#local exhaust ventilation system

Explore tagged Tumblr posts

Text

Maximize Efficiency with a Local Exhaust Ventilation System

Introduction

In today’s industrial and commercial environments, maximizing efficiency is not merely a goal but a necessity. Whether in manufacturing, laboratories, or food processing, ensuring a safe, clean, and productive atmosphere is crucial to both employee well-being and operational performance. One of the most effective solutions to improve air quality and workplace safety is the installation of a local exhaust ventilation (LEV) system.

An LEV system is designed to capture hazardous airborne contaminants directly at their source, minimizing exposure and improving air quality. However, simply installing the system is not enough. To truly maximize its efficiency, a well-maintained and regularly serviced LEV system is paramount.

Understanding the Local Exhaust Ventilation System

A local exhaust ventilation system is a specialized air filtration system that extracts contaminated air from specific sources, such as workstations, machinery, or chemical processes. Unlike general ventilation systems that circulate air throughout an entire facility, an LEV system targets areas where hazardous pollutants are generated. This targeted approach ensures that the air is filtered before contaminants can spread throughout the workplace, thus preventing the inhalation of harmful substances by workers.

These systems are typically composed of several key components: a capture hood, ductwork, a fan, and a filtration or exhaust unit. The capture hood is positioned near the source of contamination, where it captures and directs the contaminated air into the ductwork. The fan draws the air through the ductwork and pushes it toward the filtration unit, which removes harmful particles, fumes, and gases before discharging the cleaned air outside or recirculating it within the facility.

The effectiveness of an LEV system depends on various factors, including the correct installation, proper maintenance, and regular servicing. Each of these aspects plays a crucial role in ensuring that the system operates at peak efficiency.

The Importance of Proper Installation

The first step in maximizing the efficiency of a local exhaust ventilation system is ensuring its proper installation. The placement of the system components is critical to its performance. When installing an LEV system, it’s essential to accurately assess the areas where contaminants are most likely to be generated. This allows the system to be strategically placed to capture the highest concentration of harmful substances.

The LEV system installation process should always be handled by professionals who are experienced in designing and setting up these systems. Experts will consider factors such as airflow velocity, duct size, and the type of contaminants present to ensure that the system will effectively capture and remove pollutants. Moreover, they will ensure that the system complies with relevant health and safety regulations, as well as industry standards, to safeguard both employees and the environment.

Installation is not a one-size-fits-all process; each workplace has unique needs that require tailored solutions. A well-designed LEV system will significantly enhance operational efficiency, reduce health risks, and create a more comfortable working environment.

Regular Servicing for Peak Performance

While a well-installed LEV system will work efficiently, it is only through regular servicing that it can maintain its optimal performance. Over time, components such as filters, fans, and hoods can degrade, causing a reduction in airflow and system efficiency. This is why LEV servicing is essential to ensure that the system operates effectively throughout its lifespan.

Servicing involves inspecting the system for any signs of wear, such as cracks in the ductwork or damage to the capture hoods. Filters, which are the heart of the air filtration process, need to be checked and replaced periodically to ensure that they continue to capture harmful particles effectively. If the filtration unit is clogged or damaged, it can lead to a buildup of contaminants within the system, reducing its ability to protect workers.

In addition to checking the physical components, the airflow rate should also be measured to confirm that the system is drawing enough air from the work areas. A significant drop in airflow can indicate a blockage or other issues that need immediate attention. Regular servicing not only helps to prolong the life of the system but also ensures compliance with workplace safety regulations.

Neglecting LEV servicing can lead to inefficiency, greater health risks, and potentially costly repairs. Therefore, scheduling periodic maintenance checks is a vital step in maximizing the system’s efficiency and protecting workers’ health.

Testing and Ensuring Compliance

Even the most well-maintained LEV systems can become less effective over time if they are not properly tested. LEV testing is a critical component in ensuring that the system is still working as intended. Regular testing evaluates the airflow, pressure, and filter performance, and ensures that contaminants are being properly captured and filtered out of the environment. This process can identify any weaknesses in the system that may not be apparent during regular servicing.

Testing is also crucial for meeting regulatory compliance. Many industries are subject to strict guidelines that dictate the necessary levels of air quality and the operation of ventilation systems. LEV testing ensures that the system adheres to these standards, which is essential for maintaining a safe working environment and avoiding potential legal or financial penalties.

When the system is tested, technicians use specialized equipment to measure airflow velocity and capture efficiency. The results from these tests help to pinpoint areas where improvements are needed, whether it’s increasing the airflow, optimizing the placement of the capture hood, or upgrading the filtration system. For facilities that handle hazardous chemicals or dust, this testing process is not just beneficial — it’s often legally required.

Optimizing System Efficiency with SEPCOM

One of the most significant advances in local exhaust ventilation systems is the development of SEPCOM technology. SEPCOM is a system that integrates the principles of both ventilation and filtration to improve the overall efficiency of air handling systems. By using advanced filtration technology, SEPCOM units can separate and capture fine particles that might otherwise pass through conventional filtration systems.

The SEPCOM system is particularly effective in industries where ultra-fine particles or hazardous chemicals are present, such as in pharmaceutical manufacturing or metalworking. By utilizing SEPCOM in conjunction with a standard LEV system, companies can significantly reduce the concentration of airborne contaminants, further enhancing the air quality in their facilities.

Incorporating SEPCOM into your existing LEV system can be a game-changer in terms of performance and efficiency. The integration of high-performance filtration ensures that the system captures even the smallest particles, reducing risks to employee health and improving the overall safety and compliance of the facility.

Maximizing Operational Efficiency

Maximizing efficiency with an LEV system involves more than just installation and maintenance; it also means understanding the unique needs of your facility and tailoring the system to meet those needs. By considering the types of contaminants present, the layout of the workspace, and the specific tasks being performed, a customized LEV system can be designed to maximize its effectiveness.

Regular LEV testing and LEV servicing are necessary to ensure that the system is running at its peak capacity. These processes help to identify any issues early, prevent downtime, and reduce the risk of non-compliance with safety standards. Furthermore, implementing cutting-edge technology like SEPCOM enhances the performance of the system, allowing it to capture finer particles and operate more efficiently.

Ultimately, the goal of a local exhaust ventilation system is to create a safe, clean, and productive workplace. By investing in proper installation, regular maintenance, and advanced filtration solutions, businesses can protect their workforce, comply with regulations, and improve their bottom line.

For those looking to improve their LEV systems, WBT Services offers expert LEV system installation, LEV servicing, and LEV testing. Additionally, their advanced SEPCOM technology provides a powerful solution for workplaces that require enhanced filtration. With a professional team dedicated to maximizing the efficiency of your ventilation systems, WBT Services ensures that your air quality management is in good hands.

Conclusion

Maximizing the efficiency of a local exhaust ventilation system is crucial for creating a safe and healthy working environment. Proper installation, regular servicing, and ongoing testing are all essential components in ensuring the system performs optimally. Advanced filtration technologies like SEPCOM can take system efficiency to the next level. When all these elements come together, the result is an air quality management system that not only meets but exceeds industry standards, protecting both employees and the business.

0 notes

Text

LEV Systems for Laboratory Safety - VentXlabs

At Ventxlabs, we provide comprehensive LEV solutions that are integral to maintaining safe laboratory environments. Our services encompass the full spectrum from initial design and installation to regular maintenance and compliance testing. By focusing on at-source contaminant removal, our LEV systems play a crucial role in protecting personnel from hazardous fumes and vapours, aligning with the highest safety specifications and legal requirements.

#laboratory fit out#lab fit out#LEV systems#lev testing#local exhaust ventilation#fume extraction systems#welding extract systems

0 notes

Text

Writing Notes: Carbon Monoxide Poisoning

Carbon monoxide (CO) poisoning - occurs when carbon monoxide gas is inhaled.

CO - a colorless, odorless, highly poisonous gas.

Produced by incomplete combustion.

Interferes with the ability of the blood to carry oxygen.

Found in: automobile exhaust fumes, faulty stoves and heating systems, fires, and cigarette smoke.

Other sources: woodburning stoves, kerosene heaters, improperly ventilated water heaters and gas stoves, and blocked or poorly maintained chimney flues.

The result is headache, nausea, convulsions, and finally death by asphyxiation.

Symptoms

The symptoms of CO poisoning in order of increasing severity include:

headache

shortness of breath

dizziness

fatigue

mental confusion and difficulty thinking

loss of fine hand-eye coordination

nausea and vomiting

rapid heart rate

hallucinations

inability to execute voluntary movements accurately

collapse

lowered body temperature (hypothermia)

coma

convulsions

seriously low blood pressure

cardiac and respiratory failure

death

In some cases, the skin, mucous membranes, and nails of a person with CO poisoning are cherry red or bright pink. Because the color change doesn’t always occur, it is an unreliable symptom to rely on for diagnosis.

