#metal additive manufacturing

Explore tagged Tumblr posts

Text

"Revolutionizing Industries with Additive Manufacturing and Metal 3D Printing Solutions"

Discover how Additive Manufacturing, including Metal 3D Printing and Metal Additive Manufacturing, is transforming production with innovative, efficient, and scalable solutions.

0 notes

Text

The Future of Additive Manufacturing in Military Technology and Innovation

Additive manufacturing, also known as 3D printing, is changing industries around the world. From healthcare to automotive, this technology has proven to be fast, flexible, and cost-effective. In recent years, the military has shown a strong interest in additive manufacturing, using it to create custom parts, equipment, and even complex systems. As 3D printing technology evolves, its potential in military technology and innovation continues to grow.

This blog will discuss how additive manufacturing is being used in the military today, its future potential, and the challenges that need to be overcome.

What is Additive Manufacturing?

Additive manufacturing is a process that creates objects by adding layers of material, one on top of the other, until the object is complete. Unlike traditional manufacturing, which often involves cutting away material to shape an object, additive manufacturing builds objects up from scratch. This process allows for highly customized parts and designs, making it perfect for the unique needs of the military.

Current Uses of Additive Manufacturing in the Military

Today, the military uses additive manufacturing in several key ways:

Quick Repairs and Parts Replacement: One of the biggest benefits of 3D printing in the military is the ability to make replacement parts on demand. When equipment breaks, it can take weeks or months to get replacement parts delivered to soldiers in the field. With 3D printing, these parts can be made in hours or days, getting equipment back in action faster.

Prototyping and Custom Designs: The military often needs specialized equipment, which can be costly and time-consuming to produce. Additive manufacturing allows the military to quickly create prototypes of new designs, test them, and make adjustments as needed. This flexibility saves time and money while allowing for more experimentation and innovation.

Medical Applications: Additive manufacturing can also create medical supplies and devices, like custom prosthetics or surgical tools. In combat zones, 3D printing can provide medical teams with specialized equipment quickly, improving the care of injured soldiers.

Lightweight and Complex Structures: Additive manufacturing enables the creation of lightweight structures that can still be very strong. This technology can produce complex shapes that are difficult or impossible to make with traditional methods, making it ideal for creating advanced weaponry, drones, and other military equipment.

Future Potential of Additive Manufacturing in the Military

The future of additive manufacturing in the military looks very promising. Here are some exciting possibilities:

On-Site Production: In the future, military bases could be equipped with 3D printers to produce needed items directly on-site. This could allow soldiers to make parts, tools, and other items as needed, reducing supply chain dependency and response times. It could also mean that soldiers in remote or dangerous locations won’t need to wait for supplies, as they can make what they need right where they are.

Advanced Materials: As 3D printing materials improve, additive manufacturing could create parts with stronger, more durable materials. For example, researchers are working on ways to print with metal alloys, ceramics, and even materials that can conduct electricity. These advanced materials could allow the military to produce more resilient equipment that lasts longer and performs better under harsh conditions.

Drones and Autonomous Vehicles: The military is increasingly using drones and autonomous vehicles for tasks like surveillance and reconnaissance. Additive manufacturing allows for quick production of lightweight, complex parts, which are ideal for drones and other aerial devices. In the future, 3D-printed drones could be used in a variety of ways, from delivering supplies to exploring dangerous areas without putting soldiers at risk.

Bioprinting for Medical Advancements: Bioprinting, a type of 3D printing that uses cells to create tissue, is still in its early stages, but it has potential military applications. In the future, military medical teams might use bioprinting to create skin grafts or other tissue on-site, helping soldiers recover more quickly from injuries.

Challenges Facing Additive Manufacturing in the Military

While the future of additive manufacturing in the military is promising, there are still challenges to overcome:

Quality and Consistency: 3D-printed parts must meet high standards, especially in the military, where failure can mean the difference between life and death. Ensuring that printed parts are as strong and reliable as traditionally manufactured parts is a major challenge.

