#3D Bioprinting Industry Trends

Text

3D Bioprinting Market Size, Share, Development Opportunities, Growth Outlook and Global Scope Analysis by Top Players

3D bioprinting is a groundbreaking technology that has the potential to revolutionize the field of medicine. It involves the use of 3D printing technology to create living tissues and organs that can be used for research, testing, and transplantation. The process begins with the creation of a digital 3D model of the desired tissue or organ, which is then fed into a bioprinter. The bioprinter then uses bioink, a substance made up of living cells, to print the tissue or organ layer by layer, creating a three-dimensional structure that mimics the natural tissues of the human body.

One of the major benefits of 3D bioprinting is the potential to address the shortage of organs available for transplant. Every year, thousands of people die waiting for a suitable organ donor. With 3D bioprinting, it may be possible to create personalized organs that are a perfect match for the recipient, reducing the risk of rejection and increasing the chances of a successful transplant. In addition to organ transplantation, 3D bioprinting has the potential to transform the field of regenerative medicine by providing a way to create customized tissue and bone grafts for patients.

Despite the many benefits of 3D bioprinting, there are still some challenges to be addressed. One of the biggest obstacles is the need for a reliable and safe source of bioink. While some progress has been made in developing bioinks that are suitable for use in bioprinters, there is still much research to be done to ensure that these substances are both safe and effective. In addition, the process of creating complex, multi-cellular structures is still in its early stages, and much work needs to be done to refine the technology and make it more efficient. Nonetheless, the potential benefits of 3D bioprinting make it an exciting field with enormous promise for the future of medicine.

Read more @ https://techinforite.blogspot.com/2023/02/3d-bioprinting-market-by-technology.html

#3D Bioprinting Trend#3D Bioprinting size#3D Bioprinting growth#3D Bioprinting#3D Bioprinting Industry#3D Bioprinting Price#3D Bioprinting Size#3D Bioprinting Share#3D Bioprinting Analysis#3D Bioprinting Forecast#3D Bioprinting Consumption#3D Bioprinting Sales#3D Bioprinting Segmentation#3D Bioprinting Manufacturers#3D Bioprinting Prospectus#3D Bioprinting Industry Trends#3D Bioprinting Growth#3D Bioprinting Trends#Global 3D Bioprinting Industry#Global 3D Bioprinting Trends#Global 3D Bioprinting Share#Global 3D Bioprinting Size

0 notes

Text

#3D Bioprinting Market Size#3D Bioprinting Market Share#3D Bioprinting Market Trends#3D Bioprinting Market Growth#3D Bioprinting Market Analysis#3D Bioprinting Market Forecast#3D Bioprinting Market Report#3D Bioprinting Industry Report

0 notes

Text

Global 3D Bioprinting Industry Growth and Future Analysis

The 3D bioprinting market will reach a value of USD 5,873 million by 2030, propelling at a rate of 19.4%, as per a report by a market research institution, P&S Intelligence.

Get the sample pages of this report: https://bit.ly/3pq4uWg

Factors such as the development of 3D biomaterials and bioprinters, the increasing investment by the public and private sectors for bioprinting research…

View On WordPress

0 notes

Text

Biotechnology Market- Trends Shaping the Future

The modern biotech realm provides cutting-edge technologies to tackle rare diseases and minimize environmental impact. From companies leveraging human genetics to possibilities of personalized medicine, biotech influence spans a profound spectrum. This technology is capable of feeding the hungry and offering them a cure. It is a cleaner, safer, and efficient technology for the future.

Biotech holds significant promises for companies. The approach to precision medicine allows pharmaceutical companies to reduce the risk of human complications. The biomanufacturing trend is transforming the ways to produce chemicals and materials that are conventionally produced through synthetic processes. Biotechnology in manufacturing is foreseen to improve productivity and innovation.

Biotechnology is expanding in additive manufacturing processes such as 3D printing. Bioprinters print organ-like structures to benefit the healthcare sector. The potential of biotech is widespread from drug discovery to the creation of personalized medicines. Recent bioprinting innovation is foreseen to be a breakthrough in the coming years.

The biotechnology market is anticipated to hold promising growth potential in coming years driven by trends that engineer new biological systems and aim to redesign existing ones. Although there are challenges in the biotechnology market ahead, its potential outweighs the hurdles. Biotechnology is capable of delivering new solutions in agriculture, medicine, and industrial sectors foreseen to increase biotechnology market share.

2 notes

·

View notes

Text

0 notes

Link

0 notes

Text

The Future of Manufacturing Design: 3D Printing’s Emerging Trends

3D printing, or additive manufacturing, has fundamentally altered the landscape of manufacturing design, offering unprecedented capabilities for creating complex and customized products. As technology continues to advance, several emerging trends are set to shape the future of manufacturing design, expanding the horizons of what is possible and driving further innovation.

