#metal 3d printing rapid prototyping

Explore tagged Tumblr posts

Quote

ADDITIVE MANUFACTURING & 3D PRINTING

#3d metal printing companies#3d priniting post processing services#additive manufacturing companies in bangalore#additive manufacturing service in india#additive metal 3d printing#metal 3d printing companies in bangalore#metal 3d printing companies in india#metal 3d printing in rapid prototyping#metal 3d printing india#metal 3d printing rapid prototyping#metal 3d printing raw material#metal 3d printing service bangalore#metal 3d printing services in india#metal additive manufacturing service providers#post processing of 3d printed

0 notes

Text

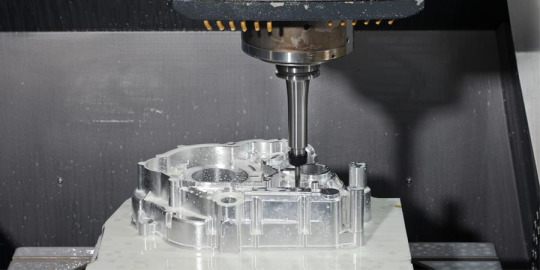

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Advantages & Applications of Metal 3D Printing

Metal 3D printing is an additive manufacturing technology that creates three-dimensional objects by stacking metal powders layer by layer. In metal 3D printing, metal powders such as titanium, aluminium and stainless steel are usually used as raw materials, which are melted and shaped by a laser or other high-energy beam stream.

With the continuous development of 3D printing technology, metal 3D printing is gaining attention as an important manufacturing process in industry. It allows the direct conversion of digitized models into metal parts. Metal 3D printing technology has many advantages over traditional manufacturing techniques.

1.Advantages of Metal 3D Printing ①High Manufacturing Efficiency Metal 3D printing technology can produce complex metal parts in a short period of time. Compared to traditional manufacturing techniques, it does not require additional machining steps and therefore significantly reduce the production cycle time. At the same time, product development from design to printing rarely requires human intervention due to the use of digital design processes, it is important for the design verification of new products, as well as small batch production, which can greatly shorten the time-to-market and improve competitiveness.

②Reduced Production Costs Metal 3D printing technology can reduce costs by saving materials and reducing labour intervention. Compared to traditional manufacturing techniques, metal 3D printing technology can make better use of materials and avoid wastage. It can also reduce costs by reducing manual intervention and links on mechanical processing and assembly among others as it can be designed and manufactured through a digital process. It can accurately control the use of materials according to actual needs, avoiding the waste of large amounts of material in traditional cutting processing, improving material utilisation and reducing costs.

③Customized Production Metal 3D printing can be customized to produce parts or products with specific shapes, specifications and properties to meet the needs of different fields. Compared to traditional manufacturing techniques, it does not require additional moulds and equipment, and can significantly increase production efficiency, while also meeting the individual needs of customers.

④Increased Design Diversity Metal 3D printing technology has made it possible to significantly reduce design constraints in the manufacturing process. It enables more complex, precise and detailed structures than traditional manufacturing methods, such as openwork, curved surfaces, and porous structures, which can dramatically improve the performance and longevity of materials. It allows the use of a wide range of metal materials, including titanium alloys, aluminium alloys, stainless steel, cobalt-chromium alloys and more, providing greater design freedom and application flexibility.

⑤Excellent Mechanical Properties Metal 3D printing technology makes the internal organisation of the formed part uniform and dense through the rapid solidification process, with excellent mechanical properties and corrosion resistance, and is able to increase strength without loss of plasticity. Compared to traditional manufacturing techniques, metal 3D printing technology provides better control over product quality and reduces the rate of product defects.

2.Applications of Metal 3D Printing ①Manufacturing Industry Metal 3D printing technology is widely used in the manufacturing industry. It can be used to produce automotive parts, aircraft parts, and a variety of mechanical parts, among others. In addition, it can also be used to manufacture some complex structural parts, such as gears, reducers and so on.

②Medical Industry Metal 3D printing technology also has a wide range of applications in the medical industry. It can be used to create prosthetics, teeth, implants, etc. Metal 3D printing technology can be better adapted to the individual needs of patients than traditional production methods.

③Aerospace Industry Metal 3D printing technology is also widely used in the aerospace industry. It can be used to manufacture a number of complex structural parts, fuel nozzles and turbine blades, among others. Compared with the traditional manufacturing technology, metal 3D printing technology can better control the quality of the products and improve the accuracy of the products.