Cybersecurity Risks: Since 3D printing relies on digital files, there is a risk of cyberattacks. Hackers could potentially alter designs or access sensitive military information. To counter this, the military needs to invest in secure systems to protect its 3D printing operations.

Training and Knowledge: To fully benefit from additive manufacturing, the military needs skilled technicians and engineers who understand the technology. Training soldiers and military staff to operate 3D printers and design parts is essential for the widespread adoption of this technology.

Cost of Advanced Materials and Printers: While 3D printing can be cost-effective, the materials and equipment needed for advanced military applications can be expensive. Investing in these resources requires a strong commitment and careful budgeting by military organizations.

Conclusion: A New Era of Military Innovation

Additive manufacturing offers many exciting possibilities for the military, from on-site production to the creation of complex, lightweight structures. As the technology advances, it could help the military become more flexible, cost-effective, and innovative.

However, for additive manufacturing to reach its full potential in military applications, challenges like quality control, cybersecurity, and high costs need to be addressed. With the right investments and strategies, additive manufacturing could become an essential part of the future of military technology, helping to keep soldiers safer and more effective in the field.

The future of additive manufacturing in military technology is bright, and it’s only a matter of time before we see even more groundbreaking applications that change the way the military operates.

#metal additive manufacturing#ded metal 3d printing#ded additive manufacturing#additive manufacturing military

0 notes

Text

Metal Additive Manufacturing Market is Estimated to Witness High Growth Owing to Reduced Production Costs

Metal additive manufacturing, also known as 3D metal printing, enables the fabrication of complex metal components using a digital file and successive layering of material under computer control. Manufacturers can produce intricate components with conformal cooling passages, lattice structures, and optimized designs that provide weight savings. As additive manufacturing reduces waste by building only the desired part geometry, it helps lower production costs compared to traditional subtractive methods such as milling and machining. The metal additive manufacturing market encompasses technologies such as direct metal laser sintering, electron beam melting, and binder jetting, among others. Manufacturers across industries adopt these technologies to produce prototypes and end-use products. Due to the potential for mass individualization and supply chain resilience, metal 3D printing demand is growing across automotive, aerospace, healthcare, and industrial equipment verticals.

Global metal additive manufacturing market is estimated to be valued at USD 5.85 Bn in 2024 and is expected to reach USD 14.37 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 13.7% from 2024 to 2031.

Key Takeaways Key players operating in the metal additive manufacturing market are GE Additive, 3D Systems, Desktop Metal, EOS GmbH, Renishaw, SLM Solutions, Stratasys, Markforged, Velo3D, DMG Mori, HP Inc., TRUMPF, ExOne (a Desktop Metal company), Materialise, Formlabs, Norsk Titanium, Optomec, Prima Additive, XJet, and VulcanForms. These players focus on expanding their production capacities and service offerings to tap growing metal 3D printing demand. Key opportunities in the Metal Additive Manufacturing Market Trends include leveraging additive manufacturing to produce jigs, fixtures, and tooling for customized production. The technology enables on-demand manufacturing, reducing inventory costs. Further, 3D metal printing facilitates the direct production of end-use implants, prosthetics, and medical devices to improve patient outcomes. Geographically, the metal additive manufacturing market witnesses high growth in North America and Europe due to early technology adoption. However, Asia Pacific is emerging as an attractive market with huge potential, led by government initiatives driving advanced manufacturing. As the technology matures, global metal 3D printing adoption will continue increasing across industries. Market Drivers Reduced production costs with additive manufacturing compared to traditional methods is a key market driver. 3D printing eliminates the need for expensive tooling and reduces waste. It facilitates mass customization by producing different parts using the same production method. Furthermore, additive manufacturing enables the production of complex parts with optimised lightweight designs that provide performance and efficiency benefits. Metal Additive Manufacturing Market Size and Trends technology helps improve design flexibility, reduce lead times, and support supply chain resilience. All these advantages are fueling increased investment in metal 3D printing globally.

