#NdFeB permanent magnet

Explore tagged Tumblr posts

Text

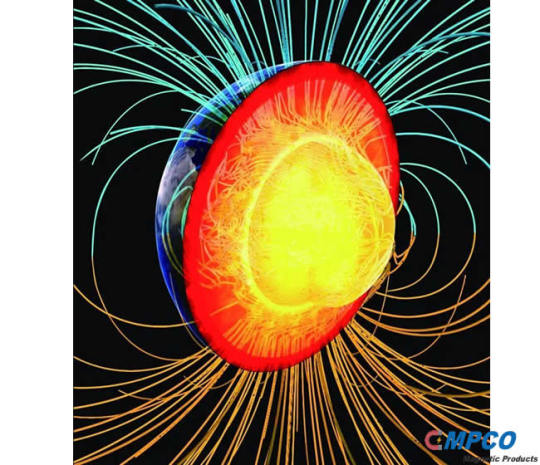

Why Does High-temperature Liquefied Iron Nucleus Produce a Huge Magnetic Field?

Bar Magnet Heating Will Lose Magnetism, Why Does High-temperature Liquefied Iron Nucleus Produce a Huge Magnetic Field? The atoms in the magnet are arranged neatly in accordance with certain rules, which is why magnets have magnetic reasons. When heating the magnet, the arrangement of the atom is disrupted and the magnetic is reduced. When heating to 770 ° C, the magnet loses magneticity. Why…

View On WordPress

#AI Magnets#Cerium Magnets#cerium-containing magnets#Grain Boundary Diffusion#high-performance magnetic materials#Magnet Maker#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Materials#Magnetic Phenomena#magnetic properties#magnetic treatment#Magneticity#NdFeB Magnet#NdFeB permanent magnet#NdFeB Surface Treatment#Neodymium iron boron#Neodymium Magnet Applications#Permanent Magnet Materials#Permanent Magnets#Rare Earth Magnets#rare earth permanent magnet#Sintered NdFeB#Sintered NdFeB Magnets#Super Magnets

2 notes

·

View notes

Text

High-Performance Magnetic Assemblies

High-Performance Magnetic Assemblies For Diverse Applications, Including EV Motors, Generators, Speakers, And Medical Devices. Types Of Magnetic Assemblies Our engineered magnetic assemblies deliver optimized industrial solutions through advanced neodymium magnets, calculated designs, and customized integration. Pot / Fishing Magnets Encased in a durable housing with an attached eyelet or hook,…

#Alnico#Custom magnets#Ferrite#holding magnetic assemblies#Industrial Magnetic Assemblies#Industrial Magnetic Assembly#magnetic assemblies#Magnetic Assembly#magnetic assembly and devices#magnetic materials#magnetic modeling#magnets#Motor Magnetic Assembly#NdFeB#Neodymium Magnetic Assembly#permanent magnet#Permanent Magnet Motors#Permanent Magnetic Assembly#PM motors#SmCo

0 notes

Text

Permanent Round NdFeB Perforated Magnet

It offers great resistance to demagnetization, corrosion, high and low temperatures, shock, and abrasion. Their strong magnetic field and superb resistance to demagnetization are achieved by using a combination of soft iron and hard magnetic alloys. These are manufactured in a unique way and require special equipment, resulting in higher production costs.

0 notes

Text

Micro magnet in ring shape

[email protected] WhatsApp: 0086 15257962734 www.wallymagnet.com

0 notes

Link

0 notes

Link

0 notes

Photo

Researchers realize selective recovery of high-value rare earth elements from waste NdFeB

Recycling high-value rare earth elements from NdFeB waste can save resources, reduce industrial waste, protect the environment and bring considerable economic benefits. However, most traditional recovery methods take a long time to process, have high acid consumption, and low selectivity.

In a study published in Separation and Purification Technology, the research group led by Prof. Yang Fan from Fujian Institute of Research on the Structure of Matter of the Chinese Academy of Sciences proposed a new integrated method for recycling permanent magnet waste by betaine hydrochloride ([Hbet]Cl) solution extraction.

The researchers first carried out leaching experiments on fully roasted magnetic clay samples, and selected [Hbet]Cl as the leaching agent.

They found that when leaching temperature was 200° Celsius, leaching time was eight hours, lixiviant [Hbet]Cl concentration was 0.2 mol/L, and solid–liquid ratio was 1:150 g/ml. They were able to get optimum leaching results of 99.81% Pr, 97.05% Nd, 95.51% Gd, 56.24% Ce and 0.20% Fe, and almost all iron oxide remained in the residue.

Read more.

10 notes

·

View notes

Text

Overview of rare earth metals and intermediate alloys

The vast majority of single rare earth metals and their intermediate alloys are used to produce new rare earth metal materials such as neodymium iron boron, samarium cobalt permanent magnet and super magnetostriction and non-ferrous metal alloys such as AI-RE, Mg-RE, Cu-RE, Zn- RE, W-RE, Mo-RE, etc. In addition, there are a few rare earth metal applications that use some special properties to prepare functional materials.

