#additive metal 3d printing

Explore tagged Tumblr posts

Text

Novel etching technique enhances absorptivity of powders for metal 3D-printing

In a significant advancement for metal additive manufacturing, researchers at Lawrence Livermore National Laboratory (LLNL) and their academic partners have developed a technique that enhances the optical absorptivity of metal powders used in 3D printing. The approach, which involves creating nanoscale surface features on metal powders, promises to improve the efficiency and quality of printed metal parts, particularly for challenging materials like copper and tungsten, according to researchers. Additive manufacturing (AM)—more commonly known as 3D printing—has transformed the way products are designed and produced, allowing for the creation of complex geometries and customized components that traditional manufacturing methods struggle to achieve.

Read more.

#Materials Science#Science#Powder#3D printing#Additive manufacturing#Etching#Absorptivity#Metals#Copper

13 notes

·

View notes

Text

Italian multinational group Legor is now using 3D technology to create jewelry and fashion accessories made from 100% precious metals from recycled sources, making progress toward its goals of enabling a circular economy.

#solarpunk#solarpunk business#solarpunk business models#solar punk#reculture#italy#recycled precious metal#3D printing#additive manufacturing

10 notes

·

View notes

Text

Unveiling Aurora Labs' AL250: A Leap Forward in Metal 3D Printing

Australian innovator Aurora Labs steals the spotlight with its groundbreaking AL250 metal 3D printer launch at Formnext 2023. Buckle up for a ride through the realms of aerospace, defence, oil and gas, engineering, and bespoke production runs as we explore the incredible features of this cutting-edge technology. The AL250 Say goodbye to the RMP-1 and welcome the AL250, Aurora Labs‘ latest laser…

View On WordPress

4 notes

·

View notes

Text

Metal 3D Printing in Bangalore: Revolutionizing Additive Manufacturing

Bangalore, often referred to as the Silicon Valley of India, has emerged as a major hub for additive manufacturing and metal 3D printing. With the rapid advancement in industrial 3D printing technologies, businesses across aerospace, automotive, healthcare, and tooling sectors are leveraging metal additive manufacturing to drive innovation and efficiency.

This article explores the growing adoption of metal 3D printing in Bangalore, the benefits of additive manufacturing, and how companies in the region are pushing the boundaries of technology.

The Rise of Metal 3D Printing in Bangalore

What is Metal 3D Printing?

Metal 3D printing, also known as metal additive manufacturing (AM), is a revolutionary technology that enables the creation of complex metal parts layer by layer using advanced digital design and fabrication processes. This method significantly reduces material waste, enhances design flexibility, and accelerates production timelines compared to traditional manufacturing techniques like casting and machining.

Bangalore, being home to some of India’s leading engineering and technology firms, has witnessed an exponential rise in the adoption of metal 3D printing technologies. Companies and research institutions in the city are harnessing the power of additive manufacturing to develop high-performance components for critical industries.

Key Drivers of Additive Manufacturing in Bangalore

Several factors are fueling the growth of metal 3D printing in Bangalore:

Booming Aerospace and Defense Industry Bangalore hosts numerous aerospace and defense organizations, including HAL (Hindustan Aeronautics Limited), ISRO (Indian Space Research Organisation), and DRDO (Defense Research and Development Organization). These institutions are leveraging additive manufacturing for lightweight, high-strength components used in satellites, aircraft, and defense equipment.

Thriving Automotive Sector The city is home to leading automobile manufacturers and engineering firms that are increasingly turning to metal additive manufacturing for rapid prototyping, custom tooling, and lightweight structural components. 3D printing in automotive engineering reduces lead time and enhances performance by enabling intricate geometries that are difficult to achieve through conventional processes.

Medical and Healthcare Innovation Metal 3D printing in Bangalore is playing a significant role in the medical industry by enabling the production of customized implants, prosthetics, and surgical instruments. The ability to create patient-specific implants from biocompatible materials such as titanium has revolutionized the medical field, improving patient outcomes and reducing surgical risks.

Growing Startup Ecosystem Bangalore’s dynamic startup ecosystem has embraced additive manufacturing as a game-changer in various industries. Several 3D printing service providers in Bangalore are offering metal 3D printing solutions for industrial applications, allowing companies to prototype and manufacture parts with greater speed and cost-effectiveness.

Advantages of Metal Additive Manufacturing in Bangalore

The adoption of metal 3D printing brings several advantages to businesses and manufacturers in Bangalore:

Design Freedom: Unlike conventional machining, metal 3D printing allows the creation of highly intricate and complex designs that were previously impossible to manufacture.

Reduced Material Waste: Traditional metalworking processes involve significant material wastage, whereas additive manufacturing uses only the required amount of metal powder, making it more sustainable.

Faster Production: With 3D printing technologies, companies can manufacture functional prototypes and end-use parts in a fraction of the time required by conventional methods.

Customization: Additive manufacturing enables on-demand production of custom parts, making it ideal for industries such as healthcare and aerospace, where tailored solutions are essential.

