#Laminated Motor Magnets

Explore tagged Tumblr posts

Text

NdFeB Motor Magnets Supplier

NdFeB Motor Magnets Supplier – HSMAG Our engineered neodymium magnets unlock new possibilities for high-efficiency motor design. With unmatched magnetic energy density, these customizable magnets advance electric motor performance through compact form factors, quiet operation, fast response times, and excellent speed control. Leveraging decades of experience, we expertly craft neodymium magnet…

#elevator magnets#elevator traction motors#Laminated Motor Magnets#Linear Motor Magnets#magnet manufacturers#magnetic generators#magnetic tractors#Motor Magnets#Motors and generators#Neodymium magnets#neodymium ring motor magnets#Permanent Magnet Motors#Radial Ring Magnets#rare earth neodymium magnets#servo motor magnets#Sintered Neodymium Magnets#Tubular Linear Motor Magnets#Voice Coil Motor Magnets

0 notes

Text

Soft Magnetic Composite SMC Material

Soft Magnetic Composite SMC Material In recent decades, trends in automotive and other industries have spiked demand for new magnetic materials. As a result, in the mid-1990s the very first components made from soft magnetic composite were born. And the trend of using these soft magnetic composites (SMCs) only continues to grow. Those first SMC parts were ignition cores, used extensively in most…

View On WordPress

#Electric Motor#Lamination steels#magnet composition#Magnet Maker#Magnetic alloy#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Metals#magnetic properties#magnetic structures#Magnetic powder#Magnetism#Nd-based magnets#Neodymium magnets#paramagnetic materials#Permanent Magnet#Rare Earth Magnets#rare earth metals#Sintered NdFeB#Sintered NdFeB Magnets#sintered soft magnetic materials#soft magnetic composite#Soft magnetic materials#SOFT MAGNETIC POWDER#Soft Magnetics#Super Magnets

2 notes

·

View notes

Text

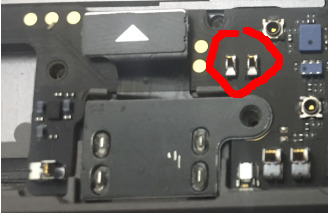

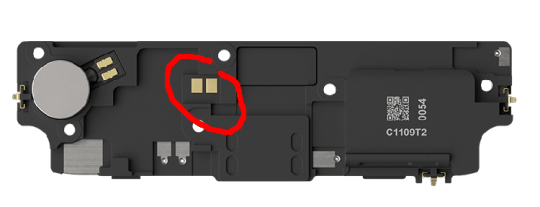

Putting a headphone jack in a Fairphone 4

TLDR with this procedure you sacrifice the lower loudspeaker, but the upper one will still behave as normal. Calls and other audio seem to work just fine. There is some interference from internals that gets picked up by amplified speakers, I'm sure there's a way to filter it, this is mainly a proof of concept. This is not really a guide and I do not guarantee anything at all.

I really liked my Fairphone 4 except that it didn't have a 3.5mm jack like normal phones used to have. And my car has never heard of Bluetooth. So I started joking about drilling a hole in it.

I found this green TRS jack on a USB DAC and found it would fit inside. I took this photo with a DSi camera. Originally I thought I might be able to fit both the jack and the speaker, and I had this elaborate plan to make a cut in the mainboard and move the vibrating motor elsewhere,

but decided against it because I had no idea what losing that one contact would do. I did a test and found no major issues with removing the bottom loudspeaker. If I needed the phone to be loud, I'd hook something else up anyway. I bought a second loudspeaker and horrendously dissected it.

I used a knife. If you do this you should absolutely use a dremel tool and not a knife. Unless you don't have a dremel tool

The plan is, remove the speaker part. You do not have to completely de-laminate the two layers of plastic. Just this section of the bottom layer. The top layer has pretty colors and conductive tape and contacts for mysterious purposes. Maybe antenna.

Next, you must drill the hole. We're not quite sure what the case is made of, but it probably involves aluminum. I had a drill press and clamps, but I went to my friend's house. He doesn't have clamps or many drill bits, but he knows metal. The jack barrel was like 5.1mm in outer diameter, and after lamenting that all our bits were in imperial, we settled on a 7/32". We removed all components from the chassis including mainboard and screen before drilling.

Here, we went for a hole that was centered on the middle hole of the speaker grill. However, if you do this, you will need to also remove some more metal, because the jack will need to be kind of submerged in the floor. We also had to sand down one side of the jack paper thin to make it sit flat against the back of the screen module. In hindsight, I should have marked where the jack wanted to sit before drilling. This would have us drill at the edge of the case, but it would be closed off by the phone's back cover anyway so it wouldn't matter. Just plan out your hole instead of eyeballing it.

Unfortunately, we did not get any pictures of the fit after we were done. Probably for the best, so no one has to see the metal carnage.

Once it was in place, it was time to wire it. The speaker module presses a flat flex cable up against these two contacts on the board.

I originally managed to solder to the flat cable, but then made a mistake and tore the pads, so I ended up soldering directly to those spring pins on the mainboard. I used magnet wire for everything. I just connected both the L and R pins of the jack to this one speaker output because I didn't feel like probing out the top speaker connector and running wire up there just yet. Ideally I would have a switched jack that interrupts the top speaker, but that's for later. I might salvage something from an Apple device, their jacks tend to be compact.

Hot glued the thing in place, and this is the end result. It works just great with passive headphones. I'll upload a demo video when I get the chance, I've already used my 1 video. I wish I had taken better pictures, but it wasn't very convenient.

The caveats in the beginning apply. It's also way too loud because it's meant to drive a speaker, and it's balanced for that too. I might be able to put a resistor divider on there to reduce the output volume and let a louder signal drown out the interference a bit better?

I have no idea if this is a thing people do, putting audio jacks in their phones. But I would think that replacing the speaker like this would work on a lot of different phones. Maybe worth trying?

