#2D/3D CAD prototypes

Explore tagged Tumblr posts

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Packaging That Performs: Insulink – The Name Behind India's Leading Vacuum Formed Solutions

In today’s world, packaging is more than just a wrapper. It is protection, presentation, and performance rolled into one. If your product demands precision, durability, and a professional edge—look no further than Insulink, a trusted vacuum formed packaging parts manufacturer catering to industries where every detail matters.

Think Inside the Tray

Imagine a tiny electronic chip shipped across states, a delicate diagnostic tool delivered to a hospital, or a high-value engine part ready to meet its assembly line. What keeps them safe and ready? A custom-fit tray that knows its job.

That’s what Insulink does best—vacuum formed packaging parts that are tailor-made for your products.

We don't just make trays. We make solutions that fit your workflow, protect your inventory, and support automation—all while saving space, time, and money.

What Is Vacuum Formed Packaging?

Vacuum forming is a thermoforming process where a heated plastic sheet is drawn over a mold by vacuum. The result? Lightweight yet durable packaging parts like:

Custom trays

Product inserts

Blister packs

Industrial containers

As an experienced vacuum formed packaging parts manufacturer, Insulink delivers both standard and customized packaging to meet industry-specific needs.

Why Choose Insulink?

🧠 Smart Design Thinking

We start by understanding your product. Shape, size, fragility, use case—we factor it all to craft the perfect packaging part.

🏭 In-House Manufacturing

From CAD modeling and mold making to vacuum forming and finishing—we control the entire process, ensuring speed and quality.

🔩 Precision in Every Curve

Our trays aren’t just made to hold—they’re made to protect, align, stack, and automate. That’s engineering-grade packaging.

🌿 Green Is Our Goal

We work with recyclable and reusable materials, helping you meet sustainability targets without compromising function.

Our Key Products

🔹 Electronics Trays – Anti-static, ESD-safe packaging for sensitive components. 🔹 Medical Packaging – Sterile-ready trays for surgical tools and diagnostics. 🔹 Automotive & Engineering Inserts – Heavy-duty trays for tools, fasteners, and parts. 🔹 Retail Packaging – Display inserts that combine strength with shelf appeal. 🔹 Warehouse Transport Trays – Stackable, space-saving solutions for bulk handling. 🔹 Tool & Maintenance Organizers – Structured trays for kits, boxes, and field use.

Each tray we manufacture is built for purpose, made for reliability, and designed to fit your product—not the other way around.

Industries We Serve

Insulink’s vacuum formed solutions serve a wide range of industries:

🔧 Automotive & Engineering

💡 Electronics & PCB Assembly

🏥 Healthcare & Pharma

🛍️ Retail & FMCG

✈️ Aerospace & Defense

⚙️ Tools & Industrial Equipment

No matter the sector, we offer packaging that meets regulatory, safety, and process requirements.

Built to Fit, Built to Last

When you partner with Insulink, you get more than packaging. You get:

✅ Tailor-Made Fit – No gaps, no shifting, no damage. ✅ Process-Friendly Trays – Designed for conveyor lines, robotic arms, and cleanrooms. ✅ Reusable Value – Strong enough for repeated handling and storage cycles. ✅ Faster Assembly & Delivery – Organized trays improve efficiency and reduce manual error. ✅ Reduced Transit Risk – Lower returns, breakage, and rework.

Our Process: What Working With Insulink Looks Like

Initial Discussion Understand your product, goals, and packaging challenges.

Design Proposal We present 2D/3D models and material recommendations.

Prototype Sample tray manufactured for testing and review.

Final Production On approval, we begin full-scale manufacturing with strict quality control.

On-Time Delivery Packaged, labeled, and shipped—on schedule, every time.

Trusted by Industry Leaders

Our clients include startups, OEMs, hospitals, tech brands, and exporters—each with unique demands. What they share is trust in Insulink’s:

Consistent quality

Honest pricing

Technical expertise

Personalized service

Long-term support

Let’s Create Packaging That Powers Your Process

Choosing the right vacuum formed packaging parts manufacturer means choosing a partner that understands your product as well as you do. At Insulink, we work not just with materials—but with purpose, precision, and pride.

📞 Get in Touch Now: +91 9205274027 | +91 7838356129 🌐 Visit Us: www.insulink.co.in 📩 Request a Free Sample or Quotation

Insulink – Made to Fit. Built to Protect. Designed to Perform.

0 notes

Text

Exploring Tools and Techniques for Effective 3D Product Development

In today’s fast-paced manufacturing and product development landscape, 3D product design has emerged as a game-changer. From consumer electronics to automotive components and medical devices, the ability to visualize, simulate, and iterate products in a digital environment has revolutionized the way businesses operate. This transformation is largely powered by advanced tools and techniques that make 3D product design services more efficient, cost-effective, and accurate. This article explores the top tools, methods, and best practices used by every successful 3D product designer today.

Importance of 3D Product Design in Development

Before diving into the tools and techniques, it’s important to understand why product 3D design holds such importance. Traditional design processes relied on 2D sketches and physical prototypes, which were often time-consuming and prone to error. In contrast, 3D design offers visual clarity, real-time modifications, and better collaboration between engineers, designers, and clients.

The role of 3D product design extends beyond mere visualization. It allows for precise simulations, easy error detection, improved communication across teams, and shorter time-to-market. For companies offering 3D product design services, this translates into a competitive edge that ensures innovation, accuracy, and client satisfaction.

Essential Tools for 3D Product Development

Modern 3D product development is largely dependent on digital tools. Here are some of the most widely used and effective software tools in the industry:

1. SolidWorks

One of the most recognized names in 3D product design, SolidWorks is known for its intuitive interface and powerful modeling capabilities. It’s ideal for mechanical parts and assemblies, offering simulation, motion analysis, and design validation.

2. Autodesk Fusion 360

Fusion 360 offers a cloud-based platform that integrates CAD, CAM, and CAE tools. It enables 3D product designers to collaborate in real time, making it a go-to choice for remote teams or design firms.

3. PTC Creo

Creo is another top-tier tool for Product 3D design, especially in industries like aerospace and automotive. It supports parametric modeling, simulation, and additive manufacturing, making it suitable for both concept and production stages.

4. Blender

While not traditionally used for mechanical design, Blender is gaining popularity in product visualization due to its excellent rendering and animation capabilities. For 3D product design services that require aesthetic presentations, Blender is a powerful asset.

5. Rhinoceros (Rhino)

Rhino specializes in freeform modeling, which is great for industrial design and consumer products. When flexibility and surface control are priorities, Rhino delivers exceptional results.

Techniques That Enhance 3D Product Development

Using the right tools is just the beginning. It’s the techniques that truly bring efficiency and innovation to the process. Below are some widely adopted practices:

1. Design Thinking Approach

Before even opening a CAD tool, many 3D product designer apply the design thinking process—empathize, define, ideate, prototype, and test. This user-centric methodology ensures that the final product meets real-world needs.

2. Rapid Prototyping

Thanks to 3D printing, teams can create quick prototypes directly from digital models. This technique reduces development cycles and allows for quick feedback. It’s a vital part of modern 3D product design services.

3. Reverse Engineering

When physical products exist but lack digital records, reverse engineering helps recreate them in 3D. Tools like 3D scanners capture precise geometry, which is then used in modeling software to generate accurate product 3D designs.

4. Simulation and Testing

Simulation tools integrated into CAD software allow 3D product designers to test stress, heat, and motion before anything is built. This reduces costly errors and supports better decision-making during the design phase.

5. Parametric Design

Parametric modeling allows designers to create geometry driven by parameters. This means changes can be made quickly without rebuilding the model from scratch—a key feature in efficient 3D product design workflows.