PEST Analysis Political: Metal additive manufacturing faces regulations regarding product quality and safety. Regulators aim to establish standards without stifling innovation. Economic: Metal 3D printing reduces waste and improves design flexibility compared to traditional manufacturing. It allows on-demand production and reduces lengthy supply chains. Social: Additive manufacturing increases access to custom-tailored solutions in industries like healthcare, consumer products, and education. It facilitates distributed manufacturing closer to end users. Technological: Advancements in metal powder composition, laser melting techniques, and printer capabilities continue increasing build size and throughput. Computer-aided design tools are optimizing machine parameters for new material formulations. Europe Europe is a major regional market, where aerospace and automotive sectors in Germany, Italy, and UK drive significant adoption of metal 3D printing technology, particularly for prototyping and low-volume production applications. Government support for advanced manufacturing research further boosts the regional market. Asia Pacific The Asia Pacific region is anticipated to witness the fastest growth over the forecast period due to rising focus on industrial modernization across industries in countries such as China, Japan, and South Korea. Establishment of local manufacturing facilities by global players also expands the regional market.

Get more insights on Metal Additive Manufacturing Market

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Coherent Market Insights#Metal Additive Manufacturing Market#Metal Additive Manufacturing#Metal AM#3D Printing Metals#Metal Fabrication#Industrial 3D Printing#Metal Prototyping#Metal Additive Processes

0 notes

Text

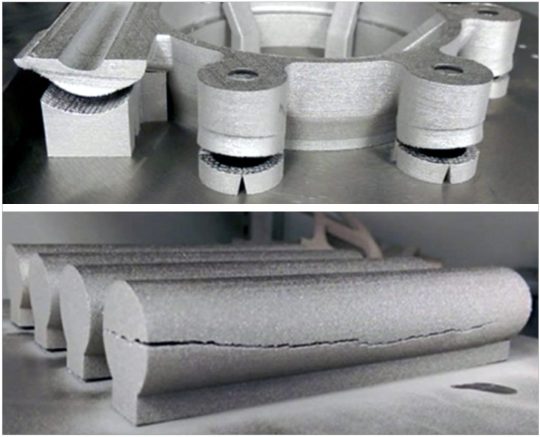

Residual Stress in Metal Additive Manufacturing

One manufacturing process in particular that needs to pay close attention to residual stresses is the fairly new field of metal additive manufacturing (AM). Most metal AM processes involve high thermal gradients and fast cooling rates, which can lead to high residual stresses in parts. These stresses can be severe enough to cause failure even during the build process, or immediately upon cooling, before parts have even been removed from the build plate. Residual stresses have been said to be the most common cause of catastrophic failure of metal AM parts. As such, heat treatments before parts are removed from the build plate are common, including heat treatments known as 'stress relieving'.

Sources/Further Reading: (Image source - Metal AM) (2022 article)

#Materials Science#Science#Stress and strain#Materials failure#Additive manufacturing#Metals#FailureFriday#2024Daily

33 notes

·

View notes

Text

Italian multinational group Legor is now using 3D technology to create jewelry and fashion accessories made from 100% precious metals from recycled sources, making progress toward its goals of enabling a circular economy.

