#membrane filter plate

Text

Trends Shaping China's Membrane Filter Plate Market

In China, trends in the membrane filter plate market are shaping up due to a growing need for bio-based medicines and stricter water cleaning rules from the government. These shifts come as businesses look for better ways to process materials without using much energy. Also, the COVID-19 pandemic has had a big effect on this industry by changing how companies work and people live their daily lives.

With an eye on clean processing methods that save on costs, China's focus turns more towards advanced solutions like high pressure membrane filter presses. This is finding its role not just in health care but across various sectors aiming for efficiency and quality in filtration tasks.

Understanding China's Membrane Filter Market

China's membrane filter market is seeing a rise, pushed by growing needs in bio-medicine and water clean-up. With the world facing COVID-19, this push became stronger. More than ever, ensuring water purity has caught government attention.

This demand fuels growth for advanced filtration methods like high-pressure membrane filter presses. In detail, low energy costs make these systems attractive for industries needing to sift through or clear up their liquids or gases without heat damage. These filters work well across many settings – from removing tiny particles in manufacturing processes to cleaning dyes from wastewater without harming sensitive materials.

The largest piece of this puzzle? Reverse osmosis technology takes the lead due to its power in demineralizing and purifying water—making it a go-to choice not just in China but globally for drinkable water solutions. However, challenges loom large.

Maintaining these delicate systems can be costly and complex if not handled with care.

Growth Drivers in Membrane Filtration Technology

Membrane filtration is key for wine and beer, making these drinks clear and stable by taking out unwanted bits. Yet, this tech faces big hurdles like strict safety rules and the challenge of membrane fouling—a buildup that spoils water or products. The COVID-19 outbreak hit this industry hard due to social distancing and lockdowns affecting operations.

In 2024, the wine and beer sector leads in using membrane filter plates in China because they help keep bones strong by upping bone density which cuts down on diseases like osteoporosis. The use of plate and frame setups is growing fast as they're great for many projects thanks to their design being easy to work with, operate smoothly, and fix without a hassle.

High Pressure Filters Reshaping the Industry

High pressure filters are changing the game in China’s membrane filter plate market, thanks to their advanced features. These plates shine because they’re built tough yet flexible and come out of CNC machining with unmatched flatness below 25µm. This precision ensures a perfect seal during pressing, eliminating leaks when feeding.

They not only meet but exceed both Chinese JB/T4333.3-2005 and German DIN7129 standards, matching European and American quality levels. Filtration speed jumps by 20%, while density, strength against fatigue and aging double up compared to standard national models. Their max feed pressure hits an impressive 1.6Mpa, supporting high temperature and pressure conditions without compromising on antisepsis or airtight sealing.

hzfilter steps it up with materials, offering plates made from various metals like cast iron or stainless steel, as well as PP or TPE for different needs. They handle pressures up to 3 Mpa easily, ensuring short filtering cycles that retain low moisture content in cakes. The introduction of membrane plates marks another leap forward.

These marvels can squeeze solid contents precisely through additional pressurization post-filtration, improving cake solidity significantly and cutting down energy use. This kind of technological evolution presented by hzfilter points towards more effective eco-friendly solutions within industry operations showcasing how high-pressure filtration technology is indeed reshaping sector standards notably.

Innovations in China’s Filter Press Manufacturing

In China's evolving filter press market, manufacturers like hzfilter Equipment Co., leading with innovation. They craft membrane filter plates vital for industries needing solid-liquid separation. These firms stand out by focusing on research and development to push the boundaries of what their filtration equipment can achieve.

hzfilter, for instance, boasts 128 valid patents including international ones. Their work in creating new products shows a dedication not just to quality but also pushing technological limits within environmental protection sectors.

These companies illustrate how investment in technology catalyzes product improvement while catering to diverse needs from sewage treatment to industrial waste management globally. Through advanced manufacturing techniques and robust service networks spanning both domestic markets and beyond, these enterprises underscore China's position as a hub for high-performance membrane filter press production offering solutions that meet varied customer requirements efficiently.

Environmental Policies Fueling Market Evolution

New green rules are changing how companies make stuff. In China, this means firms making membrane filter plates have to think about the environment more than before. These policies push for less pollution and waste.

So, factories need better tech to clean water and air they use or release. This makes them buy new types of filters that catch tiny bad bits better than old ones did. Because these cleaner methods often cost more money up front, businesses look for efficient options that save cash over time too.

This shift isn't just good news for our planet; it's also creating a big chance for makers of these advanced filters in China’s market.

Export Expansion and Global Impact

As China ramps up its membrane filter plate exports, the global market feels the impact. This move not only boosts China's economy but also changes how other countries handle their filtration needs. With more options now available, prices have become competitive worldwide.

Quality standards are pushed higher as a result of this competition, benefiting various industries from pharmaceuticals to wastewater treatment globally. Consumers and companies alike notice improvements in both cost-efficiency and performance levels of filtration products they use daily. It’s clear that through expanding export activities, China is playing a key role in shaping advancements and accessibility in the membrane filter plate industry across continents.

Future Projections for Chinese Manufacturers

Chinese manufacturers are focusing more on automation, using robots for faster and better production. They aim to cut costs and improve safety with these advanced machines. This shift means China's factories are now filled with modern tech, not old methods.

Also, they're pushing for greener ways to make things, reducing harm to our planet by cutting down waste and using clean energy like sun and wind power. Infrastructure is getting a big boost too – think smart factories powered by the latest 5G networks. And it doesn't stop there; innovation is key in staying ahead globally, making quality goods fast that meet new demands without costing the earth.

The market for membrane filter plates in China shows dynamic growth, shaped by innovation and environmental needs. As firms seek cleaner operations, high-pressure membrane filters from hzfilter stand out. Offering efficient filtration with less energy use, they meet the demand for sustainable solutions.

Their adaptability to diverse industries further pushes their appeal. With ongoing research and development, expect these technologies to evolve even more., addressing both current challenges and future demands This trend underscores a shift towards greener practices within sectors reliant on filtration technology.

#membrane filter plates in China#China’s Filter Press Manufacturing#high pressure membrane filter presses#membrane filter plate#hzfilter

0 notes

Text

Best Membrane Plate Filter Press In India

Yotana is well known best membrane plate filter presses manufacturers in Ahmedabad, Gujarat. We provide top quality membrane plate filter presses to our local and global client. Our membrane filter presses offer exceptional dewatering and reduce filtration time by over 50%, based on the suspension. Explore our Filter Press Plates for superior filtration solutions.

0 notes

Text

As an exercise in creature design and in the interest on developing my dreaming-verse/general world building lore, i thought these guys would be fun to do!

More lore / transcript:

THE STRIDER:

Peaceful lava walkers and grazers, they’re often breed and domesticated for both their use as transportation across the lava lakes and for various materials.