The Role of Collaboration in Product 3D Design

In an increasingly globalized world, 3D product design services often involve multidisciplinary and geographically dispersed teams. Collaborative tools such as cloud-based platforms (like Onshape and Fusion 360) are critical for real-time file sharing, commenting, and version control.

By maintaining transparency and open communication, teams can ensure fewer design errors, streamlined approvals, and faster project completion. The use of AR/VR in reviews and presentations also enhances client understanding, leading to better-informed decisions and higher satisfaction.

Future Trends in 3D Product Design

As technology evolves, so do the techniques and tools available to 3D product designers. Here are some emerging trends shaping the future:

1. AI-Driven Design

Artificial Intelligence is being increasingly used for generative design, where the software suggests multiple design alternatives based on predefined constraints and goals. This reduces manual effort and opens up new creative possibilities.

2. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR are enabling immersive design reviews. Clients and designers can experience product 3D designs in a virtual environment, allowing for faster feedback and iteration.

3. Sustainability Integration

New tools now allow designers to calculate the environmental impact of their design choices. Materials, manufacturing methods, and energy consumption can all be optimized for a greener footprint.

4. Cloud-First Platforms

With the rise of remote work, cloud-based design tools will continue to grow. They offer greater flexibility, easier updates, and improved collaboration—crucial for modern 3D product design services.

Choosing the Right 3D Product Designer or Service

For businesses looking to outsource, selecting the right partner is crucial. An experienced 3D product designer will not only bring technical skill but also a deep understanding of your industry’s challenges and goals.

Look for the following when evaluating 3D product design services:

Proven track record in similar projects

Proficiency in the latest design tools

Ability to provide end-to-end services (from ideation to prototyping)

Strong communication and project management skills

Investing in the right service can drastically reduce time-to-market, enhance product quality, and lower development costs.

Conclusion: Merging Innovation with Practical Design

The landscape of 3D product design is constantly evolving, driven by technological advancements and shifting consumer expectations. By understanding and applying the right tools and techniques, companies can stay ahead of the curve and deliver high-performing, innovative products.

Whether you’re a startup developing your first prototype or an enterprise upgrading your existing product line, leveraging effective 3D product design services and skilled 3D product designers can make all the difference. The key is to remain adaptable, continuously explore new tools, and embrace a mindset of innovation and user-centric design.

Frequently Asked Questions

1. What is 3D product design? 3D product design is the process of creating a digital three-dimensional model of a physical product using specialized software. It allows designers to visualize, simulate, and refine a product before it's manufactured.

2. What industries use 3D product design? Many industries use 3D product design, including consumer electronics, automotive, aerospace, medical devices, furniture, fashion, and industrial equipment manufacturing.

3. What software is commonly used in 3D product design? Popular 3D product design software includes SolidWorks, Autodesk Fusion 360, PTC Creo, Rhino, CATIA, Siemens NX, and Blender (for rendering and visualizations).

0 notes

Text

The Power of 3D Design Software: Why Invest in Innovation?

In today's fast-paced product development landscape, embracing cutting-edge technology is not just an advantage, but a necessity. Three-dimensional (3D) design software has emerged as a cornerstone for innovation, offering a transformative approach to bringing ideas to life. But what exactly is 3D design software, and why should your business consider it a vital investment?

What is 3D Design Software?

At its core, 3D design software, such as Siemens' powerful NX CAD, is a sophisticated computer-aided design (CAD) tool that empowers engineers and designers to create, modify, analyze, and optimize digital prototypes in a three-dimensional space. Unlike traditional 2D drafting, 3D software provides a comprehensive virtual representation of a product, allowing for intricate detailing and realistic visualization. It offers versatile modeling capabilities, enabling users to employ the most suitable approach for their specific design challenges.

Why Should You Invest in 3D Design Software?

The benefits of adopting 3D design software are far-reaching, impacting various stages of the product lifecycle and significantly contributing to a company's bottom line and competitive edge.

Improved Visualization and Prototyping

One of the most significant advantages of 3D design is its ability to create highly detailed virtual product models. This drastically reduces the reliance on costly physical prototypes, allowing for thorough evaluation and refinement in a digital environment. Designers can visualize complex assemblies, explore different design iterations, and identify potential issues long before manufacturing begins, saving both time and resources.

Increased Precision and Accurate Design

3D CAD tools are built on advanced hybrid modeling capabilities, leading to exceptionally high-quality and precise designs. The detailed virtual models allow for meticulous accuracy, ensuring that components fit together perfectly and function as intended. This precision minimizes errors, reduces rework, and ultimately contributes to a superior final product.

Faster Design Refining and Interactions

Modern 3D design software facilitates accelerated innovation by streamlining the design process. It enables knowledge-driven automation, efficient evaluation of ideas, and seamless management of changes. Modular design tools further enhance this, allowing multiple designers to work concurrently on complex parts. This collaborative environment enables quick subdivision into functional elements, promoting re-use, easy replacement, and faster updates, leading to a quicker time-to-market for innovative products.

Reduced Material Wastage Leading to Cost Efficiency

By significantly reducing the need for physical prototypes and enabling more accurate designs from the outset, 3D design software inherently leads to reduced material wastage. This efficiency, combined with streamlined development processes, contributes to lower overall development costs. Businesses can optimize their resource utilization and achieve greater cost efficiency throughout the product creation journey.

Compatibility with Manufacturing Technologies

3D design software is often part of a unified, integrated solution that supports advanced mechanical simulation and prepares designs for various manufacturing technologies. The digital models created in 3D CAD can be directly used for processes like 3D printing, CNC machining, and other automated manufacturing workflows, ensuring a seamless transition from design to production.

Why Choose DDSPLM?

DDSPLM offers powerful solutions like NX CAD to accelerate innovation in product design. By leveraging their expertise and the capabilities of advanced 3D design software, businesses can achieve faster time-to-market, lower development costs, and improved product quality. DDSPLM provides the tools and support necessary to harness the full potential of 3D design for your product development needs.

Conclusion

Investing in 3D design software is an investment in the future of your product development. From enhanced visualization and precision to accelerated design cycles and cost efficiency, the benefits are clear. By embracing technologies like NX CAD, businesses can not only meet the demands of today's market but also drive continuous innovation and maintain a leading edge.

0 notes

Text

3D Scanners for 3D Printing: The Complete 2025 Guide

In the rapidly evolving world of additive manufacturing, 3D scanners for 3D printing have emerged as essential tools for makers, engineers, designers, and manufacturers. These powerful devices bridge the gap between the physical and digital worlds, enabling the accurate capture of real-world objects for replication, redesign, or enhancement using 3D printers.

This comprehensive guide explores how 3D scanners work with 3D printers, the types available, their benefits, top use cases, and how to choose the right scanner for your needs.

What Is a 3D Scanner for 3D Printing?

A 3D scanner is a device that analyzes a physical object and collects data about its shape, dimensions, and surface details. This data is converted into a digital 3D model, typically in STL, OBJ, or PLY format. These models can then be edited or sent directly to a 3D printer for production.

3D scanners are widely used in reverse engineering, prototyping, product design, art restoration, medical applications, and custom manufacturing.

How 3D Scanning Works with 3D Printing

The typical workflow between 3D scanning and 3D printing follows these steps:

Scanning the Object: The 3D scanner captures the surface geometry of the object using laser triangulation, structured light, or photogrammetry.

Data Processing: The raw scan is processed using 3D modeling software to repair holes, smooth surfaces, or make design modifications.

Exporting the File: The model is saved in a printer-compatible format, such as STL.

3D Printing: The file is sliced using slicing software, then printed using an FDM, SLA, or other 3D printer.

This process makes 3D replication, customization, and product development faster and more efficient.