Cost Efficiency: While the initial setup cost of metal 3D printing can be high, it significantly reduces expenses in the long run by minimizing material waste, reducing labor costs, and enabling efficient low-volume production.

Leading Metal 3D Printing Companies in Bangalore

Several companies and research institutes in Bangalore are at the forefront of metal additive manufacturing. Some of the notable players include:

Wipro 3D – A leading provider of metal 3D printing services, offering advanced additive manufacturing solutions for aerospace, defense, healthcare, and industrial applications.

Intech Additive Solutions – One of India’s pioneers in metal 3D printing, specializing in design, development, and manufacturing of high-performance 3D-printed metal parts.

Objectify Technologies – Provides additive manufacturing services across multiple industries, including aerospace, automotive, and tooling.

Think3D – A well-established company offering comprehensive 3D printing solutions including metal additive manufacturing for industrial applications.

Government and Academic Research Labs – Institutions like IISc Bangalore (Indian Institute of Science) and DRDO are actively engaged in research and development (R&D) of metal 3D printing technologies for defense and scientific applications.

Applications of Metal 3D Printing in Bangalore

The versatility of metal additive manufacturing makes it suitable for a wide range of applications:

Aerospace & Defense – Lightweight, high-strength components for aircraft, satellites, and defense systems.

Automotive Engineering – Custom engine parts, lightweight structural components, and rapid prototyping.

Medical Implants & Prosthetics – Patient-specific implants, orthopedic devices, and dental crowns using biocompatible metals.

Industrial Tooling & Molds – Custom injection molds, dies, and jigs for manufacturing industries.

Oil & Gas Industry – High-performance metal components for extreme conditions.

Future of Metal Additive Manufacturing in Bangalore

The future of metal 3D printing in Bangalore looks incredibly promising, with continued investment in research, development, and industrial adoption. As businesses increasingly recognize the advantages of additive manufacturing, we can expect:

Increased Adoption Across Industries: More companies will integrate metal 3D printing into their production workflows for improved efficiency.

Advancements in 3D Printing Materials: New high-performance alloys and metal powders will further enhance the capabilities of additive manufacturing.

Expansion of 3D Printing Services in Bangalore: More 3D printing companies in Bangalore will offer on-demand manufacturing and custom solutions.

Government Support and Policy Initiatives: The Indian government is likely to introduce policies promoting advanced manufacturing technologies, fostering growth in metal additive manufacturing.

Conclusion

Bangalore has positioned itself as a key player in the field of metal 3D printing and additive manufacturing. With a strong industrial base, a thriving startup ecosystem, and cutting-edge research institutions, the city is leading India’s transition toward next-generation manufacturing technologies.

As more industries embrace the benefits of metal additive manufacturing, Bangalore will continue to be a hub for innovation, precision engineering, and industrial transformation. Whether it’s aerospace, automotive, healthcare, or tooling, metal 3D printing in Bangalore is set to redefine the future of manufacturing.

For businesses looking to stay ahead in the competitive landscape, investing in metal 3D printing and additive manufacturing is no longer an option but a necessity.

#Metal 3D printing in Bangalore#Additive Manufacturing in Bangalore#Additive Manufacturing Companies in Bangalore#3D Printing Service in Bangalore#3D Scanning Services in Bangalore#3D Scanning And Design in Bangalore

0 notes

Text

The Future of Additive Manufacturing in Military Technology and Innovation

Additive manufacturing, also known as 3D printing, is changing industries around the world. From healthcare to automotive, this technology has proven to be fast, flexible, and cost-effective. In recent years, the military has shown a strong interest in additive manufacturing, using it to create custom parts, equipment, and even complex systems. As 3D printing technology evolves, its potential in military technology and innovation continues to grow.

This blog will discuss how additive manufacturing is being used in the military today, its future potential, and the challenges that need to be overcome.

What is Additive Manufacturing?

Additive manufacturing is a process that creates objects by adding layers of material, one on top of the other, until the object is complete. Unlike traditional manufacturing, which often involves cutting away material to shape an object, additive manufacturing builds objects up from scratch. This process allows for highly customized parts and designs, making it perfect for the unique needs of the military.

Current Uses of Additive Manufacturing in the Military

Today, the military uses additive manufacturing in several key ways:

Quick Repairs and Parts Replacement: One of the biggest benefits of 3D printing in the military is the ability to make replacement parts on demand. When equipment breaks, it can take weeks or months to get replacement parts delivered to soldiers in the field. With 3D printing, these parts can be made in hours or days, getting equipment back in action faster.

Prototyping and Custom Designs: The military often needs specialized equipment, which can be costly and time-consuming to produce. Additive manufacturing allows the military to quickly create prototypes of new designs, test them, and make adjustments as needed. This flexibility saves time and money while allowing for more experimentation and innovation.

Medical Applications: Additive manufacturing can also create medical supplies and devices, like custom prosthetics or surgical tools. In combat zones, 3D printing can provide medical teams with specialized equipment quickly, improving the care of injured soldiers.