While not certainly an acquired taste to an overworlder, strider meat is not an uncommon food source. String and membranes from their opalescent sensory organs and hide are also valuable resources.

The membranes are heat management, courting displays, and gathering sensory input as they are near-blind.

Strider's eyes are largely vestigial, the sensory organs picking up on heat signatures exclusively.

They have spiracles for breathing along their sides and tails.

When wading through lava, their limbs are able to stretch out, this process requires the high temperature and results in the brighter, redder coloration of their skin as the heated fluids move under it. When not on lava, this fluid cools resulting in a duller coloration.

A subspecies of strider can be found in regions of the deep Neth that are blue in color.

They are long lived and migratory creatures, lichens and fungi often growing on their harder outer plates to spread across lava lakes. These are not an incident the striders, though magma barnacles, the stationary stage of a Nether-local insectoid species are considered pests.

Adolescent striders are a few meters tall, though they can grow considerably larger.

When being ridden, a lantern full of the phosphorescent warped mushrooms that Striders prefer. This lantern has the bonus effect of glowing when passing across sections of land. While Striders prefer to graze on fungi, they also spend significant amounts of time filtering minerals from the lava lakes.

Flags are displayed to help make visible where the rider and the strider are coming from and what the point of travel for the rider is.

THE GHAST:

Territorial and aggressive animals that use the updrafts of lava lakes to remain afloat in the the atriums of the Neath.

Ghats contain organs able to solidify and fire out explosive charges, when about to fire, the organ will light up, an illusion of a demonic face appearing through their spiracles and semi-transparent bodies.

They feed on minerals and airborne biological matter that filters out of the biomes in the upper-regions of the Neth with their oral arms.

The ghast tear is an organ in their center arm.

Adult ghasts release their own spores into the air to help with genetic exchange, otherwise growing young ghast on their bodies that eventually split off in a sort of mitosis.

the gelatinous bodies of ghasts are used primarily in construction and fuel, but parts of their innards, explosive organs not included, are commonly eaten.

#dreamingverse au#minecraft#world building#my art#minecraft worldbuilding#minecraft ghast#minecraft strider#speculative biology#this stuff is up to changing but I think its a good start

236 notes

·

View notes

Text

Strawberry Kisses

While searching the River House for her sisters, Nesta accidentally stumbles upon Elain sharing an intimate moment in the garden with a certain Spymaster.

Please note, that while this is technically a bonus chapter to my series, Echoes in the Hallway, it can be read as a stand alone one-shot xx

No warnings, pure fluff. 1.4k words.

ENJOY XX

Read on AO3

The skirts of Nesta’s pale blue gown, one of many gifted to her from Rhysand, fluttered around her ankles as she traipsed through the bright hallways of the River House, poking her head in and out of various rooms in search of her sisters and nephew. They hadn’t been in either of the libraries, the nursery was empty. Even the kitchen, usually the epicenter of bustling activity, had been suspiciously quiet when she’d breezed past it earlier before making her way upstairs.

Cassian was away on a business trip with Rhysand for the past few days and Nesta had been left to her own devices for just a little too long. She’d done fine on her own for the first day and a half but she’d slowly been losing her mind without her mate’s company ever since, even if she loathed to admit it. It’s why she’d practically begged Azriel to drop her off in town this morning, hoping that the promise of bookstores, patisseries, and maybe even a leisurely stroll along the glittering Sidra would be enough to ease her gloomy mood.

It worked for a couple hours but even then she had still felt the need to seek the company of her sisters. Something that had once been rare, but had slowly become a recurring urge ever since she’d found some semblance of inner peace.

Nesta huffed, cursing under her breath as she bounded down the stairs and back into the kitchen to take another peek around. She spotted a covered dish sitting to the left of the kitchen window. She lifted the plate off the top to find a tempting lemon tart, two small slices already missing. Abandoning the search for her siblings, Nesta took a fork from the cupboard and plated herself a slice, humming happily at the delicious tang of the lemon curd that she guessed Elain had made either this morning or the night before. She was halfway through her third bite when a bit of movement outside of the kitchen window caught her eye.

Nesta had always thought that Elain looked like Spring, like the very essence of life, itself - but never more so than when she was in her garden, surrounded by various plants and flowers. She wore a plain linen dress, the butter yellow fabric pooled around her, reflecting the sunshine in a way that set her face and bare arms aglow. Her long hair was unbound, the length of it falling in soft waves down her back. Elain had tied a sage coloured scarf around the crown of her head to keep the golden strands from getting into her eyes as she knelt in front of a flourishing patch of berries, one that she’d been lovingly tending to ever since the weather had started to warm a couple months ago.

Nesta was just about to turn to make her way outside to say hello to her sister as well as enquire about the whereabouts of Feyre and Nyx but she stopped, eyebrows furrowing, when she realised that Elain wasn’t out in the garden by herself.

Azriel came into view, his tall frame clad in the same black leathers he’d been wearing this morning when he’d dropped off Nesta in town. He’d told her he was headed Under the Mountain for the day yet here he was - more relaxed than she’d ever seen him - those enormous wings of his were flared out wide, the sunlight beautifully filtering through the delicate membrane as he approached Elain with a dozing Nyx cradled carefully against his chest.

Nesta watched, lips parted in disbelief, as he knelt down next to her sister. The Shadowsinger, usually so reserved and sullen, had a soft smile on his lips. His shadows were nowhere to be seen and there was a certain look in his eyes as he spoke to Elain that Nesta recognised but couldn’t quite comprehend.

She couldn’t hear the words they exchanged due to the wards Rhys had placed on every inch of this house but the manner in which Azriel conversed so freely and the carefree way Elain laughed in response to whatever he had said, was enough to pique her interest.

She continued to stand frozen in place, afraid the slightest movement would alert them to her presence, as Elain picked out a strawberry from the wicker basket she’d been collecting them in. She quickly wiped the berry off on her skirt, ensuring any lingering dirt fell away before she lifted the fruit to her lips. Nesta’s attention shifted to Azriel’s face as Elain bit into the bright red strawberry. The expression she found there should’ve been enough to make her look away but she couldn’t bring herself to do so.

Instead, her eyes stayed glued to the scene in front of her. Her gaze followed Elain’s hand as she reached out and extended that same strawberry to Azriel. She watched as he wrapped his lips around the fruit, directly over where Elain’s own lips had just been. His hazel eyes remained on Elain’s face through it all. Elain raised up on her knees when Azriel pulled back, watching the movement of his throat as he swallowed. She inched closer to him, one small hand landing on his shoulder for balance while the other came to rest on his chest.

Nesta’s breath caught in her chest when Elain, with no hesitation whatsoever, gently pressed her lips to Azriel’s.