Benefits of Using 3D Scanners for 3D Printing

1. High Accuracy 3D scanners allow for precise measurement of existing objects, which is crucial for engineering, prosthetics, and product design.

2. Time and Cost Efficiency They drastically reduce the time required to recreate objects manually in CAD and eliminate the cost of redesigning from scratch.

3. Reverse Engineering 3D scanning enables reverse engineering of components, tools, and legacy parts where no digital model exists.

4. Customization In industries like fashion, dentistry, and orthopedics, 3D scanning ensures perfect fit and personalized product design.

5. Creative Freedom Artists and designers can replicate sculptures, create digital art, or remix scanned models for new creations.

Types of 3D Scanners for 3D Printing

Handheld 3D Scanners

Portable and easy to use.

Great for scanning medium to large objects.

Ideal for makers, DIY users, and field scanning.

Desktop 3D Scanners

Provide higher resolution.

Suitable for small objects like jewelry, tools, or dental molds.

Typically offer automated turntables for ease of use.

Industrial 3D Scanners

High-speed, ultra-precise scanners for manufacturing and quality control.

Useful for scanning large machines, vehicles, or architecture.

Photogrammetry-Based Scanners

Use a series of 2D images to construct a 3D model.

Cost-effective and software-driven, but requires optimal lighting.

Popular Applications

1. Prototyping Designers can scan an existing prototype, make digital changes, and 3D print iterations faster than traditional methods.

2. Product Design and Development Scanning physical mock-ups accelerates design verification and improvements.

3. Custom Parts Manufacturing Mechanics or restoration experts can scan broken or legacy parts to reproduce them via 3D printing.

4. Education and Research Schools and labs use 3D scanners to digitize fossils, biological specimens, and artifacts.

5. Medical and Dental Custom implants, prosthetics, and dental devices are designed with high-accuracy body scans.

6. Art and Heritage Preservation 3D scanning helps preserve sculptures and artifacts digitally, allowing reproduction or study without damaging originals.

Best 3D Scanners for 3D Printing in 2025

Here are some of the top 3D scanners compatible with 3D printers:

Revopoint POP 3

Affordable and user-friendly.

Good for beginners and hobbyists.

Creality CR-Scan Ferret Pro

Excellent budget handheld scanner.

Seamless integration with 3D printers.

Shining 3D EinScan-SE

Desktop scanner with great accuracy.

Ideal for professionals in education or design.

Artec Eva Lite

Industrial-grade, full-body scans.

Best for professionals in medical, art, or research fields.

Matter and Form V2

Compact desktop scanner.

Excellent value for small-object scanning.

Factors to Consider When Choosing a 3D Scanner for 3D Printing

1. Accuracy and Resolution Higher accuracy is crucial for engineering or dental applications, while hobbyists may not need ultra-precision.

2. Object Size Choose a scanner suitable for the scale of objects you'll scan most frequently.

3. Software Compatibility Ensure the scanner software can export STL or OBJ files compatible with your 3D printer's slicer.

4. Ease of Use User-friendly interfaces and automated features improve efficiency, especially for beginners.

5. Price Budget scanners start around ₹20,000–₹50,000, while industrial models can exceed ₹5 lakhs. Match the features to your workflow and budget.

Tips for Better Scanning and Printing Results

Use adequate lighting to reduce scan noise.

Apply scanning sprays or markers on shiny or reflective surfaces.

Scan objects from multiple angles for complete geometry.

Use mesh editing software (e.g., Meshmixer, Blender) to clean and prepare your model before printing.

Test with small prints before committing to full-size 3D prints.

Future of 3D Scanning in Additive Manufacturing

The future of 3D scanners for 3D printing is headed toward greater automation, real-time processing, AI-powered mesh repair, and increased affordability. As hardware becomes more compact and powerful, we’ll see wider adoption in consumer-level 3D printing and increased use in fields like architecture, healthcare, and fashion.

Conclusion

3D scanners have revolutionized the way objects are replicated, modified, and created for 3D printing. Whether you're a hobbyist making custom figurines or an engineer developing precision parts, integrating 3D scanning with 3D printing can significantly boost productivity and design freedom.

As technology advances and prices drop, 3D scanning will continue to become more accessible, paving the way for a future where any physical object can be digitized and reproduced with unmatched accuracy and creativity.

0 notes

Text

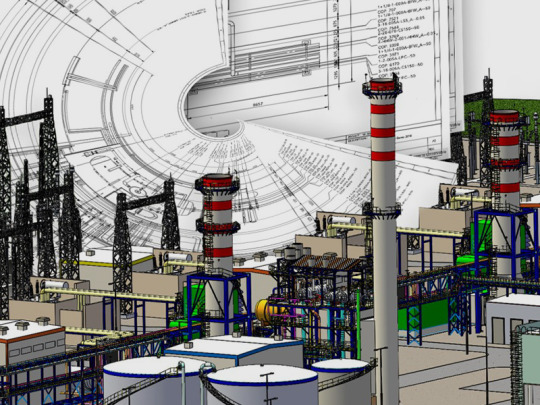

CAD and FEA Design and Analysis Overview

Computer-Aided Design (CAD) and Finite Element Analysis (FEA) are pivotal technologies in modern engineering, enabling the creation, simulation, and optimization of complex systems and components. CAD facilitates precise 2D and 3D modeling, while FEA predicts how designs perform under real-world conditions like stress, vibration, or heat. Together, they streamline product development, reduce costs, and ensure reliability across industries such as automotive, aerospace, and civil engineering. This 800-word overview explores their principles, applications, benefits, challenges, and future trends.

Principles of CAD and FEA Integration

CAD and FEA work synergistically to design and validate engineering solutions:

CAD Modeling: CAD software, such as SolidWorks, CATIA, or Autodesk Fusion 360, enables engineers to create detailed 3D models defining geometry, materials, and tolerances. These models serve as the foundation for FEA simulations.

Finite Element Analysis: FEA divides CAD models into smaller elements (meshes) to simulate physical behaviors like stress, strain, or thermal response. Software like ANSYS, Abaqus, or COMSOL solves governing equations to predict performance.

Meshing: CAD models are discretized into finite elements, with mesh density affecting simulation accuracy and computational demand. Fine meshes improve precision but increase processing time.

Boundary Conditions and Loads: Engineers apply real-world conditions, such as forces, pressures, or temperatures, to CAD models within FEA tools to replicate operational scenarios.

Simulation and Optimization: FEA analyzes system responses, identifying stress concentrations or failure points. Results guide CAD model refinements to optimize design performance.

Iterative Design Process: CAD and FEA enable iterative workflows, where simulations inform design updates, ensuring alignment with performance and safety requirements before prototyping.

Applications of CAD and FEA

CAD and FEA are integral to diverse industries:

Automotive: CAD designs vehicle components like chassis and suspension systems, while FEA tests crashworthiness, fatigue, and aerodynamic performance, ensuring safety and efficiency.

Aerospace: CAD models aircraft wings and turbine blades, and FEA simulates structural integrity under extreme loads, meeting standards like DO-160 for aviation safety.

Civil Engineering: CAD creates models of bridges, skyscrapers, and tunnels, while FEA evaluates stability against wind, seismic activity, or traffic loads, ensuring structural safety.

Consumer Electronics: CAD designs compact devices like smartphones, and FEA tests durability against drops, vibrations, or thermal stress, enhancing product reliability.

Medical Devices: CAD models prosthetics or implants, and FEA simulates biomechanical interactions to ensure compatibility and longevity in medical applications.

Manufacturing: CAD ensures precise tooling and machinery designs, while FEA optimizes material use and durability, reducing production costs and waste.

Benefits of CAD and FEA Integration

The synergy of CAD and FEA offers significant advantages:

Cost Reduction: Virtual simulations reduce the need for physical prototypes, cutting development costs by up to 25%, according to industry studies, and minimizing material waste.

