#high nickel alloys

Text

What Are 10 Practical Applications For High Nickel Alloys

High nickel alloys are the workhorses of annoying industries. Their amazing strength, corrosion resistance, and high-temperature performance make them irreplaceable in programs ranging from aerospace to chemical processing. But what takes place when those excessive-cost materials attain the quit in their service life? This blog explores the interesting international of high nickel alloy scrap, highlighting 10 practical programs that breathe new lifestyles into these valuable resources.

#High Nickel Alloys Scrap#High Nickel Alloys#High Nickel Alloys Importer#high nickel alloys importer in India

0 notes

Text

What is the nickel alloy?

In present-day speedy-paced business landscape, the call for materials that offer superb overall performance, sturdiness, and resistance to harsh environments is ever-increasing. One such elegance of materials that has won large prominence is nickel alloys. Nickel alloys, consisting of nickel-chromium alloys and high nickel alloys, have end up indispensable in a wide range of programs across various industries. From aerospace to automobile, from chemical processing to electronics, the flexibility of nickel alloys knows no bounds.

Understanding Nickel Alloys:

Nickel alloys are stainless substances composed of nickel because of the primary element, along with other alloying elements along with chromium, iron, molybdenum, and copper. These alloys showcase a unique mixture of houses that lead them to be extraordinarily suited for numerous programs.

Nickel Chromium Alloys:

Nickel chromium alloys, typically known as Nichrome alloys, are a number of the most broadly used styles of nickel alloys. These alloys normally contain nickel, chromium, and frequently iron because the primary materials, with small quantities of other factors introduced to enhance unique properties. The incorporation of chromium imparts first-rate corrosion resistance, high-temperature electricity, and oxidation resistance to these alloys, making them perfect for programs in environments where exposure to increased temperatures and competitive chemicals is common.

In industries such as aerospace, in which components need to face up to excessive temperatures and corrosive environments, nickel-chromium alloys play a crucial function. They are utilized inside the fabrication of turbine blades, exhaust systems, and different high-temperature additives, ensuring dependable overall performance beneath worrying conditions.

High Nickel Alloys:

High nickel alloys, also called super alloys, are a set of superior materials characterized by their excellent mechanical electricity, warmness resistance, and corrosion resistance. These alloys commonly contain an excessive share of nickel, at the side of widespread amounts of different elements along with chromium, cobalt, and molybdenum.

One of the distinguishing functions of excessive nickel alloys is their capability to preserve their mechanical houses at improved temperatures, regularly exceeding 1000°C. These assets make them crucial in applications concerning high-temperature environments, together with gasoline generators, nuclear reactors, and chemical processing flora.

Applications Across Industries:

The versatility of nickel alloys lends itself to a myriad of packages throughout diverse industries:

Aerospace: In the aerospace industry, nickel alloys are considerably used in the manufacture of aircraft engines, fuel turbine components, and structural elements. Their high-temperature energy and resistance to fatigue make them essential for making sure the protection and reliability of aircraft operations.

Automotive: In car packages, nickel alloys locate use in exhaust structures, catalytic converters, and engine components. Their corrosion resistance and heat tolerance contribute to stepped forward overall performance and toughness of automobile structures, especially in automobiles operating in harsh environments.

Chemical Processing: In chemical processing vegetation, wherein exposure to corrosive chemicals is a constant task, nickel alloys play an important function. Equipment which includes reactors, warmth exchangers, and piping structures made from nickel alloys offer superior corrosion resistance, thereby making sure the integrity and safety of chemical tactics.

Electronics: In the electronics enterprise, nickel alloys are utilized in the production of electrical additives, connectors, and resistance wires. Their brilliant electric conductivity, coupled with resistance to oxidation and corrosion, makes them best for packages requiring reliable performance in worrying environments.

Nickel Alloy Suppliers in India:

In the vibrant commercial landscape of India, numerous reliable providers cater to the growing demand for nickel alloys:

Vishal Tube Industries: Vishal Tube Industries is a main manufacturer and supplier of chrome steel seamless tubes, welded tubes, and U-tubes. With a committed body of workers and ultra-modern manufacturing facilities, they guarantee the delivery of top-excellent chrome steel merchandise to industries across the globe, inclusive of nickel alloys.