#solarpunk#solarpunk business#solarpunk business models#solar punk#reculture#italy#recycled precious metal#3D printing#additive manufacturing

9 notes

·

View notes

Text

Unveiling Aurora Labs' AL250: A Leap Forward in Metal 3D Printing

Australian innovator Aurora Labs steals the spotlight with its groundbreaking AL250 metal 3D printer launch at Formnext 2023. Buckle up for a ride through the realms of aerospace, defence, oil and gas, engineering, and bespoke production runs as we explore the incredible features of this cutting-edge technology. The AL250 Say goodbye to the RMP-1 and welcome the AL250, Aurora Labs‘ latest laser…

View On WordPress

4 notes

·

View notes

Text

some thoughts about Clothes For Horses

out of practicality the average ironwall citizen wears a blanket made for horses (even if they are not horses). the blankets are bulk-ordered by specialist ironwall tailor shops and modified on the premises, sometimes while the customer is waiting. the modifications lengthen the straps so that they can be easily reached. this is considered okay for casualwear but tacky for formal occasions.

the upper body can usually just wear whatever mass produced human clothing they like. the only item of clothing which is made specifically for these guys is the waist sash (sometimes with an additional cloth drape on the front, which can smarten up an outfit). these are people whose culture has a deep seam of embarrassment at being part animal, and this fact should be hidden if at all possible even though it isn't possible but you just have to try. the junction between fur and skin is always hidden. the orange blanket pictured above is about as skimpy as you could get away with in public. mane hair is usually shaved off for practicality's sake.

for practical work where harnesses and tack are required, these are usually worn over blankets and modified to include no reins/other control apparatus. for those for whom it is possible, horse-shoes are worn on the front feet for daily city life, and on all feet for hard manual labour or any activities/hobbies/etc which require good traction on the hind legs. shoes are usually not made of metal but of a composite into which grip studs can be inserted if necessary. the imagery of hard metal shoes is associated with counterculture movements and sometimes if you wanna look hard you can have your shoes spraypainted to be shiny. barefoot is actually fine in most circumstances

dedicated centaur clothing is stupid expensive because very few manufacturers produce it and the fabric yardage is insane so it is a class signifier. the garment shape & purpose is unisex though due to influence from dominant human cultures in the area, there's still a difference between a Stallion's Manly Robes and a Demure Filly Dress. ideally the full body is covered and the overall impression is of a human strapped to some mysterious shape idk what could possibly be under there. normal human legs i bet.

1K notes

·

View notes

Text

Delivering Excellence with Direct Metal Laser Sintering (DMLS) |Additive Manufacturing Solutions| Wipro-3D

Wipro 3D offers additive manufacturing solutions based on direct metal laser sintering(DMLS) technology. Which helps to deliver exceptional accuracy, speed, and quality.

Read more:

#wipro-3d#3-d printing#Metal additive Technologies#Direct Metal Laser Sintering#Additive Manufacturing Solutions

0 notes

Link

Veer O Metals was established in 1965. We are engaged in the manufacture of Stamped Parts, Precision Sheet Metal Fabrication Parts, Machined Components and Mechanical Assemblies. We have an in-house strong Mechanical Engineering and Manufacturing team for Design and Development, dedicated in providing high end design solutions which are industry specific.

We have established a strong client base at National and International level with our transparent and Global practices, and at the same time retaining robust quality management systems. By developing indigenously designed products of global standards for various sectors, we have added a new dimension to our already existing wide range of product manufacturing and assemblies.

With a core principle of innovation and enhanced technology, Veero always has been at the forefront in embracing the newest trends in the industry. Introducing first of its kind Metal Additive Manufacturing (Metal 3D Printing). Veero has augmented cutting edge manufacturing technology in the field of metal additive manufacturing. It is a Disruptive Technology, which is an automatic process of manufacturing objects (Parts, Prototypes, tools & even assemblies) directly from their CAD models without any cutter, tools and jigs & fixtures.

From inventions to innovations, energy responsibility to environment stewardship, Veer O Metals is well positioned to be a technology leader in manufacturing of sheet metal fabrication parts and mechanical assemblies.

We are proud to mention that we are the most preferred partner for our clients. We have state of the art manufacturing locations in India and Philippines.

Our core activities have been in:

Stamping Components

Precision Sheet Metal Fabrication Parts

Enclosures

Industrial and IT Racks

Mechanical Assemblies

Machined Components

Veer O Products

Metal Additive Manufacturing ( 3D Printing )

Our approach to manufacturing excellence entails stringent quality checks and continual improvements.

