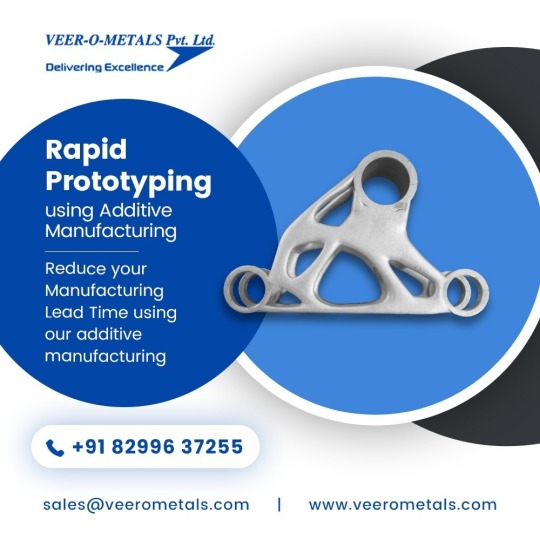

#metal additive manufacturing post processing

Photo

metal parts manufacturing companies

#what is metal additive manufacturing#metal parts#post processing of 3d printed#metals manufacturing company#metal products manufacturers#metal parts manufacturing companies#metal manufacturers in india#metal companies in india#metal additive manufacturing systems#metal additive manufacturing services#metal additive manufacturing service providers#metal additive manufacturing post processing#metal additive manufacturing materials#metal additive manufacturing machine#metal additive manufacturing in india#metal additive manufacturing companies#metal additive manufacturing applications#metal additive manufacturing#metal 3d printing services in india#metal 3d printing service bangalore#metal 3d printing raw material#metal 3d printing rapid prototyping#metal 3d printing process#metal 3d printing post processing#metal 3d printing manufacturing#metal 3d printing india#metal 3d printing in rapid prototyping#metal 3d printing in mumbai

0 notes

Note

"i wish you would write a fic where..." prompt: metal in for repairs. what got it there, what does it think of eggman's treatment of it, and how does it feel about having presumably failed the mission it was on? (angst?? eggman being a good dad??? up to you!!)

Summary: Metal Sonic receives some repairs, and some advice.

1086 words

---

“Up.” Dr. Ivo Robotnik tapped the diagnostic table as he passed it on his way to gather his tools.

Metal Sonic commanded its leg to move. Its actuators grinded in response, offering one short burst of movement before stuttering. Its left leg scraped as it dragged on the ground behind it. Before it could complete the walk cycle, something snapped, and its left hip joint went limp. An attempt to balance on the remaining leg failed. An attempt to spin up its turbine to prevent collision with the floor sent a flood of error messages tumbling to the front of its processor.

The impact darkened its visual sensors for three seconds. It used this time to dismiss the error messages. Upon regaining sight, it extended its hands across the floor ahead of it, dug its claws into the surface, and pulled. The effort of overcoming the force of friction caused its entire frame to shake.

It grabbed onto the nearest leg of the diagnostic table. The table was manufactured out of a smooth metal, and its structure contained no additional outcroppings that could be utilized as handholds. Perhaps if it could raise its torso against the leg so it could grab the surface edge-

“Metal, that’s enough.”

Metal Sonic looked up to see its creator standing over it. He set his retrieved toolbox onto the diagnostic table, before he came around and knelt down beside it.

He placed a hand on its forehead. It had enough tactile sensors left in the region to register that much.

“You really are perfect, aren’t you? Perfectly obedient. Hellishly determined, if I do say so myself.” He gave a small pat. “Today’s outcome wasn’t for a lack of effort, now was it?”

It found its vocalizer damaged but still responsive. It queued a negative ping, only for the noise to come out too garbled to communicate the intended meaning.

“Quiet, my boy. It’s alright.”

Dr. Ivo Robotnik’s tone was. . . unusual. As was the phrase he used. Metal Sonic searched its memory banks and found no matches for either.

“Stay here. Don’t move, I’ll be back.”

The door closed behind him. When it opened again, joining his footsteps was the plodding of an Egg Pawn.

“Lift him up to the diagnostic table and lay him on his back, gently.” He hissed to it.

The Egg Pawn slid its hand beneath Metal Sonic’s frame and carried it from the ground. The Pawn laid it down on its front, before rolling it over.

“I said gently, you fool!” Dr. Ivo Robotnik slapped the Pawn's arm, kicked its shin, and pushed it away. He then shooed it out of the room with a gesture.

He walked beside the table and began positioning Metal Sonic’s limbs to where he desired. He then opened his toolbox and began repair work. The first thing he attended to was its processor; he disappeared from visual range, and unscrewed its quill plating and its interior head paneling to reveal the delicate parts beneath. Here, Metal Sonic lost any register of tactile sensation. Dr. Ivo Robotnik existed by the suggestion of its audial sensors alone.

“Hmm. . . only minor damage here, few snapped wires around optical processing. . .”

Its visual sensors brightened with increased resolution. Strange, it hadn’t noticed the handicap prior. Dr. Ivo Robotnik then replaced the plating he’d removed and reconnected its tactile sensors. He then tilted its head sideways and opened the access port at the nape of its neck.

“Generate your post-action report while I work on the rest of you.” He said as he plugged in the data cable.

Metal Sonic obeyed, and soon its internal processings scrolled up the nearby computer screen. Dr. Ivo Robotnik chose to repair its left leg first, allowing him to face the screen as well. It began the report with the simplest of data. Its speed had matched and at one point exceeded Sonic’s. Its body had been stronger and more durable. Its agility and processing speed had been superior.

Yet it had suffered a near-complete chassis loss.

Yet Sonic had stolen the chaos emerald away.

It had failed, completely and utterly. It launched into a rapid-fire analysis of every frame of data it collected during the battle, attempting to sort out the reason for this outcome, only to find no pattern. It was illogical that it had failed. Its every attribute was superior. It should not have failed!

“Oh, quit moping.” Dr. Ivo Robotnik muttered.

Metal Sonic ceased its analysis.

“Sonic, the irritating little rodent, tends to defy all logic with his little escapades, so move on. Continue with your report.”

That was impossible. Sonic was as much an object bound by the laws of physics as everything else was. His and its attributes were objective, quantifiable, and therefore logic could be applied-

“Believe me when I say I understand. Check the records- I’ve been in this situation countless times before.”

Dr. Ivo Robotnik always spoke the objective and rational truth, but supplementing his statement with a quick scan of its memory banks allowed it to better grasp the concept. Indeed, its creator had been defeated by Sonic before, despite having superior technology and intelligence.

“Precisely. That’s why I say ‘there’s always next time’. Persistence and determination is my motto!” Dr. Ivo Robotnik pointed a finger into the air. “You’ll get Sonic one of these days. I have utmost confidence in your ability to do so.”

Every statement made by Dr. Ivo Robotnik was true, yet if his prior statement was also true, how could it defeat Sonic if superior attributes alone were not enough?

“Simple! You’re my technology. And my technology always triumphs. Am I clear?”

Metal Sonic gave an affirmative ping, only for its vocalizer to short out.

“Process it. Show me you understand.”

Yes, Metal Sonic affirmed. It was superior. It would triumph because of the brilliance of the man who created it.

“Good.” Dr. Ivo Robotnik paused his work to remove the data cable from its access port. The computer screen went dark. “Now, perform a quick debug, then enter standby mode until I wake you.”

Its attention turned onto itself as it began marking files within its processor for review. It flagged one potential issue with its audial sensors. It then initiated its power-down process, shutting off its cameras and spooling down its subroutines.

Before the process completed, it felt Dr. Ivo Robotnik’s hand on its forehead again. It recorded four words.

“Rest well, my boy.”

#metal sonic#fanfiction#Eggman#ivo robotnik#Eggman is a good dad#!!! My first good dad Eggman fic !!!#I must admit this isn't my strongest writing but I really wanted to fill this prompt in a timely manner#this prompt is excellent and could probably generate an entire multi-chapter fic analyzing every angle of it.