Enhanced Accuracy: FEA identifies design flaws early, enabling CAD modifications to improve structural integrity, thermal performance, or vibration resistance.

Faster Development: Iterative simulations accelerate design cycles, allowing engineers to test multiple scenarios virtually, reducing time-to-market.

Improved Safety: FEA ensures designs withstand extreme conditions, critical for safety-critical applications like automotive crash testing or aerospace components.

Material Optimization: FEA guides material selection in CAD, enabling lightweight, cost-effective designs that maintain performance, supporting sustainability goals.

Collaborative Design: CAD and FEA provide a unified platform for mechanical, structural, and thermal engineers, fostering cross-disciplinary collaboration and reducing errors.

Challenges in CAD and FEA Implementation

Despite their benefits, CAD and FEA present challenges:

Computational Demands: High-fidelity FEA simulations with fine meshes require powerful hardware, increasing costs and simulation times for complex models.

Model Accuracy: Inaccurate CAD geometries or oversimplified FEA assumptions can lead to unreliable results, necessitating expertise to balance accuracy and efficiency.

Learning Curve: Mastering CAD and FEA tools requires training in modeling, meshing, and simulation techniques, which can be time-intensive for new users.

Software Costs: Licenses for advanced CAD (e.g., CATIA) and FEA (e.g., ANSYS) software are expensive, posing barriers for small firms or startups.

Interoperability Issues: Compatibility between CAD and FEA platforms can be limited, requiring data conversion or additional tools to ensure seamless integration.

Future Trends in CAD and FEA

The evolution of CAD and FEA is driven by technological advancements:

Cloud-Based Solutions: Platforms like Autodesk Fusion 360 and ANSYS Cloud enable remote modeling and simulation, reducing hardware costs and supporting global collaboration.

AI and Machine Learning: AI optimizes mesh generation, predicts failure modes, and automates design iterations, enhancing FEA accuracy and reducing computation time.

Generative Design: CAD tools with generative design algorithms create optimized geometries based on FEA constraints, enabling lightweight, efficient designs for aerospace and automotive applications.

Digital Twins: CAD and FEA support digital twins, providing real-time virtual models for monitoring and optimizing physical systems throughout their lifecycle.

Sustainability Focus: CAD and FEA are prioritizing eco-friendly designs by optimizing material use and simulating energy-efficient systems, aligning with global sustainability goals.

Conclusion

CAD and FEA design and analysis are transformative tools in engineering, enabling precise modeling and robust performance validation. Their integration streamlines development, enhances safety, and reduces costs across industries like automotive, aerospace, and medical devices. By simulating real-world conditions, CAD and FEA ensure designs meet stringent requirements before production, minimizing risks and optimizing resources. Despite challenges like computational demands and software costs, advancements in AI, cloud computing, and generative design are expanding their capabilities. As industries demand innovative, sustainable solutions, CAD and FEA will continue to shape the future of engineering, driving efficiency, reliability, and progress in a rapidly evolving technological landscape.

0 notes

Text

Inside an Interior Design Course: What You’ll Really Learn

If you’ve ever wondered what it’s really like to study Interior Design , you're not alone. Many people assume interior design is only about choosing colors, fabrics, and stylish décor. In reality, a professional Interior Design Course goes much deeper—blending creative expression with technical skills, business strategy, and client communication.

Whether you're considering a diploma, crash course, or full-time degree, here’s a closer look at what you’ll actually learn inside a modern interior design program.

1. Design Principles and Space Planning

The foundation of every great design begins with understanding how space works. You’ll learn how to:

Apply design elements like balance, contrast, proportion, and rhythm

Create functional layouts for different types of spaces (residential, commercial, office, retail)

Maximize space, light, and flow through smart planning

Visualize how furniture and fixtures impact movement and atmosphere

Space planning is one of the most critical skills every interior designer must master.

2. Color Theory and Material Selection

Color and materials define the mood of a space. Courses dive into:

Color psychology and harmonies

Texture, pattern, and material mixing

Selecting appropriate finishes for durability, aesthetics, and safety

Creating material boards and mood boards for clients

You’ll also learn how to match design elements with user needs, brand identity, or lifestyle preferences.

3. Technical Drawing and CAD Software

Interior design is as much technical as it is artistic. You’ll train in:

Drafting floor plans, elevations, and sections

Understanding scale, proportion, and measurements

Using digital tools like AutoCAD, SketchUp, and 3ds Max for 2D and 3D designs

Creating realistic renderings and walkthroughs

These skills help you present ideas clearly and communicate with architects, contractors, and clients.

4. Lighting Design

Lighting can make or break a space. You’ll explore:

Types of lighting: ambient, task, accent, decorative

Natural vs. artificial lighting and how to balance both

Fixture selection based on purpose and aesthetics

Placement strategies to enhance mood, function, and form

You’ll learn to create lighting layouts that are both practical and visually impactful.

5. Furniture Design and Detailing

Understanding how furniture is designed and placed is essential. You’ll cover:

Furniture styles, trends, and ergonomics

Custom furniture design for unique projects

Technical detailing for cabinetry, wardrobes, and built-ins

Sourcing, budgeting, and material selection

Some courses may even include hands-on furniture prototyping.

6. Sustainable and Green Design

Modern courses emphasize eco-conscious practices. You’ll learn:

Sustainable materials and certifications (like LEED or IGBC)

Energy-efficient design and natural ventilation

Waste reduction in design and construction

Designing with environmental and health impact in mind

This knowledge is highly valued in today’s environmentally aware industry.

7. Project Management and Client Communication

Designers are also project managers. You’ll be trained to:

Develop budgets, timelines, and contracts

Collaborate with vendors, contractors, and architects

Handle client briefs, feedback, and revisions

Present and pitch your ideas professionally

These soft skills are critical in ensuring a design project runs smoothly from concept to completion.

8. Portfolio Development and Industry Exposure

Most courses, especially those from institutes like Paperloft, include:

Real-time projects and live client briefs

Site visits and fieldwork

Guest lectures and design critiques

Portfolio building and mock interviews

Your portfolio becomes your most powerful tool for job placement or launching your own design studio.

Conclusion

An Interior Designing Course is an immersive experience that equips you with both creative vision and technical ability. It prepares you to design not just beautiful spaces—but functional, sustainable, and client-focused ones. Whether you're starting from scratch or shifting careers, the skills you learn will be your foundation for building a long-term future in the design industry.

#InteriorDesignCourse#InteriorDesignInstitute#InteriorDesignClassesNearMe#InteriorDesignInstituteInBangalore#InteriorDesigning

0 notes

Text

When it comes to product development, accuracy and speed is important. This is why many businesses and individuals are turning to professional CAD designers to bring their ideas into life. Whether you are working on a prototype, a mechanical component, or a complete equipment and dye project, expert CAD designers can streamline your procedure and improve the final results. If you are searching for CAD design companies near me, you will find a wide range of cheap, fast and high quality services from experienced firms.

These cutting die manufacturers specialize in converting concepts into detailed 2D or 3D designs using the latest software and tools. From automotive parts to consumer electronics and industrial machinery, CAD professionals can help you imagine and adapt your design before production starts. It not only reduces physical waste, but also cuts amendment and delay in production. What is more, many of these companies work closely with tool and die companies, providing comprehensive solutions that go originally from concept to tooling.

Whether you are launching a new product or an established manufacturer who is looking to upgrade your designs, hiring a local CAD specialist is a smart step. I have to search for CAD design companies near me and join with the best talent in your field today - consider strength, speed and technical excellence for your next large project.