Lightweight and Complex Structures: Additive manufacturing enables the creation of lightweight structures that can still be very strong. This technology can produce complex shapes that are difficult or impossible to make with traditional methods, making it ideal for creating advanced weaponry, drones, and other military equipment.

Future Potential of Additive Manufacturing in the Military

The future of additive manufacturing in the military looks very promising. Here are some exciting possibilities:

On-Site Production: In the future, military bases could be equipped with 3D printers to produce needed items directly on-site. This could allow soldiers to make parts, tools, and other items as needed, reducing supply chain dependency and response times. It could also mean that soldiers in remote or dangerous locations won’t need to wait for supplies, as they can make what they need right where they are.

Advanced Materials: As 3D printing materials improve, additive manufacturing could create parts with stronger, more durable materials. For example, researchers are working on ways to print with metal alloys, ceramics, and even materials that can conduct electricity. These advanced materials could allow the military to produce more resilient equipment that lasts longer and performs better under harsh conditions.

Drones and Autonomous Vehicles: The military is increasingly using drones and autonomous vehicles for tasks like surveillance and reconnaissance. Additive manufacturing allows for quick production of lightweight, complex parts, which are ideal for drones and other aerial devices. In the future, 3D-printed drones could be used in a variety of ways, from delivering supplies to exploring dangerous areas without putting soldiers at risk.

Bioprinting for Medical Advancements: Bioprinting, a type of 3D printing that uses cells to create tissue, is still in its early stages, but it has potential military applications. In the future, military medical teams might use bioprinting to create skin grafts or other tissue on-site, helping soldiers recover more quickly from injuries.

Challenges Facing Additive Manufacturing in the Military

While the future of additive manufacturing in the military is promising, there are still challenges to overcome:

Quality and Consistency: 3D-printed parts must meet high standards, especially in the military, where failure can mean the difference between life and death. Ensuring that printed parts are as strong and reliable as traditionally manufactured parts is a major challenge.

Cybersecurity Risks: Since 3D printing relies on digital files, there is a risk of cyberattacks. Hackers could potentially alter designs or access sensitive military information. To counter this, the military needs to invest in secure systems to protect its 3D printing operations.

Training and Knowledge: To fully benefit from additive manufacturing, the military needs skilled technicians and engineers who understand the technology. Training soldiers and military staff to operate 3D printers and design parts is essential for the widespread adoption of this technology.

Cost of Advanced Materials and Printers: While 3D printing can be cost-effective, the materials and equipment needed for advanced military applications can be expensive. Investing in these resources requires a strong commitment and careful budgeting by military organizations.

Conclusion: A New Era of Military Innovation

Additive manufacturing offers many exciting possibilities for the military, from on-site production to the creation of complex, lightweight structures. As the technology advances, it could help the military become more flexible, cost-effective, and innovative.

However, for additive manufacturing to reach its full potential in military applications, challenges like quality control, cybersecurity, and high costs need to be addressed. With the right investments and strategies, additive manufacturing could become an essential part of the future of military technology, helping to keep soldiers safer and more effective in the field.

The future of additive manufacturing in military technology is bright, and it’s only a matter of time before we see even more groundbreaking applications that change the way the military operates.

#metal additive manufacturing#ded metal 3d printing#ded additive manufacturing#additive manufacturing military

0 notes

Text

Exploring Metal Additive Manufacturing: Revolutionizing Metal 3D Printing for Advanced Manufacturing.

Discover the world of metal additive manufacturing, a cutting-edge technology revolutionizing industries with innovative metal 3D printing techniques. Learn how this advanced manufacturing process offers enhanced precision, reduced material waste, and faster production times for complex metal parts across aerospace, automotive, and industrial sectors.

0 notes

Text

Metal Additive Manufacturing Market is Estimated to Witness High Growth Owing to Reduced Production Costs

Metal additive manufacturing, also known as 3D metal printing, enables the fabrication of complex metal components using a digital file and successive layering of material under computer control. Manufacturers can produce intricate components with conformal cooling passages, lattice structures, and optimized designs that provide weight savings. As additive manufacturing reduces waste by building only the desired part geometry, it helps lower production costs compared to traditional subtractive methods such as milling and machining. The metal additive manufacturing market encompasses technologies such as direct metal laser sintering, electron beam melting, and binder jetting, among others. Manufacturers across industries adopt these technologies to produce prototypes and end-use products. Due to the potential for mass individualization and supply chain resilience, metal 3D printing demand is growing across automotive, aerospace, healthcare, and industrial equipment verticals.

Global metal additive manufacturing market is estimated to be valued at USD 5.85 Bn in 2024 and is expected to reach USD 14.37 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 13.7% from 2024 to 2031.