5 notes

·

View notes

Text

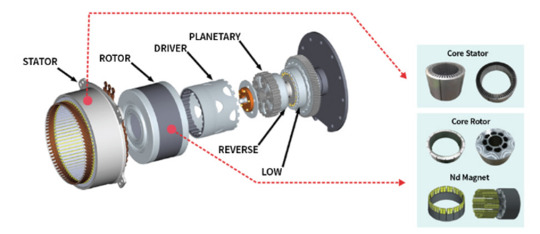

Motor Stator And Rotor: Characteristics And Functions

The motor, a ubiquitous device in modern technology, is responsible for converting electrical energy into mechanical energy. Within its intricate design, two key components play pivotal roles: the stator and the rotor. Both have unique characteristics and functions that contribute to the motor's overall performance and efficiency.

The Stator: The Stationary Backbone

The stator, as the name suggests, is the stationary part of the motor. It serves as the backbone of the motor, providing a stable structure for the rotating parts to interact with. Constructed typically from laminated steel or aluminum, the stator's primary function is to generate a rotating magnetic field.

One of the stator's defining characteristics is its windings, which are coils of wire wrapped around the stator core. When an electrical current flows through these windings, they create a magnetic field. This field is designed to rotate, thanks to the strategic placement and activation of the windings in a sequence.

The stator also acts as a support system for other motor components, such as bearings, which help to reduce friction and support the rotor's rotation. Its robust construction ensures that it can withstand the mechanical stresses and vibrations inherent in motor operation.

The Rotor: The Dynamic Converter

The rotor, on the other hand, is the moving part of the motor. It is mounted on the motor's shaft and rotates within the stator. The rotor's primary function is to convert the rotating magnetic field generated by the stator into mechanical torque.

Rotors can be classified based on their construction and operation principle. For instance, squirrel-cage rotors, common in induction motors, consist of a cylindrical core with aluminum or copper conductors embedded within its slots. When the stator's rotating magnetic field interacts with this rotor, currents are induced in the rotor conductors, generating a secondary magnetic field that opposes the stator's field, causing the rotor to rotate.

In contrast, permanent magnet rotors, used in synchronous motors, employ magnets mounted on the rotor surface or embedded within it. These magnets create a constant magnetic field that aligns with the stator's rotating magnetic field, enabling the rotor to rotate in synchrony with the stator field.

Functional Harmony and Motor Performance

The stator and rotor work in harmony to ensure the motor's efficient operation. The stator generates the necessary magnetic field, while the rotor converts this magnetic energy into mechanical rotation. This interplay enables electric motors to perform diverse tasks, from powering industrial machinery to driving everyday appliances.

Understanding the characteristics and functions of the stator and rotor is crucial for designing, maintaining, and optimizing electric motor systems for various applications. By fine-tuning the stator windings, rotor construction, and their interaction, engineers can create motors that are more efficient, reliable, and suited to specific tasks. This understanding also facilitates effective maintenance and repair, ensuring that motors continue to operate at their best throughout their lifespan.

0 notes

Text

Understanding Silicon Steel Sheets: A Crucial Material in Electrical Engineering

Silicon steel sheets, also known as electrical steel, are specialized materials widely used in the manufacturing of electrical components such as transformers, motors, and generators. These sheets are vital for their excellent magnetic properties and efficiency in minimizing energy losses. This article explores the features, types, applications, and importance of silicon steel sheets in modern electrical engineering.

Key Features of Silicon Steel Sheets 1. High Magnetic Permeability: Silicon steel sheets allow magnetic fields to pass through them with minimal resistance, enhancing the performance of electrical devices. 2. Low Core Loss: The material’s ability to minimize hysteresis and eddy current losses is critical for energy-efficient operation. 3. Silicon Content: The addition of silicon (ranging from 1% to 6%) improves the electrical resistivity, reduces core losses, and increases magnetic performance. 4. Thin Laminations: Sheets are often manufactured in thin layers to further reduce eddy current losses, ensuring efficient operation.

Types of Silicon Steel Sheets 1. Grain-Oriented Silicon Steel (GO): – Optimized for unidirectional magnetic flow. – Primarily used in transformers due to superior efficiency in reducing energy losses. 2. Non-Grain-Oriented Silicon Steel (NGO): – Suitable for applications with multi-directional magnetic fields. – Commonly used in electric motors and generators.

Applications in Electrical Engineering 1. Transformers: Silicon steel sheets are the core material in transformers, where they reduce energy losses and improve performance under alternating magnetic fields. 2. Electric Motors: Used in the stators and rotors, silicon steel improves motor efficiency and reduces overheating. 3. Generators: The material ensures high efficiency in power generation by minimizing magnetic losses. 4. Inductors and Magnetic Cores: Its excellent magnetic properties make it ideal for these applications as well.

Silicon steel sheets are indispensable in the field of electrical engineering, underpinning the functionality and efficiency of countless devices and systems. With continuous advancements in material science and manufacturing, silicon steel will remain a cornerstone in the development of energy-efficient technologies, paving the way for a more sustainable future.

0 notes

Text

Understanding Silicon Electrical Steel and Its Impact on Transformer Efficiency

In today’s world, the demand for energy efficiency is higher than ever. Power systems, especially transformers, play a critical role in maintaining the efficiency and reliability of electrical power distribution. At the heart of this efficiency lies Silicon Electrical Steel — a unique material widely used in the construction of transformer cores and transformer lamination. Understanding the properties and benefits of silicon electrical steel can help us appreciate how this material significantly impacts transformer efficiency and the broader power sector.

What is Silicon Electrical Steel?

Silicon electrical steel, also known as silicon steel or transformer steel, is a type of specialized steel alloy that incorporates a controlled amount of silicon. Typically, silicon content ranges from 1% to 3.5%, depending on the application. The addition of silicon alters the steel’s properties, giving it unique characteristics that make it ideal for electrical applications, particularly in transformers, motors, and generators. Silicon electrical steel offers a low core loss, high permeability, and increased electrical resistivity, making it an essential material in reducing energy loss in electrical systems.

Properties of Silicon Electrical Steel

The following properties of silicon electrical steel are what make it indispensable in transformer manufacturing and efficiency enhancement:

High Magnetic Permeability: This property allows silicon electrical steel to support strong magnetic fields without significant energy loss, making it ideal for transformer cores that operate at high magnetic flux densities.