The kiss they shared was chaste, as if they were being mindful of the babe between their bodies. Still, Nesta found herself blushing at the intimacy of it. The way their lips brushed together in a series of pretty, innocent kisses. The sweet way Elain held his face, her thumb stroking along his strong jaw. The firm grasp of Azriel’s free hand low on the swell of her hip, the linen of her dress scrunched up under his long fingers.

There was an ease, a natural familiarity between them that made it clear that this wasn’t anything new. It was immediately evident to Nesta, just from this singular moment, that this kiss wasn’t the first that they’d exchanged. It wasn’t even one of the first few. She’d go as far as to say that they’d done far more than simply kiss, if the comfort with which they touched each other was anything to go by.

She’d picked up on some form of tension between them once. Last Solstice. She and Elain had passed by Azriel and they’d exchanged a certain look that made Nesta think that perhaps there was something between them. She’d let it go, had convinced herself that she’d imagined it because the two of them had seemingly stopped spending any sort of time together after that night.

But now, seeing them here - together - it was clear that Nesta hadn’t imagined the yearning and desire in those shared glances. She felt a little thrill of self satisfaction zip up the length of her spine at the knowledge that she’d been right all along.

She continued to shamelessly watch until Elain finally pulled away from him, a coy smile on her lips and a pretty blush on her cheeks that matched the Shadowsinger’s own pleased expression. Elain bent down to peer at Nyx - still asleep against Azriel’s chest, completely oblivious to the secret relationship that his Aunt and Uncle were cultivating that only he had witnessed.

Until now.

Nesta finally turned away from the window, unable to keep the smile from her face as she quickly and quietly made her way out of the house, miraculously undetected by the two lovers.

She couldn’t stop thinking about it - about how much sense it made. How much sense they made. Azriel, who she was well aware believed he wasn’t deserving of love, and Elain, who loved so easily that it was like second nature to her. They were two sides of the same coin - sun and moon, day and night - perfectly balanced, the perfect complement to each other.

Nesta knew why they’d kept this quiet, why those secret looks had transpired into this secret relationship. Elain’s situation would certainly complicate things even if Nesta firmly believed her sister shouldn’t have to comply with some predetermined destiny that she seemingly wanted no part of.

Regardless, Nesta would keep this to herself until they chose to come forward, if they ever chose to come forward. She wouldn’t mention it to anyone. Not to Feyre. Not to Azriel or Elain. Not even to Cassian. Much like what she’d seen on Solstice, she knew that this was their secret to tell. Never hers.

🍓🍓🍓🍓

Thank you for reading! If you're interested, you can find the rest of my writing in my masterlist xx

#elriel#elriel fic#elriel fanfiction#listen ive had inexplicable crippling anxiety about posting anything ive written for the past three weeks#so as queen taylor would say#this is me trying#elain x azriel#azriel x elain#nesta archeron#nesta pov#acotar#elriel fluff#my writing#fic rec#ao3 fanfic

107 notes

·

View notes

Photo

ok u know what. *organics your robots*

spec bio wubbox concepts because why not! lore and rambling under the cut:

The Wubbox is an ancient species of monster dating back to the Dawn of Fire. Presumed to be extinct post-cataclysm, several caves full of dormant eggs have been found in the present day, and the species has once again become widespread in monster society. Loud, powerful, and somewhat territorial, they served as guardians of pre-contemporary monster tribes, and were regarded as gifts from the Celestials.

pic explanations

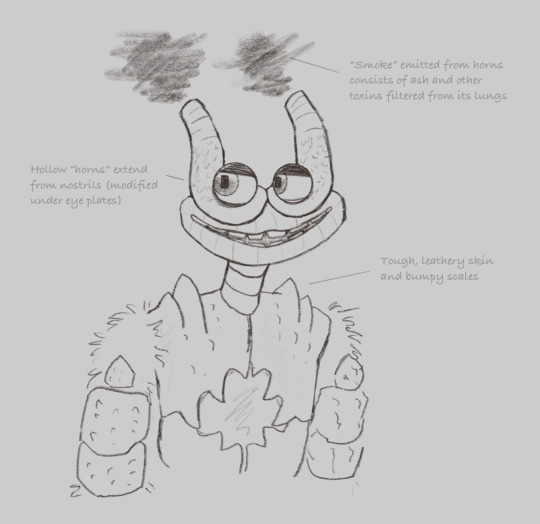

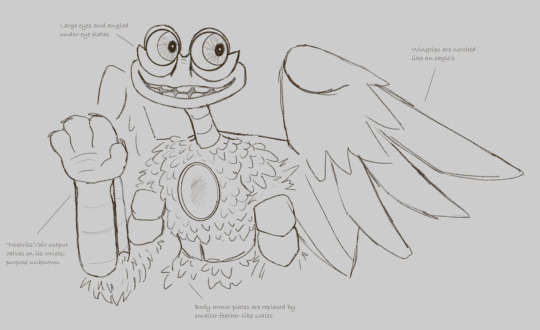

1. sketch of an adult wubbox, with different textures/components labeled. they are mostly covered in armor-like scales that are shed periodically; these can be replaced/upgraded by artificial parts, and are often repurposed into armor and instruments by other monsters.

2. sketch of a wubbox hatchling + notes:

- Baby teeth are sparse but very sharp, can and will eat almost anything (young wubboxes are notoriously ravenous, which lead to the myth that they eat other monsters)

- Protective cap over chest “speaker” (see image 4), falls off after a few weeks

- Long, fluffy fur for retaining warmth

- Simple armor plates that are shed several times while growing; initial set is made of eggshell parts that fuse onto the hatchling’s body

- Bioluminescent markings do not appear until adulthood

3. “blushing” wubbox; when flustered, their under-eye plates retract slightly, exposing patches of fur on their cheeks. these patches, like the rest of their fur, is bioluminescent, and is similar in texture to fiber optic lights

4. rough respiratory system diagram. they have very large lungs with a sort of dual output system; when speaking or “singing”, air passes through their larynx and into a hollow cavity in their chest covered by an eardrum-like membrane that functions like a speaker. this amplifies their voice and creates their signature booming roars.

5. side view of a wubbox’s head + skull concept. their mouths are full of large, flat teeth, with a diet consisting of vegetation and processed foods.

6. earth epic concept. in this scenario, “epic” wubboxes are the result of eggs being stored in certain environments for prolonged periods of time and developing specific adaptations for said environments; for example, an earth epic would be created by keeping an egg buried in volcanic ash, in/near magma, or just in a high temperature environment.

an earth epic’s horns are hollow tubes developed from their eye plates, which grow out to cover their nostrils completely; these horns are the output of a built-in air purification function in its respiratory system that filters the ash and smoke it breathes in and ejects the contaminants in mist clouds.

