#Nickel Fastener manufacturers

Explore tagged Tumblr posts

Text

Jay Steel Corporation: Leading Nickel fastener Manufacturers in India Jay Steel Corporation is a trusted and reputable manufacturer of nickel fasteners to cater to various industrial applications. Their extensive inventory includes grades like 200, 201 and many more, allowing customers to find the right material for their specific needs.

0 notes

Text

Nickel Fasteners Manufacturer, Supplier & Exporter

Ananka Group is a globally recognized manufacturer, supplier, stockist, and exporter of high-quality Nickel Fasteners, catering to a wide range of industries. Our commitment to precision and performance makes us a trusted partner for businesses across sectors. With a vast inventory and adherence to international standards, we ensure our products meet diverse industrial needs.

About Nickel Fasteners

Nickel Fasteners are renowned for their excellent corrosion resistance, high-temperature stability, and outstanding mechanical properties. Made primarily of nickel or nickel-based alloys, these fasteners perform exceptionally in harsh environments, including marine, chemical, and aerospace applications. Their ability to resist oxidation and maintain strength under extreme conditions makes them a preferred choice for critical applications.

Key Characteristics of Nickel Fasteners:

Corrosion Resistance: Exceptional resistance to acids, alkalis, and moisture.

High Strength: Retains mechanical strength at elevated temperatures.

Oxidation Resistance: Performs well in environments exposed to high heat and oxygen.

Durability: Long-lasting performance even in the most demanding applications.

Types of Nickel Fasteners

Nickel fasteners come in various forms to suit different industrial applications. Below are the common types:

Nickel Bolts: Available in hex, square, and U-bolt configurations, offering durability and resistance to corrosive environments.

Nickel Nuts: Includes hex nuts, lock nuts, and flange nuts, providing secure fastening solutions.

Nickel Washers: Used to distribute load and reduce wear between fasteners and surfaces.

Nickel Screws: Available as machine screws, socket head screws, and self-tapping screws.

Nickel Studs: Utilized in applications requiring precision and strength.

Nickel Pins: Used in alignment and connection applications in machinery.

Nickel Threaded Rods: Ideal for applications requiring extended lengths of threading.

Applications of Nickel Fasteners

Aerospace Industry: For critical components exposed to high temperatures and stresses.

Marine Industry: For parts exposed to saltwater and harsh marine environments.

Chemical Processing: In plants where resistance to corrosive chemicals is essential.

Power Plants: For equipment operating under extreme conditions.

Oil & Gas: For pipelines and other high-pressure systems.

Why Choose Ananka Group for Nickel Fasteners?

Extensive product range with customization options.

Compliance with international standards like ASTM, ASME, DIN, and more.

Competitive pricing and timely delivery across the globe.

ISO-certified manufacturing facilities with rigorous quality checks.

Conclusion

Nickel fasteners are indispensable in industries that demand durability, corrosion resistance, and high performance. At Ananka Group, we pride ourselves on delivering superior quality fasteners that meet the most stringent requirements. Whether your project is large or small, our team is ready to provide tailored solutions to ensure success.

FAQs

Q1. What are the main benefits of Nickel Fasteners?Nickel fasteners offer exceptional corrosion resistance, high strength, and durability, making them ideal for harsh environments and critical applications.

Q2. Are Nickel Fasteners suitable for marine applications?Yes, nickel fasteners are highly resistant to saltwater corrosion, making them perfect for marine environments.

Q3. Can Ananka Group customize Nickel Fasteners for specific needs?Absolutely! We offer customization to meet specific size, grade, and application requirements.

Q4. What industries commonly use Nickel Fasteners?Industries like aerospace, marine, chemical processing, oil & gas, and power generation frequently use nickel fasteners.

Q5. How do I place an order for Nickel Fasteners with Ananka Group?You can contact us through our website or email. Our team will guide you through the ordering process and provide prompt assistance.

#Ananka#AnankaFasteners#FastenerManufacturer#Fasteners#Nickel#NickelFastener#manufacturer#supplier#mumbai#hex#bolt#uk#usa