This article explores some of the most promising trends in 3D printing and their potential impact on the manufacturing industry.

1. Advanced Materials and Composites

The evolution of 3D printing technology is closely linked with the development of new materials. Advanced materials, including high-performance polymers, metal alloys, and composites, are enhancing the capabilities of 3D printing. These materials offer improved strength, durability, and functionality, making them suitable for a wide range of applications, from aerospace components to medical implants.

For instance, the use of carbon fiber-reinforced polymers and metal composites in 3D printing allows for the creation of lightweight yet robust structures that can withstand extreme conditions. As material science continues to progress, the range of materials available for 3D printing will expand, enabling manufacturers to produce even more specialized and high-performance products.

2. Large-Scale 3D Printing

Traditionally, 3D printing has been associated with small to medium-sized components. However, emerging trends are pushing the boundaries of size, with large-scale 3D printing becoming increasingly feasible. Technologies such as gantry-based and robotic arm printers are capable of producing large structures, including architectural elements and industrial components.

Large-scale 3D printing has the potential to revolutionize industries such as construction and aerospace. In construction, for example, 3D printing can be used to create entire buildings or significant structural components, reducing labor costs and material waste. Similarly, in aerospace, large-scale printing can produce parts with complex geometries that are lighter and more efficient than traditionally manufactured counterparts.

3. Integration with Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning with 3D printing is set to enhance design and manufacturing processes. AI algorithms can optimize print parameters, predict potential defects, and improve the overall quality of printed parts. Machine learning can analyze data from previous prints to refine and adjust printing processes, leading to more accurate and efficient manufacturing.

This synergy between 3D printing and AI can also facilitate more advanced design optimization. AI-driven design tools can generate complex geometries that are optimized for performance, material usage, and manufacturability, pushing the boundaries of what is achievable with additive manufacturing.

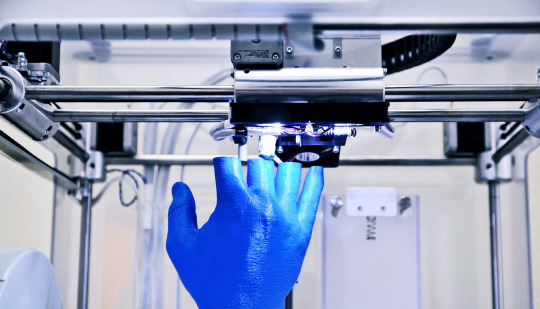

4. Bioprinting and Medical Applications

Bioprinting is a rapidly growing area of 3D printing that involves creating biological tissues and organs. This emerging trend holds the promise of revolutionizing healthcare by enabling the production of custom implants, prosthetics, and even functional organ tissues.

Researchers are making significant strides in bioprinting, with advancements in creating complex tissue structures and integrating living cells into printed constructs. While fully functional organ printing remains a future goal, current applications in medical devices and personalized implants are already making a significant impact, improving patient outcomes and expanding treatment options.

5. Sustainable Manufacturing Practices

Sustainability is a growing concern in manufacturing, and 3D printing offers several advantages in this regard. Additive manufacturing is inherently more material-efficient than traditional subtractive methods, as it uses only the material needed to build the final product, reducing waste.

Furthermore, advancements in recycling and biodegradable materials for 3D printing are contributing to more sustainable practices. For example, researchers are developing filaments made from recycled plastics and bio-based materials that can be used in 3D printers. These innovations help reduce the environmental impact of manufacturing processes and align with broader sustainability goals.

6. On-Demand and Localized Production

One of the most transformative trends in 3D printing is its ability to support on-demand and localized production. Traditional manufacturing often requires large-scale production runs and extensive supply chains, leading to increased lead times and inventory costs.

3D printing enables on-demand production, where parts and products can be manufactured as needed, reducing the need for large inventories and minimizing excess production. This capability is particularly valuable for industries with rapidly changing demands or those requiring custom components. Additionally, localized production using 3D printing can reduce transportation costs and lead times, contributing to more agile and responsive manufacturing systems.

7. Enhanced Automation and Integration

Automation is a key trend in modern manufacturing, and 3D printing is no exception. The integration of 3D printing with automated systems, such as robotic arms and conveyor belts, is enhancing production efficiency and consistency. Automated 3D printing systems can operate continuously, producing high volumes of parts with minimal human intervention.

Furthermore, the integration of 3D printing with other manufacturing technologies, such as injection molding and CNC machining, is creating hybrid manufacturing processes that combine the strengths of each method. These integrated approaches offer increased flexibility and capability, enabling manufacturers to tackle a broader range of production challenges.

Conclusion

The future of manufacturing design is being shaped by several emerging trends in 3D printing technology. From advanced materials and large-scale printing to AI integration and bioprinting, these trends are expanding the possibilities of additive manufacturing and driving innovation across various industries. As 3D printing continues to evolve, its impact on manufacturing design will grow, offering new opportunities for efficiency, customization, and sustainability. Embracing these trends will enable manufacturers to stay at the forefront of technological advancements and meet the evolving demands of the market.