7. air epic concept + notes

- Large eyes and angled under-eye plates

- Wingtips are notched like an eagle’s (air epics are very fast and agile fliers, being smaller and more lightweight than others of their species)

- “Nostrils”/air output valves on their wrists; purpose unknown (these are mainly used to emit train whistle-like shrieks for communication, but why they exist is a mystery)

- Body armor plates are replaced by smaller, feather-like scales

8. lol bald eagle

extra note bc i haven’t designed the rare versions yet: “rare” wubboxes are the result of experimentation on a common individual in an effort to “improve” the species for the modern age; all current rares are clones of the first successful specimen

141 notes

·

View notes

Text

Air Bubbles

Crash landing on a foreign planet filled with dangerous creatures could bring anyone to their knees.

Thankfully you have a large friend to keep you company, even if your first meeting was rather… unconventional.

Part 2 to Shallow Breathes

———

The sea was calm today, the soft creaking and groaning of metal resisting water pressure familiar noise as you awoke, stretching from the comfort of your bed.

In the dimness of the corridors, lit only by soft sub lighting and the ocean filtered sunlight through the windows, it was a bit difficult to completely awake, stumbling to the main common area to drink a glass of water and drink a protein pill. The air was slightly too warm for your taste, even if you were only clad in shorts and a T-shirt.

Within moments, wonderful energy broke through the fog, and your eyes focused on the water lock separating your “garage” dock from your living quarters.

You keyed it open, making a quick cup of hot sea tea, gazing grimly at the few remaining packets.

With a heavy sigh, you sat at the edge of the circle cut in the middle of your living room floor. Legs dipped down to enjoy the cool temperature.

For a few moments, you could enjoy relative piece and quiet, sipping your tea.

Your eyes closed, as you lay back against the metal floor.

Something brushed your leg-

And before you could react, something wet and rough wrapped your leg and pulled you out of your home with a smack into the water of the deep, a shriek escaping you as cold water hit you like a punch to your gut.

Your eyes briefly closed, opened in dismay and frustration as you quickly kicked back to the surface, sputtering and coughing, snorting water out of your nose.

“What the HELL Sans!”

You yelled out into the water, then felt the water vibrate with the sound of a deep chuckle.

A shadow came over the windows above your head, as you looked up to see the leviathan curve around your base, tentacles dragging with a screeching noise as his eye lights appeared below your feet as you treaded water.

You took a deep breath and dove back under, swimming down to fully take in the leviathan.

Sans was at least 20 feet long, his thick torso twice your size, as was about everything else. His bones were an oldish white, brown and black shadows highlighting scarred bone. He had a black streak over his eyes like a mask with soft blue speckles echoing those piercing eyes.

Beside his skull and ribs, his body went into a gradient of browns and blacks the further down your eyes traveled. Shoulder plates added armor along with back plating, a crest of blue membrane stretched along his forearms.

Long sweeping tentacles, a soft grey black with darker splotches, and an hypnotizing blend of blues, greens and purples under every single one.

His skull brushed along your back as he delicately nuzzled his way to press his chin into your neck, a soft purr coming from the giant creature.

You kicked back to the surface for air, Sans following as you climbed out to sit down, sopping wet. He lifted himself to rest his skull on your lap, arms circling your hips as he crooned an unknown melody.

“I missed you too,” you said softly, caressing the giant skull. You could never stay too upset with the surprisingly cuddly leviathan.

A pleased hum came from him, as he shifted to press you down upon the metal floor, head resting on your chest, his arms circling you in a protective shell of rough warmth.

“Sans, you can’t breathe up here,” you reminded him softly. It had been an odd thing to learn his name.

It was not long after your first true encounter with the leviathan, when an image, blurry and faint, yet an unmistakable face with two dark sockets, burning eye lights.

Among chirps and keens, and the sudden ringing in your ears, you heard distinct human words:

Want… keep…. safe…

The image blurred slightly. Chirps and clicks, a distorted word that ended in only a monosyllabic phrase.

Sans..

The vision has faded, but that was far from his first attempt to communicate. His vocabulary hadn’t much improved, besides a soft rumble of some sort of impression of your name.

He did so now, grumpily retreating to the water as his eyes regarding you with something you feared to call affection.

His claws reached forward, but you darted out of the way.

“No, you don’t get anymore cuddles. I’m all wet thanks to you.”

His answer caused the floor to vibrate, a displeased hum as he began to rise from the water again.

You gave him a fierce look, standing your ground.

The leviathan blinked, then huffed, retreating back to the water to wait.

A soft smile came over your lips as you hurried back to your room, the swoosh of water telling you the leviathan was following your progress. He hated he didn’t have a way to see into your quarters, but you really didn’t want to wake up in the middle of the night to see him staring as you slept.

You changed into a wetsuit, pulling on the taut material as you grabbed your flippers and mask.

An excited chirrup greeted you as you hurried back to the living room, putting on your flippers as a pleased melody echoed from below.

You had barely dipped a toe in before he was upon you, twisting and nuzzling around you, whistling and chirruping.

Y/N… pretty… keep… safe..

A soft laugh curled from your throat as you strike out, swimming wit slow kicks further out from your base, not using your portable engine yet.

Sans easily kept pace, humming as he moved beneath you, his claws tracing the curves of your body outlined by the wetsuit.

He whistled, astonishingly similar to a wolf whistle as he admired you.

You pushed his hands away with mock anger, treading water as you scanned a list for the materials you needed.

Once you had determined your needs, your hands easily found Sans’ as you swam along. Air bubbles left a trail behind as he helped tug you along, assisting you in your quest to find materials.

Even if he didn’t know what those were for.

You’d tell him one day…

…

You now enjoyed your watery trips rather than fearing them.

Time and opportunity was given to admire the twisting spirals of kelp and rock structure, nearby leviathans darting away the moment they saw Sans.

Your hand tightened on Sans’ claw as he pulled you down, showing the beauty of his homeworld.

A shame you wouldn’t be here for much longer.

———

Why couldn’t the sea emperor leviathan live!?!

Have some fluff for Mermay, and have a wonderful day!

#mermay 2023#undertale#sans#cecaelia#cecaelia sans#subnatica below zero#subnautica sans#sans x Reader#leviathan sans#x reader#fluff#wee bit of angst#cuddles

29 notes

·

View notes

Note

Okay i read through your posts again and saw some stuff i missed.

The mech replaces all life supporting vitals, so the questions about having a digestive tract and what happens to the organs solved lol

that still leaves some questions:

How do they digest inorganic substances like metal or plastic?

Are there any inorganic waste products?

Can they use what they intake to self repair damage? Does extensive damage need an engineer of some sort to repair?

i think there was more i asked but I'm really forgetful.

I hope your world building goes well, i really like this concept!

Thanks for asking - Lore Dump Incoming!