#post processing of 3d printed#additive manufacturing company#additive manufacturing application#metal 3d printing companies in bangalore#materials used in additive manufacturing#dmls machine cost in india#3d priniting post processing services#dmls printer manufacturers#metal manufacturers in india#metal 3d printing in chennai#3d metal printing machine manufacturers#metal 3d printing process#3d printing in defence industry#metal companies in india#metal 3d printing in mumbai#metal 3d printing services in india#3d metal printing near me#metal 3d printing materials#additive manufactured products#metal 3d printing manufacturing#metal 3d printing companies in india#metal 3d printing service bangalore#additive manufacturing company in india#additive manufacturing companies in bangalore#additive manufacturing service in india#metal 3d printing bangalore#metal additive manufacturing systems#additive manufacturing metal parts#additive metal 3d printing#metal additive manufacturing machine

0 notes

Text

Revolutionizing Production with Additive Manufacturing and Metal 3D Printing

The manufacturing landscape is evolving rapidly, and at the forefront of this transformation is Additive Manufacturing, often referred to as Metal 3D Printing when applied to metal fabrication. This groundbreaking technology has changed the way industries approach design, prototyping, and production, offering unprecedented flexibility and efficiency.

What is Additive Manufacturing?

Additive Manufacturing involves creating three-dimensional objects by layering material, typically guided by computer-aided design (CAD) models. Unlike traditional subtractive methods that cut away material, additive techniques build items layer by layer, reducing waste and enabling intricate designs.

The Role of Metal 3D Printing in Modern Manufacturing

One of the most promising subsets of additive technology is Metal 3D Printing. This process allows manufacturers to create high-strength, complex parts using metals such as titanium, aluminum, and stainless steel. It is particularly valuable in industries like aerospace, automotive, and healthcare, where precision and durability are critical.

Key Benefits of Metal Additive Manufacturing

Design Flexibility: Engineers can create intricate geometries that are impossible with traditional manufacturing techniques.

Material Efficiency: By using only the required material, Metal Additive Manufacturing reduces waste significantly.

Cost Savings: For low-volume production or prototyping, Additive Manufacturing can be more cost-effective than traditional methods.

Speed: Rapid prototyping enables faster innovation and reduced time-to-market for new products.

Real-World Applications of Metal Additive Manufacturing

Aerospace: Lightweight components that withstand extreme conditions.

Healthcare: Custom implants and prosthetics tailored to patient-specific needs.

Automotive: High-performance parts for electric and traditional vehicles.

The Future of Additive Manufacturing

As technology advances, the potential of Additive Manufacturing continues to grow. From improving sustainability to enabling mass customization, its applications are limitless. Companies investing in Metal 3D Printing are not just adapting—they’re leading the charge into a new era of innovation.

By leveraging the power of Metal Additive Manufacturing, businesses can remain competitive, efficient, and forward-thinking in an ever-evolving market.

0 notes

Text

Direct Energy Deposition 3D Printing: Revolutionizing Manufacturing in the Energy Sector

In recent years, 3D printing has changed many industries, and one area seeing big changes is the energy sector. One of the most exciting technologies is called Direct Energy Deposition (DED) 3D printing. This method is changing how we make parts and products in the energy industry. In this blog post, we will explore what Direct Energy Deposition is, how it works, and why it is important for the future of manufacturing in the energy sector.

What is Direct Energy Deposition?

Direct Energy Deposition is a type of 3D printing that uses focused energy to melt materials and build up parts layer by layer. Unlike traditional 3D printing, which often starts with a solid block of material and carves out the shape, DED adds material. This process can use different types of materials, such as metals and plastics.

How Does Direct Energy Deposition Work?

The DED process involves several steps:

Energy Source: DED uses focused energy sources, like lasers or electron beams, to melt the material. This energy source is directed precisely onto the material being deposited.

