#professional exhaust hood installation

Explore tagged Tumblr posts

Text

How Professional Installers Guarantee Fire Safety Compliance in Your Kitchen

Proper kitchen exhaust hood installation is essential for maintaining fire safety in both residential and commercial kitchens. Trained installers play a crucial role in ensuring your kitchen ventilation system meets all necessary fire safety standards, helping to reduce the risk of fire hazards. In this article, we’ll explore how professional installers ensure your kitchen exhaust hood is installed correctly and in compliance with local fire safety regulations.

The Role of Trained Installers in Kitchen Exhaust Hood Installation

When it comes to kitchen exhaust hood installation, trained professionals are equipped with the knowledge of ventilation systems and fire safety protocols. They follow specific guidelines to ensure the exhaust hood is installed properly, allowing for the effective removal of heat, smoke, and grease-laden vapors. This not only helps your kitchen run efficiently but also protects it from fire risks.

How Trained Installers Ensure Fire Safety Compliance

Professional installers help ensure your kitchen meets fire safety standards in the following ways:

Proper Ductwork Installation: Ducts must be made of fire-resistant materials and positioned to promote efficient airflow. Trained installers ensure the ducts are properly configured to minimize grease buildup, a leading cause of kitchen fires.

Correct Grease Filter Placement: Grease filters capture grease-laden vapors before they reach the duct system. Improper installation of these filters can lead to grease accumulation, increasing fire risks. Professionals ensure filters are installed and maintained according to fire safety regulations.

Integration of Fire Suppression Systems: In commercial kitchens, fire suppression systems are often required alongside the exhaust hood. Trained installers ensure these systems are correctly integrated, allowing them to quickly extinguish fires if necessary.

Compliance with NFPA 96: NFPA 96 is the national standard for ventilation control and fire protection in commercial cooking operations. Trained installers ensure your kitchen exhaust hood complies with NFPA 96, reducing fire risks and ensuring legal compliance.

Benefits of Hiring Trained Installers for Kitchen Exhaust Hood Installation

By choosing trained professionals for kitchen exhaust hood installation, you gain several benefits:

Fire Hazard Prevention: Professionals follow fire safety protocols, ensuring proper installation of all components to minimize fire risks in the kitchen.

Compliance with Local Codes: Trained installers ensure your kitchen ventilation system meets all relevant local fire safety codes, helping you avoid fines or shutdowns.

Improved System Efficiency: Proper installation ensures your ventilation system operates efficiently, keeping the kitchen air clean and reducing fire risks.

Long-Term Safety: Professional installers offer guidance on maintaining your kitchen exhaust system for long-term compliance with fire safety standards.

Conclusion

Trained professionals are essential to ensuring your kitchen exhaust hood installation is completed correctly and in compliance with fire safety regulations. By hiring skilled installers, you can protect your kitchen from fire hazards, improve system efficiency, and ensure long-term safety. Don’t compromise on fire safety—choose professional installation to safeguard your kitchen.

#kitchen exhaust hood installation#exhaust hood fire safety#commercial kitchen ventilation#fire suppression systems#grease filter maintenance#kitchen ventilation installation#exhaust hood compliance#kitchen ductwork installation#NFPA 96 guidelines#exhaust hood fire prevention#professional exhaust hood installation

0 notes

Text

Aligning Ventilation Needs and Compliance for Kitchen Exhaust Hood Installation

Achieving a successful kitchen exhaust hood installation in a commercial kitchen requires more than just choosing the right equipment. It involves balancing ventilation needs with compliance standards. Properly installed exhaust hoods improve air quality and ensure safety, but aligning your system with local codes is essential to avoid potential issues. Here’s how to plan your installation to meet both ventilation requirements and regulatory compliance.

The Importance of Balancing Ventilation and Compliance

A well-planned kitchen exhaust hood installation helps maintain a safe kitchen environment by removing smoke, grease, and heat. Adhering to local building codes ensures that your system operates legally and efficiently. Aligning these aspects protects your staff, reduces fire risks, and helps your kitchen pass necessary inspections.

Key Considerations for Ventilation and Compliance

To ensure that your exhaust hood installation meets both ventilation needs and regulatory standards, consider these factors:

CFM Ratings and Hood Size: Proper airflow is crucial for effective ventilation. Determining the required cubic feet per minute (CFM) based on your cooking equipment and kitchen size ensures that your exhaust hood system can efficiently remove heat, smoke, and odors. High-heat appliances like fryers and grills need a higher CFM rating for optimal performance.

Placement and Clearance: Local regulations often dictate minimum clearance distances between the exhaust hood and walls or ceilings. Proper placement allows the hood to capture fumes effectively while adhering to safety codes. Positioning the kitchen exhaust hood directly above the cooking area is ideal for optimal capture of smoke and grease.

Ductwork Design and Fire Resistance: The design of your ductwork is essential for safely directing fumes out of the kitchen. Using fire-resistant materials and minimizing bends in the ducts helps maintain good airflow. A well-designed duct system is a key part of a compliant kitchen exhaust hood installation.

Makeup Air Systems: As the exhaust hood removes air from the kitchen, it’s important to replace that air to maintain balance. Makeup air systems help maintain safe pressure levels, preventing backdrafts and ensuring overall ventilation efficiency.

Steps to Balance Ventilation and Compliance

Follow these steps to ensure that your kitchen exhaust hood installation meets both ventilation requirements and compliance standards:

1. Consult Local Building Codes

Understanding local regulations is the first step toward a compliant exhaust hood installation. This ensures that your system meets clearance requirements, CFM ratings, and fire safety standards, providing a solid foundation for your project.

2. Work with a Certified Installer

Hiring a certified professional simplifies the installation process and ensures that every aspect of the kitchen exhaust hood meets code requirements. Professionals can determine the right hood size, CFM, and duct design, making your system both effective and compliant.

3. Schedule a Pre-Installation Inspection

Consider a pre-installation inspection to verify that the planned setup meets local codes. This helps identify any necessary adjustments before the final exhaust hood installation, saving time and preventing costly rework.

Benefits of a Well-Balanced Kitchen Exhaust Hood Installation

When your kitchen exhaust hood installation is properly aligned with ventilation needs and compliance standards, you achieve improved air quality, energy efficiency, and safety. A well-installed system minimizes fire risks, lowers energy costs, and ensures that your kitchen complies with all necessary regulations, creating a more comfortable environment for staff and guests.