0 notes

Text

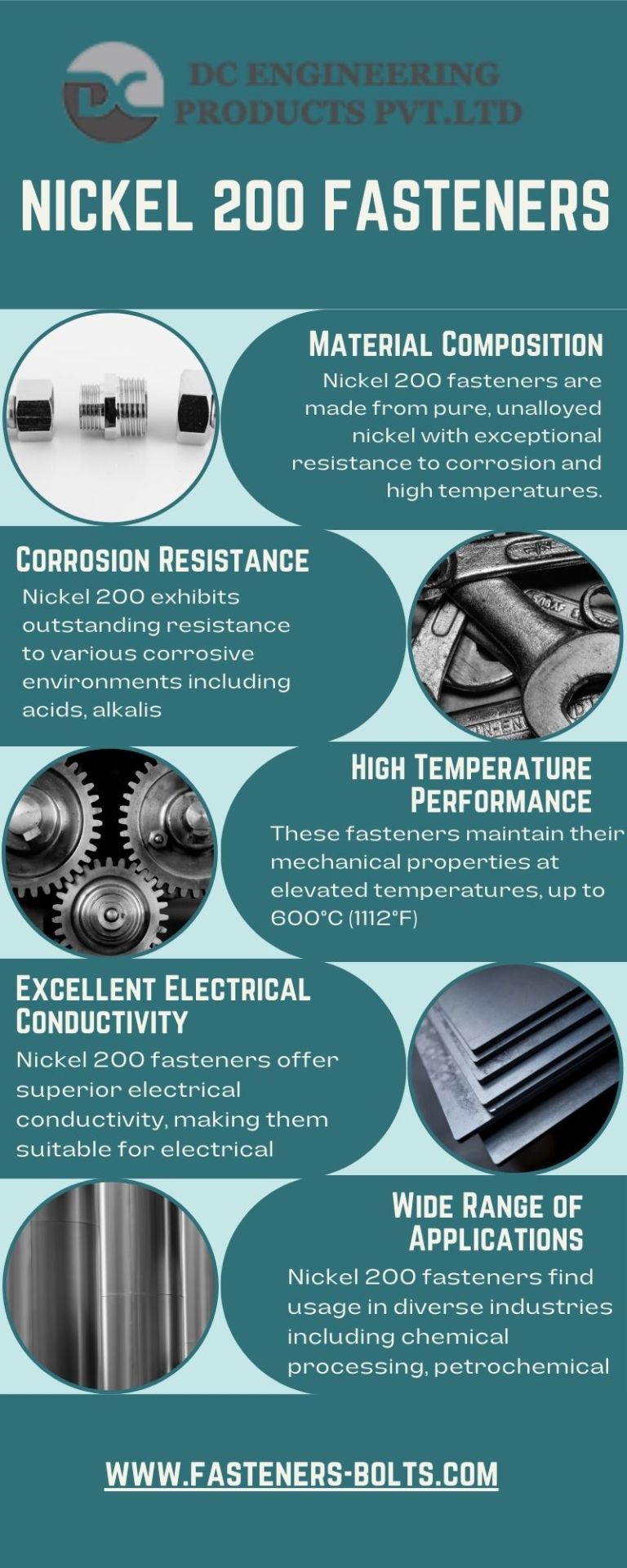

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

Nickel Alloy 200 vs 201 Fasteners: Which One Do You Need?

In the realm of fasteners, the selection between Nickel Alloy 200 and Nickel Alloy 201 pivotal. Each alloy boasts unique properties and characteristics that cater to distinct industrial necessities. Whether you are on the lookout for electricity, corrosion resistance, or ease of fabrication, understanding the disparities between those two alloys is paramount. This complete guide ambitions to elucidate the disparities among Nickel Alloy 200 and 201 fasteners, helping you in making an informed choice tailor-made in your precise desires.

Nickel Alloy 200 Fasteners: Unparalleled Corrosion Resistance

Nickel Alloy 200, a commercially pure wrought nickel, is famed for its great resistance to various corrosive environments. Its resistance spans from fairly decreasing to neutral and even alkaline solutions, making it a preferred desire in chemical processing and marine applications. The inherent homes of Nickel Alloy 200 render it pretty immune to corrosion via caustic alkalis. This robust resistance extends to distilled and herbal waters, rendering it perfect for marine device and desalination vegetation. Additionally, Nickel Alloy 200 fasteners exhibit wonderful resistance to mineral acids which includes hydrochloric and sulfuric acid, further amplifying their application in various commercial settings.

Nickel Alloy 200 Fasteners Manufacturers, Nickel Alloy 200 Fasteners supplier, Nickel Alloy 201 Fasteners Dealer and ,Nickel Alloy 200 Fasteners stockists recognize the paramount significance of sourcing Nickel Alloy 200 fasteners from reputable assets. Ensuring advanced first-rate uncooked substances and adherence to international great requirements is vital to ensuring the efficacy and toughness of fasteners in disturbing environments. Whether procured from a relied on producer or provider, Nickel Alloy 200 fasteners offer extraordinary corrosion resistance, making them integral throughout various industries.

Nickel Alloy 201 Fasteners: Enhanced Ductility and Fabricability

In assessment to its counterpart, Nickel Alloy 201 well-known shows more advantageous ductility and fabricability, owing to its decreased carbon content. This function makes Nickel Alloy 201 fasteners fantastically acceptable for applications requiring great forming and welding. Industries reliant on problematic designs and complicated fabrication tactics regularly want Nickel Alloy 201 for its ease of manipulation without compromising structural integrity. Additionally, Nickel Alloy 201 demonstrates commendable resistance to a myriad of corrosive environments, albeit slightly not as good as Nickel Alloy 200.

Fasteners made from Nickel Alloy 201 discover sizable application in industries necessitating stringent fabrication requirements. From problematic additives in aerospace engineering to intricate structures in chemical processing flowers, the flexibility of Nickel Alloy 201 fasteners is unrivaled. Nickel Alloy 200 Fasteners Manufacturers and Nickel Alloy 201 Fasteners exporters prioritize sourcing Nickel Alloy 201 from dependable suppliers to ensure adherence to considered necessary specs and standards, thereby making certain greatest overall performance in various programs.

Choosing the Right Alloy: Factors to Consider

When thinking of between Nickel Alloy 200 and 201 fasteners, several elements warrant consideration. The precise requirements of your software, ranging from environmental situations to mechanical properties, dictate the optimum desire of alloy.

Corrosion Resistance:

Nickel Alloy 200: Unparalleled resistance to a big selection of corrosive environments, together with alkaline answers and mineral acids.

Nickel Alloy 201: Demonstrates commendable corrosion resistance, albeit slightly not as good as Nickel Alloy 200.

Fabricability:

Nickel Alloy 200: Exhibits slight fabricability, suitable for applications requiring minimal forming and welding.

Nickel Alloy 201: Enhanced ductility and fabricability make it best for difficult fabrication techniques and good sized forming.

Mechanical Properties:

Nickel Alloy 200: Boasts first-rate mechanical residences, rendering it appropriate for excessive-pressure programs.

Nickel Alloy 201: Retains commendable mechanical properties even as supplying more advantageous ductility, catering to applications necessitating good sized fabrication.

Application Specifics:

Nickel Alloy 200: Preferred in environments requiring advanced corrosion resistance, together with chemical processing and marine applications.

Nickel Alloy 201: Ideal for packages necessitating elaborate fabrication strategies and substantial farming without compromising structural integrity.

Conclusion

In the end, the choice among Nickel Alloy 200 and 201 fasteners hinges at the unique requirements of your application. While Nickel Alloy 200 gives unprecedented corrosion resistance, Nickel Alloy 201 excels in fabricability and ductility. Understanding the nuances among these alloys empowers you to make a knowledgeable selection tailored to your business needs. Whether you prioritize corrosion resistance, ease of fabrication, or mechanical properties, selecting the proper alloy is paramount to making sure top-rated performance and toughness.

