

The modern biotech realm provides cutting-edge technologies to tackle rare diseases and minimize environmental impact. From companies leveraging human genetics to possibilities of personalized medicine, biotech influence spans a profound spectrum. This technology is capable of feeding the hungry and offering them a cure. It is a cleaner, safer, and efficient technology for the future.

Biotech holds significant promises for companies. The approach to precision medicine allows pharmaceutical companies to reduce the risk of human complications. The biomanufacturing trend is transforming the ways to produce chemicals and materials that are conventionally produced through synthetic processes. Biotechnology in manufacturing is foreseen to improve productivity and innovation.

Biotechnology is expanding in additive manufacturing processes such as 3D printing. Bioprinters print organ-like structures to benefit the healthcare sector. The potential of biotech is widespread from drug discovery to the creation of personalized medicines. Recent bioprinting innovation is foreseen to be a breakthrough in the coming years.

The biotechnology market is anticipated to hold promising growth potential in coming years driven by trends that engineer new biological systems and aim to redesign existing ones. Although there are challenges in the biotechnology market ahead, its potential outweighs the hurdles. Biotechnology is capable of delivering new solutions in agriculture, medicine, and industrial sectors foreseen to increase biotechnology market share.

2 notes

·

View notes

Text

How 3D Printing is Transforming Orthopedics: Precision, Customization, and Future Possibilities

The rapid evolution of orthopedics is significantly driven by 3D printing technology, a revolutionary advancement also known as additive manufacturing. This cutting-edge technology is enabling orthopedic surgeons to create custom, patient-specific solutions that transform how procedures are performed and improve patient outcomes. From customized implants to precision-based surgical guides, 3D printing offers a unique, personalized approach to orthopedic care, providing benefits that traditional manufacturing methods cannot match.

3D printing in orthopedics begins with creating a digital model based on detailed imaging scans, such as MRIs or CT scans, that map out a patient’s specific anatomy. This model acts as a blueprint for the 3D printing process, which builds objects layer by layer to match the precise contours needed. Through this process, orthopedics can produce customized implants, prosthetics, surgical instruments, and anatomical models that are specifically tailored to fit each patient. Unlike standardized implants, which may not suit all anatomical structures, these custom solutions reduce the risk of discomfort, complications, and the potential need for revision surgeries, providing a more comfortable, functional fit.

One of the most remarkable uses of 3D printing in orthopedics is the creation of surgical guides and anatomical models. These guides are designed to align perfectly with the patient’s unique bone structure, helping surgeons accurately position instruments and implants, which is essential for procedures like hip and knee replacements. This precision minimizes errors and promotes faster recovery times. Additionally, 3D-printed models enhance the education and training of orthopedic surgeons, offering a hands-on way to practice procedures and study complex structures, which ultimately leads to better surgical proficiency and patient care.

The benefits of 3D printing also extend to cost-effectiveness and efficiency. By enabling in-house production, orthopedic practices can reduce dependency on external suppliers, shorten lead times, and minimize inventory costs. As 3D printing technology advances, regulatory bodies are working to establish safety and compliance standards for these devices, ensuring patient trust and safety.

Looking forward, the future of 3D printing in orthopedics promises further innovation. Research in biocompatible materials and bioprinting techniques aims to develop implants that not only integrate with bone structures but potentially regenerate tissue, paving the way for advancements in regenerative medicine. This evolution in 3D printing technology marks a new era in orthopedic care, one defined by customization, precision, and transformative potential for patient-centered solutions.

Read The Article On: https://drmichaelgaudiani.com/transforming-orthopedic-practices-the-role-of-3d-printing-technology

0 notes

Text

3D Printing Medical Devices Market Size, Share, Growth Analysis 2031

The 3D printing medical devices market is poised for remarkable growth over the coming decade. By leveraging cutting-edge technologies, the medical industry is experiencing a paradigm shift in manufacturing, treatment personalization, and surgical interventions. The ability to produce customized implants, prosthetics, surgical guides, and bioprinted tissues is revolutionizing patient care, making treatments more efficient and personalized. As the industry continues to mature, the integration of 3D printing in healthcare is expected to not only enhance patient outcomes but also create significant business opportunities for medical device manufacturers.

The global 3D printing medical devices market was valued at USD 3.28 billion in 2023 and is projected to reach USD 11.59 billion by 2031, expanding at a CAGR of 17.1% during the forecast period. The increasing adoption of 3D printing technologies, advancements in material science, and a growing focus on personalized medicine are the key drivers behind the rapid growth of this market.