109 notes

·

View notes

Text

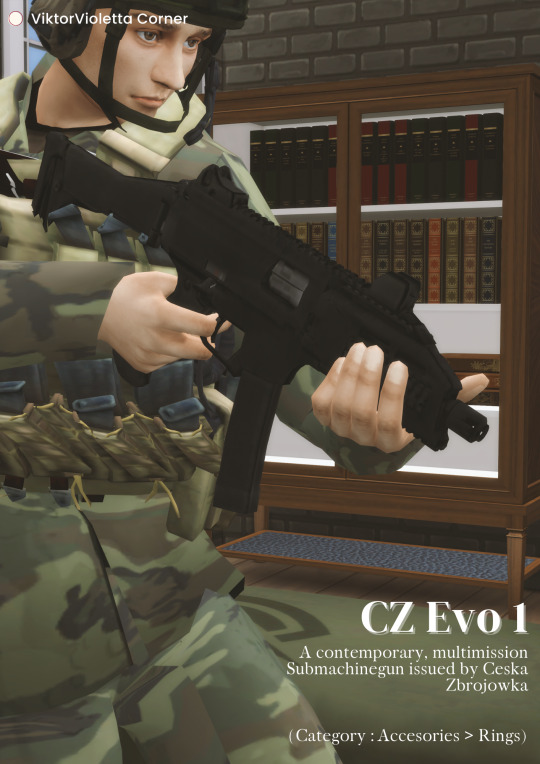

Czechslovakia Armaments

@ts4-poses @ts4-poses-masterlist

DOWNLOAD!!!!!!!!!!

Privet Tovarisch And Happy New Year For Everyone. Greetings and Salutation for us All, and hope you guys still stay with us and trusting us for your Defense Needs.

This time Around We'll Covering the Finest Weapons From Czechoslovakia (Now Czech and Slovakia). former Warsaw Pacts member who shine a bright with their breakthrough inventions, that carried until post Soviet States. the Rising Star for the west. And Sorry For Delayed Post.. We're Planning to add another Segment For VVE in format of E-Magazines. for improvement of our Bureau. for now.. stay Tuned

Pistols

The CZ 75

The Member Of Famous "The Wonder 9" Is Here

CZ75 is a semi-automatic pistol made by Česká zbrojovka Uherský Brod (CZUB) in the Czech Republic. First introduced in 1975, it is one of the original "wonder nines" featuring a staggered-column magazine, all-steel construction, and a hammer forged barrel. It has a good reputation amongst pistol shooters for quality and versatility at a reasonable price, and is widely distributed throughout the world. It is also the most common gun in the Czech Republic.

We Covering 4 Famous Version of this Gun which are CZ75B (Second-generation CZ 75 with internal firing pin safety, squared and serrated trigger guard, and ring hammer. which fire in Semi Auto Mode), CZ75A (The Machine Pistol Version of CZ75, That Popularized by Grand Theft Auto 4:The Lost And Damned & Counter Strike:Global Offensive), CZ SP01 (New generation of CZ 75 SP-01 pistol especially adapted according to suggestions as proposed by users from Law Enforcement, Military and Police communities worldwide, with an additional input from the Team CZ shooters Angus Hobdell and Adam Tyc. Based on the SP-01, it has no firing pin block resulting in improved trigger travel. It also features a slightly reshaped grip and safety, a “weaker” recoil spring for easier loading, and fiber optic front sight and tactical “Novak style” rear sight.) & CZ P-07 (The CZ P-07 DUTY is a compact, polymer-framed CZ 75 variant notable for having a redesigned trigger mechanism. The redesign has reduced the number of parts as well as improved the trigger pull. Chambered in 9mm Luger and .40 S&W, the CZ P-07 DUTY also includes the ability to change the manual safety to a decocking lever and vice versa through an exchange of parts.)

ASSAULT Rifles

1.SA Vz-58 Assault Rifle

The Samopal vzor 1958 (submachine gun, model of 1958) was the standard assault rifle of the Czechoslovak army from the late 1950s and until the dissolution of the Socialist Republic Of Czechslovakia in the 1993. At the present time the SA Vz.58 is still used by the Czech and Slovak armies, as well as sold for export in some quantities. The SA Vz.58 saw not much of real combat, so it is hard to judge how it stakes up against the most known contemporary rivals, like the Soviet / Russian AK-47 or the US M16. But the overall quality, fit and finish of this rifle is excellent. This rifle had been designed by the Czech arms designer Jiří Čermák, under the project codename "KOŠTĚ", or "Broom", in English. Development began in January 1956, and the rifle was adopted for service only 2 years later, in 1958. The rifle was manufactured by the state-owned arms factory "Česká zbrojovka", located in the town of Uherský Brod (CZ-UB).

The Czech army planned to replace the SA Vz.58 with the newest CZ-2000 and the CZ-805 rifle system, chambered for 5.56mm NATO ammunition, but the financial difficulties severely slowed down this process.

While SA Vz.58 strongly resembles externally the famous Kalashnikov AK-47 assault rifle, but internally it is entirely different and of original and well-thought out design.

We Covering 2 Famous Version of this Gun which are Vz. 58 P which is Standard fixed stock (casually called "pádlo" (paddle) by Czech soldiers) & Vz. 58 V: Metal folding stock version for vehicle crew and airborne units. (casually called "kosa" (scythe) by Czech soldiers)

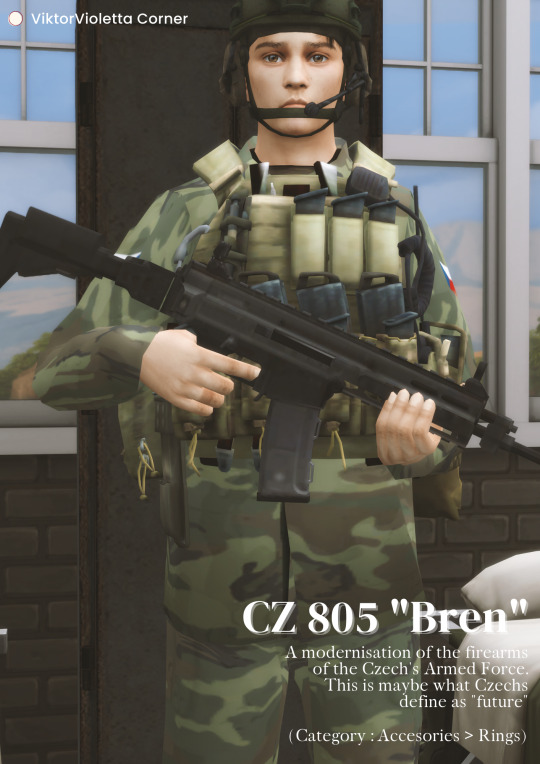

1.CZ-805 BREN Assault Rifle

The CZ 805 assault rifle was first introduced to the public in 2009, as a possible future replacement for aged SA Vz-58 assault rifles still in use by Czech Armed Forces. According to the recent news, early in 2010 the CZ 805 was selected as a next standard military rifle for Czech armed forces, with production contract issued to the famous Czech arms factory CZ-UB in the city of Uhersky Brod. The CZ 805 assault rifle is of modular, multi-caliber design, with aluminum alloy upper receiver and polymer lower receiver / fire control unit. The magazine housing is a separate detachable unit, which can be replaced in the field in the course of caliber change. CZ 805 also features quick-change barrels, allowing to change calibers and barrel lengths according to the mission profile (in each caliber there there are short carbine barrel, standard barrel and long "marksman" or "squad automatic" barrel). The basic action uses fairy common piston-operated gas action with manual gas regulator, and a rotating bolt locking. For each proposed caliber, there is a separate bolt with appropriate dimensions. Fire control unit includes ambidextrous safety/fire selector switch, which permits single shots, 2-round bursts and full automatic fire. Charging handle can be installed on either side of the gun, depending on user preferences. Feed is from detachable box magazines, which are inserted into detachable magazine housing. In standard configuration, the CZ 805 will use proprietary 5.56x45 caliber 30-round magazines made of translucent polymer. Other magazine housings will allow use of Standard STANAG AR Magazine or H&K G36 5.56mm magazines, as well as various 7.62X39 Soviet M43 and 6.8x43 magazines. CZ 805 assault rifle is fitted with integral Picatinny rail on the top of receiver, with additional rails running on the sides and the bottom of the forend. Rifle will be issued with folding iron sights, and will also accept a wide variety of additional sighting equipment (red-dot or telescope day sights, night sights, lasers etc.). Rifle is equipped with side-folding buttstock, which is adjustable for length of pull, and can be completely removed if maximum compactness is required. Additional equipment also includes new, specially designed 40mm underbarrel grenade launcher CZ G 805 and also a new knife-bayonet.

