#membrane plate filter presses manufacturers

Text

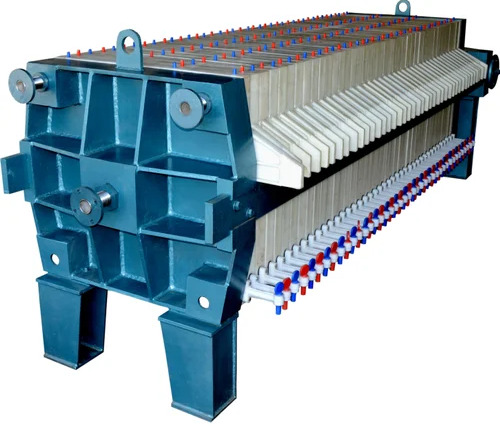

Best Membrane Plate Filter Press In India

Yotana is well known best membrane plate filter presses manufacturers in Ahmedabad, Gujarat. We provide top quality membrane plate filter presses to our local and global client. Our membrane filter presses offer exceptional dewatering and reduce filtration time by over 50%, based on the suspension. Explore our Filter Press Plates for superior filtration solutions.

0 notes

Text

Plate Pressure Oil Filter: Enhancing Oil Purity and Efficiency in Industrial Applications

In industrial settings, oil filtration is a critical process for maintaining the quality and efficiency of machinery and production lines. One of the most effective tools for this purpose is the Plate Pressure Oil Filter. This powerful filtration system is widely used to remove impurities from oils, ensuring smooth operation, longer equipment lifespan, and higher product quality. In this blog, we will delve into the workings, benefits, and applications of the Plate Pressure Oil Filter, highlighting why it is a crucial component in various industries.

What is a Plate Pressure Oil Filter?

A Plate Pressure Oil Filter is a mechanical filtration system designed to remove solid particles, contaminants, and impurities from different types of oils, such as vegetable oil, lubrication oil, or hydraulic oil. The filter consists of multiple filter plates arranged in a series, which creates a high-pressure environment to force the oil through the filter medium. This process effectively separates unwanted substances, leaving clean, pure oil for further use.

The filtration system works on the principle of pressure difference, where the oil passes through a filter cloth or mesh between the plates, trapping impurities and ensuring only clean oil exits the system. The filter plates are pressed together tightly to maintain pressure, which facilitates efficient oil purification.

How Does a Plate Pressure Oil Filter Work?

The Plate Pressure Oil Filter operates through a series of stages:

Oil Feed: The oil to be filtered is pumped into the filter under pressure. The high pressure forces the oil through the filter plates.

Filtration Process: As the oil moves through the filter plates, it passes through filter cloths or membranes that trap solid particles and contaminants. These particles accumulate on the surface of the plates, while the filtered oil continues through the system.

Discharge: Once the oil has passed through the filtration process, it is collected in a discharge chamber, free of impurities and ready for use.

Cleaning the Filter: Over time, the filter plates accumulate debris and require cleaning. Most Plate Pressure Oil Filters are designed to be easily disassembled for cleaning and maintenance, ensuring the system remains efficient over long periods of use.

Benefits of Using a Plate Pressure Oil Filter

High Filtration Efficiency

The primary advantage of the Plate Pressure Oil Filter is its ability to achieve high filtration efficiency. The system can remove even the smallest particles and contaminants from oil, resulting in a cleaner, more refined product. This high level of filtration is essential for industries that rely on the purity of oil, such as food processing or manufacturing.

Extended Equipment Life

Clean oil is vital for the smooth operation of machinery. Contaminated oil can cause wear and tear on parts, leading to increased maintenance costs and a shorter lifespan for equipment. By using a Plate Pressure Oil Filter, industries can extend the life of their machinery, reducing downtime and saving on repair costs.

Cost-Effective Solution

While investing in a Plate Pressure Oil Filter may require an initial cost, the long-term savings are significant. With cleaner oil, industries can avoid frequent oil changes and reduce maintenance expenses, making it a cost-effective solution for businesses looking to improve their operational efficiency.

Versatility

Plate Pressure Oil Filters can handle a wide variety of oils, making them versatile across different industries. Whether it's filtering edible oils in the food industry or refining lubricants for industrial machines, these filters are adaptable to various applications.

Environmentally Friendly

By effectively filtering oil and extending its usability, Plate Pressure Oil Filters contribute to environmental sustainability. They reduce the need for frequent oil disposal and help in minimizing waste, making them an eco-friendly choice for industries.