To Learn More About This Report, Request a Free Sample Copy - https://www.skyquestt.com/sample-request/3d-printing-medical-devices-market

Market Dynamics

1. Technological Advancements - The development of new materials and improved 3D printing techniques is at the heart of the medical device sector’s transformation. Metal 3D printing, especially for orthopedics and implants, is gaining traction due to its ability to produce highly durable and biocompatible devices. Similarly, the rise of bioprinting, where living cells are used to print tissues and organs, holds immense potential in regenerative medicine. These innovations open the door to highly personalized healthcare solutions.

2. Increasing Demand for Personalized Medicine - As healthcare becomes more patient-centric, the demand for personalized medical devices is surging. 3D printing technology enables the creation of customized implants, prosthetics, and surgical guides tailored to the unique anatomy of individual patients. Personalized solutions not only enhance the effectiveness of treatments but also minimize complications, leading to better patient outcomes and shorter recovery times. This trend is particularly evident in areas such as dentistry, orthopedics, and craniofacial surgery.

3. Cost-Effectiveness and Efficiency - The cost benefits of 3D printing in the medical field are substantial. Traditional manufacturing methods for medical devices involve long lead times, complex supply chains, and high production costs. In contrast, 3D printing allows for the rapid prototyping and on-demand production of devices, reducing waste, improving inventory management, and lowering costs. This is especially advantageous in developing markets, where access to affordable medical devices is crucial.

4. Regulatory Support and Market Approvals - Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and European Medicines Agency (EMA) are becoming more supportive of 3D-printed medical devices, providing clear guidelines for their approval and ensuring their safety and efficacy. The approval of several 3D-printed devices, such as custom implants and surgical tools, is contributing to the expansion of this market.

5. Growing Healthcare Expenditure - As global healthcare expenditure rises, particularly in emerging markets, the demand for advanced medical devices is growing. 3D printing offers a cost-effective alternative to traditional manufacturing processes, especially in regions where the healthcare system is under pressure to meet rising demands with limited resources. Moreover, the adoption of 3D printing is aligned with the ongoing push towards more efficient and sustainable healthcare solutions.

Market Segmentation

The 3D printing medical devices market can be categorized based on product type, technology, material, application, and region.

By Product Type

1. Prosthetics: Prosthetics are one of the largest applications for 3D printing. Custom-made prosthetic limbs, which are affordable, lightweight, and perfectly suited to a patient’s unique anatomy, are in high demand.

2. Implants: Customized implants for orthopedics, dental, and craniomaxillofacial surgeries are revolutionizing patient care. 3D printing allows for the precise manufacturing of implants that fit the unique shape and size of a patient’s body.

3. Surgical Instruments: Surgical tools and guides, including customized templates, are increasingly being 3D printed to improve precision during surgeries.

4. Bioprinted Tissues: Though still in early stages, bioprinting has the potential to produce tissues for organ transplants, wound healing, and drug testing.

By Technology

- Stereolithography (SLA)

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Inkjet Printing

- Laser Metal Deposition (LMD)

By Material

- Polymers

- Metals (Titanium, Stainless Steel, etc.)

- Ceramics

- Biomaterials (for bioprinting)

By Application

1. Orthopedic: Custom joint replacements, bone scaffolds, and spinal implants.

2. Dental: Dental implants, crowns, bridges, and orthodontic devices.

3. Craniofacial: Customized implants and surgical guides for facial surgeries.

4. Soft Tissue Engineering: Applications in wound healing and skin grafts.

5. Other Applications: Including cardiovascular devices, hearing aids, and drug delivery systems.

Competitive Landscape

The market for 3D printing medical devices is highly competitive, with several key players at the forefront of technological innovation: Stratasys Ltd., 3D Systems Corporation, EnvisionTEC, Materialize NV, GE Additive, EOS GmbH, SLM Solutions Group AG, Formlabs, Renishaw plc, Organovo Holdings Inc., Carbon, Inc., Concept Laser GmbH, HP Inc., Desktop Metal Inc., Arcam AB, Prodways Group, Voxeljet AG, Markforged Inc., Medtronic plc, Stratasys Direct Manufacturing

These companies are focusing on strategic partnerships, mergers and acquisitions, and continuous R&D to expand their product portfolios and enhance their market share.

Read 3D Printing Medical Devices Market Report Today - https://www.skyquestt.com/report/3d-printing-medical-devices-market

Challenges and Barriers

Despite its promising growth, the 3D printing medical devices market faces several challenges:

- Regulatory Hurdles: The process for regulatory approval of 3D-printed medical devices is still evolving, and navigating these regulations can be time-consuming and costly.

- Material Limitations: While 3D printing technologies have advanced, the range of materials available for medical devices remains limited, especially for high-performance applications.

- Cost of Technology: The initial cost of 3D printing equipment and software can be high, which may pose a barrier for small and medium-sized healthcare providers.