Other Notable Suppliers: Apart from Vishal Tube Industries, there are several different legitimate providers of nickel alloys in India, catering to the numerous wishes of industries together with aerospace, automotive, chemical processing, and electronics. These providers offer an extensive range of nickel alloy merchandise, sponsored by stringent pleasant management measures and spark off customer service.

Conclusion:

In conclusion, nickel alloys, which includes nickel-chromium alloys and excessive nickel alloys, represent a category of materials that epitomize versatility, performance, and reliability. From aerospace to automobiles, from chemical processing to electronics, those alloys find software

in a myriad of industries, wherein their specific aggregate of properties guarantees advanced overall performance in worrying environments.

As globalization continues to reshape the commercial panorama, the significance of super substances such as nickel alloys becomes increasingly more obvious. With respectable providers like Vishal Tube Industries leading the way, the destiny of nickel alloys in India and the past appears promising, as they maintain a pivotal position in using innovation and progress across diverse sectors.

0 notes

Text

What is Nickel Alloy Composed of?

Nickel superalloys, also called high nickel alloys or nickel based superalloys, are exceedingly regarded for their amazing nickel chromium alloy residences. These materials play a crucial role throughout diverse industries because of their unique traits. Understanding the composition and nickel chromium alloy properties is important for engineers, manufacturers, and enthusiasts alike. As a main supplier, stockist, importer, provider, dealer, and exporter of high nickel alloys, we take colossal pride in providing a complete range of nickel superalloys in numerous paperwork which includes pipes, tubes, round bars, Coils, Shims, strips, wires, sheets, and plates to satisfy a wide array of task requirements.

Unlocking the Composition of Nickel Alloys:

Nickel alloys are bendy materials famend for his or her first rate houses, consisting of corrosion resistance, high-temperature power, and awesome mechanical houses. These alloys are in wellknown composed of nickel because the base steel, augmented with numerous proportions of other elements to gain particular developments.

Nickel (Ni): As the number one detail, nickel forms the foundation of these alloys, imparting inherent power, corrosion resistance, and thermal stability.

Chromium (Cr): Renowned for its corrosion-resistant residences, chromium is a important alloying detail in nickel alloys. It office work a protective oxide layer at the floor, safeguarding in opposition to rust, oxidation, and harsh environmental situations.

Iron (Fe): Iron complements the strength, ductility, and magnetic houses of nickel alloys. It additionally plays a important role within the formation of strong stages inside the alloy form, ensuring structural integrity and sturdiness.

Aluminum (Al): Aluminum is employed to beautify the mechanical homes of nickel alloys, mainly at improved temperatures. It allows precipitation hardening and imparts advanced resistance to oxidation and sulfidation.

Molybdenum (Mo): Molybdenum complements the corrosion resistance, power, and creep resistance of nickel alloys, in particular in aggressive chemical environments. It reinforces the alloy shape, enhancing its common sturdiness and reliability.

Final Words!

Understanding the nickel chromium alloy properties, consisting of nickel chromium alloy residences, is critical for unlocking their complete ability in numerous applications. With MV Super Alloys as your depended on companion, you can rest assured knowing which you have get entry to to top class-first-rate excessive nickel alloys designed to exceed your expectancies. Contact us today to explore our giant range of nickel based superalloys and enjoy the distinction firsthand.

0 notes

Text

Carbon SS weld fittings / How to Choose the Right Carbon Steel Socket Weld Fittings

Introduction

Ganpat Metal Industries, Mumbai, India, is involved in the manufacture, supply, and export of Carbon Steel Socketweld Fittings at par with global quality standards. It is fabricated to cater to all the rigid industry standards, giving reliability and durability to their customers across different industrial applications., we will delve into the intricacies of carbon steel socketweld fittings, covering their product overview, specifications, benefits, applications, and provide a call to action for those seeking top-quality fittings.