0 notes

Text

Exploring the Advanced World of Professional 3D Printing

Introduction: The rise of 3D printing technology has revolutionized various industries, offering unprecedented flexibility, precision, and customization. Among the leaders in this domain, Stampanti 3D professionali (professional 3D printers) stand out due to their cutting-edge features and innovative applications.

The Role of Professional 3D Printers: Professional 3D printers have expanded beyond simple prototyping to become integral tools in manufacturing, healthcare, automotive, and aerospace industries. Their ability to produce complex geometries and functional parts with high precision makes them indispensable for businesses aiming to innovate and optimize their production processes.

Key Features of Stampanti 3D Professionali:

Precision and Accuracy: Professional 3D printers are designed to produce parts with exceptional precision, ensuring that every detail meets the required specifications. This is particularly important in industries where accuracy is critical, such as aerospace and medical device manufacturing.

Material Versatility: These printers support a wide range of materials, including metals, plastics, ceramics, and composites. This versatility allows companies to experiment with different materials to achieve the desired mechanical properties and aesthetics.

Advanced Software Integration: Professional 3D printers are often equipped with advanced software that enables seamless integration with CAD systems. This software simplifies the design process, allowing engineers to make quick adjustments and optimize their designs for 3D printing.

Scalability: Whether you're producing small batches or large-scale manufacturing runs, professional 3D printers offer scalability to meet the demands of various production volumes. This flexibility is crucial for businesses looking to adapt to changing market demands.

Applications in Industry:

Aerospace: Professional 3D printers are used to create lightweight yet strong components for aircraft and spacecraft. These parts often feature complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

Healthcare: In the medical field, 3D printing is used to produce custom implants, prosthetics, and even bioprinted tissues. The ability to create patient-specific solutions is revolutionizing personalized medicine.

Automotive: The automotive industry benefits from 3D printing by rapidly producing prototypes, tooling, and even end-use parts. This accelerates the development process and reduces costs associated with traditional manufacturing.

Consumer Products: From custom jewelry to personalized electronics, 3D printing allows for the creation of unique consumer products that cater to individual preferences.

Challenges and Future Trends: While the benefits of professional 3D printers are numerous, there are still challenges to overcome. These include the high initial costs, the need for skilled operators, and limitations in material properties. However, ongoing research and development are addressing these challenges, making professional 3D printers more accessible and versatile.

Looking ahead, we can expect continued advancements in 3D printing technology, including faster printing speeds, improved material options, and enhanced software capabilities. As these innovations unfold, the role of professional 3D printers in shaping the future of manufacturing will only become more significant.

Conclusion: Stampanti 3D professionali are more than just tools; they are catalysts for innovation across multiple industries. By enabling the creation of complex, customized, and high-quality parts, these printers are driving the next wave of industrial transformation. Whether you're in aerospace, healthcare, automotive, or consumer products, investing in professional 3D printing technology is a step towards staying competitive in a rapidly evolving market.

0 notes

Text

Microtissue Market Industry Forecast and Competitive Landscape Reports | Global Insight Services

“Global Insight Services company has recently revised its global market reports, now incorporating the most current data for 2024 along with projections extending up to 2033.

Microtissues are three-dimensional cell cultures that are used to study cellular behavior in a more realistic environment than traditional two-dimensional cell cultures. These cultures are created by combining different types of cells, such as stem cells, in a three-dimensional structure that closely mimics the structure of a tissue or organ in the body.

The use of microtissues has become increasingly popular in the field of regenerative medicine. By growing cells in a three-dimensional environment, scientists are able to study the behavior of cells in a more natural context, which can provide insights into the development and maintenance of organs and tissues. Microtissues can also be used to study how cells respond to different treatments, which can provide valuable information for the development of new drugs and therapies.

To Know More@ https://www.globalinsightservices.com/reports/microtissue-market/?utm_id=Pranalip

In addition to their use in research, microtissues are also being used in clinical trials. By creating three-dimensional cultures that closely mimic the structure of an organ, scientists can test how a drug or therapy will interact with the cells in the body. This can provide valuable information for clinical trials, as it allows scientists to assess the safety and efficacy of a potential treatment before it is used in humans.

Finally, microtissues are also being used to create artificial organs. By combining different types of cells into a three-dimensional structure, scientists can create an organ-like structure that closely resembles a real organ. This can be used to replace damaged or missing organs, or to create new organs for transplantation.

Overall, microtissues are an important tool for the advancement of medical science. By recreating the natural structure of organs and tissues in the lab, scientists are able to gain insight into how cells interact and respond to treatments, and are able to create artificial organs for transplantation.