Material Feed: Metal powders or wires are fed into the area where the energy is applied. As the energy source melts the material, it fuses with the layer below, creating a solid bond.

Layering: The machine moves in precise patterns to build the part layer by layer. This layering process allows for complex shapes and structures that are often difficult or impossible to create using traditional manufacturing methods.

Cooling: After each layer is added, it cools and solidifies quickly, allowing for faster production times.

Benefits of Direct Energy Deposition in the Energy Sector

Cost-Effective: DED can reduce material waste because it only uses the exact amount needed to create a part. This can lead to significant cost savings for energy companies.

Faster Production: DED allows for quicker manufacturing times. Parts can be produced in days rather than weeks, which is crucial in industries where time is money.

Customizable Parts: The ability to create complex shapes and designs means that energy companies can produce custom parts tailored to their specific needs. This flexibility can lead to better performance and efficiency.

Repair and Maintenance: DED can be used to repair existing parts instead of replacing them. This capability is especially valuable in the energy sector, where replacing large components can be expensive and time-consuming.

Sustainability: DED technology supports more sustainable manufacturing practices. By minimizing waste and allowing for repairs, it can help reduce the environmental impact of energy production.

Applications of Direct Energy Deposition in the Energy Sector

Oil and Gas: DED can be used to create complex parts for drilling equipment and pipelines. It can also repair worn-out components, extending their lifespan and reducing costs.

Renewable Energy: In wind turbines and solar panels, DED can produce lightweight and strong components. It can also help maintain these systems by repairing damaged parts quickly.

Nuclear Energy: DED can manufacture and repair components used in nuclear reactors. This ability ensures safety and efficiency in these critical systems.

Power Generation: The technology can produce specialized parts for turbines and generators, improving their performance and reliability.

Challenges and Considerations

While Direct Energy Deposition 3d printing has many advantages, it also faces some challenges:

Skill Gap: There is a need for skilled workers who understand DED technology and can operate the machinery effectively. Training is essential for companies looking to adopt this technology.

Initial Investment: Setting up DED systems can be expensive. Companies must weigh the long-term savings against the initial costs.

Material Limitations: Not all materials are suitable for DED. Research is ongoing to expand the range of materials that can be used effectively.

The Future of Direct Energy Deposition in the Energy Sector

The future looks bright for Direct Energy Deposition in the energy sector. As technology continues to advance, we can expect to see even more innovative applications. Companies that adopt DED will likely gain a competitive edge by reducing costs, speeding up production, and enhancing their ability to create custom parts.

In conclusion, Direct Energy Deposition 3D printing is revolutionizing manufacturing in the energy sector. With its ability to create complex, cost-effective parts quickly and sustainably, it is set to play a crucial role in the future of energy production. As the industry continues to evolve, embracing DED technology could lead to significant improvements in efficiency and innovation.

By understanding and utilizing this groundbreaking technology, energy companies can not only improve their operations but also contribute to a more sustainable future.

#metal additive manufacturing#ded metal 3d printing#ded additive manufacturing#direct energy deposition

0 notes

Text

"Clothing tags, travel cards, hotel room key cards, parcel labels … a whole host of components in supply chains of everything from cars to clothes. What do they have in common? RFID tags.

Every RFID (Radio Frequency Identification) tag contains a microchip and a tiny metal strip of an antenna. A cool 18bn of these are made – and disposed of – each year. And with demands for product traceability increasing, ironically in part because of concerns for the social and environmental health of the supply chain, that’s set to soar.

And guess where most of these tags end up? Yup, landfill – adding to the burgeoning volumes of e-waste polluting our soils, rivers and skies. It’s a sorry tale, but it’s one in which two young graduates of Imperial College London and Royal College of Art are putting a great big green twist. Under the name of PulpaTronics, Chloe So and Barna Soma Biro reckon they’ve hit on a beguilingly simple sounding solution: make the tags out of paper. No plastic, no chips, no metal strips. Just paper, pure and … simple … ? Well, not quite, as we shall see.