Balancing Safety and Efficiency

Balancing ventilation needs with regulatory compliance is crucial for a successful kitchen exhaust hood installation. By considering factors like CFM ratings, proper placement, and ductwork design, you can create a safe and efficient kitchen. Working with professionals and understanding local codes ensures that your installation meets all standards, offering peace of mind and long-term performance for your commercial kitchen.

#kitchen exhaust hood installation#commercial kitchen ventilation#exhaust hood installation tips#kitchen hood setup#CFM calculation for exhaust hoods#ventilation system installation#kitchen safety compliance#exhaust hood maintenance#ductwork design#fire-resistant ductwork#professional exhaust hood installation#kitchen air quality#compliant kitchen ventilation#restaurant exhaust systems#exhaust hood clearance requirements#installation guidelines#kitchen hood placement#commercial kitchen safety#ventilation code requirements#efficient kitchen exhaust systems

0 notes

Text

Understanding Ventilation Power: Selecting the Ideal CFM for Your Kitchen Exhaust Hood Installation

When it comes to kitchen exhaust hood installation, one of the most crucial factors to consider is the ventilation power, measured in cubic feet per minute (CFM). Choosing the right CFM ensures your kitchen remains free from smoke, grease, and odors, providing a safe and comfortable environment. This guide will help you understand how to select the appropriate CFM for your kitchen exhaust hood, enhancing both functionality and compliance with safety standards.

Why CFM Matters in Kitchen Exhaust Hood Installation

CFM, or cubic feet per minute, measures the volume of air a hood can exhaust in one minute. The right CFM is essential for effective ventilation, determining how quickly and efficiently smoke, steam, and grease are removed from your kitchen. An inadequate CFM can lead to poor air quality and increased fire hazards, while an excessively high CFM can be unnecessarily noisy and energy-consuming.

Calculating the Right CFM for Your Kitchen

The size of your cooking area and the type of cooking you do significantly impact the CFM requirements. For standard cooking ranges, a basic rule of thumb is 100 CFM per linear foot of cooktop. For example, a 30-inch range would need a hood with at least 250 CFM. For more intensive cooking methods, such as grilling or frying, you may need a higher CFM to ensure adequate ventilation.

Factors Influencing CFM Requirements

Several factors influence the CFM requirements for your kitchen exhaust hood installation:

Cooking Style: Heavy cooking styles like frying or grilling produce more smoke and grease, requiring higher CFM.

Kitchen Size: Larger kitchens may need more powerful hoods to ensure complete ventilation.

Ductwork Length: Longer duct runs can reduce efficiency, necessitating higher CFM to maintain performance.

Hood System Installation

Proper hood system installation is key to maximizing the effectiveness of your kitchen exhaust hood. Professional installation ensures your hood is correctly positioned and ducted, optimizing airflow and ventilation. Experts can assess your specific kitchen layout and recommend the best system and CFM for your needs, ensuring safety and compliance with local regulations.

Benefits of Choosing the Right CFM

Selecting the appropriate CFM for your kitchen exhaust hood offers several benefits:

Improved Air Quality: Efficient ventilation removes contaminants, keeping the air fresh and clean.

Enhanced Safety: Proper ventilation reduces the risk of grease fires and improves overall kitchen safety.

Energy Efficiency: Choosing the right CFM ensures your hood operates efficiently, saving on energy costs.

Noise Reduction: An appropriately powered hood operates more quietly, creating a more pleasant cooking environment.

Professional Kitchen Exhaust Hood Installation

Opting for professional kitchen exhaust hood installation guarantees your hood system is tailored to your kitchen’s specific needs. At Red Eagle – Kitchen Hood Services LA, we specialize in providing expert installation services. Our experienced team will help you choose the right CFM and ensure your hood is installed for maximum efficiency and safety.

#Kitchen Hood Installation#Commercial Vent Hood#Restaurant Hood Installation#Kitchen Ventilation#Exhaust Hood System#Kitchen Ventilation Installation#Professional Hood Installation#Range Hood Installation#Type 2 Hood Installation#Kitchen Exhaust Fan#Commercial Kitchen Hood#Vent Hood Services#Kitchen Hood Ventilation#CFM Calculation#Kitchen Exhaust System#Kitchen Hood Maintenance#Ventilation Power#Air Quality Improvement#Fire Safety#Energy Efficiency

2 notes

·

View notes

Text

Upgrade Your Cooking Space with Expert Kitchen Exhaust Hood Installation

When it comes to creating a comfortable and efficient cooking environment, kitchen exhaust hood installation is a vital step every homeowner should consider. A quality exhaust hood not only enhances the aesthetics of your kitchen but also significantly improves air quality by removing smoke, steam, and unpleasant odors.

Why Invest in Kitchen Exhaust Hood Installation?

Red Eagle Fire Protection Riverside County (951) 877-5756 Riverside County https://redeaglefireprotectionriverside.com/

#Kitchen Exhaust Hood Installation#Riverside County#Kitchen Safety#Home Improvement#Professional Installation

0 notes

Text

Top-Quality Kitchen Exhaust Hood Installation Services in Encino, CA

Looking for reliable kitchen exhaust hood installation in Encino, CA? Our expert team ensures your kitchen stays safe and well-ventilated by professionally installing exhaust hoods that efficiently remove smoke, grease, and heat. We specialize in setting up systems tailored to your kitchen's needs, enhancing air quality and meeting local regulations. Enjoy a cleaner, safer cooking environment with our top-notch installation services. Upgrade your kitchen today and breathe easy knowing the job is done right!

Red Eagle Fire Protection Encino Encino, CA https://redeaglerestfirehoo

#kitchen exhaust hood installation#professional hood installation#Encino CA kitchen services#kitchen ventilation#air quality improvement#ductwork setup#grease and smoke removal#exhaust fan installation#kitchen safety#energy-efficient ventilation#local kitchen upgrades

0 notes

Text

Top-Quality Kitchen Exhaust Hood Installation by Red Eagle Fire Protection

Red Eagle Fire Protection offers top-quality kitchen exhaust hood installation. Keep your kitchen safe, efficient, and compliant with our expert services. Contact us for a free consultation!