For advanced satisfactory Nickel Alloy 200 and 201 fasteners synthetic in accordance with worldwide fine requirements, appearance no further than Bhagyalaxmi Industrial. As a good producer, supplier, stockist, provider, and exporter of a variety of ferrous and non-ferrous metals, Bhagyalaxmi Industrial guarantees unparalleled high-quality and patron pride. Contact Bhagyalaxmi Industrial nowadays to procure top rate fasteners on the maximum reasonable costs, tailor-made in your unique requirements.

#Nickel Alloy 200 Fasteners Manufacturer#Nickel Alloy 200 Fasteners Supplier#Nickel Alloy 200 Fasteners Stockist#Nickel Alloy 201 Fasteners Exporter#Nickel Alloy 201 Fasteners Dealer

0 notes

Text

Nickel 201 Fasteners Manufacturers in India

#business#manufacturers#Nickel 201 Fasteners#Nickel 201 Fasteners Manufacturers#Nickel 201 Fasteners Exporters

0 notes

Text

Nickel Strips Suppliers in Mumbai

Forged Fittings

Buttweld Fittings

Fastener

Nickel Strips

Nickel Busbars

Round Bar

Pipes & Tubes

Sheets & Plates

Got any Questions? Call us Today!

(022) 67437682

QUICK ENQUIRY

Nickel Strips Manufacturers, Nickel Strips Suppliers, Nickel Strips Stockists, Nickel Strips Exporters

Nickel Strips Manufacturers in India, Nickel Strips Suppliers in India, Nickel Strips Stockists in India, Nickel Strips Exporters in India

Technolloy Inc

#Forged Fittings#Buttweld Fittings#Fastener#Nickel Strips#Nickel Busbars#Round Bar#Pipes & Tubes#Sheets & Plates#Got any Questions?#Call us Today!#(022) 67437682#[email protected]#QUICK ENQUIRY#Name#Email#Phone Number#Message#Nickel Strips Manufacturers#Nickel Strips Suppliers#Nickel Strips Stockists#Nickel Strips Exporters#Nickel Strips Manufacturers in India#Nickel Strips Suppliers in India#Nickel Strips Stockists in India#Nickel Strips Exporters in India#Technolloy Inc

1 note

·

View note

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Monel 400: A Reliable Alloy for Aerospace Fuel & Hydraulic Systems

The aerospace industry demands materials that exhibit exceptional strength, corrosion resistance, and durability under extreme conditions. Monel 400 is one such alloy that has proven to be highly reliable for aerospace fuel and hydraulic systems. Known for its outstanding performance, Alloy 400 Monel is widely used in critical aerospace applications due to its superior mechanical and chemical properties.

Why is Monel 400 Preferred in Aerospace Applications?

Monel 400 (UNS N04400) is a nickel-copper alloy that offers excellent resistance to corrosion, especially in acidic and marine environments. This makes it a suitable choice for aerospace fuel and hydraulic systems, where exposure to harsh conditions is inevitable. Some of the key reasons for choosing Monel 400 bar in aerospace applications include:

High Strength & Durability: Monel 400 has a high tensile strength, making it ideal for withstanding extreme pressure and temperature variations.

Excellent Corrosion Resistance: The alloy exhibits remarkable resistance to oxidation and corrosion, even in highly acidic or alkaline environments.

Thermal Stability: Monel 400 retains its mechanical properties even at elevated temperatures, ensuring reliability in aerospace fuel and hydraulic systems.

Superior Weldability & Machinability: Components made from ASTM B164 N04400 material can be easily welded and machined, allowing for seamless integration into aerospace systems.

Monel 400 Round Bar for Aerospace Applications

One of the most commonly used forms of Monel 400 in aerospace is the Monel 400 round bar. These bars are extensively utilized in the manufacturing of aerospace components due to their robust properties and versatility. Monel 400 round bar suppliers ensure high-quality products that comply with industry standards, making them a preferred choice for aerospace manufacturers.

Applications of Monel 400 in Aerospace

Fuel Systems: Monel 400 is used in aircraft fuel tanks and fuel transport systems due to its exceptional resistance to fuel corrosion.

Hydraulic Lines: The alloy's high-pressure resistance makes it an ideal choice for hydraulic lines and components.

Engine Components: Various engine parts, including valves and fasteners, are made from Monel 400 bar for enhanced durability.

Exhaust Systems: Monel 400’s ability to withstand extreme temperatures makes it useful in exhaust systems and heat exchangers.

Choose the Best Monel 400 Round Bar Suppliers

When sourcing Monel 400 round bar, it is essential to partner with trusted Monel 400 round bar suppliers who offer high-quality materials that meet aerospace industry standards. At Amardeep Steel Centre LLP, we specialize in supplying premium-grade ASTM B164 N04400 bars that adhere to stringent quality norms. Our Monel 400 bars are tested for durability, strength, and corrosion resistance, ensuring reliability in aerospace applications.

Why Choose Amardeep Steel Centre LLP?

Certified and high-quality UNS N04400 materials

Competitive pricing and timely delivery

Custom sizes and specifications available

Global supply network catering to the aerospace industry

Conclusion

Monel 400 continues to be a trusted material for aerospace fuel and hydraulic systems due to its exceptional strength, corrosion resistance, and high-temperature stability. With its UNS N04400 material properties and UNS N04400 chemical composition, Alloy 400 Monel is an optimal choice for critical aerospace applications. If you are looking for high-quality Monel 400 round bar suppliers, Amardeep Steel Centre LLP is your go-to source for premium ASTM B164 N04400 products.

