#Nickel 200 Fasteners

Explore tagged Tumblr posts

Text

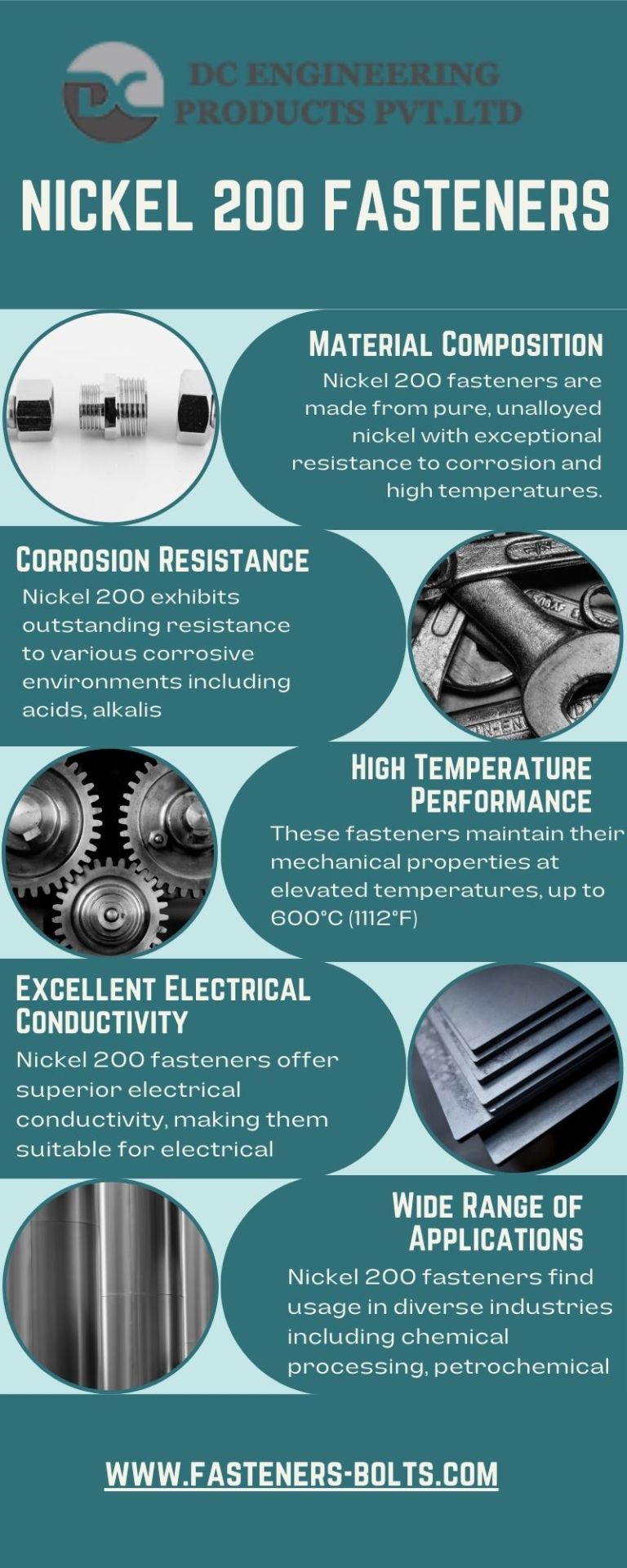

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

Manufacture and Supplier of High quality Nickel Alloy 200 Fasteners. JF Engineering Products LLP is Leading Manufacturer in Mumbai, India. We also offer Stainless Steel Fasteners, Sud Bolts, Nuts and Bolts at best price. Order Now.

#Nickel 200 Fasteners#ASTM B160 Nickel 200 Fasteners#Werkstoff Nr. 2.4066 Fasteners#Stud Bolt#Nickel 200 Hex Bolts#UNS N02200 Fasteners#Nickel 200 Stud Bolt

0 notes

Text

Nickel 200 Flanges Exporters In India

Navneet Metal Corporation stands as a beacon of reliability in the industry, revered for their expertise as a nickel 200 flange manufacturer, supplier, and exporter. Their commitment to quality is evident in the diverse array of flanges they produce, tailored to meet various specifications, shapes, and angles. In the intricate web of pipelines, valves, and pumps, these meticulously crafted flanges play a crucial role. They serve as the linchpin, connecting pipes with precision and ensuring the seamless flow of fluids and gases. Whether welded or screwed, these nickel 200 flanges provide steadfast support to the entire system.

What sets Nickel 200 flanges apart is their composition—being low-alloy nickel, they boast exceptional mechanical properties. Enduring harsh conditions with resilience, these flanges emerge as stalwart protectors in challenging environments. Their thermodynamic and electrical conductivity is unparalleled, further solidifying their reputation as the go-to choice for industries where reliability is paramount. In every step of the manufacturing process, Navneet Metal Corporation's dedication to durability and quality shines through. Their unwavering commitment to producing flanges that stand the test of time underscores their position as industry leaders. As these flanges find their place in the intricate network of industrial applications, they do more than just connect pipes; they establish a foundation of reliability upon which countless processes rely.

UNS N02200 nickel flanges are helpful in several fields, obviously flying, paper and squash adventures, chemical transportation, food dealing, petrochemicals, medicine, and so forth. We offer these nickel 200 flanges in organised sorts, including nickel 200 hung flanges, nickel 200 blind flanges, and nickel 200 plate flanges. Starting there, the sky is the limit. In addition, all the nickel alloy flanges completely acclimatise to general guidelines like ASME, ANSI, ASTM, BS, and so forth. Mercifully reach out to us to purchase these flanges at the most reasonable cost.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Nickel 201 Round Bars Exporters In India#Nickel 200 Pipe Fittings Exporters In India#Nickel 201 Pipe Fittings Exporters In India#Nickel 200 Flanges Exporters In India#Nickel 201 Flanges Exporters In India#Nickel 200 Fasteners Exporters In India

0 notes

Text

Nickel Alloy 200 vs 201 Fasteners: Which One Do You Need?