Although most CO poisoning is acute, or sudden, it is possible to suffer from chronic CO poisoning. This condition exists when a person is exposed to low levels of the gas over a period of days to months.

Symptoms are often vague and include (in order of frequency) fatigue, headache, dizziness, sleep disturbances, cardiac symptoms, apathy, nausea, and memory disturbances.

Little is known about chronic CO poisoning, and it is often misdiagnosed.

Treatment

Immediate treatment: Remove the victim from the source of carbon monoxide gas and get him or her into fresh air.

If the victim is not breathing and has no pulse, cardiopulmonary resuscitation (CPR) should be started.

Depending on the severity of the poisoning, 100% oxygen may be given with a tight fitting mask as soon as it is available.

Taken with other symptoms of CO poisoning, COHb levels of over 25% in healthy individuals, over 15% in patients with a history of heart or lung disease, and over 10% in pregnant women usually indicate the need for hospitalization.

In the hospital, fluids and electrolytes are given to correct any imbalances that have arisen from the breakdown of cellular metabolism.

In severe cases of CO poisoning, patients are given hyperbaric oxygen therapy. This treatment involves placing the patient in a chamber breathing 100% oxygen at a pressure of more than one atmosphere (the normal pressure the atmosphere exerts at sea level). The increased pressure forces more oxygen into the blood.

Prevention

Carbon monoxide poisoning is preventable.

Particular care should be paid to situations where fuel is burned in a confined area. Portable and permanently installed carbon monoxide detectors that sound a warning similar to smoke detectors are available for less than $50.

Specific actions that will prevent CO poisoning include:

Stopping smoking. Smokers have less tolerance to environmental CO.

Having heating systems and appliances installed by a qualified contractor to assure that they are properly vented and meet local building codes

Inspecting and properly maintaining heating systems, chimneys, and appliances

Not using a gas oven or stove to heat the home

Not burning charcoal indoors

Making sure there is good ventilation if using a kerosene heater indoors

Not leaving cars or trucks running inside the garage

Keeping car windows rolled up when stuck in heavy traffic, especially if inside a tunnel.

Source ⚜ More: Writing Notes & References ⚜ Poison ⚜ Fictional Poisons

#writing notes#poison#fiction#writeblr#dark academia#writing reference#spilled ink#writing inspiration#creative writing#writers on tumblr#literature#poets on tumblr#writing prompt#poetry#light academia#writing ideas#michael sowa#writing resources

113 notes

·

View notes

Text

jouissance (5)

Phillip Graves x Reader | political marriage, reader gets her husband back, Graves wins a bet | word count: 1,657

Coming to is an annoying series of flashes, snippets of awareness even when Phil’s sure he couldn’t have been out for more than a few seconds; proven by the fact that he’s still falling, sliding over a slope that used to be solid ground. Rain pelts down on his head, adding to the disconcert of being suddenly hauled back to a relatively stable section of the floor by the vest.

“Commander, you good?”

Phillip nods as well as he can at the moment, surveying the damage from his new perch. There’s a hole where the back of the building used to be, three stories collapsed in an angle lucky enough to form a makeshift exit all the way to the street. The same kinda luck that smothered out the fire via the downpour and the secondary explosion.

He sees heads poke out, looking up at him from this brand new, primitive ventilation system. And the comms are as down as the antenna that used to sit on the roof, so Phil starts signing along as he shouts for those close enough to hear.

The evacuation goes far more smoothly than it could, bless their mandatory beginner’s ASL course. And thank fuck they were on the way out of this shitshow. As long as they can make it to the meeting point, even if the satellite phone’s probably sitting pretty under a mountain of rubble, this’ll be a fun story Phillip can keep secret from his wife, lest she worry about him.

The idea puts a pep in his step, one he shouldn’t have with the couple casualties and this bullshit rat-scurrying they’re forced to do across the city. But it’s such a selfish bit of pleasure to imagine his beautiful, unshakable wife caring about whether he comes home or not. Not because of the consequences of widowhood, just ‘cause she’d rather still have him in her bed.

That bit of personal joy sours after the first four hours of moving in starts and stops, trying to clear their way through these local defense forces that don’t know and don’t care that the Shadows aren’t here for them. Phillip glances at his watch for the millionth time, they’re a couple hours late for their first checkpoint and that’s assuming these assholes didn’t force that team to fall back too.

Fuck it, they’re exhausted. He chooses to take advantage of the relative safety of the semi basement they squirreled themselves into, for his team to catch a few hours of sleep. While he works with half of the first guard to liberate a couple vehicles.

As Phil sees it, the closer it gets to dawn, the messier this fight gets, which increases the Shadow Company’s chances to slip away in the confusion. So he waits for first light to haul ass in two stolen vans, blowing past the abandoned first checkpoint and hoping to hell that the gas holds out to the next one a hundred clicks away.

In the end, it takes almost a full day to get his ass to the relative civilization of the Shadow main camp, where Phillip and his team are welcomed as if they're coming back from the dead. Shouts and clapping shoulders as far as the eye can see, not to mention the medical set up with enough supplies to stitch them up. And God, he wishes he could sleep on the ride back, but that’s not even a possibility when he phones HQ and the first thing out of Vance’s mouth is that his wife is currently at the premises, terrorizing the home team. Well, terrorizing might be a strong word when, from hearing Vance tell it, she’s been locked up in Phil’s quarters, refusing whatever comforts they can offer beyond the privacy of his room.

It makes him antsy, knowing she’s waiting. He’d been planning a shower, at least, before showing up at the house with a win under his belt. Not her brilliant eyes on him the second he steps off the transport to more ruckus, the familiar chatter of a job well done despite whatever setbacks try to shit on their party. Phillip isn’t braced for the uncertainty of her, pretty as a picture in one of his shirts, watching as he hollers orders still, to check on the injured and account for the casualties. It’s a shock to get to the end of the long walkway and see the dark circles under her eyes. To hear her voice, quiet and breathy —for him and only him to hear—, call his name like a prayer.

“You win,” she whispers, reaching out slowly to try and brush the blood staining whatever skin of his neck is visible under his gear, “I missed you.”

His girl gives him the same smile she did, over a year ago, as if she’s making a joke at her own expense. There’s no victory in this, not really, Phil might have a fluid relationship with the truth in general, but he’s not in the business of lying to himself. It's been quite a long time since his ego was the only thing on the line. All he feels now is the rabid pleasure of being back in these hands that own him so completely.

“Oh honey,” Phillip’s fingers close around her wrist, pulling her in by the waist until he can feel her heartbeat next to his and all it would take to taste the one, solitary tear that rolls down her cheek would be to lean in. And he manages to voice the aching truth at the end of his clusterfuck of a day, “All I thought about in that shithole was coming home to you.”

Her laughter shakes him, hiccuped and sudden, startling him into remembering there’s quite a few Shadows moving around them, trying to pretend they’re not paying attention to this reunion.

“Ryan, you’re team leader while I get reacquainted with the missus, alright? Don’t come looking for me unless the building is on fire.”

…

The walk back to his quarters is a blur. Phil’s half convinced that he died out there and his brain’s being sweet on him for his troubles before it conks out for good. His skin feels prickly all over, not just where there’s dried blood crinkling off in flakes, as he sheds pieces of his gear one handed, since he refuses to let go of his wife’s hip.

His wife. It burns beneath his ribs in the residual adrenaline high, with the same bite as the twenty seven stitches he sports from shoulder to collarbone, tying together a cut deep enough to glance the muscle. A little agony every time he moves, now that the morphine’s starting to wear off.

But his wife, she’s here, for him. Kneeling between his feet, unlacing his boots. In his bed with the world on the other side of his locked door. Their door. Phillip could be bleeding out all over her smart fingers and not give a good goddamn about it. He crowds her against the pillows like he’s coming home after a normal day, as if he isn’t raining fucked up dry blood confetti all over both of them. And god, she fucking giggles into his kiss.

She minds his shoulder and cups his half chub over his jeans, until he can’t help the desperate little rocking of his hips into her palm. Then this monster he married pulls away, leaves him to stumble his way out of pants and underwear, while she pulls a burlesque slow slide off of clothes.