0 notes

Text

MONEL 400 ROUND BARS IN AEROSPACE APPLICATIONS: A DEEP DIVE

Monel 400, an alloy composed primarily of nickel and copper, is renowned for its exceptional resistance to corrosion, especially in high-stress environments. It plays a pivotal role in various industries, including aerospace, due to its remarkable strength, durability, and resistance to seawater and acidic environments. At SMM Industries, we specialize in providing high-quality Monel 400 round bars, which are extensively used in aerospace applications, making them ideal for critical components in aircraft and space vehicles.

The aerospace industry demands materials that can withstand extreme conditions, including high temperatures, pressure, and corrosive environments. Monel 400 round bars meet these requirements with outstanding performance, offering high tensile strength and good weldability. This makes them suitable for manufacturing components such as valves, pumps, and high-performance fasteners used in aircraft engines and structural parts. The alloy’s resistance to saltwater corrosion also makes it a preferred choice for aerospace applications in coastal or marine environments.

Another key attribute of Monel 400 round bars is their ability to perform under extreme temperatures. The alloy can endure both cryogenic and high temperatures without compromising its structural integrity, ensuring reliability and safety in critical aerospace components. Additionally, its resistance to oxidation and scaling at elevated temperatures ensures that the material maintains its mechanical properties even in harsh conditions.

At SMM Industries, our Monel 400 round bars are meticulously crafted to meet the stringent standards of the aerospace industry. We ensure that our products undergo thorough testing for quality control, ensuring they are free from defects and meet the precise specifications required for aerospace applications. Whether it’s for turbine components, pressure vessels, or specialized aircraft parts, our Monel 400 round bars are the trusted solution for manufacturers and engineers looking for superior materials.

The use of Monel 400 in aerospace is not just limited to its mechanical properties. The alloy’s ability to withstand corrosive gases, including sulfur and carbon dioxide, ensures longevity and performance in aircraft systems exposed to the atmosphere. This makes Monel 400 round bars an indispensable part of the aerospace supply chain, particularly in parts exposed to the harsh conditions of flight.

In conclusion, Monel 400 round bars continue to be an essential material in aerospace applications, offering unmatched corrosion resistance, mechanical strength, and performance under extreme conditions. SMM Industries is proud to supply these high-quality round bars, providing aerospace engineers and manufacturers with the material needed for precision-engineered components that meet the most demanding specifications.

For more information on our Monel 400 round bars and their applications in aerospace, feel free to contact SMM Industries today!

To Know More https://www.smmindustriesllp.com/monel-400-round-bar/

0 notes

Text

Jay Steel Corporation is leading manufacturers, suppliers and exporters of Nickel , Titanium and Stainless steel product.

#nuts and bolts manufacturers#stainless steel products#flanges types#steel product manufacturers in india#nickel alloy products#titanium alloy products#fasteners manufacturers#pipe and tube manufacturers#pressure vessel manufacturer#ss fasteners

0 notes

Text

Inconel Fasteners: A Comprehensive Guide

Introduction to Inconel

Inconel is a family of nickel-chromium-based superalloys known for their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. Developed by Special Metals Corporation, Inconel alloys are widely used in aerospace, marine, chemical processing, and power generation industries.

The primary advantage of Inconel is its ability to retain mechanical strength even in high-temperature and corrosive environments. It resists oxidation, carburization, and chloride-induced stress corrosion cracking, making it an ideal material for fasteners used in critical applications.

What Are Inconel Fasteners?

Inconel fasteners are bolts, nuts, washers, screws, and studs made from Inconel alloys. These fasteners are designed to perform in extreme conditions where ordinary steel or stainless steel fasteners would fail. The combination of nickel, chromium, and iron (along with other elements in varying amounts) provides outstanding durability, even in the harshest environments.

Characteristics of Inconel Fasteners

High-Temperature Resistance: Can withstand temperatures exceeding 1000°C.

Corrosion Resistance: Excellent resistance to oxidation, pitting, and crevice corrosion.

Superior Strength: High tensile and yield strength.

Resistance to Creep and Fatigue: Maintains integrity under prolonged exposure to stress and heat.

Non-Magnetic: Some Inconel alloys exhibit non-magnetic properties, making them suitable for specific applications.

Different Types of Inconel Fasteners

1. Inconel Bolts

Hex bolts

Anchor bolts

U-bolts

J-bolts

Stud bolts

2. Inconel Nuts

Hex nuts

Lock nuts

Wing nuts

Flange nuts

Dome nuts

3. Inconel Washers

Flat washers

Spring washers

Belleville washers

Fender washers

4. Inconel Screws

Machine screws

Socket head cap screws

Set screws

Self-tapping screws

5. Inconel Studs

Fully threaded studs

Double-end studs

Tap-end studs

Each type of fastener is available in different grades of Inconel, such as Inconel 600, Inconel 625, Inconel 718, and Inconel 925, depending on the application and environment.

Uses of Inconel Fasteners

1. Aerospace Industry

Used in jet engines, gas turbines, and exhaust systems due to high heat resistance.

2. Marine Industry

Ideal for shipbuilding, offshore drilling platforms, and seawater applications due to exceptional corrosion resistance.

3. Chemical Processing Industry

Used in reactors, heat exchangers, and pressure vessels to withstand harsh chemicals and extreme temperatures.

4. Power Generation

Essential in nuclear reactors, steam turbines, and other high-temperature power generation equipment.

5. Oil and Gas Industry

Used in pipelines, valves, and drilling equipment exposed to high pressure and corrosive fluids.

6. Medical Industry

Applied in medical implants and surgical instruments due to its non-reactive properties.

7. Automotive Industry

Used in high-performance and racing vehicles for exhaust systems and turbocharger components.