Key Takeaways Key players operating in the metal additive manufacturing market are GE Additive, 3D Systems, Desktop Metal, EOS GmbH, Renishaw, SLM Solutions, Stratasys, Markforged, Velo3D, DMG Mori, HP Inc., TRUMPF, ExOne (a Desktop Metal company), Materialise, Formlabs, Norsk Titanium, Optomec, Prima Additive, XJet, and VulcanForms. These players focus on expanding their production capacities and service offerings to tap growing metal 3D printing demand. Key opportunities in the Metal Additive Manufacturing Market Trends include leveraging additive manufacturing to produce jigs, fixtures, and tooling for customized production. The technology enables on-demand manufacturing, reducing inventory costs. Further, 3D metal printing facilitates the direct production of end-use implants, prosthetics, and medical devices to improve patient outcomes. Geographically, the metal additive manufacturing market witnesses high growth in North America and Europe due to early technology adoption. However, Asia Pacific is emerging as an attractive market with huge potential, led by government initiatives driving advanced manufacturing. As the technology matures, global metal 3D printing adoption will continue increasing across industries. Market Drivers Reduced production costs with additive manufacturing compared to traditional methods is a key market driver. 3D printing eliminates the need for expensive tooling and reduces waste. It facilitates mass customization by producing different parts using the same production method. Furthermore, additive manufacturing enables the production of complex parts with optimised lightweight designs that provide performance and efficiency benefits. Metal Additive Manufacturing Market Size and Trends technology helps improve design flexibility, reduce lead times, and support supply chain resilience. All these advantages are fueling increased investment in metal 3D printing globally.

PEST Analysis Political: Metal additive manufacturing faces regulations regarding product quality and safety. Regulators aim to establish standards without stifling innovation. Economic: Metal 3D printing reduces waste and improves design flexibility compared to traditional manufacturing. It allows on-demand production and reduces lengthy supply chains. Social: Additive manufacturing increases access to custom-tailored solutions in industries like healthcare, consumer products, and education. It facilitates distributed manufacturing closer to end users. Technological: Advancements in metal powder composition, laser melting techniques, and printer capabilities continue increasing build size and throughput. Computer-aided design tools are optimizing machine parameters for new material formulations. Europe Europe is a major regional market, where aerospace and automotive sectors in Germany, Italy, and UK drive significant adoption of metal 3D printing technology, particularly for prototyping and low-volume production applications. Government support for advanced manufacturing research further boosts the regional market. Asia Pacific The Asia Pacific region is anticipated to witness the fastest growth over the forecast period due to rising focus on industrial modernization across industries in countries such as China, Japan, and South Korea. Establishment of local manufacturing facilities by global players also expands the regional market.

Get more insights on Metal Additive Manufacturing Market

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Coherent Market Insights#Metal Additive Manufacturing Market#Metal Additive Manufacturing#Metal AM#3D Printing Metals#Metal Fabrication#Industrial 3D Printing#Metal Prototyping#Metal Additive Processes

0 notes

Text

Delivering Excellence with Direct Metal Laser Sintering (DMLS) |Additive Manufacturing Solutions| Wipro-3D

Wipro 3D offers additive manufacturing solutions based on direct metal laser sintering(DMLS) technology. Which helps to deliver exceptional accuracy, speed, and quality.

Read more:

#wipro-3d#3-d printing#Metal additive Technologies#Direct Metal Laser Sintering#Additive Manufacturing Solutions

0 notes

Text

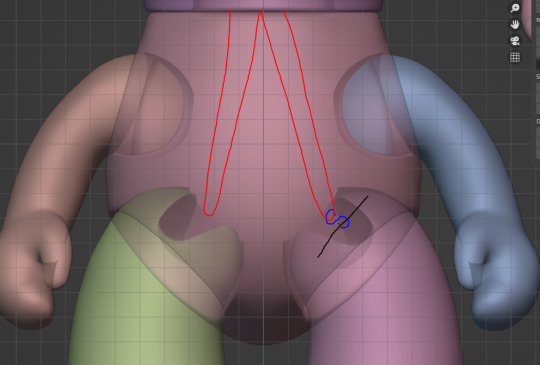

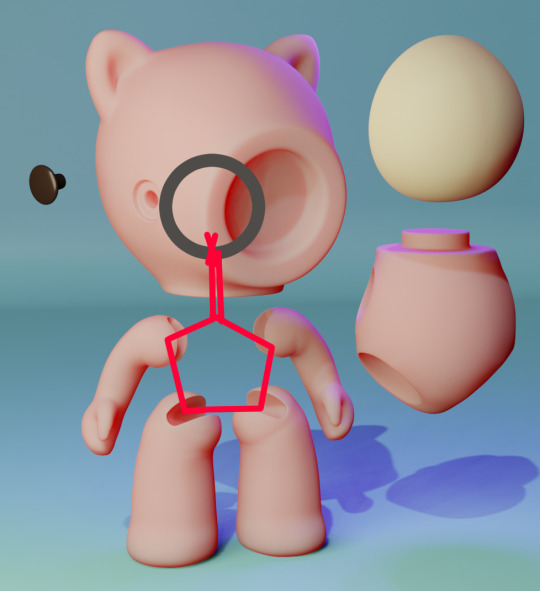

Takara Pony model file (.blender)

Linked is the file for the Takara pony I made (pictured above in pink). As a reminder, this is made from scratch and I don't have my own takara pony but I used as many references as possible. The joints are ball-joints but will require some additional work to use them properly, the joints need a bar across the opening to attach a hook and elastic to.

see below, black bar is a metal rod, blue S is an S-Hook and red is an elastic.