Low Core Loss: Core loss, which includes both hysteresis and eddy current losses, is one of the primary contributors to energy loss in transformers. Silicon electrical steel minimizes these losses, enabling transformers to operate more efficiently.

High Electrical Resistivity: The silicon in this type of steel increases its electrical resistivity, reducing the eddy currents within the material. This further helps in lowering the core loss, especially at higher frequencies.

Thermal Stability: Silicon electrical steel exhibits strong thermal stability, allowing it to withstand high temperatures without degrading, an essential quality in high-performance transformers.

Ductility and Formability: Although silicon electrical steel has a high silicon content, it remains ductile and formable, making it easy to create thin sheets for transformer lamination.

These properties make silicon electrical steel the go-to material for transformers, which need to operate efficiently over long periods under varying load conditions.

Role of Silicon Electrical Steel in Transformer Lamination

Transformer lamination is a critical manufacturing process where thin layers or laminations of silicon electrical steel are stacked to form the transformer core. By stacking multiple thin layers instead of using a solid block, the laminations reduce eddy currents, which significantly reduces core losses. Silicon electrical steel is particularly suited for transformer lamination because of its high electrical resistivity and low core loss. Here’s how it contributes to enhancing transformer efficiency:

Reduction of Eddy Currents: When an alternating current flows through a transformer, it generates eddy currents in the core. These currents can cause significant power loss if not properly controlled. The laminated structure of silicon electrical steel minimizes eddy currents by breaking up the pathways, thus reducing energy waste.

Improved Magnetic Properties: The magnetic properties of silicon electrical steel allow transformers to maintain high efficiency even under heavy loads. The high permeability ensures that the material can handle high magnetic flux, which directly enhances the transformer’s performance.

Durability in High-Temperature Operations: As transformers can generate heat during operation, especially under heavy loads, the thermal stability of silicon electrical steel ensures that it can withstand these conditions without losing its magnetic properties.

Using silicon electrical steel in transformer lamination therefore not only improves energy efficiency but also enhances the overall performance and durability of the transformer. This directly translates to lower operational costs and longer service life for power transformers.

Types of Silicon Electrical Steel Used in Transformers

There are two primary types of silicon electrical steel used in transformer manufacturing:

Grain-Oriented Electrical Steel (GOES): GOES is specifically processed to align its crystal structure in the rolling direction. This orientation enhances the steel’s magnetic properties along that axis, making it ideal for high-efficiency transformers. GOES is commonly used in large transformers that require high levels of efficiency, such as power and distribution transformers.

Non-Grain-Oriented Electrical Steel (NGOES): NGOES does not have a specific grain orientation, which gives it isotropic magnetic properties, meaning it performs uniformly in all directions. This type of steel is typically used in smaller transformers, motors, and generators where magnetic flux does not need to be aligned in a particular direction.

Both types of silicon electrical steel have their unique applications in the electrical industry, with GOES being the preferred choice for transformer lamination due to its superior magnetic efficiency.

Impact of Silicon Electrical Steel on Transformer Efficiency

Using silicon electrical steel in transformers has a direct impact on energy efficiency, helping reduce power losses and overall energy consumption. Here’s a closer look at how this material contributes to more efficient transformers:

Lower Operational Costs: By minimizing core losses, transformers made with silicon electrical steel consume less power, which translates to lower electricity costs over time. This is particularly important in large-scale power distribution, where even small efficiency improvements can lead to significant savings.

Enhanced Longevity of Transformers: High-performance materials like silicon electrical steel reduce the wear and tear on transformers, extending their operational lifespan. A longer-lasting transformer means fewer replacements and maintenance costs for utility companies and industrial users.

Environmental Impact: Reduced energy losses mean that less fuel is required to generate electricity, leading to a smaller carbon footprint. This aligns with global efforts to reduce greenhouse gas emissions and create more sustainable power systems.

Reliable Power Distribution: Transformers play a crucial role in the power grid, and their efficiency directly affects the reliability of electricity supply. Silicon electrical steel helps ensure that transformers can handle variable loads and fluctuations without significant energy loss, thus stabilizing the power supply.

Future of Silicon Electrical Steel in Transformer Applications

As the demand for energy-efficient solutions continues to rise, the role of silicon electrical steel in transformer manufacturing will become even more vital. Ongoing research in material science is likely to lead to new advancements in silicon electrical steel technology, further improving its magnetic properties and energy efficiency. Manufacturers are also exploring ways to reduce the environmental impact of producing silicon electrical steel, which could make this material even more sustainable.

Given the critical role of transformers in modern power systems, the continued use of silicon electrical steel in transformer lamination is a promising step towards achieving greater energy efficiency on a global scale.

In summary, silicon electrical steel is an essential material that drives the efficiency and reliability of transformers. Its unique properties — high permeability, low core loss, and thermal stability — make it ideal for use in transformer lamination. As the world continues to prioritize energy efficiency and sustainability, the impact of silicon electrical steel in transformer applications is expected to grow, contributing to a more reliable and eco-friendly power grid.

0 notes

Text

The Top 10 Inspirational Kindergarten Class Decoration Ideas.

Kindergarten Class Decoration Ideas

For a kindergarten classroom to be welcoming, engaging, and instructive, it must be decorated. The classroom may be made a place where children are eager to study and explore by adding the correct décor, which can greatly improve their educational experience. These 10 thorough kindergarten class decoration ideas include thorough explanations, necessary supplies, advantages, and firsthand accounts of my own classroom experiences.

1. Interactive Wall Displays

Interactive wall displays are dynamic tools that allow children to engage directly with the learning material. Examples include weather charts where kids can update the weather conditions daily, or calendars where they can mark special events and holidays. Another idea is a 'Daily Schedule' where kids can move pieces to indicate current activities.

Materials Needed:

Large bulletin board

Velcro or magnetic strips

Weather symbols (sun, clouds, rain, snow, etc.)

Calendar numbers and month labels

Felt or laminated pieces for durability

Benefits: These kindergarten class decoration ideas make learning hands-on and interactive, which helps children grasp abstract concepts like time and weather more concretely. They also encourage daily participation and responsibility, enhancing fine motor skills as children manipulate the pieces.

