#inconelfasteners

Explore tagged Tumblr posts

Text

Inconel 625: Properties, Applications, and Advantages

Introduction

Inconel 625 is a superalloy nickel-based metal created by Special Metals Corporation that is highly prized for its exceptional mechanical strength, corrosion resistance, and stability in harsh environments. No matter how it is exposed to high temperatures, aggressive chemicals, or sea environments, Inconel 625 always produces a worthwhile outcome. Its broad scope of properties has made it a favorite in top industries such as aerospace, chemical processing, marine engineering, oil & gas, and nuclear power.

In this comprehensive guide, we will explore:

The chemical composition of Inconel 625

Its key properties and benefits

Industrial applications

A comparative analysis with other materials

Considerations for machining and welding

Chemical Composition of Inconel 625

The high performance of the alloy results from its carefully designed chemical composition. Inconel 625 is mainly made up of Nickel, Chromium, Molybdenum, and Niobium, supplemented by trace elements that enhance its performance in adverse conditions.

Key Properties and Characteristics of Inconel 625

1. High-Temperature Strength

Maintains structural integrity up to 1800°F (982°C)

Excellent creep resistance and stress rupture strength in prolonged high-heat conditions

2. Superior Corrosion Resistance

Withstands oxidation and corrosion in aggressive environments such as:

Seawater

Acids (sulfuric, nitric, hydrochloric)

Chloride-containing environments

Ideal for offshore and chemical processing environments

3. Fatigue and Wear Resistance

High fatigue strength under cyclic loading

Outstanding erosion and abrasion resistance, even in turbulent or corrosive flow environments

4. Excellent Weldability and Fabrication

Welds readily using TIG, MIG, and laser techniques

Post-weld heat treatment is usually not necessary

Maintains mechanical properties across the welded zone

Applications of Inconel 625

Inconel 625’s ability to handle extreme stress, heat, and corrosion makes it a staple in various industries:

Aerospace Industry

Jet engine parts including exhaust ducts, turbine blades, and seals.

Rocket motor casings and fuel line systems

Heat shielding for high-temperature zones

Chemical Processing

Heat exchangers, transfer piping, and reactor vessels

Handling of acidic or oxidizing chemicals in process equipment

Marine & Offshore Engineering

Subsea valves, pumps, and fasteners

Propeller shafts, risers, and seawater handling components

Oil & Gas Sector

Downhole tubing, wellhead parts, and separation systems

High-pressure, high-temperature (HPHT) equipment

Nuclear Power Plants

Core containment, steam lines, and radiation shielding

Long-lasting reliability in radioactive and high-temperature environments

Advantages Over Other Materials

When comparing Inconel 625 to popular alternatives like Stainless Steel (316L) and Titanium (Grade 5), it consistently outshines in extreme environments:

Inconel 625 is superior where strength, corrosion resistance, and temperature stability cannot be compromised. Although more costly, it reduces long-term maintenance and enhances system life.

Machining and Welding Considerations

Machining Tips

Use carbide or ceramic tools to handle its abrasiveness

Adopt low cutting speeds and high feed rates to reduce work hardening

Apply high-pressure coolant systems to prevent overheating

Welding Guidelines

TIG welding is ideal for precision and strength

Inconel 625 filler material should always be used to preserve optimal corrosion resistance.

Post-weld heat treatment is optional but may be beneficial in stress-relief applications

Conclusion

Inconel 625 is a robust superalloy specifically designed for high-demand environments that push regular material to its limits. Its strong resistance to corrosion, heat, and fatigue makes it an indispensable material in industries where performance and reliability are paramount. Though its initial price tag is higher, its longer lifespan, minimal maintenance, and higher performance easily offset the cost.

Final Thoughts

If your application demands a material that can endure high stress, resist corrosive chemicals, or perform at extreme temperatures, Inconel 625 is one of the most dependable choices available. Its properties allow engineers and designers to push the boundaries of innovation and safety.

#ananka#anankafasteners#inconel#inconelfasteners#fasteners#fastenersmanufacturer#manufacturing#articles#blog#advantages#inconel625#inconelbolts#inconelnut#manufacturer#supplier#mumbai#blog tumblr#tumblr

0 notes

Text

Choose Right Fasteners for Your Project

Aashish Steel is a reputable manufacturer, supplier, and exporter of stainless steel Inconel Fasteners Manufacturer in India. Stainless steel Inconel Fasteners Manufacturer in India are adaptable goods that fall under various requirements and classifications. Aashish Steel is a leading Monel Fastener Manufacturer in India. Monel Fasteners are versatile items that come in a variety of specifications and categories. We are also the leading Bolt Supplier in Ludhiana and Bolt Supplier in Ahmedabad.

Types of Fastener

Stainless Steel Fasteners

One of the greatest and most reputable Stainless Steel Fasteners Manufacturers in India is Aashish Steel. Stainless steel fasteners are adaptable goods that are available in a range of standards and classifications. One of the things we produce is stainless steel fasteners, such as stainless steel bolts, nuts, screws, washers, and other fasteners. Fasteners made of stainless steel are excellent at resisting corrosion, therefore they are unaffected in industrial situations. It is resistant to dangerous substances like phosphoric acid, sulfuric acid, and chlorine.

Hastelloy Fasteners

Aashish Steel is a top Hastelloy Fastener Manufacturer in India. Hastelloy Fasteners are versatile items that come in a variety of specifications and categories. Hastelloy Bolts, Hastelloy Nuts, Hastelloy Screws, Hastelloy Washers, and other Hastelloy Fasteners are manufactured by us. Hastelloy fasteners have exceptional corrosion resistance, allowing them to function normally in industrial settings. It's resistant to chlorine, sulfuric acid, phosphoric acid, and other potentially harmful chemicals.

Monel Fasteners

One of the top Monel Fasteners in Manufacturers India is Aashish Steel. Monel Fasteners are adaptable goods that are available in a wide range of standards and classifications. Among the products we produce are Monel Bolts, Monel Nuts, Monel Screws, Monel Washers, and other Monel Fasteners.

We produce all grades of Monel fasteners in compliance with national and international standards. The most demanding goods in the chemical processing business, marine water supply industries, pulp and paper industry, petrochemical industry, desalination plant, aerospace, oil and gas refineries, and other industries are Monel fasteners. We produce all Monel Fasteners in accordance with customer specifications.

Specification of Inconel Fasteners :

Specifications: ASTM / ASME SB 160 / 164 / 166 / 425 /446 / 574 / 472

Standard: ASTM / ASME

Length: UPTO 1 METRE

Size: M10 TO M100

Type: Nuts, Bolts, Screws, Sockets, Studs, Screw, Hex Set Screw, Socket Screw, Cap Screw, Pan Head Screw, Machine Screw, Socket Head Cap Screw, Allen Cap screw, Wing Screw, Washers, Spring Washers, Studs, Anchors, Marine Anchors, Nut, Hexagon Nut, Hex Nut, Hex Coupling Nut, Hex Domed Cap Nuts, Square Nut, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolt, U-bolts, J-bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Wing Screw, Eye Bolt, Foundation Bolts, and Structural Bolts

Application & Uses Of Inconel Fasteners

Inconel Fasteners used in Petroleum Industry

Hex Nut used in Aerospace Industry

Square Nut used in Chemical Industry

Dome Nut used in oil & Gas Industry

Nylock Nut used in Nuclear Energy Sector

Wing Nut used in Automotive Industries

Visit: asnutbolt.com

0 notes

Text

Inconel Fasteners

Solitaire Overseas Is One Of The Leading Suppliers Of Inconel Fasteners. Our Focus Is To Deliver Best & Vast Varieties Of Alloy Products And Excellent Services As Per Industry Standards To Fulfil The Applications Demands.

https://www.inconelpipestube.com/inconel-fasteners/

0 notes

Text

Monel 400: A Comprehensive Guide

Introduction to Monel 400

Monel 400 is a durable nickel-copper alloy recognized for its outstanding corrosion resistance and superior strength. It is widely used in marine, chemical, and aerospace industries due to its outstanding properties. The alloy is composed primarily of nickel (around 67%) and copper (about 23%), with trace amounts of iron, manganese, carbon, and silicon. This unique composition gives Monel 400 superior resistance to harsh environments, making it a preferred choice for various applications.