Phil straight up growls a complaint, full on rumbling in his throat as she straddles him, laughing. Wet enough that he slides home in a single thrust. Vaguely, his mind’s gearing up to worry he might come too soon, but the injury screams red behind his eyelids when he tries to readjust for leverage. It grounds him, makes him flop his back onto the mattress, half cackling. Only to see his girl smiling her pleased-cat smile, the happiest little camper he ever did see, riding his cock for all he’s worth.

“There’s my smile,” Phillip doesn’t register he’s saying it out loud until she squeezes around him and his name tumbles out of her a choked, airy sound. “That’s my girl.”

The claim turns her sharp, stretching her grin so it shows teeth and she picks up the pace of her hips. He’s not gonna last, Phil figures, even if she chose to dig her nails into his wound, so he resorts to rubbing tiny circles of his thumb, firm over her clit, to the deafening tempo of his heart.

Blessedly, she comes first, whispering his name against his mouth in two bites and tightening her pretty cunt around him on purpose.

Phill-ip. It sounds like ‘husband’ , like ‘darling’ and ‘I missed you’ and ‘you win’ as his orgasm hits, sudden like a shot.

He doesn’t know how long he lies there, boneless under her but for the hand he smooths up and down her thigh. It’s the first time in their marriage that he doesn’t hit the ground running on the clean up and, to be honest, he could get fucking used to doing this every time from now on. His wife —and he’s obsessed with the word now, holds it in a tight grip, like everything that’s his —doesn’t move much either, just settles into his side.

“We’re fucked, aren’t we?”

She laughs, the flakes turned to red smudges over her collarbones from sweat, and Phil understands what she means instinctively; hears the three words under the breathlessness and the flippancy.

“I believe we are, honey.” It’s a mumble against the crown of her head, followed by a kiss to her temple.

Soon he’ll drag her with him to the shower and then back home. And one day, he swears to himself, he’ll convince her to tell her she loves him the proper way.

19 notes

·

View notes

Text

Hidden Costs of Patio Enclosures That Homeowners Should Know

A patio enclosure sounds like a dream—extra living space, protection from the elements, and a cozy spot to enjoy your backyard without worrying about bugs or weather. But before you start imagining lazy afternoons in your enclosed patio, there’s something you need to know: hidden costs can sneak up fast.

Sure, you’ve budgeted for the materials and installation, but what about permits, electrical work, and long-term maintenance? These are the costs homeowners don’t always think about until it’s too late. Let’s break down the hidden expenses that come with patio enclosures—so you can plan ahead and avoid surprises.

1. Permit Fees and Inspection Costs

You know what’s worse than an unexpected fee? A fine for not getting the right permits. Many cities—including South Bend—require permits for enclosed patios, especially if they involve structural changes.

What to expect:

Building permits can range from $200 to $1,500, depending on your location and the scope of the project.

If electrical or plumbing work is involved, expect additional inspection fees.

Some HOAs (Homeowners Associations) have their own approval process, which may include extra costs.

How to avoid surprises: Before you start, check with your local municipality or ask your contractor if permit fees are included in their quote.

2. Foundation and Structural Modifications

You might assume your current patio is ready to go, but not all patios are built to support an enclosure. If the foundation is uneven, cracked, or not up to code, you could be looking at some serious prep work.

Possible added costs:

Leveling an uneven slab – $500 to $2,000

Reinforcing or replacing a weak foundation – $2,000 to $5,000

Extending an existing patio to fit the enclosure – $3,000+

How to avoid surprises: Have a contractor inspect your foundation first to see if it needs work before adding an enclosure.

3. Electrical Work and Lighting

If you’re planning to use your patio at night or in colder months, you’ll likely need lighting, ceiling fans, or even heating elements. That means hiring an electrician, which adds to your budget.

Potential electrical costs:

Basic wiring for lights and outlets – $500 to $1,500

Ceiling fan installation – $200 to $800

Electric heater installation – $300 to $1,500 (not including the heater itself)

How to avoid surprises: If you need electrical work, bundle it with your enclosure project—some contractors offer discounts for multiple services.

4. Hidden Costs of Windows and Screens

Not all glass and screens are created equal. Many homeowners go with the cheapest option upfront, only to realize later that they need better insulation or stronger materials.

Extra costs you might not expect:

Upgrading to insulated glass – Adds $1,000 to $5,000, but helps with energy efficiency.

Impact-resistant or pet-proof screens – Adds $300 to $1,500, but prevents tears and damage.

Tinted or UV-protected windows – Adds $500 to $2,000, but keeps the enclosure cooler in summer.

How to avoid surprises: If you plan to use your enclosure year-round, investing in quality materials upfront saves money on energy bills and repairs.

5. Heating and Cooling Costs

Ever sat inside a car on a hot summer day? A patio enclosure with poor ventilation or no insulation can feel the same way. Likewise, in winter, an unheated enclosure can be too cold to use.

Additional climate control expenses:

Portable heater or AC unit – $200 to $800

Ductless mini-split system – $2,000 to $5,000 (for heating & cooling)

Ceiling fans or exhaust vents – $200 to $1,500

How to avoid surprises: If your enclosure will be used year-round, factor in heating and cooling solutions before installation—it’s much cheaper than trying to fix it later.

6. Increased Home Insurance Premiums

Here’s something most homeowners don’t think about: your home insurance might go up after installing a patio enclosure. Some insurance providers classify enclosed patios as an addition, which can slightly increase premiums.

How much?

Small increases of $100 to $300 per year are common.

If the enclosure includes electrical work or expensive upgrades, expect higher coverage costs.

How to avoid surprises: Call your insurance provider before starting your project to see how an enclosure affects your policy.

7. Maintenance and Repairs Over Time

Like anything else in your home, a patio enclosure requires maintenance. Even high-quality materials will wear down over time, especially if exposed to harsh weather.

Long-term costs homeowners forget:

Screen repairs – $50 to $300 (for minor rips or damage)

Glass panel replacements – $200 to $800 per panel

Roof panel maintenance – $500 to $2,000 (for polycarbonate or glass roofing)

Sealing leaks or cracks – $100 to $500 per repair

How to avoid surprises: Ask your contractor about warranty coverage and long-term upkeep recommendations.

8. Cleaning and Upkeep Costs

Nobody thinks about cleaning until their beautiful glass enclosure gets covered in pollen, dirt, or streaks.

Cleaning costs:

Professional glass cleaning – $150 to $400 per visit

DIY cleaning supplies – $50 to $150 per year

Pressure washing screens and flooring – $100 to $300

How to avoid surprises: If your enclosure has large glass panels, consider self-cleaning glass coatings to cut down on maintenance.

How to Avoid Hidden Costs When Installing a Patio Enclosure

Now that you know what to watch for, here’s how to keep your project within budget:

Get an all-inclusive quote – Make sure your contractor lists every possible fee upfront.

Ask about warranties – A good warranty can save you thousands on future repairs.

Prioritize essential upgrades – If you’re on a budget, invest in structural quality first and add extras later.

Time your project wisely – Contractors often offer discounts in fall and winter when demand is lower.

Check financing options – Some companies offer payment plans to spread costs over time.

Final Thoughts

A patio enclosure is a fantastic investment—but only if you plan for the real cost, not just the sticker price. From permits and structural work to heating, cooling, and maintenance, understanding these hidden expenses upfrontwill save you stress, time, and money in the long run.

If you’re in South Bend or nearby, Screenmobile offers transparent pricing and expert guidance—so you get a high-quality patio enclosure without unexpected costs.

Want a free quote? Contact Screenmobile of Michiana Shores, MI, today and start planning your patio enclosure the right way!

2 notes

·

View notes

Text

How to Solve Overheating Issues in Electrical Panels

Electrical panels are the nerve centers of industrial, commercial, and residential power systems. Their reliability is crucial, yet one of the most common and dangerous issues that can arise is overheating. Left unaddressed, overheating in electrical panels can lead to equipment failure, costly downtime, fires, or even fatal accidents. Understanding the root causes and adopting preventive as well as corrective measures is essential to ensure electrical safety and operational efficiency.

Causes of Overheating in Electrical Panels

To solve the problem of overheating, we must first identify its sources. Some of the most common causes include:

1. Loose or Corroded Connections

Electrical current encounters resistance at loose or oxidized joints. This resistance generates heat, especially under load, leading to localized hotspots which may not be visible until failure occurs.

2. Overloaded Circuits

Each circuit is rated for a specific current. Drawing more current than the rated capacity results in excess heat generation within breakers, busbars, and wires.

3. Inadequate Ventilation

Poor airflow in and around the panel restricts natural or forced heat dissipation. In high ambient temperature environments, this can quickly push the panel beyond safe thermal limits.

4. Improper Component Sizing

Undersized breakers, conductors, or transformers struggle to handle load currents, leading to thermal stress and degradation over time.