Specifications of Inconel Fasteners

Common Standards for Inconel Fasteners

ASTM B166 (Rod and bar)

ASTM B167 (Pipe and tubing)

ASTM B168 (Plate, sheet, and strip)

ASTM F2281 (Bolting materials)

UNS N06600 (Inconel 600)

UNS N06625 (Inconel 625)

UNS N07718 (Inconel 718)

Mechanical Properties of Inconel 625 Fasteners (Example)

Tensile Strength: 930 MPa (135 ksi)

Yield Strength (0.2% Offset): 517 MPa (75 ksi)

Elongation: 50%

Hardness: Rockwell B88

Chemical Composition of Inconel 625

Conclusion

Inconel fasteners are an essential component in industries requiring high-performance fastening solutions. Their ability to resist extreme temperatures, corrosion, and mechanical stress makes them a preferred choice in aerospace, marine, oil and gas, and many other industries.

Ananka Fasteners is a leading manufacturer, supplier, and exporter of Inconel fasteners, offering high-quality products that meet international standards. If you are looking for reliable and durable Inconel fasteners, get in touch with us today!

Frequently Asked Questions (FAQs)

Q1: What makes Inconel fasteners different from stainless steel fasteners?

Inconel fasteners offer superior high-temperature and corrosion resistance compared to stainless steel, making them suitable for extreme environments.

Q2: What is the most commonly used Inconel grade for fasteners?

Inconel 625 and Inconel 718 are the most widely used grades due to their excellent mechanical and chemical properties.

Q3: Are Inconel fasteners expensive?

Yes, Inconel fasteners are more expensive than stainless steel fasteners due to their superior properties and complex manufacturing process.

Q4: Can Inconel fasteners be used in seawater applications?

Yes, Inconel fasteners, especially Inconel 625, are highly resistant to seawater corrosion and are used in marine applications.

Q5: Where can I buy high-quality Inconel fasteners?

You can purchase premium-quality Inconel fasteners from Ananka Fasteners, a trusted manufacturer and supplier in the industry.

#ananka#anankafastenrs#fasteners#fastenersmanufacturer#linkedin#articles#inconel#inconelfasteners#blog#anankafasteners#manufacturer#supplier#mumbai#hex#bolt#usa

0 notes

Text

Nitronic 50 Fasteners Suppliers In India

Introduction:-

Nitronic 50 fasteners are high-strength, corrosion-resistant austenitic stainless steel components widely used in marine, chemical processing, and petrochemical industries. Known for their superior resistance to pitting, crevice corrosion, and stress corrosion cracking, Nitronic 50 (UNS S20910/XM-19) offers excellent mechanical properties even in harsh environments. In India, several reputable suppliers and manufacturers provide high-quality Nitronic 50 fasteners, including bolts, nuts, screws, washers, and studs, catering to diverse industrial needs. Companies such as Prashaant Steel & Alloys, Amigo Impex, Grand Metal Corporation, and Siddhgiri Tubes are well-known for supplying these fasteners with international standards and certifications. When choosing a supplier, factors like material quality, certification, pricing, and delivery reliability should be considered to ensure the best performance and durability.

Product Overview:-

Shasan Piping Solution is a basic Manufacturers and exporters of the ferrous and nonferrous things. We likewise manage the whole family stainless steel and Nitronic 50 and XM 19 Fasteners. We anyway, gathering the changed kind of the thing according to the bearing from the client and course. Nitronic 50 and XM 19 fastener are made with substance sytheses like carbon, nickel, silicon, manganese, chromium, aluminum, and sulfur. These Fasteners are composed with both physical and mechanical properties like assurance, yield strength, enlarging, and silly adaptability, and modulus of progress, warm conductivity, electrical conductivity, and dissolving point also.

These Fasteners are moreover made with the different sorts of terminations like centers, shape, size, thickness, length, width, string methodology, types, finish, application, and surface. These fastener are open in many plans, for example, cold shaped, hot made, bar stock machined, bar stock managing, etc too.

Specifications:-

ASTM: ASTM A 193/194 / ASME SA 193/194

Dimension Standard: DIN, ASTM, BS and all International Standards

Length: 3 mm to 200 mm

Bolt / Screw Size: M3 - M56 | 3/6" to 2" | Custom Sizes

Nuts Size: M02 to M33 | Custom Sizes

Washers Size: M3 - M56 | 3/6" to 2" | Custom Sizes

Benefits:-

ASTM A194 Stainless Steel Grade Nitronic® XM 19 Fastener, Nitronic 50 fastener, Nitronic 50 stainless Steel Fasteners, Nitronic Compound S20910 fastener, Nitronic XM 19 Fasteners, Nitronic XM 19 Screws, Nitronic Combination 1.3964 Fastener, Nitronic 50 Fastener Manufacturers In Mumbai, India. Nitronic 50 and XM 19 fastener are significant in different endeavors and various specialists purposes, for example, arranged making due, gas making due, petrochemicals affiliations, contamination control, paper industry, pound industry, refining, around the sea oil debilitating affiliations, material undertakings, atomic plant, nuclear energy station, heat exchanger, condensers, marine stuff, valves, springs, boat screwing, oil encounters, etc too.

Conclusions:-

Nitronic 50 and XM 19 fastener are made with the mix of formability, handiness, and welding for better persevering through hindrance. These Fasteners have the high strength of the austenitic composites and effectively thought out plan the whole isolating. This general use area s followed, for example, detached disintegrating, stress breaking use, sulfide use, seawater rust, and pitting use. These are the best materials for organizing home mechanical parties and electrical contraptions.

Email Id :[email protected]

Contact Number:-88797-09191

0 notes

Text

How to Choose the Right Washer Material for Your Project

Selecting the right washer material is crucial to ensuring the success of your project. Whether you’re sourcing spring lock washers, fender washers, or hex washers, understanding material properties will help ensure durability and optimal performance. From shim washers to industrial washers, the material choice impacts overall functionality.

Key Factors in Choosing Washer Material:

1. Strength and Durability:

The strength of washers is essential for heavy-duty applications. Carbon steel and alloy steel offer strength, while stainless steel provides corrosion resistance. For high-performance needs, shim washers and machined washers made from these materials are ideal, whether sourced from shim washer manufacturers or a reputable washer manufacturer.