Sub Machine Guns

1.SA VZ.23

The CZ Model 25 (properly, Sa 25 or Sa vz. 48b/samopal vz. 48b – samopal vzor 48 výsadkový, "submachine gun model year 1948 para") was perhaps the best known of a series of Czechoslovak designed submachine guns introduced in 1948. There were four generally very similar submachine guns in this series: the Sa 23, Sa 24, Sa 25, and Sa 26. The primary designer was Jaroslav Holeček (September, 15 1923–October, 12 1997), chief engineer of the Česká zbrojovka Uherský Brod arms factory.

Despite The Weapon was SA.26 which fired 7.62×25mm Tokarev. it basically still a same gun despends on Storytelling

2.Škorpion vz. 61

The Škorpion vz. 61 is a Czechoslovak 7.65 mm submachine gun developed in 1959 by Miroslav Rybář (1924–1970) and produced under the official designation Samopal vzor 61 ("submachine gun model 1961") by the Česká zbrojovka arms factory in Uherský Brod. Although it was developed for use with security forces and special forces, the weapon was also accepted into service with the Czechoslovak Army, as a personal sidearm for lower-ranking army staff, vehicle drivers, armored vehicle personnel and special forces.

We Covering 2 Famous Version of this Gun which are Famous Vz. 61 which chambered in .32 ACP & Vz. 68 Which Chambered with more popular 9mm Cartridge, despite the First was more popular than former.

3.Scorpion EVO 3

is a 9mm submachine gun manufactured by Česká zbrojovka Uherský Brod. The EVO 3 designation denotes that the firearm is a third generation of CZ's line of small submachine guns started by the Škorpion vz. 61. Skorpion Evo 3 evolved from a Slovakian prototype submachine gun called the Laugo. Chambered in 9×19mm Parabellum, the Scorpion EVO 3 is a light weight, compact submachine gun designed to be easily maneuvered in constrained spaces. The A1 variant features a select fire switch, giving the operator the choice of 'safe,' semi-automatic, three-round burst, or fully automatic fire, while the S1's switch only features 'safe' and semi-automatic fire. The standard version comes equipped with a folding, adjustable and fully removable stock for easy transport. The hand guard is lined with multiple Picatinny Rails for the addition of attachments such as grips, sights, flashlights and lasers.

MISC

CAA Roni +CZ P-09

Carbine Version of CZ P-09 Which combined by CAA Roni Pistol Carbine Conversion Kit.

#the sims#the sim#the sims 4#the sims 4 cc#the sims 4 custom content#the sims 4 gun#the sims 4 military#ts4gun#ts4military#ts4acc#ts4cc#life is strange#the sims 4 life is strange#TS4#ts4lis#ts4 cc#czech#czechslovakia#Slovakia#CZ

45 notes

·

View notes

Photo

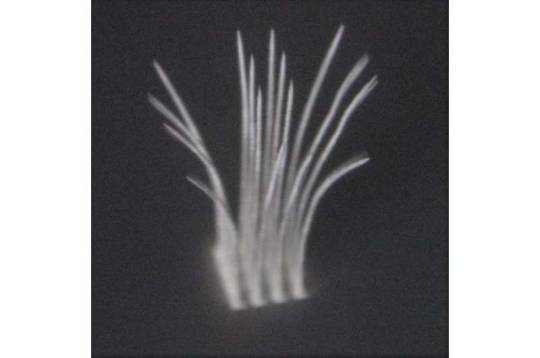

3D printing near net shape parts with no post-processing

Carnegie Mellon University Professor Rahul Panat, and his team, were developing a new type of 3D printed Brain-Computer Interface (or BCI) device where custom micropillars capture the communication signals from neurons when they stumbled upon an unexpected problem: the micropillars in the array bent during sintering. These BCI devices, now called "CMU Arrays," stack millions of metal nanoparticles in 3D space and then sinter, i.e., fuse them together.

In a rather dramatic illustration, a time-lapse film from their experiment, the silver micropillars opened in a highly coordinated fashion like a blooming flower during the 12-hour sintering process to 150-300 °C. This phenomenon was completely unexpected as sintering theory predicts no permanent distortion, even under variable temperatures.

Panat led an interdisciplinary team of researchers from Carnegie Mellon and Washington State University on a quest to not only determine why there was such a distortion, but to more importantly, find a way to control it. In fact, if controlled, the research would lead to world's first illustration of sintering as mechanism of "4D printing," a relatively new discipline within additive Manufacturing (AM) where 3D printed objects are transformed into another shape using sources like heat, water, or other environmental stimuli.

Read more.

#Materials Science#Science#3D printing#Nanoparticles#Sintering#Nanotechnology#4D printing#Additive manufacturing#Carnegie Mellon

14 notes

·

View notes

Text

Technologies revolutionizing 3D Dental sector

Additive manufacturing has reached a significant number of sectors and industries, subsequently offering important advantages in terms of productivity, costs, customization and lead times. In the field of dentistry the technology creates solutions adapted to the needs of each patient. It is also a flourishing industry, not too long ago the consulting firm QY Research announced that dental 3D printing was expected to reach $930 million by the end of 2025. In other words, the market is expected to grow at an annual rate of 17%, which can be explained by the constant development of 3D technologies and their materials. Indeed, dental 3D printing includes different processes such as stereolithography or direct metal sintering and therefore a variety of materials: resins, plastics, metals, etc. The application of 3D printing in dental is wide, it is possible to make surgical guides, crowns, trays and dentures and each solution is adapted to each patient with high precision.

We also find metal additive manufacturing as a process in dentistry. Mainly used to produce implants, stellites, or nickel-chromium screeds. Oliver Bellaton comments, “This technology requires sustained production to absorb investments of up to several hundred thousand euros with skills coming from the industrial world rather than the dental sector.” Metal printers are much more expensive than other technologies and will sometimes require more post-processing work reducing productivity for some. After talking with a dental technician, he explained that a crown made by machining requires 15 minutes of work, however a 3D printed metal one requires 5 hours of printing. On the other hand, in terms of cost per unit, additive manufacturing is much more interesting, 75 cents for the latter against more than 7 euros.

Dental 3D Printing Technologies and their Materials

When we talk about dental additive manufacturing, it is important to understand that several technologies are involved, whether it is fused deposition modeling, photopolymerisation or laser sintering, the choice will depend on the type of application at stake. For example, the FDM process will manufacture pieces “at a cost of a couple of pennies and no post-processing after printing. However, speed, accuracy and biocompatibility are not present.” Generally, the latter technology will be used to create orthodontic dental models for thermoform gutters, whether for alignment, bleaching or restraint. On the other hand, 3D printed dental solutions using PEEK are emerging. The 3D printer manufacturer, IEMAI3D said, “There are many advantages to making partial prostheses with PEEK. It is a strong and lightweight material that will improve patient comfort. The frame of the prosthesis is produced without metal and is completely neutral in terms of taste.”

Another additive manufacturing process used in the dental sector and probably the main one is photopolymerisation. Whether we are talking about stereolithography (SLA) or DLP, this process offers a much higher resolution, and most importantly biocompatible materials. In this case, liquid resins. Anton Lopez, Channel Sales Manager France at EnvisionTEC told us, “Combined with CE/FDA approved materials, photopolymerisation and especially DLP, gives more accurate printing which allows more accurate devices to be created. The finishing is much less complex, which reduces manufacturing time. Also, it is very easy to change materials and print for different applications. This is very beneficial for the dental industry because professionals can treat their patients more quickly”. In terms of applications, this technology offers more possibilities due to its precision; we are talking about surgical guides, temporary crowns and bridges, calcinable elements such as dental stellites, etc.

For more details on our products and services, please feel free to visit us at: Clear retainer package Idaho, dental 3d printing Idaho, digital bracket removal, dental 3d printer & orthodontic lab.

Please feel free to visit us at: https://www.3ddentalprints.com/

2 notes

·

View notes

Text

Aegis A A Commitment to Exceptional Quality

Aegis AV stands out in the market for its exceptional high-quality products, meticulously designed to elevate your home entertainment experience. Here’s a deeper dive into what makes their offerings truly exceptional:

Unmatched Craftsmanship

Every Aegis AV cabinet is a testament to superior craftsmanship. The use of high-quality materials such as solid wood, tempered glass, and durable metals ensures that each piece is not only visually appealing but also built to last. The attention to detail in the construction process is evident in the flawless finishes and sturdy structures that can withstand the test of time.