Product Overview

Carbon steel socketweld fittings are designed for high-pressure applications and are extensively used in industries such as oil and gas, petrochemicals, power generation, and more. These fittings are engineered to provide a strong, leak-proof connection between pipes, ensuring the integrity of the piping system. The socketweld design involves inserting the pipe into a recessed area of the fitting and then applying a fillet weld around the joint. This method provides a secure and permanent bond, making it ideal for critical applications.

To read more about the product you can website our website :

#carbon steel socketweld fittings manufacturers#high nickel alloy socketweld fittings stockists#carbon steel socketweld fittings suppliers#high nickel alloy socketweld fittings suppliers#tumblr#aesthetic#love#like#tumblrgirl#follow#instagram#instagood#photography#likeforlikes#s#art#likes#tumblrboy#frasi#grunge#girl#o#cute#fashion#sad#photooftheday#photo#frases#followforfollowback#frasitumblr

8 notes

·

View notes

Text

Shokz OpenSwim Pro - TDP Review

The Shokz OpenSwim Pro are the latest innovation in bone conduction headphones, specifically designed for multisport athletes. Combining features from the popular OpenRun and OpenSwim models, these headphones promise superior performance both in and out of the water. They offer a comfortable and secure fit, Bluetooth and MP3 playback, and are fully waterproof, making them a versatile choice for…

#Athletes#Audio Quality#awareness#battery life#Bluetooth#bone conduction#Comfort#customizable controls#cycling#dual playback#Durability#earplugs#features#Fitness#Fitness Tech#Flexibility#headphones#High Performance#high quality#innovation#IP68#MP3 playback#multisport#multisport athletes#music#Nickel-titanium alloy#OpenSwim Pro#outdoor#podcasts#Price

0 notes

Text

What are Flanges?

Flanges, meticulously crafted by Meta Aerospace, are critical components designed to attach pipes, valves, pumps, and different devices in aerospace fluid structures. These circular discs with frivolously spaced bolt holes permit for the stable assembly and disassembly of various additives, making sure a leak-unfastened and green fluid glides within aerospace structures.

#Stainless Steel#Carbon Steel#Alloy Steel#Duplex & Super Duplex Steel#Titanium#Hastelloy#High Nickel Alloy

0 notes

Text

Exploring ASTM B619 Welded Pipe: Applications and Advantages

ASTM B619 is a standard specification for welded nickel-chromium-molybdenum-copper alloy (UNS N06022) and nickel-chromium-molybdenum-tungsten alloy (UNS N10665) pipe. These alloys are designed for use in corrosive environments, particularly those containing reducing and oxidizing chemicals. ASTM B619 welded pipes are critical in industries such as chemical processing, petrochemicals, pharmaceuticals, and power generation. This blog explores the properties, applications, and benefits of ASTM B619 welded pipes, emphasizing their importance in modern industrial applications.

What is ASTM B619 Welded Pipe?

ASTM B619 specifies seamless and welded pipes made from nickel-chromium-molybdenum-copper (Alloy C276, UNS N06022) and nickel-chromium-molybdenum-tungsten (Alloy B-2, UNS N10665) alloys. These materials are highly resistant to corrosion in a wide range of aggressive environments, including acids, chlorides, and seawater. Welded pipes under ASTM B619 are manufactured using fusion welding processes, ensuring uniformity, strength, and integrity throughout the pipe length.

Key Properties of ASTM B619 Welded Pipe

ASTM B619 welded pipes exhibit several critical properties that make them suitable for corrosive environments:

Corrosion Resistance: Nickel-based alloys like C276 and B-2 offer exceptional resistance to a wide range of corrosive chemicals, including acids (sulfuric, hydrochloric), chlorides, and seawater.

High Temperature Performance: These alloys maintain their mechanical strength and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications.

Mechanical Strength: ASTM B619 welded pipes provide excellent mechanical properties, including high tensile strength and toughness, ensuring reliability in demanding conditions.

Weldability: The alloys are easily weldable using conventional welding techniques, allowing for easy fabrication and repair of piping systems.