Red Eagle Fire Protection Agoura Hills Agoura Hills, CA (747) 326-2084 https://redeaglerestfirehood.com/agoura-hills-ca/

#vent hood installation#kitchen exhaust hood installation#near me#professional hood installation#agoura hills#california

0 notes

Text

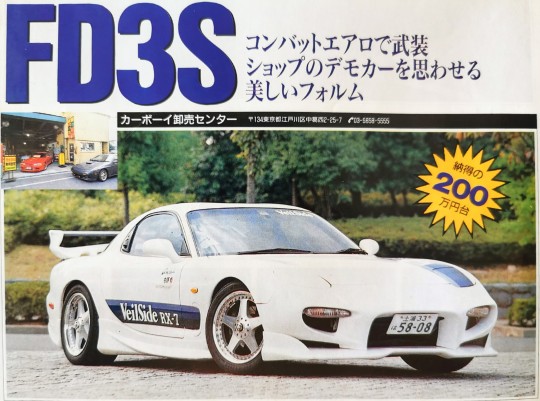

FD3S

Armed with combat aero, a beautiful form reminiscent of a shop demo car

Cowboy Wholesale Center 2-25-7 Nakakasai, Edogawa-ku, Tokyo 134 03-5658-5555

Sharp nose and wedge shape

Shaped body line. The domestic product

with elegant styling that stands out from the car.

Although the FD3S RX-7 is very popular, the price of used cars has become much more affordable due to the increase in the number of cars and the impact of new car pricing. There is also a wide selection of tuned used cars, many of which have been finished with aero parts to give them a more aggressive look, and are very popular.

The same goes for the FD introduced here. From the flashy, wide-open front bumper to the huge rear wing and wheels, everything is made of Veilside, and the hood also features a VeilSide decal. The finish is perfectly reminiscent of a shop's demo car. That's no wonder; in fact, the previous owner of this FD was a staff member from Veilside. It's a Veilside Special that can almost be called a demo car.

The engine is stock, with only the intake and exhaust system tuned and fuel control using the F-con V, but the exhaust system has been replaced, from the front pipe to the muffler, so it runs smoothly. The power at high revolutions is also increased. In addition, not only the parts themselves, but also the installation and finishing are done with great attention to detail and are of high quality.

The light-tuned specs tend to be considered unappealing in terms of driving performance when compared to more aggressively modified cars, but the completeness of the car, including the exterior, is such that it is truly a professionally finished car. . Although it is a tuned used car, it is one that you can buy with confidence.

PIC CAPTIONS

●The seat is a 4-point Recaro SP-G+ Willans made of fiberglass. Like the exterior, the interior is of high quality, and it is a machine with high cost performance.

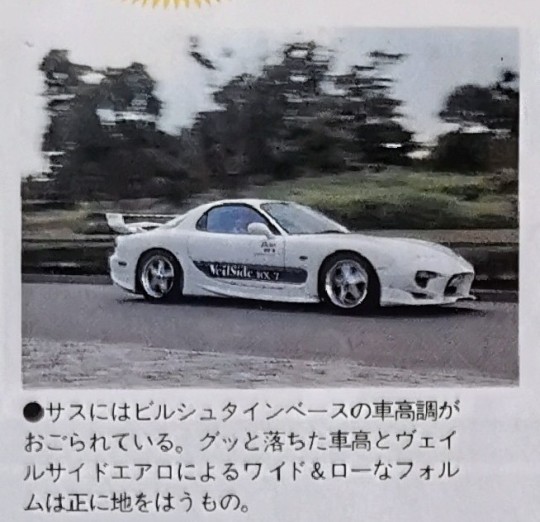

●The suspension is equipped with Bilstein-based coilovers. The wide and low form created by the drastically lowered vehicle height and veil side aero is truly impressive.

●The engine is basically normal. Air cleaner + intercooler pipe kit, front pipe + muffler, intake and exhaust system, and F-con V light tune specification.

INFO BOX

Infini RX-7 Type R

1995 model inspected April 2010

Mileage 19,000km 2,980,000 yen

Tune data: HKS Super Filter

HKS Racing Plug

HKS Front Pipe

Knight Sports Catalyst Straight Pipe

HKS Inter Cooler PipingKit

VeilSide Sports Muffler

HKS/F ConV

Bilstein Vehicle Adjustment

VeilSide Full Aero

Veilside Andrews wheels

Recaro SP-G Seat

46 notes

·

View notes

Text

How To Stop Gas Leakage On Commercial Kitchen Devices

Gas leaks in commercial kitchens are a grave issue. They might lead to safety dangers, such as fires or explosions, or produce health-related problems. For those operating commercial kitchens in Canada, preventing gas leaks is vital for employee and customer safety. Proper maintenance and safety techniques implemented by commercial kitchen equipment repair will avoid operational risks associated with commercial appliances, and appliances will serve these facilities safely and effectively.

Importance of gas leakage prevention Leaks in commercial kitchen appliances might be hazardous compared to traditional kitchens. Exposure to leaking gas for an extended period may also cause dizziness, headache, and other critical illnesses. Thus, both human beings and belongings require the prevention of such leaks.

Periodical Inspection and Maintenance of Appliances One of the best ways to prevent gas leaks is to inspect and maintain commercial kitchen appliances regularly. Appliances that rely on gas, such as ovens, stoves, and grills, should be checked periodically for wear or damage. Ensuring all components, including gas lines, valves, and connections, are in good condition is essential.

Proper Installation of Appliances Another critical factor in preventing gas leaks is the proper installation of commercial kitchen appliances. If appliances are not installed properly, gas lines and connections can loosen or be poorly sealed, resulting in possible leaks. A qualified technician should install all gas-powered kitchen equipment. Do not hesitate to seek the professional help of experts in commercial kitchen equipment repair if you are unsure about how the appliance was installed.

Ventilation and Airflow Proper ventilation is essential for preventing gas leaks and safety in the kitchen environment. A well-ventilated kitchen will help spread any gas that might leak out, preventing accumulation. Commercial kitchen appliances, especially gas-powered ones, should be installed in areas with proper ventilation.

Ensure your kitchen has exhaust systems, like range hoods and vents, to remove excess gas or smoke. Commercial kitchen equipment repair should clean and maintain these regularly so that they work correctly.

Train staff on gas leak detection Employees must be taught how to identify a gas leak and what to do during an emergency. They must also be instructed on how to shut off the gas supply without creating further leakage.

Staff should be aware of the smell of natural gas, often added with a sulphur-like odour, for easy detection. In case of a suspected gas leak, staff should know to evacuate the area immediately and contact emergency services. Regularly practicing gas leak drills can help ensure everyone knows how to react in an emergency.

Repair Leaks Now The leak should not be attempted to be repaired unless experienced in gas appliances. Gas leaks should only be repaired by authorized professionals who know how to work with such problems.