0 notes

Text

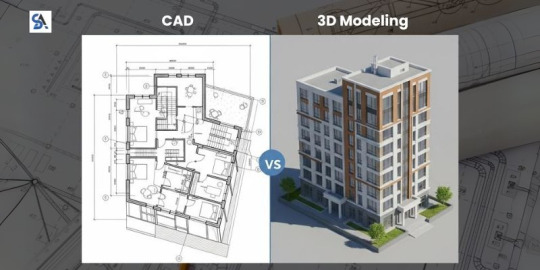

CAD vs 3D Modeling: Understanding the Key Differences

In the world of design and engineering, two terms often come up—3D Modeling and CAD (Computer-Aided Design). While many people use these terms interchangeably, they are not exactly the same. Both are powerful tools used in architecture, engineering, construction, and manufacturing, but they serve different purposes and have different capabilities.

At Steelarch Designers, we often work with both 3D Modeling and CAD software depending on the needs of the project. In this blog, we will explain what each term means, how they are different, and when to use which one.

What is CAD?

CAD stands for Computer-Aided Design. It is a type of software used to create precise 2D drawings and technical plans. CAD is widely used by engineers, architects, and draftsmen to prepare layouts, blueprints, and schematics for construction or manufacturing.

Common Uses of CAD:

Creating floor plans for buildings

Drafting engineering diagrams

Electrical and plumbing layouts

Machine part detailing

Popular CAD Software:

AutoCAD

SolidWorks

DraftSight

CAD is known for its accuracy and is ideal for creating detailed technical drawings that follow engineering standards.

What is 3D Modeling?

3D Modeling refers to the process of creating a digital three-dimensional object using specialized software. It is used to visualize real-world structures, products, or environments in a more realistic way.

Common Uses of 3D Modeling:

Visualizing buildings and interiors

Creating prototypes of products

Game and animation design

Simulations and walkthroughs

Popular 3D Modeling Software:

SketchUp

Blender

Revit

Tekla

3D models are more visual and are often used to present concepts to clients or to understand how a final structure will look.

Key Differences Between CAD and 3D Modeling

Let’s break down the key differences in a simple comparison:FeatureCAD3D ModelingPurposeTechnical drawings and plansRealistic visualization of objectsOutput Type2D drawings or 2.5D plansFully 3D modelsMain UsersEngineers, architects, draftsmenDesigners, architects, animatorsDetail LevelFocuses on dimensions, accuracy, specsFocuses on appearance and realismUse in ConstructionBlueprints, permits, and execution plansPresentations, conceptual visualizationSoftware ExampleAutoCAD, DraftSightSketchUp, Blender, RevitSkill RequirementTechnical drawing skillsDesign and visualization skills

Which One Do You Need?

The choice between CAD and 3D modeling depends on the stage and purpose of your project.

Use CAD when:

You need precise measurements and scaling

You’re working on structural and engineering designs

You need to prepare shop drawings, MEP layouts, or fabrication details

We often create 3D models of buildings and structures to help clients better understand how their finished project will appear.

Can CAD and 3D Modeling Work Together?

Absolutely! Many projects benefit from both. Here’s how:

Start with CAD to design the technical side of a product or building

Use 3D modeling to visualize how it will look in real life.

Combine both for a complete, accurate, and beautiful final presentation.

At Steelarch Designers, we often blend our CAD services with high-quality 3D modeling to give clients a full package, from blueprint to final look.

Making the Right Choice for Your Project

Let’s say you’re building a commercial structure with steel framing.

CAD is used to create precise shop drawings, column layouts, beam details, and fabrication drawings—essential for manufacturing and construction accuracy.

3D modeling, on the other hand, helps visualize the final structure with cladding, roofing, lighting, and finishes, giving the client a realistic view of the end result.

Both tools are equally important. Together, they ensure accuracy, clarity, and confidence throughout the entire process—from planning to execution.

Conclusion

Both CAD and 3D modeling are powerful tools in the design world, but they serve different purposes. CAD focuses on accuracy and detail for construction and manufacturing, while 3D modeling brings ideas to life through visuals.

At Steelarch Designers, we offer both CAD services and 3D modeling under one roof. Whether you're an architect, builder, entrepreneur, or homeowner, our team is here to help you choose the right tools for your project.

Have a project in mind? Let’s build something great together.

Contact Steelarch Designers today for expert CAD services and stunning 3D modeling that bring your ideas to life.

Know More: https://www.steelarchdesigners.com/blog/cad-vs-3d-modeling.php

0 notes

Text

Top Mechanical Engineering Design Companies in India Driving Industry 4.0

Target Keyword: mechanical engineering design companies in india

Pure Machine Design proudly stands among the most forward-thinking mechanical engineering design companies in India, playing a vital role in the country’s Industry 4.0 journey. Our team brings together innovation, technical expertise, and smart design tools to craft solutions that bridge the gap between concept and execution.

From 2D/3D CAD modeling to CAE, prototyping, and validation, our approach is comprehensive and agile. Whether it’s a welding fixture, a special purpose machine, or a custom-designed prototype, we apply meticulous engineering to deliver high-performance solutions across industries. Read more-Revolutionizing Automotive Manufacturing with BIW Welding Fixture Design Services in India

0 notes

Text

What Is SolidWorks? A Beginner-Friendly Look at the 3D Design Tool Everyone’s Talking About

Have you ever wondered how cars, phones, or even furniture are designed before they’re made? The answer lies in powerful 3D design tools—and SolidWorks is one of the best out there.

Whether you're a student, an engineer, or just someone curious about how products are brought to life, SolidWorks makes designing easy, fast, and professional. Let’s break down what SolidWorks is and why it’s such a big deal.

What Is SolidWorks?

SolidWorks is a 3D design software that lets you create, test, and improve your ideas—virtually.

Instead of sketching something on paper or building a prototype by hand, you can use SolidWorks to:

• Create digital 3D models of your product • Test how it works under pressure or motion • Make adjustments without wasting materials • Show clients or manufacturers exactly what you’re building

It’s all done inside your computer—and when it’s time to build it for real, your designs are ready to go.

What Can You Design With SolidWorks?

You’d be surprised how many things around you were designed using SolidWorks. It’s used by people in almost every industry:

• Cars and bikes – from engines to outer frames • Airplanes – including wings, turbines, and cabin parts • Boats and marine tools – for both deep sea and leisure use • Phones and cameras – everything from casing to tiny switches • Household gadgets – vacuum cleaners, lighting, fans, and more • Furniture and interiors – cabinets, chairs, and even room layouts • Medical devices – prosthetic limbs, tools, and more • Toys and games – including action figures and plastic kits

If something is built, chances are SolidWorks helped design it first.

Key Features That Make SolidWorks Awesome

Here’s why SolidWorks is a favorite tool among designers and engineers:

• 3D modeling – Draw, shape, and customize 3D objects from scratch • 2D drawings – Turn your models into clean technical drawings • Assembly creation – Combine parts into a working machine or object • Simulation tools – Test how parts move, heat up, or break under pressure • Animation – See how your final design will work in real life • Rendering – Create realistic photos of your 3D model to show off • Design sharing – Export your files to work with teams, clients, or manufacturers

All of this is done with just a few clicks and drags, using tools that are beginner-friendly but powerful enough for pros.

Who Can Use SolidWorks?

The best part? You don’t need to be an expert to start using SolidWorks.

It’s perfect for:

• Engineering students learning design principles • Product developers creating new inventions • Small business owners who want to design their own products • Industrial designers making machines and mechanical parts • Teachers and trainers offering CAD instruction • Freelancers offering design services to companies • Companies in manufacturing, electronics, automotive, and more

Whether you’re just learning or running a full production line, SolidWorks can scale to your needs.

Why SolidWorks Stands Out

There are lots of CAD (Computer-Aided Design) tools out there, but SolidWorks has built a reputation for being powerful and easy to use.