Applications of Plate Pressure Oil Filters

Food Industry

In the food processing industry, the Plate Pressure Oil Filter is commonly used to purify vegetable oils, ensuring that the final product is of high quality. The filter removes solid particles, debris, and contaminants, making the oil safe for consumption and enhancing its shelf life.

Chemical and Pharmaceutical Industries

These filters are used in the chemical and pharmaceutical industries to refine oils and other liquids used in the production process. Ensuring the purity of these liquids is critical for maintaining product integrity and meeting regulatory standards.

Automotive and Industrial Machinery

Plate Pressure Oil Filters are widely used in the automotive and manufacturing industries to filter lubricating oils and hydraulic oils. Clean oils are essential for the smooth operation of engines, pumps, and other machinery.

Biodiesel Production

In the renewable energy sector, Plate Pressure Oil Filters play a key role in biodiesel production. They help filter out impurities from the raw oils used to create biodiesel, ensuring a cleaner and more efficient fuel source.

Conclusion

The Plate Pressure Oil Filter is an indispensable tool for industries that rely on clean, pure oils for their operations. Its ability to efficiently remove impurities, extend equipment life, and provide cost-effective solutions makes it a valuable asset in sectors ranging from food production to industrial manufacturing. With its versatility and environmental benefits, this filtration system is a wise investment for any business looking to enhance its productivity and sustainability.

0 notes

Text

Sachin Industries Limited (SIL) is a leading provider of filter presses, glass reactors & special alloys offering a broad portfolio of products, services, and expertise to support industrial customers.

Since 1982, SIL has been manufacturing, designing, and supplying filter presses, polypropylene filter plates, and P.P. Membrane Filter Plates in India. As a part of innovation & growth in 2011, the organization started developing a glass-lined equipment manufacturing plant “SILGLAS” that served as a global benchmark. The facility was built in technical collaboration with JP Laboratories, Inc., a US company with more than 80 patents globally. We take great pride in introducing ourselves as one of the largest, most qualified, and most experienced technocrat teams in the country.

For more information visit the website https://www.sachininternational.com/

1 note

·

View note

Text

Press Plate Supplier in Ahmedabad, Gujarat

Press Plate Supplier in Ahmedabad, Gujarat:

Elenox Steel Provides Architectural Applications As Well As The Finest Stainless Steel Sheets. In the most advanced manufacturing facility, we carry out the etching process on the surface of stainless steel sheets.

Etching is the process of engraving, scratching, and creating fine lines and grooves on the surface of stainless steel sheets. Elenox Is Known For His Specially Designed Stainless Steel Sheets With Innovative And Unique Designs. We also design stainless steel sheets based on the needs of the customer.

Our large warehouse has all of the amenities needed for the products to be properly stored. Our professional team also ensures that our warehouse system runs smoothly. Customers in Ahmedabad, India, and other markets are encouraged to contact us.

Advantages of Recessed Filter Plates:

• Filtration pressures of up to 50 bar

• Detachable Membrane

• Suitable for high filtration temperatures

• Robust design with reinforced edges.

We Provide Press Plate Supplier in Ahmedabad, Gujarat with other cities such as Kathwada, Kalol, Kadi, Vatva, Naroda, Singarva, Odhav, Rakhial, Sanand, Vani, Daskroi, Chhatral, Narol, Dhandhuka, Dholka, Kadi, Kalol, Kerala, Asarva, Bakrol, Bodakdev, Ankleshwar, Gandhinagar, Bhavnagar, Patan, Porbandar, Kutch, Vapi, Bharuch, Dahod, Amreli, Navsari, Kheda, Panchmahal, Sabarkantha, Surendranagar, Mehsana, Morbi, Gir Somnath, Palanpur.

Read the full article

#PressPlateSupplierinAhmedabad#PressPlateSupplierinBharuch#PressPlateSupplierinBhavnagar#PressPlateSupplierinDaskroi#PressPlateSupplierinKalol#PressPlateSupplierinKathwada#PressPlateSupplierinNaroda#PressPlateSupplierinPorbandar#PressPlateSupplierinSanand#PressPlateSupplierinSingarva#PressPlateSupplierinValsad#PressPlateSupplierinVapi

0 notes

Text

All About Filter Press Manufacturer

To satisfy your needs, we provide a wide range of filter press sizes. From our huge 2000mm lab filter press down to 200mm. Additionally, the filter press manufacturer may be fitted with a system for automatically washing clothes, a drop tray, a shaking system, etc.