If you smell gas or suspect leakage, switch off the gas supply to the appliance. Leave the surrounding area and seek professional commercial kitchen equipment repair and servicing to fix this issue.

0 notes

Text

The Importance of a Reliable Kitchen Exhaust Ducting System for Commercial Kitchens

In the fast-paced environment of a commercial kitchen, maintaining optimal air quality and safety is paramount. One essential component that ensures this is the kitchen exhaust ducting system. Designed to remove heat, smoke, grease, and odors, a well-maintained kitchen exhaust ducting system plays a critical role in keeping your kitchen functional, safe, and compliant with regulations. At WCT Systems, we specialize in providing top-notch solutions tailored to meet the unique needs of your kitchen.

What Is a Kitchen Exhaust Ducting System?

A kitchen exhaust ducting system is an interconnected series of ducts, fans, and vents designed to extract polluted air from the kitchen and release it outside. This system is crucial for regulating indoor air quality, reducing fire risks, and ensuring the comfort and safety of kitchen staff. The ducting system typically consists of:

Hood: Captures smoke and grease particles.

Ducts: Channel the contaminated air to the outside environment.

Fans: Facilitate the movement of air through the system.

Filters: Trap grease and other particles to prevent clogging and maintain efficiency.

Why Is the Kitchen Exhaust Ducting System Vital?

Improves Air Quality: In a commercial kitchen, cooking processes release smoke, grease particles, and odors into the air. Without a proper exhaust system, these contaminants can accumulate, leading to poor air quality and health issues for employees. A reliable Kitchen Exhaust Ducting System effectively removes these pollutants, ensuring a clean and safe working environment.

Reduces Fire Hazards: Grease buildup in the ductwork is one of the leading causes of kitchen fires. A well-maintained exhaust system equipped with effective grease filters minimizes the risk of fire by preventing grease accumulation.

Enhances Ventilation: Proper ventilation is critical for maintaining a comfortable temperature in the kitchen. By removing excess heat, the kitchen exhaust ducting system helps maintain a cooler environment, which is essential for staff productivity and comfort.

Ensures Regulatory Compliance: Local health and safety regulations often mandate the installation of a certified kitchen exhaust system. Partnering with experts like WCT Systems ensures your kitchen is compliant with these regulations, avoiding potential fines and penalties.

Key Features of a High-Quality Kitchen Exhaust Ducting System

Durable Materials: Stainless steel is the preferred choice for ducting systems due to its resistance to heat, corrosion, and grease buildup. A high-quality system ensures longevity and reliability.

Custom Design: Every kitchen has unique requirements. A customized kitchen exhaust ducting system ensures optimal performance, tailored to the layout and size of your kitchen.

Efficient Filters: Effective grease and particulate filters are crucial for reducing maintenance needs and enhancing fire safety.

Powerful Fans: Fans are the heart of the system. High-performance fans ensure efficient removal of air pollutants and maintain steady airflow.

Maintenance Tips for Your Kitchen Exhaust Ducting System

Regular Cleaning: Clean the ducts and filters regularly to prevent grease buildup and maintain optimal airflow. Professional cleaning services ensure thorough removal of grease and debris.

Inspection and Repairs: Schedule routine inspections to identify wear and tear or potential issues. Addressing problems early prevents costly repairs and ensures continuous operation.

Upgrade Components When Needed: Over time, components like fans and filters may wear out. Replacing outdated parts improves efficiency and safety.

Why Choose WCT Systems for Your Kitchen Exhaust Needs?

At WCT Systems, we are committed to delivering comprehensive solutions for all your kitchen exhaust ducting system requirements. With years of experience, we offer:

Expert Consultation: Tailored advice to design the perfect system for your kitchen.

Quality Installation: Skilled professionals ensure seamless installation of ducting systems.

Ongoing Support: Maintenance services to keep your system in top condition.

Compliance Assurance: Systems designed to meet all regulatory standards.

Conclusion

A reliable kitchen exhaust ducting system is an investment in the safety, efficiency, and compliance of your commercial kitchen. By partnering with WCT Systems, you can ensure your kitchen operates at its best, providing a safe and comfortable environment for your team. Whether you’re setting up a new kitchen or upgrading an existing system, our team is here to help. Contact us today to learn more about our services and how we can enhance your kitchen’s performance.

0 notes

Text

Enhance Your Kitchen Safety with Professional Kitchen Exhaust Hood Installation in Santa Barbara, CA

A well-functioning kitchen exhaust hood is essential for maintaining a safe and healthy cooking environment. Not only does it help eliminate smoke, grease, and odors from your kitchen, but it also prevents the accumulation of harmful gases and ensures better air quality.

When considering kitchen exhaust hood installation, here are some key benefits:

Our team of professionals in Santa Barbara, CA, is dedicated to providing high-quality installations that meet your kitchen's specific requirements. We handle everything from selecting the right hood to ensuring proper installation, giving you peace of mind and a cleaner kitchen.

If you're ready to elevate your cooking experience and ensure safety in your kitchen, contact us today for a consultation!

Red Eagle Fire Protection Santa Barbara Santa Barbara County (805) 301-7261 redeaglefireprotectionsantabarbara.com

#Kitchen Exhaust Hood Installation#Santa Barbara#CA#Kitchen Safety#Home Improvement#Professional Installation

0 notes

Text

Maximize Efficiency with a Local Exhaust Ventilation System

Introduction

In today’s industrial and commercial environments, maximizing efficiency is not merely a goal but a necessity. Whether in manufacturing, laboratories, or food processing, ensuring a safe, clean, and productive atmosphere is crucial to both employee well-being and operational performance. One of the most effective solutions to improve air quality and workplace safety is the installation of a local exhaust ventilation (LEV) system.

An LEV system is designed to capture hazardous airborne contaminants directly at their source, minimizing exposure and improving air quality. However, simply installing the system is not enough. To truly maximize its efficiency, a well-maintained and regularly serviced LEV system is paramount.

Understanding the Local Exhaust Ventilation System

A local exhaust ventilation system is a specialized air filtration system that extracts contaminated air from specific sources, such as workstations, machinery, or chemical processes. Unlike general ventilation systems that circulate air throughout an entire facility, an LEV system targets areas where hazardous pollutants are generated. This targeted approach ensures that the air is filtered before contaminants can spread throughout the workplace, thus preventing the inhalation of harmful substances by workers.