5. Dust and Contamination

Dust accumulation acts as an insulating layer, trapping heat inside components. Combined with humidity or oil vapors, this can further degrade insulation and create tracking paths.

How to Identify Overheating Problems

1. Thermal Imaging

Using infrared thermography is one of the most effective ways to detect hotspots. It provides a non-contact, real-time temperature map of the panel and highlights abnormally heated components.

2. Manual Temperature Monitoring

For panels without thermal sensors, regularly measuring surface temperatures using contact thermometers can provide early warnings of rising heat levels.

3. Visual Inspection

Signs like discoloration, melted insulation, or the smell of burning plastic indicate overheating. Ensure regular visual checks are part of your maintenance routine.

Solutions to Overheating in Electrical Panels

1. Tighten and Maintain Electrical Connections

Schedule regular maintenance to tighten terminals and busbar connections. Apply proper torque settings using calibrated tools to avoid over- or under-tightening.

2. Balance and Distribute Loads

Ensure that the load across phases is balanced. Uneven distribution causes one phase to overwork, which leads to overheating and inefficiency.

3. Upgrade Panel Capacity

If the electrical demand exceeds the panel’s rated capacity, consider upgrading to a higher-rated panel or adding sub-panels to spread the load.

4. Enhance Cooling and Ventilation

· Install forced ventilation systems like exhaust fans or panel coolers.

· Use heat exchangers or air conditioners in environments with high ambient temperatures.

· Ensure adequate spacing between panels and walls for natural convection.

5. Use Appropriately Rated Components

All breakers, fuses, contactors, and wiring must match the system’s voltage and current ratings. Derate components appropriately if operating in high-temperature environments.

6. Install Thermal Sensors or Smart Monitoring

Modern panels can be equipped with thermal sensors that provide real-time data to a building management system (BMS) or SCADA. This allows predictive maintenance before issues escalate.

Preventive Measures and Best Practices

· Design with Expansion in Mind: Avoid loading a panel to its full capacity. Always leave a 20–30% margin for future growth and safety.

· Implement a Routine Maintenance Schedule: Quarterly or bi-annual inspections reduce the risk of unexpected failures.

· Train Maintenance Personnel: Staff should be equipped to detect early signs of thermal distress and follow lockout/tagout (LOTO) procedures.

· Keep Panels Clean and Sealed: Use gasketed enclosures in dusty environments and clean panels regularly to prevent dust build-up.

Conclusion

Overheating in electrical panels is a preventable issue that, if neglected, can have severe consequences. By adopting systematic inspection routines, upgrading infrastructure as needed, and leveraging modern monitoring technologies, businesses and facility managers can safeguard both equipment and personnel. The key is proactive action: identify, analyze, correct, and prevent — the four pillars of managing thermal risk in electrical systems.

6 notes

·

View notes

Text

Complete Air Conditioning Services for Homes and Businesses in Central Coast

Living in Central Coast, NSW, means experiencing warm summers and chilly winters, making reliable air conditioning a must for every home and business. At Tech Air Solutions, we provide top-notch air conditioning services tailored to meet the diverse needs of residents across Central Coast.

With over 10 years of experience, we are committed to ensuring your comfort year-round with our comprehensive range of air conditioning solutions.

Why Choose Tech Air Solutions?

Tech Air Solutions is a locally owned and operated company serving the Central Coast, Newcastle, and Sydney regions. We pride ourselves on quality workmanship, clear communication, and exceptional customer service.

Whether you're installing a new system, upgrading an existing unit, or scheduling maintenance, we are here to help. Our team is fully licensed, insured, and dedicated to delivering solutions that match your specific requirements.

Our Comprehensive Air Conditioning Services

Here’s a breakdown of the air conditioning services we provide across Central Coast, NSW:

1. Split System Air Conditioning Installation

Split systems are perfect for individual rooms or small spaces. They’re energy-efficient, easy to install, and provide effective cooling and heating. We assess your space to recommend and install the ideal unit, ensuring maximum comfort and efficiency.

2. Ducted Air Conditioning Installation

For larger homes and businesses, ducted systems are an excellent choice. These systems offer centralized control, providing consistent temperatures throughout the property. Our experts handle every step, from planning and installation to maintenance, ensuring your system performs optimally.

3. Air Conditioning Repairs and Maintenance

A well-maintained air conditioning system runs efficiently and lasts longer. We offer regular servicing and prompt repairs to prevent breakdowns and minimize energy consumption. Our maintenance services include:

Cleaning and inspecting filters

Checking refrigerant levels

Ensuring optimal airflow

Testing electrical components

4. Custom Air Conditioning Solutions

No two properties are the same, and we understand that your air conditioning needs may be unique. We provide custom solutions, such as custom-made grills, to enhance functionality and aesthetics.

5. Upgrades and Modernization

We can upgrade your system to include advanced features like Wi-Fi connectivity and smart wall controllers. These upgrades make managing your indoor climate more convenient and energy-efficient.

6. Commercial Air Conditioning Services

From small offices to large commercial spaces, we provide tailored air conditioning solutions that ensure your business environment stays comfortable for employees and customers alike.

7. Exhaust and Ventilation Systems

Proper ventilation is essential for healthy indoor air quality. Our exhaust and ventilation services help remove stale air, reduce humidity, and eliminate odors, creating a fresher indoor atmosphere.

Serving All of Central Coast, NSW

From Gosford to Wyong and everywhere in between, Tech Air Solutions is proud to serve the entire Central Coast community. Whether you’re in need of a new air conditioning installation or a quick repair, we’re just a call away.

Why Regular Maintenance Matters

Many homeowners overlook the importance of regular air conditioning maintenance. Routine servicing not only ensures your system works efficiently but also extends its lifespan and prevents unexpected breakdowns. Our technicians can create a maintenance schedule tailored to your system's needs, giving you peace of mind and optimal performance year-round.

Trust Tech Air Solutions for Your Air Conditioning Needs

At Tech Air Solutions, we go above and beyond to ensure your air conditioning system performs at its best. Our experienced team, competitive pricing, and dedication to customer satisfaction make us the go-to choice for air conditioning services across Central Coast, NSW.

Contact us today to discuss your air conditioning needs or schedule a service. Let us help you stay comfortable, no matter the season!

#Tech Air Solutions#Split System Air Conditioners#Ducted Air Conditioners#Air Conditioning Maintenance#Air Conditioner Repair#Ductless Air Conditioner#Mini Split Air Conditioner#Split Air Conditioner#Emergency Air Conditioner Repair#Air Conditioner Cleaning Service#Split Ac Installation#Split Air Conditioner Installation

2 notes

·

View notes

Text

DP2 - Wandering Earth

Week 19:

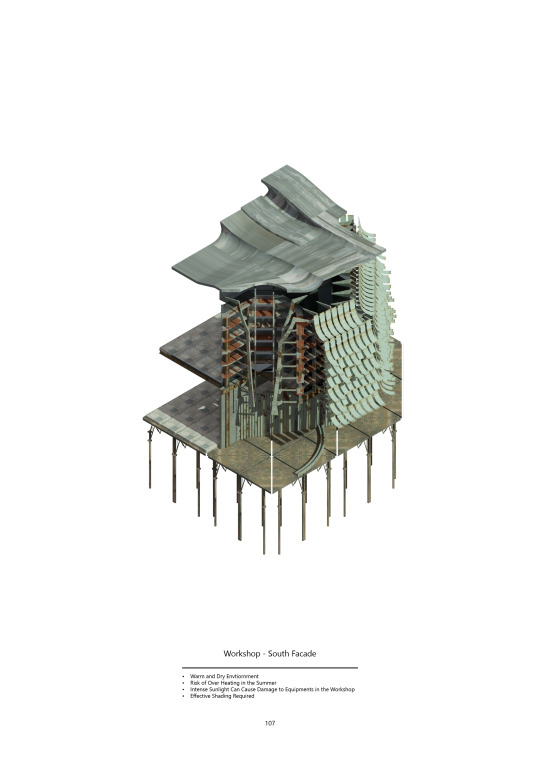

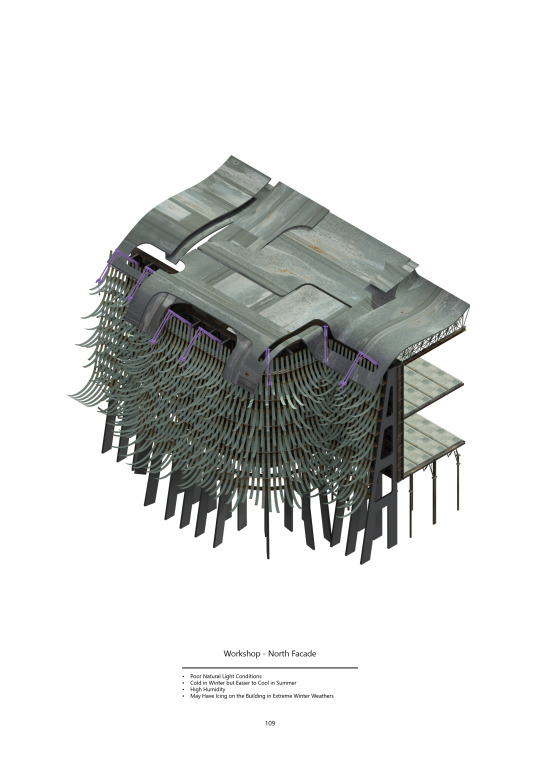

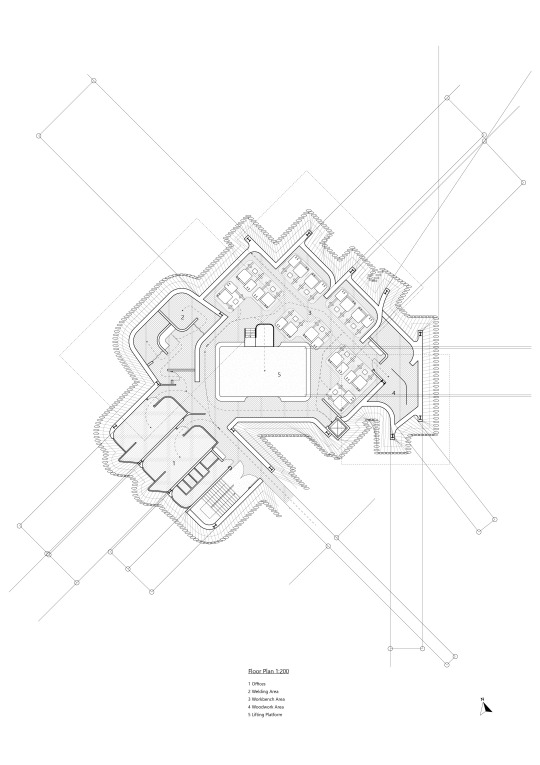

This week I kept focusing on the workshop by first improving on the plan and then choosing three zones from the plan and designed the roof, facade and structural systems specifically to the environmental conditions required by each zone:

The south facing facade receives the highest level of solar radiation and activities including cutting and drilling take place in this zone, which can lead to overheating in the space, especially at summer. Therefore a layered strategy is implemented on the facade with dense and wide rain-fuel/solar panels acting also as shading devices which can result in effective cooling off the space.

The East Facing Facade provides excellent natural light in the morning and has a good view down the hill towards the city, therefore there are voids on the facades to provide opportunities for a balcony area. The facade panels are more curled up to further provide natural lighting and views as there are workbenches behind the east facade.

The North Facade in 2050 will encounter more severed environmental conditions as it receives poor natural light and is normally cold and damp. Therefore the facade panels are less dense to allow more light entering the space and more gaps on the roof to provide lighting. Deicing systems inspired by the aviation industry extends out from the roof to clean the icing that may form on the facade.

The Roof has different levels and grooves to direct the rainwater to drip down onto the facade elements and utilises its potential energy to regenerate energy; but also recycled into the bathroom to be reused. The roof has a curved shape that rises at certain points for lighting purposes.

I should keep working on these three design modules and use line drawings in combination with these renders to reveal the HVAC, structural and water systems of the space. Doing lighting and heating simulations on the interior space to prove the systems function properly

Key ideas mentioned:

Hollow tiles for heating and ventilation systems running through

shape the tiles so it guides the cool down streaming air around the furniture in the room

Pneumatically designed air exhaustion systems for manufacturing area (Reference to Zaha Science Museum)

Shelving systems on the facade to hang and dry the pieces manufactured in the workshop

Light pipes bringing light to the working area that is integrated with the furniture

furniture suspended from the ground with localized heating, water running through the furniture

Ramps connecting the buildings that extend out into the forest and foreshadowing the theme and emotions that the next building is going to bring to the visitors. Buildings get cut through similarly to canyons.

When presenting, show how spatial organization, facade systems and furniture systems are designed differently according to the hot and cold environment and lux levels.

8 notes

·

View notes

Text

Understanding Ventilation Power: Selecting the Ideal CFM for Your Kitchen Exhaust Hood Installation

When it comes to kitchen exhaust hood installation, one of the most crucial factors to consider is the ventilation power, measured in cubic feet per minute (CFM). Choosing the right CFM ensures your kitchen remains free from smoke, grease, and odors, providing a safe and comfortable environment. This guide will help you understand how to select the appropriate CFM for your kitchen exhaust hood, enhancing both functionality and compliance with safety standards.

Why CFM Matters in Kitchen Exhaust Hood Installation

CFM, or cubic feet per minute, measures the volume of air a hood can exhaust in one minute. The right CFM is essential for effective ventilation, determining how quickly and efficiently smoke, steam, and grease are removed from your kitchen. An inadequate CFM can lead to poor air quality and increased fire hazards, while an excessively high CFM can be unnecessarily noisy and energy-consuming.

Calculating the Right CFM for Your Kitchen

The size of your cooking area and the type of cooking you do significantly impact the CFM requirements. For standard cooking ranges, a basic rule of thumb is 100 CFM per linear foot of cooktop. For example, a 30-inch range would need a hood with at least 250 CFM. For more intensive cooking methods, such as grilling or frying, you may need a higher CFM to ensure adequate ventilation.

Factors Influencing CFM Requirements

Several factors influence the CFM requirements for your kitchen exhaust hood installation:

Cooking Style: Heavy cooking styles like frying or grilling produce more smoke and grease, requiring higher CFM.

Kitchen Size: Larger kitchens may need more powerful hoods to ensure complete ventilation.

Ductwork Length: Longer duct runs can reduce efficiency, necessitating higher CFM to maintain performance.

Hood System Installation

Proper hood system installation is key to maximizing the effectiveness of your kitchen exhaust hood. Professional installation ensures your hood is correctly positioned and ducted, optimizing airflow and ventilation. Experts can assess your specific kitchen layout and recommend the best system and CFM for your needs, ensuring safety and compliance with local regulations.

Benefits of Choosing the Right CFM

Selecting the appropriate CFM for your kitchen exhaust hood offers several benefits:

Improved Air Quality: Efficient ventilation removes contaminants, keeping the air fresh and clean.

Enhanced Safety: Proper ventilation reduces the risk of grease fires and improves overall kitchen safety.

Energy Efficiency: Choosing the right CFM ensures your hood operates efficiently, saving on energy costs.

Noise Reduction: An appropriately powered hood operates more quietly, creating a more pleasant cooking environment.

Professional Kitchen Exhaust Hood Installation

Opting for professional kitchen exhaust hood installation guarantees your hood system is tailored to your kitchen’s specific needs. At Red Eagle – Kitchen Hood Services LA, we specialize in providing expert installation services. Our experienced team will help you choose the right CFM and ensure your hood is installed for maximum efficiency and safety.

#Kitchen Hood Installation#Commercial Vent Hood#Restaurant Hood Installation#Kitchen Ventilation#Exhaust Hood System#Kitchen Ventilation Installation#Professional Hood Installation#Range Hood Installation#Type 2 Hood Installation#Kitchen Exhaust Fan#Commercial Kitchen Hood#Vent Hood Services#Kitchen Hood Ventilation#CFM Calculation#Kitchen Exhaust System#Kitchen Hood Maintenance#Ventilation Power#Air Quality Improvement#Fire Safety#Energy Efficiency

2 notes

·

View notes

Text

Why Melbourne Homeowners Are Choosing Sustainable Bathroom Renovations in 2025

Sustainability isn’t just a buzzword anymore—it’s a way of life for many Melburnians. From reusable coffee cups to solar panels, we’re all making more thoughtful choices. So, it’s no surprise that Melbourne bathroom renovations are following suit.

In 2025, we’re seeing a strong shift towards eco-conscious design and renovation practices. Homeowners are no longer just thinking about tiles and tapware—they’re considering water usage, materials, energy efficiency, and long-term impact.

If you're planning to renovate, here’s why going green is more than just good karma—it’s a smart investment in your home and the planet.

1. Water Efficiency Is a Top Priority

Melbourne might be known for its unpredictable weather, but water conservation remains a serious issue. Sustainable bathrooms in 2025 are built with this in mind.