The 3D printing medical devices market is set to experience exponential growth by 2031. As the technology continues to evolve, it will enable the development of more personalized, cost-effective, and innovative medical solutions. Key factors driving growth include advancements in 3D printing technology, increased demand for personalized healthcare, and growing regulatory acceptance. However, challenges related to material limitations, regulatory hurdles, and high upfront costs need to be addressed to unlock the full potential of 3D printing in the medical field. For companies operating in this space, staying ahead of technological developments and regulatory requirements will be essential to capitalize on this rapidly growing market.

#3DPrinting#MedicalDevices#HealthcareInnovation#Bioprinting#PersonalizedMedicine#MedicalTechnology#MedTech#3DPrintingHealthcare#OrthopedicDevices#Dental3DPrinting#CraniofacialSurgery#Prosthetics#MedicalManufacturing#3DPrintedImplants#SurgicalDevices#RegenerativeMedicine#HealthcareTrends#3DPrintingRevolution#FutureOfHealthcare#MedicalResearch#TechInMedicine#3DPrintingMarket#DigitalHealth#MedTechInnovation#MedicalIndustry#3DPrintingGrowth

0 notes

Text

3D Printing Market — Forecast(2024–2030)

3D Printing Market Overview:

However, artificial 3D printing has opened up scope in the modern medical industry for people to opt for advanced, cost-effective, and appealing designed prosthetics. Healthcare sector has helped in generating a huge demand in the 3D printing market owing to its versatile application in dental implants, hearing aids, artificial organs, etc. 3D bioprinting fills up the gap between animal and human experimental trials with advanced bio-printed human skin, thyroid gland, and many other vital parts. Technological advancement has extended the manufacturing of almost every possible subject for 3D printing: automotive parts, metal printing, sample architectures and constructions, prototypes of footwear, energy production, food, educational, aeronautical approaches, robotics and drones, and many others. Moreover, continuous and limitless breakthroughs in 3D printing have created an enormous impact on the industrial and commercial field thereby expanding the 3D printing economy. The extensive market opportunity is expected to advance at a robust compound annual growth rate (CAGR) of 23% through 2030.

Sample Request :

3D printing or additive manufacturing employs layer-by-layer deposition of suitable materials to create an object. Acceptance of 3D printing has increased progressively from prototyping to low-volume manufacturing of customized products. Different types of 3D printing technologies are Stereo-lithography (SLA), Fused Deposition Modeling (FDM), and Selective Laser Sintering (SLS), among others. These above-mentioned technologies are deployed in various industries such as consumers, automotive, construction, aerospace, medical and others.

This report incorporates an in-depth assessment of the 3D printing market by type, technology, application, end user industries and geography. The offering types of 3D printing encompassed in the scope include hardware, software and services. The hardware segment is further sub segmented into printers, scanners and materials.

The 3D printing market is witnessing a surge in material diversity, with advancements in composite materials, biodegradable plastics, and metal alloys. This trend allows for more versatile and application-specific 3D printing, catering to industries such as aerospace, healthcare, and automotive. The 3D printing trend toward large-scale manufacturing is reshaping industries traditionally reliant on massive components. From building construction to shipbuilding, the ability to 3D print large structures is revolutionizing design possibilities, streamlining production, and ushering in a new era of efficiency and customization. Large-scale additive manufacturing is gaining traction, allowing for the production of bigger and more complex structures. Industries like construction, shipbuilding, and infrastructure are exploring the potential of 3D printing for large components, reducing assembly requirements and lead times.

Inquiry Before Buying :

Market Snapshot:

Report Coverage

The “3D Printing Market Report — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Bulletproof Glass Industry.

By Product: Hardware [Printers (Industrial, Consumer), Scanners], Software (Design, Scanning, Inspection, Printing), Services (Parts on Demand, Prototypes, Others)

By Material: Polymers [Thermoplastics (Polylactic Acid (PLA), Acrylonitrile Butadiene Styrene (ABS), Polyvinyl Alcohol (PVA ), Polyamide, Polypropylene, Others), Photopolymers], Metals and Alloys (Steel, Titanium, Silver, Gold, Nickel, Bronze, Aluminum, Copper, Iron, Manganese, Others), Fibers (Carbon, Glass, Kevlar, Others), Ceramics (Quartz, Silica, Glass, Others), Wax, Paper, Wood, Others

By Form: Filament, Liquid, Powder

By Technology: Stereolithography (SLA), Fuse deposition modeling (FDM), Selective laser sintering (SLS), Inkjet printing, Electron beam melting (EBM), Laser metal deposition (LMD), PolyJet printing, Digital Light Processing (DLP), Others