We are able to provide the entire filter press dewatering plant along with the filter press, including the thickener and all other required plant ancillaries like the feeding pump, compressors, conveyor, and even special chemical-resistant paint.

Every piece of equipment we offer is designed to increase your production over time.The feed pump for filters is often referred to as a filter press pump. Delivering slurry to the maker of the filter press is the function of the feed pump.

The filter press's rate of filtration is determined by the feed pressure, which is affected by the power of the filter press manufacturer and the head of the feed pump.Therefore, compatibility with the filter press and slurry performance should be taken into account while selecting the feed pump.

Nearly every form of slurry can be processed using a filter press china, including slurries from the ceramics, stone, glass, mining, petrochemical, culinary, pharmaceutical, textile, leather, and municipal industries, as well as slurries from the washing of coal, sand, and minerals.

using solid carbon steel that resists corrosion, has high rigidity, meets structural stability standards, and has a long service life; Filter press china are produced using a unique, patented process and high polymer PE.

The benefits include being lightweight, resistant to corrosion, resistant to acids and bases, virulent, and tasteless;A well-known brand of component is used in the electrohydraulic integration control system.

Precision machining and dependable, long-lasting service are the benefits of hydraulic systems;high-quality production methods and tools. It is an ideal solid-liquid separation device that is easy to use, safe to operate, convenient to service; utilizing cutting-edge production methods and technology to ensure that every product is at the highest degree of advantage.

A wide range of adjustable parameters, including inlet quantity, discharge clearance, pull plate tension, pull plate speed, and other factors, allow this machine to produce any specification (chamber or membrane) of 630mm1250mm, which is nearly the same as the ordinary automatic filter press with the same filtering area. It also has a simple structure, high production efficiency, stable and reliable operation, and low maintenance costs.

In order to address the problem of the difficult-to-clean sticky muck on filter cloth, the pneumatic shaking function was carefully devised. When compared to a standard filter press, rapid filtering and one-time pull plate discharge can significantly cut labor costs, boost production capacity of a single machine, and shorten process times.

0 notes

Text

Filter press & its working principles | Filter Machines

What is a Filter Press?

A filter press is a piece of equipment used in liquid/solid separation. Specifically, the filter press separates the liquids and solids using pressure filtration, wherein a slurry is pumped into the filter press and is dewatered under pressure. Each filter press is designed based on the volume and type of slurry that needs to be dewatered. Filter Machines Pvt ltd is a trusted expert in liquid/solid separation and offers a wide range of filter press types and capacities to suit specific application needs for trouble-free, economical dewatering. These include configurations - sidebar automatic, manual overhead, automatic dual overhead beam, stainless steel clad, explosion-proof filter presses, vacuum filter presses, and hand filter presses.

The four main components of a filter press include the frame, filter plates, manifold (piping and valves), and filter cloth, a key ingredient for optimizing filter press operations.

How Does a Filter Press Work?

The working principle of filter presses is that slurry is pumped into the machine such that solids are distributed evenly during the filling cycle. Solids build up on the filter cloth, forming the filter cake; the filtrate exits the filter plates through the corner ports into the manifold, yielding clean filtered water.

Filter presses are a pressure filtration method and as such, as the filter press feed pump builds pressure, solids build within the chambers until they are completely chock-full of solids, forming the cake. Once the chambers are full, the cycle is complete and the filter cakes are ready to be released. At many higher capacity filter presses, fast-action automatic plate shifters are employed, speeding cycle time. Some filter presses are specifically designed for fully automatic, 24-hour operation in harsh environments such as mines or chemical manufacturing plants.

Filter Press Applications

Filter presses can be built in a wide range of sizes, from small, lab-scale 630 MM X 630 MM presses, to those with much larger capacities, such as those with 2000 MM X 2000 MM filter plates. Filter presses are used for liquid/solid separation in an extensive range of industries and applications including:

Food and beverage processing

Chemical manufacturing

Mining

CLAY & MARBLE AND TILES production

Know More About us:

Filter Machines Pvt ltd is a renowned Company for manufacturing Filter Press. The company has ISO certification. Its inception is dedicated to providing premium Filter Press. Established in 1979 the company is into manufacturing, supplying, and exports. With sophisticated infrastructure facilities, we pioneer in the field of solid-liquid separation. By understanding customers’ needs and requirements we manufacture the Filter Press. Our objective is to go beyond customers’ expectations.