Neodymium metal, praseodymium and praseodymium neodymium alloy

Neodymium has the hard-magnetic properties caused by the good 4f electron spin arrangement, and has become the largest user of neodymium iron boron permanent magnet materials. In recent years, the global neodymium iron boron materials have developed rapidly, and the large application of neodymium metal in neodymium iron boron permanent magnet materials has driven the rapid development of the rare earth industry. In addition, neodymium metal as an alloy additive has good purification, modification and alloying effects on many non-ferrous metal alloys. Adding 1.5%-2.5% neodymium to magnesium or aluminum alloy can improve the high temperature performance, air tightness and corrosion resistance of the alloy.

Praseodymium is a synergistic element that can improve magnetic properties. Adding an appropriate amount of praseodymium to samarium drill permanent magnets and neodymium iron boron permanent magnets can effectively improve and improve the performance of permanent magnetic materials. Adding part of Pr to SmCo5 to replace Sm can improve the magnetic energy product of water magnetic materials. Adding 5% to 8% Pr to NdFeB, up to 10% can replace 13 neodymium alloy, which can improve the magnet's oxidation resistance, coercive force and Mechanical properties. The neodymium alloy has become an independent product, which can be used not only in water magnetic materials, but also as a non-ferrous metal alloy modification additive.

Dysprosium and terbium

Metal dysprosium and dysprosium iron alloys and metal terbium and terbium iron alloys are used as modifying additives for high-performance NdFeB permanent magnet materials. Adding 2% to 5% of metal dysprosium and lower amounts of metal terbium in the NdFeB magnet It can significantly improve the coercivity and service temperature of NdFeB permanent magnet materials. Dysprosium and terbium are essential elements for preparing rare earth giant magnetostrictive materials (Tb0.3 Dy0.7Fe1.95 alloy, called Terfenol-D). The magneto-optical properties of dysprosium and terbium are used to prepare amorphous thin-film RE-TM high-performance magneto-optical discs with transition metals. Dysprosium metal is alloyed with some nonferrous metals and precious metals, such as a film sputtering target with dysprosium added to a silver alloy, which can be used as a wiring film or a reflective film for flat panel display devices.

Samarium Metal

Samarium metal has excellent hard magnetic properties and is used as the main raw material for the preparation of SmCo5, Sm2Co17, Sm2Fe17Nx permanent magnet materials. The samarium thermal neutron trap has a large cross section, reaching 650 MPa, and metal samarium is made into rods for controlling the amount of thermal neutrons in the nuclear reactor. Samarium as a non-ferrous metal micro-alloying additive such as Cu added Sm to generate SmCu5 intermetallic compounds play a role of micro-alloying, improve the mechanical properties and workability of copper alloys.

Metal lanthanum

The metal lanthanum is active and used as a metal reducing agent. The thermal reduction process is used to reduce other rare earth metals. Lanthanum is also used as a purifying agent and modifier for non-ferrous alloys. It is usually used in the form of a lanthanum intermediate alloy. Lanthanum metal is used to make LaN5i alloy. It is an excellent hydrogen storage material. It can store about 160L of hydrogen per kilogram. It can absorb and release hydrogen. It can be used as a hydrogen purifier to purify hydrogen with a purity of 99.999%. To 99.9999%.

Metal yttrium, cerium, scandium and gadolinium

Metal yttrium and cerium are excellent scavengers and modification additives for nonferrous metals such as magnesium, aluminum, and titanium. Yttrium-magnesium alloy has good high-temperature mechanical properties and excellent high-temperature oxidation resistance, and is used as a lightweight structural material in aviation and aerospace. The addition of 0.5%-4% yttrium metal to the iron-chromium aluminum alloy can improve the oxidation resistance of the alloy, increase the resistivity and high-temperature strength; iron-chromium-aluminum stainless steel containing metal cerium has been widely used as a metal platinum carrier for motorcycle exhaust purification catalysts. Scandium metal is a high-quality modified additive element of aluminum, magnesium and titanium. Adding 0.2%-0.4% Sc to aluminum can significantly improve the high temperature strength, alloy structural stability, welding performance and corrosion resistance of aluminum alloys. The world has developed a series of aluminum scandium and magnesium scandium alloys with excellent performance, which are ideal aerospace materials. Scandium metal is also used in neutron generators, which can produce high-energy neutrons and is a neutron source for activation analysis and geological prospecting. Gadolinium metal is a more suitable magnetic refrigeration material, and gadolinium and gadolinium intermetallic compounds are used as working materials for magnetic refrigeration. In addition, metal gadolinium and gadolinium-iron alloys have been used as neodymium-iron-boron hydromagnetic materials as additives to replace some of the metal dysprosium, which can not only improve the performance of the magnet but also make up for the lack of supply of metal dysprosium.

https://www.edge-techind.com/category/Rare-Earth-Elements-17-1.html

https://www.edge-techind.com/category/Neodymium-Nd-106-1.html

0 notes

Text

Human Beings Can Feel Magnetic Field and Maybe Predict The Future!