Innovative Features

Aegis AV cabinets are packed with innovative features designed to optimize the functionality and longevity of your AV equipment:

1. Filtered Smart Cooling System: This advanced cooling system is a standout feature, designed to monitor and maintain optimal temperatures within each AV compartment. By preventing overheating, it ensures that your equipment performs at its best and has a longer lifespan. The cooling system operates quietly, so it won't disrupt your viewing or listening experience.

2. Integrated Cable Management: Tangled wires and messy cables are a thing of the past with Aegis AV’s integrated cable management solutions. These systems keep all your cables neatly organized, reducing clutter and enhancing the overall aesthetic of your entertainment setup. This thoughtful design feature also makes it easier to connect and disconnect devices as needed.

3. Customization Options: Understanding that every home is unique, Aegis AV offers a wide range of customization options. Customers can choose from different finishes, sizes, and additional features to create a cabinet that perfectly fits their space and needs. This level of personalization ensures that each cabinet is as functional as it is stylish.

Design Aesthetics

Aegis AV cabinets are available in various styles to match different decor preferences. Whether you prefer the sleek, contemporary look of the Modern Collection or the rustic charm of the Southern Farm Collection, there’s a design to suit every taste. Each cabinet is designed to seamlessly blend with your home’s interior, adding a touch of elegance and sophistication.

User-Centric Approach

The team at Aegis AV places a strong emphasis on the user experience. This is reflected not only in the product features but also in their approach to customer service. From the initial consultation to post-purchase support, Aegis AV ensures that every customer feels valued and satisfied. Their knowledgeable staff is always ready to assist with product recommendations, customization queries, and any other concerns.

Sustainability and Responsibility

Aegis AV is committed to sustainable practices. They source their materials responsibly and prioritize environmentally friendly manufacturing processes. This commitment to sustainability not only ensures the longevity of their products but also reduces their environmental impact.

Awards and Recognition

The quality and innovation of Aegis AV products have not gone unnoticed. The company has received multiple accolades, including the prestigious CEPro BEST Product Award for five consecutive years. This recognition is a testament to their dedication to excellence and their position as a leader in the AV cabinet industry.

Conclusion

Aegis AV’s commitment to exceptional quality is evident in every aspect of their products, from the materials used to the innovative features and thoughtful design. Whether you’re looking for a modern, sleek cabinet or a rustic, charming piece, Aegis AV offers something for everyone. With their focus on craftsmanship, customization, and customer satisfaction, Aegis AV continues to set the standard for high-quality audio video cabinets in the USA.Visit Aegis AV to explore their exceptional range of products and discover how they can enhance your home entertainment experience. Learn more

website:https://aegisav.com/

0 notes

Text

What to offer by laser engraving companies

Laser engraving companies can provide a range of services to cater to various industries and applications. These services typically encompass the use of laser technology for precise and intricate engraving, marking, and cutting on a wide variety of materials. Here are some of the key services that laser engraving companies can offer:

Custom Laser Engraving and Marking:

These companies specialize in creating customized laser engravings and markings on materials such as metals, plastics, wood, glass, and more.

They can engrave logos, text, serial numbers, barcodes, or any other design onto the surface of the material with high precision and clarity.

Laser Cutting Services:

In addition to engraving, many laser engraving companies also offer laser cutting services.

This allows them to precisely cut through materials to create intricate shapes, designs, or components for various applications.

Design and Consultation Services:

Some companies offer design services to help customers create custom engravings or cutting patterns.

They can also provide consultation on material selection, engraving options, and the overall feasibility of a project.

Rapid Prototyping and Sample Creation:

Laser engraving companies can quickly produce prototypes or samples for customers to evaluate before committing to a larger production run.

This can be especially useful for product designers, manufacturers, or anyone needing to test a new design or concept.

Material Processing and Handling:

They have the expertise and equipment to handle a variety of materials, including pre- and post-processing steps such as material preparation, cleaning, and finishing.

High-Quality Output:

With laser technology, these companies can produce engravings and cutouts with extremely fine detail and accuracy.

The results are often of a higher quality than traditional engraving or cutting methods.

Fast Turnaround Times:

Many laser engraving companies pride themselves on their ability to provide quick turnaround times for projects.

This can be crucial for customers who need their products or components in a hurry.

Technical Support and After-Sales Service:

Some companies provide technical support and after-sales service to help customers troubleshoot any issues that may arise with their laser-engraved products.

They may also offer maintenance and repair services for laser equipment.

Compliance with Industry Standards:

Laser engraving companies often comply with industry standards and regulations related to the materials they work with and the applications of their products.

It's important to note that the specific services offered by laser engraving companies can vary depending on their equipment, expertise, and target industries. To get a more accurate understanding of the services available from a particular company, it's recommended to contact them directly or visit their website for more information.

0 notes

Text

The History and Evolution of uPVC

Unplasticized polyvinyl chloride, commonly known as uPVC, is a material that has significantly impacted the construction and manufacturing industries. Its journey from a simple plastic compound to a highly regarded building material is a fascinating story of innovation and adaptation. In this blog post, we’ll explore the history and evolution of uPVC, tracing its development and growing importance over the years.

Early Beginnings

The story of uPVC begins with the discovery of polyvinyl chloride (PVC) itself. PVC was first created by the German chemist Eugen Baumann in 1872. However, it wasn’t until the 1920s that Waldo Semon, an American scientist working for B.F. Goodrich Company, developed a practical method for synthesizing PVC. Semon was looking for a material that could be used to bond metal and rubber, and his work paved the way for PVC’s commercial use.

The Birth of uPVC

PVC is a versatile material, but its flexibility can be a drawback in certain applications. To address this, chemists developed unplasticized polyvinyl chloride (uPVC) by removing plasticizers, making the material rigid and durable. This innovation occurred in the mid-20th century, and the resulting uPVC quickly found a niche in construction, where its strength and resistance to weathering were highly valued.

Adoption in Construction

The first major use of uPVC in construction was for water and sewage pipes in the 1950s and 1960s. Traditional materials like iron and concrete were heavy, prone to corrosion, and difficult to install. uPVC offered a lightweight, corrosion-resistant alternative that was easier to handle and install, leading to its widespread adoption.

By the 1970s, uPVC began to be used for windows and doors. Its durability, low maintenance, and excellent thermal insulation properties made it an attractive option for homeowners and builders. Unlike wood, uPVC doesn’t rot, warp, or require regular painting, and it provides better insulation than aluminum. These advantages helped uPVC windows and doors gain popularity in Europe and North America.

Technological Advancements

As the demand for uPVC grew, so did the need for improved production techniques and enhanced material properties. Manufacturers began to experiment with additives and formulations to increase uPVC’s strength, UV resistance, and aesthetic appeal. These advancements led to a broader range of uPVC products, including different colors, finishes, and textures, allowing for greater design flexibility.

In the 1980s and 1990s, uPVC manufacturing technology continued to evolve. The development of co-extrusion techniques enabled the production of multi-layered profiles, improving the material’s thermal and acoustic insulation properties. These technological improvements solidified uPVC’s reputation as a high-performance building material.

Modern Applications and Sustainability

Today, uPVC is used in a wide array of applications beyond pipes and windows. It is found in siding, fencing, roofing, and even furniture. Its versatility, combined with its environmental benefits, has made it a go-to material for sustainable construction.

One of the significant advantages of uPVC is its recyclability. At the end of its life cycle, uPVC can be recycled and reprocessed into new products, reducing the demand for virgin materials and minimizing waste. This aligns with the growing emphasis on sustainability and environmental responsibility in the construction industry.

The Future of uPVC

As we look to the future, the role of uPVC in construction is likely to expand even further. Innovations in uPVC formulations and manufacturing processes continue to enhance its properties and performance. For instance, new additives and coatings are being developed to improve UV resistance and reduce heat absorption, making uPVC an even more attractive option for energy-efficient buildings.

Moreover, the integration of smart technologies with uPVC products is opening up new possibilities. Smart windows and doors with built-in sensors and automation features are becoming increasingly popular, providing added convenience, security, and energy management capabilities.