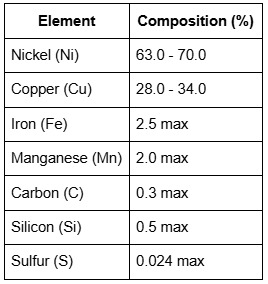

Chemical Composition of Monel 400

The high nickel and copper content makes Monel 400 an excellent choice for extreme environments where high resistance to acids, alkalis, and seawater is required.

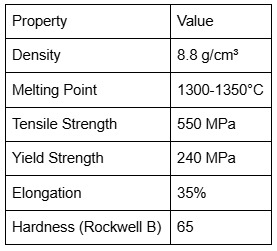

Mechanical Properties of Monel 400

These mechanical properties indicate that Monel 400 offers excellent strength and ductility, making it suitable for both high-temperature and cryogenic applications.

Key Characteristics of Monel 400

Corrosion Resistance: Excellent resistance to seawater, hydrofluoric acid, sulfuric acid, and alkaline solutions.

High Strength: Retains strength across a broad temperature range.

Good Ductility: Can be easily fabricated, machined, and welded.

Thermal Stability: Performs well under extreme temperatures.

Magnetic Properties: Slightly magnetic at room temperature.

Applications of Monel 400

Due to its superior properties, Monel 400 is extensively used in:

1. Marine Industry

Shipbuilding

Submarine parts

Heat exchangers

Seawater piping

2. Aerospace Industry

Aircraft fuel tanks

Engine components

Hydraulic lines

3. Chemical Processing Industry

Pumps and valves

Heat exchangers

Chemical storage tanks

4. Oil and Gas Industry

Offshore drilling components

Pipeline systems

Valves and pumps

5. Power Generation

Nuclear and fossil fuel power plants

Boiler feedwater heaters

Advantages of Monel 400

Exceptional corrosion resistance in harsh environments

High tensile strength and durability

Good machinability and weldability

Superior resistance to high-temperature oxidation

Long lifespan and reliability

Disadvantages of Monel 400

Expensive compared to other alloys

Challenging to machine due to high strength and work-hardening nature

Limited availability in some forms and sizes

Monel 400 vs. Other Alloys

Monel 400 vs. Stainless Steel

Monel 400 has superior corrosion resistance in marine and acidic environments.

Stainless steel is generally more affordable and readily accessible.

Monel 400 exhibits better performance in high-temperature applications.

Monel 400 vs. Inconel

Inconel offers better oxidation resistance at extreme temperatures.

Monel 400 is better suited for seawater and acidic conditions.

Inconel is used for aerospace applications due to its high-temperature performance.

Conclusion

Monel 400 is a premium nickel-copper alloy with remarkable corrosion resistance, high strength, and excellent durability. Its widespread use in marine, chemical, and aerospace industries is a testament to its outstanding properties. While it may be more expensive and challenging to machine than other materials, its long-term performance and reliability make it a valuable choice for demanding applications.

Frequently Asked Questions (FAQ)

1. What makes Monel 400 corrosion-resistant?

Monel 400's high nickel and copper content provide exceptional resistance to seawater, acids, and alkaline solutions.

2. Can Monel 400 be welded?

Yes, Monel 400 can be welded using gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and gas metal arc welding (GMAW) methods.

3. Is Monel 400 magnetic?

Monel 400 is slightly magnetic at room temperature due to its nickel content.

4. What is the temperature range of Monel 400?

Monel 400 can operate in temperatures ranging from cryogenic levels up to approximately 1000°F (538°C).

5. Is Monel 400 suitable for seawater applications?

Yes, Monel 400 is widely used in marine environments due to its excellent resistance to seawater corrosion.

#ananka#anankafasteners#monel#monelfasteners#articles#blog#monel400#monel500#inconel#inconelfasteners#inconelbolts#manufacturer#fasteners#supplier#mumbai#bolt#tumblr#blog tumblr

0 notes

Text

Inconel 600: Properties, Applications, and Benefits

Introduction to Inconel 600

Inconel 600 is a nickel-chromium alloy known for its superior resistance to oxidation and corrosion at high temperatures. This alloy is widely used in industries requiring high strength and excellent corrosion resistance in extreme environments, such as aerospace, chemical processing, and nuclear reactors. With its unique chemical composition, Inconel 600 exhibits remarkable mechanical properties and oxidation resistance, making it one of the most sought-after alloys in high-performance applications.

Chemical Composition of Inconel 600

Inconel 600 is primarily composed of nickel, with substantial amounts of chromium and iron to enhance its resistance to various corrosive conditions. The typical composition includes:

Nickel (Ni): 72.0% minimum

Chromium (Cr): 14.0 - 17.0%

Iron (Fe): 6.0 - 10.0%

Carbon (C): 0.15% max

Manganese (Mn): 1.0% max

Silicon (Si): 0.5% max

Sulfur (S): 0.015% max

Copper (Cu): 0.5% max

This composition provides Inconel 600 with remarkable stability across a wide range of temperatures and chemical exposures.

Mechanical Properties of Inconel 600

Inconel 600 maintains excellent mechanical strength across a wide temperature range. Some of its key mechanical properties include:

Density: 8.47 g/cm³

Melting Point: 1354-1413°C (2470-2575°F)

Tensile Strength: 550 MPa (80,000 psi)

Yield Strength (0.2% Offset): 240 MPa (35,000 psi)

Elongation: 30%

Hardness: Rockwell B80

Key Characteristics of Inconel 600

High-Temperature Resistance: Inconel 600 performs exceptionally well at temperatures up to 1093°C (2000°F), maintaining strength and oxidation resistance.

Corrosion Resistance: Excellent resistance to oxidation, carburization, and chloride-ion stress-corrosion cracking.

Good Mechanical Strength: Maintains its integrity in extreme environments, making it ideal for high-stress applications.

Non-Magnetic: Inconel 600 remains non-magnetic under most conditions, adding to its versatility.

Resistant to Organic and Inorganic Compounds: Effectively withstands attacks from acids, alkalis, and other corrosive substances.

Applications of Inconel 600

Due to its outstanding properties, Inconel 600 is used in various industries, including:

Aerospace Industry: Used in jet engine components, exhaust liners, and turbine blades.

Chemical and Petrochemical Processing: Heat exchangers, distillation columns, and piping systems handling aggressive chemicals.

Power Generation and Nuclear Industry: Steam generators, reactor components, and heat shields.

Heat Treatment Equipment: Retorts, baskets, and furnace components that require resistance to high-temperature oxidation.

Marine Industry: Components exposed to saltwater and high-temperature environments.

Food Processing: Equipment used in high-temperature food processing and sterilization.

Benefits of Using Inconel 600

Enhanced Longevity: Withstands harsh conditions, reducing maintenance and replacement costs.

Improved Performance in Extreme Environments: Ideal for high-temperature and corrosive applications.

Versatile in Various Industries: Suitable for aerospace, nuclear, chemical, and marine sectors.

Superior Mechanical Strength: Maintains structural integrity even under heavy stress and thermal cycling.

Excellent Weldability: Can be welded using standard welding methods without losing its properties.

Conclusion

Inconel 600 is a highly versatile and durable alloy with superior resistance to heat and corrosion. Its applications span across various industries where high performance is essential. Whether in aerospace, power generation, or chemical processing, Inconel 600 ensures reliability and longevity. Investing in this alloy means enhanced efficiency and durability, making it a preferred choice for critical applications.

Frequently Asked Questions (FAQs)

1. How does Inconel 600 compare to stainless steel?

Inconel 600 has higher nickel content, making it more resistant to extreme temperatures and corrosion compared to stainless steel.

2. Can Inconel 600 be welded easily?

Yes, Inconel 600 has excellent weldability and can be welded using conventional welding techniques like TIG and MIG.

3. Is Inconel 600 resistant to acid attacks?

Yes, Inconel 600 resists strong acids such as hydrochloric, sulfuric, and nitric acids, making it ideal for chemical processing.

4. What industries use Inconel 600 the most?

Aerospace, nuclear, chemical, marine, and power generation industries commonly use Inconel 600 for its high performance.