Key Trends

Microtissue technology is a rapidly growing field of research that has the potential to revolutionize the way medical treatments are developed and delivered. Microtissues are microscopic 3D structures that can be used to mimic the structure and function of real tissues. They are made up of living cells and can be used to study tissue development, drug delivery, and disease modeling.

The key trends in Microtissue technology can be divided into four categories: 3D printing, bioprinting, organoid technology, and tissue engineering.

3D printing is a process that uses a computer-controlled device to create three-dimensional objects from a digital file. This technology has been used to create microtissues with a wide range of geometries and structures. By using 3D printing, researchers can create complex microtissues that accurately mimic the structure of real tissues.

Bioprinting is a process that uses living cells to create 3D structures. This technology has been used to create microtissues with precise shapes and sizes. By combining this technology with 3D printing, researchers can create microtissues with complex shapes and structures.

Organoid technology is a type of tissue engineering that involves the creation of 3D organ-like structures. This technology has been used to create microtissues that mimic the structure and function of real organs. By using this technology, researchers can study the development of tissues in a more realistic way.

Finally, tissue engineering is a process that involves the creation of 3D structures from living cells. This technology has been used to create microtissues with complex structures and functions. By combining this technology with 3D printing and bioprinting, researchers can create functional tissues that can be used for medical treatments.

Overall, the key trends in Microtissue technology are 3D printing, bioprinting, organoid technology, and tissue engineering. By combining these technologies, researchers can create complex microtissues that accurately mimic the structure and function of real tissues. These technologies have the potential to revolutionize the way medical treatments are developed and delivered.

Key Drivers

Microtissues are a type of three-dimensional cell culture system that mimics the structure and function of native tissue. These tissues are produced from a variety of cell sources, such as stem cells, immortalized cell lines, or primary cells. Microtissues are used to study a variety of biological processes, including tissue development, cell-cell interactions, and tissue engineering.

The microtissue market is driven by several factors, including advances in tissue engineering, increasing research in regenerative medicine, and growing demand for personalized medicine.

Advances in tissue engineering and regenerative medicine have led to a greater understanding of the cellular and molecular mechanisms of tissue formation and regeneration. This has enabled researchers to develop more sophisticated microtissues that more closely mimic the structure and function of native tissues. These microtissues have been used to better understand how tissue develops, how cells interact, and how to engineer new tissues.

Request Sample@ https://www.globalinsightservices.com/request-sample/GIS26130/?utm_id=Pranalip

The increasing research in regenerative medicine has also been a key driver of the microtissue market. Regenerative medicine is an emerging field of medicine that focuses on the development of therapies that use the body’s own cells and tissues to repair or replace damaged or diseased tissues. Microtissues can be used to study how regenerative therapies can be used to treat a variety of diseases and conditions, such as diabetes, cardiovascular disease, and neurological disorders.

The growing demand for personalized medicine is also driving the microtissue market. Personalized medicine is an emerging field of medicine that uses a patient’s genetic information to tailor treatments and therapies to the individual patient. Microtissues can be used to study how personalized medicine can be used to develop more effective treatments and therapies for a variety of diseases and conditions.

Finally, the global demand for microtissues is being driven by the increasing need for cost-effective and reliable cell culture systems. The use of microtissues provides researchers with a cost-effective and reliable way to study a variety of biological processes. Microtissues can also be used to produce large quantities of cells, which can be used for drug screening, tissue engineering, and other applications.

In conclusion, the microtissue market is being driven by advances in tissue engineering, increasing research in regenerative medicine, growing demand for personalized medicine, and increasing need for cost-effective and reliable cell culture systems. These factors are driving the global demand for microtissues, which is expected to continue to grow in the coming years.

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS26130/?utm_id=Pranalip

Market Segmentation

The market can be segmented by type, application, and region. By Type, the market can be divided into 3D Organoid Culture and Biochemical Cues. By Application, the market can be divided into Biopharmaceutical Companies, Contract Research Organizations, and Academics and Research Institutes. By Region, the market is divided into North America, Europe, Asia-Pacific, and the Rest of the World.

Key Players

The market includes players such as Merck (DE), Corning (US), STEMCELL Technologies (CA), Lonza (CH), Prellis Biologics (US), amsbio (UK), Cellesce (UK), DefiniGEN (UK), Ocello (US), and HUB Oranoid Technology (KR).

Buy your copy here@ https://www.globalinsightservices.com/checkout/single_user/GIS26130/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com

About Global Insight Services:

lobal Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

#3D Bioprinting Market#3D Bioprinting Size#3D Bioprinting Growth#3D Bioprinting Trend#3D Bioprinting segment#3D Bioprinting Opportunity#3D Bioprinting Analysis 2024#3D Bioprinting Forecast

0 notes

Text

The 3D printing in healthcare was valued at USD 1.2 Million in 2023 and is expected to reach USD 6.43 Million in 2032, growing at a CAGR of 20.5% between 2024 and 2032.In recent years, the integration of 3D printing technology in the healthcare sector has revolutionized medical practices, promising enhanced patient outcomes, cost-efficiency, and unprecedented customization. The 3D printing in healthcare market is experiencing exponential growth, driven by technological advancements, increasing healthcare needs, and the demand for personalized medical solutions.