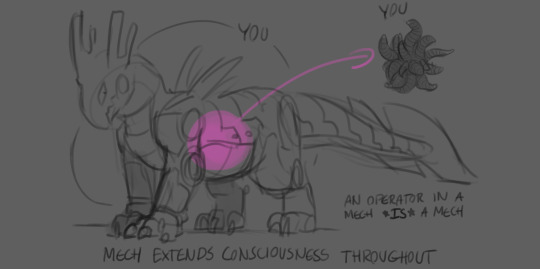

Biomechanical life as an Operator Mech in this sense follows slightly different rules than fully biological beings.

1) Digestion isn't really a thing they do - they refuel on synthetic mech fuel, and only have minimal nutrition requirements. As such they generally cannot and have no reason to eat metal or plastic. Fuel is transported between, and burned within fuel cells in all parts of the mech's Actua (machine muscle), providing mechanical, chemical and electric energy as needed.

2) Not many waste products, as biological components are mostly self-contained and use mech fuel as an outside power source to facilitate all the necessary catasysed and chemical functions within. There is a small cycling of chemical intake and waste which can require mechs to "eat" or otherwise intake nutrition, but they can generally function for a very long time on just fuel and water. They do not have a digestive tract - machine muscle interconnects make up all chemical transport throughout their body.

3) After integration, an operator is permanently reliant on machine life support - blood pressure, filtering, oxygenation, as well as nutritional cycling and recycling, stem cell repair and more.

The operator's brain just about the only thing that remains of their previous body. The process splices machine muscle into the prospective operator's entire nervous system, starting at extremities and seeking inwards against the current of neural output, until it eventually reaches the brain. This is what becomes the "You" part I labeled on the anatomy chart - what remains of your mind, along with neural I/O strands of machine muscle! But an operator entity is technically separable from its mech - just not for long (as they'd die without life support).

(this allows an operator to move to a different mech body, if absolutely necessary)

Mechs contain the necessary life support systems, and those systems are able to self-repair and maintain. This is just about the only thing mechs need to intake non-fuel substance for. Each mech typically has multiple backup life support systems for redundancy, such that critical damage done to any of them can be repaired by replacing the component.

Some mechs are able to print components out of spare material internally, but this requires specific bioorganic systems for this - an example are Solar Moth Mechs that can continuously print membrane-thin solar cells, which can be used as a secondary power source to fuel.

Most other repairs are done externally in one of a few ways:

- By themselves by physically replacing damaged components that are superficially accessible. This can be done mainly for the Shell and Plating, and installation of systems that integrate into the shell.

- with the help of a Mech Repair Engineer, using replacement components, that are either printed or salvaged.

- Using a Proxy Workbench - supporting the ability for the Operator to extend their consciousness into the workbench robotics, to perform repairs / surgery on their own body from an outside point of view.

Mechs feel pain (along with all other sensations the operator was capable of prior to integration). This can complicate self repair sometimes.

Life support and Operator systems are the hardest to repair, and the least abundant as spare parts, making it critical for a mech to protect these from all significant damage. For this reason, those components are usually housed deep within the center of their body, surrounded by shock aborbing machine muscle, and alloy plating.

I have some sketches that illustrate a couple of the concepts mentioned above, which I'll try and upload shortly!

EDIT: I forgot, but I think I have a note somewhere that machine muscle is printable, meaning at least some mechs would be able to repair or synthesize strands from raw material intake.

34 notes

·

View notes

Text

How Androids Function - Circulation and "Sentience"

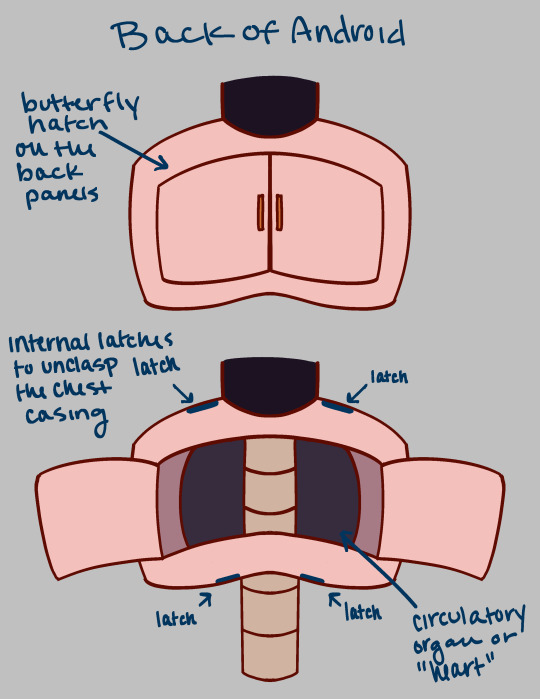

The main way to access the circulatory organ in an android is through the butterfly hatch in the back of the chest casing. On the inside of the chest case, there are four internal clasps that keep the case put together, and right behind the butterfly hatch is the reinforced tungsten “spine” made of detachable links that click together with a sliding mechanism.

Once the casing has been removed, the circulatory organ can be safely removed for repair or replacement.

The circulatory organ is made of an aluminum alloy with copper and magnesium to retain a low weight and good conductivity, and there are four separated chambers (similar to a human heart). On top of the organ is a battery component that is welded to the top of the circulatory organ, which is used to electrify the hydraulic fluid and increase its efficiency in energizing the robot’s circuits. In all of the chambers, there is a semi-permeable insulating gel that keeps the organ from sparking due to electric overload. The membrane cannot pass the gel through, but it allows the hydraulic fluid to pass through easily whether Sparked (electrified) or Inert (no electric current).

Starting from unelectrified hydraulic fluid from the body, it goes into the top right (riva talcum) chamber, and is filtered into the bottom right (riva bexum) chamber. The hydraulic fluid is pumped up to the battery component, where it’s run through the Sparking Chamber and is given an electric current. The Sparked fluid is then pushed into the top left (lacra talcum) chamber and pumped into the bottom left (lacra bexum) chamber. Once the Sparked hydraulic fluids have been pumped into the lacra bexum, it’s then pumped out of the circulatory organ and through the body to disperse energy throughout the body.

The circulatory organ is safely placed under the chest piece, hidden from the exterior. Vivian, the ship's "motherboard", is the first one to have gotten the optimization of the circulatory organs.

Another part of the circulatory organ is a transmission sensor. This transmission sensor connects to a storage unit inside the android’s head, which is hidden behind the face plate and carefully cushioned by a foam support. The storage unit is called a Sentience Core, or a SenCore.

Despite the name, the core does not provide complete sentience, as this is impossible for artificial intelligence to be 100% sentient without a central nervous system. The core merely stores the algorithmic code from the transmission sensor. The sensor connects to the entire body and creates evolving code, which allows the AI to develop a “personality” around their duties and life. Though this is not true sentience, the AI are treated as though they have complete sentience, which aids in developing their own personality.