5. Is Inconel 600 magnetic?

No, Inconel 600 is non-magnetic, making it suitable for applications requiring non-magnetic properties.

Inconel 600 continues to be a preferred material for demanding applications due to its unmatched properties and performance. If you're looking for a material that can handle high temperatures and aggressive environments, Inconel 600 is the ideal choice.

#inconel#inconelfasteners#fasteners#articles#inconel600#manuafacturing#blog#trending#blogging#ananka#anankafasteners#manufacturer#supplier#mumbai#bolt#tumblr blog

0 notes

Text

Inconel 625 Fasteners: Manufacturer, Supplier & Exporter

Introduction to Inconel 625 Fasteners

Inconel 625 fasteners are high-performance fastening components made from a nickel-based superalloy known for its exceptional strength, corrosion resistance, and heat tolerance. Developed to withstand the most extreme environments, these fasteners are extensively used in industries that demand superior mechanical properties and durability. The unique combination of nickel, chromium, molybdenum, and niobium provides excellent oxidation resistance and protects against pitting, crevice corrosion, and stress corrosion cracking.

Unlike conventional stainless steel fasteners, Inconel 625 fasteners maintain their structural integrity even in aggressive conditions, such as high-pressure, high-temperature, and seawater-exposed environments. Their ability to resist deformation under extreme stress makes them the preferred choice for aerospace, marine, chemical processing, power generation, and oil & gas applications.

Properties of Inconel 625 Fasteners

Inconel 625 is a nickel-based superalloy known for its outstanding properties, including:

High Corrosion Resistance: Excellent resistance to oxidation and corrosion in a wide range of temperatures.

Exceptional Strength: High tensile, yield, and fatigue strength.

Heat Resistance: Withstands extreme temperatures up to 982°C (1800°F).

Good Weldability: Can be welded without the risk of sensitization and post-weld cracking.

Oxidation Resistance: Maintains stability even in highly oxidizing environments.

Chemical Composition of Inconel 625

The primary chemical composition of Inconel 625 includes:

Mechanical Properties of Inconel 625

Applications of Inconel 625 Fasteners

Due to its remarkable properties, Inconel 625 fasteners are used in various industries, including:

Aerospace Industry: Used in aircraft exhaust systems, turbine seals, and engine thrust-reverser systems.

Marine Industry: Ideal for seawater applications, including propeller blades and submarine fittings.

Chemical Processing: Withstands highly acidic environments, making it suitable for heat exchangers and reactors.

Power Generation: Used in nuclear reactors and gas turbines.

Oil & Gas Industry: Suitable for high-temperature and high-pressure applications.

Types of Inconel 625 Fasteners

Inconel 625 Bolts

Inconel 625 Nuts

Inconel 625 Washers

Inconel 625 Stud Bolts

Inconel 625 Screws

Inconel 625 Threaded Rods

Advantages of Inconel 625 Fasteners

High resistance to oxidation and corrosion

Excellent strength and durability

Superior thermal stability

Non-magnetic and highly versatile

Long service life in extreme environments

Why Choose Ananka Group for Inconel 625 Fasteners?

Ananka Group is a leading manufacturer, supplier, and exporter of Inconel 625 fasteners. We offer:

High-Quality Products: Manufactured using premium-grade raw materials.

Customization: Available in different sizes, standards, and coatings.

Global Supply: Exporting to various countries worldwide.

Competitive Pricing: Cost-effective solutions for industries.

Conclusion

Inconel 625 fasteners are an excellent choice for industries requiring extreme strength, corrosion resistance, and high-temperature performance. Their superior properties make them a go-to solution for aerospace, marine, chemical, and power industries. If you are looking for high-quality Inconel 625 fasteners, Ananka Group is your trusted partner.

FAQs

1. What makes Inconel 625 fasteners different from other fasteners?

Inconel 625 fasteners offer superior corrosion resistance, high strength, and excellent heat resistance compared to stainless steel and other alloys.

2. Are Inconel 625 fasteners suitable for seawater applications?

Yes, Inconel 625 fasteners are ideal for marine and seawater applications due to their excellent resistance to saltwater corrosion.

3. Can Inconel 625 fasteners be welded?

Yes, Inconel 625 has excellent weldability and can be welded without the risk of cracking or sensitization.

4. What industries use Inconel 625 fasteners the most?

Industries such as aerospace, marine, chemical processing, power generation, and oil & gas widely use Inconel 625 fasteners.

5. Does Ananka Group supply Inconel 625 fasteners globally?

Yes, Ananka Group is a global supplier and exporter of Inconel 625 fasteners, catering to various industries worldwide.

#ananka#anankafasteners#articles#blog#inconel#inconelfasteners#inconel625#fasteners#fastenersmanufacturer#exporter#manufacturer#supplier#mumbai#hex#bolt#tumblr#tumblr blog

0 notes

Text

Inconel 718: A High-Performance Nickel Alloy for Extreme Applications

Introduction

Inconel 718 is a precipitation-hardened nickel-chromium alloy known for its exceptional strength, corrosion resistance, and high-temperature performance. It is widely used in aerospace, marine, and industrial applications where extreme environments demand superior material properties. This blog explores the characteristics, applications, advantages, and specifications of Inconel 718 fasteners and components.

Characteristics of Inconel 718

Inconel 718 possesses remarkable properties that make it a preferred choice in various industries:

High Strength and Durability: This alloy maintains outstanding mechanical properties at temperatures ranging from cryogenic levels to 1300°F (704°C).

Corrosion and Oxidation Resistance: It resists corrosion in harsh environments, including acidic and high-temperature conditions.

Excellent Weldability: Unlike other nickel-based alloys, Inconel 718 can be readily welded without post-weld cracking.

Creep Resistance: It maintains stability under prolonged stress and high temperatures.

Non-Magnetic: This makes it suitable for applications where magnetic interference must be minimized.

Applications of Inconel 718

Due to its superior properties, Inconel 718 is used in multiple industries, including:

Aerospace Industry:

Jet engine components

Turbine blades

Exhaust systems

Fasteners and bolts

Marine Industry:

Submarine components

Offshore drilling equipment

Propeller shafts

Oil & Gas Sector:

Downhole tubing

High-pressure valves

Heat exchangers

Power Generation:

Gas turbines

Nuclear reactors

Automotive & Motorsport:

Turbochargers

Exhaust manifolds

Advantages of Inconel 718 Fasteners

Inconel 718 fasteners, such as bolts, nuts, and washers, provide significant advantages in demanding applications:

Withstand extreme temperatures and pressures

Prevent galling and seizing in high-stress environments

Maintain mechanical integrity in corrosive and oxidizing conditions

Reduce maintenance costs due to prolonged service life

Chemical Composition of Inconel 718

Mechanical Properties of Inconel 718

Inconel 718 Fasteners Standards and Specifications

Conclusion

Inconel 718 is an exceptional alloy that meets the demands of high-performance industries. Its superior strength, corrosion resistance, and high-temperature capabilities make it ideal for aerospace, marine, oil & gas, and power generation applications. Inconel 718 fasteners offer reliability and longevity, ensuring structural integrity in the harshest conditions. If you're looking for durable and high-quality fasteners, Inconel 718 is a premium choice for your needs.

FAQs

Q1: What is Inconel 718 used for?A: Inconel 718 is used in aerospace, marine, oil & gas, and power generation applications due to its high strength and corrosion resistance.

Q2: Is Inconel 718 better than stainless steel?A: Yes, Inconel 718 offers superior strength, heat resistance, and corrosion resistance compared to standard stainless steel.

Q3: Can Inconel 718 be welded?A: Yes, Inconel 718 has excellent weldability and can be welded without post-weld cracking.

Q4: What is the temperature range for Inconel 718?A: It retains its mechanical properties from cryogenic temperatures up to 1300°F (704°C).

Q5: Where can I buy Inconel 718 fasteners?A: You can purchase Inconel 718 fasteners from reputable manufacturers, suppliers, and stockists specializing in high-performance alloys.