And this would be roughly how to string it, this is inspired by Dollightful's bunny doll but I also advise that the elastic between the legs be pulled upto the hoop as well if possible. The head is not a ball joint, the head + body and head + nose are meant to come together with a peg-in-socket. For the head, the tightness of an elastic should keep it on ideally, but honestly I don't know if the nose will stick in perfectly and might need to be glued, I'm not sure.

In addition to the ball-jointed takara pony, who is 9 separate pieces, I included a simple little sculpt of the "baby pony" takaras. These are just 2-part sculpts and don't need elastics or anything, they have a "peg" and "hole"

Takara baby ponies are already common on the market so I'm not sure if anyone will actually want the babies but I included it anyway. The eyes + nose are just cosmetic, the whole head is just one piece.

Anyways, a reminder that I don't have a 3D printer so I haven't tested it but feel free to download and play with the files and print them yourself if you have a 3D printer! Please credit and also tag me so I can see if someone prints them!

395 notes

·

View notes

Text

Recently my son has gotten more interested in music. A month or two ago, I helped him research and buy a small headphone amplifier for his desktop PC setup.

However, in addition to the amp, he wanted a vacuum tube preamp since he's seen the one I have for my PC (you can see part of it in the last pic) and wanted a similar configuration. :)

So I set about gathering some parts I had on hand to put one together for him. He selected the wood for the case from my stash, and the white aesthetic to match the rest of his PC setup. I used 2 6C4 tubes because I had them and they seemed like a fun choice for this.

Most of the work came in constructing the enclosure. I used my chop saw to cut pieces to length, then resawed them on my bandsaw so they were thinner. I then glued up the wooden box with some support blocks to increase the strength and give me somewhere to mount the metal plate that will hold the parts.

I'd recently scored a bunch of aluminum and steel sheet, so I used one of the aluminum plates to mount all the parts. The thicker plate was really nice to work and drill and allowed me to chamfor the holes so the wires won't scrape. Then I painted it up and mounted in the components.

This project involved a lot of 3D printing as well, all the transformer covers and the capacitor brackets were printed on my FlashForge 3. Boiled Linseed Oil was used on the wood for a natural finish, and the power light enclosure is an old glass bottle that I 3D printed a diffusion cap for.

Overall I'm really happy with this project, and so is my son who's been using it constantly over the Thanksgiving break. :)

Stay tuned for more fun with tubes!

12 notes

·

View notes

Text

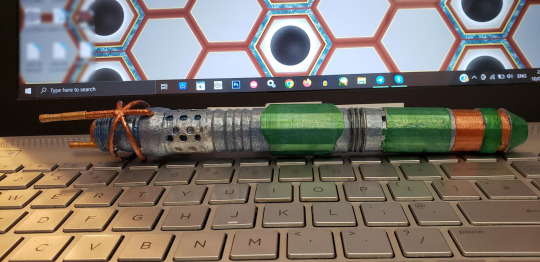

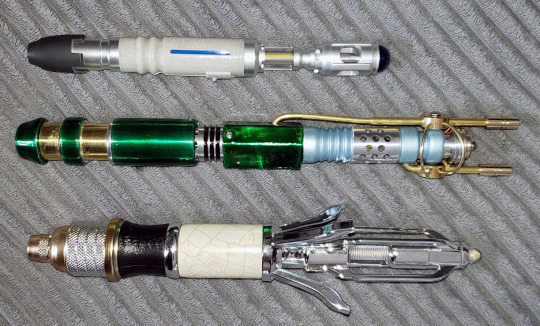

So last year when the 15th Doctor's Sonic Screwdriver was revealed...

A lot of people were going on about how it doesn't look enough like a screwdriver. It made me think "well, what does a Sonic Screwdriver look like?" And the more I thought about it, the more I thought, ultimately, you can get away with a lot with the Sonic Screwdriver so long as it's at least cylindrical.

So I opened up Maya and made a bunch of pieces and swapped them in and out until...

I had designed my own Sonic Screwdriver. Quite proud of it, too!

But to fabricate it, all I could really do was 3D print it, and while it's lovely for a hunk of plastic it just doesn't do anything.

So I asked a wizard.

Custom Sonics are absolutely amazing at making Sonic Screwdrivers. I sent them 3D turnarounds, photographs, and design documents and good (time) lord did they knock it out of the park.

Look at this!

It's absolutely beautiful!

Machined in real metal, with brass accents and durable resin grips, and fitted with lights and sound. Its weighty but light, feeling good in the hand.

I feel like it certainly measures up to other Sonic Screwdrivers!

I am so happy and so proud to have this in my collection.

If you want your own Sonic Screwdriver, definitely consider Custom Sonics for replicas, original designs, or to get a quote on your own custom design! (I'm not being paid to advertise, I promise lmao)

About the design:

I wanted this to look like the original Sonic Screwdriver had been built upon over the years, rather than simply being replaced. So there are elements of the Sonic Screwdriver seen in the Classic series acting as a base for the design, with everything else added on over the top.

