#Nickel alloy products

Explore tagged Tumblr posts

Text

Jay Steel Corporation Provide The Best Pressure Vessels in India

Jay Steel Corporation is the leading company that specializes in manufacturing pressure vessels in India. Pressure vessels are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. They play a crucial role in various industries, including chemical processing, petrochemical, pharmaceuticals, food processing, and more. We are manufacturing all type of Pressure Vessels like titanium, Nickel, Stainless Steel & Duplex Steel in India & World Wild.

#nickel alloy products#PRESSURE VESSEL MANUFACTURER#REACTOR VESSELS SUPPLIERS#INDUSTRIAL REACTORS SUPPLIER IN INDIA

0 notes

Text

Guide to Selecting a Trustworthy Fastener Manufacturer

“Fasteners & Fixtures is a leading fastener manufacturer offering high-performance fasteners made of different materials. Their robust fasteners work well under critical conditions and are available in extensive designs and material types.”

Fasteners are essential in all industries for the structural integrity of the system. These fasteners are available as screws, nuts, bolts, screws, studs, washers, and more. Since these fittings are available in different types, one must choose the right type per their application. Choosing the right fastener type ensures you do not exceed your budget, system longevity, and ease of maintenance. The following guide helps identify a reputed and trustworthy fastener manufacturer.

Ways to select a fastener supplier for your project

Check the manufacturer’s experience:

It is essential to check the manufacturer’s experience in fastener manufacturing. It will ensure the company can fulfill your requirements and guarantee timely delivery, preventing project delays. The experience of the fastener manufacturer also showcases that they can provide fastener solutions as per your project requirements,

Check whether the manufacturer provides fastener prototypes

Fastener selection requires careful consideration, especially when your project needs custom fasteners. In such cases, the experience of a fastener manufacturer proves useful as they can create a prototype for your business. When the manufacturer provides fastener prototypes, it helps you prevent defects, project failure, and material wastage. Prototyping ensures you add a testing phase for your project.

Check the fastener types available at the fastener manufacturer

A reputed fastener manufacturer provides a range of fastener designs. They also ensure the fasteners are available in different materials and sizes. It ensures the manufacturer can offer versatile fasteners.

Check the manufacturer’s facility

A reputed fastener manufacturer will use the latest equipment for manufacturing fasteners. It ensures customers receive high-quality fasteners. It also guarantees product manufacturing per industrial standards.

Check the certifications

It is essential to confirm the fastener manufacturer presents certifications for their products. It ensures the products adhere to the quality standards and are compatible with international standards. Fastener manufacturers like Fasteners & Fixtures are ISO-certified and offer certifications for the same.

Check the company’s quality assurance processes

It is essential to check the manufacturer’s quality assurance processes, especially when opting for customized fasteners. A reputed company will enforce rigorous quality assurance testing to ensure the products are robust and high quality. The manufacturer will always provide information about the quality tests, inspections, raw material testing, and more. A reputed manufacturer will ensure they adhere to manufacturing standards and provide ISO certifications. Ensuring the fastener manufacturer adheres to quality standards guarantees zero defects in the fasteners.

Check whether the manufacturer offers customization options

A reputed fastener manufacturer will always provide customization options and offer tailored and unique products. The fastener manufacturer will ensure they satisfy your requirements in case of custom sizes and designs. The company will ensure they fulfill your design and modification requirements. A reputed manufacturer has an in-house team of engineers that can help you customize products in terms of design, guaranteeing top functionality and performance for fasteners.

Check the fastener manufacturer’s material expertise

A fastener manufacturer must have essential experience in dealing with fastener materials. The right fastener material ensures the materials are compatible with your system. Fasteners are available in extensive materials like stainless steel, brass, aluminum, and alloys. Experts at a reputed fastener manufacturer will help you select the right material for your project and choose a material per requirements like fastener strength, temperature range, corrosion resistance, cost-effectiveness, and more.

Check customer reviews

It is essential to check the customer reviews to ensure you are choosing a reputed fastener manufacturer. You can check the company’s online reviews, consult with their clients, and select the best manufacturer per your project requirements.

Final thoughts

The above guide will help you choose a trustworthy fastener manufacturer. Fasteners & Fixtures LLP features a range of fasteners like nuts, bolts, studs, crews, washers, and more in different materials like stainless steel, Monel alloy, nickel alloy, and more. For more information, visit their website today!