Personal Experience: In my classroom, the interactive weather wall is a favorite. Each morning, a student is responsible for changing the weather symbols and updating the calendar. This routine activity helps them understand weather patterns and the concept of days and months. It also fosters a sense of duty and teamwork as they take turns managing the display.

2. Alphabet and Number Walls

Alphabet and number walls are foundational for early literacy and numeracy skills. By creating a wall with movable letters and numbers, children can engage with the content actively.

Materials Needed:

Alphabet and number cutouts (preferably laminated)

Velcro strips for easy attachment and removal

Pockets or containers to hold small objects corresponding to each letter/number

Colorful borders and background paper to make it visually appealing

Benefits: These kindergarten class decoration ideas aid in letter and number recognition, phonetic awareness, and basic counting skills. They provide continuous visual reinforcement of daily lessons, making learning a natural part of the classroom environment.

Personal Experience: Our alphabet wall includes pockets for each letter, where children place objects that start with that letter. For example, for the letter "A," they might put in a small apple or ant toy. This interactive approach keeps them engaged and reinforces their learning. It also encourages peer teaching, as children often help each other find the right objects for each letter or number.

3. Reading Corner

A cozy reading corner creates a dedicated space for children to immerse themselves in books. It can be decorated with bean bags, colorful rugs, shelves filled with books, and posters of favorite story characters.

Materials Needed:

Comfortable seating options like bean bags or cushions

Soft, colorful rugs

Bookshelves or book racks

Posters and banners of storybook characters and motivational quotes

String lights or decorative lamps to create a cozy ambiance

Benefits: A reading corner fosters a love for books and reading, encourages independent reading, and provides a quiet space for children to enjoy stories. This area helps improve literacy skills and promotes a lifelong interest in reading.

Personal Experience: Our reading corner, decorated with vibrant colors and plush toys, has become a sanctuary for the kids. They eagerly spend their free time there, flipping through picture books and listening to stories. The comfortable setting makes reading a positive and enjoyable experience, encouraging them to spend more time with books.

4. Theme-Based Decorations

Theme-based decorations transform the classroom based on different themes throughout the year, such as seasons, holidays, or popular children's books. These themes can be reflected in the decorations, activities, and learning materials.

Materials Needed:

Themed decorations like leaves, pumpkins, snowflakes, etc., for seasonal themes

Craft supplies like paper, glue, scissors, and markers

Bulletin board borders and backgrounds that match the theme

Posters, banners, and themed props

Benefits: These kindergarten class decoration ideas make learning about different times of the year more engaging and relatable. They help children connect classroom learning with the world outside and keep the environment fresh and exciting. Regularly changing themes spark curiosity and anticipation.

Personal Experience: During the fall, we decorated the classroom with leaves, pumpkins, and scarecrows. Each child brought a fall-themed item from home, which added a personal touch to the decorations. This approach kept the kids excited and engaged, and they loved seeing the classroom transform with each season. It also provided opportunities for themed activities and discussions about the season.

5. Art Display Boards

Art display boards are dedicated spaces to showcase children's artwork. These boards can be rotated regularly to display new pieces and ensure every child gets a chance to show their work.

Materials Needed:

Large bulletin board or dedicated wall space

Clips, pins, or Velcro strips to hang artwork

Decorative borders and backgrounds

Labels for artists' names and titles of their work

Benefits: Displaying artwork boosts children's self-esteem, encourages creativity, and creates a sense of accomplishment. It also adds vibrant color and personality to the classroom.

Personal Experience: We have an "Art Gallery" in our classroom where each child gets to display their masterpiece. Kids feel proud seeing their work showcased, and it motivates them to be creative. It also fosters a sense of community as students admire and compliment each other's work.

Also Check: Classroom Decoration ideas for Preschool

6. Nature and Sensory Wall

A sensory wall with different textures and nature elements like leaves, bark, and sandpaper allows children to explore through touch.

Materials Needed:

Various textures (fabric, sandpaper, faux grass, etc.)

Adhesive for attaching materials to the wall

Nature elements (dried leaves, small branches, etc.)

Labels for different textures

Benefits: Sensory walls stimulate touch and exploration, which are crucial for sensory development. They can also calm children and help with focus, particularly those with sensory processing issues.

Personal Experience: Our sensory wall includes various textures and elements like faux grass, sandpaper, and fabric swatches. Kids love exploring the different textures with their hands. It’s a calming activity that also helps them focus better during lessons.

7. Educational Posters and Charts

Use posters and charts about shapes, colors, emotions, and other essential topics. Ensure they are placed at eye level for the kids.

Materials Needed:

Educational posters

Laminating supplies (optional)

Adhesive for walls

Bulletin board borders

Benefits: Posters and charts serve as constant visual aids, reinforcing concepts and vocabulary. They make it easier for kids to remember lessons and provide a colorful, informative classroom environment.

Personal Experience: We have posters of shapes, colors, and a feelings chart. Kids refer to them often during activities and discussions, which reinforces their learning. It’s great to see them independently use these resources to answer questions or solve problems.

8. Classroom Jobs Chart

A jobs chart assigns roles like line leader, door holder, or plant waterer to each student. Use colorful pockets or magnets to make it interactive.

Materials Needed:

Bulletin board or chart paper

Pockets or magnets

Labels for different jobs

Decorative elements (borders, stickers, etc.)

Benefits: A jobs chart teaches responsibility and teamwork. It helps children understand the importance of contributing to the classroom community and fosters a sense of ownership and pride.

Personal Experience: Our classroom jobs chart has been a great success. Each week, kids eagerly check to see their new responsibilities. This system instills a sense of responsibility and helps the classroom run smoothly. The kids love having their own roles and take their duties very seriously.

9. Positive Affirmation Wall

Dedicate a wall to positive affirmations and quotes. Include phrases like "You are brave," "You can do it," and "You are loved."

Materials Needed:

Poster board or wall space

Markers or printed quotes

Adhesive for walls

Decorative elements (borders, stickers, etc.)

Benefits: Positive affirmations promote a healthy self-image, build confidence, and create a supportive classroom environment. Reading these affirmations daily helps children internalize positive messages.