2. Corrosion Resistance:

Washers exposed to harsh environments should be made of materials like stainless steel, brass, or titanium. Sealing washers, wedge lock washers, and fender washers benefit from these materials, ensuring resistance to moisture and corrosive substances. Ogee washers and tab washers also rely on these corrosion-resistant materials for their effectiveness.

3. Temperature Resistance:

For applications exposed to high temperatures, titanium or nickel alloys are best. Conical washers, self-locking washers, and spring lock washers are often made from these materials to maintain stability in extreme conditions.

Popular Washer Types and Their Materials:

Spring Lock Washer: Perfect for vibration resistance, commonly used in machinery and aerospace applications.

Fender Washer: Ideal for distributing load over wide areas, often used in construction or electronics.

Hex Washer: Offers added grip in high-torque situations, ideal for automotive or industrial applications.

Shim Washer: Thin washers used for precise spacing, commonly made from stainless steel or aluminum.

Machined Washer: For precision applications, often made from brass or titanium by specialized washer manufacturers.

Ogee Washer: Used in electrical assemblies, made from materials like brass or stainless steel for high conductivity.

Tab Washer: Prevents loosening, typically used in automotive or industrial washer applications.

Conical Washer: Provides a spring-like effect, suitable for suspension systems in automotive or aerospace industries.

Square Washer: Designed for even load distribution, commonly used in large machinery and construction.

Countersunk Washer: Fits flush with a surface, ideal for applications requiring smooth finishes.

External Tooth Lock Washer: Prevents loosening by biting into the material and the bolt head, often used in fastener applications.

Manufacturing Processes for Washers:

The quality and durability of washers depend on the manufacturing process. Stamping is commonly used for industrial washers, while machining creates precision washers like machined washers and shim washers.

Heat Treatment: Used to enhance washer properties, heat treatment strengthens washers like self-locking washers and wedge lock washers for high-stress environments.

Conclusion:

Choosing the right material for washers is essential for durability and performance. Whether sourcing spring lock washers, fender washers, or hex washers, consider factors like strength, corrosion resistance, and temperature resistance. Understanding the manufacturing process, whether from shim washer manufacturers or washer manufacturers, ensures you select the right product for your project’s success.

#WasherMaterials#ProjectPlanning#DIYProjectTips#ChoosingTheRightMaterial#EngineeringEssentials#HardwareSolutions#WashersForProjects

0 notes

Text

Understanding the Different Grades of Stainless Steel Fasteners Available in South Africa

Stainless metal fasteners are a cornerstone of many industries, presenting unequalled durability, corrosion resistance, and power. Whether you are taking walks in manufacturing, marine engineering, or organization production, choosing the proper grade of chrome steel fastener is critical to ensure the success and durability of your mission.

South Africa, with its numerous industries and specific environmental demanding conditions, has a massive name for wonderful stainless steel fasteners. This blog delves into the right grades of chrome steel fasteners, their fabric houses, and why deciding on the proper grade is critical for numerous programs.

Why Stainless Steel Fasteners Are Essential

Stainless metallic fasteners are prized for their remarkable homes, making them appropriate for a big shape of industries and environments:

Corrosion Resistance: The chromium content fabric cloth in chrome steel office works a passive layer of chromium oxide, presenting fantastic resistance to corrosion and rust.

Strength and Durability: Stainless metal is thought for its capability to stand as much as excessive stress and heavy masses without deforming.

Versatility: Available in various grades, stainless steel fasteners can meet the proper dreams of industries like introduction, marine, vehicle, and manufacturing.

Flanges Bolt, a trusted employer in South Africa, offers a big form of chrome steel fasteners tailor-made to meet those organization desires.

Understanding Stainless Steel Grades

The grade of chrome steel carried out in fasteners is a crucial element in figuring out its overall performance. The choice of grade is based totally upon the software software, environmental situations, and required houses. Here’s a better check a few commonly used grades in South Africa:

1. Grade 304 Stainless Steel

Overview: Grade 304 is the maximum drastically used chrome steel grade for fasteners, presenting splendid corrosion resistance, strength, and affordability.

Material Properties:

Contains 18% chromium and eight% nickel.

Excellent resistance to oxidation and outstanding corrosion.

Suitable for temperatures as a good deal as 870°C.

Applications:

Ideal for stylish-motive applications.

Frequently executed in production, automobile, and meals processing industries.

2. Grade 316 Stainless Steel

Overview: Known because of the reality the “marine grade,” Grade 316 gives superior corrosion resistance, specifically in chloride-rich environments.

Material Properties:

Contains 16% chromium, 10% nickel, and a couple of-3% molybdenum.

Exceptional resistance to pitting and crevice corrosion.

Suitable for immoderate environments, on the facet of marine and chemical processing.

Applications:

Widely applied in marine engineering, chemical plants, and coastal advent.

Perfect for South Africa’s coastal regions wherein salt publicity is immoderate.

3. Grade 410 Stainless Steel

Overview: Grade 410 is a martensitic stainless steel recognised for its immoderate energy and moderate corrosion resistance.

Material Properties:

Contains 11.5-13.5% chromium and minimal nickel.

High tensile electricity however lower corrosion resistance in assessment to 304 and 316.

Ideal for packages requiring electricity over corrosion resistance.

Applications:

Suitable for fasteners in vehicle and aerospace industries.

Used in environments with confined publicity to moisture and corrosive factors.

4. Duplex Stainless Steel Grades

Overview: Duplex stainless steels integrate the homes of austenitic and ferritic stainless steels, supplying outstanding energy and corrosion resistance.

Material Properties:

High chromium (20-28%) and slight nickel raw material (4.5-8%).

Twice the energy of 304 and 316 grades.

Exceptional resistance to pressure corrosion cracking and fatigue.

Applications:

Used in oil and fuel, chemical processing, and marine industries.

Ideal for duties in South Africa’s harsh enterprise environments.