0 notes

Text

WERE DOING SPECBIO STUFF AGAIN BABY. Feels fucking good to get back to my roots (i get to close 50 tabs worth of research now. Delightful)

Terminators are made of a Titanium Alloy (Im going with ferrotitanium which is a mix of iron and titanium. They never specify in the movie what the titanium is mixed with so fuck it we ball baby)) skeleton contains limited amounts of Mimetic Polyalloy (fake material used for the terminator in terminator two). Mimetic polyalloy can be hard or flexible and will be used to create new structures that the iron collected from food will later fully establish. This will allow his metal endoskeleton to mimic standard growth that a regular skeleton would have growing up.

When first introduced to the foster system (medical checkups are required once entering the foster system. The police probably do some checkups on Robbie also just to make sure hes okay when they find him), medical tests show that he has anemia, so it’s recommended he be put on iron supplements. My reasoning is any iron in his blood is almost instantly sent to work on growing his endoskeleton. That means the actual amount of iron left in his blood is pretty low (the opposite of this is hemochromatosis which is when there's too much iron in your blood). I could see him probably trying to stop iron supplements but I think there would be some side effects to convince him to start taking them again. His joints might ache or I could see child terminator Robbie saying some mildly concerning shit like ‘my bones feel hungry’. I also think he might crave foods that are high in iron. Like beef/chicken liver, canned tuna, and seafood. Idk how frequently he could AFFORD these things but yk. The endoskeleton hungers eternal ¯\_(ツ)_/¯

Nanobots are used to repair wiring for his nervous system, synthetic muscular system, acts as his immune system and sometimes accelerates healing for his organic systems (organic parts of his muscular system, skin, and nerves). For the most part his organic systems heal on their own at about the same pace as a normal human person. Nanomachines/nanoparticles are fueled by glucose (if Robbie needs work done by the nanobots he might need to eat or crave sugar both before and afterwards).

He probably has a fairly (?) normal digestive system and circulatory system. The spread of his circulatory system is just more limited because some parts of him don't really need blood. . The primary job of the nanomachines when they aren't busy healing or growing his body is to harvest as much heme iron from the food/supplements he consumes as possible so that it can be repurposed later. His immune system is taken care of by the nanobots so all he has to worry about is red blood cell and plasma production. Similar to adults, most of this takes place in his spine, ribs, skull and breastbone. The red bone marrow is stored inside these metal parts and the red blood cells are then released into his bloodstream. Plasma is created in the liver and also in bone marrow so most of that stays the same

Another fun bit about the endoskeleton:

Bones close to his skin that are in danger of being exposed (knuckles, kneecaps, cheekbones) have a very thin enamel coating to preserve the illusion that they are bones. But underneath it’s all just the same Ferrotitanium.

onto the muscular system

Muscles are laced with a Shape Memory Alloy called Nitinol. A flexible (SURPRISINGLY durable godamn) metal material made of nickel and titanium that reacts to electrical and thermal impulses. It’s already used in the medical field (I can not fucking BELIVE that this is real thats so so so SO fucking cool). Superficial muscles are more organic (80% muscle 20% nitinol) but as the muscles go deeper they become more and more synthetic (20% muscle 40% nitinol 40% titanium wiring for durability). Superficial muscles are more muscle for stealth purposes. If injuries go deeper than anticipated he will still be able to fly mostly under the radar, assuming no wires have been significantly dislodged. If he’s been injured into the deeper layers then there’s no use in trying to lay low anymore. He’s clearly in a combat situation and stealth protocols no longer matter.

ALSO I did some math to try and figure out how heavy Robbie would be with all this metal in his system. Heres the logic for my equation:

CONTENT WARNING. MATH.

About 12 - 15% of your body mass is bone. A person weighing 155 lbs will have about 22lbs of bones. One Cubic centimeter of bones will weigh about 1.85 grams.

Ferrotitanium alloy is 4.5 grams per cubic centimeter.

The equation 1.85/4.5 = 22/x in which x is his new bodyweight. Multiply 1.85 by 2.43 to get 4.5. Because the equation must be symmetrical you then multiply 22 by 2.43 to get 53.5 lbs.

With all of the extra metal in his system, I think it would be reasonable to assume that he LOOKS like he should be about 155 lbs but his actual weight is around 250 lbs. I have. NO idea how doctors are going to deal with this.