These systems are typically composed of several key components: a capture hood, ductwork, a fan, and a filtration or exhaust unit. The capture hood is positioned near the source of contamination, where it captures and directs the contaminated air into the ductwork. The fan draws the air through the ductwork and pushes it toward the filtration unit, which removes harmful particles, fumes, and gases before discharging the cleaned air outside or recirculating it within the facility.

The effectiveness of an LEV system depends on various factors, including the correct installation, proper maintenance, and regular servicing. Each of these aspects plays a crucial role in ensuring that the system operates at peak efficiency.

The Importance of Proper Installation

The first step in maximizing the efficiency of a local exhaust ventilation system is ensuring its proper installation. The placement of the system components is critical to its performance. When installing an LEV system, it’s essential to accurately assess the areas where contaminants are most likely to be generated. This allows the system to be strategically placed to capture the highest concentration of harmful substances.

The LEV system installation process should always be handled by professionals who are experienced in designing and setting up these systems. Experts will consider factors such as airflow velocity, duct size, and the type of contaminants present to ensure that the system will effectively capture and remove pollutants. Moreover, they will ensure that the system complies with relevant health and safety regulations, as well as industry standards, to safeguard both employees and the environment.

Installation is not a one-size-fits-all process; each workplace has unique needs that require tailored solutions. A well-designed LEV system will significantly enhance operational efficiency, reduce health risks, and create a more comfortable working environment.

Regular Servicing for Peak Performance

While a well-installed LEV system will work efficiently, it is only through regular servicing that it can maintain its optimal performance. Over time, components such as filters, fans, and hoods can degrade, causing a reduction in airflow and system efficiency. This is why LEV servicing is essential to ensure that the system operates effectively throughout its lifespan.

Servicing involves inspecting the system for any signs of wear, such as cracks in the ductwork or damage to the capture hoods. Filters, which are the heart of the air filtration process, need to be checked and replaced periodically to ensure that they continue to capture harmful particles effectively. If the filtration unit is clogged or damaged, it can lead to a buildup of contaminants within the system, reducing its ability to protect workers.

In addition to checking the physical components, the airflow rate should also be measured to confirm that the system is drawing enough air from the work areas. A significant drop in airflow can indicate a blockage or other issues that need immediate attention. Regular servicing not only helps to prolong the life of the system but also ensures compliance with workplace safety regulations.

Neglecting LEV servicing can lead to inefficiency, greater health risks, and potentially costly repairs. Therefore, scheduling periodic maintenance checks is a vital step in maximizing the system’s efficiency and protecting workers’ health.

Testing and Ensuring Compliance

Even the most well-maintained LEV systems can become less effective over time if they are not properly tested. LEV testing is a critical component in ensuring that the system is still working as intended. Regular testing evaluates the airflow, pressure, and filter performance, and ensures that contaminants are being properly captured and filtered out of the environment. This process can identify any weaknesses in the system that may not be apparent during regular servicing.

Testing is also crucial for meeting regulatory compliance. Many industries are subject to strict guidelines that dictate the necessary levels of air quality and the operation of ventilation systems. LEV testing ensures that the system adheres to these standards, which is essential for maintaining a safe working environment and avoiding potential legal or financial penalties.

When the system is tested, technicians use specialized equipment to measure airflow velocity and capture efficiency. The results from these tests help to pinpoint areas where improvements are needed, whether it’s increasing the airflow, optimizing the placement of the capture hood, or upgrading the filtration system. For facilities that handle hazardous chemicals or dust, this testing process is not just beneficial — it’s often legally required.

Optimizing System Efficiency with SEPCOM

One of the most significant advances in local exhaust ventilation systems is the development of SEPCOM technology. SEPCOM is a system that integrates the principles of both ventilation and filtration to improve the overall efficiency of air handling systems. By using advanced filtration technology, SEPCOM units can separate and capture fine particles that might otherwise pass through conventional filtration systems.

The SEPCOM system is particularly effective in industries where ultra-fine particles or hazardous chemicals are present, such as in pharmaceutical manufacturing or metalworking. By utilizing SEPCOM in conjunction with a standard LEV system, companies can significantly reduce the concentration of airborne contaminants, further enhancing the air quality in their facilities.

Incorporating SEPCOM into your existing LEV system can be a game-changer in terms of performance and efficiency. The integration of high-performance filtration ensures that the system captures even the smallest particles, reducing risks to employee health and improving the overall safety and compliance of the facility.

Maximizing Operational Efficiency

Maximizing efficiency with an LEV system involves more than just installation and maintenance; it also means understanding the unique needs of your facility and tailoring the system to meet those needs. By considering the types of contaminants present, the layout of the workspace, and the specific tasks being performed, a customized LEV system can be designed to maximize its effectiveness.

Regular LEV testing and LEV servicing are necessary to ensure that the system is running at its peak capacity. These processes help to identify any issues early, prevent downtime, and reduce the risk of non-compliance with safety standards. Furthermore, implementing cutting-edge technology like SEPCOM enhances the performance of the system, allowing it to capture finer particles and operate more efficiently.

Ultimately, the goal of a local exhaust ventilation system is to create a safe, clean, and productive workplace. By investing in proper installation, regular maintenance, and advanced filtration solutions, businesses can protect their workforce, comply with regulations, and improve their bottom line.

For those looking to improve their LEV systems, WBT Services offers expert LEV system installation, LEV servicing, and LEV testing. Additionally, their advanced SEPCOM technology provides a powerful solution for workplaces that require enhanced filtration. With a professional team dedicated to maximizing the efficiency of your ventilation systems, WBT Services ensures that your air quality management is in good hands.

Conclusion

Maximizing the efficiency of a local exhaust ventilation system is crucial for creating a safe and healthy working environment. Proper installation, regular servicing, and ongoing testing are all essential components in ensuring the system performs optimally. Advanced filtration technologies like SEPCOM can take system efficiency to the next level. When all these elements come together, the result is an air quality management system that not only meets but exceeds industry standards, protecting both employees and the business.

0 notes

Text

How Proper Kitchen Exhaust Hood Installation Improves Safety and Functionality

In any commercial kitchen, the exhaust hood is a vital piece of equipment, playing a key role in maintaining safety and operational efficiency. However, the effectiveness of an exhaust hood depends heavily on how well it is installed. Proper kitchen exhaust hood installation ensures that your ventilation system operates efficiently, reducing fire risks and improving air quality.

The Safety Benefits of Professional Installation

One of the primary purposes of an exhaust hood is to minimize fire hazards. During cooking, grease, smoke, and heat are released into the air. These particles can accumulate in the exhaust hood and ducts if not properly vented, creating a highly flammable environment.