How to Choose the Right Stainless Steel Grade

Selecting the perfect grade of stainless-steel fastener is predicated upon on numerous elements:

Environmental Conditions

Coastal or marine environments: Opt for Grade 316 or Duplex grades for superior corrosion resistance.

Dry or indoor environments: Grade 304 offers notable regular fashionable ordinary usual overall performance at a lower rate.

Strength Requirements

High-strength applications: Consider Grade 410 or Duplex stainless-steel fasteners.

General-motive programs: Grade 304 is commonly sufficient.

Budget Considerations

For charge-sensitive obligations, Grade 304 offers a balance among traditional everyday not unusual average overall performance and affordability.

For prolonged-time charge in harsh conditions, making an investment in Grade 316 or Duplex grades is more low-rate range.

Flanges Bolt allows clients in South Africa to make informed options, ensuring they pick out the right grade for their precise goals.

Industrial Applications of Stainless Steel Fasteners in South Africa

South Africa’s numerous industries rely cautiously on stainless-steel fasteners for critical infrastructure and operations. Here are a few key packages:

1. Marine and Coastal Industries

Shipbuilding, dock introduction, and offshore systems name for fasteners with excessive corrosion resistance.

Grade 316 and Duplex stainless-steel are the well-known alternatives.

2. Construction and Architecture

Stainless metallic fasteners are vital for structural balance and aesthetics in houses, bridges, and architectural designs.

Grade 304 is extensively used for its mixture of energy and fee-effectiveness.

3. Manufacturing and Heavy Industry

Fasteners play a crucial function in assembling machines and tools.

Duplex grades offer the critical power and resistance to position on.

4. Energy Sector

Wind turbines, solar panel mounts, and oil rigs require long lasting and corrosion-resistant fasteners.

Grade 316 and Duplex grades make sure prolonged-lasting common common normal normal typical performance.

Advantages of Stainless Steel Fasteners

Corrosion Resistance: Protects in opposition to rust and degradation, ensuring durability even in harsh environments.

Strength and Durability: Withstands heavy hundreds, excessive temperatures, and mechanical pressure.

Low Maintenance: Reduces repair and opportunity charges, presenting prolonged-time period fee.

Sustainability: Stainless metal is one hundred% recyclable, making it an inexperienced preference.

Versatility: Available in several grades to shape a big shape of programs and industries.

Understanding the high-quality-of-a-kind grades of chrome steel fasteners is critical for deciding on the proper product in your assignment. Whether it’s the corrosion resistance of Grade 316, the energy of Grade 304, or the superior power of Duplex grades, each type offers unique blessings tailor-made to precise packages.

Flanges Bolts, a primary company in South Africa, presents a whole shape of stainless steel fasteners designed to satisfy the desires of industries at a few stages inside the area. By choosing the proper grade, you could ensure the achievement, safety, and sturdiness of your responsibilities in 2025 and beyond.

Invest in notables. Choose chrome steel fasteners that carry out under pressure!

0 notes

Text

Overview of the Properties and Composition of Aluminum Bronze Round Bars

Rajkrupa Metal Industries is one of the High Quality Aluminium Bronze Round Bar Manufacturer In India. We have emerged as the market leader in Aluminium Bronze Round Bar. Because of its superior corporate and technical people skills, Rajkrupa Metal Industries has purposefully positioned itself as a top-tier manufacturer and retailer in the global market for aluminium bronze round bars.

Key Properties of Aluminium Bronze Round Bars

1. High Strength and Hardness:

Aluminium Bronze Round Bars are known for their exceptional strength and hardness, making them suitable for heavy-duty applications. The presence of aluminium and other alloying elements significantly enhances these properties, allowing the material to withstand high mechanical stresses.

2. Excellent Corrosion Resistance:

One of the standout features of Aluminium Bronze is its outstanding resistance to corrosion, particularly in marine environments. The aluminium in the alloy forms a thin, protective oxide layer on the surface, preventing further oxidation and corrosion. This makes Aluminium Bronze Round Bars ideal for use in seawater and other corrosive environments.

3. Good Wear and Abrasion Resistance:

The addition of iron and nickel not only improves strength but also provides excellent wear and abrasion resistance. This makes Aluminium Bronze Round Bars suitable for applications involving heavy friction and wear, such as bearings, bushings, and gears.

4. Superior Thermal and Electrical Conductivity:

While not as high as pure copper, Aluminium Bronze still offers good thermal and electrical conductivity. This property is beneficial in applications where heat dissipation and electrical performance are important, such as in heat exchangers and electrical connectors.

5. Non-Sparking Characteristics:

Aluminium Bronze is non-sparking, which means it doesn’t produce sparks when struck against hard surfaces. This property is critical in environments where flammable gases or liquids are present, making Aluminium Bronze Round Bars a safe choice for use in hazardous locations.

6. Good Machinability and Weldability:

Despite their high strength and hardness, Aluminium Bronze Round Bars can be machined and welded relatively easily. This makes them convenient to work with in manufacturing processes, allowing for the production of complex components with precision.

Composition of Aluminium Bronze Round Bars

Aluminium Bronze is an alloy primarily composed of copper and aluminium, with the aluminium content typically ranging from 5% to 12%. The exact composition can vary depending on the specific grade and intended application. In addition to aluminium, these alloys often contain other elements such as iron, nickel, manganese, and silicon, which enhance specific properties.

- Copper (Cu): The primary element, providing the base for the alloy.

- Aluminium (Al): Typically 5% to 12%, contributing to strength and corrosion resistance.

- Iron (Fe): Enhances hardness and wear resistance.

- Nickel (Ni): Improves strength and resistance to corrosion.

- Manganese (Mn): Adds to the overall strength and durability.

- Silicon (Si): Enhances the alloy's ability to withstand high temperatures.

The combination of these elements results in an alloy that exhibits superior properties compared to pure copper or other copper-based alloys.