In the realm of fasteners, the selection between Nickel Alloy 200 and Nickel Alloy 201 pivotal. Each alloy boasts unique properties and characteristics that cater to distinct industrial necessities. Whether you are on the lookout for electricity, corrosion resistance, or ease of fabrication, understanding the disparities between those two alloys is paramount. This complete guide ambitions to elucidate the disparities among Nickel Alloy 200 and 201 fasteners, helping you in making an informed choice tailor-made in your precise desires.

Nickel Alloy 200 Fasteners: Unparalleled Corrosion Resistance

Nickel Alloy 200, a commercially pure wrought nickel, is famed for its great resistance to various corrosive environments. Its resistance spans from fairly decreasing to neutral and even alkaline solutions, making it a preferred desire in chemical processing and marine applications. The inherent homes of Nickel Alloy 200 render it pretty immune to corrosion via caustic alkalis. This robust resistance extends to distilled and herbal waters, rendering it perfect for marine device and desalination vegetation. Additionally, Nickel Alloy 200 fasteners exhibit wonderful resistance to mineral acids which includes hydrochloric and sulfuric acid, further amplifying their application in various commercial settings.

Nickel Alloy 200 Fasteners Manufacturers, Nickel Alloy 200 Fasteners supplier, Nickel Alloy 201 Fasteners Dealer and ,Nickel Alloy 200 Fasteners stockists recognize the paramount significance of sourcing Nickel Alloy 200 fasteners from reputable assets. Ensuring advanced first-rate uncooked substances and adherence to international great requirements is vital to ensuring the efficacy and toughness of fasteners in disturbing environments. Whether procured from a relied on producer or provider, Nickel Alloy 200 fasteners offer extraordinary corrosion resistance, making them integral throughout various industries.

Nickel Alloy 201 Fasteners: Enhanced Ductility and Fabricability

In assessment to its counterpart, Nickel Alloy 201 well-known shows more advantageous ductility and fabricability, owing to its decreased carbon content. This function makes Nickel Alloy 201 fasteners fantastically acceptable for applications requiring great forming and welding. Industries reliant on problematic designs and complicated fabrication tactics regularly want Nickel Alloy 201 for its ease of manipulation without compromising structural integrity. Additionally, Nickel Alloy 201 demonstrates commendable resistance to a myriad of corrosive environments, albeit slightly not as good as Nickel Alloy 200.

Fasteners made from Nickel Alloy 201 discover sizable application in industries necessitating stringent fabrication requirements. From problematic additives in aerospace engineering to intricate structures in chemical processing flowers, the flexibility of Nickel Alloy 201 fasteners is unrivaled. Nickel Alloy 200 Fasteners Manufacturers and Nickel Alloy 201 Fasteners exporters prioritize sourcing Nickel Alloy 201 from dependable suppliers to ensure adherence to considered necessary specs and standards, thereby making certain greatest overall performance in various programs.

Choosing the Right Alloy: Factors to Consider

When thinking of between Nickel Alloy 200 and 201 fasteners, several elements warrant consideration. The precise requirements of your software, ranging from environmental situations to mechanical properties, dictate the optimum desire of alloy.

Corrosion Resistance:

Nickel Alloy 200: Unparalleled resistance to a big selection of corrosive environments, together with alkaline answers and mineral acids.

Nickel Alloy 201: Demonstrates commendable corrosion resistance, albeit slightly not as good as Nickel Alloy 200.

Fabricability:

Nickel Alloy 200: Exhibits slight fabricability, suitable for applications requiring minimal forming and welding.

Nickel Alloy 201: Enhanced ductility and fabricability make it best for difficult fabrication techniques and good sized forming.

Mechanical Properties:

Nickel Alloy 200: Boasts first-rate mechanical residences, rendering it appropriate for excessive-pressure programs.

Nickel Alloy 201: Retains commendable mechanical properties even as supplying more advantageous ductility, catering to applications necessitating good sized fabrication.

Application Specifics:

Nickel Alloy 200: Preferred in environments requiring advanced corrosion resistance, together with chemical processing and marine applications.

Nickel Alloy 201: Ideal for packages necessitating elaborate fabrication strategies and substantial farming without compromising structural integrity.

Conclusion

In the end, the choice among Nickel Alloy 200 and 201 fasteners hinges at the unique requirements of your application. While Nickel Alloy 200 gives unprecedented corrosion resistance, Nickel Alloy 201 excels in fabricability and ductility. Understanding the nuances among these alloys empowers you to make a knowledgeable selection tailored to your business needs. Whether you prioritize corrosion resistance, ease of fabrication, or mechanical properties, selecting the proper alloy is paramount to making sure top-rated performance and toughness.

For advanced satisfactory Nickel Alloy 200 and 201 fasteners synthetic in accordance with worldwide fine requirements, appearance no further than Bhagyalaxmi Industrial. As a good producer, supplier, stockist, provider, and exporter of a variety of ferrous and non-ferrous metals, Bhagyalaxmi Industrial guarantees unparalleled high-quality and patron pride. Contact Bhagyalaxmi Industrial nowadays to procure top rate fasteners on the maximum reasonable costs, tailor-made in your unique requirements.