Professional kitchen exhaust hood installation ensures that the system captures and removes grease-laden air effectively. By positioning the hood correctly and integrating it seamlessly with your ventilation system, experts reduce the risk of grease buildup and improve airflow. Additionally, a properly installed exhaust hood complies with fire safety regulations, giving you peace of mind that your kitchen is protected from potential hazards.

Improved Functionality and Efficiency

An exhaust hood isn’t just about safety—it also enhances the overall functionality of your kitchen. Proper installation ensures optimal airflow, removing heat, smoke, and odors from the cooking area. This creates a more comfortable environment for your staff, allowing them to work efficiently even during peak hours.

Incorrect installation, on the other hand, can lead to uneven airflow and inefficient grease removal, which not only impacts kitchen performance but also increases energy consumption. A professionally installed exhaust hood operates smoothly, reducing strain on your HVAC system and lowering utility costs.

Key Features of Expert Installation

Correct Positioning and Sizing Professional installers evaluate your kitchen’s layout and cooking equipment to determine the best size and placement for the exhaust hood. This ensures maximum coverage and effective removal of airborne contaminants.

Seamless Integration with Fire Suppression Systems Many commercial kitchens rely on integrated fire suppression systems. Proper kitchen exhaust hood installation ensures these systems work in tandem, offering an additional layer of protection in case of fire.

Compliance with Safety Codes Local fire and health regulations often mandate specific installation standards. Professional installation guarantees that your exhaust system meets these requirements, helping you avoid fines and ensuring smooth inspections.

Long-Term Benefits of Proper Installation

Investing in professional installation offers long-term advantages for your business:

Reduced Maintenance Costs: A correctly installed exhaust hood requires less frequent maintenance and is less prone to breakdowns, saving you time and money.

Extended Equipment Lifespan: Proper installation minimizes wear and tear, helping your ventilation system last longer.

Enhanced Air Quality: By effectively removing smoke and odors, your kitchen maintains a healthier atmosphere for staff and customers alike.

Conclusion

Proper kitchen exhaust hood installation is essential for maximizing the safety and functionality of your commercial kitchen. From reducing fire risks to improving air quality and energy efficiency, expert installation ensures your exhaust system performs at its best. Protect your business and enhance your kitchen’s operations by investing in professional installation services today.

#kitchen exhaust hood installation#commercial kitchen ventilation#exhaust hood performance#fire safety in kitchens#professional hood installation#grease removal#kitchen air quality#energy-efficient ventilation#kitchen safety#ventilation system installation#exhaust hood maintenance#commercial kitchen safety

0 notes

Text

Understanding Common Engine Problems in Mercedes: Causes and Solutions

Mercedes-Benz vehicles are renowned for their luxury, performance, and engineering excellence. However, like all automobiles, they can experience mechanical issues over time. One area that often requires attention is the engine—a critical component that can encounter a variety of problems. Understanding these issues, their causes, and how to address them is vital for maintaining the performance and reliability of your Mercedes.

1. Oil Leaks

Symptoms:

Visible oil spots under the car.

Burning oil smell.

Low oil levels despite regular top-ups.

Common Causes:

Faulty valve cover gaskets.

Worn-out oil pan seals.

Cracked oil cooler seals.

Solutions:

Promptly addressing oil leaks is crucial to avoid engine damage. Replacing damaged gaskets or seals and ensuring proper installation by a professional technician can resolve the issue effectively.

2. Misfiring or Rough Idling

Symptoms:

Vibrations while idling.

Loss of power during acceleration.

Check engine light illuminated.

Common Causes:

Worn spark plugs or ignition coils.

Fuel injector problems.

Clogged air filters or faulty sensors.

Solutions:

Regular maintenance, including spark plug and coil replacement, is essential to avoid misfires. Cleaning or replacing fuel injectors and sensors can restore smooth engine operation.

3. Turbocharger Failure (for Turbocharged Models)

Symptoms:

Reduced engine power.

Excessive smoke from the exhaust.

Whining or grinding noise from the engine.

Common Causes:

Lack of proper oil circulation.

Build-up of carbon deposits.

Physical damage to turbocharger components.

Solutions:

Timely oil changes and the use of high-quality oil prevent carbon build-up. If the turbocharger fails, professional repair or replacement is necessary to restore performance.

4. Timing Chain Issues

Symptoms:

Rattling noises from the engine, especially during startup.

Engine misalignment or loss of synchronization.

Check engine light on.

Common Causes:

Worn or stretched timing chain.

Faulty tensioners or guides.

Solutions:

Timing chain issues can cause severe engine damage if left unaddressed. Regular inspections and replacing worn components as needed are crucial for long-term reliability.

5. Engine Overheating

Symptoms:

Rising temperature gauge.

Steam coming from under the hood.

Coolant leaks.

Common Causes:

Faulty water pump.

Leaking or clogged radiator.

Malfunctioning thermostat.

Solutions:

Inspecting the cooling system and promptly repairing or replacing defective parts can prevent overheating. Routine coolant flushes and radiator maintenance are essential to ensure optimal performance.

6. Diesel Engine-Specific Problems

Mercedes diesel engines, while efficient, are prone to unique issues such as:

Symptoms:

Excessive black smoke from the exhaust.

Loss of power during acceleration.

Hard starting or stalling.

Common Causes:

Clogged diesel particulate filter (DPF).

Malfunctioning fuel injectors.

Build-up of soot in the intake manifold.

Solutions:

Regular cleaning of the DPF and intake manifold, along with injector servicing, can address diesel-specific issues effectively.

Prevention Tips for Mercedes Engine Problems

Adhere to Regular Maintenance: Follow the manufacturer’s recommended service intervals, including oil changes, filter replacements, and inspections.

Use Quality Parts and Fluids: Opt for genuine Mercedes parts and high-quality oils and fluids to ensure compatibility and performance.

Monitor Warning Signs: Address check engine lights and unusual noises promptly to prevent minor issues from escalating.

Drive Responsibly: Avoid aggressive driving habits that can strain the engine and its components.

When to Seek Professional Help

While some maintenance tasks can be handled by DIY enthusiasts, complex engine problems require professional expertise. Certified Mercedes technicians use specialized diagnostic tools to identify issues accurately and perform repairs using manufacturer-approved methods.

