#motor magnets

Explore tagged Tumblr posts

Text

NdFeB Motor Magnets Supplier

NdFeB Motor Magnets Supplier – HSMAG Our engineered neodymium magnets unlock new possibilities for high-efficiency motor design. With unmatched magnetic energy density, these customizable magnets advance electric motor performance through compact form factors, quiet operation, fast response times, and excellent speed control. Leveraging decades of experience, we expertly craft neodymium magnet…

#elevator magnets#elevator traction motors#Laminated Motor Magnets#Linear Motor Magnets#magnet manufacturers#magnetic generators#magnetic tractors#Motor Magnets#Motors and generators#Neodymium magnets#neodymium ring motor magnets#Permanent Magnet Motors#Radial Ring Magnets#rare earth neodymium magnets#servo motor magnets#Sintered Neodymium Magnets#Tubular Linear Motor Magnets#Voice Coil Motor Magnets

0 notes

Text

Temperature Condition for Brushless Motor Magnets

Temperature Condition for Brushless Motor Magnets Brushless motors use permanent magnet as one of their key components. These magnets usually use high-performance permanent magnet materials, such as rare earth neodymium strong magnets, mainly arc-shaped, fan-shaped, wedge-shaped, and rectangular. Today, this article mainly introduces the temperature requirements of brushless (DC) motor…

#AC motors#bonding neodymium iron boron#Brushless motor magnets#DC motors#Embedded Permanent Magnets#Ferrite magnet#high-performance permanent magnet motors#interior permanent magnet motors#IPM motors#magnet working temperature#Magnetic alloy#magnetic field#magnetic fields#magnetic flux density#magnetic forces#magnetic parameters#magnetic properties#Magnetic stators#Magnetic torque#magnetization direction#Magnets Temperature#motor magnets#permanent magnet motors#Permanent Magnets#PM Motors#rotor and stator#SPM motors#surface permanent magnet motors#Surface Permanent Magnets

0 notes

Text

IT SPINS! Handmade electric motor! Entirely out of wire! They said it couldn't be done, but I have proven -- it merely shouldn't be done!

Photos don't really capture how ridiculously complicated this thing was to build, so I managed to film myself assembling the components too! Very proud of that.

In total, I've been working on this project on and off for roughly two years. This motor is my third version, though I went through something like seven designs of the commutator section (not counting how many failures it took to build a working example of a given design). I'm very proud of getting this to work at all.

Some close-up photos of all the components:

Six-way commutator. As the motor spins, this delivers electricity to only the correct pair of magnets at a time, leaving the other four off.

Magnet coils. I wound these by hand from very thin insulated wire. The center is a spiral of thicker insulated wire (darker orange) that protects the thin stands from the steel core and then wraps around the outside to hold everything in place.

Spring-loaded arms. These deliver electricity from the stationary frame into the rotating axle. They also have to hinge up out of the way or else there's no room to fit the rotor in place during assembly.

All the components laid out together before assembly.

And the full motor in all its glory!

#wire#crafting#electric motor project#steampunk I guess#IT FINALLY SPINS#and it's made entirely of wire#no permanent magnets just metal and electricity#even just making the video was a decent-sized project on its own#so proud of this

4K notes

·

View notes

Text

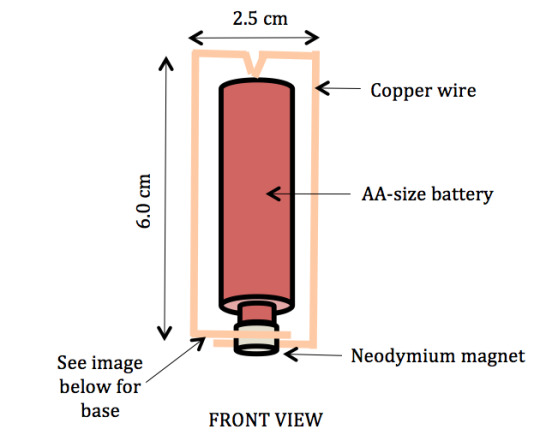

A homopolar motor is built with a battery, a magnet and some conductive wire. The magnet provides a magnetic field that will interact with the magnetic field induced by the current in the wire.

A homopolar motor is a type of electric motor that uses a magnetic field to create motion. It is also known as a disc motor, a Faraday disk, or a disc dynamo.

The homopolar motor is made up of three main parts:

A battery: This provides the electrical current that flows through the wire.