Low-flow showerheads, dual-flush toilets, and water-saving tapware are now standard in quality bathroom renovations. These upgrades don’t just save water—they also reduce your utility bills. It’s a win-win.

2. Recycled and Sustainable Materials Are on the Rise

Many renovators are moving away from mass-produced, synthetic finishes in favour of recycled timber vanities, reclaimed tiles, and natural stone. These materials add character and reduce your renovation’s carbon footprint.

Melbourne suppliers are catching on too, offering more eco-conscious options that don’t sacrifice on style. Think terrazzo made from recycled glass or sustainable bamboo cabinetry that’s both sleek and sturdy.

3. Energy Efficiency Is Built In

Lighting and ventilation are key to any bathroom—but in 2025, energy use matters just as much as aesthetics. Today’s Melbourne bathroom renovations often include LED lighting, energy-efficient exhaust fans, and even underfloor heating systems that are timed to reduce power consumption.

Some homeowners are even integrating solar energy systems into their bathroom upgrades—particularly in new builds or major extensions.

4. Better Indoor Air Quality

Many older bathrooms used materials and adhesives that contained VOCs (volatile organic compounds), which can affect indoor air quality over time.

Now, eco-conscious renovators are choosing low-VOC paints, sealants, and grouts that are safer for both the environment and your family’s health.

Add proper ventilation and greenery (yes, plants love bathrooms!), and you’ve got a space that feels as fresh as it looks.

5. Longevity Over Fast Trends

One of the biggest shifts in 2025 is a move away from throwaway design. Instead of choosing the trendiest tiles or tapware, homeowners are prioritising timeless design and durable materials.

Why? Because sustainability is about more than materials—it’s about reducing waste. A bathroom that lasts 20 years is far more eco-friendly than one that needs a makeover every five.

6. Local Sourcing Matters

Supporting local businesses is a growing part of the sustainable renovation movement. Whether it’s a handcrafted vanity from a Victorian woodworker or tiles made right here in Melbourne, locally sourced products reduce emissions and support the local economy.

More renovators are also working with Melbourne-based bathroom designers who understand the region’s building codes, climate, and eco-conscious values.

Final Thought: Sustainability Is the Future of Renovation

More than ever, Melbourne bathroom renovations are about building smarter, not just prettier. The growing trend towards sustainability reflects a deeper awareness: that how we build our homes affects more than just our lifestyles—it affects the world around us.

By choosing sustainable materials, water-saving fixtures, and energy-efficient systems, you’re not just investing in your home—you’re investing in the future.

Ready to start your renovation? Choose a bathroom renovator who shares your values and knows how to blend sustainability with beautiful, functional design.

1 note

·

View note

Text

Kitchen Exhaust Cleaning Ontario: An Essential Service for Your Kitchen

Kitchen exhaust cleaning Ontario is essential to maintaining a safe and efficient kitchen environment. At Canadian Kitchen Flue Cleaners, we specialize in kitchen exhaust cleaning and hood cleaning, ensuring your kitchen remains clean, safe, and compliant with local regulations.

As business owners and operators in Ontario, one of the most important tasks you should prioritize is kitchen exhaust cleaning Ontario. Over time, your kitchen exhaust system collects grease, oil, and other debris that can significantly affect the health, safety, and efficiency of your kitchen. At Canadian Kitchen Flue Cleaners, we are dedicated to providing professional kitchen exhaust cleaning Ontario and kitchen hood cleaning Ontario services. Our team of experts is here to ensure that your kitchen remains safe, clean, and fully compliant with all necessary health and safety regulations.

Why is Kitchen Exhaust Cleaning Ontario So Important?

Kitchen exhaust cleaning Ontario isn’t just about keeping your kitchen tidy—it’s about protecting your staff, customers, and your business from fire hazards and other safety risks. The buildup of grease and grime in your exhaust system can lead to several issues, including:

Fire Hazards: Grease is flammable, and over time, it can build up in your kitchen exhaust system, putting your business at risk of a dangerous fire.

Poor Air Quality: A clogged exhaust system can lead to bad air circulation, making your kitchen uncomfortable for your staff to work in.

Inefficient Operation: When your exhaust system is clogged with debris, it must work harder to maintain airflow, leading to higher energy costs and reduced efficiency.

That’s where our kitchen exhaust cleaning Ontario services come in. We ensure that your exhaust system is free from any buildup, promoting better air quality and reducing fire risks, while also improving the overall efficiency of your kitchen.

The Importance of Kitchen Hood Cleaning Ontario

When it comes to kitchen hood cleaning Ontario, many kitchen owners often overlook this critical task. The kitchen hood is responsible for venting smoke, heat, grease, and odors out of your kitchen, so it’s essential that it remains clean. Dirty hoods are less effective at capturing heat and smoke, which can negatively impact your kitchen environment. Our professional kitchen hood cleaning Ontario services ensure that your hoods are thoroughly cleaned, allowing them to function at their best.

By regularly maintaining and cleaning your kitchen hoods, you also improve the safety of your kitchen. Accumulated grease on the hood can easily catch fire, which is why our cleaning process includes thorough attention to all parts of the exhaust system, including the hoods, ducts, and fans.

The Benefits of Kitchen Exhaust Cleaning Ontario Services

There are many advantages to choosing Canadian Kitchen Flue Cleaners for your kitchen exhaust cleaning Ontario needs. Here are just a few:

Fire Prevention: With regular kitchen exhaust cleaning Ontario, you can significantly reduce the risk of grease fires in your kitchen. Our cleaning service removes all grease buildup, ensuring your kitchen is as safe as possible.

Improved Air Quality: A clean exhaust system ensures better airflow and ventilation, which leads to a healthier environment for your kitchen staff. No more lingering odors or smoke that could affect the taste of your food or the comfort of your employees.

Compliance with Health and Safety Regulations: Ontario’s health regulations require that commercial kitchens keep their exhaust systems clean. By hiring Canadian Kitchen Flue Cleaners for kitchen exhaust cleaning Ontario, you ensure compliance with local regulations, avoiding potential fines or penalties.

Reduced Energy Costs: When your kitchen exhaust system is clean and working efficiently, it uses less energy to operate. A clean system puts less strain on your HVAC system, resulting in lower operating costs for your business.

Why Choose Canadian Kitchen Flue Cleaners for Kitchen Exhaust Cleaning Ontario?

At Canadian Kitchen Flue Cleaners, we are dedicated to offering reliable and high-quality kitchen hood cleaning Ontario services. Here’s why we’re the best choice for your business:

Experienced Team: Our team has years of experience in providing professional kitchen exhaust cleaning services. We have the knowledge and expertise to handle any job, big or small.

Thorough Cleaning Process: We take the time to carefully clean all parts of your exhaust system, including hoods, ducts, fans, and filters. Our goal is to ensure that your entire kitchen exhaust system is functioning optimally.

Tailored Solutions: We understand that each kitchen is different, which is why we customize our cleaning services to meet the specific needs of your kitchen.

Flexible Scheduling: We offer flexible scheduling to minimize disruption to your kitchen operations. Whether you need a one-time cleaning or ongoing maintenance, we are here to work around your schedule.

Affordable Pricing: Our services are competitively priced, ensuring that you get the best value for your money. We offer upfront quotes with no hidden fees.

How Often Should You Schedule Kitchen Exhaust Cleaning Ontario?

To keep your kitchen safe and running smoothly, it’s recommended to schedule kitchen exhaust cleaning Ontario at least every 3 to 6 months, depending on the size of your kitchen and how often it is used. If your kitchen sees heavy traffic or cooks greasy foods frequently, more frequent cleanings may be necessary.

At Canadian Kitchen Flue Cleaners, we can work with you to create a cleaning schedule that best suits your kitchen’s needs. We’ll ensure that your exhaust system stays in top shape, preventing any issues before they arise.

Frequently Asked Questions (FAQs)

Q1: How often should I have my kitchen exhaust cleaned? It’s recommended to clean your kitchen exhaust system every 3-6 months, depending on usage. High-volume kitchens may require more frequent cleaning.

Q2: What happens if I don’t clean my kitchen exhaust system regularly? Failure to clean your kitchen exhaust system regularly can lead to grease buildup, fire hazards, and poor air quality, all of which can affect your business operations and safety.

Q3: Can you clean my kitchen hood as well? Yes, we specialize in both kitchen exhaust cleaning Ontario and kitchen hood cleaning Ontario. Our team ensures that both your hoods and exhaust systems are thoroughly cleaned for optimal performance.

Q4: Is your cleaning service compliant with Ontario regulations? Yes, all of our cleaning services meet Ontario’s health and safety regulations for commercial kitchens. We ensure that your kitchen is fully compliant with local standards.