Low Maintenance: Due to their corrosion resistance, ASTM B619 welded pipes require minimal maintenance, reducing downtime and operational costs.

Longevity: These pipes have a long service life in aggressive environments, offering reliable performance over extended periods.

Applications of ASTM B619 Welded Pipe

ASTM B619 welded pipes find extensive use in industries requiring resistance to corrosive environments:

Chemical Processing: They are used in chemical plants for transporting acids, alkalis, and other corrosive chemicals.

Petrochemical Industry: ASTM B619 pipes are employed in oil refineries, gas processing plants, and offshore platforms where exposure to corrosive fluids is common.

Pharmaceutical Industry: These pipes are used in pharmaceutical manufacturing processes that involve corrosive solvents and chemicals.

Power Generation: ASTM B619 pipes are utilized in power plants for handling corrosive cooling water, steam, and chemicals in boiler systems.

Waste Treatment: They are used in wastewater treatment facilities for conveying corrosive liquids and gases.

Pulp and Paper Industry: ASTM B619 pipes find application in pulp and paper mills for handling corrosive chemicals used in bleaching and processing.

Benefits of Using ASTM B619 Welded Pipe

ASTM B619 welded pipes offer numerous advantages, making them a preferred choice in corrosive environments:

Corrosion Resistance: Superior resistance to a wide range of corrosive chemicals ensures longevity and reliability.

High Performance: These pipes maintain their mechanical properties at high temperatures, ensuring consistent performance in demanding conditions.

Safety: Reliable corrosion resistance reduces the risk of leaks and failures, enhancing operational safety.

Cost-Effectiveness: Despite their initial cost, ASTM B619 welded pipes offer long-term savings due to reduced maintenance and extended service life.

Versatility: Available in various sizes and configurations, they can be tailored to meet specific application requirements.

Environmental Sustainability: Nickel-based alloys are fully recyclable, promoting environmental sustainability and compliance with green initiatives.

Conclusion

ASTM B619 welded pipes made from alloys such as C276 and B-2 play a crucial role in industries where corrosion resistance and reliability are paramount. Their exceptional properties make them ideal for handling corrosive chemicals in chemical processing, petrochemicals, pharmaceuticals, and power generation. Understanding the benefits and applications of ASTM B619 welded pipes underscores their critical importance in ensuring efficient, safe, and sustainable operations in modern industrial environments.

#ASTM B619 Welded Pipe#Nickel-Chromium-Molybdenum Alloys#Corrosion Resistance#Chemical Processing#Petrochemical Industry#Power Generation#Mechanical Strength#High Temperature Performance