By Application: Production, Prototyping, Research & Education

By End Use Industry: Consumers [Decorative Items/Art Work (Freeform Art and Sculpture, Jewelry, Collectible Trinkets, Hospitality, Interior Decorative Items, Others), Others], Industrial (Machine Parts, Dies, Molds and Patterns, Others), Automotive [Exterior (Bumpers, Wind Breakers, Body Panels, Others), Interior (Dashboards, Seat Frames, Others), Engines and Engine Components (Cylinder Heads, Intake Manifolds, Engine Blocks, Others), Transmission Housings, Hubcaps, Tires, Suspension Spring, Others], Aerospace (Complex Gear Cases and Covers, Fuel Tanks, Transmission Housings, Components Requiring Draft Free Walls, Impellers, Turbine Blades, Lightweight Engine Parts, Structural Hinges, Others), Medical [Surgical Instruments, Implants (Dental (Sub-Periosteal Implants, Endosteal Implants), Orthopedic Implants, Prosthetic Implants, Spinal Rods, Bone Plates, Cranial Implants, Others), Tissue Engineering, Others], Construction (Commercial, Residential, Infrastructure, Industrial), Others

By Geography: North America, South America, Europe, APAC, and RoW

What are the major end users for 3D Printing?

The report includes an assessment of various end user industries such as automotive, construction, aerospace, medical, consumers and others. Medical industry is one of the major end users for 3D printing and holds a tremendous opportunity in the near future. This segment is expected to dominate the market in the short to long term. 3D Printing in the medical industry can be employed for multiple applications such as surgical instruments, dental implants, orthopedic implants, prosthetic implants, cranial implants and others.

Market Research and Market Trends of 3D Printing Ecosystem

• The American space company, SpaceX has sent a Dragon capsule to the International Space Station (ISS) which carried the first ever zero-G 3D printer. In addition, increasing traction by space agencies such as the National Aeronautics and Space Administration (NASA), European Space Agency (ESA) and others are anticipated to show a significant impact on the 3D printing market in the near future.

• The bio printers’ technology is in the experimental stage and is anticipated to provide prospects for the 3d printing market in the food industry. Furthermore, the importance of this technology has resulted in growing R&D investments by food companies such as chocolate & confectionery manufacturers.

• According to Oxford Performance Materials, more than 75% of American patients’ damaged skulls by disease or trauma were replaced with an implant from Oxford Performance Materials 3D printer and hence brought a revolution in the healthcare industry

The consumer 3D printers market is becoming highly consolidated with Stratasys Ltd. and 3D Systems Corp. being the global behemoths in this industry. 3DSystems has been highly active with a string of acquisitions of smaller companies across the globe

Schedule A Call :

Who are the Major Players in the 3D Printing Market?

The companies referred to in the market research report include Flashforge 3D Technology Co., Ltd., Hewlett-Packard, 3D Systems, Inc., Stratasys Ltd., SLM Solutions Group AG, ExOne Company LLC., Organovo Holdings, Inc., EOS GmbH, General Electric Company, XYZprinting, Inc., and others and more than 15 other companies.

What is our report scope?

The report incorporates an in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and their impact during the forecast period 2024–2030.

All our reports are customizable to your company’s needs to a certain extent, we do provide 20 free consulting hours along with the purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Key Takeaways from this Report

• Evaluate market potential by analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level — for product types, end use applications and by different industry verticals.

• Understand the different dynamics influencing the market — key driving factors, challenges and hidden opportunities.

• Get in-depth insights on your competitor’s performance — market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

• Analyze the sales and distribution channels across key geographies to improve top-line revenues.

• Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

• Get a quick outlook on the market entropy — M&A’s, deals, partnerships, and product launches of all key players for the past 4 years.

• Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than the top 20 countries globally for the market.

3D Printing Market Outlook:

Computer-aided high-quality 3D printing designs of delicate human organs and vascular systems provide a better chance for medical experts to perform risk-free preliminary trials of critical surgery. Earlier 3D printing was accomplished with inkjet printers but vernacular mediums and innovations have made it comparatively easier to print 3D models of any object successfully in modern times. Prototyping is the major push towards 3D printing industries leaving behind conventional practices of manufacturing models and machineries. It uses high-performing materials such as thermoplastics for yielding engineered aeronautical, automotive, and medical utilities. Booming 3D printing market is anticipated to leverage a mounting demand from the automotive industry with an outstanding CAGR of 15% during the period 2024–2030. Apart from North America other provinces are susceptible to the 3D printing market transition with compelling revenue income during the forecast period.

Buy Now :

3D Printing Market Growth Drivers:

• Surgical trials on 3D printed organ models lead to minimal risks, proper surgery planning, identifying suitable tools for a particular case, and shrinks surgical complications, consequently, enhancing medical prowess and driving the global 3D printing market demand.

• Designing new tools and their effective application generates amplifying prospects for 3D printing companies.