#dokelion#dokelore#dokelion elemental exchange#writer#artist#lore#character design#android characters#robot characters

2 notes

·

View notes

Text

Valley of the Shadow of Death, Page 58

MASTERPOST

Talking about the armor to distract myself from the other things happening:

I've portrayed the inner mechanisms of the Chozo combat exostuit before in this comic, but those were mostly limited to the support machinery and the exoskeleton frame just beneath the plates, and I didn't detail how the lowermost artificial musculature system interfaces with the structure and the pilot. For this, I leaned slightly on how these systems were portrayed in Dread.

The muscle network and its associated systems are responsible for giving the suit its great speed and strength, and are closely integrated with the wearer's own body. Although the suit has an exoskeletal structure that uses hinges and linkages between the armor plate sections, (especially around single-axis joints like elbows and knees) the structural soundness is greatly improved around the more flexible joints by locking directly into the wearer's own bones, which are genetically modified to accept injections of metallic nanocomposite. Both the suit's structure and the wearer's skeleton are hardened by the same power shield system that the outer layers use, which renders both indestructible until the energy reserves are depleted. The musculature system itself is also hardened by the power shield, though not to the same degree, since so much of its microscopic structure needs to be devote to actually acting like muscles. It is wrapped in a blackish metallic weave in the gaps between plates.

During operation, the tight tolerances and immense forces at work within the musculature layer requires the whole space to be pressurized with lubricating gel, which contains special polymerizing compounds that are able to form emergency membranes to seal cracks and punctures. During the events of Fusion, when Federation scientists were forced to remove all higher layers and additional machinery, the suit began secreting massive amounts of excess gel as soon as Samus regained consciousness, which scabbed over the entire system in this way, giving the fusion suit its signature look.

A few other surgical attachment points are visible on this page, including the spinal jacks used to control the muscles and provide tactile feedback, the life support systems on the left breast responsible for filtering blood and administering nutrients and medical additives, and a catheter for draining waste water.

#metroid#samus aran#comic#fan comic#graphic novel#aliens#xenomorph#horror#valley of the shadow of death

18 notes

·

View notes

Text

Sachin Industries Limited (SIL) is a leading provider of filter presses, glass reactors & special alloys offering a broad portfolio of products, services, and expertise to support industrial customers.

Since 1982, SIL has been manufacturing, designing, and supplying filter presses, polypropylene filter plates, and P.P. Membrane Filter Plates in India. As a part of innovation & growth in 2011, the organization started developing a glass-lined equipment manufacturing plant “SILGLAS” that served as a global benchmark. The facility was built in technical collaboration with JP Laboratories, Inc., a US company with more than 80 patents globally. We take great pride in introducing ourselves as one of the largest, most qualified, and most experienced technocrat teams in the country.

For more information visit the website https://www.sachininternational.com/

1 note

·

View note

Text

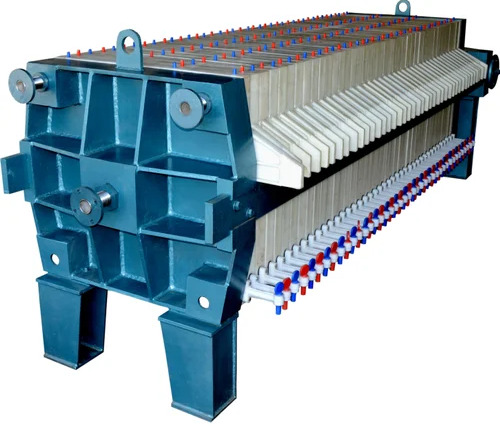

Introduction to high-pressure membrane filter press

The high-pressure membrane filter press is an intermittent pressurized filtration equipment, used for filtration of various media, with good filtration effect and low moisture content of the filter cake. The high-pressure membrane filter press adopts a building block structure. Each part has a reasonable structure and simple connection. It can be used in different combinations to meet the requirements of different users. The whole machine has the characteristics of high degree of automation, large production capacity, the ability to operate under high pressure, low liquid content of filter cake, high unit output, and small floor space: its use effect is comparable to that of imported filter presses.

1.filter effect

As a solid-liquid separation equipment in sewage treatment, filter press has a high usage rate. In most cases, ordinary chamber filter press can meet the demand. But there is another situation where a high-pressure membrane filter press can be used when the moisture content of the mud cake is high. Compared with ordinary chamber filter presses, high-pressure membrane filter presses are resistant to high pressure and have higher dehydration rates. The mud cake produced after filtration by ordinary chamber filter press is much drier. The moisture content of the filter cake after filtration is generally around 60%-65% (sometimes it can reach 40-45% depending on the industry and process).

2.working principle

With the assistance of the feed pump, the filter press inputs the filtered material into the filter chamber of the filter press, and then passes through the filter cloth outside the filter chamber (generally the filter cloth can only allow liquid and very small solid particles to pass). It seeps out, and the solids are intercepted on the filter cloth, thus completing the filtration effect of a general filter press.

The characteristic of the membrane filter press is that it can perform secondary pressing to further reduce the moisture content of the filter cake. Compared with the chamber filter press, the difference is that the diaphragm filter plates and the chamber filter plates with the same appearance are staggered to form filter chambers. When the material is filtered and pressed in the first stage, a fixed pressure is injected into the diaphragm filter plate cavity. The gas (or liquid) causes the diaphragm plate to bulge and squeeze the filter cake in reverse direction to reduce the moisture content of the filter cake. High-pressure air passes through the filter cake to squeeze out and separate the capillary water, structural water and other moisture in the filter cake.

If you choose water pressure for secondary pressing, the diaphragm filter press needs to be equipped with two pumps to work, one is a feed pump and the other is a press pump. The feed pump of the diaphragm filter press is normally equipped with a pump, and the secondary press pump can use a water pump ( Multi-stage centrifugal pump) for squeezing, the use of water pump requires a water tank at the same time. If you choose air pressure, the feed pump is normally equipped. An air compressor can be used instead of a water pump for secondary pressing. If air pressure is used, a water tank is not required.

3.Structural features of membrane filter press:

The diaphragm filter press is composed of a diaphragm plate and a chamber filter plate arranged to form a filter chamber. Under the pressure of the feeding pump, the slurry is input into the filter chamber, and the solids and liquids in the slurry are separated through the filter medium (filter cloth). After the solids in the slurry form a cake, air is introduced into the membrane to fully squeeze the solids in the filter chamber and reduce the moisture content. For users who filter viscous materials and have higher requirements for moisture content, this machine has its own unique characteristics.

The same as the conventional configuration, automatic turning plates, automatic water flushing, conveyors, mud storage hoppers and other devices can be added according to needs.

The filter plate of the membrane filter press is composed of a chamber filter plate and a membrane filter plate arranged at intervals. The diaphragm plate of the diaphragm filter press is equipped with an air pipe device for the secondary pressing function. welcome send your inquiry!