#Nickel Alloy 200 Fasteners Manufacturer#Nickel Alloy 200 Fasteners Supplier#Nickel Alloy 200 Fasteners Stockist#Nickel Alloy 201 Fasteners Exporter#Nickel Alloy 201 Fasteners Dealer

0 notes

Text

The Strength of Nickel Alloy 200/201 Washers | Anand steels

Because in their wonderful electricity, resistance to corrosion, and flexibility, nickel alloys have become more and more utilized in a huge variety of industries. For use in Nickel Alloy 200/201 nuts, Nickel Alloy 200/201 bolts, Nickel Alloy 200/201 washers, Nickel Alloy 200/201 screws, and other Nickel Alloy 200/201 fasteners, Nickel Alloy is an extremely reliable alloy. In this blog, we're going to examine the sturdiness and strength of Nickel Alloy 200/201 washers in addition to their advantages and packages in numerous industrial programs.

Understanding approximately Nickel Alloy 200/201

Commercially pure wrought nickel grades 200 and 201 have precise homes that lead them to be appropriate for quite a few programs. These alloys have a wonderful track file for not corroding easily in a number of situations, inclusive of acids and alkalis.

Nickel Alloy 200/201 Fasteners:

Fasteners are crucial additives of many commercial strategies, and that they need to be crafted from substances which can be every structurally sound and proof against terrible environments. Fasteners, which include Nickel Alloy 200/ 201 screws, Nickel Alloy 200/ 201 bolts, and Nickel Alloy 200/ 201 nuts, are essential in sectors wherein resistance to corrosion is crucial. These fasteners are in particular useful for naval programs, petrochemical industries, and chemical processing facilities.

Because of Nickel Alloy 200/201's durability, these fasteners are ideal for locations with corrosive materials, strong chemical compounds, and high temperatures. Even under annoying running instances, their first-rate resistance to corrosion guarantees sturdiness and dependability.

Nickel Alloy 200/201 Washers:

Nickel Alloy 200/201 washers, with their unique fabric residences, add an extra layer of reliability to the fastening gadget.

High Temperature Applications: Nickel Alloy 200/201 washers show off tremendous thermal balance, making them suitable for packages related to expanded temperatures. This function is particularly beneficial in industries consisting of aerospace, automobile, and production, wherein components are uncovered to varying degrees of warmth pressure.

Chemical Processing: In chemical processing plant life, wherein publicity to competitive chemical substances is regular, Nickel Alloy 200/201 washers show valuable. Their resistance to corrosive materials makes them a preferred preference in chemical reactors, storage tanks, and pipelines.

Sealing Properties: Nickel Alloy 200/201 washers provide powerful sealing, stopping leakage in joints and connections. This feature is vital in industries like oil and fuel, in which retaining a leak-unfastened surroundings is essential for safety and operational performance.

Applications Across Industries:

The versatility of Nickel Alloy 200/201 washers extends to various industries, making them a favored preference for critical programs. Let's discover how these washers are utilized in distinct sectors:

Chemical Processing: Nickel Alloy 200/201 washers discover giant use in chemical processing flowers for sealing joints and connections in reactors, vessels, and piping structures. Their resistance to corrosive materials ensures the reliability of these vital additives.

Aerospace and Defense: The aerospace and protection industries demand materials that may face up to extreme situations. Nickel Alloy 200/201 washers, with their excessive-temperature resistance and corrosion resilience, are applied in planes, missiles, and other protection programs.

Marine Engineering: In marine engineering, in which publicity to saltwater and harsh climate situations is regular, Nickel Alloy 200/201 washers offer vital corrosion safety. They are utilized in shipbuilding, offshore platforms, and marine infrastructure.

Manufacturing and Construction: The manufacturing and creation sectors enjoy the power and durability of Nickel Alloy 200/201 washers in numerous applications. Whether it is securing structural elements or ensuring leak-free connections, these washers make contributions to the general reliability of the built surroundings.

Anand Steels – Your Trusted Partner in Nickel Alloys:

Their commitment to great and client pleasure units them apart with:

Comprehensive Product Range: Anand Steels gives a huge range of merchandise, which include sheets, plates, coils, foils, round bars, and more. This complete product range allows them to offer tailored solutions for various applications throughout industries.

Duplex and Super Duplex Sheets and Plates: Serving as a stockist of duplex and remarkable duplex sheets and plates, Anand Steels caters to the precise desires of industries requiring durable and corrosion-resistant substances.

Unwavering Commitment to Quality: Anand Steels' dedication to exceptionalism is obvious in each product they provide. They try for excellence, ensuring that their clients get hold of the very best fine chrome steel solutions. This commitment extends to their nickel alloy products, which include Nickel Alloy 200/201 screws.

Customer-Centric Approach: Anand Steels prioritizes consumer satisfaction and takes satisfaction in their customer-centric approach. They work intently with clients to apprehend their needs, providing personalized answers and ensuring that the delivered products meet the highest requirements.

Conclusion:

In summary, the energy and sturdiness of Nickel Alloy 200/201 washers are fundamental components in numerous industries. Their corrosion resistance, high-temperature stability, and sealing homes make contributions to the reliability of fastening structures in vital programs. Anand Steels, as a depended on provider of nickel alloys and stainless steel solutions, sticks out for its dedication to nice and patron delight. For all your chrome steel and nickel alloy needs, which includes Nickel Alloy 200/201 washers, Anand Steels is the associate you could depend upon. Contact them these days to revel in the distinction that includes years of industry information and unwavering willpower to quality.