#inconel#inconelfasteners#inconel718#grade#gradematerial#blog#articles#nicklealloy#nickle#inconelgrade#ananka#anankafasteners#manufacturer#fasteners#supplier#mumbai#bolt#tumblr#blog tumblr

0 notes

Text

Inconel 600: A Comprehensive Guide to Properties, Applications, and Benefits

Introduction

Inconel 600 is a high-performance nickel-chromium-iron alloy known for its exceptional resistance to high temperatures and corrosion. This superalloy is widely utilized in extreme environments where conventional stainless steels and other materials fail. Inconel 600 fasteners, such as bolts, nuts, screws, and washers, play a critical role in various industries, ensuring durability and strength under challenging conditions. This detailed blog explores the properties, chemical composition, mechanical characteristics, applications, and benefits of Inconel 600 fasteners.

What is Inconel 600?

Inconel 600 is a non-magnetic, oxidation-resistant alloy with superior strength and corrosion resistance. It was developed to withstand extreme conditions, such as high temperatures and aggressive chemical environments, making it one of the most sought-after materials in industrial applications. The alloy's ability to maintain mechanical properties over a broad temperature range (cryogenic to 2000°F or 1093°C) makes it ideal for demanding engineering projects.

Key Characteristics of Inconel 600

Exceptional High-Temperature Resistance: It retains its mechanical properties at elevated temperatures and does not succumb to thermal degradation.

Superior Corrosion Resistance: Highly resistant to oxidation, carburization, and chloride-ion stress corrosion cracking, even in acidic and alkaline environments.

Outstanding Mechanical Strength: The alloy maintains high tensile strength and durability, even under prolonged exposure to high heat and pressure.

Non-Magnetic: Inconel 600 remains non-magnetic even after exposure to extreme conditions.

Good Fabricability: It can be welded, machined, and formed into complex shapes with ease.

Chemical Composition of Inconel 600

The unique composition of Inconel 600 contributes to its superior resistance and performance:

Nickel (Ni): 72% min – Enhances corrosion resistance and strength.

Chromium (Cr): 14-17% – Provides oxidation and corrosion resistance.

Iron (Fe): 6-10% – Adds mechanical stability and strength.

Manganese (Mn): 1% max – Improves workability.

Carbon (C): 0.15% max – Enhances hardness and strength.

Silicon (Si): 0.5% max – Increases oxidation resistance.

Sulfur (S): 0.015% max – Minimizes impurity levels.

Copper (Cu): 0.5% max – Enhances corrosion resistance.

Mechanical Properties of Inconel 600

Inconel 600 fasteners are valued for their robust mechanical characteristics:

Tensile Strength: 550 MPa (80,000 psi)

Yield Strength (0.2% Offset): 240 MPa (35,000 psi)

Elongation: 30%

Hardness: 85 HRB

Types of Inconel 600 Fasteners

Bolts: Includes hex bolts, carriage bolts, U-bolts, and eye bolts.

Nuts: Options include hex nuts, lock nuts, flange nuts, and wing nuts.

Washers: Includes flat washers, spring washers, and fender washers.

Screws: Includes socket head cap screws, machine screws, and self-tapping screws.

Studs: Includes threaded rods, double-end studs, and single-end studs.

Applications of Inconel 600 Fasteners

Due to their excellent performance characteristics, Inconel 600 fasteners are widely used in several industries:

Aerospace Industry: Used in jet engines, gas turbines, and exhaust systems where high heat and stress are present.

Chemical Processing: Essential for heat exchangers, reactors, and processing equipment exposed to harsh chemicals.

Marine Industry: Highly resistant to seawater corrosion, making them ideal for marine applications.

Power Generation: Found in nuclear reactors, steam generators, and boiler components due to their heat and corrosion resistance.

Food Processing Equipment: Used in industrial food processing systems that handle acidic and corrosive substances.

Electronics & Automotive: Utilized in specialized automotive components and electrical connectors requiring extreme durability.

Advantages of Inconel 600 Fasteners

Long Service Life: Their superior strength and corrosion resistance significantly reduce maintenance and replacement costs.

Exceptional Thermal Stability: Performs well under extreme heat conditions, making them ideal for high-temperature applications.

Excellent Corrosion Resistance: Protects against oxidation, acids, and alkalis, making them ideal for aggressive environments.

Lightweight & High Strength: Offers a high strength-to-weight ratio, ensuring efficiency in demanding applications.

Versatility: Suitable for use in diverse industries, from aerospace to chemical processing.

Why Choose Ananka Group for Inconel 600 Fasteners?

Ananka Group is a trusted manufacturer and supplier of Inconel 600 fasteners, providing premium-quality products engineered for superior performance. We ensure our fasteners meet international standards and specifications, catering to a broad spectrum of industrial applications. Our fasteners are available in various sizes, coatings, and customized designs to meet specific requirements.

Our Offerings:

High-quality Inconel 600 fasteners with precise engineering

Compliance with ASTM, ASME, DIN, and other international standards

Customization options for different industrial applications

Competitive pricing and fast delivery worldwide

Conclusion

Inconel 600 fasteners are the preferred choice for industries that require high-performance materials capable of withstanding extreme heat, pressure, and corrosive environments. Their exceptional mechanical and chemical properties make them indispensable for applications in aerospace, marine, chemical processing, and power generation. Choosing a reputable supplier like Ananka Group ensures that you get premium quality fasteners tailored to your needs, offering durability, reliability, and long-term performance.

FAQs

1. What makes Inconel 600 different from stainless steel?Inconel 600 contains a higher nickel content, making it more resistant to heat and corrosion than stainless steel.

2. Are Inconel 600 fasteners suitable for high-pressure applications?Yes, they are widely used in high-pressure and high-temperature environments like nuclear reactors and chemical processing plants.

3. Can Inconel 600 fasteners be customized?Yes, manufacturers like Ananka Group provide customized fasteners in various sizes, coatings, and specifications.

4. How do Inconel 600 fasteners compare to Inconel 625?While both offer excellent corrosion and heat resistance, Inconel 625 has higher strength and better resistance to pitting and crevice corrosion.

5. Where can I buy high-quality Inconel 600 fasteners? Ananka Group offers premium-grade Inconel 600 fasteners tailored to industrial needs, ensuring top performance and reliability.

#Inconel#inconelfasteners#inconel600#inconel625#ananka#anankafasteners#fasteners#grade#highnickle#nicklefasteners#manufacturer#blog#articles#supplier#mumbai#blog tumblr#tumblr#tumblr blog

0 notes

Text

High Nickel Fasteners Manufacturer & Supplier Worldwide

Introduction to High Nickel Fasteners

High Nickel Fasteners are known for their excellent corrosion resistance, high strength, and exceptional durability. These fasteners are widely used in industries such as aerospace, marine, chemical processing, power generation, and oil & gas. The high nickel content in these fasteners makes them resistant to extreme temperatures, oxidation, and harsh environments, making them ideal for critical applications.

Properties of High Nickel Fasteners

High Nickel Fasteners possess several outstanding properties, including:

Corrosion Resistance: Excellent resistance to corrosive environments, including acids and alkalis.

High-Temperature Strength: Withstands extreme temperatures without losing strength or integrity.

Oxidation Resistance: Provides protection against oxidation and scaling.

Non-Magnetic Nature: Some nickel alloys offer non-magnetic properties, ideal for specific applications.

Excellent Mechanical Strength: High tensile and yield strength ensure durability.

Types of High Nickel Fasteners

High Nickel Fasteners are available in various types, including:

High Nickel Bolts: Hex bolts, carriage bolts, eye bolts, anchor bolts, U-bolts, etc.

High Nickel Nuts: Hex nuts, lock nuts, dome nuts, wing nuts, etc.

High Nickel Washers: Flat washers, spring washers, fender washers, etc.

High Nickel Screws: Self-tapping screws, machine screws, wood screws, etc.

High Nickel Studs: Threaded rods, double-ended studs, etc.

High Nickel Rivets: Structural rivets, blind rivets, etc.

Common Nickel Alloys Used in Fasteners

Several nickel-based alloys are used in manufacturing high nickel fasteners, including:

Inconel (Alloy 600, 625, 718): Excellent corrosion and heat resistance.

Monel (Alloy 400, K500): Superior resistance to seawater and acidic environments.