Had some VERY FUN hypotheticals from @moosemonstrous (thank you for proofreading my insanity once again <3) about his body shedding as much water as possible and like. shriveling his organs to drop as much weight as possible before doctors appointments. But given that he is a cyborg and not an android I do think that might kill him so Im thinking??? Maybe people just assume the scale is broken.... every single time he's in.

IDK man if they have access to his wack ass file then his breaking the conservation of mass is the least weird thing in there.

OKAY YAYYYYY NOW THAT I HAVE HIS INTERWORKINGS LAID OUT I CAN DO FUN CYBORG GORE!!!!! <33

64 notes

·

View notes

Text

Max Planck scientists design a process that merges metal extraction, alloying and processing into one single, eco-friendly step. Their results are now published in the journal Nature. Metal production is responsible for 10% of global CO2 emissions, with iron production emitting two tons of CO2 for every ton of metal produced, and nickel production emitting 14 tons of CO2 per ton and even more, depending on the ore used. These metals form the foundation of alloys that have a low thermal expansion, called Invar. They are critical for the aerospace, cryogenic transport, energy and precision instrument sectors. Recognizing the environmental toll, scientists at the Max Planck Institute for Sustainable Materials (MPI-SusMat) have now developed a new method to produce Invar alloys without emitting CO2 while saving a vast amount of energy -- achieving this in a single-step process that integrates metal extraction, alloying, and thermomechanical processing into a single reactor and process step.

Read more.

16 notes

·

View notes

Text

HUgE Feb 2012

Comme des Garçons champion ring

The first championship ring by Comme des Garçons

College rings are a status symbol in America. They are rings given only to commemorate graduation as a symbol of achievement. When college rings are applied to the world of sports, they are called championship rings. These rings are made to commemorate winning the postseason in major American sports such as MLB, NFL and NBA, and are prestigious items for players. Jostin's, a long-established company founded in America over 100 years ago, has been involved in the production of rings for many prestigious colleges and championship rings for famous athletes, and continues to create rings with highly designed designs that other manufacturers cannot imitate, going through over 250 processes. They are not often available on the market.

Vintage rings, military rings, and rings from prestigious schools are so popular that they can be traded at high prices. Now, Comme des Garçons is releasing its first championship ring, ordered by Jostens. The body is made of Rustrum, an alloy of nickel and chrome, which is a strong and durable material. The decorative stone is zirconia. It shines sharply depending on the angle, giving the ring a strong presence. The bezel and sides, which usually show the school name and graduation year, are engraved with logos and messages that represent the brand, such as "CDG", "LIVE FREE", "STRONG ENERGY FREEDOM", and "CREATE", which convey the spirit of the brand. Four sizes from 8.1/2 to 10 are available for men, and three sizes from 6 to 7 for women. Orders will be accepted until December 31st. This rare ring combines the quality and design of a long-established brand.

Rings from Shop Comme des Garcons: from left: ¥115,500, ¥131,250, ¥99,750 (all from Comme des Garcons)

#my scans#fashion#archive fashion#avantgarde#japanese fashion#2010s fashion#comme des garcons homme plus#comme des garçons

2 notes

·

View notes

Text

United Technologies, Pratt and Whitney J 58 information. The SR 71 and the A- 12( except for the trainer version it had J 75 engines.) All had these engines.

Legislation Twin United Technologies, corporation, UTC, Pratt and Whitney J 58 engines powered the United States, Air Force, Lockheed corporation, SR,- 71 Blackbird reconnaissance aircraft holds the record for the fastest coast-to-coast records for speed. A little history about the J 58 engine.

J 58 engine studies began in 1955. Design of the basic J 58 engine, which could dash to Mach three began in 1956 as a US Navy program the first Engine run came on Christmas Eve 1957 it evolve to meet the requirements for an engine to operate continuously at more than Mach 3 (2000 mph) and go higher than 80,000 feet.

A unique design feature of the J 58 was It’s bleed bypass system that consisted of three large diameter pipes, running along each side of the engine. At high Mach, a portion of the air would bypass the compressor and the turbine section giving it a stall-free operation, the bleed feature lead to the popular description of the J 58 engine, as being a turbo ramjet.

Prototype J 58 engines were flown as early as 1962 and the first production engines known as “YJ’s” flew a short time later.