Conclusion

The history and evolution of uPVC is a testament to human ingenuity and the relentless pursuit of better materials for building and manufacturing. From its early days as a simple plastic compound to its current status as a versatile, sustainable, and high-performance material, uPVC has come a long way. As technology continues to advance, uPVC will undoubtedly play a crucial role in the future of construction, offering solutions that are not only durable and efficient but also environmentally friendly.

Visit our website:

#upvc#upvc casement doors#upvc casement windows#upvc french doors#upvc sliding doors#upvc profiles#upvc window repairs near me#upvc windows and doors#upvc window suppliers#upvc windows manufacturer

0 notes

Text

Is Compression Molding Expensive?

Compression molding is a widely used manufacturing process in various industries, including automotive, aerospace, electronics, and consumer goods. It involves placing a material, usually a thermosetting polymer, into a heated mold cavity, where it is compressed and cured to take the shape of the mold. This technique is known for producing high-strength and durable parts, but is it expensive? To answer this question comprehensively, we must consider various factors that influence the cost of compression molding.

Factors Influencing the Cost of Compression Molding

1. Material Costs

The choice of material is a primary factor in determining the cost of compression molding. Thermosetting polymers like phenolic, epoxy, and polyester are commonly used. These materials vary in price based on their properties, such as thermal resistance, mechanical strength, and chemical resistance. Advanced materials like carbon fiber-reinforced composites are significantly more expensive than standard polymers, but they offer superior performance for high-end applications.

2. Tooling Costs

Tooling, or mold creation, is a substantial upfront investment in compression molding. The cost of designing and manufacturing a mold depends on its complexity, size, and the material used. High-precision molds made from durable metals like steel are more expensive but essential for producing high-quality parts with tight tolerances. For lower production volumes, using less expensive materials like aluminum for molds can reduce costs, but they may not last as long.

3. Production Volume

4. Cycle Time

Cycle time refers to the time required to complete one molding cycle, including loading the material, heating, compressing, curing, and cooling. Shorter cycle times can increase production rates and reduce labor costs. However, achieving shorter cycle times may require advanced equipment and optimized process parameters, which can increase initial costs.

5. Labor Costs

The complexity of the compression molding process and the level of automation involved can affect labor costs. Manual operations increase labor costs and the likelihood of human error. Investing in automated systems can reduce labor costs and improve consistency and quality but requires higher initial capital.

6. Post-Molding Operations

Additional processes, such as trimming, machining, painting, or assembly, add to the overall cost of compression-molded parts. The need for these operations depends on the part design and end-use requirements. Simplifying part design and minimizing post-molding operations can help reduce costs.

Cost Comparison with Other Molding Techniques

Injection Molding

Injection molding, another popular molding technique, often competes with compression molding. Injection molding is typically more cost-effective for high-volume production due to faster cycle times and lower labor costs. However, for large, thick-walled parts or those requiring high mechanical strength, compression molding may be more suitable despite potentially higher costs.

Transfer Molding

Transfer molding is similar to compression molding but involves transferring the material from a chamber into the mold. It offers better control over material flow and is ideal for intricate parts with complex geometries. While transfer molding can be more expensive due to additional equipment and process steps, it provides higher precision and reduced material wastage.

Blow Molding

Strategies to Reduce Compression Molding Costs

Material Selection

Choosing cost-effective materials that meet performance requirements is crucial. Collaborating with material suppliers to identify suitable alternatives can lead to significant cost savings without compromising quality.

Tooling Optimization

Investing in high-quality, durable molds can reduce long-term costs by minimizing maintenance and replacement expenses. Additionally, designing molds for ease of manufacturing and maintenance can improve efficiency.

Process Optimization

Implementing advanced process control systems and optimizing cycle times can enhance productivity and reduce labor costs. Continuous monitoring and adjustment of process parameters ensure consistent quality and minimize material wastage.

Design for Manufacturability (DFM)

Designing parts with manufacturability in mind can simplify the molding process, reduce cycle times, and minimize post-molding operations. Collaboration between design engineers and manufacturing experts during the early stages of product development is essential for achieving cost-effective designs.

Conclusion

Is compression molding expensive? The answer depends on various factors, including material costs, tooling expenses, production volume, cycle time, labor costs, and post-molding operations. While compression molding may have higher upfront costs compared to some other molding techniques, it offers unique advantages for producing high-strength, durable parts with complex geometries. By carefully considering these factors and implementing cost-saving strategies, manufacturers can optimize the cost-effectiveness of compression molding for their specific applications.

In summary, the perceived expense of compression molding must be weighed against its benefits and suitability for the intended application. When done correctly, compression molding can be a cost-effective solution that delivers high-quality parts with excellent performance characteristics.

0 notes

Text

Galvanized Fasteners Manufacturer in Benin - Sachiya Steel International

Galvanized Fasteners are indispensable in industrial hardware, ensuring structural integrity and longevity across various sectors such as construction, infrastructure, automotive, and marine industries. Sachiya Steel International Private Limited stands out in this field due to its dedication to quality, innovation, and customer satisfaction, distinguishing itself as an industry leader. This article delves into the technical details, benefits, manufacturing processes, and why Sachiya Steel International remains a popular choice in Benin and beyond.

Understanding Galvanized Fasteners

Galvanized fasteners are standard metal fasteners—bolts, nuts, screws, and washers—that undergo galvanization to enhance their corrosion resistance properties. Galvanization involves coating each fastener in an anodic layer of zinc, which acts as a protective barrier against corrosion. This process significantly increases the lifespan of fasteners, making them suitable for outdoor and marine environments where corrosion presents a significant threat.

Benefits of Galvanized Fasteners

Corrosion Resistance: The zinc coating provides excellent protection against corrosion, making galvanized fasteners ideal for outdoor applications, coastal regions, and high-humidity environments.

Durability and Longevity: Galvanized fasteners are known for their superior durability and extended lifespan compared to untreated fasteners, reducing maintenance costs over time.

High Strength: Zinc plating enhances the mechanical properties of fasteners, increasing their strength and load-bearing capability.

Cost-Effectiveness: Despite their higher initial costs, galvanized fasteners offer exceptional cost-effectiveness due to their extended lifespan and decreased need for replacements, providing outstanding value in the long run.

Manufacturing Process

Sachiya Steel International employs modern manufacturing techniques and adheres to stringent quality control measures in its fastener production process to produce high-grade galvanized fasteners:

Material Selection: High-grade raw materials such as carbon steel or stainless steel are selected based on application requirements.

Cleaning and Preparation: Raw materials undergo thorough cleaning and surface preparation to remove contaminants and ensure optimal adhesion of the zinc coatings.

Galvanization: Fasteners are immersed in a molten zinc bath or undergo electroplating to coat every surface evenly with zinc. This coating process is closely monitored to achieve the desired thickness and consistency.

Post-Galvanization Processes: Fasteners may undergo additional processes like quenching, passivation, and sealing to further enhance their corrosion resistance and durability.

Quality Assurance

Sachiya Steel International prioritizes quality assurance through rigorous testing and inspection procedures:

Dimensional Accuracy: Fasteners undergo careful dimensional inspections to ensure they meet international standards such as ASTM or DIN.

Mechanical Testing: Strength and performance tests are conducted to ensure fasteners meet or exceed specified load capacities.

Corrosion Resistance: Salt spray testing and other corrosion tests are performed to verify the effectiveness of the zinc coatings.

Customization and Specialization

Sachiya Steel International offers tailor-made solutions to meet individual customer requirements:

Custom Sizes and Coating Options: Fasteners can be manufactured to non-standard sizes and dimensions. In addition to traditional zinc coating, options like galvannealing or organic coatings may also be available.

Packaging and Labeling Solutions: Tailored packaging solutions ensure safe transportation and storage of fasteners.

Applications and Industries

Sachiya Steel International’s galvanized fasteners find applications across various industries:

Construction and Infrastructure: Used in structural steel connections, bridges, and building frameworks.

Automotive and Transportation: Essential for vehicle assembly and railway infrastructure.

Marine and Coastal Applications: Ideal for environments with high exposure to saltwater and humidity.

As Benin continues to develop its industrial capabilities, the demand for reliable and high-performance fasteners grows. Sachiya Steel International Private Limited is ready to meet this demand by manufacturing fasteners that conform to international standards, providing robust solutions across a range of applications within Benin’s industries.