0 notes

Text

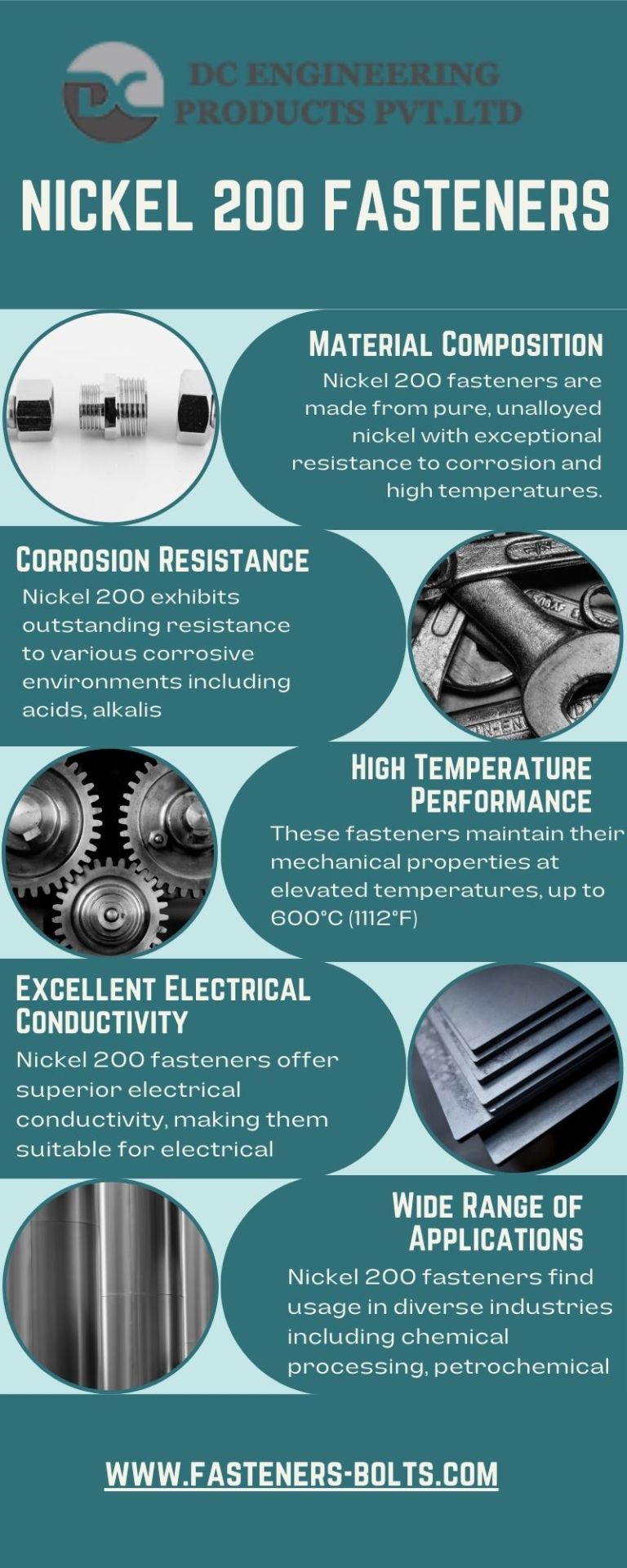

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

IPM vs SPM Electric Motors

IPM vs SPM Electric Motors

A PM motor can be separated into two main categories: surface permanent magnet motors (SPM) and interior permanent magnet motors (IPM) . Neither motor design type contains rotor bars. Both types generate magnetic flux by the permanent magnets affixed to or inside of the rotor.

SPM motors have the magnets affixed to the exterior of the rotor surface. Because of this…

View On WordPress

#aluminum nickel cobalt#bonding neodymium iron boron#Embedded Permanent Magnets#Ferrite magnet#high-performance permanent magnet motors#interior permanent magnet motors#IPM motors#Magnetic alloy#magnetic field#magnetic fields#magnetic flux density#magnetic forces#magnetic parameters#magnetic properties#Magnetic torque#magnetization direction#motor magnets#Nd-Fe-B#Nd-Fe-B magnets#Nd2Fe14B#NdFeB#NdFeB bonded magnet#NdFeB Grinding Process#Neodymium iron boron#Neodymium Magnet#Neodymium Magnets are Made#Neodymium Motor Magnet#permanent magnet motors#Permanent Magnets#PM Motors

1 note

·

View note

Text

Complete Guide on High Nickel Alloy Scraps

Vardhman Ferro Alloys is a leading high nickel alloy scrap importer and metal scrap supplier in India, offering metal scrap, ferroalloys, and nickel alloy scrap. The company features high-quality products, competitive metal scrap prices, and timely delivery. The company performs extensive checks on all its products and delivers its products to customers globally. For more information on their products, visit their website today!

Nickel alloys consist of a mixture of nickel and other additional metals like aluminum, titanium, chromium, and iron. Nickel and high nickel alloys find extensive applications in different industries. New nickel is often recycled into alloys. For instance, nickel alloy like stainless steel finds usage in multiple industrial and domestic applications.

Nickel alloys from high nickel alloys scrap suppliers have multiple properties like oxidation resistance, corrosion resistance, high workability, strength, durability, and temperature resistance up to 1000 degrees. The average life span of nickel and high nickel alloy ranges from 25 to 35 years (more than most metals).

Why do nickel alloy and high nickel alloy scraps have great value?