The only major modification to the Engine’s Design occurred in 1964 when a lightweight afterburner and a variable vane inlet case were incorporated, making “K” engine. The continuous operation in military and after-burning conditions were also unique to this engine design requirement. It was in 1990 the only engine rated for continuous after burning. The engine can operate continuously at more than Mach three temperatures generated by the speed require that the engine parts be made of high temp alloys., next is a description of those metals that were chosen. Titanium in the very front of the engine was chosen for weight considerations. WASPALOY, a nickel-iron alloy, was chosen for most other components, other alloys used include INCONEL, ASTROLOY, HASTELLOY-X, AND HAYNES-25.

The fuel J-1 was latter called J-7 is used not only for combustion, but as a Hydraulic fluid, and it is the primary coolant of all controlled system components, even the engine oil is unique it is pure synthetic polyphenyl ether, and chemically stable up to 650°F. I found this information in my father's notes. ~ Linda Sheffield Miller

@Habubrats71 via X

21 notes

·

View notes

Text

Folding bowie knives and dirks, 19th century

The terms “folding dirk” and “folding bowie knife” are used, often interchangeably, to refer to large, well-made, usually ornate jack knives of the mid-19th century that were designed primarily as weapons. Strictly speaking, “folding dirk” refers only to such knives that have double-edged “dirk” or dagger blades. “Folding bowie,” the more general term, encompasses larger folding dirks, as well as big folding combat knives with clip-point or spear-point blades.

Folding dirks and bowies were the pocket-carry counterparts of the better-known fixed-blade bowie knives. Bowie knives leapt to national attention in 1827 with the notorious Sandbar Fight involving James Bowie and remained in vogue for about half a century. The folding bowie may have been just as popular as the less costly fixed blade in the 1830s, the enthusiastic early years of the bowie trend. By the 1850s, the big folders were in eclipse. After the Civil War, only small folding dirks were still available.

Almost all folding dirks and bowie knives were made in Sheffield and are over 4 1/2 inches long closed. They are generally slender, and most have a cross-guard integral with the front bolsters. Ornamental appearance was an important consideration in the design of folding dirks and bowies. Consequently, they were made in a wide variety of shapes. Another factor in their diversity of shape is that most were made from circa 1830 to 1860, before mass production and pattern standardization had taken hold in the cutlery industry. Not only are the shapes of the big knives varied but so, too, are their decorations. Their bolsters are almost always ornately embossed.

Though the knives were handmade, their fancy nickel-silver bolsters were mass-produced. Standard designs were stamped out by specialist companies and sold to the makers. Some of the original dies used to stamp these fancy mounts still exist, which helps account for a certain amount of counterfeiting—most of which is inept—and questionable repair work.

Handle materials on folding dirks and bowies are generally of high quality. Stag, ivory and mother-of-pearl are the most often encountered. Horn and tortoise shell are more unusual. We have not observed bone or wood handles on them, but some may exist.

The principal makers of folding dirks and bowies seem to have been Samuel C. Wragg, William and Samuel Butcher, George Wostenholm & Sons, and Robert and Joseph Lingard. Many other Sheffield names are found on the knives as well.

— Roger Baker and Bernard Levine, Blade's Guide to Knives & Their Values (Krause Publications, 2009) (abridged)

Descriptions:

A FOLDING BOWIE KNIFE FOR THE AMERICAN MARKET, JOSEPH HOLMES, CIRCA 1870, with robust folding locking blade formed with a clipped-back point, signed ‘Jph Holmes Warranted Cutlery’ at the ricasso, German silver cross-piece (one quillon face missing), German silver pommel cast with foliage and a horse on each face, milled copper alloy fillets, mother-of-pearl scales and vacant German silver escutcheon, 15.3 cm (closed)

A LINGARD PATENT SPRING-KNIFE, CIRCA 1860, with tapering blade retaining some stamped inscription including ‘February 9th 1850’, ricasso stamped ‘Lingard, Peacroft Sheffield, secondary blade stamped en suite, German silver fillets, mother-of-pearl scales each retained by five rivets, and embossed German silver cross-guard and pommel each decorated with scrolls and foliage, in its leather scabbard with belt loop, 13.5 cm (closed)

A FOLDING LOCK KNIFE FOR THE AMERICAN MARKET, SIMPSON, CIRCA 1860-70, with double-edged folding sprung locking blade struck ‘Simpson’ at the forte, German silver cross-piece cast with scrolls in low relief, German silver horsehead pommel seated on a cannon, milled copper allot fillets, and natural staghorn scales with German silver release stud locked by a small sliding bolt, 15.5 cm closed