Personal Experience: Our positive affirmation wall is filled with bright, encouraging messages. Kids often stop to read them, visibly boosting their mood and confidence. This simple addition has had a profound impact on creating a positive, nurturing classroom atmosphere.

10. Learning Centers

Set up various learning centers around the room focused on different subjects like math, science, reading, and art. Decorate each center with relevant materials and posters.

Materials Needed:

Small tables or designated spaces

Subject-specific materials (math manipulatives, science tools, art supplies, etc.)

Posters and charts related to each subject

Storage bins or shelves

Benefits: Learning centers provide hands-on learning experiences and cater to different interests and learning styles. They### Top 10 Kindergarten Class Decoration Ideas to Inspire Kids

Creating a welcoming, engaging, and instructive atmosphere in a kindergarten classroom requires careful decorating. A classroom may be made an exciting location for children to learn and explore by using the appropriate décor, which can greatly improve their educational experience. I've included ten thorough kindergarten class decoration ideas below, along with thorough explanations, necessary supplies, advantages, and firsthand accounts.

Also Check: School Parent app

0 notes

Text

Top Benefits of Using Glass Epoxy Slot Wedges in High-Performance Motors

In the realm of high-performance motors, every component counts towards efficiency and durability. Among these, glass epoxy slot wedges stand out for their critical role in enhancing motor function and longevity. This article explores why glass epoxy, a type of thermoset composite, is increasingly favored for slot wedges in various motor applications.

2. Advantages of Using Thermosets for Slot Wedges

Thermoset composites are renowned for their high structural integrity and ability to withstand harsh environmental conditions. This makes them particularly suitable for use in high-performance motor components like slot wedges.

a. Why Are Thermoset Composites Ideal for Slot Wedges?

Thermoset composites such as glass epoxy offer exceptional mechanical strength, thermal stability, and chemical resistance. In slot wedges, these properties ensure that the wedges can endure the thermal and mechanical stresses of high-speed motor operations without degrading.

b. Why Choose Atlas Fibre for Slot Wedge Materials

Atlas Fibre is a leader in manufacturing high-quality thermoset composites, including glass epoxy materials that are perfect for slot wedges. Their products are known for consistent quality and performance, which is essential for the precise demands of motor manufacturing.

3. Magnetic Stator Wedges: The Challenges and Solutions

Magnetic stator wedges are crucial for the efficient functioning of motors, but they come with their set of challenges.

a. MAGNETIC WEDGING

Magnetic wedging plays a pivotal role in reducing the air gap irregularities that can lead to losses in motor efficiency. Glass epoxy slot wedges help maintain the integrity of these wedges, thanks to their robust material properties.

b. DETECTING FAILED MAGNETIC WEDGES

One major challenge is detecting when a magnetic wedge fails, as this can significantly impair motor performance. Regular inspections and the use of sophisticated diagnostic tools are recommended to identify and address any issues promptly.

c. MAINTENANCE CONSIDERATIONS

Proper maintenance is key to ensuring the longevity and efficiency of magnetic stator wedges.

Wedge Size: Correct sizing of the glass epoxy slot wedges is crucial to fit the slot dimensions accurately.

Lamination Shuffle: Ensuring that the laminations are properly aligned and shuffled can prevent premature wear and tear.

Slot Length: The length of the slot must be accurately measured to ensure that the wedges fit securely.

Bonding Material: The choice of bonding material can affect the durability and performance of the wedges, with glass epoxy offering superior bonding capabilities.

Conclusion

Glass epoxy slot wedges represent a significant advancement in motor technology, particularly for high-performance applications. Their superior material properties ensure that motors can operate at higher efficiencies while reducing the risk of failure and downtime. As industries continue to push the boundaries of motor performance, the role of advanced materials like glass epoxy in slot wedges becomes ever more crucial. Whether you’re designing new motors or looking to upgrade existing ones, consider glass epoxy slot wedges for the best in performance and reliability.

0 notes

Text

What are the functions of stator core laminations

The stator core laminations play a vital role in the operation of electrical machines, particularly in motors and generators. These laminations are not just an insignificant component but have several key functions that contribute to the overall performance and efficiency of the device.

One of the primary functions of stator core laminations is to reduce eddy current losses. When a magnetic field changes within a solid piece of conducting material, such as a stator core, it induces circulating currents known as eddy currents. These eddy currents result in energy dissipation in the form of heat, which not only wastes energy but can also cause overheating and potential damage to the stator core. By laminating the stator core into thin sheets, the electrical resistance along the direction of the induced currents is increased, effectively minimizing the formation and magnitude of eddy currents. This reduction in energy loss leads to improved efficiency and better heat management within the machine.

Stator core laminations also enhance the magnetic flux path within the stator. The laminations are made of materials with high magnetic permeability, such as silicon steel, which allows for a more concentrated and directed magnetic field. This ensures that the magnetic flux generated by the stator windings interacts optimally with the rotor, maximizing the torque production or electrical output depending on whether it's a motor or a generator. A well-defined and efficient magnetic flux path leads to better performance and more reliable operation of the device.

Another important function is to improve the mechanical strength and stability of the stator core. The individual laminations are stacked and held together, providing a rigid structure that can withstand the mechanical stresses and vibrations during operation. This helps to prevent deformation or damage to the stator core, ensuring its longevity and consistent performance over time.

For example, in large industrial motors that operate continuously under heavy loads, the mechanical integrity provided by the stator core laminations is crucial. Even minor deformations in the core can lead to misalignment of the magnetic fields, increased noise, and reduced efficiency. The laminations act as a reinforcing structure, maintaining the precise alignment and functionality of the stator.

In addition, stator core laminations contribute to reducing magnetic hysteresis losses. Hysteresis occurs when the magnetic material of the stator core undergoes repeated magnetization and demagnetization cycles. The laminated structure helps to minimize the energy expended during these cycles, further enhancing the overall efficiency of the machine.

To illustrate the significance of these functions, consider an electric vehicle motor. The efficient operation of the stator core laminations ensures that the motor delivers maximum power while minimizing energy consumption, extending the driving range of the vehicle. Without the proper design and quality of the laminations, the motor's performance would suffer, resulting in shorter battery life and compromised driving experience.