④Construction Industry Metal 3D printing technology has a wide range of applications in the construction industry as well. It can be used to manufacture building structural parts, doors and windows, etc. Compared with traditional manufacturing methods, metal 3D printing technology can better meet the individual needs of customers and can significantly reduce the production cycle.

Metal 3D printing technology has significant advantages in terms of high manufacturing efficiency, rapid prototyping, customized production, material utilization and sustainability, but it also suffers from drawbacks such as slow manufacturing speeds and difficulties in subsequent processing. In practical application, it is necessary to comprehensively consider its advantages and disadvantages and select suitable applications to maximize its advantages.

#design#business#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#3d printed#3d printing#3d printing services#3d printing plastics market#metal 3d printing#rapid prototype

1 note

·

View note

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Overview of Metal 3D Printing Services

Metal 3D printing (DMLS) services have reshaped the manufacturing industry by offering innovative and efficient solutions for creating complex metal components. This technology, also known as additive manufacturing or metal additive manufacturing, has gained global acknowledgement for its ability to produce intricate and functional metal parts, previously thought impossible through conventional manufacturing methods.

Metal 3D printing services involve the layer-by-layer deposition of metal powders or wire to build three-dimensional objects. The process begins with a digital design or 3D model of the desired component. This model is sliced into thin horizontal layers using computer-aided design (CAD) software, and the 3D printer follows these instructions to create the final product. The range of metals that can be used in metal 3D printing is extensive and includes stainless steel, titanium, aluminum, copper, and more.

One of the primary advantages of metal 3D printing services is the ability to produce highly complex geometries. Traditional manufacturing processes often require extensive tooling and machining, which limits design possibilities. Metal 3D printing eliminates these constraints, making it possible to create detailed and customized parts with precision and consistency. This capability is especially valuable in industries such as aerospace, automotive, and healthcare, where components must meet specific requirements and standards.

Another benefit of metal 3D printing services is the reduction in material wastage. Unlike subtractive manufacturing processes, which often generate a significant amount of scrap. Metal 3D printing is an additive process. This means that only the necessary material is used, minimizing waste, and saving costs. Additionally, metal 3D printing allows for more efficient use of expensive and exotic materials, as they can be deposited only where needed, further reducing production expenses.

Furthermore, metal 3D printing services offer faster turnaround times compared to traditional manufacturing methods. The ability to produce prototypes and end-use parts quickly has made it a preferred choice in industries where rapid product development is crucial. It enables manufacturers to iterate designs rapidly and respond to market demands with agility.

Quality control and consistency are essential in manufacturing, and metal 3D printing services are equipped with advanced monitoring and quality assurance tools. These machines can ensure the production of high-quality, defect-free parts, reducing the risk of human error and inconsistencies commonly found in traditional manufacturing processes.

In terms of applications, metal 3D printing services have a wide range of uses. Aerospace companies use it to create lightweight yet durable components for aircraft and spacecraft. The automotive industry relies on it for producing customized parts for racing cars, reducing weight, and improving performance. Healthcare professionals use metal 3D printing to create patient-specific implants and prosthetics. Moreover, it's becoming increasingly popular in the jewelry and fashion industry for crafting unique and intricate designs.

In conclusion, metal 3D printing services have transformed the manufacturing industry, offering a cost-effective, efficient, and versatile way to produce metal components. Its ability to create complex geometries, minimize material waste, provide rapid turnaround times, and maintain high-quality standards makes it a powerful tool for various industries. As technology continues to evolve and become more accessible, the possibilities for innovation and customization are limitless, making it an essential part of the modern manufacturing ecosystem.

It is great to know that because of the additive nature of the 3D printing process, it offers greater design flexibility compared to conventional manufacturing methods. To fully harness the potential of HLH's cutting-edge technologies, it's advisable to tailor your 3D model to suit the process.

Create customized 3D printed prototypes and production parts made from metal and plastic, with a turnaround time as fast as 2 days! Do you want to get a Free Instant Quote? Visit our website at www.hlhrapid.com or send an email to [email protected].

0 notes

Text

What is the Process of DMLS 3D Printing

Direct metal laser sintering (DMLS) is an industrial additive manufacturing technology that builds parts from metals. The process crafts the tangible version of your design one layer at a time by sintering the powdered metals. Because of this, DMLS 3D printing can achieve highly complex shapes, which may be more challenging or impossible to make with other methods. That makes it worth considering, especially when you want to understand how a metal part or product functions or looks.

Create functional prototypes

Like selective laser sintering, DMLS is ideal for crafting rapid prototypes and low-volume end-use components. The difference between them is the materials used for printing the parts. Reputable service providers offer a range of materials, such as stainless steel, tool steel, aluminum, copper, and titanium.