Membrane Automatic Filter Press, Automatic Chamber Filter Press, Semi-Automatic Chamber Filter Press, Hydraulic Chamber Filter Press, Semi Hydraulic Chamber Filter Press, Manual Chamber Filter Press, Membrane Plate, Recessed Plate, PP Plate & Frame Plate

1 note

·

View note

Text

Filter Press Manufacturers

Our filter press Manufacturers are designed with recess or membrane plates to optimize production and minimize cake moisture. A channel press is a bunch activity, fixed volume machine that isolates fluids and solids utilizing pressure filtration. We make physically worked channel presses with capstan shutting gadgets and stuff and fastener systems

1 note

·

View note

Photo

pp filter plates and membrane plates and various types filter press we present at a reasonable price all over India and us one of the Top manufacturers filter plates in India so you have any felter plates need then communicate us we accommodate you according to your choices. Filter Plate

1 note

·

View note

Text

Membrane Filter Press

Membrane Filter Press Price, Membrane Plate Filter Press Machine Manufacturers – INFODIRECTORY B2B.

Info Directory B2B – Providing info on Membrane Filter Press, Membrane Filter Press Machine Manufacturers, Suppliers, Dealers and Exporters, Membrane Filter Plates Manufacturer, Membrane Plate Filter Press Price, Membrane Filter Presses, Buy Membrane Filtration Filter Online, Automatic Membrane Filter Press for Sale in India, China, USA, UK, Japan, South Korea, Australia and other countries.

https://www.infodirectoryb2b.com/subcategories/9861/Membrane-Filter-Press.html

0 notes

Text

Apple Juice Market is estimated to reach USD 8989.6 million by 2027, growing at a CAGR of 3.1 % between 2019 and 2027

Overview

The U.S. apple juice market is driven by factors including the growing health consciousness and the rising number of mergers and acquisitions and the strategic collaborations between companies coupled with the increasing investment of vendors to maintain a steady supply of apples. The introduction of new products and flavours has also contributed to the growth of the market.

Apple Juice Market is categorized by product type into unfiltered apple juice and filtered apple juice. The unfiltered kind is loaded with phytochemicals that fight everything from cancer to Alzheimer’s to heart attacks. (Phytochemicals are usually related to plant pigments, and the brightest colours like bright red apples usually contain the most phytochemicals and nutrients. Most of the consumer usually prefer unfiltered juice because it contains high levels of antioxidants, vitamins and dietary fibre which is very beneficial for health.

The purpose of filtration is to remove hard particles from a fluid medium. In apple juice processing, the largest elements are removed by passing the juice from the press through a web screen or a continuous self-cleaning separator. This step is sufficient for an unclarified product. To obtain a totally clear product, juice must go through a second phase of mechanical filtration. Several types of equipment are used for this: leaf, plate and frame, vacuum, bag or sock, and membrane filters.

By application, the apple juice market in U.S. is segmented into commercial, household and others. The commercial segment is anticipated to witness significant growth over the forecast period. Also, household segment is projected to witness moderate growth over the forecast period. While coming Apple Juice bars thrive in spas, gyms and health food stores, while Government programs in U.S. Large amount of juice to low-income children and pregnant mothers. The commercial juice industry is happy to take benefit of this idea to maximize their profit and growth in the U.S. market.

By geographical wise, the North American region consists of the U.S., and Canada. Latin America region consists of Mexico and Brazil. The North America region holds the major stake in the aggregate income of Global Apple juice market and is projected to maintain its dominance over the forecast period because of notable growth in consumption brought about by established different distribution channels. This can be attributed to changing lifestyle of individuals and increasing preference for consumption of healthy food products in the region. Also, the markets in Latin America is projected to witness moderate growth over the forecast period.

Major Players and participants in U.S. Apple Juice Market are Martinelli’s Gold Medal, Simply Orange Juice, Eden Foods, Innocent, Manzana Products, TreeTop, SunRype, Santa Cruz, Mott’s, Minute Maid (Coca-Cola), James White Drinks. The apple juice market will continue to witness sales due to the aforementioned health benefits, over the next eight years. Apple is one of the most widely cultivated tree fruits, and the third-most internationally traded fruit, following banana and grapes. There has been significant growth in the consumption rate of apple flavoured juices, sauces, as well as apple juice which is inspiring manufacturers of U.S. to deliver unique and consistent product to get maximum profit in market.