The apparent simplicity is achieved by some pretty cutting-edge technical innovation, aimed at stripping away both the metal antennae and the chips. If you can get rid of those, as Biro explains, you solve the e-waste problem at a stroke. But getting rid of things isn’t the typical approach to technical solutions, he adds. “I read a paper in Nature that set out how humans have a bias for solving problems through addition – by adding something new, rather than removing complexity, even if that’s the best approach.”

And adding stuff to a world already stuffed, as it were, can create more problems than it solves. “So that became one of the guiding principles of PulpaTronics”, he says: stripping things down “to the bare minimum, where they are still functional, but have as low an environmental impact as possible”.

...how did they achieve this magical simplification? The answer lies in lasers: these turn the paper into a conductive material, Biro explains, printing a pattern on the surface that can be ‘read’ by a scanner, rather like a QR code. It sounds like frontier technology, but it works, and PulpaTronics have patents pending to protect it.

The resulting tag comes in two forms: in one, there is still a microchip, so that it can be read by existing scanners of the sort common within retailers, for example. The more advanced version does away with the chip altogether. This will need a different kind of scanner, currently in development, which PulpaTronics envisages issuing licences for others to manufacture.

Crucially, the cost of both versions is significantly cheaper than existing RFID kit – making this a highly viable proposition. Then there are the carbon savings: up to 70% for the chipless version – so a no-brainer from a sustainability viewpoint too. All the same, industry interest was slow to start with but when PulpaTronics won a coveted Dezeen magazine award in late 2023, it snowballed, says So. Big brands such as UPS, DHL, Marks & Spencer and Decathlon came calling. “We were just bombarded.” Brands were fascinated by the innovation, she says, but even more by the price point, “because, like any business, they knew that green products can’t come with a premium”."

-via Positive.News, April 29, 2024

--

Note: I know it's still in the very early stages, but this is such a relief to see in the context of the environmental and human rights catastrophes associated with lithium mining and mining for rare earth metals, and the way that EVs and other green infrastructure are massively increasing the demand for those materials.

I'll take a future with paper-based, more humane alternatives for sure! Fingers crossed this keeps developing and develops well (and quickly).

#I do really wish it could be read by regular scanners already though#that's what I thought at first#and that would've been fucking amazing#but this is still pretty cool#electronics#science and technology#green technology#ewaste#landfill#lithium#lithium mining#human rights#environment#climate action#climate hope#rfid#rfid technology#rfid tags#good news#hope

451 notes

·

View notes

Text

Novel etching technique enhances absorptivity of powders for metal 3D-printing

In a significant advancement for metal additive manufacturing, researchers at Lawrence Livermore National Laboratory (LLNL) and their academic partners have developed a technique that enhances the optical absorptivity of metal powders used in 3D printing. The approach, which involves creating nanoscale surface features on metal powders, promises to improve the efficiency and quality of printed metal parts, particularly for challenging materials like copper and tungsten, according to researchers. Additive manufacturing (AM)—more commonly known as 3D printing—has transformed the way products are designed and produced, allowing for the creation of complex geometries and customized components that traditional manufacturing methods struggle to achieve.

Read more.

#Materials Science#Science#Powder#3D printing#Additive manufacturing#Etching#Absorptivity#Metals#Copper

13 notes

·

View notes

Text

(SOMEWHAT) LESSER KNOWN FACTS ABOUT COLUMBINE AND THE AFTERMATH.

Note: this post is purely for educational purposes. Do your best to be normal, thanks.

(facts under the cut)

• John Savage, who was asked to identify himself in the library by Eric, and shortly after spared by Dylan, would go on to become a sex offender. He’s on the registry, but the incident itself happened in North Carolina. (This would actually be the second instance of a survivor of Columbine becoming a SO, with the first being Brooks Brown.)