Q5: How long does the cleaning process take? The cleaning time depends on the size and complexity of your kitchen’s exhaust system. However, we always work efficiently to minimize downtime for your business.

Contact Canadian Kitchen Flue Cleaners Today!

📞 Let’s get your kitchen back to clean

If you're tired of second-guessing the safety and hygiene of your exhaust system, it's time to talk to us. At Canadian Kitchen Flue Cleaners, we’re ready when you are. Whether you need a one-time deep clean or a scheduled maintenance plan, we’re just a call away.

📍 Visit us: https://g.co/kgs/PC5p9Hi 📞 Call us now: +1 437-557-7111

When it comes to kitchen exhaust cleaning Ontario, no one does it like we do. Let’s make your kitchen safer, cleaner, and compliant—without breaking the bank.

Conclusion

Kitchen exhaust cleaning Ontario and kitchen hood cleaning Ontario are essential services for maintaining a safe and efficient kitchen. At Canadian Kitchen Flue Cleaners, we are committed to providing high-quality, reliable cleaning services that help keep your kitchen safe, clean, and compliant with local regulations. Contact us today at +1 437-557-7111 to schedule your next cleaning and ensure your kitchen operates at its best.

#kitchen exhaust cleaning Ontario#kitchen hood cleaning Ontario#kitchen cleaning Ontario#exhaust cleaning services#commercial kitchen cleaning Ontario#grease cleaning Ontario#kitchen ventilation cleaning Ontario#Canadian Kitchen Flue Cleaners#Ontario kitchen cleaning services#hood cleaning Ontario

0 notes

Text

Unlocking the Power of Bulk Handling Systems in Manufacturing

Introduction

In the realm of modern manufacturing, the efficiency of processes often hinges on the seamless movement and management of materials. Bulk handling systems have emerged as a critical component in optimizing the manufacturing workflow, ensuring that materials are transported, stored, and processed with minimal disruption. These systems are designed to manage large quantities of materials, such as powders, grains, and liquids, which are often integral to industries like food processing, chemicals, and pharmaceuticals.

Bulk handling systems are not merely operational tools; they are the backbone of manufacturing efficiency. By automating and streamlining material handling, businesses can experience greater productivity, reduced labor costs, and improved safety. This article delves into the various facets of bulk handling systems, their benefits, and how they can revolutionize manufacturing processes.

What Are Bulk Handling Systems?

At their core, bulk handling systems are a network of equipment designed to manage the movement of bulk materials in a manufacturing or processing environment. These systems encompass a wide range of technologies, including conveyors, elevators, pneumatic systems, and silo storage units, all working in concert to ensure materials flow seamlessly from one point to another.

The importance of bulk handling systems lies in their ability to move large quantities of materials quickly and efficiently, often without the need for manual intervention. In industries where time is money, having a reliable and fast system in place can significantly improve production times and reduce the risk of human error.

Components of Bulk Handling Systems

The design of bulk handling systems varies based on the nature of the materials being handled and the specific needs of the manufacturer. However, there are several common components that are integral to most systems:

Conveyors: These are used to move materials along a predetermined path, often in a continuous manner. Conveyors can be belt-driven, screw-driven, or even operate on rollers, depending on the type of material being transported.

Elevators: Bulk elevators are designed to lift materials vertically. This is particularly useful when dealing with bulk materials that need to be transported to higher levels or stored in silos.

Pneumatic Systems: Pneumatic conveying uses air pressure to move powders or granular materials through pipelines. This is ideal for handling materials that are prone to contamination or those that need to be kept dry.

Silos and Hoppers: These storage solutions are essential for holding bulk materials before they are processed or shipped out. Silos are typically used for long-term storage, while hoppers are used for short-term storage and dispensing.

Dust Collection Systems: As bulk materials are moved, they can often generate dust, which can pose a risk to both safety and air quality. Dust collection systems, including local exhaust ventilation systems (LEV), are installed to capture and remove harmful dust particles from the air.

The Benefits of Bulk Handling Systems

The advantages of implementing a bulk handling system in manufacturing are multifaceted. For industries where materials need to be moved quickly and efficiently, these systems offer considerable benefits that go beyond just speed and productivity.

Increased Efficiency and Reduced Labor Costs

By automating the movement of bulk materials, businesses can drastically reduce the amount of manual labor required in the production process. Employees no longer need to manually move materials from one area to another, which frees them up for more valuable tasks.

Additionally, the automation of these processes reduces the risk of errors and ensures that materials are handled in a consistent manner. With fewer people involved in material handling, the risk of accidents or workplace injuries is also significantly lowered, making the manufacturing environment safer.

Enhanced Safety and Compliance

Safety is a key consideration in any manufacturing environment. Bulk handling systems can improve safety in several ways. First, by reducing manual labor, workers are less likely to be exposed to dangerous tasks, such as lifting heavy loads or working in hazardous conditions. Second, bulk handling systems are often equipped with safety features, such as emergency stop buttons, sensors, and alarms, that can quickly address any malfunctions or accidents.

Moreover, many bulk handling systems are designed to comply with industry standards and regulations, ensuring that businesses remain compliant with safety and environmental requirements. For instance, the use of a well-maintained LEV system can ensure that harmful dust is efficiently removed from the air, preventing potential health hazards and meeting regulatory guidelines.

Optimized Inventory Control

A crucial element in manufacturing is the management of raw materials. With bulk handling systems, businesses can improve their inventory control by ensuring that materials are stored and moved in an organized manner. Automation systems can track the flow of materials, providing real-time data on inventory levels, usage, and storage. This data can then be used to predict when new materials are needed, reducing the risk of stockouts or overstocking.

Improved Product Quality

For industries that process sensitive materials, maintaining quality standards is paramount. Bulk handling systems can help ensure that materials are handled gently and consistently, reducing the risk of contamination or damage. For example, pneumatic conveying systems, which are gentle on materials, can prevent the degradation of powders or fragile substances, ensuring that the quality of the final product is maintained.

Scalability and Flexibility

Another key advantage of bulk handling systems is their scalability. As manufacturing demands grow, bulk handling systems can be easily expanded or adapted to meet the changing needs of the business. Whether it’s adding more storage capacity with additional silos, increasing the throughput with additional conveyors, or implementing more advanced dust collection systems, bulk handling systems can be customized and scaled up to accommodate growth.

The Role of SEPCOM in Bulk Handling Systems

Incorporating a reliable system for handling waste and byproducts is also critical to a comprehensive bulk handling solution. SEPCOM is a specialized system designed to separate solids from liquids efficiently. It plays a crucial role in bulk handling operations that involve wet or semi-solid materials, such as in the food and beverage industry or chemical manufacturing.

SEPCOM systems use advanced separation technology to extract solid materials from liquid streams, ensuring that waste is properly disposed of or repurposed. By implementing a SEPCOM system, manufacturers can reduce waste, optimize resource use, and enhance the sustainability of their operations.

How to Ensure Optimal Performance of Bulk Handling Systems

While the installation of a bulk handling system can deliver substantial benefits, it’s crucial to ensure that these systems are properly maintained and regularly updated. One important aspect of bulk handling system maintenance is the installation of local exhaust ventilation (LEV) systems. These systems remove harmful dust and airborne particles, preventing workplace hazards and promoting a healthier environment for employees.

Furthermore, regular LEV testing is essential to ensure that the system operates efficiently. Testing helps identify any issues or inefficiencies in the system, allowing for timely repairs or upgrades. Routine maintenance of conveyors, elevators, and other components of the bulk handling system is also essential to prevent downtime and maintain consistent performance.

Conclusion

Bulk handling systems are a critical asset in the modern manufacturing landscape. From improving efficiency and reducing labor costs to enhancing safety and ensuring compliance with industry regulations, these systems offer unparalleled advantages for businesses seeking to optimize their operations. By integrating components like conveyors, elevators, pneumatic systems, and dust collection units, manufacturers can create a robust, efficient, and safe workflow that supports their long-term growth and sustainability.

For those looking to implement or upgrade their bulk handling systems, it is essential to work with experienced professionals who can tailor solutions to specific needs. Whether it’s lev system installation, implementing a SEPCOM waste management system, or testing and maintaining existing equipment, these systems can unlock significant potential for manufacturing operations. The future of manufacturing is undoubtedly automated, and bulk handling systems are at the heart of this transformation.