A magnet: This creates the magnetic field that interacts with the current in the wire.

A conductive wire: This is the wire that carries the electrical current and interacts with the magnetic field.

The wire is typically shaped into a disc, and it is placed between the poles of the magnet. When the battery is connected to the wire, a current flows through the wire. This creates a magnetic field around the wire. The magnetic field of the wire interacts with the magnetic field of the magnet, and this causes the wire to rotate.

The speed of the homopolar motor depends on the strength of the magnetic field, the amount of current flowing through the wire, and the size and shape of the wire.

Homopolar motors are simple to construct and can be used to generate small amounts of electricity. They are often used in educational demonstrations and experiments.

Here is a diagram of a homopolar motor:

The battery is connected to the wire, which is shaped into a disc. The disc is placed between the poles of the magnet. When the battery is connected, a current flows through the wire, creating a magnetic field around the wire. The magnetic field of the wire interacts with the magnetic field of the magnet, and this causes the wire to rotate.

Thank you for reading! I hope you found this post informative. If you did, please share it with your friends and followers. 😊🙏

380 notes

·

View notes

Text

IM FREEEEEE

#(FROM PROJECTS)#personal#the engineering chronicles#WILL HOPEFULLY NEVER NEED TO SLEEP THREE NIGHTS ON THE FLOOR OF THE ENGINEERING BUILDING AGAIN!!!#one class the final project was to build a karaoke machine which my partner and i had planned on making look like actual speakers and#microphone but we couldn’t find the stuff in time and her mom made a joke abt singing into hairbrushes and we decided to take that and#run lol we used a pink sparkly makeup box to store our circuit and cut out holes for the speakers and decorated it with makeup and put the#hairbrush mics inside and it was very fun actually and our class voted us as one of the groups to go to project day which was pretty cool!!#project day did get canceled bc of. asnow day which was unfortunate especially considering we stayed up until 4am the night before#preparing our documents for it and trying to perfect the karaoke machine when we could have been putting that time toward project number#2 😐 but whatever we still get our extra credit and i can say i qualified for it so im happy enough#then project 2 was for another class but we’re lab partners in both (+ another guy for this project) and it was digital monster pet so we#made a dragon i was mostly on design so i hand CADed the whole thing which was living hell if i never want to lay eyes on solidworks#again but also he came out very cute after MUCH hasle putting him together with all the wires and components bc our wires from the kit are#so bad they’re constantly getting disconnected from each other which we didn’t know would happen bc the labs we usually do we don’t have to#connect them together like that since you’re not routing them thru bodies etc and they’ve worked great until now but anywya.#i did the lcd faces and the light sensor and a couple other things + a lot of the code was copy and paste from past labs and fitting it to#suit the project but for the most part it was a shit ton of hardware on my end while she and the other guy managed the rest of the code#which i really wish i could have been more involved with but oh well. as it is though he’s my baby i birthed him <3 we’re planning on#meeting up over weekends next semester to change some stuff and add other extra features that we missed we got a decent grade 85% but we#all agreed we don’t want to leave him like this we want to add the extra features we had come up with and also i think we should switch out#our motors for servos bc the motors we were required to use#instead suck they’re not strong at all compared to what a servo can do for you. also we want to make it so you can not only pet him which w#already have with light sensors but also wash him with a Hall effect sensor and magnet so like we’d stick the sensor inside and the magnet#inside a little cad brush or sponge is what im envisioning and i have an expression in mind for what we’d do then. also paint him and#redesign the platform he stands on bc it’s rlly cramped and also make a pcb bc we only have him with the microcontroller and breadboards rn#and i might mess with his face piece a bit too im not sure. oh and speakers!!! those were technically a requirement but we didn’t get them#done on time but i want to make him play music sooooo bad so definitely that. anyway want to be more involved in the software when we do#all this. pretty excited actually :]

9 notes

·

View notes

Text

youtube

Anyone have any idea what the name of this kinda PCB is?

#Youtube#have seen similar things labeled '2d magnetic actuators'#or '2d stepper motors'#or like those smart chess sets that automatically move the pieces without just having a xy electromagnet gantry underneath#specifically smth that can move electromagnets independently#ideally w no actual moving parts underneath

10 notes

·

View notes

Note

what do you think of linear induction motors

Better than linear synchronous motors as it doesn’t require complex start up logic

And induction is a cool as hell way to create motion! Like yeah imagine a transformer, but short 1 part and allow it to move???? And it moves!????