Hastelloy (C22, C276): Exceptional resistance to chemical corrosion.

Nickel 200/201: Pure nickel with excellent conductivity and corrosion resistance.

Alloy 20: High resistance to sulfuric acid and pitting corrosion.

Applications of High Nickel Fasteners

High Nickel Fasteners are used in a wide range of industries due to their robust characteristics:

Aerospace Industry: Used in jet engines, airframes, and turbine components.

Marine Industry: Ideal for shipbuilding and offshore structures due to seawater resistance.

Chemical Processing: Resistant to highly acidic and caustic environments.

Oil & Gas Industry: Used in refineries, pipelines, and offshore drilling platforms.

Power Generation: Applied in nuclear power plants and thermal power stations.

Automotive Industry: Utilized in performance vehicles and specialized applications.

Advantages of High Nickel Fasteners

Long-lasting and durable in extreme conditions.

Resistant to oxidation, pitting, and crevice corrosion.

Suitable for high-pressure and high-temperature environments.

Ideal for both acidic and alkaline conditions.

Low maintenance requirements, reducing long-term costs.

High Nickel Fasteners Manufacturer & Supplier Worldwide

Why Choose Us as Your High Nickel Fasteners Manufacturer?

We are a leading High Nickel Fasteners Manufacturer, Supplier, and Exporter serving clients across the globe. Our fasteners are made from premium quality nickel alloys and are designed to meet international standards such as ASTM, ASME, DIN, ISO, and more. Our manufacturing facility is equipped with advanced technology to ensure precision engineering and superior quality.

Our Manufacturing Capabilities

State-of-the-Art Facility: Advanced CNC machines, heat treatment units, and testing labs.

Custom Fasteners: Manufacturing fasteners as per client specifications and requirements.

Stringent Quality Control: Each product undergoes rigorous testing to ensure compliance with industry standards.

Global Supply Chain: Supplying fasteners to major industries worldwide.

Timely Delivery: Ensuring quick turnaround times and efficient logistics.

Countries We Supply To

We are a trusted supplier of High Nickel Fasteners in the following regions:

North America: USA, Canada, Mexico

Europe: UK, Germany, France, Italy, Spain

Middle East: UAE, Saudi Arabia, Oman, Qatar

Asia: India, China, Japan, South Korea, Singapore

Australia & New Zealand

Africa & South America

Quality Assurance & Certifications

We adhere to the highest quality standards and have certifications such as:

ISO 9001:2015 - Quality Management System

ASTM & ASME Standards Compliance

Third-Party Inspection (TPI) Available

Material Test Certificates (MTC) Provided

RoHS & REACH Compliance

Conclusion

High Nickel Fasteners are essential components for industries that demand strength, corrosion resistance, and high performance. As a leading High Nickel Fasteners Manufacturer & Supplier, we provide top-quality fasteners that meet global standards. Our expertise, state-of-the-art manufacturing, and global supply network make us a reliable partner for your fastener needs.

For inquiries and orders, contact us today and get the best-quality High Nickel Fasteners for your applications.

Frequently Asked Questions (FAQ)

1. What are High Nickel Fasteners used for?

High Nickel Fasteners are used in industries such as aerospace, marine, chemical processing, oil & gas, and power generation due to their high strength and corrosion resistance.

2. Which nickel alloys are commonly used in fasteners?

Popular nickel alloys include Inconel, Monel, Hastelloy, Nickel 200/201, and Alloy 20.

3. Are High Nickel Fasteners resistant to corrosion?

Yes, these fasteners offer excellent resistance to corrosion, oxidation, and extreme temperatures, making them ideal for harsh environments.

4. Can I get custom High Nickel Fasteners?

Yes, we manufacture custom fasteners based on client specifications, including different sizes, coatings, and thread types.

5. Do you provide bulk supply for industrial applications?

Yes, we offer bulk supply and wholesale orders with competitive pricing and timely delivery worldwide.

#ananka hashtag#fasteners hashtag#Nickel hashtag#Nickelfasteners hashtag#HighNickelAlloy hashtag#Fastenersmanufacturer hashtag#Anankafasteners hashtag#Monel hashtag#Inconel hashtag#Inconelfasteners#anankafasteners#ananka#manufacturer#fasteners#supplier

0 notes

Text

Inconel 600 Fasteners: Manufacturer, Supplier & Exporter

Introduction to Inconel 600 Fasteners

Inconel 600 fasteners are a type of high-performance fastening solutions made from Inconel 600, a nickel-chromium alloy renowned for its excellent resistance to oxidation, corrosion, and high temperatures. These fasteners are widely used in industries that demand durability, strength, and resistance to extreme environments, including aerospace, marine, power generation, and chemical processing industries.

Properties of Inconel 600 Fasteners

Inconel 600 fasteners are known for their unique combination of mechanical and chemical properties, including:

High Temperature Resistance: Capable of withstanding extreme temperatures up to 1093°C (2000°F).

Excellent Corrosion Resistance: Resistant to oxidation, carburization, and chloride-ion stress corrosion cracking.

Superior Mechanical Strength: Maintains its integrity under high stress and temperature conditions.

Good Weldability and Fabricability: Can be easily fabricated and welded, making it versatile for various applications.

Types of Inconel 600 Fasteners

1. Inconel 600 Bolts

Hex Bolts

U Bolts

Eye Bolts

Carriage Bolts

T Bolts

Flange Bolts

Anchor Bolts

2. Inconel 600 Nuts

Hex Nuts

Lock Nuts

Heavy Hex Nuts

Wing Nuts

Nylock Nuts

Flange Nuts

3. Inconel 600 Washers

Plain Washers

Spring Washers

Lock Washers

Fender Washers

Star Washers

4. Inconel 600 Screws

Machine Screws

Self-Tapping Screws

Wood Screws

Socket Head Cap Screws

Countersunk Screws

5. Inconel 600 Stud Bolts

Full Threaded Studs

Double-End Studs

Tap-End Studs

Applications of Inconel 600 Fasteners

Due to their outstanding performance, Inconel 600 fasteners are widely used in various industries, including:

Aerospace Industry: Used in aircraft exhaust systems, jet engines, and turbine blades.

Chemical Processing Industry: Ideal for heat exchangers, reactor vessels, and piping systems handling corrosive chemicals.

Marine Industry: Resistant to seawater corrosion, making them suitable for shipbuilding and offshore applications.

Power Generation: Found in nuclear reactors, steam generators, and gas turbines.

Electronics and Semiconductor Industry: Used in electrical and electronic components exposed to extreme conditions.

Inconel 600 Fasteners: Standard Specifications

Advantages of Using Inconel 600 Fasteners

Long Service Life: Resistant to extreme environments, ensuring durability.

Versatile Usage: Suitable for a broad range of applications in various industries.

Non-Magnetic: Ideal for applications requiring non-magnetic fasteners.

High Strength-to-Weight Ratio: Provides strong and lightweight fastening solutions.

Resistance to Scaling: Prevents surface degradation even at high temperatures.

Why Choose Ananka Group for Inconel 600 Fasteners?

Ananka Group is a leading manufacturer, supplier, and exporter of Inconel 600 fasteners in India and worldwide. We offer a wide range of high-quality fasteners that meet international standards, ensuring optimal performance in demanding environments.

Our Offerings:

Custom Sizes & Specifications

Stringent Quality Control Measures

Timely Delivery Across Global Markets

Competitive Pricing & Bulk Supply Availability

Conclusion

Inconel 600 fasteners are an excellent choice for industries requiring high-performance fastening solutions resistant to heat, corrosion, and extreme conditions. Their remarkable properties make them a preferred choice in aerospace, marine, and chemical industries. With Ananka Group, you can be assured of superior quality, precision, and reliability in every fastener we manufacture and supply.

Frequently Asked Questions (FAQs)

1. What are Inconel 600 fasteners used for?

Inconel 600 fasteners are widely used in high-temperature and corrosive environments, including aerospace, marine, chemical processing, and power generation industries.

2. Are Inconel 600 fasteners corrosion-resistant?

Yes, they exhibit excellent resistance to oxidation, corrosion, and stress corrosion cracking in harsh environments.

3. What standards do Inconel 600 fasteners comply with?

They are manufactured following ASTM B166 and ASME SB166 standards.