0 notes

Text

Local Exhaust Ventilation (LEV) Design & Installation | VentXLabs VentXLabs specializes in local exhaust ventilation systems that target toxic fumes, vapors, and particles right where they originate. Serving the chemical, pharmaceutical, and education sectors, our LEV solutions minimize health risks and ensure regulatory compliance. Our team designs systems tailored to your facility’s layout, from extraction arms for welding stations to ductwork for labs. With rigorous testing and maintenance plans, we guarantee long-term performance—because your staff’s safety is non-negotiable.

#local exhaust ventilation#welding extract systems#laboratory fit out#lab fit out#LEV systems#lev testing#fume extraction systems

1 note

·

View note

Text

Top Exhaust & Ventilation Manufacturer in Bangalore – Reliable Solutions for Commercial Kitchens

Proper air circulation is essential for any commercial kitchen. Whether you’re running a restaurant, hotel, bakery, or industrial food production unit, maintaining a clean and safe kitchen environment is crucial. At Mountain Kitchen Equipment, we are a trusted Exhaust & Ventilation Manufacturer in Bangalore, offering complete solutions to manage smoke, heat, steam, and odors from your cooking space.

We specialize in designing, manufacturing, and installing customized exhaust and ventilation systems that ensure your kitchen remains safe, fresh, and compliant with hygiene standards. With years of experience and a focus on quality, we help businesses across Bangalore build efficient and long-lasting kitchen environments.

Why Exhaust & Ventilation Systems Matter in Commercial Kitchens

Commercial kitchens generate a large amount of smoke, grease particles, steam, and odor. Without a proper exhaust and ventilation system, these elements can:

Affect the health of kitchen staff

Increase the risk of fire due to grease buildup

Reduce the lifespan of kitchen appliances

Lead to poor air quality and discomfort

Fail to comply with local safety and hygiene regulations

This is why choosing the right Exhaust & Ventilation Manufacturer in Bangalore is not just important—it’s essential for your business success.

Why Choose Mountain Kitchen Equipment?

As a leading Exhaust & Ventilation Manufacturer in Bangalore, Mountain Kitchen Equipment offers tailor-made solutions based on the layout, size, and cooking requirements of your kitchen.

What Sets Us Apart?

✅ Custom-designed solutions

✅ High-quality stainless steel material

✅ Durable and easy-to-maintain systems

✅ Efficient air flow and suction power

✅ Compliance with safety and fire regulations

✅ Complete installation and support

✅ Quick delivery and expert service

Whether you need a small exhaust hood for a café or a full-scale industrial kitchen ventilation setup, we have the tools, experience, and workforce to get the job done right.

Our Range of Exhaust & Ventilation Systems

We manufacture and supply a wide variety of products that fall under exhaust and ventilation solutions, suitable for all types of commercial kitchens.

1. Kitchen Exhaust Hoods

We manufacture heavy-duty exhaust hoods in various designs such as wall-mounted, island, and low-height hoods. These are ideal for removing smoke, grease, and steam directly from the cooking area.

2. Ducting Systems

Our ducting systems are made with high-grade GI or SS material, designed to carry air efficiently from the hood to the outlet, maintaining smooth air flow throughout the kitchen.

3. Blowers and Exhaust Fans

We provide powerful centrifugal and axial fans that ensure high air suction and discharge efficiency. These fans work silently and are built for 24/7 kitchen operations.

4. Fresh Air Units

Ventilation is not just about removing hot air—introducing fresh air is equally important. Our fresh air systems maintain positive pressure inside the kitchen and improve overall air quality.

5. Filters and Grease Traps

Our hoods come with efficient baffle filters and grease traps to collect oil and particles before they reach the ducting, reducing cleaning efforts and improving fire safety.

Benefits of Choosing Our Exhaust & Ventilation Systems

As a trusted Exhaust & Ventilation Manufacturer in Bangalore, we focus on building systems that offer long-term benefits:

✔ Improved Air Quality: Keep your kitchen environment clean and breathable

✔ Energy Efficiency: Designed to minimize energy usage

✔ Safety Compliance: Fire-safe and in line with government safety standards

✔ Noise Control: Silent motors and fans that won’t disturb your staff

✔ Low Maintenance: Easy-to-clean parts and long-lasting components

We understand every kitchen has unique needs, and our systems are made to fit your exact space, budget, and cooking style.

Industries We Serve

Mountain Kitchen Equipment is known as the go-to Exhaust & Ventilation Manufacturer in Bangalore for a wide range of industries:

Restaurants & Cloud Kitchens

Hotels & Hospitality Groups

Bakeries & Cafés

Industrial & Institutional Canteens

Food Courts & Malls

Catering Services & Banquet Halls

Our experienced team visits your site, understands your kitchen layout, and offers a complete solution that fits your business goals.

Our Process – From Concept to Completion

We provide complete end-to-end services when it comes to exhaust and ventilation systems.

Step 1: Site Visit & Consultation

We start by visiting your kitchen space and understanding your cooking style, equipment load, and space constraints.

Step 2: Custom Planning & Design

Our experts design a solution tailored for your specific requirements using AutoCAD or 3D drawings.

Step 3: Manufacturing

We manufacture the hoods, ducting, and fans in our advanced facility using high-quality materials.

Step 4: Installation

Our technicians install the system on-site, ensuring everything is properly sealed, connected, and aligned.

Step 5: Testing & Handover

We test the airflow, suction power, and overall performance before handing it over for regular use.

Our Commitment to Quality

At Mountain Kitchen Equipment, we believe that performance starts with quality. As a certified Exhaust & Ventilation Manufacturer in Bangalore, we follow stringent quality checks at every stage—from raw material selection to final installation.

All our products are made using rust-proof stainless steel, energy-efficient motors, and fire-safe components. We ensure that every installation is durable, safe, and built to last for years.

Client Testimonials

“Mountain Kitchen Equipment did a fantastic job with our kitchen ventilation setup. The team was professional and quick, and the system works perfectly. Highly recommended for anyone looking for an exhaust & ventilation manufacturer in Bangalore.” – Vishal R., Restaurant Owner

“They helped us solve our kitchen smoke problem with a customized solution that really works. Great service and reasonable pricing.” – Asha T., Bakery Chain Manager

FAQs – Exhaust & Ventilation Systems

Q: How do I choose the right size of exhaust hood? A: It depends on the number of cooking ranges, type of food, and kitchen size. Our team will guide you through it.

Q: Can you install systems in old kitchens? A: Yes, we provide exhaust upgrades and retrofitting for existing kitchens.

Q: What is the delivery time? A: Standard systems can be delivered within 7–10 days in Bangalore.

Q: Do you provide after-sales service? A: Yes, we offer regular maintenance and servicing contracts.

Conclusion

If you're looking for a reliable, efficient, and affordable Exhaust & Ventilation Manufacturer in Bangalore, Mountain Kitchen Equipment is your ideal partner. We are committed to providing high-performance systems that keep your kitchen clean, safe, and compliant with modern standards.

From planning and manufacturing to installation and servicing, we offer everything under one roof. Let us help you create a healthy kitchen environment where your staff can work comfortably, and your business can thrive.

📞 Contact us today for a free site consultation and get a quote tailored to your kitchen setup!

0 notes

Text

Enhancing Building Safety with Expert Fire Solutions in Abu Dhabi

Welcome to Global Alarms Safety & Security Equipment LLC, your trusted ADCD-approved ventilation contractors in Abu Dhabi. We take pride in delivering advanced smoke ventilation systems and smoke control systems to protect lives and property, while ensuring full compliance with ADCD regulations.

Fire Rated Doors – Safety That Seals the Difference

As a reliable fire rated doors supplier in Abu Dhabi, we offer premium, certified doors that provide crucial protection during fire emergencies. Our doors are engineered to contain fire and smoke, offering critical time for safe evacuation and minimizing structural damage.

Tailored Annual Maintenance for Long-Term Safety

Every building has unique safety needs. That’s why we provide customized annual maintenance packages in Abu Dhabi for residential, commercial, and industrial spaces. Regular inspections and maintenance keep your fire safety systems in top condition and ensure they are always ready when it matters most.

Fire Safety Consulting – Compliance Made Simple

As experienced Fire Safety Consultants in Abu Dhabi, we assist clients in navigating local fire codes and regulations. Whether you're constructing a new building or upgrading an existing one, our experts provide reliable, code-compliant solutions that prioritize safety and performance.

Clean, Quick, and Powerful – FM-200 Fire Suppression Systems

We specialize in FM-200 Fire Suppression Systems in UAE, a waterless, clean agent solution perfect for safeguarding sensitive equipment in data centers, control rooms, and server areas. FM-200 extinguishes fire rapidly without leaving residue or causing water damage.

Fire Pumps – Backbone of Fire Protection Systems