Browse the full report at https://www.credenceresearch.com/report/3d-printing-in-healthcare-market

Market Overview

The 3D printing in healthcare market has witnessed significant expansion, with a compound annual growth rate (CAGR) projected to be robust over the next decade. This growth is attributed to the increasing adoption of 3D printing technologies for a range of medical applications, including prosthetics, implants, surgical instruments, and tissue engineering. North America currently leads the market due to its advanced healthcare infrastructure, substantial investments in research and development, and a high prevalence of chronic diseases requiring innovative medical solutions. Europe and the Asia-Pacific regions are also showing considerable growth, driven by rising healthcare expenditures and technological advancements.

Key Drivers

1. Technological Advancements: Continuous innovations in 3D printing technologies, such as bioprinting and the development of new, biocompatible materials, are expanding the capabilities and applications of 3D printing in healthcare. These advancements allow for the creation of complex and precise medical devices and tissues, enhancing treatment effectiveness.

2. Personalized Medicine: The shift towards personalized medicine is a major driver for the 3D printing in healthcare market. 3D printing enables the customization of medical devices and implants to match the unique anatomical and physiological needs of individual patients, improving the success rates of treatments and patient satisfaction.

3. Cost Efficiency: 3D printing reduces the cost of manufacturing complex medical devices and prosthetics by minimizing material wastage and reducing production times. This cost efficiency makes advanced medical solutions more accessible, particularly in developing regions.

4. Aging Population: The global aging population is driving demand for medical devices and treatments that 3D printing can provide. Elderly patients often require customized implants and prosthetics, which are efficiently produced through 3D printing technologies.

Applications

1. Prosthetics and Implants: One of the most prominent applications of 3D printing in healthcare is the production of customized prosthetics and implants. Traditional manufacturing methods are often unable to produce the precise dimensions required for individual patients. 3D printing allows for the creation of patient-specific devices that fit perfectly, enhancing comfort and functionality.

2. Surgical Instruments: Surgeons are increasingly using 3D-printed surgical instruments tailored to specific procedures. These instruments can be designed with unique geometries to improve surgical outcomes and reduce the risk of complications.

3. Tissue Engineering and Organ Printing: While still in the experimental stage, bioprinting holds the potential to revolutionize organ transplantation. Researchers are working on printing functional tissues and organs, which could address the shortage of donor organs and eliminate the risk of organ rejection.

4. Dental Applications: The dental industry is leveraging 3D printing for the production of crowns, bridges, dentures, and orthodontic devices. The precision and speed of 3D printing enhance the efficiency of dental treatments and improve patient outcomes.

Challenges and Future Outlook

Despite its promising potential, the 3D printing in healthcare market faces several challenges. Regulatory hurdles, high initial costs of 3D printing equipment, and the need for specialized training are significant barriers to widespread adoption. Moreover, ensuring the biocompatibility and durability of 3D-printed medical devices remains a critical concern.

However, ongoing research and development efforts are addressing these challenges. The future of 3D printing in healthcare looks promising, with potential advancements in bioprinting, the development of new materials, and the integration of artificial intelligence to enhance precision and efficiency.

Key Players

Organovo Holdings Inc.

Stratasys Ltd

The ExOne Company

General Electric (GE Additive)

3D Systems Corporation

Oxford Performance Materials Inc.

Formlabs Inc.

SLM Solutions Group AG

Materialise NV

Protolabs Inc.

Others

Segmentation

By Technology

Stereolithography (SLA)

Fused Deposition Modeling (FDM)

Selective Laser Sintering (SLS)

Digital Light Processing (DLP)

PolyJet/MultiJet Printing

Bioprinting

By Material

Plastics

Metals

Ceramics

Biomaterials

By Application

Medical Models and Anatomical Structures

Dental Products (Crowns, Bridges, etc.)

Orthopedic Implants

Prosthetics and Orthotics

Patient-Specific Surgical Guides

Tissue Engineering and Bioprinting

By End-User

Hospitals and Clinics

Dental Laboratories

Research Institutions

Pharmaceutical Companies

Biotechnology Companies

By Process

Powder Bed Fusion

VAT Photopolymerization

Material Extrusion

Binder Jetting

Directed Energy Deposition

By Type

3D Printers

Materials

Services

By Regulatory Approval Status

FDA-Approved Products

CE Marked Products

By Region

North America

S.

Canada

Mexico

Europe

Germany

France

K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/3d-printing-in-healthcare-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Artificial Skin Market Poised to Grow at Highest Pace Owing to Rising Burn Injuries

The artificial skin market deals with products that act as a temporary or permanent synthetic skin replacement for burn victims or those suffering from skin diseases or disorders. Artificial skins contain live cells or are made from biocompatible materials that mimic natural skin's structure and functions. They offer barrier protection against infection and fluid loss while promoting wound healing. With rising burns and traumatic injuries worldwide, the demand for skin grafts and substitutes is expanding rapidly.