4. Do Inconel 600 fasteners withstand high temperatures?

Yes, they can withstand temperatures up to 1093°C (2000°F), making them ideal for extreme applications.

5. Where can I buy high-quality Inconel 600 fasteners?

You can purchase premium-grade Inconel 600 fasteners from Ananka Group, a trusted manufacturer and supplier worldwide.

#ananka#anankafasteners#articles#blog#fasteners#inconel#inconel600#inconelfasteners#manufacturer#supplier#mumbai#tumblr#tumblr blog

0 notes

Text

A Comprehensive Guide to Inconel Alloy 718

Introduction

Inconel 718 is a high-performance nickel-chromium alloy known for its exceptional strength, corrosion resistance, and heat resistance. It is widely used in industries such as aerospace, power generation, marine, and chemical processing. Developed in the 1950s, Inconel 718 remains one of the most versatile and reliable superalloys in demanding applications.

Inconel 718 fasteners are high-strength, corrosion-resistant fasteners made from a nickel-based superalloy known for its exceptional performance in extreme environments. These fasteners are widely used in industries such as aerospace, marine, chemical processing, and power generation due to their superior mechanical properties, oxidation resistance, and excellent weldability.

Composition of Inconel 718

Inconel 718 is primarily composed of nickel, chromium, and iron, with additional elements that enhance its properties. Below is a typical chemical composition of Inconel 718:

Key Properties of Inconel 718

1. High Strength and Toughness

One of the most notable features of Inconel 718 is its outstanding mechanical strength. It has excellent tensile and yield strength, making it ideal for applications that require durability under extreme stress.

2. Corrosion and Oxidation Resistance

Inconel 718 offers superior resistance to corrosion and oxidation in harsh environments. It performs exceptionally well in high-temperature, high-pressure, and chemically aggressive conditions.

3. Excellent Weldability

Unlike many other superalloys, Inconel 718 can be welded easily without the risk of cracking. This is due to its slower precipitation hardening response, which prevents strain-age cracking.

4. High-Temperature Stability

It maintains its mechanical properties at elevated temperatures, up to 1300°F (704°C). This makes it suitable for aerospace and gas turbine applications.

5. Creep and Fatigue Resistance

The alloy demonstrates excellent creep resistance and fatigue strength, making it ideal for components subjected to cyclic loads over extended periods.

Applications of Inconel 718

1. Aerospace Industry

Inconel 718 is extensively used in jet engines, gas turbines, and aerospace components, including:

Turbine blades and discs

Combustion chambers

Fasteners and structural components

2. Power Generation

The alloy is used in nuclear reactors, steam turbines, and power plants due to its ability to withstand extreme temperatures and pressures.

3. Oil and Gas Industry

Inconel 718 is widely used in drilling equipment, downhole tools, and pipelines due to its resistance to corrosion, pressure, and temperature.

4. Marine Industry

Naval and marine applications, including submarine and offshore structures, benefit from the alloy’s resistance to saltwater corrosion.

5. Chemical Processing Industry

Inconel 718 is used in chemical plants for heat exchangers, reactor vessels, and piping systems exposed to aggressive chemicals.

Manufacturing and Processing of Inconel 718

Heat Treatment

Inconel 718 is typically heat-treated to achieve its full mechanical properties. The standard heat treatment process includes:

Solution Annealing - Heating to 980-1010°C followed by rapid cooling.

Aging Treatment - Heating at lower temperatures (720°C) to enhance hardness and strength.

Machining and Fabrication

Due to its toughness, Inconel 718 is challenging to machine. Specialized cutting tools and techniques, such as carbide tooling and slow cutting speeds, are used.

Welding

The alloy is readily weldable using conventional welding techniques like TIG and MIG welding. Post-weld heat treatment is recommended to prevent potential issues like stress corrosion cracking.

Comparison of Inconel 718 with Other Alloys

Conclusion

Inconel 718 is a superior superalloy known for its exceptional strength, corrosion resistance, and thermal stability. Its extensive use in aerospace, power generation, oil & gas, marine, and chemical industries highlights its importance in high-performance applications. Although it is expensive and challenging to machine, its unique combination of properties makes it an indispensable material in critical environments.

If you are looking for a high-strength, corrosion-resistant alloy with excellent performance under extreme conditions, Inconel 718 is undoubtedly one of the best choices available.

FAQs

Q1: What makes Inconel 718 different from other Inconel alloys?A: Unlike other Inconel alloys, Inconel 718 has superior weldability and a unique precipitation hardening mechanism that enhances its strength.

Q2: Can Inconel 718 be used at cryogenic temperatures?A: Yes, Inconel 718 retains good mechanical properties at cryogenic temperatures, making it useful for applications requiring low-temperature performance.

Q3: What is the lifespan of Inconel 718 components?A: Due to its excellent fatigue and creep resistance, Inconel 718 components have a long operational lifespan, often exceeding several decades in the right conditions.

Q4: How does Inconel 718 compare with stainless steel?A: Inconel 718 is much stronger and more resistant to heat and corrosion compared to stainless steel, but it is also more expensive and harder to machine.

For more technical details and applications of Inconel 718, feel free to reach out to experts or consult material data sheets from manufacturers.

#ananka#fasteners#articles#inconel#inconel718#inconelfasteners#fastenersmanufacturer#inconelalloy#anankafasteners#manufacturer#supplier#hex#mumbai#blogs#tumblr blog#bolt

0 notes

Text

Inconel Fasteners: A Comprehensive Guide

Introduction to Inconel

Inconel is a family of nickel-chromium-based superalloys known for their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. Developed by Special Metals Corporation, Inconel alloys are widely used in aerospace, marine, chemical processing, and power generation industries.

The primary advantage of Inconel is its ability to retain mechanical strength even in high-temperature and corrosive environments. It resists oxidation, carburization, and chloride-induced stress corrosion cracking, making it an ideal material for fasteners used in critical applications.

What Are Inconel Fasteners?

Inconel fasteners are bolts, nuts, washers, screws, and studs made from Inconel alloys. These fasteners are designed to perform in extreme conditions where ordinary steel or stainless steel fasteners would fail. The combination of nickel, chromium, and iron (along with other elements in varying amounts) provides outstanding durability, even in the harshest environments.

Characteristics of Inconel Fasteners

High-Temperature Resistance: Can withstand temperatures exceeding 1000°C.

Corrosion Resistance: Excellent resistance to oxidation, pitting, and crevice corrosion.

Superior Strength: High tensile and yield strength.

Resistance to Creep and Fatigue: Maintains integrity under prolonged exposure to stress and heat.

Non-Magnetic: Some Inconel alloys exhibit non-magnetic properties, making them suitable for specific applications.

Different Types of Inconel Fasteners

1. Inconel Bolts

Hex bolts

Anchor bolts

U-bolts

J-bolts

Stud bolts

2. Inconel Nuts

Hex nuts

Lock nuts

Wing nuts

Flange nuts

Dome nuts

3. Inconel Washers

Flat washers

Spring washers

Belleville washers

Fender washers

4. Inconel Screws

Machine screws

Socket head cap screws

Set screws

Self-tapping screws

5. Inconel Studs

Fully threaded studs

Double-end studs

Tap-end studs

Each type of fastener is available in different grades of Inconel, such as Inconel 600, Inconel 625, Inconel 718, and Inconel 925, depending on the application and environment.

Uses of Inconel Fasteners

1. Aerospace Industry

Used in jet engines, gas turbines, and exhaust systems due to high heat resistance.

2. Marine Industry

Ideal for shipbuilding, offshore drilling platforms, and seawater applications due to exceptional corrosion resistance.

3. Chemical Processing Industry

Used in reactors, heat exchangers, and pressure vessels to withstand harsh chemicals and extreme temperatures.

4. Power Generation

Essential in nuclear reactors, steam turbines, and other high-temperature power generation equipment.

5. Oil and Gas Industry

Used in pipelines, valves, and drilling equipment exposed to high pressure and corrosive fluids.

6. Medical Industry

Applied in medical implants and surgical instruments due to its non-reactive properties.

7. Automotive Industry

Used in high-performance and racing vehicles for exhaust systems and turbocharger components.