Nickel and high nickel alloys are popular in the industry and find extensive applications due to their properties like:

Versatility

High corrosion resistance

Electronic properties

Resistance to oxidation

Magnetic properties

High strength for a range of temperatures

Oxidation resistance

As nickel finds extensive usage, it is among the top recycled metals globally. Hence, high nickel alloys are available in different varieties extensively.

Where can you find high nickel alloys?

Scrap metal suppliers like Vardhman Ferro Alloys feature nickel alloys and high nickel alloy scraps like Monel 400 and Inconel 600 alloy. The company offers competitively high nickel alloy scrap prices. One can find nickel scrap metal in:

Cell phones

Medical equipment

Food preparation equipment

Aircraft

Transportation

Laboratory equipment

Power generation turbines

Building materials

The above applications feature the versatility of nickel scrap metal. It prominently finds applications in the aerospace and chemical industries, especially for manufacturing stainless steel.

The cobalt and iron content in nickel offers ferromagnetic properties to nickel. When other scrap metals or metals are added to nickel, nickel alloy scrap, and high nickel alloy scrap works a strong magnet. Its combination with other metals also offers heat and electricity conduction properties to nickel alloys.

High nickel alloy scrap from Vardhman Ferro Alloys

Vardhman Ferro Alloys feature high nickel alloy scrap and nickel alloys in the form of rods. These alloys also do not contain impurities. High nickel alloys can be melted easily, ensuring high energy efficiency. Nickel alloy scrap can be burnt in small and large furnaces.

High nickel alloy scrap offers maximum output due to its lower burning loss, increasing demand for scrap metal in the market. These scrap metal alloys find application in induction furnaces and casting units. After recycling high nickel alloy scrap one can make multiple components, assemblies, enclosures, tools, etc. These recycled components find applications in the chemical industry, marine industry, petrochemical, and oil and gas refineries.

Vardhman Ferro Alloys offers high nickel alloy scrap manufactured using advanced technologies, making their products suitable for extensive industrial applications. The scrap metal also offers international compatibility. The company also presents nickel alloys and Hastelloy C22 plates with global compatibility and international delivery.

Final thoughts

Nickel alloy scrap is among the top scrap metals available. Recycling high nickel alloy scrap and nickel scrap at Vardhman Ferro Alloys, a leading metal scrap manufacturer follows an efficient process. Given the global requirement for scrap metal, especially, high nickel alloys, the market recycles extensive quantities of nickel alloy.

0 notes

Text

Buy High-Quality High Nickel Alloys Scrap Importer in India

Looking for top-quality high nickel alloys for your project? Look no further than Vardhman Ferro Alloys, a trusted importer in India offering reliable, compatible, and ISO-certified products. Explore our customizable range and enjoy excellent customer support and timely delivery. Trust us to be your go-to source for high nickel alloys scrap.

#nickel scrap metal#High Nickel Alloys#high nickel alloys importer in india#high nickel alloys scrap suppliers#high nickel alloys scrap importer

0 notes

Text

Nickel 200 Fasteners Exporters In India

Deep Steel Center is a most acclaimed Nickel Compound 200 Latches producer, provider, and exporter in India. Whether you are searching for odd size Latches, it basically puts you get as the need might arise. Here we besides take stand-out orders for express basics made by the clients. For the overall important applications, we additionally store these latches in different principles, assignments, nuances and custom perspectives. We are avow as ISO guaranteed relationship as we produce things as indicated by the set present day standards.

The offered degree of clasp is known for its closeness against antagonistic circumstances. The grade depicts the higher strength and durability even in the terms of effect applications.

#These clasp are utilized for brief relationship of two sections. The joint is made with no harms of outside parts; likewise the obliterating#no spillages.#Nickel 200 is business unadulterated made nickel having UNS N02200 task. It has magnificent mechanical constants and wonderful resistivity#for example#charming properties#low gas content and high warm conductivities#and low smoke pressure.#It has a good plan of alloying parts makes it protection from endless negative conditions. This grade has a good capacity to oversee most s#Specifications:#Standard : DIN#ASTM#BS and all International Standards#Size : 3 mm to 200 mm#Bolt / Screw Size : M3 - M56 | 3/6“ to 2” | Custom Sizes#Nuts Size : M3 - M56 | 3/6“ to 2” | Custom Sizes#Washers Size : M1 - M64 |#4 to 3" | Custom Sizes#Length : M02 to M33#For More Information:#Visit Our Website -#Call Us: (+91) 993 046 6755#E-mail:[email protected]