The Global bioengineered artificial skin market is estimated to be valued at US$ 3.32 Billion in 2024 and is expected to exhibit a CAGR of 16% over the forecast period 2023 to 2030.

Key Takeaways

Key players operating in the bioengineered artificial skin market are Genoskin, Smith and Nephew Inc., Genzyme Biosurgery, Vericel Corporation, AROA BIOSURGERY LIMITED, Integra LifeSciences Corp, COOK BIOTECH, Mölnlycke Health Care AB, Avita Medical, MiMedx Group, Inc., and Organogenesis Holdings Inc.

The global artificial skin market is driven by the rising incidence of burn injuries, especially in developing nations where industrial safety norms are still evolving. As per the World Health Organization (WHO), over 300,000 people die annually from burns worldwide. Moreover, the increasing application of artificial skins in wound care management and reconstruction surgeries is also fueling market revenue.

Technological advancements focus on developing skin substitutes that resemble natural skin more closely. Researchers are working on creating multilayered, vascularized artificial skins with hair follicles, sweat glands, and seamless integration with the recipient's skin. Such next-gen artificial skins can help achieve superior cosmetic outcomes and quality of life for patients.

Market Trends

Some key trends in the artificial skin market include the development of bioprinted and 3D printed skin substitutes. Researchers are adopting advanced bioprinting methods to develop patient-specific skin substitutes by combining skin cells and biomaterials through 3D printing. This facilitates mass production of artificial skins with precise anatomical features.

Another trend gaining traction is the incorporation of advanced therapies into artificial skins. For example, combining stem cell therapy and skin grafting/substitutes to accelerate wound healing. Such combination therapies may enable developing "smart skins" capable of tissue regeneration.

Market Opportunities

The growing demand for skin tissue engineering and regenerative therapies in underpenetrated regions presents significant opportunities for artificial skin market players. Expanding access to advanced wound care and burns management in rural healthcare systems also opens lucrative prospects.

Customization capability is another opportunityarea. As artificial skins become more affordable, customizable options specific to wound type, location, and patient needs can augment the market potential.

#Bioengineered Artificial Skin Market Growth#Bioengineered Artificial Skin Market Trend#Bioengineered Artificial Skin Market Demand.

0 notes

Text

0 notes

Text

Discovered Information on the Leading 3D Printing Companies

At the moment one of the most dominating and rapidly developing trends in the manufacturing industry all over the world is the 3D print. When talking about the biggest 3d printing companies, some of them have achieved great outcomes and contributed to the mutational reinvention of several sectors. Therefore, this article will focus on finding out who the current key players are in the context of 3D printing, the technologies that the players are utilizing in their operations, and 3D printing in some vital sectors, namely, aerospace, automotive, health, and architectural sectors.

What is 3D printing?

3D printing involves the manufacturing of an object by deposition of a large number of layers to come up with a part that has been designed using a drawing application. In this technique of fabrication, there is a buildup of one layer of materials on another to give the final product as an outcome. It creates designs that are seemingly impossible to create using other principles of manufacturing engineering.

Applications of 3D Printing

Aerospace

Lightweight Parts: 3D printing has the advantage of thinning the parts and reducing the weight of the components, especially in the aviation technology aspect. Reducing the weight of car parts consequently decreases fuel consumption and lowers gas emissions.

Complex Geometries: Components in aerospace structures are often geometrically advanced and, as such, challenging to create employing conventional processes. It is with this ease that 3D printing can produce these parts.

Rapid Prototyping: The method and versatility of creating prototypes help aerospace firms determine designs for production in a shorter period.

Automotive

Customization: The use of 3D printing leads to the development of particular components required by peculiar vehicles; this is because 3D printing makes it possible for the makers to produce part by part.

Tooling and Jigs: Using 3D-printed tools and jigs will go a long way in cutting down a lot of time and money spent on manufacturing.

Spare Parts: The Original Equipment Manufacturers should design systems that allow the manufacturing of spare parts in real-time and thus the users receive genuine parts that may be required to replace damaged ones to get the equipment back to service.

Healthcare

Prosthetics and Implants: Despite the current state of progress in possessing the tools for 3D printing of prosthetics and implants, there are more and more inventions and individually designed ones.

Surgical Guides: These guides enable surgeons to achieve greater accuracy during both simple and complex surgeries, providing a valuable benefit for patients.

Bioprinting: The science of producing living body structures and organs is often referred to as bioprinting, with promises for medicine’s future.