#Nickel Alloy 200/201 Fasteners#Nickel Alloy 200/201 Nuts#Nickel Alloy 200/201 Bolts#Nickel Alloy 200/201 Screws#Nickel Alloy 200/201 Washers

0 notes

Text

Jay Steel Corporation: Leading Nickel fastener Manufacturers in India Jay Steel Corporation is a trusted and reputable manufacturer of nickel fasteners to cater to various industrial applications. Their extensive inventory includes grades like 200, 201 and many more, allowing customers to find the right material for their specific needs.

0 notes

Text

Nickel Alloys Fastener Supplier - Fasteners LLP

Fasteners LLP is a leading supplier of nickel alloys fasteners, including nickel alloy 200 and nickel alloy 201 fasteners. We offer a wide range of nickel alloys fasteners in a variety of sizes and finishes to meet the needs of our customers. Our nickel alloys fasteners are known for their durability, corrosion resistance, and high temperature performance.

0 notes

Text

Nitronic 50 Fasteners Suppliers In India

Introduction:-

Nitronic 50 fasteners are high-strength, corrosion-resistant austenitic stainless steel components widely used in marine, chemical processing, and petrochemical industries. Known for their superior resistance to pitting, crevice corrosion, and stress corrosion cracking, Nitronic 50 (UNS S20910/XM-19) offers excellent mechanical properties even in harsh environments. In India, several reputable suppliers and manufacturers provide high-quality Nitronic 50 fasteners, including bolts, nuts, screws, washers, and studs, catering to diverse industrial needs. Companies such as Prashaant Steel & Alloys, Amigo Impex, Grand Metal Corporation, and Siddhgiri Tubes are well-known for supplying these fasteners with international standards and certifications. When choosing a supplier, factors like material quality, certification, pricing, and delivery reliability should be considered to ensure the best performance and durability.

Product Overview:-

Shasan Piping Solution is a basic Manufacturers and exporters of the ferrous and nonferrous things. We likewise manage the whole family stainless steel and Nitronic 50 and XM 19 Fasteners. We anyway, gathering the changed kind of the thing according to the bearing from the client and course. Nitronic 50 and XM 19 fastener are made with substance sytheses like carbon, nickel, silicon, manganese, chromium, aluminum, and sulfur. These Fasteners are composed with both physical and mechanical properties like assurance, yield strength, enlarging, and silly adaptability, and modulus of progress, warm conductivity, electrical conductivity, and dissolving point also.

These Fasteners are moreover made with the different sorts of terminations like centers, shape, size, thickness, length, width, string methodology, types, finish, application, and surface. These fastener are open in many plans, for example, cold shaped, hot made, bar stock machined, bar stock managing, etc too.

Specifications:-

ASTM: ASTM A 193/194 / ASME SA 193/194

Dimension Standard: DIN, ASTM, BS and all International Standards

Length: 3 mm to 200 mm

Bolt / Screw Size: M3 - M56 | 3/6" to 2" | Custom Sizes

Nuts Size: M02 to M33 | Custom Sizes

Washers Size: M3 - M56 | 3/6" to 2" | Custom Sizes

Benefits:-

ASTM A194 Stainless Steel Grade Nitronic® XM 19 Fastener, Nitronic 50 fastener, Nitronic 50 stainless Steel Fasteners, Nitronic Compound S20910 fastener, Nitronic XM 19 Fasteners, Nitronic XM 19 Screws, Nitronic Combination 1.3964 Fastener, Nitronic 50 Fastener Manufacturers In Mumbai, India. Nitronic 50 and XM 19 fastener are significant in different endeavors and various specialists purposes, for example, arranged making due, gas making due, petrochemicals affiliations, contamination control, paper industry, pound industry, refining, around the sea oil debilitating affiliations, material undertakings, atomic plant, nuclear energy station, heat exchanger, condensers, marine stuff, valves, springs, boat screwing, oil encounters, etc too.

Conclusions:-

Nitronic 50 and XM 19 fastener are made with the mix of formability, handiness, and welding for better persevering through hindrance. These Fasteners have the high strength of the austenitic composites and effectively thought out plan the whole isolating. This general use area s followed, for example, detached disintegrating, stress breaking use, sulfide use, seawater rust, and pitting use. These are the best materials for organizing home mechanical parties and electrical contraptions.

Email Id :[email protected]

Contact Number:-88797-09191

0 notes

Text

High Nickel Alloy Fasteners: Comprehensive Guide

Introduction

High Nickel Alloy Fasteners are essential components in industries where extreme environmental conditions demand superior performance and durability. These fasteners are known for their exceptional resistance to corrosion, heat, and stress, making them indispensable in sectors such as aerospace, marine, chemical processing, and power generation. This blog delves into the types, characteristics, applications, and benefits of high nickel alloy fasteners, showcasing why they are the go-to choice for demanding applications.

Types of High Nickel Alloy Fasteners

High Nickel Alloy Fasteners come in various forms to suit diverse applications. Some popular types include:

1. Bolts:

Hex Bolts

Carriage Bolts

Flange Bolts

Eye Bolts

2. Nuts:

Hex Nuts

Lock Nuts

Wing Nuts

3. Washers:

Flat Washers

Spring Washers

Lock Washers

4. Screws:

Machine Screws

Socket Head Cap Screws

Self-Tapping Screws

5. Studs:

Double-ended Studs

Fully Threaded Studs

Characteristics of High Nickel Alloy Fasteners

High Nickel Alloys are defined by their unique properties that contribute to their performance advantages:

Corrosion Resistance: High resistance to oxidation, pitting, and crevice corrosion, even in highly acidic environments.