Conclusion

Understanding common engine problems in Mercedes vehicles and their causes is the first step to maintaining your car’s legendary performance and longevity. Regular maintenance and timely repairs by skilled professionals can save you from costly breakdowns and ensure that your Mercedes continues to deliver the driving experience you expect.

#mercedes car#mercedes car engine problem#mercedes engine service#mercedes car maintenance#mercedes car mechanic#mercedes engine oil change

0 notes

Text

Essential Warning Signs of Exhaust Hood Failure Every Commercial Kitchen Must Watch For

In commercial kitchens, an efficiently working exhaust hood is critical for maintaining proper ventilation, controlling heat and odors, and preventing fire hazards. However, like any equipment, exhaust hoods can develop problems over time, and ignoring these warning signs can lead to costly repairs or even dangerous incidents. In this article, we’ll highlight the key warning signs of exhaust hood failure that every commercial kitchen should be aware of to keep operations safe and efficient.

Decreased Airflow and Poor Ventilation

One of the most noticeable signs of exhaust hood failure is reduced airflow. If your kitchen is filling with smoke or steam faster than usual, or if odors linger even after cooking, it may indicate that your exhaust hood is struggling to remove air properly. This issue can arise due to blocked ductwork, worn-out fans, or excessive grease buildup in the system. Reduced ventilation is not just an inconvenience; it increases the risk of grease fires and can make the kitchen environment unsafe for staff.

Addressing poor airflow early by inspecting and cleaning the system can prevent more severe problems down the line.

Unusual Noises Coming from the Hood

A healthy exhaust hood should operate with minimal noise. If you start hearing grinding, rattling, or squealing sounds coming from the system, it’s a red flag. These noises often point to mechanical issues such as loose parts, motor problems, or a damaged fan. Continuing to operate the exhaust hood under these conditions can lead to total system failure, leaving your kitchen without proper ventilation.

Calling in a professional to inspect and repair the system as soon as you hear these noises can save you from costly repairs or replacements.

Excessive Grease Buildup

While some grease accumulation is normal, seeing excessive grease buildup on or around the exhaust hood can be a major sign of trouble. If grease is dripping from the hood or visibly coating surfaces more than usual, it’s a sign that your exhaust hood isn’t effectively removing airborne grease particles. This could be due to a malfunctioning fan or clogged filters, both of which increase the risk of a grease fire—a serious safety hazard in commercial kitchens.

Regular cleaning and maintenance are essential to prevent grease buildup and keep your kitchen safe from potential fire risks.

Fluctuating or Inconsistent Airflow

An exhaust hood should provide consistent, strong airflow throughout the kitchen. If the airflow seems to weaken or fluctuate during use, this inconsistency may indicate that something is wrong with the system. Possible causes include a clogged filter, a malfunctioning fan, or issues with the ductwork. Inconsistent airflow reduces the hood’s ability to effectively expel smoke, heat, and grease, leading to poor air quality and an increased risk of fire.

Addressing fluctuating airflow promptly can help maintain safe kitchen conditions and prevent system breakdown.

Persistent Odors

One of the primary functions of an exhaust hood is to eliminate cooking odors from the kitchen. If unpleasant smells remain even when the exhaust hood is running, it could signal a malfunction. A clogged filter, faulty fan, or blockages in the ductwork might prevent the hood from removing odors properly. Persistent odors can not only create an uncomfortable environment but also indicate that grease and smoke are accumulating in the system, increasing fire risks.

Resolving this issue early can improve both air quality and kitchen safety.

Electrical Issues

If your exhaust hood experiences flickering lights, intermittent fan operation, or power failures, it’s a sign of underlying electrical problems. Faulty wiring, a failing motor, or circuit overloads can cause these issues, and continuing to operate the system without addressing them can lead to a fire or complete system failure. Electrical problems should never be ignored and require immediate professional attention to prevent safety hazards.

Conclusion

Every commercial kitchen must be aware of the warning signs of exhaust hood failure to maintain a safe and efficient operation. From reduced airflow and unusual noises to excessive grease buildup and electrical issues, recognizing these early warning signs allows for timely intervention, preventing expensive repairs or dangerous incidents. Regular maintenance and professional inspections are key to ensuring that your exhaust hood continues to operate effectively, keeping your kitchen safe and compliant with fire safety standards.

#kitchen exhaust hood repair#commercial hood repair#exhaust fan repair#ventilation system repair#kitchen ventilation maintenance#exhaust hood troubleshooting#grease hood repair#ductwork repair#professional hood repair services#exhaust system maintenance#exhaust fan motor repair#exhaust filter replacement#commercial kitchen ventilation repair#hood cleaning and repair#fire safety hood repair#kitchen air quality solutions#exhaust hood installation and repair#kitchen hood motor repair#emergency exhaust hood repair#restaurant hood repair services.

0 notes

Text

Upgrade Your Home with Decenzo Electric’s EV Charger Services in PA and Ceiling Fan Solutions in Broomall

At Decenzo Electric, LLC, our priority is creating safe, efficient, and comfortable spaces for your home or business. With a wide range of specialized electrical services throughout Pennsylvania, we’re committed to delivering convenience, safety, and style. From integrating clean energy solutions to enhancing ventilation and overall comfort, our team is here to ensure your systems are modern, functional, and reliable.

Here’s a closer look at some of the professional services we proudly offer and how they can make a difference in your day-to-day life.

Drive Into the Future with EV Charger Services in PA

The rise of electric vehicles (EVs) has made sustainable transportation more accessible than ever. That’s why our EV charger services in PA are designed to bring the convenience of charging directly to your home. If you’re an EV owner, installing a charging station where you park is one of the best investments you can make.

At Decenzo Electric, our EV charger installation services focus on creating streamlined, safe, and user-friendly solutions for your vehicle-charging needs. Here are some key benefits of having a home EV charger installed by professionals like us:

Convenience: No more relying on public charging stations or waiting in long lines. With a home charging station, simply plug in your vehicle and charge it overnight while you sleep.

Cost-Effective: Avoid costly charging fees at public stations. By charging at home, you can take advantage of lower electricity rates during off-peak hours.

Energy Efficiency: Modern EV chargers can be integrated with your existing electrical system, ensuring optimized energy usage. We also install smart chargers that allow you to monitor and control charging remotely.

Future-Proofing: EV adoption continues to rise, and adding a charger to your home increases its value and appeal to potential buyers down the road.

Whether you’re installing a Level 1 or 2 charger, our skilled electricians take care of every detail, from assessing your home’s electrical capacity to ensuring the charger is safely and efficiently installed. For businesses, we also provide commercial EV charger solutions that help attract customers and promote sustainability.