A FOLDING DIRK FOR THE AMERICAN MARKET, SHEFFIELD, LATE 19TH CENTURY, with folding locking blade stamped ‘S*H Sheffield’ at the ricasso, German silver pivoting cross-piece, hardwood scales inlaid with mother-of-pearl, and German silver pommel with Federal eagle and shield, 11.0 cm, blade

A HORSEHEAD LOCKBACK SHEFFIELD FOLDING DIRK, 9" Overall open, 4" blade “HANCOCK / & / SONS / SHEFFIELD”, blade has stamped cipher ”BEST QUALITY” horn slab grips, vacant German silver escutcheon. CONDITION: good to very good overall, blade is gray w/ sharpening, 1.5" German silver floral cross guard, horse head pommel worn through at snout w/ solder exposed. (02-15586/JS).

A LOCK KNIFE, MOORE, PROBABLY SHEFFIELD, LATE 19TH CENTURY AND TWO FURTHER LOCK KNIVES, the first with folding locking blade, signed rectangular ricasso, two-piece German silver guard, natural staghorn scales over brass fillets, and vacant German silver escutcheon; the second and third of similar form, with German silver guards and pommels each cast with scrolling foliage in low relief, and polished horn scales, the first: 13.2 cm (closed) (3)

James Rodgers & Sons Folding Dirk with Pearl Grip Panels and Relief German Silver Mountings 4 3/8-inch spearpoint locking blade, with "V[crown]R/James/Rodgers/Sheffield" on ricasso. Overall length when opened, 9 3/8-inches. Relief acanthus leaf and shell German silver mountings, the mother-of-pearl grip panels with oval escutcheon inlay on one side. Late 19th century. Very good to fine. Scattered pitting on steel and sharpening marks, gray patina to tang. Pearl with minor chipping. 4/20/07 RLW #297E

A 19th century folding Bowie type knife, 9¾” open, the 4½” clipped back blade etched on one side with panel of scrolling foliage, and on the other side with a bunch of grapes and vines (evidently added later), the base of the blade stamped “John B. Hobson” (has been pitted and cleaned); with German silver crosspiece and pommel, the crosspiece embossed with foliate scrolls, pommel with flutes, vines and bunches of grapes; bone sideplates, one side inset with openwork white metal panel, the other side scratched “1859 Tesmaker” (or Tes Maker?). Good Condition (small crack in one sideplate). Plate 5

A MID-VICTORIAN FOLDING DIRK OR BOWIE KNIFE BY W RODGERS, CIRCA 1850, 11cm flattened diamond section blade stamped W RODGERS CELEBRATED CUTLERY, foliate embossed white metal crossguard, riveted two-piece natural stag horn grips, the white metal pommel decorated with flowers and foliage. This is an earlier and rarer W Rodgers and not to be confused with the later William Rodgers

37 notes

·

View notes

Text

The Commonly Used Metal 3D Printing Materials

Metal 3D printing uses a variety of metal powders, wires, and even liquid resins infused with metal. Almost any metal can be 3D printed, from stainless steel to nickel-based alloys, and in practice, about 8 are most commonly used. The most common question about metal 3D printing is: Will the final part have the same mechanical properties as a machined, moulded or forged metal part? The answer is yes, and sometimes even better mechanical quality, but it depends a lot on the metal 3D printing technology you use, the type of feedstock used, post-processing and the shape of the part. In addition, the comparison depends on the aspects you are concerned about: for example, tensile strength, static load strength, high cycle fatigue, and so on.

In general, the material properties of metal parts made by metal bond jetting are equivalent to those of metal parts produced by metal injection moulding, and it is one of the most widely used manufacturing methods for the mass production of metal parts. These 8 metal alloys below are just the beginning of what is possible today as metal material producers continue to push the boundaries and customize metal alloys for specific needs using specific metal 3D printing technologies.

1.Stainless Steel Feature: All-round Stainless steel is not the material most commonly used in 3D printing, but many alloy varieties. The first two are 316L and 17-4 PH, but also 304L, 15-5 PH, 420, 254, PH1, GP1, 630, and 410 can be printed, as well as custom blends produced by material manufacturer. These steels are specifically designed to resist corrosion. They are a lightweight and affordable metal that is ideal for 3D printing. This is because it is faster and cheaper than traditional methods and can print small batches and complex parts. 3D printing is the preferred option for companies that need a single tool or several replacement parts. Stainless steel can be used in almost any type of 3D printing, from economical wire for extruded 3D printing on benchtop machines to powder for binder jetting and laser powder bed fusion, and even resin.