Industrial 3D printer companies

industrial 3d printer companies are the leaders in additive manufacturing, as they are interested in expanding the potential of this form of production. They are companies that create sophisticated machines that can manufacture superior-quality, robust components for their respective uses. They are invaluable in areas and vocations that require accuracy, power, and dependability.

Industrial 3D Printers: Features and Capabilities

High Precision: Distinguishing 3D printers from industrial machines, one can state that this technology allows manufacturing parts with the accuracy and the necessary tolerance. Such accuracy is attributed to the ability to provide complex geometries together with fine details characterized by the high standards of the current industry.

Material Variety: It also can print many kinds of material including metal, plastic, and composite its capability of printing is almost limitless. This flexibility enables the creation of new components and the production of parts for new materials that can be used for making portable consumer goods to aerospace equipment parts.

Scalability: Developing 3D printers is said to be superior and facilitates mammoth production and building and this fits the industry. These printers can accommodate big numbers of production and are thus suitable for both batch production and continuous production.

Advanced Fabrication Techniques: Industrial 3D printers use intricate manufacturing technologies such as AM technologies including SLA, FDM, and SLS. They enable the manufacturing of complicated components with great staking strength and imaginative geometries.

The Threats and Opportunities of 3D Printing

Challenges

Cost: The capital cost includes higher cost of purchasing high-quality 3D printers and the still extremely high cost of 3D printing materials. Advanced models of 3D printers are expensive and require high capital investment at the start and there is always the cost of materials.

Material Limitations: Not all materials can be or need to be printed through 3D printing some of them might be quite a problem. Some materials are difficult to manage mostly where there are poor quality prints or unless there is a high cost.

Quality Control: Consistency in the quality of the 3D-printed parts is another problem that is more pronounced in the vital fields. Printed items have many parts of the whole and to make them have the same quality standard, measures of quality control need to be implemented and equipment needs to be recalibrated often.

Opportunities

Customization: The utility of 3D printing in customizing solutions is another benefit since it implements a mass production of products, making a solution for need all about it.

On-Demand Production: It also supports on-demand manufacturing, thus getting rid of big inventories and stocks that usually accumulate and turn out to be valueless. This model also assists in the correct allocation of resources within a business and in satisfying consumers' needs.

Innovation in Design: 3D printing promotes creativity since designers can expand their creativity and design in many unique ways. This leads to the possibility to design some structures and products that could not be designed before utilizing the technology

Future Prospects

Technological Advancements: Long-term advancements should be expected in new materials, improvements in the printing process, and the realized rate of manufacturing.

Increased Adoption: With the decrease in cost and advancement of technologies, more sectors should move towards 3D printing.

Sustainability: 3D printing can play a role in sustainability because the method is more of a waste-saving technique and can produce lighter parts.

Conclusion:

Architectural solutions are creating new opportunities. architect 3d enable designers to model or prototype their designs in ultra-realism and high detail. With this technology, architects can conceptualize improvements to their designs, develop new structures, and efficiently execute their architectural plans.

So, if industrial 3D printer companies keep on improving and proving themselves in their craft, this will create new chances and advancements in the future. 3D printing is proving to be a disruptor of traditional methods through the use of architectural 3d tools in design and construction, hence the importance of 3D printing in the creation and construction processes.

1 note

·

View note

Text

4D Printing in Healthcare Market Projections: Future Growth and Trends

4D Printing in Healthcare Market Outlook, Scope & Overview:

Reports indicate that the global 4D printing in healthcare market was valued at USD 30.45 billion in 2023 and is projected to reach USD 124.23 billion by 2031, growing at a CAGR of 19.21% over the forecast period 2024-2031.

Technological Advancements to Drive Growth of Global 4D Printing in Healthcare Market

The adoption of 4D printing technology in healthcare applications will continue to influence global market revenues. This innovative technology offers dynamic structures that can adapt to various conditions, enhancing its utility in medical devices, prosthetics, and tissue engineering.

As a technology segment, 4D printing currently holds a significant share of the global healthcare market. This segment is anticipated to grow at a year-over-year rate of 19.21% from 2024 to 2031, reaching new heights in terms of market size and application diversity.

4D Printing Technology in Healthcare – Market Dynamics

Drivers:

4D printing technology is revolutionizing healthcare by enabling the creation of adaptive and responsive medical devices and implants. This technology allows for the development of patient-specific implants and prosthetics that can change shape or function in response to physiological changes or external stimuli. The increasing demand for personalized healthcare solutions and the growing applications in surgical planning and drug delivery systems are driving the adoption of 4D printing in healthcare.

Restraints:

Despite its potential, challenges such as high initial costs, technical complexities, and regulatory hurdles are limiting the widespread adoption of 4D printing technology in healthcare. Moreover, the need for specialized expertise and infrastructure for designing and printing complex 4D structures poses challenges to market growth.

4D Printing Technology in Healthcare – Market Outlook

The effective outcomes observed from the use of 4D printing technology in creating customized medical solutions have boosted its prominence in the global market. The healthcare industry is witnessing a rapid evolution towards integrating 4D printing into various medical disciplines, including orthopedics, cardiology, and neurology.