High-Temperature Performance: Excellent strength and stability under extreme temperatures.

Mechanical Strength: High tensile and yield strength, providing robustness under heavy loads.

Stress Corrosion Cracking Resistance: Ideal for applications prone to stress and cracking under pressure.

Durability: Superior longevity even under harsh operating conditions.

Popular High Nickel Alloys Used in Fasteners

Inconel®: Renowned for its high oxidation and corrosion resistance, widely used in aerospace and chemical industries.

Monel®: Known for its resistance to seawater and acidic environments, often used in marine and chemical applications.

Hastelloy®: Superior corrosion resistance for highly aggressive chemical environments.

Nickel 200/201: Pure nickel fasteners with excellent electrical conductivity and corrosion resistance.

Alloy 20: Specifically designed for sulfuric acid applications.

Applications of High Nickel Alloy Fasteners

These fasteners are employed across a wide range of industries, including:

Aerospace: Used in jet engines and aerospace components due to their high strength and heat resistance.

Marine: Essential for shipbuilding and offshore platforms due to resistance to saltwater corrosion.

Chemical Processing: Applied in reactors, heat exchangers, and storage tanks.

Power Generation: Ideal for turbines and nuclear power plants.

Pharmaceutical Industry: Ensures contamination-free operations in sensitive environments.

Benefits of High Nickel Alloy Fasteners

Superior Corrosion Resistance: Withstand harsh chemicals and environments.

Extended Service Life: Reduced maintenance costs due to longevity.

High Strength-to-Weight Ratio: Perfect for weight-sensitive applications such as aerospace

Versatility: Suitable for multiple industries and applications.

Reliability: Perform consistently under extreme stress and temperatures.

Manufacturing Expertise of Ananka Group

At Ananka Group, we specialize in the production and supply of premium High Nickel Alloy Fasteners. Our state-of-the-art manufacturing facility and stringent quality control processes ensure that our fasteners meet international standards and exceed customer expectations. We offer a wide range of custom fastener solutions tailored to specific industrial requirements.

Quality Standards We Adhere To:

ASTM

ASME

DIN

ISO

Customization Options:

Material Grades

Sizes and Dimensions

Coatings and Finishes

Conclusion

High Nickel Alloy Fasteners are a critical component for industries requiring exceptional performance in extreme environments. Their unmatched properties make them a preferred choice for numerous applications across diverse sectors. By choosing reliable suppliers like Ananka Group, businesses can ensure they receive top-quality fasteners designed to deliver durability, strength, and resilience.

Frequently Asked Questions (FAQ)

1. What are High Nickel Alloy Fasteners?

High Nickel Alloy Fasteners are components made from nickel-based alloys, known for their superior corrosion resistance, heat resistance, and mechanical strength.

2. Where are High Nickel Alloy Fasteners used?

These fasteners are commonly used in aerospace, marine, chemical processing, power generation, and pharmaceutical industries.

3. Why choose High Nickel Alloy Fasteners over regular stainless steel fasteners?

High Nickel Alloy Fasteners offer better performance in extreme conditions, superior corrosion resistance, and higher temperature stability than regular stainless steel fasteners.

4. Can High Nickel Alloy Fasteners be customized?

Yes, they can be customized based on material grade, size, coating, and specific industrial needs.

5. How do I ensure the quality of High Nickel Alloy Fasteners?

Choose reputable manufacturers like Ananka Group, who adhere to stringent quality standards and offer comprehensive testing and certification for their products.

#HighNickelAlloy#FastenersGuide#IndustrialFasteners#CorrosionResistance#EngineeringMaterials#AerospaceFasteners#AnankaFasteners#Manufacturing#MetalAlloys#FastenerIndustry#Durability#HeatResistance#ChemicalProcessing#MarineApplications#Ananka#Monel#Inconel#manufacturer#fasteners

0 notes

Text

SAPT/EVE 4S 10P Busbars and Hardware blog of 200 words

SAPT/EVE 4S 10P Busbars and Hardware: Optimizing Battery Pack Performance

When building high-capacity battery packs using SAPT or EVE lithium-ion cells, proper busbars and hardware selection is essential for efficient power flow, safety, and longevity. A 4S 10P configuration, featuring four cells in series (4S) and ten parallel groups (10P), is commonly used in applications that require a stable 14.8V output and high current capability, such as electric bikes (e-bikes), energy storage systems (ESS), and portable power solutions.

The busbars in a 4S 10P setup play a crucial role in connecting the cells while minimizing resistance and heat generation. Made from high-conductivity materials like copper or nickel-plated copper, these busbars ensure smooth energy flow between the cells, improving overall efficiency and performance. Since the 10P parallel configuration demands higher current, choosing busbars with low resistance and robust design is essential for preventing energy loss and thermal issues.

The choice of hardware—typically M6 bolts, nuts, and washers—is equally important. M6 hardware is favored due to its mechanical strength, ensuring tight and secure connections between the busbars and cells. Properly fastened connections reduce the risk of loose terminals or short circuits, ensuring the safe operation of the battery pack.

Incorporating high-quality busbars and hardware in a SAPT/EVE 4S 10P configuration ensures a reliable, efficient, and safe battery pack that will perform consistently over time.

Contact

+𝟭 𝟳𝟳𝟵-𝟳𝟳𝟬-𝟯𝟭𝟬𝟵

1585 Beverly CT, Unit 121, Auror

0 notes

Text

Nickel Alloy 201 Bolt Manufacturers

Nascent Pipe & Tubes is one of the prominent whole seller and supplier of quality Nickel Alloy 200 Fasteners (Bolts / Nuts), which is the higher carbon (0.04 – 0.10) version of the alloy. These Nickel 200 Hex Head Bolts has slightly improved corrosion resistance over stainless steel in strongly oxidizing environments.