#high-pressure membrane filter press#plate and a chamber filter plate#solid-liquid separation equipment

0 notes

Text

Advantages of Auto Membrane Filter Presses from Professional Manufacturers

The use of Automatic Membrane Filter Presses in industrial applications has grown significantly in recent years, and for good reason. These types of filter presses offer a number of benefits over Conventional filter presses, making them a popular choice among filter press manufacturers.

One of the main benefits of automatic membrane filter presses is their ability to save time and labor. Unlike traditional filter presses, which require manual operation, automatic membrane filter presses can be operated remotely, allowing for continuous operation without the need for constant monitoring. This not only saves on labour costs, but it also increases the efficiency of the filtration process.

In addition to saving time and labour, automatic membrane filter presses also offer improved performance and higher solids retention rates. This is due to the use of membrane plates, which are made from polypropylene or polyethylene, as opposed to traditional filter cloths. Membrane plates are able to retain a higher percentage of solids, resulting in a more efficient filtration process and a higher quality end product.

Another benefit of automatic membrane filter presses is their ability to handle a wide range of applications, from waste water treatment to industrial processing. These filter presses are able to handle a wide range of materials, including liquids, slurries, and suspensions, making them a versatile option for a variety of industries.

When it comes to choosing a filter press manufacturer, it is important to choose a reputable company that offers a wide range of products and services. Leading filter press manufacturers will offer a variety of automatic membrane filter press options, as well as customization options to meet the specific needs of the customer. They will also offer technical support and after-sales service, including maintenance and repair services.

One of the key factors to consider when choosing a filter press manufacturer is their level of expertise and experience in the industry. A reputable filter press manufacturer will have a wealth of knowledge and experience in the design, engineering, and manufacturing of filter presses, as well as a deep understanding of the various applications for which their products are used.

In conclusion, automatic membrane filter presses offer a number of benefits over traditional filter presses, including improved performance, higher solids retention rates, and increased efficiency. When choosing a filter press manufacturer, it is important to choose a reputable company with a wide range of products and services, as well as a strong level of expertise and experience in the industry. With the help of a leading filter press manufacturer, you can be sure that your filtration needs will be met with the highest level of efficiency and quality.

In addition, automatic membrane filter presses are also known for their durability and long service life, making them a cost-effective solution for many industrial applications.

Established in 1972 in Ahmedabad, India, Yotana is a Professional manufacturer of filter presses. Yo-Tana Machine Tools Pvt. Ltd. is the leading manufacturer of high-quality membrane filter presses, Membrane Plate Filter Press, fully automatic filter presses, and PP filter presses in India.

0 notes

Text

Semiconductor Plating Lithography Filters Market Global Analysis, Outlook, Opportunities, Size, Share Forecast and Supply Demand 2031

The global "Semiconductor Plating Lithography Filters Market Market" report indicates a consistent and robust growth trend in recent times, projecting a positive trajectory expected to persist until 2031. A significant trend observed in the Semiconductor Plating Lithography Filters Market market is the rising consumer inclination towards environmentally sustainable and eco-friendly products. Furthermore, a notable advancement in this market is the increasing incorporation of technology to elevate both product quality and efficiency. Cutting-edge technologies like artificial intelligence, machine learning, and block chain are actively employed to develop innovative products that outperform traditional options in terms of effectiveness and efficiency. The Semiconductor Plating Lithography Filters Market Market Research Report for 2024 highlights emerging trends, growth opportunities, and potential scenarios envisioned up to the year 2031.

By delving into the latest trends, the report keeps businesses abreast of the dynamic market environment, helping them identify emerging opportunities and navigate potential challenges. The meticulous analysis covers various aspects, offering valuable insights into the historical performance of the market and presenting the current (CAGR) status.

Get a Sample Copy of the Report at: https://www.proficientmarketinsights.com/enquiry/request-sample-pdf/1796

Who are the biggest Semiconductor Plating Lithography Filters Market manufacturers worldwide?

Entegris (U.S.)

Pall (U.S.)

Camfil (Sweden)

Nippon Seisen (Japan)

Exyte Technology (Germany)

Porvair (U.K.)

AAF International (U.S.)

Cobetter (China)

The Semiconductor Plating Lithography Filters Market Market is described briefly as follows:

The global Semiconductor Plating Lithography Filters Market size was estimated at USD 284.1 million in 2024 and is projected to reach USD 410 million by 2031, exhibiting a CAGR of 6.30% during the forecast period.

SWOT Analysis of Semiconductor Plating Lithography Filters Market Market:

A SWOT analysis involves evaluating the strengths, weaknesses, opportunities, and threats of a particular market or business. In the case of the keyword market, we'll be looking at the factors that can impact the industry's performance.

Pestle Analysis of Semiconductor Plating Lithography Filters Market Market:

To better comprehend the market environment, a five-force analysis is performed, which takes into account the bargaining power of the customer, the supplier, the threat of substitutes, the threat of new entrants, and the threat of competition.

Get a Sample Copy of Semiconductor Plating Lithography Filters Market Market Report

What are the Types in Semiconductor Plating Lithography Filters Market Market?

Nylon66 Membrane

HDPE Membrane

What are Applications in Semiconductor Plating Lithography Filters Market Market?

Wafer Fabrication

Chip Production

Others

Inquire or Share Your Questions If Any before the Purchasing This Report: https://www.proficientmarketinsights.com/enquiry/queries/1796

Geographical Segmentation:

Geographically, this report is segmented into several key regions, with sales, revenue, market share, and Semiconductor Plating Lithography Filters Market market growth rate in these regions, from 2017 to 2028, covering

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia, and Vietnam)

South America (Brazil etc.)

Middle East and Africa (Egypt and GCC Countries)

Some of the key questions answered in this report:

Who are the worldwide key Players of the Semiconductor Plating Lithography Filters Market Industry?

How the opposition goes in what was in store connected with Semiconductor Plating Lithography Filters Market ?

Which is the most driving country in the Semiconductor Plating Lithography Filters Market industry?

What are the Semiconductor Plating Lithography Filters Market market valuable open doors and dangers looked by the manufactures in the worldwide Semiconductor Plating Lithography Filters Market Industry?

Which application/end-client or item type might look for gradual development possibilities? What is the portion of the overall industry of each kind and application?

What centered approach and imperatives are holding the Semiconductor Plating Lithography Filters Market market?

What are the various deals, promoting, and dissemination diverts in the worldwide business?

What are the key market patterns influencing the development of the Semiconductor Plating Lithography Filters Market market?

Financial effect on the Semiconductor Plating Lithography Filters Market business and improvement pattern of the Semiconductor Plating Lithography Filters Market business?