Thinking of how the Doctor might improve on that original design in-universe, I thought about its weaknesses as an item. The Doctor could easily drop it and it might roll away, so I added a flat-edged grip. It also gets used a lot, so I thought it should have a ventilation system to prevent overheating. There are two sets of vents: the round ones near the top, and more subtle square ones near the grip.

The War Doctor uses the original Sonic Screwdriver but with the emitter head removed. We're never told why, but I like to think this, along with the additional piece added to the base, was done to give it more power. With that in mind, I thought perhaps an even more powerful Sonic Screwdriver - without an emitter ring - would need something to focus and stabilize the sonic waves. The Eleventh Doctor's and Fourteenth Doctor's Sonic Screwdrivers have "petals" which may or may not serve that function. This design has two additional emitters mounted on antennae to focus and stabilize the beam. The emitter head has a screw thread so a new emitter ring can be screwed on. I did design an emitter head, but with the stabilizers, the shape wasn't very satisfying, so that went unfabricated.

The base was left with an opening, which I imagined would allow it to plug into the TARDIS. This worked out well as it left room for Custom Sonics to install a charging port.

The brass rings were inspired by the Dalek Time Controller and The Rani's TARDIS console.

The silvery metallic blue colour was inspired by K-9.

The emerald and brass colours were chosen simply because it's my favourite colour combination. The use of brass was also inspired by clockwork, with its obvious relation to time travel and my own personal enjoyment of clockwork.

So that's my custom Sonic Screwdriver!

15 notes

·

View notes

Text

North Carolina State University researchers have demonstrated a technique that allows people who manufacture metal machine parts with 3D printing technologies to conduct automated quality control of manufactured parts during the finishing process. The technique allows users to identify potential flaws without having to remove the parts from the manufacturing equipment, making production time more efficient. "One of the reasons people are attracted to 3D printing and other additive manufacturing technologies is that these technologies allow users to quickly replace critical machine components that are otherwise difficult to make outside of a factory," says Brandon McConnell, co-corresponding author of a paper on the work. "And additive manufacturing tools can do this as needed, rather than dealing with supply chains that can have long wait times. That usually means using 3D printing to create small batches of machine parts on demand." McConnell is an assistant research professor in NC State's Edward P. Fitts Department of Industrial and Systems Engineering.

Read more.

#Materials Science#Science#North Carolina State University#3D printing#Metals#Defects#Additive manufacturing

12 notes

·

View notes

Text

Printed engines propel the next industrial revolution

In the fall of 2023, NASA hot fire tested an aluminum 3D printed rocket engine nozzle. Aluminum is not typically used for 3D printing because the process causes it to crack, and its low melting point makes it a challenging material for rocket engines. Yet the test was a success.

Printing aluminum engine parts could save significant time, money, and weight for future spacecraft. Elementum 3D Inc., a partner on the project, is now making those benefits available to the commercial space industry and beyond.

The hot fire test was the culmination of a relationship between NASA and Elementum that began shortly after the company was founded in 2014 to make more materials available for 3D printing. Based in Erie, Colorado, the company infuses metal alloys with particles of other materials to alter their properties and make them amenable to additive manufacturing. This became the basis of Elementum's Reactive Additive Manufacturing (RAM) process.

NASA adopted the technology, qualifying the RAM version of a common aluminum alloy for 3D printing. The agency then awarded funding to print the experimental Broadsword rocket engine, demonstrating the concept's viability.

Meanwhile, a team at NASA's Marshall Space Flight Center in Huntsville, Alabama, was working to adapt an emerging technology to print larger engines. In 2021, Marshall awarded an Announcement of Collaborative Opportunity to Elementum 3D to modify an aluminum alloy for printing in what became the Reactive Additive Manufacturing for the Fourth Industrial Revolution project.

The project also made a commonly used aluminum alloy available for large-scale 3D printing. It is already used in large satellite components and could be implemented into microchip manufacturing equipment, Formula 1 race car parts, and more.

The alloy modified for the Broadsword engine is already turning up in brake rotors and lighting fixtures. These various applications exemplify the possibilities that come from NASA's collaboration and investment in industry.

IMAGE: A laser powder directed energy deposition (LP-DED) 3D printer at RPM Innovations’ facility additively manufactures a large-scale aerospike rocket engine nozzle from one of Elementum 3D’s specialized, 3D-printable aluminum alloys. Credit: RPM Innovations Inc.

5 notes

·

View notes

Text

Stratasys is ready to take the lead.

View On WordPress

0 notes

Text

3D Printing and Scanning Services in Bangalore: Revolutionizing the Additive Industry

Introduction

Bangalore, often referred to as the "Silicon Valley of India," has been at the forefront of technological advancements in various industries. One of the most rapidly growing sectors in the city is the additive manufacturing industry, encompassing 3D printing services and 3D scanning services. These services are transforming industries such as healthcare, automotive, aerospace, architecture, and product design by offering cost-effective, precise, and innovative solutions.