• Automotive industry is a major driving force in the 3D printing market owing to better customization, lower material wastage, accuracy and less time consumption, and flexible designing.

• Research on 3D printing organ transplantation is conducted on a large scale to replace the complication of live organ transplantation owing to cost-inefficiency, inadequate donor availability, and donor-receiver incompatibility. Around 13 people die every day without a kidney transplantation. Persistent biomedical engineering advances will increase the efficacy of 3D bio-printed organs and will accomplish sophisticated applications in the medical field in the forthcoming years.

3D Printing Market Challenge:

Critical problems associated with the trending 3D printing progression include limited material variety, limited repetition process, and narrow scale of niche expertise. Albeit the low-cost 3D printing products, exorbitant rates of manufacturing procedure, equipment installation, and post-processing necessities thwart the global 3D market development. However, the optimistic approach of the manufacturing companies outpaces these market challenges with rigorous investment in the technologies and embracing strategic changes.

3D Printing Market Key Players:

The leading market innovators of the global 3D printing market include Flashforge 3D Technology Co., Ltd., Hewlett-Packard, 3D Systems, Inc., Stratasys Ltd., SLM Solutions Group AG, ExOne Company LLC., Organovo Holdings, Inc., EOS GmbH, General Electric Company, XYZprinting, Inc., and others.

XYZ Printing is a 3D printer manufacturing company incorporating the 3D printing experience in offices, schools, and homes with accessible and less expensive printers. With 8500 engineers, they deliver products such as 3D pen, mini, and nano series, original and junior series, color, pro, nobel, and 3D scanner series.

3D Printing Market Trends:

3D Printing Bunion Rectification

Traumatic bunion development on the foot leads to difficulty in walking and toe movement. MedShape Orthopedic Solution Company has invented a new device for correcting hallux valgus deformity with an FDA-administered bone tether plate sculpted through 3D titanium alloy printing. Furthermore, mechanical drilling of bones will be escaped owing to the innovative FastForward bunion correction plate.

Revolutionary Bio-Printed Human Skin

Recent research directed by the unique 3D bio-printer to create a lab-made skin is suitable for testing chemicals, cosmetics, and pharmaceutical experiments as well as compatible with transplantation in burn incidences. A close replica of human skin bio-printing, this method is cost-effective as compared to manual production of artificial skin.

Persuasive Prosthetic Designs

Prosthetics have improved physical deformity with newer advances keeping an eye on the quality, design, and comfort level of the patients. Amputees’ changed outlook on the modern world has shaped their personal preferences. Designer prosthetics in the form of modern bionics of popular characters such as artificial hero arms are widely gaining traction among children worldwide. Widely accepted by teenagers and young amputees, the bionic trend is gradually overpowering the 3D printed prosthetics market.

3D Printing Market Research Scope:

The base year of the study is 2023, with forecasts done up to 2030. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the 3D printing market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the type of 3D printing in the 3D printing market and their specific applications in different areas.

3D Printing Market: Industry Coverage:

Global 3D printing market is segmented based on offering, application, and end user. Bifurcation based on offering includes printer, scanner, material, software, service, and others. Based on application categorization includes production, prototyping, and research and education. By end user, this market is divided into consumers, automotive, construction, and so on.

The 3D printing market also analyzes the major geographic regions for the market as well as the major countries for the market in these regions.

The regions and countries covered in the study include:

• North America: The U.S., Canada, Mexico

• South America: Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, Costa Rica

• Europe: The U.K., Germany, Italy, France, the Netherlands, Belgium, Spain, Denmark

• APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

More information about 3D Printing Market report click here

0 notes

Text

3D Bioprinting Market to Hit $5.19 Billion by 2032

The global 3D Bioprinting Market was valued at USD 1.20 Billion in 2024 and it is estimated to garner USD 5.19 Billion by 2032 with a registered CAGR of 20.1% during the forecast period 2024 to 2032.

Global 3D Bioprinting Market Research Report 2024, Growth Rate, Market Segmentation, 3D Bioprinting Market. It affords qualitative and quantitative insights in phrases of market size, destiny trends, and nearby outlook 3D Bioprinting Market. Contemporary possibilities projected to influence the destiny capability of the market are analyzed in the report. Additionally, the document affords special insights into the opposition in particular industries and diverse businesses. This document in addition examines and evaluates the contemporary outlook for the ever-evolving commercial enterprise area and the prevailing and future outcomes of the market.

Get Sample Copy of Report @ https://www.vantagemarketresearch.com/3d-bioprinting-market-1235/request-sample

** Note: You Must Use A Corporate Email Address OR Business Details.

The Major Players Profiled in the Market Report are:-

Envisiontec Inc., Organovo Holdings Inc., Inventia Life Science PTY LTD, Poietis, Vivax Bio LLC, Allevi, Cyfuse Biomedical K.K., 3D Bioprinting Solutions, Cellink Global, Regemat 3D S.L. and others.