Here’s why people love it:

• Simple interface – Even beginners can figure it out quickly • Fast learning curve – Tons of tutorials and videos available • Accurate output – Get dimensions and designs ready for real-life use • Trusted by companies – Most industries accept SolidWorks files • All-in-one – Design, simulate, and test in the same space

It’s a smart choice whether you’re building a product for fun, for school, or for a full-scale company.

Real-Life Examples of SolidWorks in Action

Still not sure what SolidWorks can do? Check these examples:

• A student uses SolidWorks to model a robot arm for a science fair • A startup designs a new eco-friendly water bottle, testing for leaks • An architect uses it to create custom furniture for an office • A mechanical engineer builds a car engine that works in virtual simulation • A toy maker designs a puzzle with moving parts that snap together perfectly

From small projects to huge machines, SolidWorks helps make ideas real.

Should You Try SolidWorks?

If you’re interested in 3D design, engineering, product development, or even DIY invention, SolidWorks is absolutely worth exploring. It makes designing more fun, more visual, and way more efficient.

You don’t need to build prototypes with cardboard and glue anymore—now, you can design in 3D and test it before building anything physical.

0 notes

Text

Why SOLIDWORKS 3D CAD Software is the Go-To Choice for Modern Product Design in India

In today’s fast-paced industrial landscape, precision, efficiency, and innovation are no longer optional—they are essential. From automotive to aerospace, and from industrial design to consumer products, every sector demands high-performance tools that can bring ideas to life faster and more accurately. SOLIDWORKS 3D CAD Software stands as a benchmark in this domain, empowering professionals with an intuitive platform for 3D modeling, simulation, design validation, and manufacturing readiness.

At Tech Savvy Engineers Pvt. Ltd., a premier SOLIDWORKS Authorized Reseller in India since 2002, we understand the design challenges faced by Indian industries. That’s why we offer genuine SOLIDWORKS solutions tailored to the needs of engineers, product designers, and manufacturers in Delhi, Haryana, and the Delhi NCR region.

💡 What is SOLIDWORKS 3D CAD Software?

SOLIDWORKS 3D CAD Software is an industry-leading computer-aided design (CAD) solution developed by Dassault Systèmes. It allows users to design products in a 3D environment, helping them visualize, simulate, and refine designs before they ever reach the production floor. Whether you're creating a simple mechanical part or a complex assembly, SOLIDWORKS offers a unified platform that enhances creativity, ensures design accuracy, and shortens development cycles.

🚀 Key Features That Make SOLIDWORKS 3D CAD Stand Out

Parametric and Direct Modeling Quickly create and edit models using intuitive parametric controls and direct geometry manipulation.

Advanced Assembly Capabilities Manage large assemblies with powerful tools that ensure smooth performance and easy navigation.

Integrated Simulation Tools Validate your designs with integrated simulation to test stress, strain, motion, and thermal impacts early in the process.

Sheet Metal, Weldments, and Mold Tools Specialized features for manufacturing processes like sheet metal design, welding, and mold tooling.

Automated Drawing Creation Generate 2D drawings directly from 3D models with accurate dimensions, tolerances, and annotations.

Data Management Integration Seamless collaboration with SOLIDWORKS PDM for version control, access control, and data integrity.

🏭 Industries Benefiting from SOLIDWORKS 3D CAD Software in India

Automotive & Transportation

Aerospace & Defense

Heavy Engineering & Machinery

Consumer Electronics

Medical Devices

Tool & Die Manufacturing

With the rise of Industry 4.0 and digital manufacturing in India, SOLIDWORKS helps engineers transition from 2D legacy systems to a modern, connected product development platform.

📈 Benefits of Choosing SOLIDWORKS from Tech Savvy Engineers Pvt. Ltd.

Authorized Reseller Since 2002 We’ve been delivering genuine SOLIDWORKS solutions for over two decades. When you buy from us, you're not just purchasing software—you’re investing in proven reliability.

Certified Training & Support Our SOLIDWORKS-certified experts provide hands-on training, onboarding, and support to ensure your teams are always productive.

Engineering Consultancy Services Our engineers work closely with clients across sectors, offering simulation, modeling, and manufacturing guidance.

Flexible Licensing Options Choose from perpetual or term licenses tailored to your company’s size and growth trajectory.

PAN India Service with a Focus on NCR Based in Delhi NCR, we serve clients across Delhi, Haryana, Gurugram, Faridabad, and surrounding regions with unmatched customer care.

🎯 Why SOLIDWORKS 3D CAD Software Is the Future of Design

Innovation Speed: Drastically reduce time from concept to product.

Accuracy & Error Reduction: Simulate real-world conditions to catch design flaws early.

Collaboration: Share models, drawings, and revisions effortlessly across departments.

Sustainability: Optimize material usage and reduce prototyping waste.

Whether you're a startup designing your first prototype or an established enterprise scaling up your product portfolio, SOLIDWORKS gives you the edge to compete locally and globally.

🛠 SOLIDWORKS Packages Available

At Tech Savvy, we offer all editions of SOLIDWORKS 3D CAD Software:

SOLIDWORKS Standard: Perfect for core 3D modeling needs.

SOLIDWORKS Professional: Includes tools for design validation, data management, and photorealistic rendering.

SOLIDWORKS Premium: Adds advanced simulation and motion analysis tools.

We help you choose the right package based on your business goals and technical requirements.

💬 What Our Customers Say

“Switching to SOLIDWORKS from a 2D platform was a game-changer. With Tech Savvy's support, we were up and running in no time.” – Rahul V., Mechanical Design Engineer, Gurugram

“Their post-sales service is excellent. Any issue is resolved with priority. Highly recommended!” – Anita S., Product Manager, Faridabad

🔚 Final Thoughts

In an era where design innovation drives business success, having the right tools is crucial. SOLIDWORKS 3D CAD Software is not just a design platform—it’s a complete ecosystem that enhances every phase of product development.

As a trusted name in engineering solutions, Tech Savvy Engineers Pvt. Ltd. is your ideal partner to unlock the full potential of SOLIDWORKS in India. Our commitment to genuine software, expert guidance, and long-term support makes us the preferred choice for businesses serious about design excellence.

📞 Let’s Get Started Today!

For consultation, demo, licensing, or training, reach out to us:

📞 Call: +91-9650032300 📧 Email: [email protected] 🌐 Website: https://techsavvy.co.in/

#solidworks cad software#solidworks 3d cad software#solidworks cad#solidworks training#training solidworks

0 notes

Text

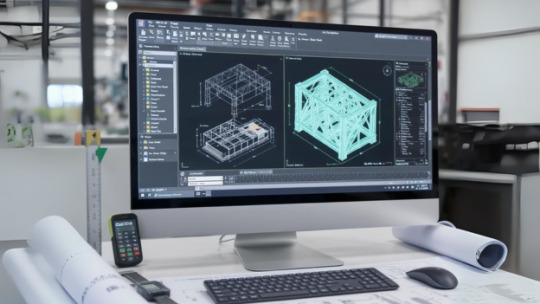

AutoCAD in Mechanical vs Civil Engineering: Key Differences in 2025

Introduction

AutoCAD is one of the most widely used computer-aided design (CAD) tools in the engineering world. Developed by Autodesk, it is essential for drafting, modeling, and designing across various engineering disciplines. Among these, mechanical and civil engineering are two major fields where AutoCAD plays a pivotal role. Although the software remains the same at its core, its application varies significantly between the two.

AutoCAD in Mechanical Engineering

In mechanical engineering, AutoCAD is mainly used to design mechanical components, assemblies, and machinery. It helps engineers create precise 2D and 3D models of parts that are later manufactured or assembled.