Purchase this Report (Price 3200 USD for A Single-User License) at: https://www.proficientmarketinsights.com/purchase/1796

TOC of Global Semiconductor Plating Lithography Filters Market Market Research Report 2023

1 Semiconductor Plating Lithography Filters Market Market Overview

2 Market Competition by Manufacturers

3 Semiconductor Plating Lithography Filters Market Production by Region

4 Semiconductor Plating Lithography Filters Market Consumption by Region

5 Segment by Type

6 Segment by Application

7 Key Companies Profiled

8 Industry Chain and Sales Channels Analysis

9 Semiconductor Plating Lithography Filters Market Market Dynamics

10 Research Finding and Conclusion

11 Methodology and Data Source

0 notes

Text

Diving into the World of Hollow Fiber Membranes: More than Just Filtration

So, you’ve stumbled upon the fascinating universe of Hollow Fiber Membranes — the unsung heroes in the quest for clean water, gas separation, and even in medical devices. It’s not your typical superhero story, but hey, who said saving the world had to be flashy?

The Billion-Dollar Quest for Clean Water:

Our journey begins with a whopping USD 11.29 billion valuation in 2021, and brace yourselves, we’re on track to reach the magical USD 25.33 billion mark by 2030. That’s a growth spurt of 9.4%, making these membranes the underappreciated rockstars of the filtration world.

Why the Fuss? Water, Water Everywhere:

The buzz around Hollow Fiber Membranes isn’t just hot air — it’s driven by the global thirst for water and wastewater treatment solutions. With an ever-growing population, the demand for clean water has hit a high note. These membranes step up to the plate, tackling contaminants like fungi, viruses, and bacteria, ensuring our water is as pure as the morning dew (well, almost).

Market Dynamics:

Where’s the Action? Microfiltration, ultrafiltration, and reverse osmosis are the filtration types doing the heavy lifting. Polymer and ceramic are the materials of choice, and water and wastewater treatment take the lead, claiming over 85% of the market share. Hold your breath — the food & beverages segment is the dark horse, set to be the fastest-growing star.

Global Playground:

Where Hollow Fibers Roam Free: The game is strong in North America, with the U.S. and Canada holding their ground. But don’t underestimate Asia Pacific, where the Hollow Fiber Membrane market is making waves. China, in particular, has undergone a transformative shift, proving that change is the only constant in this dynamic market.

The Heroes and Their Tools:

Microfiltration steals the show with a 52.64% market share. Why? Because it’s like the superhero of low-pressure techniques, separating the good stuff from the bad. On the other hand, ultrafiltration is gearing up for a growth spurt, being the fastest-growing segment — a rising star in cost-effective, ultrapure water technologies.

Challenges? Yeah, They Exist:

Sure, these membranes are saving the day, but the substantial initial investment required for setup throws a curveball. It’s like trying to save the world with a budget — not easy, right? Technical intricacies and the need for skilled personnel add more layers to the challenge.

For More Information: https://www.skyquestt.com/report/hollow-fiber-membranes-market

Who’s Who in the Hollow Fiber Membrane World? In this arena, names like Sartorius AG, Repligen Corporation, and Danaher Corporation are the unsung heroes. Innovation is the name of the game, with smaller players making a splash with specialized solutions for meat processing needs. Because who doesn’t love a good customized blend?

Global Hollow Fiber Membranes Key Market Trends:

The rise of strict regulatory standards globally, especially in water quality, is pushing the envelope. The Clean Water Act and National Primary Drinking Water Regulations are like the rulebooks for the game. These regulations are not just guidelines; they are the fuel propelling the demand for water treatment facilities.

Conclusion:

A Glimpse into the Future of Filtration: As we bid adieu to this whirlwind tour of Hollow Fiber Membranes, one thing is clear — these unassuming filters are the unsung heroes we never knew we needed. From water treatment plants to food processing, they’re silently working to make our lives cleaner, safer, and just a tad more fantastic.

So, the next time you take a sip of water, thank the Hollow Fiber Membranes silently doing their job behind the scenes. They may not wear capes, but they sure know how to make a splash!

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

What Are Pressure Line Filters?

Pressure filters are a type of filtration system used to remove impurities from liquids or gases by passing them through a porous filtering medium. These filters operate under pressure, forcing the fluid through the filter to separate solids from liquids or gases. Pressure filters are commonly employed in various industries for water treatment, wastewater treatment, industrial processes, and air filtration. There are different types of pressure filters, each designed for specific applications. Here are some common types:

Sand Filters:

Sand filters use a bed of sand as the filtering medium. Water passes through the sand bed, and impurities are trapped within the sand particles.

Cartridge Filters:

Cartridge filters use a replaceable cartridge as the filtering element. These cartridges can be made of various materials such as paper, polyester, or other porous materials.

Activated Carbon Filters:

Activated carbon filters utilize activated carbon as the filtering medium. Activated carbon is effective in absorbing impurities, including organic compounds and certain chemicals.

Diatomaceous Earth (DE) Filters:

DE filters use a fine powder made from fossilized diatoms as the filtering agent. These filters are commonly used in swimming pools and other applications where fine filtration is required.

Membrane Filters:

Membrane filters employ a semi-permeable membrane to separate particles and contaminants based on size. This type of filter is often used for sterilization and ultrafiltration processes.

Pressure Leaf Filters:

Pressure leaf filters consist of a series of vertical leaves that are mounted on a manifold. The leaves have a filtering medium, and liquid is pumped through the leaves to remove impurities.

Nutsche Filters:

Nutsche filters are batch filters commonly used in pharmaceutical and chemical industries. They consist of a filter plate covered with a filter medium, and the material to be filtered is pumped into the filter.

Belt Filters:

Belt filters use a moving belt as the filtering surface. The belt passes through a series of rollers, and slurry is applied to the belt. As the belt moves, the liquid is drained, leaving behind the filtered solids.

Pressure filters are chosen based on the specific characteristics of the fluid or gas being filtered and the type of impurities that need to be removed. They are essential components in many industrial processes and play a crucial role in maintaining the quality of liquids and gases used in various applications.

For More Details Visit us…

Pressure line Filter

0 notes

Text

VICTOR MARINE CS5000 Original New Parts we have for sale

Contact us for more details

Worldwide delivery

We sale all types of ship machinery filters-Ows filters membrane Coalescer , crane filters , M/E backwash filters worldwide.

IDEAL DIESEL MARINE

E-MAIL: [email protected] (Primary)

#Victor Marine CS5000 Oily water separator-parts-1st stage pack#Victor Marine CS5000#Victor Marine CS5000 Oily water separator-parts-#OOLY WATER SEPARATOR Victor Marine CS5000 Oily water separator-parts-1st stage pack#Victor Marine OILY WATER SEPARATOR CS5000 Oily water separator-parts-1st stage pack#PARTS FOR Victor Marine CS5000 Oily water separator#OWS PARTS VICTOR MARINE#CS5000 Victor marine

0 notes