3D Bioprinting Market 2024 covers powerful research on global industry size, share, and growth which will allow clients to view possible requirements and forecasts. Opportunities and drivers are assembled after in-depth research by the expertise of the construction robot market. The 3D Bioprinting Market report provides an analysis of future development strategies, key players, competitive potential, and key challenges in the industry.

Global 3D Bioprinting Market Report 2024 reveals all critical factors related to diverse boom factors inclusive of contemporary trends and traits withinside the worldwide enterprise. It affords a complete review of the top manufacturers, present-day enterprise status, boom sectors, and commercial enterprise improvement plans for the destiny scope.

The 3D Bioprinting Market document objectives to offer nearby improvement to the market using elements inclusive of income revenue, destiny market boom rate. It gives special observation and analysis of key aspects with quite a few studies strategies consisting of frenzy and pestle evaluation, highlighting present-day market conditions. to be. Additionally, the document affords insightful records approximately the destiny techniques and opportunities of worldwide players.

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/3d-bioprinting-market-1235/0

Global 3D Bioprinting Market, By Region

1) North America- (United States, Canada, Mexico, Cuba, Guatemala, Panama, Barbados, and many others)

2) Europe- (Germany, France, UK, Italy, Russia, Spain, Netherlands, Switzerland, Belgium, and many others)

3) the Asia Pacific- (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Vietnam, and many others)

4) the Middle East & Africa- (Turkey, Saudi Arabia, United Arab Emirates, South Africa, Israel, Egypt, Nigeria, and many others)

5) Latin America- (Brazil, Argentina, Colombia, Chile, Peru, and many others)

This 3D Bioprinting Market Research/analysis Report Contains Answers to your following Questions

What trends, challenges, and barriers will impact the development and sizing of the global market?

What is the 3D Bioprinting Market growth accelerator during the forecast period?

SWOT Analysis of key players along with its profile and Porter’s five forces analysis to supplement the same.

How much is the 3D Bioprinting Market industry worth in 2019? and estimated size by 2024?

How large is the 3D Bioprinting Market? How long will it keep growing and at what rate?

Which section or location will force the market and why?

What is the important thing current tendencies witnessed in the 3D Bioprinting Market?

Who are the top players in the market?

What and How many patents are filed by the leading players?

What is our Offering for a bright industry future?

The Research Objectives of this Report are to:-

Company, key regions/countries, merchandise and applications, historical records from 2018 to 2022, and global 3D Bioprinting Market till 2032. Study and analyze the market length (cost and volume).

To recognize the structure of 3D Bioprinting Market via way of means of figuring out its numerous subsegments.

3D Bioprinting Market on the subject of the primary regions (with every essential country). Predict the cost and length of submarkets.

To examine the 3D Bioprinting Markets with appreciation to person boom trends, destiny prospects, and their contribution to the general market.

To examine aggressive trends consisting of expansions, contracts, new product launches, and acquisitions withinside the market.

Strategic profiling of key gamers and complete evaluation of growth strategies.

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/3d-bioprinting-market-1235

Reasons to Buy Market Report

The market record presents a qualitative and quantitative analysis of the market based on segmentation that includes each economic and non-economic element.

3D Bioprinting Market through the region. The market evaluation highlights the consumption of products/services in areas and well-known shows elements influencing the market in every region.

3D Bioprinting Market. It consists of an in-depth analysis of the market from specific views via Market Porter's Five Forces Analysis and provides insights into the market via the Value Chain.

The 3D Bioprinting Market file provides an outline of market fee (USD) information for every segment and sub-segment.

It consists of an in-depth analysis of the market from distinct views via a 5 forces analysis of the 3D Bioprinting Market and offers insights into the market through the fee chain.

Check Out More Reports

Global Gaming Market: Report Forecast by 2032

Global ICU Beds Market: Report Forecast by 2032

Global Cryptocurrency Exchange Platforms Market: Report Forecast by 2032

Global Botanicals Market: Report Forecast by 2032

Global Flavored Syrup Market: Report Forecast by 2032

#3D Bioprinting Market#3D Bioprinting Market 2024#Global 3D Bioprinting Market#3D Bioprinting Market outlook#3D Bioprinting Market Trend#3D Bioprinting Market Size & Share#3D Bioprinting Market Forecast#3D Bioprinting Market Demand#3D Bioprinting Market sales & price

0 notes

Link

0 notes

Text

Mesenchymal Stem Cells Market Expansion 2024-2033: Growth Drivers and Dynamics

The mesenchymal stem cells global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Mesenchymal Stem Cells Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The mesenchymal stem cells market size has grown rapidly in recent years. It will grow from $3.00 billion in 2023 to $3.38 billion in 2024 at a compound annual growth rate (CAGR) of 12.5%. The growth in the historic period can be attributed to the regenerative medicine paradigm shift, collaborative research efforts, increased public awareness of stem cell research and patient advocacy, international collaboration, and standardization initiatives.