• Days before the shooting, Daniel Mauser would discuss the gunshow loophole with his father- the same loophole that would lead to his death.

• Cassie Bernall suffered from homicidal ideations, she was sent to therapy and claimed that finding Jesus helped her manage these thoughts.

• The police cleaned out Eric’s house before viewing the Basement Tapes. After they viewed them, they realized they missed an entire section of the house, and had to return to gather the rest of the weapons.

• Chris Morris found out about the shooting through the news that day, as it was happening. Allegedly, he immediately realized Eric and Dylan were behind it- he tried to go to the school and attempt to talk them out of it, but the police wouldn’t let him enter.

• Eric, despite his journal entries, was not the women hating guy a lot of people seem to believe. Dylan, on the other hand, had a track-record of hitting girls. One of these girls was named Michele, his manager (or supervisor) at Blackjack pizza. Upon Michele writing him up, Dylan hit her. Dylan also allegedly hit a girl in gym class, and Eric called him out for it.

• After all was said and done, the police had all the casualties in body bags. Eric and Dylan were placed in a separate room so that their victims wouldn’t be near them. At the end, there was one victim and one shooter left- the police ordered an additional ambulance so that the victim wouldn’t be in an ambulance with their killer.

• As soon as Eric and Dylan’s bodies were brought out of the school, it started snowing- which isn’t very common for that time of year in Colorado.

• The weather on 04/20/1999 was poor, to say the least. Columbine had a digital sign board, where a “thought of the day” was shown. On the day of the massacre, it read some variation of “It’s a great day to not be here” / “Today is the day you wish you weren’t here” - this was referring to the weather, but it doesn’t make it any less unsettling.

• There was an armed security guard, Neil Gardner, at Columbine that day, but when the shooting started, he was in his car eating lunch on the other side of the parking lot. He ended up being the one to exchange gunfire with Eric near the West doors.

• Eric had a Shakespeare quote in his calendar for the Mother’s Day after Columbine. It read “good wombs have borne bad sons.”

• Eric and Dylan had a “distraction” bomb in a field roughly 3 miles away. The original plan was that cops would be called to that location rather than Columbine. It failed to go off, but if it had (as well as the various bombs placed around the school) the death toll would have been much higher.

• The only reason the bombs failed was because of one object. The alarm clocks they used, which usually contain metal, had been switched to a plastic part by the manufacturer. The metal part is what was needed to make the bombs go off.

• This one is quite well known, but there’s a theory that Rachel was doomed regardless. Two years after Columbine, the subway she worked at had two people murdered inside of it- one, an employee, and the other, his girlfriend. They both attended Columbine. The killer was never found, and nobody else was injured. “Subway Murders Columbine” if you’d like to read more about this.

# Thank you for reading! I’m not sure how much of these facts are “lesser known” but I very rarely see people talk about them, if at all, so I thought I’d bring them up. If you have any questions about these, feel free to let me know, I will do my best to answer them. I genuinely have forgotten how to grow a following on here, I’m getting desperate.

#tcc#tcc tumblr#tcc columbine#tccblr#dylan columbine#eric columbine#columbine school shooting#columbine 1999#true crime#true cringe community#teeceecee#columbine massacre#columbine high massacre#eric and dylan#eric 1999#dylan 1999#shadowsresearch

152 notes

·

View notes

Text

Desktop Metal Faces NYSE Scrutiny

Introduction: Hey folks, buckle up for some recent news from the stock market! You know, the kind that raises eyebrows and triggers a flurry of discussions? So, here’s the scoop: Desktop Metal has landed on the New York Stock Exchange’s (NYSE) radar due to a bit of a hiccup in its stock price. Let’s dive into the details and unravel what’s been going on. Desktop Metal’s NYSE Spotlight In a…

View On WordPress

1 note

·

View note