How does it work?

DMLS 3D printing follows the standard sequence of processes for most additive manufacturing technologies: modeling, slicing, and printing one layer at a time. After creating a 3D model and slicing it with software, the code is sent to the printer to commence printing.

The printer is filled with your chosen metal powder heated to an ideal sintering range temperature of the alloy. Inert gas protects the heated powder and the component as it is constructed in the build chamber.

The building process starts when the printer dispenses a thin layer of metal powder onto the build chamber for the laser to selectively sinter the material into a solid state, continuing until the part is complete. After which, the component cools, and the loose metal powders are removed.

DMLS has specific capabilities and design guidelines. Be sure to check with the service provider to be guided accordingly. Ask about sizes, layer thickness, tolerances, and surface finishes. It also helps to be familiar with the material options, expertise, scale, project management capabilities, and the quality control process of the service provider.

Applications

DMLS 3D printing is extensively used in aerospace, medical, and automotive industries with needs like part consolidation and weight-saving applications. It’s more cost-effective for manufacturing complex geometries and shapes. However, due to the weight of metals, overhanging sections typically require support, which will be removed post-process. Machining may be necessary to achieve tight tolerances for threads and holes.

Is DMLS ideal for your project?

Find a reputable service provider that can review your project for free. With their help, they can give further design tips to make your part suitable for DMLS 3D printing. Otherwise, they can recommend other additive manufacturing technologies.

0 notes

Text

3D printing little model houses is so soothing I love you rapid prototyping I love you STL file I love you full metal hotend I love you additive manufacturing I love you stepper motor

10 notes

·

View notes

Text

What is 3D printing?

3D printing is a manufacturing process that involves creating three-dimensional objects from a digital design. The process involves building up layers of material, such as plastic or metal, until the final object is complete.

2 notes

·

View notes

Text

Unlocking the Potential of 3D Printing: A Guide to PrintPrizm3D

Welcome to the world of 3D printing with PrintPrizm3D! Whether you’re a hobbyist, a small business owner, or an innovator looking to turn your ideas into reality, 3D printing offers limitless possibilities. At PrintPrizm3D, we specialize in providing high-quality 3D printing services that cater to a wide range of needs. Discover how our services can help you bring your visions to life and explore the benefits of incorporating 3D printing into your projects.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. By layering materials such as plastic, metal, or resin, 3D printers can produce complex shapes and intricate designs with precision and accuracy. This technology has revolutionized industries, including aerospace, automotive, healthcare, and fashion, by offering rapid prototyping, custom manufacturing, and cost-effective production.

Why Choose PrintPrizm3D?

At PrintPrizm3D, we pride ourselves on delivering top-notch 3D printing services. Here’s why you should choose us for your next project:

High-Quality Prints: We use advanced 3D printers and materials to ensure your prints are of the highest quality. Whether you need a prototype, a functional part, or a decorative item, we’ve got you covered.

Expertise and Experience: Our team has extensive experience in 3D printing and design, enabling us to handle a variety of projects with skill and efficiency.

Customer Satisfaction: We are committed to providing exceptional customer service. From the initial consultation to the final product, we work closely with you to meet your specific needs and expectations.

Our Services

PrintPrizm3D offers a comprehensive range of 3D printing services to cater to various requirements:

Prototyping: Quickly and accurately create prototypes to test and refine your designs.

Custom Manufacturing: Produce custom parts and products tailored to your specifications.

Design Services: Our expert designers can help you create and optimize your 3D models for printing.

Educational Workshops: Learn about 3D printing technology and its applications through our informative workshops.

Visit Our Online Stores

Explore our wide range of 3D printed products and services on our online platforms:

PrintPrizm3D Website: PrintPrizm3D Website

PrintPrizm3D eBay Store: PrintPrizm3D eBay Store

Connect with Us on Social Media

Stay updated with our latest projects, promotions, and 3D printing tips by following us on social media:

Facebook: PrintPrizm3D Facebook Page

Instagram: PrintPrizm3D Instagram

Rippin-R-Us Instagram: Rippin-R-Us Instagram

Rippin-R-Us Facebook: Rippin-R-Us Facebook

Get in Touch

Have questions or need assistance with your 3D printing project? Contact us at [email protected]. We’re here to help you every step of the way!

Conclusion

3D printing is transforming the way we create and innovate. At PrintPrizm3D, we’re dedicated to providing high-quality 3D printing services that help you turn your ideas into reality. Visit our online stores, connect with us on social media, and discover how we can assist you with your next project. Embrace the future of manufacturing with PrintPrizm3D!