#yeah induction is way cooler than just attracting a magnet#but rotary motors are way more useful#what do YOU thinks of linear induction motors?#first ask yay 🎉

5 notes

·

View notes

Photo

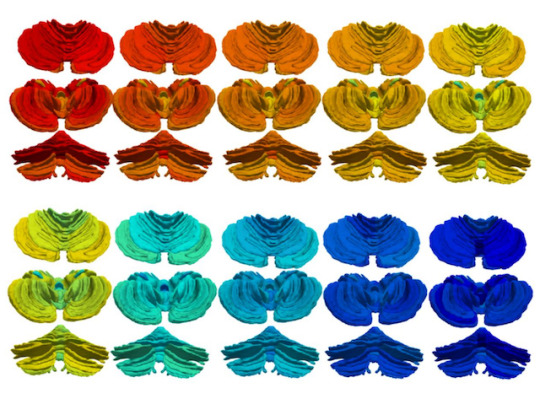

Baby Brains

The human body carries on developing after birth – but the rate of these changes is still in question for developmental biologists. Here scientists take magnetic resonance imaging (MRI) scans of sleeping children’s cerebellums over the first two years of life, showing months 1–5 (top row) and regular intervals afterwards (bottom) from three different angles. While the young brain is constantly growing, it’s growing at a faster rate (warmer colours) during the first six months. The researchers investigated further, analysing the scans from 235 healthy children and looking at how 27 individual regions of their cerebellums change – finding, for example, that changes in specific ‘lobules’ corresponded with milestones in fine motor skills. This data could be used to pinpoint developmental windows for further study, or even to diagnose health issues or injuries during a toddler’s early life.

Written by John Ankers

Image from work by Ya Wang and Liangjun Chen, and colleagues

Department of Radiology and Biomedical Research Imaging Center, University of North Carolina at Chapel Hill, Chapel Hill, NC, USA: UNC/UMN Baby Connectome Project Consortium

Image originally published with a Creative Commons Attribution 4.0 International (CC BY 4.0)

Published in Cell Reports, April 2023

You can also follow BPoD on Instagram, Twitter and Facebook

#science#biomedicine#brains#brain development#developmental biology#babies#brain#mri#magnetic resonance imaging#motor skills

6 notes

·

View notes

Text

This is so wierd!

5 notes

·

View notes

Text

High-Performance Magnetic Assemblies

High-Performance Magnetic Assemblies For Diverse Applications, Including EV Motors, Generators, Speakers, And Medical Devices. Types Of Magnetic Assemblies Our engineered magnetic assemblies deliver optimized industrial solutions through advanced neodymium magnets, calculated designs, and customized integration. Pot / Fishing Magnets Encased in a durable housing with an attached eyelet or hook,…

#Alnico#Custom magnets#Ferrite#holding magnetic assemblies#Industrial Magnetic Assemblies#Industrial Magnetic Assembly#magnetic assemblies#Magnetic Assembly#magnetic assembly and devices#magnetic materials#magnetic modeling#magnets#Motor Magnetic Assembly#NdFeB#Neodymium Magnetic Assembly#permanent magnet#Permanent Magnet Motors#Permanent Magnetic Assembly#PM motors#SmCo

0 notes

Text

Type And Advantage of Magnets In Electric Motors

Type And Advantage of Magnets In Electric Motors We all know that magnets are commonly used on motors, but the magnets used by different motors are not only different sizes, but also different shapes. The basic shapes are arc/wedge/bread-shaped, rectangle, ring and flat (plane) shapes, Let’s talk about their respective characteristics. First, Motor arc magnets (segment magnet, bread magnet,…

#AC motors#bonding neodymium iron boron#DC motors#Embedded Permanent Magnets#Ferrite magnet#high-performance permanent magnet motors#interior permanent magnet motors#IPM motors#Magnetic alloy#magnetic field#magnetic fields#magnetic flux density#magnetic forces#magnetic parameters#magnetic properties#Magnetic stators#Magnetic torque#magnetization direction#motor magnets#permanent magnet motors#Permanent Magnets#PM Motors#rotor and stator#SPM motors#surface permanent magnet motors#Surface Permanent Magnets

1 note

·

View note

Text

One of the Smallest T Gauge Model Railway Layouts with Self-Propelled Model Trains

youtube

#linear motor#linear mosfet#t gauge#1/440 scale#tiny#tiny train#magnetic field#model railway#layout#model trains#cutting edge scale modeling#miniatures#youtube

1 note

·

View note

Text

Exploring the Uses of Rare Earth Elements

Rare earth elements find applications in technologies ranging from high-tech devices, clean energy, and hybrid vehicles to wind power turbines, hard disk drives, and defence systems. All elements in the lanthanide series share similar chemical, magnetic, and spectroscopic properties; their role in a wide range of applications is attributed to these shared characteristics.