Global 4D Printing in Healthcare Market

The surge in demand for 4D printing applications in North America, Europe, and Asia Pacific regions is expected to drive market growth over the forecast period. North America currently leads the global 4D printing in healthcare market, followed by Europe and Asia Pacific. These regions are witnessing increased investments in research and development to enhance the capabilities and applications of 4D printing technology in healthcare.

Key Players in the 4D Printing Technology Market

Leading companies in the 4D printing technology market include Stratasys Ltd., 3D Systems Corporation, Organovo Holdings Inc., and Materialise NV. These companies are at the forefront of developing innovative 4D printing solutions tailored for healthcare applications, ranging from bioprinting tissues to creating advanced medical implants.

In conclusion, the global 4D printing in healthcare market is poised for robust growth over the forecast period, driven by technological advancements, increasing investments, and the expanding applications in personalized medicine and patient-specific treatments.

Read Our Other Reports

Wound Care Market

Wearable Medical Devices Market

Vitamins Market

Proteomics Market

#4D Printing in Healthcare Market#4D Printing in Healthcare Market Size#4D Printing in Healthcare Market Share#4D Printing in Healthcare Market Trends#4D Printing in Healthcare Market Growth#4D Printing in Healthcare Market Analysis#4D Printing in Healthcare Market Outlook

0 notes

Text

From Concept to Creation: How 3D Printing is Redefining Design Possibilities

In recent years, 3D printing has revolutionized the design and manufacturing industries, transforming ideas into tangible realities with unprecedented speed and precision. This innovative technology, which builds objects layer by layer from digital models, is redefining design possibilities across various sectors, from architecture and engineering to fashion and healthcare.

The Rise of 3D Printing

Initially developed in the 1980s, 3D printing, also known as additive manufacturing, has evolved from a niche prototyping tool to a mainstream technology with extensive applications. Early 3D printers were costly and limited in capability, but advancements in materials, software, and hardware have made 3D printing more accessible and versatile. Today, it is a powerful tool for rapid prototyping, custom manufacturing, and even large-scale production.

Transforming Design Processes

One of the most significant impacts of 3D printing is its ability to streamline the design process. Traditional manufacturing methods often involve multiple steps and substantial lead times, especially for complex geometries. In contrast, 3D printing allows designers to create intricate shapes and structures that would be impossible or prohibitively expensive to produce using conventional techniques. This capability is particularly valuable in industries like aerospace, automotive, and medical devices, where precision and customization are critical.

With 3D printing, designers can iterate quickly, testing and refining their ideas with physical prototypes. This iterative process accelerates development cycles and fosters innovation, enabling companies to bring products to market faster. Additionally, the ability to produce functional prototypes allows for more rigorous testing and validation, ensuring higher-quality end products.

Customization and Personalization

The customization potential of 3D printing is another game-changer. Traditional manufacturing often relies on mass production, which can be limiting when it comes to personalized products. 3D printing, however, excels in creating bespoke items tailored to individual specifications. This capability is transforming industries such as healthcare, where custom prosthetics, implants, and orthodontic devices are becoming more common. Similarly, in the fashion and consumer goods sectors, 3D printing enables the creation of unique, made-to-order items, catering to the growing demand for personalized products.

Sustainability and Efficiency

Sustainability is an increasingly important consideration in modern manufacturing, and 3D printing offers several environmental benefits. Unlike subtractive manufacturing, which cuts away material to create objects, 3D printing is an additive process that builds objects layer by layer, minimizing waste. Additionally, 3D printing can reduce the need for inventory and transportation, as products can be printed on demand and closer to the point of use.

Moreover, the ability to use recycled and sustainable materials in 3D printing is advancing. Researchers and companies are exploring biodegradable plastics, recycled polymers, and even organic materials like algae and mycelium for use in 3D printing. These innovations have the potential to further reduce the environmental impact of manufacturing.

Future Possibilities

The future of 3D printing holds exciting possibilities. As the technology continues to advance, we can expect even greater precision, faster print times, and broader material options. Emerging trends include the development of multi-material printers, which can combine different materials in a single print, and bioprinting, which aims to create human tissues and organs for medical applications.

In architecture and construction, large-scale 3D printers are being used to create entire buildings and structures, pushing the boundaries of what's possible in urban design and infrastructure. These advancements could lead to more sustainable, efficient, and innovative construction methods, revolutionizing the built environment.

Conclusion

From concept to creation, 3D printing is redefining design possibilities, enabling rapid prototyping, customization, and sustainable manufacturing. As this transformative technology continues to evolve, its impact will only grow, opening new frontiers in design and production across a wide range of industries. Embracing 3D printing means not only staying at the cutting edge of innovation but also contributing to a more efficient and sustainable future.

0 notes