#Nickel Alloy 201 Bolt Stockists#Nickel Alloy 201 Bolt Exporters#Nickel Alloy 201 Bolt Manufacturers In India#Nickel Alloy 201 Bolt Suppliers In India

0 notes

Text

Incoloy 825 Fasteners Exporters

In the realm of industrial fasteners, one name stands out for its remarkable resilience and dependability—Incoloy 825. Used across a variety of sectors, from chemical processing to marine engineering, these fasteners are known for their unmatched performance in demanding environments. But what exactly makes Incoloy 825 fasteners so special, and why should you consider them for your projects? Let’s dive into the unique features and benefits of these high-performance fasteners.

What are Incoloy 825 Fasteners? Incoloy 825 fasteners are made from a nickel-iron-chromium alloy known for its exceptional resistance to various corrosive elements. The alloy is further enriched with molybdenum, copper, and titanium, which enhance its resistance to pitting, crevice corrosion, and stress-corrosion cracking. These fasteners are designed to perform in highly aggressive environments, such as chemical processing plants, offshore oil and gas facilities, and seawater applications.

Key Properties of Incoloy 825 Fasteners Corrosion Resistance: Incoloy 825 exhibits outstanding resistance to both reducing and oxidizing acids, making it ideal for use in environments with sulfuric acid, phosphoric acid, and other corrosive chemicals. High Temperature Tolerance: The alloy maintains its mechanical strength and corrosion-resistant properties even at elevated temperatures, which makes it suitable for heat-exposed applications. Durability and Strength: Incoloy 825 fasteners provide high mechanical strength and are known for their long lifespan, reducing the need for frequent replacements. Resistance to Pitting and Crevice Corrosion: Thanks to the molybdenum content, these fasteners can withstand pitting and crevice corrosion in chloride-containing environments.

Specifications of Incoloy 825 Fasteners Standards: DIN, ASTM, BS, and all international standards Size Range: 3 mm to 200 mm Bolt/Screw Size: M3 - M56 | 3/6" to 2" | Custom sizes available Nut Size: M3 - M56 | 3/6" to 2" | Custom sizes available Washer Size: M1 - M64 | #4 to 3" | Custom sizes available Length: M02 to M33 Types: Includes nuts, bolts, screws, sockets, studs, hex head bolts, machine screws, marine anchors, eye bolts, foundation bolts, structural bolts, and more. Benefits of Incoloy 825 Fasteners Long-Term Cost Savings: Their durability and resistance to harsh chemicals reduce the frequency of replacements, leading to long-term savings. High Corrosion Resistance: Ideal for applications exposed to saltwater, acidic, and alkaline environments. Wide Range of Applications: Used in multiple industries, from chemical processing and oil & gas to marine engineering. Easy Customization: Available in various sizes and shapes, with custom sizes upon request to meet specific project requirements. Consistency and Reliability: Conforms to international standards ensuring dependable performance across diverse applications.

Applications of Incoloy 825 Fasteners Incoloy 825 fasteners are utilized in various industries due to their remarkable properties. Some of the key applications include:

Chemical Processing: Used in processing plants dealing with sulfuric, phosphoric, and other aggressive acids. Oil & Gas Industry: Suitable for offshore drilling, oil refining, and gas extraction, where exposure to corrosive environments is common. Marine Engineering: Employed in shipbuilding, marine hardware, and seawater desalination plants due to their resistance to saltwater corrosion. Pollution Control Equipment: Ideal for use in components exposed to polluted or contaminated environments. Heat Exchangers: These fasteners hold up well in heat exchangers and other equipment that operates at high temperatures.

Why Choose Sankalp Alloys Overseas for Incoloy 825 Fasteners? Sankalp Alloys Overseas is a trusted leader in the manufacturing, exporting, stocking, and supply of Incoloy 825 fasteners in India and internationally. Here’s why you should consider partnering with them:

Expertise and Experience: With years of experience in the industry, Sankalp Alloys Overseas has developed a reputation for delivering high-quality fasteners that meet the stringent requirements of various industrial applications. Wide Range of Products: They offer an extensive selection of Incoloy 825 fasteners, including custom sizes and configurations to suit specific needs. Quality Assurance: Sankalp Alloys Overseas adheres to international quality standards such as DIN, ASTM, and BS, ensuring that their products consistently deliver exceptional performance. Competitive Pricing: They provide cost-effective solutions without compromising on quality, ensuring that you get the best value for your investment. Global Reach: As exporters, they serve clients not only in India but around the world, ensuring prompt and efficient delivery regardless of location. Customer-Centric Approach: Committed to customer satisfaction, they offer personalized services, including technical support and product recommendations tailored to your specific requirements.

Conclusion When it comes to industrial fasteners, Incoloy 825 fasteners stand out for their superior corrosion resistance, high strength, and versatility across a range of applications. Whether you are dealing with harsh chemicals, high temperatures, or seawater environments, these fasteners offer unmatched performance. For the best quality and service, Sankalp Alloys Overseas is your go-to partner. With their expertise, comprehensive product range, and commitment to quality, you can trust them to meet all your fastening needs.

Contact Details For inquiries, quotations, or more information, get in touch with Sankalp Alloys Overseas:

Contact Number: +91-8828369483 Email: [email protected] Website: https://www.sankalpalloys.com

Sankalp Alloys Overseas is your reliable source for top-quality Incoloy 825 fasteners—delivering excellence and precision for all your industrial requirements.