The mesenchymal stem cells market size is expected to see rapid growth in the next few years. It will grow to $5.45 billion in 2028 at a compound annual growth rate (CAGR) of 12.7%. The growth in the forecast period can be attributed to continued advancements in genetic engineering technologies, the adoption of personalized medicine approaches, the integration of artificial intelligence (AI) and data analytics, advances in biomaterials science and 3D bioprinting technologies, the development of microfluidic devices and organ-on-a-chip models, the adoption of next-generation manufacturing technologies. Major trends in the forecast period include bioprinting and tissue engineering, gene editing, clinical application expansion, combination therapies, and MSC-derived extracellular vesicles (EVs).

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/mesenchymal-stem-cells-global-market-report

Scope Of Mesenchymal Stem Cells Market The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Mesenchymal Stem Cells Market Overview

Market Drivers - The growing awareness regarding regenerative medicine is expected to propel the growth of the mesenchymal stem cells (MSC) market going forward. Regenerative medicine is an emerging interdisciplinary field that focuses on the repair, replacement, or regeneration of cells, tissues, or organs to restore impaired function resulting from any cause, including congenital defects, disease, trauma, and aging. Regenerative medicine is increasing due to several key factors, such as growing clinical trials, the growing incidence of chronic conditions, age-related conditions, and personalized medicine. Mesenchymal stem cells (MSCs) offer significant potential in regenerative medicine due to their ability to differentiate into multiple cell types, modulate immune responses, and promote tissue repair and regeneration across a wide range of medical conditions. For instance, in August 2023, according to a report by the Alliance for Regenerative Medicine, a US-based non-profit organization, there were 2,760 cells, gene, and tissue-engineering therapeutic developers worldwide in Q1 2023, up 101% since 1,369 in Q1 2022. Moreover, financing for regenerative medicine and advanced therapies in 2021 MSCl (mesenchymal stromal cell-like) reached $22.7 billion, compared to $19.9 billion in 2020. Therefore, growing awareness regarding regenerative medicine is driving the growth of the mesenchymal stem cell (MSC) market.

Market Trends - Major companies operating in the mesenchymal stem cells (MSCs) market are adopting innovative technologies, such as GMP-compliant isolation, to strengthen their position in the market. GMP (Good Manufacturing Practice)-compliant isolation refers to the process of isolating cells, including mesenchymal stem cells (MSCs), according to GMP regulations to ensure consistent production and control of product quality. For instance, in July 2023, PromoCell, a Germany-based biotechnology company, announced the launch of PromoExQ MSC Growth Medium XF, a serum- and xeno-free medium designed for the expansion of human mesenchymal stem cells (MSCs) in a Good Manufacturing Practice (GMP)-regulated environment. This medium is manufactured under the highest quality standards and is certified by the EXCiPACT GMP certification scheme, ensuring consistent growth and maintenance of MSCs from various sources such as bone marrow, umbilical cord matrix, and adipose tissue.

The mesenchymal stem cells market covered in this report is segmented –

1) By Type: Autologous, Allogeneic 2) By Product Type: Cells And Cell Lines, Kits, Media And Reagents, Other Product Types 3) By Workflow Type: Cell Sourcing And Isolation, Culture And Cryopreservation, Differentiation, Characterization 4) By Indication : Bone And Cartilage Repair, Cardiovascular Diseases, Inflammatory And Immunological Diseases, Liver Diseases, Cancer, GvHD, Other Indications 5) By Application: Disease Modeling, Drug Development And Discovery, Stem Cell Banking, Tissue Engineering, Toxicology Studies, Other Applications

Get an inside scoop of the mesenchymal stem cells market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=16116&type=smp

Regional Insights - North America was the largest region in the mesenchymal stem cells market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the mesenchymal stem cells market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the mesenchymal stem cells market are Thermo Fischer Scientific Inc., Danaher Corporation, Merck KgaA, Becton, Dickinson, and Company, Fujifilm Holdings Corporation, Corning Inc., Daiichi Sankyo, Lonza Group, Terumo Corporation, Sartorius AG, Getinge AB, Bio-Rad Laboratories, Eppendorf AG, Bio-Techne Corporation, STEMCELL Technologies Inc., Miltenyi Biotec GmBH, Takara Bio Group, Organogenesis Holdings Inc., Vericel Corporation, HiMedia Laboratories, PromoCell GmbH, CellGenix GmBH, Anterogen Co. Ltd., Pluristem Therapeutics Inc., American Cryostem Corporation