In conclusion, the functions of stator core laminations are multi-faceted and essential for the optimal performance, efficiency, and reliability of electrical machines. Their role in minimizing eddy current and hysteresis losses, enhancing the magnetic flux path, and providing mechanical stability makes them a critical component in the design and operation of motors and generators in a wide range of applications, from industrial machinery to modern transportation systems.

0 notes

Text

Electrical Motor Heat

Electrical motor heat in water pumps is a significant aspect of their operation and efficiency. Here’s a detailed look at how heat is generated in electrical motors, its impacts, and how to manage it:

Sources of Heat Generation in Electrical Motors

Electrical Resistance (I²R Losses):

Stator and Rotor Windings: As electric current flows through the copper or aluminum windings of the stator and rotor, electrical resistance causes heat. This is often the largest contributor to heat in electric motors.

Eddy Currents: These are circulating currents induced within the motor’s iron core, causing additional heating.

Magnetic Losses:

Hysteresis Losses: As the motor’s magnetic field reverses, energy is lost in the form of heat due to the hysteresis in the magnetic materials.

Core Losses: These occur in the laminated steel core of the motor due to alternating magnetic fields.

Mechanical Losses:

Bearing Friction: The bearings supporting the motor’s rotor experience friction, generating heat.

Windage Losses: Air resistance (windage) within the motor as the rotor turns can also produce heat.

Stray Load Losses:

These losses are due to imperfections in the motor’s design and manufacturing, including misalignment and surface roughness of components, leading to additional heat.

Impact of Electrical Motor Heat

Thermal Stress:

Component Degradation: Prolonged exposure to high temperatures can degrade insulation materials, windings, and bearings, reducing the motor’s lifespan.

Efficiency Reduction: Higher temperatures increase resistance in electrical components, further reducing efficiency.

Performance Issues:

Reduced Torque: Excessive heat can reduce the motor’s ability to generate torque, affecting its performance.

Thermal Expansion: Uneven thermal expansion of motor parts can lead to misalignment and increased wear.

Safety Concerns:

Fire Hazard: Overheating can pose a fire risk, especially if the insulation materials catch fire.

Shutdowns: Thermal protection systems may shut down the motor to prevent damage, leading to operational downtime.

Managing Heat in Electrical Motors

Cooling Systems:

Air Cooling: Most electric motors use air cooling, with external fans or fins to increase surface area for heat dissipation.

Liquid Cooling: For high-power applications, liquid cooling systems can be used to effectively remove heat.

Proper Ventilation:

Ensuring adequate airflow around the motor can help dissipate heat. Installing motors in well-ventilated areas can prevent overheating.

High-Efficiency Motors:

Using motors with higher efficiency ratings can reduce the amount of heat generated, as they convert more electrical energy into mechanical energy and less into heat.

Regular Maintenance:

Lubrication: Regularly checking and maintaining proper lubrication reduces frictional heat.

Cleaning: Keeping the motor and its cooling system clean from dust and debris ensures efficient heat dissipation.

Temperature Monitoring and Control:

Sensors: Installing temperature sensors in critical areas of the motor can provide real-time data on operating temperatures.

Automatic Shutdowns: Implementing automatic shutdown features when temperatures exceed safe thresholds can protect the motor from damage.

Material Selection:

Using materials with good thermal properties in motor construction can help manage and dissipate heat more effectively.

Load Management:

Ensuring the motor operates within its rated load limits can prevent excessive heat generation. Overloading a motor can lead to significant increases in heat production.

By understanding and managing the sources of heat generation in electrical motors, the performance and longevity of water pumps can be significantly enhanced. Proper cooling, maintenance, and monitoring are crucial to keeping motors operating efficiently and safely. For more info contact Water Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

SOFT MAGNETIC POWDER VS LAMINATE MATERIAL for Electric Motor Efficiency

SOFT MAGNETIC POWDER VS LAMINATE MATERIAL for Electric Motor Efficiency Which is easier to trust — a 1,300-component assembly with shaky performance, or a 10-component one with reliable data? Many manufacturers have worked with the standard, stamped lamination steels for decades. Engineers know the obstacles associated with them, and they accept them as law. But the emergence of powder-based soft…

View On WordPress

#Electric Motor#Lamination steels#magnet composition#Magnet Maker#Magnetic alloy#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Metals#magnetic properties#magnetic structures#Magnetic powder#Magnetism#Nd-based magnets#Nd-Fe-B magnets#NdFeB analysis#NdFeB permanent magnet#Neodymium magnets#paramagnetic materials#Permanent Magnet#Rare Earth Magnets#rare earth metals#Sintered NdFeB#Sintered NdFeB Magnets#sintered soft magnetic materials#soft magnetic composite#Soft magnetic materials#SOFT MAGNETIC POWDER#Soft Magnetics

1 note

·

View note

Text

Electrical Steel Market Up-and-Coming Trend

According to HTF Market Intelligence, theGlobal Electrical Steel market to witness a CAGR of % during forecast period of 2024-2030. Global Electrical Steel Market Breakdown by Application (Energy and Power Generation, Automotive, Industrial Equipment, Consumer Electronics) by Type (CRNO (Cold Rolled Non Grain Oriented Steel), CRGO (Cold Rolled Grain Oriented Steel)) and by Geography (North America, South America, Europe, Asia Pacific, MEA). The Electrical Steel market size is estimated to increase by USD Billion at a CAGR of % from 2024 to 2030.. Currently, market value is pegged at USD 37.8 Billion.

Get Detailed TOC and Overview of Report @

Electrical steel, also known as silicon steel or lamination steel, is a type of specialty steel designed to optimize magnetic properties. It is commonly used in the cores of transformers, electric motors, and generators.

Some of the key players profiled in the study are Nippon Steel Corporation (Japan), U.S. Steel (United Sates), POSCO (South Korea), Thyssenkrupp AG (Germany), JFE Steel Corporation (Japan), AK Steel (United States), Baosteel Group (China), Voestalpine AG (Austria), ArcelorMittal (Luxembourg), Novolipetsk Steel (NLMK) (Russia), China Steel Corporation (Taiwan). Additionally, other players that are part of this detailed analysis are Cogent Power (Canada), ATI (Allegheny Technologies Incorporated) (United States), CSC (Cleveland-Cliffs Steel) (United States), SAIL (Steel Authority of India Limited) (India), Essar Steel (India)..