AutoCAD in Mechanical, a specialized version of AutoCAD, offers features tailored to mechanical design. These include standard parts libraries, automatic part number generation, bill of materials (BOM) creation, and support for Geometric Dimensioning and Tolerancing (GD&T). These tools help streamline the mechanical design process, reduce manual effort, and minimize the chances of error.

Mechanical engineers also use AutoCAD to perform simulations and stress tests on models, ensuring parts function correctly before physical prototyping begins. Whether it's designing automotive parts, HVAC systems, or industrial machines, AutoCAD allows for a high level of accuracy and efficiency.

AutoCAD in Civil Engineering

Civil engineers, on the other hand, use AutoCAD for designing infrastructure like roads, bridges, drainage systems, and buildings. The focus here is on large-scale site planning, terrain modeling, and layout design.

AutoCAD Civil 3D, a specialized toolset built on AutoCAD, is widely used in the civil sector. It provides features like grading tools, contour lines, corridor modeling, surface creation, and integration with Geographic Information Systems (GIS). These tools help civil engineers design projects in the context of real-world topography and regulatory requirements.

Unlike mechanical engineers who focus more on machine components, civil engineers use AutoCAD to work with land surveys, plot plans, elevation drawings, and utility designs. Collaboration and project sharing are crucial in civil engineering, and AutoCAD's compatibility with other Autodesk products enhances this capability.

Key Differences Between Mechanical and Civil Applications

While both disciplines use AutoCAD for drafting and modeling, their focus areas differ:

Mechanical Engineering emphasizes part design, assemblies, and mechanical simulations.

Civil Engineering focuses on site layout, structural elements, and integration with land data.

Mechanical designs are often compact and require intricate detail, whereas civil projects cover larger geographical areas and must align with environmental and legal constraints.

Conclusion

AutoCAD serves as a powerful and flexible tool for both mechanical and civil engineers, but the way it's utilized reflects the unique demands of each discipline. Mechanical engineers benefit from detailed modeling and automated part management, while civil engineers use its advanced terrain and layout capabilities for infrastructure development. Understanding these distinctions helps students and professionals select the right toolset and approach within AutoCAD for their specific field of work.

0 notes

Text

Why the SpaceMouse Pro Wireless Is Becoming a Must-Have for 3D Creators

In the fast-evolving world of 3D design, engineering, and digital creation, precision and fluidity are everything. Whether sculpting digital environments, designing intricate product prototypes, or crafting architectural blueprints, tools need to feel less like limitations and more like creative extensions.

One tool that’s quietly reshaping the workflow of professionals across industries is the SpaceMouse Pro Wireless by 3Dconnexion. It’s not just another input device — it’s a new way of interacting with 3D environments that brings ease, control, and flexibility to the design table.

Understanding the SpaceMouse Pro Wireless

Unlike traditional mice, which are built primarily for 2D navigation, the SpaceMouse Pro Wireless is designed with 3D navigation at its core. The central component is a controller cap equipped with a 6-Degrees-of-Freedom (6DoF) sensor. This allows smooth rotation, zooming, and panning of 3D models — all at the same time.

Rather than clicking and dragging through dozens of steps, the SpaceMouse enables fluid, intuitive movement across digital space. It allows for more natural control of perspective and orientation — which is a game-changer in any 3D-intensive workflow.

Key Features at a Glance

Some standout features that make the SpaceMouse Pro Wireless truly functional:

6DoF Sensor: Enables effortless 3D navigation using subtle hand pressure — rotate, pan, and zoom simultaneously.

Wireless Capability: Offers a clean, clutter-free workspace with both Bluetooth and USB receiver support.

Customizable Function Keys: Four intelligent keys adapt to different software environments, speeding up common commands.

Ergonomic Design: Built with long sessions in mind, it features a soft wrist rest and a thoughtfully contoured layout.

Portable Setup: Comes with a professional travel case for those who work from multiple locations.

Why Wireless Makes a Real Difference

Going wireless isn’t just about fewer cords on the desk. In practice, it creates more freedom — both physically and mentally. Without the usual cable constraints, designers can work from different positions, set up their workspace more flexibly, and maintain a cleaner, more focused environment.

Battery lasts up to 2 months on a single charge.

Uses a unified USB receiver, which can connect up to five 3Dconnexion devices.

Excellent for hybrid workers, traveling professionals, or studios with shifting setups.

Compatible With Leading Software

The SpaceMouse Pro Wireless isn’t tied down to one niche program. It supports a wide variety of industry-standard applications across CAD, BIM, 3D modeling, and animation platforms:

AutoCAD

Revit

SolidWorks

Fusion 360

Blender

Rhino

CATIA

Siemens NX

SketchUp

Inventor

Function keys and navigation behavior can be customized for each software using the 3DxWare® 10 driver, giving users a personalized experience no matter the application.

The Power of Two-Handed Workflow

When paired with a regular mouse, the SpaceMouse Pro Wireless enables a true two-handed workflow. One hand handles view manipulation, while the other focuses on commands, modeling, or selection. This approach isn’t just faster — it’s more natural.

Reduces repetitive strain by spreading tasks between both hands.

Enhances productivity through smoother transitions and less visual reorientation.

Minimizes interruptions that come from constantly adjusting views with keyboard shortcuts.

Over time, this kind of workflow can significantly improve both output speed and user comfort.

Who Benefits Most?

The SpaceMouse Pro Wireless isn’t designed for just one kind of professional. Its versatility makes it a great asset across fields:

Engineers working with detailed assemblies benefit from precise control and faster reviews.

Architects can walk through 3D floor plans in real time with smooth, lifelike navigation.

3D artists enjoy better camera control in modeling, sculpting, and animating environments.

Product designers gain easier access to hidden components and complex angles.

Students and educators get a clearer understanding of spatial relationships in 3D learning tools.

Wherever 3D models are part of the process, this device adds value.

Built for Modern Creativity

The design of the SpaceMouse Pro Wireless reflects what today’s creators need: comfort, accuracy, and adaptability. Its ergonomic form ensures minimal hand fatigue, even during long creative sessions. Its wireless nature suits both minimal desk setups and dynamic workspaces. And its software integration allows professionals to customize workflows that work best for them.

This isn’t about replacing the traditional mouse. It’s about enhancing the interaction with 3D design space — turning it from a set of clicks and drags into a fluid, immersive experience.

A Smarter Way to Design

3D design is more than technical execution — it’s a deeply creative process. And like any creative work, it requires tools that enable better focus, better flow, and fewer frustrations.

The SpaceMouse Pro Wireless fits into this vision. It simplifies navigation, boosts productivity, and keeps creators in their zone. For any serious 3D professional, animator, designer, or student — this device is a worthy addition to the toolkit.

Explore more or get yours here: 👉 https://www.tridaxsolutions.com/product/spacemouse/

#3Ddesign#SpaceMouse#ProductivityTools#CADtools#ArchitectureTools#Blender#SolidWorks#AnimationGear#WirelessDevices

0 notes

Text

How Do 3D Designing Services Transform Your Ideas into Reality?

Introduction:

Today's fast-paced, innovation-driven world requires the ability to turn abstract ideas into tangible, visualized products. This transformation relies on 3D designing services. These services bridge the gap between imagination and implementation by providing detailed, lifelike visualisations of ideas before they are physically created. Whether it's for product development, architecture, or animation, 3D design helps stakeholders see, understand and perfect their concepts early in the process.

3D design is fundamentally about visualizing complex ideas in three dimensions. Traditional 2D sketches or blueprints often fall short when conveying depth, proportions, and the full vision of a project. With 3D modeling, clients and teams can view a virtual prototype that closely resembles the final output. This makes it easier to detect design flaws, make improvements, and ensure alignment with the original vision. This is before any materials or resources are invested.