Specifications of Inconel Fasteners

Common Standards for Inconel Fasteners

ASTM B166 (Rod and bar)

ASTM B167 (Pipe and tubing)

ASTM B168 (Plate, sheet, and strip)

ASTM F2281 (Bolting materials)

UNS N06600 (Inconel 600)

UNS N06625 (Inconel 625)

UNS N07718 (Inconel 718)

Mechanical Properties of Inconel 625 Fasteners (Example)

Tensile Strength: 930 MPa (135 ksi)

Yield Strength (0.2% Offset): 517 MPa (75 ksi)

Elongation: 50%

Hardness: Rockwell B88

Chemical Composition of Inconel 625

Conclusion

Inconel fasteners are an essential component in industries requiring high-performance fastening solutions. Their ability to resist extreme temperatures, corrosion, and mechanical stress makes them a preferred choice in aerospace, marine, oil and gas, and many other industries.

Ananka Fasteners is a leading manufacturer, supplier, and exporter of Inconel fasteners, offering high-quality products that meet international standards. If you are looking for reliable and durable Inconel fasteners, get in touch with us today!

Frequently Asked Questions (FAQs)

Q1: What makes Inconel fasteners different from stainless steel fasteners?

Inconel fasteners offer superior high-temperature and corrosion resistance compared to stainless steel, making them suitable for extreme environments.

Q2: What is the most commonly used Inconel grade for fasteners?

Inconel 625 and Inconel 718 are the most widely used grades due to their excellent mechanical and chemical properties.

Q3: Are Inconel fasteners expensive?

Yes, Inconel fasteners are more expensive than stainless steel fasteners due to their superior properties and complex manufacturing process.

Q4: Can Inconel fasteners be used in seawater applications?

Yes, Inconel fasteners, especially Inconel 625, are highly resistant to seawater corrosion and are used in marine applications.

Q5: Where can I buy high-quality Inconel fasteners?

You can purchase premium-quality Inconel fasteners from Ananka Fasteners, a trusted manufacturer and supplier in the industry.

#ananka#anankafastenrs#fasteners#fastenersmanufacturer#linkedin#articles#inconel#inconelfasteners#blog#anankafasteners#manufacturer#supplier#mumbai#hex#bolt#usa

0 notes

Text

Inconel Alloy 718 Fasteners: Manufacturer, Supplier & Exporter

Introduction

Inconel Alloy 718 is a high-strength, corrosion-resistant nickel-chromium alloy that is well-suited for extreme environments, including high-temperature and high-pressure applications. Due to its superior properties, Inconel 718 is widely used in the aerospace, marine, and chemical processing industries. Fasteners made from this alloy exhibit excellent mechanical strength, outstanding oxidation resistance, and superior weldability.

Properties of Inconel 718 Fasteners

High Strength: Inconel 718 fasteners maintain their structural integrity at high temperatures.

Corrosion Resistance: Exceptional resistance to oxidation and corrosion in various harsh environments.

Excellent Weldability: Can be readily welded without cracking, which is rare for high-strength nickel alloys.

Creep and Stress Rupture Resistance: Ensures long service life in demanding conditions.

Cryogenic Suitability: Performs well even in extremely low temperatures.

Types of Inconel 718 Fasteners

Inconel 718 Bolts – Hex bolts, carriage bolts, eye bolts, U-bolts, etc.

Inconel 718 Nuts – Hex nuts, lock nuts, dome nuts, wing nuts, etc.

Inconel 718 Washers – Flat washers, spring washers, fender washers, etc.

Inconel 718 Screws – Machine screws, self-tapping screws, wood screws, etc.

Inconel 718 Studs – Full thread studs, double-ended studs, etc.

Applications of Inconel 718 Fasteners

Aerospace Industry: Used in jet engines, turbine blades, and exhaust ducts due to high-temperature resistance.

Marine Industry: Applied in naval vessels, offshore platforms, and seawater applications.

Power Generation: Utilized in nuclear reactors and gas turbines.

Chemical Processing: Resistant to corrosive chemicals, making it suitable for processing plants.

Automotive Industry: Used in turbochargers and exhaust systems.

Standard Specifications

ASTM B637 – Standard specification for Inconel 718 forged products.

AMS 5662, 5663, 5664 – Aerospace material specifications.

UNS N07718 – Unified numbering system designation.

Chemical Composition of Inconel 718

Nickel (Ni): 50-55%

Chromium (Cr): 17-21%

Iron (Fe): Balance

Niobium (Nb) + Tantalum (Ta): 4.75-5.5%

Molybdenum (Mo): 2.8-3.3%

Titanium (Ti): 0.65-1.15%

Cobalt (Co): ≤ 1.0%

Aluminum (Al): 0.2-0.8%

Carbon (C): ≤ 0.08%

Silicon (Si): ≤ 0.35%

Manganese (Mn): ≤ 0.35%

Sulfur (S): ≤ 0.015%

Mechanical Properties of Inconel 718

Tensile Strength: 135 ksi (931 MPa)

Yield Strength (0.2% offset): 70 ksi (482 MPa)

Elongation: 30%

Hardness: 30-40 HRC

Advantages of Inconel 718 Fasteners

Withstands high-pressure and high-temperature environments.

Excellent fatigue and creep resistance.

Resistant to pitting and crevice corrosion.

Long service life with minimal maintenance.

Why Choose Ananka Group for Inconel 718 Fasteners?

Ananka Group is a trusted manufacturer, supplier, and exporter of Inconel 718 Fasteners. We provide high-quality, precision-engineered fasteners that meet international standards. Our fasteners are available in various sizes, grades, and custom specifications to suit industry needs.

Key Benefits of Choosing Us:

High-Quality Materials: We use premium-grade raw materials for manufacturing.

Precision Engineering: Advanced machinery ensures accurate dimensions and performance.

Global Supply Network: We export to countries worldwide with timely delivery.

Competitive Pricing: Affordable rates without compromising on quality.

Conclusion

Inconel Alloy 718 Fasteners are ideal for applications requiring superior strength, corrosion resistance, and durability. Their ability to withstand extreme conditions makes them indispensable in aerospace, marine, and industrial applications. Choosing a reliable manufacturer like Ananka Group ensures you get the best quality fasteners that meet stringent industry standards.

FAQs

Q1: What makes Inconel 718 different from other Inconel grades?A1: Inconel 718 has excellent weldability and high strength, which sets it apart from other Inconel alloys like 625. It is precipitation-hardened, making it ideal for high-stress applications.

Q2: Can Inconel 718 fasteners be used in seawater applications?A2: Yes, they offer excellent resistance to seawater corrosion, making them suitable for marine and offshore environments.

Q3: Are Inconel 718 fasteners expensive?A3: While they are more costly than stainless steel fasteners, their durability, high performance, and corrosion resistance justify the investment.

Q4: Do you provide custom sizes for Inconel 718 fasteners?A4: Yes, Ananka Group offers customized fasteners in different sizes and specifications as per client requirements.

For premium-quality Inconel 718 Fasteners, contact Ananka Group today!

#Ananka#fasteners#Inconel#Inconelfasteners#Inconel718#fastenersmanufacturer#article#blog#Anankafasteners#manufacturer#supplier#mumbai#bolt#usa#tumblr#blog tumblr#articles

1 note

·

View note

Text

Inconel Fasteners: Manufacturers, Suppliers, and Uses

Introduction

Inconel fasteners are specialized components designed for extreme environments where high strength, corrosion resistance, and excellent mechanical properties are paramount. This article delves into the world of Inconel fasteners, including their types, chemical composition, mechanical properties, benefits, applications, and why they are a reliable choice for critical industries.

Inconel fasteners are among the most reliable and durable fasteners used across various industries due to their exceptional properties. These high-performance fasteners are manufactured using Inconel, a nickel-chromium-based alloy known for its ability to withstand extreme environments. As a leading manufacturer, supplier, and exporter of Inconel fasteners, we at Ananka Group take pride in delivering products that meet the highest quality standards.

What is Inconel?

Inconel is a family of nickel-chromium-based superalloys known for its high performance in extreme conditions. Its unique composition provides superior resistance to oxidation, corrosion, and thermal degradation.