Book Latest Edition of Global Electrical Steel Market Study @ https://www.htfmarketintelligence.com/buy-now?format=1&report=6403

About Us:

HTF Market Intelligence is a leading market research company providing end-to-end syndicated and custom market reports, consulting services, and insightful information across the globe. HTF MI integrates History, Trends, and Forecasts to identify the highest value opportunities, cope with the most critical business challenges and transform the businesses. Analysts at HTF MI focuses on comprehending the unique needs of each client to deliver insights that are most suited to his particular requirements.

Contact Us:

Craig Francis (PR & Marketing Manager) HTF Market Intelligence Consulting Private Limited Phone: +15075562445 [email protected]

0 notes

Text

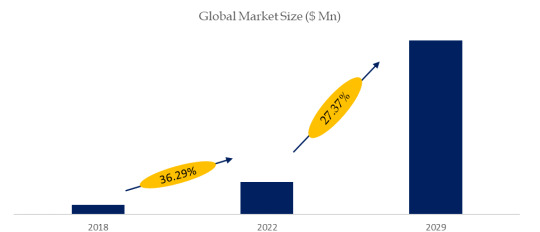

Automotive Traction Motor Core, Global Market Size Forecast, Top 5 Players Rank and Market Share

Automotive Traction Motor Core Market Summary

The Automotive Traction Motor Core refers to a critical component used in the construction of traction motors for electric vehicles (EVs). Traction motors are responsible for converting electrical energy into mechanical energy to propel the vehicle. The core is a key part of the motor's stator, which is the stationary component of the motor that surrounds the rotor. The core typically consists of a stack of laminated steel sheets or cores, which are precision-cut and stacked together. These laminations are made of high-grade electrical steel with specific magnetic properties to minimize energy losses and maximize motor efficiency. The core's design and construction play a crucial role in determining the motor's performance, efficiency, and overall effectiveness.

According to the new market research report "Global Automotive Traction Motor Core Market Report 2023-2029", published by QYResearch, the global Automotive Traction Motor Core market size is projected to grow from USD 3,104.96 million in 2023 to USD 13,256.48 million by 2029, at a CAGR of 27.37% during the forecast period.

Figure. Global Automotive Traction Motor Core Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Automotive Traction Motor Core Market Report 2023-2029.

Market Drivers:

1. Rapid Growth of Electric Vehicle (EV) Market: The increasing adoption of electric vehicles worldwide is a primary driver for the automotive traction motor core market. As governments implement stricter emission regulations and consumers demand cleaner and more sustainable transportation options, automakers are investing heavily in electric vehicle development. This surge in EV production translates into growing demand for traction motor cores to power electric drivetrains.

2. Advancements in Motor Technology: Ongoing advancements in motor technology, including improvements in efficiency, power density, and thermal management, are creating opportunities for innovation in traction motor core design. Manufacturers are developing new core materials, such as advanced electrical steels and permanent magnets, to enhance motor performance and efficiency, driving demand for specialized traction motor cores tailored to these applications.

Restraint:

1. Material Sourcing and Cost Pressures: Traction motor cores require high-quality materials with specific magnetic properties to ensure optimal performance and efficiency. Fluctuations in the prices of raw materials such as electrical steel, rare-earth magnets, and copper can impact production costs and profit margins for traction motor core manufacturers. Securing a stable and cost-effective supply of materials is a key challenge in the market.

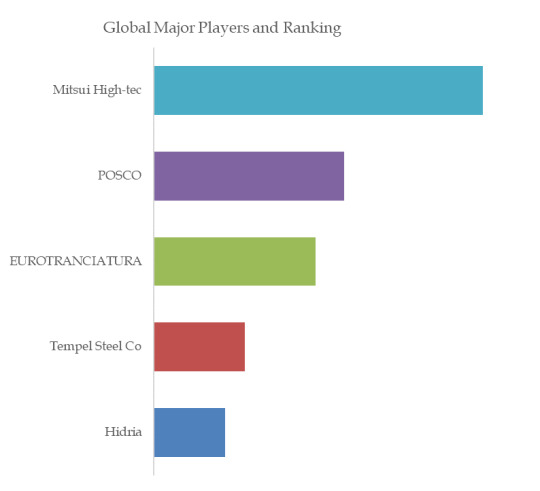

Figure. Global Automotive Traction Motor Core Top 5 Players Ranking and Market Share(Continually updated)

Based on or includes research from QYResearch: Global Automotive Traction Motor Core Market Report 2023-2029.

This report profiles key players of Automotive Traction Motor Core such as Mitsui High-tec, POSCO, EUROTRANCIATURA, Tempel Steel Co, Hidria.

In 2022, the global top five Automotive Traction Motor Core players account for 70.29 % of market share in terms of revenue. Above figure shows the key players ranked by revenue in Automotive Traction Motor Core.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

What Is The Main Rotor Function?

Introduction

The rotor is a crucial component in various mechanical and electrical systems, playing a pivotal role in their functionality. Understanding the main rotor function is essential for anyone involved in engineering, aviation, or motor technology. This article delves into the intricacies of the rotor, its significance, and its applications, particularly focusing on its role in high-speed motors.

Understanding the Rotor

The rotor is the rotating part of an electrical or mechanical system. It works in conjunction with the stator, the stationary part, to create motion or generate electricity. In essence, the rotor converts electrical energy into mechanical energy or vice versa, depending on the application.

Types of Rotors

There are several types of rotors, each designed for specific applications. The most common types include:

Squirrel Cage Rotor: Used in induction motors, known for its simplicity and durability.

Wound Rotor: Found in slip ring motors, offering better control over speed and torque.

Permanent Magnet Rotor: Utilized in synchronous motors, providing high efficiency and precision.

Rotor Construction

The construction of a rotor varies based on its type and application. Generally, it consists of a core made of laminated steel sheets, which reduces energy losses due to eddy currents. The core is surrounded by conductive bars or windings, which interact with the magnetic field to produce motion.