Moreover, 3D designing services enhance the communication among team members, clients, and investors. When you showcase a concept as a realistic 3D model or animation, others can understand and support your idea. This is particularly beneficial during pitches or presentations, where strong visuals can leave a lasting impression. It also helps with gathering early feedback, and ensuring that the final product meets the expectations of all stakeholders.

3D design also boasts flexibility and adaptability. Designers can easily change a 3D model in response to feedback, allowing rapid iterations. This speeds up the development cycle significantly compared to traditional design methods. For example, if a client wants to see the product in a different color or with modified features, the designer can adjust the model instantly without starting from scratch. This saves time, reduces costs, and enhances creativity.

In industries such as architecture and construction, 3D design services play a crucial role in project planning and execution. With Building Information Modeling (BIM), for instance, architects and engineers can simulate entire buildings in 3D, complete with structural details, lighting, and materials. This allows them to identify potential issues like spatial conflicts or design inefficiencies before breaking ground, ensuring smoother project management and better resource allocation.

Product development is another area where 3D designing transforms ideas into reality. From concept to prototype, designers use 3D CAD (Computer-Aided Design) software to create models that can be tested, simulated and even 3D printed. This reduces the time-to-market and improves the final product accuracy. Whether it’s a consumer gadget, medical device, or automotive part, 3D design allows detailed visualization, functional testing and cost-effective production planning.

The impact of 3D design also extends to marketing and user experience. By creating photorealistic renderings or interactive 3D animations, businesses can showcase products before manufacturing. This is especially valuable in industries like real estate, fashion, and consumer electronics, where visual appeal is critical. Virtual tours, augmented reality experiences, and immersive product demos made possible by 3D design attract customers and boost engagement.

In summary, 3D designing services transform abstract concepts into concrete realities. They enhance visualization, collaboration, reduce development time, and increase final output accuracy. From architects to engineers, marketers to entrepreneurs, anyone with a creative idea can benefit from 3D design technology. As the demand for faster innovation and immersive experiences grows, 3D designing will remain an essential part of turning imagination into innovation.

More information:

Call: +91-9791995601

Mail ID: [email protected]

Website: www.fitfuturegroup.com

0 notes

Text

Finite Element Analysis and CAD Overview

Finite Element Analysis (FEA) and Computer-Aided Design (CAD) are cornerstone technologies in modern engineering, enabling the design, simulation, and optimization of complex systems and components. FEA simulates physical behavior to predict how designs will perform under real-world conditions, while CAD facilitates precise modeling of those designs. Together, they streamline product development across industries like automotive, aerospace, and manufacturing. This 800-word overview explores the principles, applications, benefits, challenges, and future trends of FEA and CAD integration.

Principles of FEA and CAD

FEA and CAD work in tandem to create and validate engineering designs:

CAD Modeling: CAD software, such as SolidWorks, AutoCAD, or CATIA, allows engineers to create detailed 2D and 3D models of components or systems. These models define geometry, materials, and boundary conditions for further analysis.

Finite Element Analysis: FEA divides complex geometries into smaller, manageable elements (meshes) to simulate physical phenomena like stress, deformation, or heat transfer. Software like ANSYS, Abaqus, or COMSOL solves mathematical equations to predict system behavior.

Mesh Generation: FEA relies on meshing, where CAD models are discretized into finite elements. The mesh quality and density impact simulation accuracy and computational efficiency.

Boundary Conditions and Loads: Engineers apply real-world conditions, such as forces, pressures, or temperatures, to CAD models within FEA software to simulate operational scenarios.

Simulation and Analysis: FEA software solves equations for each element, analyzing responses like stress distribution, vibration, or thermal performance, enabling engineers to identify potential failure points.

Iterative Optimization: CAD and FEA enable iterative design refinement, where engineers modify models based on simulation results to improve performance, safety, and efficiency.

Applications of FEA and CAD

FEA and CAD are integral to a wide range of industries:

Automotive: CAD designs vehicle components like chassis and engines, while FEA simulates crashworthiness, structural integrity, and thermal management, ensuring safety and performance.

Aerospace: FEA analyzes aircraft wings, fuselages, and turbine blades for stress, fatigue, and aerodynamics, while CAD creates precise models to meet stringent regulatory standards like DO-160.

Civil Engineering: CAD models bridges, buildings, and dams, and FEA evaluates their stability under loads like wind, earthquakes, or traffic, ensuring structural safety.

Consumer Products: CAD designs ergonomic products like smartphones or appliances, while FEA tests durability, drop resistance, and thermal performance for reliability.

Manufacturing: FEA optimizes tooling and machinery designs, reducing material waste and wear, while CAD ensures precise fabrication and assembly processes.

Medical Devices: CAD models prosthetics or implants, and FEA simulates biomechanical interactions to ensure compatibility and durability in the human body.

Benefits of FEA and CAD Integration

The integration of FEA and CAD offers significant advantages:

Reduced Prototyping Costs: Virtual simulations in FEA reduce the need for physical prototypes, saving up to 30% in development costs, according to industry studies.

Improved Design Accuracy: FEA identifies stress concentrations, deformations, or thermal issues early, enabling CAD modifications to enhance design reliability and performance.

Faster Time-to-Market: Iterative simulations streamline the design process, allowing engineers to test multiple scenarios virtually, accelerating development cycles.

Enhanced Safety: FEA ensures designs meet safety standards by simulating extreme conditions, reducing risks in applications like automotive crash testing or aerospace components.

Material Optimization: FEA analyzes material performance, enabling engineers to select lightweight, cost-effective materials in CAD, reducing production costs and environmental impact.

Cross-Disciplinary Collaboration: CAD and FEA provide a common platform for mechanical, structural, and thermal engineers, fostering collaboration and reducing design errors.

Challenges in FEA and CAD

Despite their benefits, FEA and CAD integration presents challenges:

Computational Demands: High-fidelity FEA simulations require significant computational resources, especially for complex models with fine meshes, increasing processing time and hardware costs.

Model Accuracy: Inaccurate CAD geometries or oversimplified FEA assumptions can lead to unreliable results, requiring expertise to balance accuracy and computational efficiency.

Learning Curve: Mastering CAD and FEA software demands training in modeling, meshing, and simulation techniques, which can be time-consuming for new users.

Software Costs: Licenses for advanced CAD and FEA tools, such as ANSYS or SolidWorks, are expensive, posing a barrier for small organizations or startups.

Interoperability Issues: Compatibility between CAD and FEA platforms can be limited, requiring data conversion or additional software to ensure seamless integration.

Future Trends

The future of FEA and CAD is shaped by technological advancements and industry needs:

Cloud-Based Simulation: Cloud platforms like ANSYS Discovery or Autodesk Fusion 360 enable remote CAD modeling and FEA simulations, reducing hardware costs and supporting global collaboration.

AI and Machine Learning: AI optimizes mesh generation, predicts failure modes, and automates design iterations, enhancing FEA accuracy and reducing computation time.

Generative Design: CAD tools with generative design algorithms create optimized geometries based on FEA constraints, enabling lightweight, efficient designs for aerospace and automotive applications.

Digital Twins: FEA and CAD are integral to digital twins, providing real-time virtual models for monitoring and optimizing physical systems throughout their lifecycle.

Sustainability Focus: FEA and CAD are supporting eco-friendly designs by optimizing material use and simulating energy-efficient systems, aligning with global sustainability goals.

Conclusion

FEA and CAD are indispensable tools in modern engineering, enabling precise design and robust analysis of complex systems. Their integration streamlines development, reduces costs, and enhances reliability across industries like automotive, aerospace, and medical devices. While challenges like computational demands and software costs persist, advancements in AI, cloud computing, and generative design are expanding their capabilities. As industries demand innovative, sustainable solutions, FEA and CAD will continue to drive progress, shaping the future of engineering design and performance optimization.

0 notes