Applications of Aluminium Bronze Round Bars

Due to their unique combination of properties, Aluminium Bronze Round Bars find applications in a wide range of industries, including:

- Marine Engineering: Propellers, valve stems, and underwater fasteners.

- Aerospace: Landing gear components and aerospace bushings.

- Oil and Gas: Pump components, valve guides, and offshore drilling equipment.

- Automotive: Heavy-duty bearings and gear components.

- Construction: Structural supports and decorative architectural elements.

Our company, which manufactures with ISO 9001:2015 certification. Aluminium Bronze Round Bar Manufacturer that adheres to International Quality Standard (IQS) is one of the leading manufacturers of aluminum bronze round bars.

Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, corrosion resistance, thermal and electrical conductivity, and other properties. We are also the leading Round bars manufacturer in India.

#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar Manufacturer in India#Aluminium Bronze Round Bar Suppliers#Round bars manufacturer in India

0 notes

Text

The Role of Nickel Alloy Washers in Enhancing Mechanical Performance

Common performance and dependability in mechanical systems are largely determined by the quality of the components used. Nickel alloy washers are key in improving mechanical performance, sturdiness, and protection. At Fasteners & Fixtures LLP, we specialize in exceptional fasteners, including alloy 20 washers, ensuring top-notch performance for industries international. As an ISO-licensed organisation, we adhere to stringent requirements for sturdiness, corrosion resistance, and high-temperature balance.

What Are Nickel Alloy Washers?

Nickel alloy or carpenter washers are crafted from nickel blended with metals like chromium, molybdenum, and iron, imparting terrific corrosion resistance and strength. These washers assist steady fasteners, distribute masses lightly, and save you ground harm. Industries such as aerospace, cars, electricity, and chemical processing rely upon these washers, wherein durability and precision are important.

We manufacture nickel alloys or carpenter washers using modern-day techniques. Our washers are designed for reliable, general performance inside the most demanding environments.

Why Are Nickel Alloy Washers Critical for Mechanical Performance?

1. Superior Corrosion Resistance

One of the standout capabilities of Alloy 20 washers is their corrosion resistance. Unlike metallic washers, they excel in environments exposed to moisture, chemical compounds, and excessive climate. These washers are pleasant for industries including oil and gas, marine, and chemical processing, wherein corrosion can compromise tool integrity.

Inconel and Monel alloys, often utilized in those washers, provide long-lasting safety in opposition to rust, minimizing preservation and growing the life of the equipment.

2. High-Temperature Stability

Mechanical structures regularly perform in excessive-temperature situations, which could motivate deformation and failure. Nickel alloy washers are engineered to maintain their structural integrity under severe warmth. They perform continuously in excessive-temperature environments, maintaining fasteners stable in crucial sectors like aerospace, auto, and electricity plants.

By the usage of those washers, you put off problems inclusive of expansion, contraction, and thermal distortion of fasteners, ensuring the equipment features optimally even in intense warm temperatures.

3. Durability and Strength

Alloy 20 washers offer exceptional power and sturdiness, making them perfect for heavy-duty programs. They can face up to excessive pressures without deformation or failure, ensuring the reliability of machinery in industries like production, mining, and vehicles.

By assisting fasteners with their energy, the washers reduce the need for common replacements and ensure the sturdiness of the machine.

4. Enhanced Mechanical Performance

These washers distribute the load of fasteners equally, preventing floor damage and securing fasteners in the area for longer durations. This reduces the danger of loosening and enables keeping away from issues like galling. Additionally, nickel alloy washers soak up vibrations, contributing to smoother operation and improving device efficiency.

By minimizing vibrations, those washers prevent excessive wear and tear, making them ideal for immoderate vibration environments like automobile engines or strength plants.

Case Study: Aerospace Industry

Challenge: An aerospace manufacturer struggled with fastener failures of their turbine engines due to immoderate temperatures and vibrations, inflicting premature washing gadgets wear and costly protection.

Solution: We furnished nickel alloy washers crafted from Inconel 718, regarded for their warmth resistance and strength, to face as much as intense conditions.

Outcome: Switching to Inconel 718 washers substantially reduced protection downtime and disasters. The washers’ sturdiness in excessive temperatures and vibrations stepped up the reward turbine engine's performance and decreased operational fees.

Why Fasteners & Fixtures LLP is Your Trusted Partner for Nickel Alloy Washers

We pride ourselves on our ISO certification, making sure our products meet the very exceptional requirements. Our production unit in Navi Mumbai follows strict control over the approaches to supply washers that exceed agency expectations. Here’s why we stand out:

1. Quality Assurance

All nickel alloy washers go through rigorous testing to ensure strength, sturdiness, and corrosion resistance. We use tremendous substances from relied-on providers, making sure every washer is built to the very last.

2. Customization

We offer custom solutions tailored to your precise requirements, whether or not you want specialised alloys or sizes for particular programs.

3. Competitive Pricing

We offer carpenter washers at competitive expenses without compromising on satisfaction, supplying outstanding value to your funding.

4. Timely Delivery

Our efficient production method and robust delivery chain ensure well-timed transport, supporting you to avoid undertaking delays.

5. Client Testimonials

Our clients take delivery of as actual with us for our steady satisfactory and overall performance. Here’s what certainly one of our happy customers says:

"Fasteners & Fixtures LLP has been our cross-to supplier for first-rate nickel alloy washers. Their products consistently exceed our expectations, mainly in important aerospace responsibilities." – Aerospace Industry Client

Conclusion: Enhance Mechanical Performance with Nickel Alloy Washers from Us

In conclusion, nickel alloy washers provide awesome benefits for mechanical performance. From corrosion resistance to immoderate-temperature stability and durability, these washers are engineered to carry out even within harsh environments. At Fasteners & Fixtures LLP, we provide alloy 20 washers that meet the best agency standards.

As an ISO-licensed manufacturer, we ensure our fasteners deliver exceptional performance, reliability, and durability. Choose us for all your nickel alloy washer wishes and experience the difference in great service.

0 notes