What Are Inconel Fasteners?

Inconel fasteners are components made from Inconel alloys, such as Inconel 600, 625, 718, and others. These alloys are renowned for their high resistance to oxidation, corrosion, and heat. This makes Inconel fasteners ideal for use in challenging environments such as aerospace, marine, chemical processing, and power generation industries.

Types of Inconel Fasteners

Bolts

Hex Bolts

Stud Bolts

U-Bolts

Eye Bolts

Nuts

Hex Nuts

Heavy Hex Nuts

Jam Nuts

Washers

Flat Washers

Lock Washers

Screws

Socket Head Cap Screws

Machine Screws

Self-Tapping Screws

Other Custom Fasteners

Threaded Rods

Pins

Chemical Composition of Inconel Fasteners

Mechanical Properties of Inconel Fasteners

Tensile Strength: 850-1,600 MPa

Yield Strength: 415-1,200 MPa

Elongation: 20-50%

Melting Point: ~1,350°C (2,462°F)

Hardness: Rockwell B85-C40

Key Benefits of Inconel Fasteners

High Temperature ResistanceWith the ability to maintain strength and structural integrity at temperatures exceeding 1,000°C, Inconel fasteners are ideal for high-heat environments.

Corrosion ResistanceExceptional resistance to oxidation, pitting, and crevice corrosion makes Inconel suitable for chemical and marine applications.

Strength and DurabilityThe alloy's excellent mechanical properties ensure long-term reliability in demanding applications.

Stress Corrosion Cracking ResistanceInconel's resistance to stress corrosion cracking ensures performance under high-stress conditions.

Applications of Inconel Fasteners

Aerospace IndustryUsed in jet engines, turbines, and exhaust systems due to their ability to withstand high temperatures and mechanical stress.

Chemical ProcessingIdeal for equipment exposed to aggressive chemicals, such as reactors and heat exchangers.

Marine IndustryResistant to saltwater corrosion, making them suitable for offshore platforms and submarines.

Power GenerationCommonly used in nuclear reactors and steam turbines.

Oil & Gas IndustryPerforms well in high-pressure, high-temperature environments, such as pipelines and drilling rigs.

Manufacturing Expertise in Inconel Fasteners

At Ananka Group, we specialize in manufacturing high-quality Inconel fasteners that meet international standards such as ASTM, ASME, DIN, and ISO. Our manufacturing process involves precision forging, machining, and heat treatment to ensure the highest quality.

Why Choose Inconel Fasteners from Ananka Group?

Custom SolutionsTailored to meet specific industrial requirements.

Quality AssuranceEach batch undergoes stringent testing, including tensile, hardness, and corrosion tests.

Global ShippingWe supply to industries worldwide with reliable logistics.

Competitive PricingHigh-quality fasteners at affordable rates.

Conclusion

Inconel fasteners are the ultimate choice for industries requiring components that can endure extreme temperatures, resist corrosion, and provide exceptional strength. With their unique properties, these fasteners deliver unmatched performance in the most demanding environments. At Ananka Group, we are committed to delivering top-quality Inconel fasteners for diverse industrial applications.

FAQs

Q1: What are Inconel fasteners made of?Inconel fasteners are made from nickel-chromium-based superalloys, often alloyed with iron, molybdenum, and other elements.

Q2: Which industries use Inconel fasteners?Industries like aerospace, chemical processing, marine, power generation, and oil & gas widely use Inconel fasteners.

Q3: Are Inconel fasteners expensive?Yes, Inconel fasteners are relatively more expensive due to their specialized properties and the cost of raw materials.

Q4: Can Inconel fasteners be used in marine environments?Yes, Inconel fasteners are highly resistant to saltwater corrosion, making them suitable for marine applications.

Q5: What is the temperature range of Inconel fasteners?Inconel fasteners can perform effectively in temperatures ranging from cryogenic levels up to 1,000°C or more.

#Ananka#fasteners#inconel#inconelfasteners#inconel625#Inconelmanufacturer#Anankafasteners#Blog#Article#Supplier#Exporter#inconel600#fastenersmanufacturer#manufacturer#mumbai#bolt

0 notes

Text

Choosing the Right Fasteners for Your Project

Aashish Steel is a reputable manufacturer, supplier, and exporter of stainless steel Inconel Fasteners Manufacturer in India. Stainless steel Inconel Fasteners Manufacturer in India are adaptable goods that fall under various requirements and classifications. Aashish Steel is a leading Monel Fastener Manufacturer in India. Monel Fasteners are versatile items that come in a variety of specifications and categories. We are also the leading Bolt Supplier in Ludhiana and Bolt Supplier in Ahmedabad.

Types of Fastener

Stainless Steel Fasteners

One of the greatest and most reputable Stainless Steel Fasteners Manufacturers in India is Aashish Steel. Stainless steel fasteners are adaptable goods that are available in a range of standards and classifications. One of the things we produce is stainless steel fasteners, such as stainless steel bolts, nuts, screws, washers, and other fasteners. Fasteners made of stainless steel are excellent at resisting corrosion, therefore they are unaffected in industrial situations. It is resistant to dangerous substances like phosphoric acid, sulfuric acid, and chlorine.

Hastelloy Fasteners

Aashish Steel is a top Hastelloy Fastener Manufacturer in India. Hastelloy Fasteners are versatile items that come in a variety of specifications and categories. Hastelloy Bolts, Hastelloy Nuts, Hastelloy Screws, Hastelloy Washers, and other Hastelloy Fasteners are manufactured by us. Hastelloy fasteners have exceptional corrosion resistance, allowing them to function normally in industrial settings. It's resistant to chlorine, sulfuric acid, phosphoric acid, and other potentially harmful chemicals.

Monel Fasteners

One of the top Monel Fasteners in Manufacturers India is Aashish Steel. Monel Fasteners are adaptable goods that are available in a wide range of standards and classifications. Among the products we produce are Monel Bolts, Monel Nuts, Monel Screws, Monel Washers, and other Monel Fasteners.

We produce all grades of Monel fasteners in compliance with national and international standards. The most demanding goods in the chemical processing business, marine water supply industries, pulp and paper industry, petrochemical industry, desalination plant, aerospace, oil and gas refineries, and other industries are Monel fasteners. We produce all Monel Fasteners in accordance with customer specifications.

Specification of Inconel Fasteners :

Specifications: ASTM / ASME SB 160 / 164 / 166 / 425 /446 / 574 / 472

Standard: ASTM / ASME

Length: UPTO 1 METRE

Size: M10 TO M100

Type: Nuts, Bolts, Screws, Sockets, Studs, Screw, Hex Set Screw, Socket Screw, Cap Screw, Pan Head Screw, Machine Screw, Socket Head Cap Screw, Allen Cap screw, Wing Screw, Washers, Spring Washers, Studs, Anchors, Marine Anchors, Nut, Hexagon Nut, Hex Nut, Hex Coupling Nut, Hex Domed Cap Nuts, Square Nut, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolt, U-bolts, J-bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Wing Screw, Eye Bolt, Foundation Bolts, and Structural Bolts

Application & Uses Of Inconel Fasteners

Inconel Fasteners used in Petroleum Industry

Hex Nut used in Aerospace Industry

Square Nut used in Chemical Industry

Dome Nut used in oil & Gas Industry

Nylock Nut used in Nuclear Energy Sector

Wing Nut used in Automotive Industries

Visit: asnutbolt.com

#InconelFasteners #MonelFasteners #boltmanufacturer

0 notes

Text

Manufacturer of Top Quality Inconel Fasteners & Monel Fasteners

Aashish Steel is an esteemed producer, distributor, and exporter of stainless steel. Inconel Fasteners Manufacturer in India. Aluminium alloy Inconel Fasteners Manufacturer in India provide flexible products that may be categorised and categorised according to different criteria. Aashish Steel is a leading Monel Fastener Manufacturer in India. Monel Fasteners are versatile items that come in a variety of specifications and categories.

Contact us:

Website: asnutbolt.com

Mail: [email protected]

Visit us for more information: Inconel Fasteners Manufacturer in India

You may also like: Allen Bolt Manufacturer in India and Bolt Manufacturers in India

0 notes