The Applications of Rare Earths

The primary sources of rare earth elements are bastnaesite and monazite. In India, monazite tops the list of mineral materials for the production of rare earths. It includes many lanthanides; approximately 50–70% of them are light rare earth elements (LREE).

Here are the various uses of rare earth elements:

Cerium (Ce) is one of the most abundant rare earth elements in the Earth’s crust. It is used to polish glass items such as lenses, liquid-crystal displays and plasma-display panels. It is also used as a fuel additive in fuel material like petrol and diesel. In combination with lanthanum, it has a use as an environmentally friendly substitute of cadmium in red pigments. Mischmetal, a mix of cerium and some other rare metals, is used to keep steel clean during its production phase.

Lanthanum (La) and neodymium (Nd) find application as glass additives in optical lenses and display screens. Along with yttrium (Y), they help store elements like magnesium, aluminum, and hydrogen. They act as catalysts to minimise sulphur dioxide emissions in automobiles. Nd also finds uses in welding in heavy industries and in medical equipment like MRI scanners.

Samarium (Sm), dysprosium (Dy), praseodymium (Pr), and terbium (Tb) are utilized in electronics, electric motors and audio equipment for their magnetic properties. Pr is used as neodymium’s replacement in magnets.

Scandium (Sc) is primarily used in aluminium alloys for sports equipment. This metal is mixed in small amounts in semiconductors and halogen bulbs.

Rare earth magnets, such as neodymium-iron-boron (NdFeB), are used in anti-lock brakes in cars to prevent the wheels from locking when you brake hard. These magnets also find applications in small gadgets such as digital cameras.

Nickel metal hydride (NiMH) batteries are considered special batteries. They have a mix of rare metals, including mischmetal, and are used in laptops, camcorders, and mobile phones to power them.

GMDC is committed to establish a comprehensive value chain for rare earths’ mining and their production. Our vision is to develop a sustainable supply chain of permanent magnets in India. For more information, visit our website https://www.gmdcltd.com/.

0 notes

Text

Permanent Magnet Motor Assembly Manufacturer

Motor is an electromagnetic device which achieves conversion between mechanical energy and electric energy via the magnetic field. The air gap magnetic field for electromechanical energy conversion can be produced by applying the electric current to excitation winding or utilize permanent magnet. Permanent magnet motor refer to those motor which utilize permanent magnetic field to instead excitation windings.

Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

Japan has Launched New Generation Transport SHOCKING Saudi A

youtube

Another new video from the "AI Evolves" channel. In this video, we explore Japan's revolutionary new-generation transport system and its shocking impact on Saudi Arabia. Keep watching this entire video. Stay up to date by subscribing to our channel.

Innovative Transport Devices: Companies like Honda, Segway, Toyota, and Coco Motors are developing cutting-edge transportation solutions like single-wheeled unicycles and egg-shaped vehicles that revolutionize personal mobility.

Honda U3X: A user-friendly electric unicycle weighing 10 kg, operated by shifting body weight, and designed for short trips with a 6 km/h speed and 30 minutes of charge time.

Segway S-Pod: An egg-shaped, joystick-controlled self-balancing chair capable of reaching 38 km/h and 70 km per charge, ideal for campuses and parks.

Toyota FV2 and PM: Toyota's futuristic single-person vehicles operate through body movements. They feature features like color-changing panels and extreme maneuverability and focus on personalization and urban mobility.

Toyota Micro Pallet: An autonomous robot for last-mile delivery with interactive features, showcasing Toyota’s vision for efficient, modern transportation solutions.

We hope you enjoyed this video. Make sure you click the "Like" button and share this video with your friends and others who might also be interested in learning more about this video.

#transportation revolution#future of travel#magnetic levitation technology#transportation innovation#technology#robotics#Walkcar By Cocoa Motors#Youtube

0 notes

Text

This is so COOL! An xy stepper motor moves magnets which move the chess pieces. But beware of the knight! Knights can jump over pieces!

1 note

·

View note