Read More: Galvanized Fastener Manufacturers in Benin

0 notes

Text

Crafting The Future: The Rise Of 3D Printed Jewelry

In an era defined by technological innovation, the fusion of 3D printing with Jewelry design has created a transformative impact on the world of fashion and luxury. 3D printed Jewelry is revolutionizing the way designers conceptualize, create, and bring their visions to life. This article explores the intricate world of 3D printed Jewelry, examining its fabrication process, advantages, applications, and the future potential of this cutting-edge technology.

Understanding 3D Printing in Jewelry:

3D printing, also known as additive manufacturing, involves building three-dimensional objects layer by layer from a digital model. In Jewelry design, this process allows for the creation of intricate, customized pieces that were previously difficult or impossible to achieve with traditional methods. The fabrication process typically includes the following steps:

Design and Modeling: Jewelry designers use computer-aided design (CAD) software to create detailed digital models of their designs. This digital approach allows for precise control over every aspect of the piece, from complex geometries to delicate patterns.

Material Selection: Depending on the desired final product, designers choose from a variety of materials, including precious metals like gold, silver, and platinum, as well as innovative materials such as resin and biocompatible polymers.

Printing Process: Several 3D printing technologies are employed in Jewelry making, including stereolithography (SLA), selective laser sintering (SLS), and direct metal laser sintering (DMLS). Each technology offers unique advantages in terms of detail resolution, material compatibility, and production speed.

Post-Processing: After printing, the raw piece undergoes post-processing steps such as polishing, plating, and setting of gemstones. These finishing touches ensure the final product meets the high standards of quality and aesthetics expected in the Jewelry industry.

https://insidermarketresearch.com/wp-content/uploads/2024/06/2.2-Quality-Control-and-Customization-1.jpg

Advantages of 3D Printed Jewelry:

3D printed Jewelry offers several significant advantages over traditional manufacturing methods:

Design Freedom: One of the most compelling benefits is the ability to create complex, intricate designs that are challenging to produce using conventional techniques. This opens up new possibilities for creativity and innovation in Jewelry design.

Customization: 3D printing allows for unprecedented levels of customization. Customers can personalize their Jewelry with specific designs, engravings, and modifications, ensuring a truly unique piece.

Rapid Prototyping: Designers can quickly produce prototypes to test new designs and make adjustments before final production. This accelerates the design process and allows for more experimentation and innovation.

Material Efficiency: Additive manufacturing is inherently material-efficient, as it builds objects layer by layer, minimizing waste. This is particularly important in Jewelry making, where the cost of precious metals can be high.

Cost-Effectiveness: While the initial investment in 3D printing technology can be significant, the ability to produce detailed designs without the need for expensive molds and tooling can lead to cost savings over time.

Current Applications:

The versatility of 3D printing technology has led to its adoption in various aspects of Jewelry design and manufacturing:

Custom Jewelry: 3D printing is ideal for creating bespoke Jewelry pieces tailored to individual preferences. From engagement rings to personalized pendants, customers can collaborate with designers to bring their unique visions to life.

Intricate Designs: Designers are using 3D printing to create intricate, avant-garde pieces that push the boundaries of traditional Jewelry design. This includes complex lattice structures, organic forms, and detailed filigree work.

Mass Customization: Jewelry brands are leveraging 3D printing to offer mass customization options, where customers can select from a range of base designs and customize elements such as size, material, and finish.

Sustainable Jewelry: The material efficiency and reduced waste associated with 3D printing make it an attractive option for sustainable Jewelry production. Additionally, the ability to use recycled materials and minimize the environmental impact aligns with the growing demand for eco-friendly products.

Future Prospects:

The future of 3D printed Jewelry is filled with exciting possibilities driven by ongoing advancements in materials science, printing technologies, and design methodologies. Some key trends and future directions include:

Advanced Materials: The development of new materials, including high-strength polymers, biocompatible metals, and innovative composites, will expand the range of applications for 3D printed Jewelry. These materials can enhance the durability, functionality, and aesthetic appeal of the pieces.

Hybrid Manufacturing: Combining 3D printing with traditional Jewelry-making techniques, such as hand-finishing and stone setting, can create hybrid manufacturing processes that offer the best of both worlds. This approach allows for greater design flexibility and craftsmanship.

Wearable Technology: The rise of wearable technology presents opportunities for incorporating smart features into 3D printed Jewelry. This includes integrating sensors, connectivity, and other functionalities to create Jewelry that is not only beautiful but also functional.

Sustainability and Ethical Practices: As consumers become more conscious of sustainability and ethical practices, 3D printing offers a way to produce Jewelry with a reduced environmental footprint. The use of recycled materials and on-demand production can further support sustainable and ethical manufacturing.

Conclusion:

3D printed Jewelry represents a groundbreaking advancement in the world of fashion and luxury, offering unparalleled design freedom, customization, and efficiency. From bespoke creations and intricate designs to sustainable practices and innovative materials, the applications of this technology are vast and continually expanding. As advancements in 3D printing technology and materials science continue to evolve, the future of 3D printed Jewelry holds immense promise, paving the way for a new era of creativity, personalization, and sustainability in the Jewelry industry. The ongoing integration of this technology into design and manufacturing processes promises to enhance the way we create, wear, and experience Jewelry, revolutionizing the industry for years to come.

0 notes

Photo

metal additive manufacturing - metal 3d printing services in india

#metal additive manufacturing additive manufacturing process additive printing additive manufacturing design additive metal 3d printing addit#metal additive manufacturing applications#metal additive manufacturing companies#metal additive manufacturing in india#metal additive manufacturing machine#metal additive manufacturing materials#metal additive manufacturing post processing#metal additive manufacturing service providers#3d metal printing companies 3d metal printing machine 3d metal printing machine manufacturers 3d metal printing near me 3d metal printin#3d metal printing companies#3d priniting post processing services#3d printing in defence industry#additive manufactured products#additive manufacturing companies in bangalore#additive manufacturing company in india#additive manufacturing material#additive manufacturing metal parts#additive manufacturing service in india#additive metal 3d printing#dmls printer manufacturers#materials for additive manufacturing#metal 3d printing bangalore#metal 3d printing companies in bangalore#metal 3d printing companies in india#metal 3d printing in mumbai#metal 3d printing in rapid prototyping#metal 3d printing india#metal 3d printing manufacturing#metal 3d printing post processing#metal 3d printing process

1 note

·

View note

Text

CNC Casting vs. CNC Machining: A Comprehensive Comparison

When it comes to manufacturing custom parts and components, there are several methods available. Among these, CNC casting and CNC machining are two of the most popular techniques used in Canada. Both methods have their own unique set of advantages and disadvantages that make them suitable for different applications.

Overview of CNC Casting

CNC (Computer Numerical Control) casting is a process where molten metal is poured into a mold, which is then allowed to solidify. Once the metal has cooled and hardened, it is removed from the mold and finished using CNC machining techniques. This method allows for the creation of complex shapes and designs that would be difficult or impossible to achieve with traditional casting methods. It also offers a high degree of accuracy and repeatability, making it ideal for mass production.

Overview of CNC Machining

CNC machining, on the other hand, involves cutting away material from a solid block of metal using computer-controlled tools. This method can produce precise and intricate parts with tight tolerances. It is commonly used to create prototypes or low-volume production runs.

Differences between CNC Casting and CNC Machining

Material: CNC casting involves pouring molten metal into a mold, while CNC machining uses blocks of solid metal. This gives CNC casting an advantage when working with materials that are difficult to machine, such as cast iron or stainless steel.

Tooling: While both methods use computer-controlled tools, the type and complexity of the tools differ. CNC machining requires more specialized tools for cutting and shaping, while CNC casting tools are designed for pouring and finishing.

Complexity: CNC casting is better suited for creating complex shapes and designs, as it can produce parts with undercuts and internal cavities. On the other hand, CNC machining is limited by the size and shape of the starting material.

Applications of CNC Casting and CNC Machining in Canada

CNC casting and machining are widely used in various industries in Canada, such as aerospace, automotive, and medical. In the aerospace industry, CNC casting is used to create lightweight yet strong components for aircraft engines. CNC machining is often utilized for precision parts in smaller aircraft or drones. In the automotive industry, CNC casting is commonly used for engine blocks and transmission components due to their durability and strength. CNC machining is also used for creating custom parts for high-performance vehicles.

In the medical field, both methods are employed to create prosthetics and medical devices with intricate designs and precise measurements. CNC casting is often used for complex orthopedic implants, while CNC machining is utilized for creating surgical instruments.