Improve Indoor Comfort with Exhaust Fan Installation Services in PA

Indoor air quality greatly affects your health and comfort, especially in areas like bathrooms, kitchens, and laundry rooms that generate excess moisture. That’s why Decenzo Electric, LLC, specializes in exhaust fan installation services in PA to help you maintain a clean and moisture-free environment.

Here’s why installing or upgrading exhaust fans is so essential for your home or business:

Moisture Control: Bathrooms and kitchens are prone to steam and humidity, which can lead to mold, mildew, and structural damage over time. A well-functioning exhaust fan effectively removes excess moisture, protecting your indoor spaces.

Improved Air Quality: Exhaust fans remove odors, smoke, fumes, and other airborne particles, ensuring fresh and breathable air for your family or employees.

Energy Efficiency: Modern exhaust fans are designed with energy efficiency in mind, reducing utility costs while maintaining optimal performance.

Enhanced Comfort: By efficiently ventilating small, enclosed spaces, exhaust fans help regulate the temperature and ensure a more pleasant environment.

Our team at Decenzo Electric is experienced in installing high-quality, energy-efficient exhaust fan systems across Pennsylvania. Whether you need a discreet bathroom fan or a powerful kitchen range hood, we’ll work with you to select the right product and install it with precision.

Stay Cool and Comfortable with Ceiling Fan Services in Broomall, PA

Few home upgrades are as versatile as ceiling fans. They not only provide comfort through improved airflow but also contribute to energy savings year-round. At Decenzo Electric, LLC, we offer comprehensive ceiling fan services in Broomall, PA, including installation, replacement, and repairs.

Ceiling fans serve multiple purposes that make them a worthwhile addition or upgrade to your home. Here’s how they can enhance your comfort and efficiency:

Cooling in summer: A properly installed ceiling fan circulates air effectively, creating a wind-chill effect that makes the room feel cooler. This means you can reduce your reliance on air conditioning, saving money on energy bills.

Warmth in winter: During colder months, ceiling fans can rotate in reverse mode, pushing warm air down from the ceiling to evenly distribute heat throughout the room.

Energy Savings: Because ceiling fans complement your HVAC system, they help reduce overall energy usage, making them an eco-friendly option.

Style and Convenience: Available in various designs, ceiling fans add a touch of sophistication to any room. Many modern fans come with remote controls or smart features for added convenience.

Our skilled electricians handle everything from wiring new ceiling fans to ensuring existing ones function efficiently. If your ceiling fan wobbles, makes unusual noises, or isn’t circulating air effectively, we also offer prompt repair services.

Why Choose Decenzo Electric, LLC?

At Decenzo Electric, LLC, we’re more than just electricians—we’re your trusted partners in creating efficient and innovative electrical solutions. Here’s why Pennsylvania homeowners and business owners alike trust us with their electrical needs:

Experience and Expertise: With years of hands-on experience, we bring unmatched knowledge and skill to every project.

Safety First: From EV chargers to ceiling fans, every installation is completed with strict adherence to safety standards and local codes.

Custom Solutions: We tailor our services to meet your unique needs, ensuring personalized results.

Customer Satisfaction: We value your trust and strive to deliver top-tier service and lasting results.

If you’re in need of EV charger services in PA, reliable exhaust fan installation services in PA, or professional ceiling fan services in Broomall, PA, look no further than Decenzo Electric, LLC.

Don’t hesitate to contact us with questions or to schedule your next electrical project. Together, we’ll create smarter, safer, and more comfortable spaces designed to meet the demands of modern living. Call Decenzo Electric today and experience the difference of working with a team dedicated to excellence!

Contact us –

#Ev charger services in pa#Exhaust fan installation services in pa#Ceiling fan services in Broomall pa#smoke detector installation in pa

0 notes

Text

HVAC Design and Installation in Cafes

A well-designed HVAC system is crucial for any cafe, as it significantly impacts customer comfort and overall business operations. By ensuring optimal temperature and air quality, you can create a pleasant dining experience that keeps your customers coming back. Let's delve into the key aspects of HVAC design and installation for cafes.

Understanding Your Cafe's Unique Needs

Before diving into the design phase, it's essential to assess your cafe's specific requirements:

Size and Layout: The size and layout of your cafe will determine the capacity of your HVAC system.

Cuisine Type: The type of cuisine you serve can influence the heat and humidity levels generated in your kitchen.

Customer Capacity: The number of customers you expect to accommodate will impact the cooling and heating load.

Local Climate: Consider the local climate to determine the appropriate HVAC system and its energy efficiency.

Key HVAC Components for Cafes

A typical HVAC system for a cafe includes:

Heating, Ventilation, and Air Conditioning (HVAC) Units: These units provide heating, cooling, and ventilation to maintain a comfortable indoor environment.

Ductwork: A network of ducts distributes conditioned air throughout the cafe.

Thermostats: These devices regulate the temperature settings.

Air Filters: Filters remove pollutants and allergens from the air, improving air quality.hvac

HVAC Design Considerations for Cafes

Zone Control: Divide your cafe into different zones (e.g., dining area, kitchen, bar) and install separate thermostats for each zone. This allows you to customize temperature settings based on specific needs.

Ventilation: Proper ventilation is essential to remove cooking odors, smoke, and excess heat from the kitchen area. Install powerful exhaust hoods and ventilation fans to maintain air quality.

Energy Efficiency: Choose energy-efficient HVAC equipment and practices to reduce operating costs. Consider options like variable refrigerant flow (VRF) systems and high-efficiency air filters.

Noise Control: Restaurant kitchens can be noisy. Use sound-dampening materials in the ductwork and equipment enclosures to minimize noise levels.

Maintenance: Regular maintenance is crucial to ensure optimal performance and energy efficiency. Schedule routine inspections and cleaning of filters, coils, and other components.

HVAC Installation Tips

Professional Installation: Hire a qualified HVAC contractor to ensure proper installation and system efficiency.

Code Compliance: Ensure that the installation complies with local building codes and regulations.

Proper Sizing: The HVAC system should be appropriately sized to handle your cafe's specific needs.

Airflow Balance: Ensure proper airflow distribution throughout the cafe to maintain consistent temperature and humidity levels.

By carefully considering these factors and working with experienced HVAC professionals, you can create a comfortable and efficient dining environment that enhances your customers' experience and contributes to your business's success.

0 notes