For further insights and tips on 3D printing, subscribe to our blog and stay tuned for more updates. Happy printing!

#ShopNow#OrderNow#BuyNow#LimitedEdition#NewArrival#3DPrinting#AdditiveManufacturing#3DPrint#3DPrintingCommunity#3DPrintingTechnology#3DPrinted#3DPrinter#3DPrintingService#Prototyping#ProductDesign#CustomManufacturing#RapidPrototyping#Engineering#ProductDevelopment#TechInnovation#eBayStore#eBayDeals#ShopOnEbay#EbayFinds#EbaySeller#FacebookMakers#3DPrintingFB#MakerSpace#Insta3DPrinting#3DPrintingArt

2 notes

·

View notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Photo

Additive Manufacturing & 3D Printing are interchangeable terms as they both describe the same process. It’s a technology where 3D parts are produced layer by layer from a material.

Additive manufacturing Process

The Additive manufacturing Process involves uploading your Computer-Aided-Design (CAD) designs directly to 3D Printer to deposit material, layer upon layer, in precise geometric shapes creating the desired Metal 3D model.

Metal Additive Manufacturing

Metal Additive Manufacturing or Metal 3D Printing is Production of 3D Parts layer by layer from a metal Material.

The print head moves horizontally and vertically and puts a new layer of build material with every pass making it possible to manufacture objects using a variety of materials.

The Metal Additive Manufacturing Technique is also involves using 3D object scanners to scan the object and direct 3D Printer to deposit material, layer upon layer creating the metal 3D Model.

This technology makes it possible for manufacturers to produce complex metal parts without any design constraints of traditional manufacturing. There are numerous benefits of 3D printing over Traditional Manufacturing namely no design constraints and complex parts can be corrected and printed quickly.

Metal Additive Manufacturing Materials

The most common Metal Additive Manufacturing Materials are namely Aluminum Alloy - AISi10Mg, Super/ Nickel Alloy - Inconel 718, PH1, GP1 and CX, Inconel 625 and HX, Stainless Steel - SS316L, Titanium - Ti6AI4V and Ti6AI4V ELI, Cobalt Chrome- MP1, Maraging Steel- MS1, Copper- CU etc.

Metal Additive Manufacturing Applications

There are numerous Metal Additive Manufacturing Applications as Additive Manufacturing is ideal for production of Low Volume and speciality Parts. We can design Functional Metal Prototypes, spare and obsolete Parts, Surgical and Dental Implants, Jewellery and decorative Arts and custom Tools quickly.

Metal Additive Manufacturing Advantages

There are numerous Metal Additive Manufacturing Advantages namely

• Design Flexibility - Use Smarter Design Geometries

• Quick Evaluation of Designs

• Create Complex Parts to deliver Maximum Performance

• Eliminate Tooling and Fixture Costs

• Rapid Product Development

• Low Raw Material Wastage

• Simplify Supply Chain using On Demand Tooling

Benefits of Metal Additive Manufacturing (Metal 3D - Printing) in Aerospace, Space, Defense, Automotive, Tooling, Oil & Gas Industry

We are outlining the benefit of Metal Additive Manufacturing across various Industries

• Create Complex Parts to deliver Maximum Performance

• Use Smarter Design Geometries

• Eliminate Tooling and Fixture Costs

• Increase Durability and Lifecycle of Parts

Benefits of Metal Additive Manufacturing in Defense Industry

• Rapid Product Development

• Reduce Part Weight by Producing optimised components

• Low Raw Material Wastage

• Produce Custom Spares and Components

Benefits of Metal Additive Manufacturing in Automotive Industry

• Design of 3D Printed Scale Models

• Prototype Validation in Pre - Manufacturing Stage

• Produce Samples and Tools at Low Cost

• Produce Custom and Lightweight Parts

Benefits of Metal Additive Manufacturing in Oil & Gas Industry

• Design Flexibility & Faster Product Development

• Economic Low Volume Production

• Faster Re-Manufacturing of High Value Components

• Simplyfy Supply Chain using On Demand Tooling

Veer-O-Metals is one of the leading Metal Additive Manufacturing company In India offering complete Metal 3D Printing Solution across Industries namely Aerospace, Space, Defense, Automotive, Heat Sink, Oil and Gas, Product Development, Conformal Cooling, Medical, Digital Inventory etc.

Veer-O-Metals (VOM) was established in 1965 and has augmented cutting edge manufacturing technology in the field of metal additive manufacturing which is an automatic process of manufacturing objects (Parts, Prototypes, tools & even assemblies) directly from their CAD models without any cutter, tools and jigs & fixtures.