Advantages of CNC Casting and Machining in Canada

Cost-effective: Both CNC casting and machining can produce large quantities of parts at a faster rate compared to traditional manufacturing methods. This results in cost savings for businesses.

Accuracy and repeatability: As both methods are computer-controlled, they offer high precision and consistency in producing parts. This is crucial for industries that require exact measurements for their products.

Material versatility: With advancements in technology, CNC casting and machining can work with a wide range of materials, including metals, plastics, and composites. This allows for greater flexibility in product design and development.

Reduced labor costs: Due to the automation in both processes, there is less need for manual labor. This not only reduces costs but also increases safety in the workplace.

Faster production time: Both methods can produce parts at a faster rate compared to traditional methods, resulting in shorter lead times for product delivery.

Better surface finish: CNC casting and machining can produce parts with smooth and precise finishes, reducing the need for additional post-processing steps.

In conclusion, CNC castings and machining in Canada have revolutionized numerous industries with their exceptional benefits. They offer cost-effectiveness, precision, material versatility, reduced labor costs, faster production times, and superior surface finishes. Such advantages underscore why CNC casting and machining have become key components in sectors such as automotive, medical, aerospace, and more. For businesses looking to elevate their production efficiency and product quality, investing in CNC castings Canada and machining Canada is a strategic and beneficial move. By leveraging these advanced manufacturing methods, companies can stay competitive in today's fast-paced industrial landscape.

0 notes

Text

Trends Shaping China's Membrane Filter Plate Market

In China, trends in the membrane filter plate market are shaping up due to a growing need for bio-based medicines and stricter water cleaning rules from the government. These shifts come as businesses look for better ways to process materials without using much energy. Also, the COVID-19 pandemic has had a big effect on this industry by changing how companies work and people live their daily lives.

With an eye on clean processing methods that save on costs, China's focus turns more towards advanced solutions like high pressure membrane filter presses. This is finding its role not just in health care but across various sectors aiming for efficiency and quality in filtration tasks.

Understanding China's Membrane Filter Market

China's membrane filter market is seeing a rise, pushed by growing needs in bio-medicine and water clean-up. With the world facing COVID-19, this push became stronger. More than ever, ensuring water purity has caught government attention.

This demand fuels growth for advanced filtration methods like high-pressure membrane filter presses. In detail, low energy costs make these systems attractive for industries needing to sift through or clear up their liquids or gases without heat damage. These filters work well across many settings – from removing tiny particles in manufacturing processes to cleaning dyes from wastewater without harming sensitive materials.

The largest piece of this puzzle? Reverse osmosis technology takes the lead due to its power in demineralizing and purifying water—making it a go-to choice not just in China but globally for drinkable water solutions. However, challenges loom large.

Maintaining these delicate systems can be costly and complex if not handled with care.

Growth Drivers in Membrane Filtration Technology

Membrane filtration is key for wine and beer, making these drinks clear and stable by taking out unwanted bits. Yet, this tech faces big hurdles like strict safety rules and the challenge of membrane fouling—a buildup that spoils water or products. The COVID-19 outbreak hit this industry hard due to social distancing and lockdowns affecting operations.

In 2024, the wine and beer sector leads in using membrane filter plates in China because they help keep bones strong by upping bone density which cuts down on diseases like osteoporosis. The use of plate and frame setups is growing fast as they're great for many projects thanks to their design being easy to work with, operate smoothly, and fix without a hassle.

High Pressure Filters Reshaping the Industry

High pressure filters are changing the game in China’s membrane filter plate market, thanks to their advanced features. These plates shine because they’re built tough yet flexible and come out of CNC machining with unmatched flatness below 25µm. This precision ensures a perfect seal during pressing, eliminating leaks when feeding.

They not only meet but exceed both Chinese JB/T4333.3-2005 and German DIN7129 standards, matching European and American quality levels. Filtration speed jumps by 20%, while density, strength against fatigue and aging double up compared to standard national models. Their max feed pressure hits an impressive 1.6Mpa, supporting high temperature and pressure conditions without compromising on antisepsis or airtight sealing.

hzfilter steps it up with materials, offering plates made from various metals like cast iron or stainless steel, as well as PP or TPE for different needs. They handle pressures up to 3 Mpa easily, ensuring short filtering cycles that retain low moisture content in cakes. The introduction of membrane plates marks another leap forward.

These marvels can squeeze solid contents precisely through additional pressurization post-filtration, improving cake solidity significantly and cutting down energy use. This kind of technological evolution presented by hzfilter points towards more effective eco-friendly solutions within industry operations showcasing how high-pressure filtration technology is indeed reshaping sector standards notably.

Innovations in China’s Filter Press Manufacturing

In China's evolving filter press market, manufacturers like hzfilter Equipment Co., leading with innovation. They craft membrane filter plates vital for industries needing solid-liquid separation. These firms stand out by focusing on research and development to push the boundaries of what their filtration equipment can achieve.

hzfilter, for instance, boasts 128 valid patents including international ones. Their work in creating new products shows a dedication not just to quality but also pushing technological limits within environmental protection sectors.

These companies illustrate how investment in technology catalyzes product improvement while catering to diverse needs from sewage treatment to industrial waste management globally. Through advanced manufacturing techniques and robust service networks spanning both domestic markets and beyond, these enterprises underscore China's position as a hub for high-performance membrane filter press production offering solutions that meet varied customer requirements efficiently.

Environmental Policies Fueling Market Evolution

New green rules are changing how companies make stuff. In China, this means firms making membrane filter plates have to think about the environment more than before. These policies push for less pollution and waste.

So, factories need better tech to clean water and air they use or release. This makes them buy new types of filters that catch tiny bad bits better than old ones did. Because these cleaner methods often cost more money up front, businesses look for efficient options that save cash over time too.

This shift isn't just good news for our planet; it's also creating a big chance for makers of these advanced filters in China’s market.

Export Expansion and Global Impact

As China ramps up its membrane filter plate exports, the global market feels the impact. This move not only boosts China's economy but also changes how other countries handle their filtration needs. With more options now available, prices have become competitive worldwide.

Quality standards are pushed higher as a result of this competition, benefiting various industries from pharmaceuticals to wastewater treatment globally. Consumers and companies alike notice improvements in both cost-efficiency and performance levels of filtration products they use daily. It’s clear that through expanding export activities, China is playing a key role in shaping advancements and accessibility in the membrane filter plate industry across continents.

Future Projections for Chinese Manufacturers

Chinese manufacturers are focusing more on automation, using robots for faster and better production. They aim to cut costs and improve safety with these advanced machines. This shift means China's factories are now filled with modern tech, not old methods.

Also, they're pushing for greener ways to make things, reducing harm to our planet by cutting down waste and using clean energy like sun and wind power. Infrastructure is getting a big boost too – think smart factories powered by the latest 5G networks. And it doesn't stop there; innovation is key in staying ahead globally, making quality goods fast that meet new demands without costing the earth.

The market for membrane filter plates in China shows dynamic growth, shaped by innovation and environmental needs. As firms seek cleaner operations, high-pressure membrane filters from hzfilter stand out. Offering efficient filtration with less energy use, they meet the demand for sustainable solutions.

Their adaptability to diverse industries further pushes their appeal. With ongoing research and development, expect these technologies to evolve even more., addressing both current challenges and future demands This trend underscores a shift towards greener practices within sectors reliant on filtration technology.

#membrane filter plates in China#China’s Filter Press Manufacturing#high pressure membrane filter presses#membrane filter plate#hzfilter

0 notes

Text

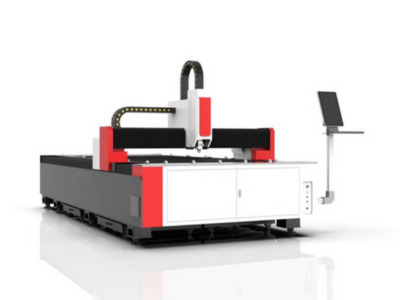

Second Hand Fiber Metal Cutting

As the owner of GK Laser Enterprises, exploring cost-effective solutions to enhance your business operations is paramount. Investing in second-hand fiber metal cutting machines can provide a strategic advantage, offering advanced technology at a fraction of the cost. This article delves into the benefits and considerations of incorporating second-hand fiber metal cutting technology into your business.