Inquiry about report OR ask for Sample Report @

https://www.profsharemarketresearch.com/inquiry/apple-juice-market-report-inquiry/

Apple Juice Market: Product Type

· Unfiltered Apple Juice

· Filtered Apple Juice

Apple Juice Market: Application

· House Hold

· Commercial

· Others

Apple Juice Market: Competitive Analysis

· Matinelli’s Gold Medal

· Simply Orange Juice

· Eden Foods

· Innocent

· Manzana Products

· TreeTop

· SunRype

· Santa Cruz

· Mott’s

· Minute Maid (Coca-Cola)

· James White Drinks

Apple Juice Market: Regional Analysis

· North America

· U.S.A

· Canada

· Europe

· France

· Germany

· Spain

· UK

· Rest of Europe

· Asia Pacific

· China

· Japan

· India

· South East Asia

· Latin America

· Brazil

· Middle East and Africa

Access Full Report @

https://www.profsharemarketresearch.com/apple-juice-market/

Apple Juice Market Report delivers comprehensive analysis of :

· Market Forecast for 2019-27

· Market growth drivers

· Challenges and Opportunities

· Emerging and Current market trends

· Market player Capacity, Production, Revenue (Value)

· Supply (Production), Consumption, Export, Import analysis

· End user/application Analysis

About Profshare

Profshare Market Research is a full service market research company that delivers in depth market research globally. We operate within consumer and business to business markets offering both qualitative and quantitative research services. We work for private sector clients, along with public sector and voluntary organisations. Profshare Market Research publishes high quality, in-depth market research studies, to help clients obtain granular level clarity on current business trends and expected future developments. We are committed to our client’s needs, providing custom solutions best fit for strategy development and implementation to extract tangible results.

For more information, visit https://www.profsharemarketresearch.com/

OR Email us at [email protected]

Contact :

Mia Cox

Sales Manager

0 notes

Text

Advantages of Auto Membrane Filter Presses from Professional Manufacturers

The use of Automatic Membrane Filter Presses in industrial applications has grown significantly in recent years, and for good reason. These types of filter presses offer a number of benefits over Conventional filter presses, making them a popular choice among filter press manufacturers.

One of the main benefits of automatic membrane filter presses is their ability to save time and labor. Unlike traditional filter presses, which require manual operation, automatic membrane filter presses can be operated remotely, allowing for continuous operation without the need for constant monitoring. This not only saves on labour costs, but it also increases the efficiency of the filtration process.

In addition to saving time and labour, automatic membrane filter presses also offer improved performance and higher solids retention rates. This is due to the use of membrane plates, which are made from polypropylene or polyethylene, as opposed to traditional filter cloths. Membrane plates are able to retain a higher percentage of solids, resulting in a more efficient filtration process and a higher quality end product.

Another benefit of automatic membrane filter presses is their ability to handle a wide range of applications, from waste water treatment to industrial processing. These filter presses are able to handle a wide range of materials, including liquids, slurries, and suspensions, making them a versatile option for a variety of industries.

When it comes to choosing a filter press manufacturer, it is important to choose a reputable company that offers a wide range of products and services. Leading filter press manufacturers will offer a variety of automatic membrane filter press options, as well as customization options to meet the specific needs of the customer. They will also offer technical support and after-sales service, including maintenance and repair services.

One of the key factors to consider when choosing a filter press manufacturer is their level of expertise and experience in the industry. A reputable filter press manufacturer will have a wealth of knowledge and experience in the design, engineering, and manufacturing of filter presses, as well as a deep understanding of the various applications for which their products are used.

In conclusion, automatic membrane filter presses offer a number of benefits over traditional filter presses, including improved performance, higher solids retention rates, and increased efficiency. When choosing a filter press manufacturer, it is important to choose a reputable company with a wide range of products and services, as well as a strong level of expertise and experience in the industry. With the help of a leading filter press manufacturer, you can be sure that your filtration needs will be met with the highest level of efficiency and quality.

In addition, automatic membrane filter presses are also known for their durability and long service life, making them a cost-effective solution for many industrial applications.

Established in 1972 in Ahmedabad, India, Yotana is a Professional manufacturer of filter presses. Yo-Tana Machine Tools Pvt. Ltd. is the leading manufacturer of high-quality membrane filter presses, Membrane Plate Filter Press, fully automatic filter presses, and PP filter presses in India.

0 notes

Text

Press Plate Supplier in Ahmedabad, Gujarat

Press Plate Supplier in Ahmedabad, Gujarat:

Elenox Steel Provides Architectural Applications As Well As The Finest Stainless Steel Sheets. In the most advanced manufacturing facility, we carry out the etching process on the surface of stainless steel sheets.