As an organization VOM holds equal responsibility in meeting the industry standards, which keep us abreast of all the mandatory certifications, needed for a healthy sustenance. VOM has obtained the below certifications to meet the standards.

• AS 9100D: Certified ISO 9001

• ISO-45001:2018

• EN 15085 LL-C (Certification)

• ISO 14001: 2015

• Certified IATF 16949: 2016

• ISO 27001: 2013

You can call us at +91- 9739991967 or contact us at [email protected] or visit www.veerometals.com for all you Additive Manufacturing requirements.

#post processing of 3d printed#metal additive manufacturing service providers#metal 3d printing services in india#metal 3d printing service bangalore#metal 3d printing raw material#metal 3d printing rapid prototyping#metal 3d printing india#metal 3d printing in rapid prototyping#metal 3d printing companies in india#metal 3d printing companies in bangalore#additive metal 3d printing#additive manufacturing service in india#additive manufacturing companies in bangalore#3d priniting post processing services#3d metal printing companies

1 note

·

View note

Text

#lasercutting #cncprocessing #cnc #cncservices

#cnc milling service#cnc car parts#online cnc machining services#sheet metal fabrication#sheet metal processing services#custom sheet metal fabrication#cnc turning services#cnc machining services#online cnc precision machining

2 notes

·

View notes

Text

What are the classification of Rapid Prototyping Technologies?

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

The Common Technical Classification in Processing Techniques

CNC Machining

2. 3D Printing

3. Vaccum Casting

4. Sheet Metal

5. Low-volume Manufacturing

#design#autos#business#cnc machining#precision machining#prototype machining#prototyping#machining parts#prototype#rapid prototyping#3d printing#vacuum casting#injection molding#sheet metal fabrication#sheet metal manufacturing#sheet metal services tauranga#sheet metal work contractor financing

1 note

·

View note

Text

GD prototyping is a Prototypes&low volume manufacturer, provide (3&4&5axis)CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and surface finish. https://www.gd-prototyping.com/

2 notes

·

View notes

Text

The Craftsmanship behind Fittings Manufacturing

Fittings like plastic fittings China are connectors that connect pipes, tubes, or hoses. They are intended to form a secure and leak-proof connection, allowing for the uninterrupted passage of liquids, gasses, or even solid objects. Plumbing, HVAC systems, hydraulic and pneumatic machinery, oil and gas pipelines, and other applications all employ fittings. These little components are the unsung heroes of numerous sectors, keeping together contemporary society's complicated architecture.

Fittings: An Art Form Manufacturing

Manufacturing fittings is a complex procedure that necessitates accuracy and attention to detail. Here's a rundown of the stages required in making fittings:

Material Selection: The selection of materials is critical in the manufacture of fittings. diverse materials, such as brass, stainless steel, PVC, or copper, are required for diverse uses. The material used must be corrosion-resistant, long-lasting, and suitable for the contents transported.

Engineers design fittings with accuracy, taking into account parameters such as pressure ratings, temperature, and flow needs. To generate precise and trustworthy products, the design process may use computer-aided design (CAD).

Machining: Machining procedures like as turning, milling, and drilling are commonly used to make fittings from metal fittings manufacturer. These operations shape and refine the material into the correct shape, guaranteeing that the fitting will work properly.

Quality Control: Throughout the production process, stringent quality control methods are employed. Inspections, testing, and monitoring are performed to ensure that the fittings fulfill industry standards and requirements.

Surface Finish: Depending on the application, fittings may be polished, plated, or coated to improve their durability and appearance.

Manufacturing Fittings Innovations

In recent years, the field of fittings production has undergone considerable developments. These advancements seek to boost efficiency, decrease environmental impact, and increase product performance. Among the significant advancements are:

3D Printing: Additive manufacturing, including 3D printing, is becoming more popular for producing complicated, bespoke fits with minimal material waste.

Sustainable Materials: To lessen its environmental imprint, the industry is investigating eco-friendly materials and manufacturing procedures.

Rapid prototype: Computer-aided design and rapid prototype techniques enable the creation and testing of novel fitting designs to be completed more quickly.

IoT technology is being integrated into fittings from plastic fittings manufacturers to monitor and optimize fluid flow, identify leaks, and increase system performance.

Follow our Facebook and Twitter for more information about our product.

#Metal fittings manufacturer#Metal fittings manufacturer China#Professional Metal Manufacturer#Metal Manufacturer China

2 notes

·

View notes