Advantages of Second-Hand Fiber Metal Cutting Machines

Cost-Effectiveness

One of the most significant advantages of purchasing second-hand fiber metal cutting machines is the cost savings. New fiber lasers can be prohibitively expensive, particularly for small to medium-sized enterprises. By opting for a pre-owned machine, you can access advanced cutting technology without the hefty price tag, freeing up capital for other investments within GK Laser Enterprises.

Advanced Technology at Lower Costs

Fiber laser technology has revolutionized the metal cutting industry with its precision, speed, and efficiency. By acquiring a second-hand machine, you can leverage these benefits without waiting for new technology to become affordable. Many pre-owned fiber lasers still possess cutting-edge capabilities that can enhance your production quality and efficiency.

Depreciation and Value Retention

New machines depreciate rapidly in the first few years. By purchasing a second-hand fiber laser, you bypass the steepest part of the depreciation curve. This means the value of your investment will remain more stable over time, which is beneficial if you plan to upgrade again in the future.

Sustainability

In today's environmentally conscious market, sustainability is a crucial consideration. Buying second-hand machinery is a form of recycling that reduces waste and the demand for new manufacturing. This not only lowers your carbon footprint but also aligns your business with eco-friendly practices, which can be attractive to environmentally-conscious customers.

Key Considerations When Buying Second-Hand

Machine Condition and Maintenance History

Before purchasing a second hand fiber metal cutting, it's essential to assess its condition thoroughly. Request detailed maintenance records and inspect the machine for any signs of wear and tear. A well-maintained machine can offer years of reliable service, but a poorly kept one can become a costly burden.

Source Reliability

The source from which you purchase your second-hand machine is crucial. Opt for reputable dealers or certified pre-owned programs that offer warranties or service contracts. This ensures you are not only getting a quality machine but also have support in case any issues arise post-purchase.

Technological Compatibility

Ensure that the second-hand machine you are considering is compatible with your current operations and software. Compatibility issues can lead to additional costs and downtime, negating the financial benefits of buying second-hand. It's advisable to consult with a technician or the machine's manufacturer regarding integration with your existing systems.

Upgradability

The ability to upgrade the machine is another important factor. Technology is continuously advancing, and having a machine that can be upgraded with new software or hardware can extend its useful life and maintain its competitiveness.

Implementation Strategy for GK Laser Enterprises

Needs Assessment

Begin with a comprehensive assessment of your business needs. Identify the specific requirements of your production processes and how a second-hand fiber metal cutting machine can meet these needs. Consider factors such as cutting speed, precision, material types, and thicknesses you commonly work with.

Budget Planning

Develop a detailed budget that includes the purchase price of the machine, transportation, installation, potential upgrades, and ongoing maintenance costs. Ensure that your budget aligns with your financial goals and does not compromise other critical areas of your business.

Vendor Research

Conduct thorough research to find reputable vendors offering second-hand fiber metal cutting machines. Look for vendors with positive reviews, transparent pricing, and comprehensive service packages. Engage with multiple vendors to compare options and negotiate the best deal.

Inspection and Testing

Arrange for a professional inspection and testing of the machine before finalizing the purchase. This can be done by a certified technician who can provide an unbiased evaluation of the machine's condition and performance.

Training and Integration

Once the machine is acquired, invest in training for your staff to ensure they are proficient in operating the new equipment. Proper training minimizes the risk of errors and maximizes the efficiency of your new machine. Additionally, plan for a seamless integration of the machine into your existing production line to avoid disruptions.

Conclusion

Investing in second-hand fiber metal cutting technology can be a game-changer for GK Laser Enterprises. It offers a cost-effective way to enhance your production capabilities while maintaining high standards of quality and efficiency. By carefully considering the machine's condition, source reliability, and compatibility with your operations, you can make a smart investment that drives your business forward. With a strategic approach to implementation, you can reap the benefits of advanced cutting technology and position GK Laser Enterprises for sustained growth and success. Contact us to learn more about how second-hand fiber metal cutting technology can transform your business.

0 notes

Text

Powder Metallurgy Market Size & Share to Hit USD 14.4 billion by 2031, Garnering a 7.7% CAGR from 2021 to 2031

The global powder metallurgy market was estimated to have acquired US$ 6.4 billion in 2020. It is anticipated to register a 7.7% CAGR from 2021 to 2031 and by 2031, the market is likely to gain US$ 14.4 billion.

One unique opportunity in the powder metallurgy market is the growing demand for advanced powder metallurgy techniques in the development of additive manufacturing (3D printing) materials. Powder metallurgy offers the ability to create intricate and highly customized metal components, making it well-suited for 3D printing applications in various industries, including aerospace, healthcare, and automotive.

This emerging trend provides a niche for powder metallurgy to play a vital role in producing high-performance, complex, and lightweight parts, opening up new avenues for innovation and market growth.

Download PDF Brochure: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3468

Market Segmentation

The powder metallurgy market can be segmented based on service type, sourcing type, application, industry vertical, and region.

By Service Type

Production Services: Including compacting, sintering, and post-processing services.

Material Services: Involving the supply of metal powders and additives.

By Sourcing Type

In-house Manufacturing: Companies with in-house PM capabilities.

Contract Manufacturing: Outsourcing PM processes to specialized manufacturers.

By Application

Automotive: Components like gears, bearings, and filters.

Aerospace: Lightweight structural components and engine parts.

Medical: Orthopedic implants and dental devices.

Electronics: Magnetic materials and conductive components.

By Industry Vertical

Automotive

Aerospace

Medical

Electronics

Industrial Machinery

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America

North America is a leading market for powder metallurgy, driven by significant demand in the automotive and aerospace sectors. The presence of major manufacturers and ongoing research and development initiatives further bolster the market in this region.

Europe

Europe holds a substantial share in the powder metallurgy market, with Germany, France, and the UK being key contributors. The region's focus on sustainable manufacturing practices and advancements in PM technology are driving growth.

Asia-Pacific

The Asia-Pacific region is expected to witness the highest growth rate, supported by rapid industrialization, especially in China, Japan, and India. The automotive and electronics industries are major drivers of PM market expansion in this region.

Latin America and Middle East & Africa

These regions are gradually increasing their adoption of powder metallurgy, with growing investments in the automotive and aerospace sectors. However, the market share remains relatively smaller compared to North America, Europe, and Asia-Pacific.

Market Drivers and Challenges

Drivers

Technological Advancements: Innovations in PM processes and materials are enhancing efficiency and expanding application areas.

Environmental Benefits: Reduced material waste and energy consumption make PM a preferred choice for sustainable manufacturing.

Increasing Demand in Key Industries: The automotive, aerospace, and medical industries are major consumers of PM components, driving market growth.

Challenges

High Initial Costs: The setup costs for PM manufacturing can be substantial, posing a barrier for new entrants.

Technical Limitations: Some limitations in material properties and the complexity of certain shapes may restrict the adoption of PM.

Market Trends

Additive Manufacturing Integration: The combination of PM with additive manufacturing techniques is creating new opportunities for complex and customized components.

Sustainable Practices: There is a growing emphasis on environmentally friendly manufacturing processes, driving the adoption of PM.

Material Innovations: Development of new metal powders and composites is expanding the capabilities and applications of PM.

Future Outlook

The future of the powder metallurgy market looks promising, with continuous advancements in technology and materials expected to overcome current limitations. The increasing demand for lightweight, high-strength components in automotive and aerospace sectors will further propel market growth.

Key Market Study Points

The market is set to grow at a CAGR of 4.5% from 2021 to 2031.

Automotive and aerospace industries are the primary drivers of demand.

Technological advancements and sustainable practices are key trends.

North America and Asia-Pacific are the leading regions in market growth.

Competitive Landscape

The powder metallurgy market is highly competitive, with key players including GKN Powder Metallurgy, Höganäs AB, Sumitomo Electric Industries, and Sandvik AB. These companies are focusing on strategic partnerships, acquisitions, and innovations to maintain their market position.

Place an Order Copy of Powder Metallurgy Market Report at: https://www.transparencymarketresearch.com/checkout.php?rep_id=3468<ype=S

Recent Developments

GKN Powder Metallurgy: Recent investments in expanding production capacity and enhancing material capabilities.

Höganäs AB: Development of new metal powders tailored for additive manufacturing applications.

Sumitomo Electric Industries: Introduction of advanced sintering technologies to improve component performance.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.