Etching is the process of engraving, scratching, and creating fine lines and grooves on the surface of stainless steel sheets. Elenox Is Known For His Specially Designed Stainless Steel Sheets With Innovative And Unique Designs. We also design stainless steel sheets based on the needs of the customer.

Our large warehouse has all of the amenities needed for the products to be properly stored. Our professional team also ensures that our warehouse system runs smoothly. Customers in Ahmedabad, India, and other markets are encouraged to contact us.

Advantages of Recessed Filter Plates:

• Filtration pressures of up to 50 bar

• Detachable Membrane

• Suitable for high filtration temperatures

• Robust design with reinforced edges.

We Provide Press Plate Supplier in Ahmedabad, Gujarat with other cities such as Kathwada, Kalol, Kadi, Vatva, Naroda, Singarva, Odhav, Rakhial, Sanand, Vani, Daskroi, Chhatral, Narol, Dhandhuka, Dholka, Kadi, Kalol, Kerala, Asarva, Bakrol, Bodakdev, Ankleshwar, Gandhinagar, Bhavnagar, Patan, Porbandar, Kutch, Vapi, Bharuch, Dahod, Amreli, Navsari, Kheda, Panchmahal, Sabarkantha, Surendranagar, Mehsana, Morbi, Gir Somnath, Palanpur.

Read the full article

#PressPlateSupplierinAhmedabad#PressPlateSupplierinBharuch#PressPlateSupplierinBhavnagar#PressPlateSupplierinDaskroi#PressPlateSupplierinKalol#PressPlateSupplierinKathwada#PressPlateSupplierinNaroda#PressPlateSupplierinPorbandar#PressPlateSupplierinSanand#PressPlateSupplierinSingarva#PressPlateSupplierinValsad#PressPlateSupplierinVapi

0 notes

Text

All About The Filter Press Price

Slurry is pumped into the empty areas between the plates in the chamber by a high filter press price slurry pump to dewater it. Filters are used to separate the solids from the water in order to do this. The fluid is then prepared for discharge after passing through a final filter that eliminates any particulates that may have remained.

An industrial filter press is a tool used in separation procedures, specifically to separate solids and liquids. The apparatus stacks a variety of filter parts, allows for rapid removal of the filtered solids, and facilitates cleaning or replacement of the filter media.

Although filter presses cannot be used in a continuous process, they can nevertheless perform extremely well, especially when a low residual liquid content in the solid is desired.

In marble manufacturers, filter presses are used, among other things, to separate water from mud so that the water can be used again for cutting marble.

The manual filter press was one of the early filtering devices. It produces the highest cake solid concentration of any mechanical dewatering apparatus. For managing modest volumes of material, manual filter press price are helpful.

When compressed, the filter material itself may act as a gasket, the filter membrane may have an edge seal built in, or the stack may be compressed tightly enough tothe seal between each plate and frame must be water-tight.

Filter press pump is another name for the feed pump for filters. The feed pump's job is to deliver slurry to the filter press manufacturer. The feed pressure, which is influenced by the filter press's strength and the feed pump's head, determines the filter press's rate of filtration.

As a result, while choosing the feed pump, consideration should be given to the filter press's compatibility as well as the slurry's performance.

The Centrifugal Pump, Screw Pump, Roots Pump, Diaphragm Pump, and Plunger Pump are some of the most popular feed pumps.

The majority of pumps used in industry today are centrifugal pumps, which include common pumps, stainless steel pumps, mud pumps, slurry pumps, corrosion-resistant plastic pumps, etc.

From early feeding with a high flow rate to later pressing with a long-term high pressure rate, the motor must not be overwhelmed. The curve for performance is steep. The automatic conversion of big flow low pressure and small flow high pressure can be accomplished with a change in feeding resistance. Maintain a constant.

0 notes

Text

MIT researchers build new way to clear pollutants from water

When it will come to taking away incredibly dilute concentrations of pollutants from water, present separation procedures have a tendency to be vitality- and chemical-intensive. Now, a new process developed at MIT could present a selective substitute for taking away even extremely minimal levels of unwelcome compounds.

The new method is explained in the journal Strength and Environmental Science, in a paper by MIT postdoc Xiao Su, Ralph Landau Professor of Chemical Engineering T. Alan Hatton, and five some others at MIT and at the Specialized College of Darmstadt in Germany.

The program makes use of a novel process, relying on an electrochemical system to selectively take away natural and organic contaminants these kinds of as pesticides, chemical waste solutions, and prescription drugs, even when these are existing in tiny but hazardous concentrations. The method also addresses important constraints of traditional electrochemical separation procedures, these kinds of as acidity fluctuations and losses in functionality that can materialize as a consequence of competing surface area reactions.