In this blog, we will explore the significance of 3D printing services in Bangalore and 3D scanning services in Bangalore, their applications, and how they are shaping the future of manufacturing and design.

The Rise of 3D Printing Services in Bangalore

3D printing, also known as additive manufacturing, is a revolutionary technology that enables the creation of three-dimensional objects by layering materials based on a digital model. Over the past decade, Bangalore has emerged as a hub for 3D printing services, with numerous startups and established firms offering cutting-edge solutions.

Why is 3D Printing Gaining Popularity in Bangalore?

Technological Advancements: Bangalore’s strong IT and R&D ecosystem has fueled innovations in 3D printing, making it more accessible and efficient.

Cost-Effective Prototyping: Startups and businesses leverage 3D printing to create prototypes at a fraction of the cost of traditional manufacturing.

Customization & Rapid Production: Industries such as healthcare and fashion benefit from the ability to produce customized products quickly.

Sustainable Manufacturing: 3D printing reduces material waste, making it an environmentally friendly alternative to conventional methods.

Applications of 3D Printing in Bangalore

1. Healthcare & Medical

Custom prosthetics, dental implants, and anatomical models for surgical planning.

Bio-printing of tissues and organs for medical research.

2. Automotive & Aerospace

Rapid prototyping of components and lightweight parts for enhanced efficiency.

Reduction in production costs and lead times for vehicle and aircraft manufacturing.

3. Architecture & Real Estate

Creation of scaled models for visualization and design approval.

3D printing of construction materials for sustainable buildings.

4. Product Design & Engineering

Iterative prototyping for product development and functional testing.

On-demand manufacturing of customized consumer goods.

With the increasing demand for 3D printing services in Bangalore, service providers are expanding their capabilities to include SLA (Stereolithography), SLS (Selective Laser Sintering), FDM (Fused Deposition Modeling), and DMLS (Direct Metal Laser Sintering) technologies to cater to diverse industry requirements.

The Role of 3D Scanning Services in Bangalore

Alongside 3D printing, 3D scanning technology is playing a crucial role in industries that require precision and digital replication of physical objects. 3D scanning services in Bangalore are widely used for reverse engineering, quality inspection, and digital archiving.

What is 3D Scanning?

3D scanning is a process of capturing the shape and dimensions of an object using laser or structured light technology to create a digital 3D model. This data can be used for various applications, including quality control, CAD modeling, and digital twin creation.

Benefits of 3D Scanning Services in Bangalore

High Precision & Accuracy: Captures intricate details of objects with exceptional accuracy, essential for industries like aerospace and healthcare.

Time-Saving & Cost-Effective: Reduces manual measurement errors and accelerates the design and manufacturing process.

Reverse Engineering: Enables the recreation of legacy parts that lack CAD documentation.

Customization & Personalization: Facilitates the design of personalized medical implants, consumer products, and automotive parts.

Industries Utilizing 3D Scanning in Bangalore

1. Manufacturing & Engineering

Quality control and inspection of manufactured parts.

Reverse engineering to improve and reproduce legacy parts.

2. Healthcare & Biomechanics

Creation of personalized orthotics, prosthetics, and dental implants.

Digital modeling of human anatomy for medical research and training.

3. Art & Heritage Preservation

Digital restoration of historical artifacts and sculptures.

Virtual museums and AR/VR applications for cultural heritage conservation.

4. Education & Research

Enhanced learning through 3D models and virtual simulations.

Research in biomechanics, material science, and industrial design.

Leading 3D Printing and Scanning Service Providers in Bangalore

The 3D printing and 3D scanning service in Bangalore is thriving, with numerous companies offering specialized solutions. Some of the leading providers include:

Think3D: One of India’s top 3D printing and scanning service providers.

Intech Additive Solutions: Specializing in metal 3D printing and additive manufacturing.

Morphing Machines: Offering high-precision 3D scanning and reverse engineering.

Bangalore 3D: A local service provider offering rapid prototyping and product design solutions.

Fabheads: Focuses on composite 3D printing for aerospace and defense applications.

These companies cater to businesses of all sizes, from startups to large enterprises, providing customized solutions for their manufacturing and design needs.

The Future of Additive Manufacturing in Bangalore

The future of 3D printing and scanning services in Bangalore looks promising, driven by continuous advancements in technology and increased adoption across various industries. Some key trends to watch out for include:

Advancements in Metal 3D Printing: More industries, especially aerospace and automotive, will adopt metal 3D printing for high-performance parts.

AI and Automation Integration: AI-powered 3D scanning and printing will enhance precision, reduce material waste, and streamline workflows.

Sustainable Materials & Eco-Friendly Manufacturing: The shift towards biodegradable and recyclable materials in 3D printing will reduce environmental impact.

On-Demand & Distributed Manufacturing: Localized production through 3D printing hubs will minimize supply chain dependencies.

Medical Innovations: From bioprinting tissues to creating fully functional implants, 3D printing in healthcare will witness exponential growth.

Conclusion

The 3D printing and scanning industry in Bangalore is set to revolutionize the way products are designed, developed, and manufactured. Whether you're a startup looking for rapid prototyping or an enterprise seeking high-precision engineering solutions, 3D printing services in Bangalore and 3D scanning services in Bangalore offer unparalleled benefits.