The sixth sense of magnetism is first confirmed That Human Beings Can Feel Magnetic Field and Maybe Predict The Future! In our real life, there are often strange experiences, and sometimes I always feel that my crow’s mouth is said. There is always a feeling of feeling that something is going on, but I did not expect to be fulfilled in a few days. When walking on the road, I always feel that…

View On WordPress

#AI Magnets#Cerium Magnets#cerium-containing magnets#ferrite permanent magnets#Grain Boundary Diffusion#Halbach Array#high-performance magnetic materials#Magnet Maker#Magnetic air conditioners#Magnetic Application#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Materials#Magnetic Phenomena#magnetic properties#magnetic treatment#NdFeB Magnet#NdFeB permanent magnet#NdFeB Surface Treatment#Neodymium iron boron#Neodymium Magnet Applications#Permanent Magnet Materials#Permanent Magnets#Rare Earth Magnets#rare earth permanent magnet#Sintered NdFeB#Sintered NdFeB Magnets#Super Magnets

2 notes

·

View notes

Text

Mitre Magnet - A Revolutionary Advancement In Precision Magnet

Mitre Magnet – A Revolutionary Advancement In Precision Magnet In a significant leap for the magnetics industry, the introduction of the Mitre Magnet is setting new standards for precision and efficiency. This innovative product is designed to cater to the ever-evolving needs of various industrial applications, from manufacturing to scientific research. The Mitre Magnet’s unique configuration and…

#bespoke magnets#Custom magnets#Customer Design Magnets#customized magnet#Customized magnets#Encapsulated NdFeB Magnets#Encapsulated Neodymium Magnets#IP-magnet#isotropic NdFeB magnets#magnetic assemby#permanent magnet

0 notes

Link

AdroitMarketResearch.com has published the “Global Permanent Magnets Market 2018-2025” research report to its store. Need for energy efficient and...

0 notes

Text

NdFeB Ring Magnets: Applications and Advantages

Ring NdFeB magnets are highly reliable permanent magnets. This product has great applicability in a wide range of industries, including electronics and electrical engineering, communication, transportation, and medical devices.

0 notes

Text

Exploring the Uses of Rare Earth Elements

Rare earth elements find applications in technologies ranging from high-tech devices, clean energy, and hybrid vehicles to wind power turbines, hard disk drives, and defence systems. All elements in the lanthanide series share similar chemical, magnetic, and spectroscopic properties; their role in a wide range of applications is attributed to these shared characteristics.

The Applications of Rare Earths

The primary sources of rare earth elements are bastnaesite and monazite. In India, monazite tops the list of mineral materials for the production of rare earths. It includes many lanthanides; approximately 50–70% of them are light rare earth elements (LREE).

Here are the various uses of rare earth elements:

Cerium (Ce) is one of the most abundant rare earth elements in the Earth’s crust. It is used to polish glass items such as lenses, liquid-crystal displays and plasma-display panels. It is also used as a fuel additive in fuel material like petrol and diesel. In combination with lanthanum, it has a use as an environmentally friendly substitute of cadmium in red pigments. Mischmetal, a mix of cerium and some other rare metals, is used to keep steel clean during its production phase.

Lanthanum (La) and neodymium (Nd) find application as glass additives in optical lenses and display screens. Along with yttrium (Y), they help store elements like magnesium, aluminum, and hydrogen. They act as catalysts to minimise sulphur dioxide emissions in automobiles. Nd also finds uses in welding in heavy industries and in medical equipment like MRI scanners.

Samarium (Sm), dysprosium (Dy), praseodymium (Pr), and terbium (Tb) are utilized in electronics, electric motors and audio equipment for their magnetic properties. Pr is used as neodymium’s replacement in magnets.

Scandium (Sc) is primarily used in aluminium alloys for sports equipment. This metal is mixed in small amounts in semiconductors and halogen bulbs.

Rare earth magnets, such as neodymium-iron-boron (NdFeB), are used in anti-lock brakes in cars to prevent the wheels from locking when you brake hard. These magnets also find applications in small gadgets such as digital cameras.

Nickel metal hydride (NiMH) batteries are considered special batteries. They have a mix of rare metals, including mischmetal, and are used in laptops, camcorders, and mobile phones to power them.

GMDC is committed to establish a comprehensive value chain for rare earths’ mining and their production. Our vision is to develop a sustainable supply chain of permanent magnets in India. For more information, visit our website https://www.gmdcltd.com/.

0 notes

Text

0 notes