0 notes

Text

Nickel Alloys Stockist

At MV Super Alloys, we are a leading stockist and trader of nickel alloys, including copper-nickel alloys, nickel-copper alloys, nickel-based super alloys, iron-nickel alloys, nickel-iron alloys, nickel-chromium alloys, and other high nickel alloys in Hyderabad, India.

#iron nickel alloys Stockist#nickel chromium alloys Traders#high nickel alloys#nickel chromium alloys

0 notes

Text

Carbon Steel ASTM A694 Flanges: Overview and Applications

Introduction

Carbon Steel ASTM A694 flanges are essential components in piping systems, providing a reliable means of connecting various pipes, valves, and fittings. Designed to meet rigorous industry standards, these flanges are widely used in high-pressure and high-temperature applications, particularly in the oil, gas, and petrochemical sectors.

What is ASTM A694?

ASTM A694 is a standard specification developed by ASTM International that outlines the requirements for carbon and alloy steel flanges used in high-pressure service. The specification covers various grades, with each designed to provide specific mechanical properties and performance capabilities.

Key Features of ASTM A694 Flanges

Material Composition

Carbon Steel ASTM A694 flanges are typically made from carbon steel, which offers excellent strength and durability. The material composition can include various alloys to enhance performance under specific conditions.

Pressure Ratings

These flanges are available in different pressure ratings, typically ranging from 150 to 2500 psi. This allows them to be used in a wide range of applications, from moderate to extremely high-pressure environments.

Temperature Resistance

Designed to withstand high temperatures, ASTM A694 flanges are suitable for applications that require stability and strength at elevated temperatures, making them ideal for use in harsh industrial settings.

Corrosion Resistance

While carbon steel is inherently susceptible to corrosion, ASTM A694 flanges can be treated with coatings or materials to enhance their resistance to environmental factors, ensuring longevity and reliability.

Common Grades of ASTM A694 Flanges

Grade F42: Suitable for moderate pressure and temperature applications.

Grade F52: Offers higher strength for more demanding environments.

Grade F60: Designed for high-pressure applications with excellent toughness.

Grade F65: Used in severe service conditions, providing superior strength.

Applications

Oil and Gas Industry

ASTM A694 flanges are commonly used in pipelines that transport oil and gas, ensuring secure connections that can withstand high pressures.

Petrochemical Plants

These flanges are critical in various processes within petrochemical facilities, where they connect pipes and valves in systems handling aggressive chemicals.

Power Generation

In power plants, particularly those utilizing steam, ASTM A694 flanges play a vital role in connecting high-pressure steam lines.

Water Treatment Facilities

They are also utilized in water treatment systems, where robust connections are required for transporting treated and untreated water.

Conclusion

Carbon Steel ASTM A694 flanges are a crucial element in ensuring the integrity and reliability of high-pressure piping systems. Their robust design, combined with their ability to withstand harsh conditions, makes them a preferred choice in various industrial applications. When selecting flanges, it’s important to consider the specific requirements of your project, including pressure, temperature, and corrosion resistance, to ensure optimal performance and longevity.

Call to Action

For more details

Email: [email protected]

Contact: +91-22-2389-3333

If any enquiries please contact us our support team will connect you as soon as possible

#high nickel alloy socketweld fittings stockists#industrial#industry data#industry hbo#steel#juno steel#tubes

0 notes

Note

Hi I saw your reply on a post about weird things people believe in (in terms of science) and you wrote about that unless one stands on a volcano, its solid rock down to the outer core and I had to google it because I was always taught that THE MANTLE IS LIQUID not by movies but by SCHOOL and now I learn it's a case of 'technically-' and I'm shaking so, uh, thanks.