With technological advancements, reduced costs, and increased accessibility, the adoption of additive manufacturing will continue to grow, solidifying Bangalore’s position as a leading hub for innovation and industrial transformation.

If you're looking to integrate 3D printing or 3D scanning into your business operations, now is the perfect time to explore the endless possibilities that these cutting-edge technologies offer.

Have you tried 3D printing or scanning services in Bangalore? Share your experiences in the comments below! 🚀

#Metal 3D printing in Bangalore#Additive Manufacturing in Bangalore#Additive Manufacturing Companies in Bangalore#3D Printing Service in Bangalore#3D Scanning Services in Bangalore#3D Scanning And Design in Bangalore#Best Trumpf TruPrint 1000 Metal 3D Printer#Best Trumpf TruPrint 2000 Metal 3D Printer#Best Trumpf TruPrint 3000 Metal 3D Printer#Best Trumpf TruPrint 5000 Metal 3D Printer

0 notes

Text

Direct Energy Deposition 3D Printing: Revolutionizing Manufacturing in the Energy Sector

In recent years, 3D printing has changed many industries, and one area seeing big changes is the energy sector. One of the most exciting technologies is called Direct Energy Deposition (DED) 3D printing. This method is changing how we make parts and products in the energy industry. In this blog post, we will explore what Direct Energy Deposition is, how it works, and why it is important for the future of manufacturing in the energy sector.

What is Direct Energy Deposition?

Direct Energy Deposition is a type of 3D printing that uses focused energy to melt materials and build up parts layer by layer. Unlike traditional 3D printing, which often starts with a solid block of material and carves out the shape, DED adds material. This process can use different types of materials, such as metals and plastics.

How Does Direct Energy Deposition Work?

The DED process involves several steps:

Energy Source: DED uses focused energy sources, like lasers or electron beams, to melt the material. This energy source is directed precisely onto the material being deposited.

Material Feed: Metal powders or wires are fed into the area where the energy is applied. As the energy source melts the material, it fuses with the layer below, creating a solid bond.

Layering: The machine moves in precise patterns to build the part layer by layer. This layering process allows for complex shapes and structures that are often difficult or impossible to create using traditional manufacturing methods.

Cooling: After each layer is added, it cools and solidifies quickly, allowing for faster production times.

Benefits of Direct Energy Deposition in the Energy Sector

Cost-Effective: DED can reduce material waste because it only uses the exact amount needed to create a part. This can lead to significant cost savings for energy companies.

Faster Production: DED allows for quicker manufacturing times. Parts can be produced in days rather than weeks, which is crucial in industries where time is money.

Customizable Parts: The ability to create complex shapes and designs means that energy companies can produce custom parts tailored to their specific needs. This flexibility can lead to better performance and efficiency.

Repair and Maintenance: DED can be used to repair existing parts instead of replacing them. This capability is especially valuable in the energy sector, where replacing large components can be expensive and time-consuming.

Sustainability: DED technology supports more sustainable manufacturing practices. By minimizing waste and allowing for repairs, it can help reduce the environmental impact of energy production.

Applications of Direct Energy Deposition in the Energy Sector

Oil and Gas: DED can be used to create complex parts for drilling equipment and pipelines. It can also repair worn-out components, extending their lifespan and reducing costs.

Renewable Energy: In wind turbines and solar panels, DED can produce lightweight and strong components. It can also help maintain these systems by repairing damaged parts quickly.

Nuclear Energy: DED can manufacture and repair components used in nuclear reactors. This ability ensures safety and efficiency in these critical systems.

Power Generation: The technology can produce specialized parts for turbines and generators, improving their performance and reliability.

Challenges and Considerations

While Direct Energy Deposition 3d printing has many advantages, it also faces some challenges:

Skill Gap: There is a need for skilled workers who understand DED technology and can operate the machinery effectively. Training is essential for companies looking to adopt this technology.

Initial Investment: Setting up DED systems can be expensive. Companies must weigh the long-term savings against the initial costs.

Material Limitations: Not all materials are suitable for DED. Research is ongoing to expand the range of materials that can be used effectively.

The Future of Direct Energy Deposition in the Energy Sector

The future looks bright for Direct Energy Deposition in the energy sector. As technology continues to advance, we can expect to see even more innovative applications. Companies that adopt DED will likely gain a competitive edge by reducing costs, speeding up production, and enhancing their ability to create custom parts.

In conclusion, Direct Energy Deposition 3D printing is revolutionizing manufacturing in the energy sector. With its ability to create complex, cost-effective parts quickly and sustainably, it is set to play a crucial role in the future of energy production. As the industry continues to evolve, embracing DED technology could lead to significant improvements in efficiency and innovation.

By understanding and utilizing this groundbreaking technology, energy companies can not only improve their operations but also contribute to a more sustainable future.

#metal additive manufacturing#ded metal 3d printing#ded additive manufacturing#direct energy deposition

0 notes