#Incoloy 825 Fasteners Exporters#Incoloy 825 Fasteners Exporters in India#Incoloy 825 Fasteners Manufacturers#Incoloy 825 Fasteners Manufacturers in India#Incoloy 825 Fasteners#Fasteners#exporter#suppliers#business#exporters#innovation#stockists#manufacturers#metalwork#sankalpalloys#india#mumbai#uae

1 note

·

View note

Text

Monel K500 Washers Manufacturers

Monel K500 is a nickel-copper alloy that stands out for its exceptional corrosion resistance, high strength, and durability, even in harsh environments. These characteristics make it an essential material for various industries, particularly in the manufacturing of washers. Monel K500 washers are widely used in marine, chemical, oil and gas, and aerospace industries, where they play a critical role in ensuring the reliability and longevity of assemblies.

The Importance of Quality Monel K500 Washers

Washers are small, flat rings that are used to distribute the load of a threaded fastener, such as a screw or nut. In many applications, the choice of material for washers can have a significant impact on the performance and safety of the entire assembly. Monel K500 washers are particularly valued for their ability to resist corrosion, even in saltwater or acidic environments, which makes them ideal for use in marine and chemical processing applications.

Moreover, the alloy’s high tensile strength and hardness ensure that Monel K500 washers maintain their integrity under extreme conditions, such as high pressure or temperature. This reliability is crucial in industries like oil and gas, where the failure of a single component can lead to catastrophic results.

The Role of Exporters in the Global Supply Chain

Exporters of Monel K500 washers play a vital role in the global supply chain, ensuring that these critical components are available to industries around the world. The demand for Monel K500 washers is global, with significant markets in North America, Europe, Asia, and the Middle East. Exporters must navigate complex logistics, international trade regulations, and varying quality standards to deliver products that meet the exacting specifications of their clients.

Chhajed Steel Limited is one of the renowned makers and suppliers of Monel K500 Washers, which are precipitation cementing washers manufactured from copper nickel composite with development of titanium and aluminum. With the parts of aluminum and titanium, Monel K500 Flat Washers offers the wonderful insurance from utilization of Alloy 400; with raised quality, hardness, breaking down security and oxidation shortcoming assurance. We make a wide scope of Monel K500 Machined Washers in all shapes and sizes. We moreover give passivation, quality covering in Monel K500 Punched Washers also dealing with as per client's need. All our delivered Monel K500 Round Washers are according to national and furthermore overall models. Monel K500 Square Washers are into two halves string and full string length with arranged movement, material in stock.

MONEL ALLOY K500 WASHERS SPECIFICATION

Material

Specification

Standards

Size

Length

Monel Alloy K500

IS

BS

ASTM

ASTM B865-04

3 mm to 200 mm

M02 to M33

MONEL ALLOY K500 WASHERS GRADE DESIGNATION

Alloy

Common Name

Related Specification

British

European

ASTM

UNS

Alloy K500

Monel K500 ®

BS 3076 NA18

4.4375

B865-04

N05500

Conclusion

Monel K500 washers are indispensable in various high-performance applications, and choosing the right exporter is crucial to ensuring that these components meet the stringent demands of your industry. By focusing on quality, experience, supply chain capabilities, and customer support, you can find a reliable partner to supply you with Monel K500 washers that deliver optimal performance and durability in your specific applications.

For More Information:

Visit Our Website -https://www.chhajedfastners.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

Duplex Steel S31803 Stud Bolt

Introduction

In the world of industrial fasteners, the right material choice can make all the difference in ensuring the longevity and safety of structures and machinery. Duplex Steel S31803, known for its superior strength and corrosion resistance, stands out as a top choice for stud bolts used in demanding environments. This article explores the unique properties of Duplex Steel S31803 stud bolts, their applications, and the advantages they offer over other materials.

Understanding Duplex Steel S31803

Duplex Steel S31803, also referred to as UNS S31803, is a widely used duplex stainless steel grade that combines the best attributes of austenitic and ferritic stainless steels. It contains approximately 22% chromium, 5-6.5% nickel, and 3% molybdenum, along with nitrogen, which enhances its strength and corrosion resistance. The microstructure of Duplex S31803 consists of a roughly equal mix of austenite and ferrite phases, offering a unique balance of mechanical and corrosion resistance properties.

Compared to conventional stainless steels, Duplex S31803 provides:

Higher strength: Almost double the yield strength of common austenitic stainless steels.

Superior corrosion resistance: Particularly in chloride-containing environments, which makes it ideal for use in seawater, brackish water, and chemical processing industries.

Improved stress corrosion cracking resistance: A critical advantage in environments with fluctuating temperatures and pressures.

Advantages of Duplex Steel S31803 Stud Bolts

Duplex Steel S31803 stud bolts offer numerous advantages:

Corrosion Resistance: Exceptional resistance to pitting, crevice corrosion, and general corrosion in harsh environments.

High Strength and Durability: The high yield strength reduces the need for thicker sections, allowing for lighter, more compact designs without compromising performance.

Cost-Effectiveness: Despite the initial higher cost compared to standard stainless steels, the extended lifespan and reduced maintenance requirements of Duplex S31803 make it a cost-effective choice in the long term.