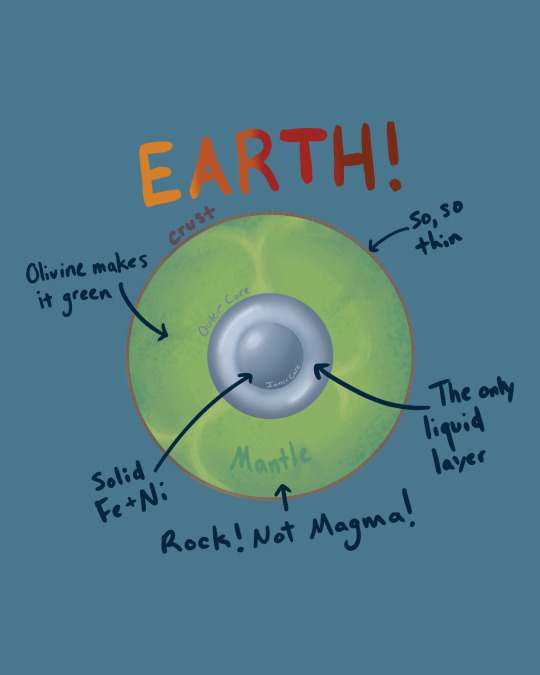

Hello! Sorry I sat on this, I wanted to respond with this earth structure diagram I've been working on. I think most public schools in the US do a terrible job of teaching geology and it actually drives me insane lol. Also, if learning the mantle is not liquid blew your mind, then this is gonna blow your mind too...

The mantle is green!

This is a pretty quick and dirty diagram, but I wanted to show the earth in a way that we don't usually think about (usually it just looks "hotter" as you go toward the center). Here are some earth facts I wish everyone knew:

The Crust - relatively super thin, very brittle, mostly granite, and things get weird where the crust transitions to mantle and where plates collide (might make a second post on that).

The Mantle - primarily made up of a rock called peridotite, which has lots of olivine in it and is blasphemously green. Also the mantle is pretty much all rock, maybe a little magma here and there, but it's pretty minor. But because all that rock is really, really hot it can deform plastically and it actually undergoes convection (it moves!) Mantle upwelling (shown in that lighter green) is actually a huge driver of plate tectonics.

The Core - made of an iron and nickel alloy, the outer core is liquid (because it's so hot) and the inner core is solid (because the pressure is so high). This dual metallic core generates Earth's magnet field (our planet is one big magnet). We also suspect that inner core has Widmanstätten patterns, similar to those we find in meteorites.

So yeah, hoped you liked some more earth facts 😅

#geology#rocks#minerals#earth#science#earth science#planets#probably gonna put this on redbubble?#my art#geolife

5K notes

·

View notes

Note

How significant is powder metallurgy for the use of bastardly-to-machine stuff like inconel these days? it's just i was checking out some quotes for DMLS printing recently and there wasn't *that* much of a price delta between alu and stuff like maraging steel and superalloys

I can’t speak to other industries, but in rocket engineering and fusion engineering it’s huge. Everybody loves to 3D print inconel, as well as funky copper alloys (shoutout to GRCop-84) and steel. It has terrific mechanical properties and you can make almost any arbitrary shape. The hot new thing to do is to 3D print as much of your rocket as possible.

HOWEVER, in nuclear fusion, inconel in general is kind of going out of fashion. For those of you in the room who aren't familiar, inconel refers to a class of "superalloys," structural metals that can retain their strength while very close to their melting point. One would think this would be a super useful property in a fusion reactor, and one would be absolutely correct. JET in the UK went hog-wild with inconel, as did TFTR at Princeton.

But, depending on the alloy, inconel is anywhere from 50% to 70% nickel. Nickel is particularly problematic in areas of high neutron flux (like, say, in a fusion reactor), where it captures neutrons and "activates." Almost every element does this to one extent or another, but it's real bad when it happens to nickel.

I'm not a neutronics person, but from what they tell me, the various transmutation reactions give you both radioactive byproducts with annoyingly long half-lives, and pockets of helium that lead to severe embrittlement. A nickel-rich alloy is just not going to have a good time in a fusion power plant, long term.

96 notes

·

View notes