Current techniques for working with these kinds of dilute contaminants include membrane filtration, which is costly and has confined efficiency at minimal concentrations, and electrodialysis and capacitive deionization, which generally demand higher voltages that have a tendency to deliver aspect reactions, Su states. These procedures also are hampered by extra history salts.

In the new program, the water flows among chemically taken care of, or “functionalized,” surfaces that serve as beneficial and negative electrodes. These electrode surfaces are coated with what are recognised as Faradaic components, which can undergo reactions to develop into positively or negatively billed. These active groups can be tuned to bind strongly with a distinct variety of pollutant molecule, as the group shown employing ibuprofen and many pesticides. The researchers identified that this system can proficiently take away these kinds of molecules even at components-per-million concentrations.

Prior reports have usually centered on conductive electrodes, or functionalized plates on just a single electrode, but these generally reach higher voltages that deliver contaminating compounds. By employing properly functionalized electrodes on both equally the beneficial and negative sides, in an asymmetric configuration, the researchers virtually absolutely removed these aspect reactions. Also, these asymmetric techniques let for simultaneous selective removal of both equally beneficial and negative harmful ions at the same time, as the group shown with the herbicides paraquat and quinchlorac.

The same selective system must also be used to the restoration of higher-benefit compounds in a chemical or pharmaceutical generation plant, exactly where they could possibly otherwise be squandered, Su states. “The program could be utilized for environmental remediation, for harmful natural and organic chemical removal, or in a chemical plant to recuperate benefit-extra solutions, as they would all rely on the same basic principle to pull out the minority ion from a elaborate multi-ion program.”

The program is inherently really selective, but in follow it would likely be designed with numerous phases to offer with a selection of compounds in sequence, based on the specific software, Su states. “Such techniques could possibly eventually be handy,” he sugggests, “for water purification techniques for remote areas in the producing earth, exactly where pollution from pesticides, dyes, and other chemical compounds are generally an difficulty in the water offer. The really successful, electrically operated program could run on electric power from photo voltaic panels in rural areas for example.”

Not like membrane-based mostly techniques that demand higher pressures, and other electrochemical techniques that work at higher voltages, the new program performs at reasonably benign minimal voltages and pressures, Hatton states. And, he details out, in contrast to traditional ion exchange techniques exactly where release of the captured compounds and regeneration of the adsorbents would demand the addition of chemical compounds, “in our scenario you can just flip a switch” to reach the same consequence by switching the polarity of the electrodes.

The investigate group has by now racked up a series of honors for the ongoing growth of water procedure technology, like grants from the J-WAFS Options and Massachusetts Thoroughly clean Strength Catalyst competitions, and the researchers were the major winners last year’s MIT Drinking water Innovation Prize. The researchers have used for a patent on the new system. “We definitely want to apply this in the serious earth,” Hatton states. In the meantime, they are operating on scaling up their prototype devices in the lab and improving the chemical robustness.

This method “is really substantial, as it extends the capabilities of electrochemical techniques from basically nonselective towards really selective removal of important pollutants,” states Matthew Suss, an assistant professor of mechanical engineering at Technion Institute of Technology in Israel, who was not included in this do the job. “As with several rising water purification methods, it must nevertheless must be analyzed less than serious-earth disorders and for lengthy intervals to verify sturdiness. Even so, the prototype program accomplished around 500 cycles, which is a really promising consequence.”

These researchers “have systematically explored a selection of product configurations and a selection of contaminants,” states Kyle Smith, a professor of mechanical science and engineering at the College of Illinois, who also was not included in this do the job. “In the system they have discovered general design and style principles by which to reach selective removal of contaminants. In this regard, I discover Hatton and co-workers’ study to be incredibly thorough and thoughtful. It supplies a framework or paradigm for other researchers to emulate.” But, he provides, “A substantial challenge that stays is the scale-up of these technologies.”

The group also incorporated Kai-Jher Tan, Johannes Elbert, and Robert R. Taylor Professor of Chemistry Timothy Jamison at MIT and Christian Ruttiger and Markus Gallei at the Specialized College of Darmstadt. The do the job was supported by a seed grant from the Abdul Latif Jameel Environment Drinking water and Food stuff Safety Lab (J-WAFS) at MIT.

Pertaining to Filtration-Merchandise.com:

Filtration-Merchandise.com page posts the warm off the press breaking news, statements and separation improvements straight from the separation current market.