Table of Contents 1. Executive Summary 2. Mesenchymal Stem Cells Market Report Structure 3. Mesenchymal Stem Cells Market Trends And Strategies 4. Mesenchymal Stem Cells Market – Macro Economic Scenario 5. Mesenchymal Stem Cells Market Size And Growth ….. 27. Mesenchymal Stem Cells Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

The Rise of 3D Printed Drugs: How Additive Manufacturing is Shaping the Pharmaceutical Industry

3D Printed Drug technology represents an innovative leap in personalized medicine, offering a customizable approach to drug manufacturing. Unlike traditional drug manufacturing processes, 3D printing allows for the precise layering of drugs into specific shapes and dosages tailored to individual patient needs. This technology holds tremendous potential for creating customized medications with specific release profiles, sizes, and combinations, addressing unique patient requirements that traditional mass-production methods struggle to meet. The first FDA-approved 3D Printed Drug, Spritam (for treating epilepsy), has paved the way for further research and development, showcasing the potential of this cutting-edge technology to transform pharmaceutical manufacturing.

According to MRFR analysis, the market size for 3D printed drugs was projected to reach $4.45 billion (USD billion) in 2022. It is anticipated that the market for 3D printed drugs will increase from 5.63 billion USD in 2023 to 46.6 billion USD in 2032. The projected compound annual growth rate (CAGR) for the 3D printed drug market is around 26.47% from 2024 to 2032.

3D Printed Drug Analysis

A thorough 3D Printed Drug analysis reveals multiple factors driving interest in this emerging field, including the demand for customized medications and the advantages of on-demand drug manufacturing. With the ability to produce drugs with precise dosages and specific release timings, 3D printing technology caters particularly well to patients with chronic conditions requiring tailored medications. For example, individuals with epilepsy, cardiovascular diseases, or mental health conditions often need precise dosages that may vary over time. 3D Printed Drug analysis also highlights that the technology can reduce manufacturing waste, lower production costs, and create opportunities for more sustainable practices in the pharmaceutical industry. Furthermore, pharmaceutical companies can respond faster to market demands, producing specific drugs only when needed, potentially reducing the risks associated with excess stock and expired medications.

3D Printed Drug Trends

Current 3D Printed Drug trends indicate a growing focus on personalized medicine, driven by technological advancements and a shift towards patient-centric healthcare. As 3D printing continues to evolve, researchers are exploring the development of multi-drug pills that can contain multiple medications in a single, easy-to-administer form, benefiting patients with complex medication regimens. Another trend in the 3D Printed Drug space is the exploration of bioprinting, where 3D-printed tissue models can be used for drug testing, potentially accelerating the drug development timeline and reducing reliance on animal testing. Additionally, the integration of artificial intelligence (AI) and machine learning in 3D printing processes is enhancing production precision, enabling more complex drug structures. These trends suggest that the field of 3D Printed Drugs will continue to expand, offering innovative solutions to longstanding challenges in the pharmaceutical industry.

Reasons to Buy the Reports

Detailed Market Analysis: Gain comprehensive insights into the 3D Printed Drug market, including emerging trends, growth drivers, and challenges.

Investment Opportunities: Identify lucrative areas within the market, making it easier to understand which technologies and applications have the highest growth potential.

Technological Innovations: Learn about the latest developments in 3D printing technology and how it’s transforming drug manufacturing, allowing companies to stay competitive.

Regulatory Landscape Insights: Understand regulatory guidelines and approvals essential for the development and commercialization of 3D Printed Drugs.

Competitive Positioning: Get information on leading players in the market and their strategies, helping businesses navigate the competitive landscape effectively.

Recent Developments

Recent developments in the 3D Printed Drug market highlight the rapid advancement and adoption of this technology. In 2022, Aprecia Pharmaceuticals, the first company to receive FDA approval for a 3D Printed Drug, announced plans to expand its product line with additional personalized medications. Another notable development is the partnership between FabRx and the University of Santiago de Compostela, aimed at creating 3D-printed medications for pediatrics, focusing on accurate dosages and patient-friendly designs. Furthermore, in early 2023, researchers in Germany developed a 3D-printed multi-drug pill for patients with Parkinson's disease, designed to release different drugs at specified intervals throughout the day. These breakthroughs demonstrate the growing versatility and relevance of 3D Printed Drugs in personalized medicine, underscoring the technology's potential to meet unique patient needs while improving healthcare outcomes.

As 3D printing technology advances, the potential for widespread implementation of 3D Printed Drugs across various therapeutic areas becomes increasingly viable, making it an exciting field for

Related reports :

fungal keratitis treatment market

gastrointestinal stent market

gene therapy clinical trial service market

0 notes