ChhajedSteel Limited is one of the outstanding exporters and suppliers of ASTM A479 Duplex Steel UNS S31803 and UNS S32205 Stud Bolts, which has eminent weldability and can be joined by a lot of strategies. The game plan of ASTM A479 Duplex Steel UNS S32205 Tie Rods fuses austenite pools encased by an unending ferrite compose. ASME SA 479 Duplex Steel UNS S31803 Tie Bars is hot worked in temp extent of 1750 Deg F to 2100 Deg F. This planned to reduce profundities being utilized in produces diving the enormity that is of definite consequences in things like weight vessels, assistant limits, for instance, ranges, accumulating tanks, etc. ASTM A479 Duplex Steel UNS S32205 Threaded Bars has common power that is around multiple times of SS 304. ASME SA 479 Duplex Steel UNS S31803 Threaded Rods are excessively alluring, a component which can be utilized to effectively remember them from basic austenitic assessments of composite.

DUPLEX STEEL UNS S31803 & UNS S32205 STUDBOLT SPECIFICATION

Material

Specification

Standards

Size

Length

Duplex Steel

IS

BS

ASTM

ASTM / ASME - A/ SA 479 / 479

3 mm to 200 mm

M02 to M30

Conclusion

Duplex Steel S31803 stud bolts are an excellent choice for industries requiring high strength, corrosion resistance, and durability. Their unique blend of mechanical properties and resistance to harsh environments makes them a reliable and cost-effective solution for critical applications. By adhering to the correct standards and best practices in installation and maintenance, these stud bolts can significantly extend the service life of industrial equipment and structures.

For More Information

Visit Our Website -https://www.chhajedfastners.com

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

Nickel 200 Washers Stockists / Manufactures / Exporters.

Introduction

Nickel 200 washers are essential components used in various industrial applications due to their excellent mechanical properties, corrosion resistance, and durability. Whether you are in the chemical processing industry, power generation, or any other field requiring reliable fasteners, understanding the benefits and applications of Nickel 200 washers is crucial. This guide will explore the properties, applications, and highlight some of the top suppliers of Nickel 200 washers.

What is Nickel 200?

Nickel 200 is a commercially pure nickel alloy with excellent mechanical properties and resistance to various corrosive environments. This alloy is known for its high thermal and electrical conductivity, low gas content, and magnetic properties. It is highly versatile and suitable for many industrial applications.

Key Properties of Nickel 200 Washers

Corrosion Resistance: Exceptional resistance to a wide range of corrosive environments, including acids and alkalis.

Thermal Conductivity: High thermal conductivity makes it suitable for applications involving high temperatures.

Mechanical Strength: Maintains good mechanical properties over a wide temperature range.

Magnetic Properties: Exhibits magnetic properties useful in specific industrial applications.

Electrical Conductivity: High electrical conductivity for applications requiring efficient current flow.

Applications of Nickel 200 Washers

Nickel 200 washers are used in various industries due to their unique properties:

Chemical Processing: Ideal for use in equipment and machinery exposed to harsh chemicals and corrosive environments.

Power Generation: Used in power plants for components that require high strength and corrosion resistance at elevated temperatures.

Electronics: Suitable for electronic applications requiring high electrical conductivity.

Aerospace: Used in aerospace applications that demand high-performance materials with excellent thermal stability.

Marine: Provides excellent resistance to seawater corrosion, making it suitable for marine applications.

Benefits of Using Nickel 200 Washers

Durability: Long-lasting performance in harsh environments.

Versatility: Suitable for a wide range of applications across multiple industries.

Reliability: Maintains integrity under high temperatures and corrosive conditions.

Ease of Fabrication: Good machinability and weldability, facilitating easy manufacturing and installation.

How to Choose a Reliable Supplier for Nickel 200 Washers

Quality Assurance Ensure the supplier provides high-quality Nickel 200 washers that meet industry standards. Look for certifications such as ISO 9001 to verify their commitment to quality.

Range of Products A good supplier should offer a variety of washer sizes and specifications to meet your specific needs. Custom fabrication services are a plus.

Customer Reviews and Testimonials Check customer reviews and testimonials to gauge the supplier’s reputation. Positive feedback on product quality, delivery times, and customer service is a good indicator of reliability.

Technical Support Choose a supplier that offers technical support and assistance in selecting the right products for your applications.

Competitive Pricing Compare prices from different suppliers, but ensure that lower prices do not mean compromised quality. Balance cost with quality to get the best value.

Top Supplier: Nascent Group

Nascent Group is a leading supplier of Nickel 200 washers, known for their commitment to quality and customer satisfaction. They offer a wide range of high-performance washers suitable for various industrial applications.

Why Choose Nascent Group?

Quality Products: Nascent Group ensures all their Nickel 200 washers meet stringent industry standards.

Wide Selection: They offer an extensive selection of washer sizes and specifications, catering to diverse industrial needs.

Excellent Customer Service: Known for their responsive customer support and technical assistance.

Competitive Pricing: Offers high-quality products at competitive prices, ensuring good value for your investment.

Conclusion

Nickel 200 washers are essential components in many industrial applications, offering excellent corrosion resistance, high-temperature performance, and durability. When selecting a supplier, consider factors like quality assurance, product range, customer reviews, technical support, and pricing. Nascent Group stands out as a reliable supplier, providing high-quality Nickel 200 washers tailored to your needs. For more information or to place an order, contact Nascent Group today.

For more details

Email: [email protected]

Contact: 8779038854If any enquiries please contact us our support team will connect you as soon as possible

#exporters#manufacturers#metal#suppliers#steel#Nickel 200 Washers Manufacturers In India#Nickel 200 Washers Suppliers In India#Nickel 200 Washers Stockists In India#Nickel 200 Washers Exporters In India

0 notes

Text

Nickel 200 Fasteners Manufacturers

0 notes