Filtration-Merchandise retains you experienced on filtration and all the main marketplace tools like string wound filter cartridges, pleated filter aspects, meltblown filters, sock filtration, Pre-Reverse Osmosis filtration, from manufacturers these kinds of as Lakos utilized in particle separation, and just about anything else the separation area has to notify.

from Filtration Products https://ift.tt/2pL5PEs

0 notes

Text

Press Plate Supplier in Ahmedabad

Press Plate Supplier in Ahmedabad:

Elenox Steel Provides Architectural Applications As Well As The Finest Stainless Steel Sheets. In the most advanced manufacturing facility, we carry out the etching process on the surface of stainless steel sheets.

Etching is the process of engraving, scratching, and creating fine lines and grooves on the surface of stainless steel sheets. Elenox Is Known For His Specially Designed Stainless Steel Sheets With Innovative And Unique Designs. We also design stainless steel sheets based on the needs of the customer.

Our large warehouse has all of the amenities needed for the products to be properly stored. Our professional team also ensures that our warehouse system runs smoothly. Customers in Ahmedabad, India, and other markets are encouraged to contact us.

Advantages of Recessed Filter Plates:

• Filtration pressures of up to 50 bar

• Detachable Membrane

• Suitable for high filtration temperatures

• Robust design with reinforced edges.

We Provide Press Plate Supplier in Ahmedabad like Kathwada, Kalol, Kadi, Vatva, Naroda, Singarva, Odhav, Rakhial, Sanand, Vani, Daskroi, Chhatral, Narol, Dhandhuka, Dholka, Viramgam, Kerala, Asarva, Bakrol, Bodakdev.

Read the full article

#PressPlateSupplierinAhmedabad#PressPlateSupplierinAsarva#PressPlateSupplierinBakrol#PressPlateSupplierinChhatral#PressPlateSupplierinDaskroi#PressPlateSupplierinDhandhuka#PressPlateSupplierinDholka#PressPlateSupplierinKadi#PressPlateSupplierinKalol#PressPlateSupplierinKathwada#PressPlateSupplierinKerala#PressPlateSupplierinNaroda#PressPlateSupplierinNarol#PressPlateSupplierinOdhav#PressPlateSupplierinRakhial#PressPlateSupplierinSanand#PressPlateSupplierinSingarva#PressPlateSupplierinVani#PressPlateSupplierinVatva#PressPlateSupplierinViramgam

0 notes

Text

Press Plate Supplier in Ahmedabad

Press Plate Supplier in Ahmedabad:

Elenox Steel Offers Architectural Applications And The Finest Stainless Steel Designed Sheets. We carry out the process of etching on the surface of stainless steel sheets in the most cutting-edge manufacturing facility.

The process of engraving, scratching, and creating fine lines and grooves on the surface of stainless steel sheets is called etching. Elenox Is Known For His Specially Designed Stainless Steel Sheets, Which Are Known For Their Innovative And Unique Designs. In accordance with the needs of the customer, we also design stainless steel sheets.

All the amenities required for the products to be stored properly are provided in our sizable warehouse. Our professional team also runs our warehouse system efficiently. Customers in Ahmedabad, India, and other markets are welcome to get in touch with us to order our product based on their requirements.

Advantages of Recessed Filter Plates:

• Filtration pressures of up to 50 bar

• Detachable Membrane

• Suitable for high filtration temperatures

• Robust design with reinforced edges.

We Provide Press Plate Supplier in Ahmedabad like Kathwada, Kalol, Kadi, Vatva, Naroda, Singarva, Odhav, Rakhial, Sanand, Vani, Daskroi, Chhatral, Narol, Dhandhuka, Dholka, Viramgam, Kerala, Asarva, Bakrol, Bodakdev.

Read the full article

#PressPlateSupplierinAhmedabad#PressPlateSupplierinAsarva#PressPlateSupplierinBakrol#PressPlateSupplierinChhatral#PressPlateSupplierinDaskroi#PressPlateSupplierinDhandhuka#PressPlateSupplierinDholka#PressPlateSupplierinKadi#PressPlateSupplierinKalol#PressPlateSupplierinKathwada#PressPlateSupplierinKerala#PressPlateSupplierinNaroda#PressPlateSupplierinNarol#PressPlateSupplierinOdhav#PressPlateSupplierinRakhial#PressPlateSupplierinSanand#PressPlateSupplierinSingarva#PressPlateSupplierinVani#PressPlateSupplierinVatva#PressPlateSupplierinViramgam

0 notes