Main Rotor Function

The primary function of the rotor is to convert energy. In electric motors, the rotor transforms electrical energy into mechanical energy, enabling the motor to perform work. Conversely, in generators, the rotor converts mechanical energy into electrical energy, supplying power to various devices.

Energy Conversion

In electric motors, the rotor receives electrical energy from the stator's magnetic field. This interaction generates a force that causes the rotor to spin, producing mechanical motion. In generators, the rotor is driven by an external mechanical force, such as a turbine, to generate electricity.

Speed and Torque Control

The rotor plays a vital role in controlling the speed and torque of a motor. By adjusting the rotor's design and the type of motor, engineers can achieve the desired performance characteristics. For instance, a wound rotor allows for precise control over speed and torque, making it ideal for applications requiring variable speeds.

Rotor for High-Speed Motors

High-speed motors demand rotors that can withstand extreme conditions and deliver consistent performance. The rotor for high-speed motor applications is typically designed with advanced materials and engineering techniques to ensure reliability and efficiency.

Material Selection

High-speed motor rotors are often made from high-strength materials, such as carbon fiber or advanced composites, to endure the stresses of rapid rotation. These materials offer excellent strength-to-weight ratios, reducing the overall mass of the rotor and enhancing its performance.

Cooling Mechanisms

To maintain optimal performance, high-speed motor rotors are equipped with efficient cooling mechanisms. These may include air or liquid cooling systems that dissipate heat generated during operation, preventing overheating and ensuring longevity.

Balancing and Precision

Precision balancing is crucial for high-speed motor rotors to minimize vibrations and ensure smooth operation. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, are employed to achieve the required precision and balance.

Applications of Rotors

Rotors are integral to a wide range of applications, from household appliances to industrial machinery and aviation. Some notable applications include:

Electric Vehicles: Rotors in electric motors drive the wheels, providing efficient and eco-friendly transportation.

Wind Turbines: In wind turbines, rotors convert wind energy into electrical energy, contributing to renewable energy generation.

Helicopters: The main rotor in helicopters generates lift and thrust, enabling vertical takeoff and landing.

Conclusion

In summary, the rotor is a fundamental component in various systems, responsible for converting energy and enabling motion. Its design and construction are tailored to meet the specific demands of different applications, from high-speed motors to renewable energy solutions. Understanding the main rotor function and its significance can provide valuable insights into the operation and optimization of these systems.

0 notes

Text

Understanding Silicon Steel Laminations: Key Components in Electrical Systems

Silicon steel laminations, also known as electrical steel laminations, are essential components in the construction of transformers, motors, and generators. Their unique properties improve energy efficiency and reduce energy loss in electrical systems.

What Are Silicon Steel Laminations? Silicon steel is a special alloy of steel containing silicon, which enhances its magnetic properties. These laminations are thin sheets, typically ranging from 0.25 to 0.5 millimeters in thickness, manufactured through cold rolling.

Key Features and Benefits 1. High Magnetic Permeability: Silicon steel laminations allow magnetic flux to pass through with minimal resistance, enhancing performance. 2. Reduced Energy Loss:The thin layers minimize eddy current losses, which are crucial for efficient energy use in power systems. 3. Durability and Versatility:These laminations can be customized into various shapes and sizes for different applications.

Applications Silicon steel laminations are widely used in: – Transformer cores – Stator and rotor cores in electric motors – Generators.

These components are vital for achieving high efficiency and reliability in electrical and electronic equipment.

0 notes

Text

A Magnetic Core is a device used for storing and transforming electromagnetic energy. Made primarily of iron or other magnetic materials, it is widely used in power converters, electric motors, inductors, and other electronic devices, serving to enhance energy efficiency and stabilize current.

Specific Information for Magnetic Core

Magnetic cores are an integral part of many inductor designs, as they help enhance the inductance and magnetic field strength. Here is some specific information about magnetic cores:

Types of Magnetic Cores: There are various types of magnetic cores used in inductors, including ferrite cores, powdered iron cores, laminated cores, and toroidal cores. Each type has its own unique properties and is suitable for different applications.

Ferrite Cores: Ferrite cores are made from a ceramic material composed of iron oxide and other metal oxides. They have high magnetic permeability and are commonly used in high-frequency applications due to their low losses and excellent magnetic properties at high frequencies.

Powdered Iron Cores: Powdered iron cores are made by compressing iron powder into a desired shape. They have high magnetic permeability and are often used in power applications due to their ability to handle high currents and high magnetic flux densities.

Laminated Cores: Laminated cores are made by stacking thin layers of magnetic material, such as silicon steel, to reduce eddy current losses. They are commonly used in low-frequency applications where low core losses are important.

Toroidal Cores: Toroidal cores are ring-shaped cores with a hole in the center. They provide a closed magnetic circuit, resulting in low magnetic leakage and high inductance. Toroidal cores are often used in applications where compact size and high efficiency are required.

Core Materials: The choice of core material depends on factors such as frequency range, power handling capacity, and desired performance characteristics. Different core materials have different saturation levels, temperature stability, and frequency response.

Core Losses: Magnetic cores can experience losses due to hysteresis and eddy currents. Hysteresis losses occur when the magnetic field is repeatedly reversed, while eddy current losses occur due to circulating currents induced in the core material. Minimizing core losses is important to improve the efficiency and performance of the inductor.

Core Selection: Selecting the right magnetic core involves considering factors such as the required inductance value, operating frequency, current handling capacity, temperature stability, and size constraints. Manufacturers provide datasheets and application notes to assist in selecting the appropriate core for a specific inductor design.

High-Frequency Magnetic Ring Series

Our High-Frequency Magnetic Rings are designed for superior performance in high-frequency applications. They offer excellent magnetic properties, high saturation magnetic induction, and low core loss. Ideal for use in power supplies, inverters, and other high-frequency electronic equipment.

Ferrite Magnetic Ring Series

Our Ferrite Magnetic Rings are made from high-quality ferrite materials, offering excellent magnetic conductivity and high resistance to demagnetization. They are perfect for use in a wide range of applications, including EMI suppression, inductors, transformers, and more.

0 notes