2.Tool Steel Feature: High hardness, good wear resistance Tool steels, like stainless steels, come in different varieties with different tensile strengths, ductility, hardness and other properties. Tool steels are a variety of alloy steels designed specifically for the manufacture of tools. They are known for their hardness, wear resistance and ability to hold a cutting edge at high temperatures. This 3D printing steel is commonly used in the manufacture of injection mould inserts, aerospace components, military applications, manufacturing tools, as well as construction and architecture. The main advantage of 3D printed tool steel is not only its strength, but also its unique ability to create parts with internal channels (e.g. cooling channels in moulding tools) and lattice fillings that cannot be manufactured by traditional methods.

3.Low-Alloy Steel All 3D printing steels are alloys, but this category includes steels with low or less than 5 per cent of other elements. These low alloy steels are designed to have higher mechanical properties and greater resistance to wear and corrosion than other steels which are commonly used in automotive, aerospace and structural applications.

4.Aluminum Feature: Lightweight and corrosion resistant For aerospace, automotive and industry, the design freedom and cost efficiency of 3D printing further enhances the lightweight and chemical resistance of aluminum components. The use of aluminum and aluminum alloys in 3D printing is surging because the metal is economical and easy to 3D print. Like most metals, aluminum can be used as wire or powder for a variety of 3D printing techniques. Aluminium has good chemical resistance, is very light and has one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it is the choice of many in the aerospace and automotive industries because of its ability to withstand harsh conditions.

5.Titanium Feature: Lightweight and biocompatible As strong as steel but half the weight, titanium is a complex metal that is practically made for 3D printing. Titanium has become one of the most commonly used metals in additive manufacturing, with a wide range of applications in aerospace, joint replacement and surgical tools, racing car and bicycle frames, electronics and other high-performance products. Titanium and titanium-based alloys offer high mechanical strength, high strength-to-weight ratios and better corrosion resistance than stainless steel. It makes rockets and aircraft lighter, thus saving fuel and increasing payload capacity. In the medical industry, 3D printed titanium implants have been successfully used in the spine, hips, knees and extremities due to the inherent biocompatibility and good mechanical properties of the metal, coupled with the ability to customize porous structures with 3D printing, allowing for osseointegration and mass customization for better patient outcomes.

6.Copper Feature: Electrical and thermal conductivity 3D printing using pure copper and space-age copper alloys is available with a range of metal 3D printers and services. You can create rapid copper prototypes using copper filament on an FDM 3D printer and large copper rocket boosters using copper alloys on a laser powder bed fusion 3D printer. There is also copper wire and copper resin for micro 3D printing. In fact, copper plays a huge role in the global sustainable development goals as a key component of electric motors, charging infrastructure, solar energy and batteries.

7.Nickel Alloy Feature: Extreme environments resistant Nickel-based alloys and "high-temperature alloys" are known for their excellent high-temperature strength, corrosion and oxidation resistance. These alloys retain their strength and mechanical properties at high temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing and marine environments. In recent years, these alloys have also become increasingly popular in 3D printing, especially in the aerospace and automotive industries. When referring to nickel alloys, you may hear the term inconel. Inconel is the trade name for a range of nickel-chromium-based high-temperature alloys, including IN625, IN718 and IN939. Nickel alloys are generally more expensive than other materials such as steel and aluminium and may not be suitable for low temperature applications.

8.Cobalt Chrome Feature: High temperature and corrosion resistance 3D printed cobalt chrome has a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It is also biocompatible and is often used in orthopaedic implants, dental prosthetics and medical devices that require long-term contact with biological tissue. Cobalt-chromium alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows complex geometries and customized parts to be produced with minimal material waste, making it attractive to industries adopting advanced manufacturing techniques.

To sum up, metal 3D printing uses a wide range of metal powders and wires, including stainless steel, tool steel, etc. to print complex parts with superior mechanical properties. Commonly used metals in 3D printing include aluminum, titanium, copper, nickel alloys, tool steel, cobalt-chromium alloys, stainless steel for aerospace, medical and jewellery applications and more.

#design#business#autos#prototype#prototyping#prototype machining#rapid prototyping#3d printed#3d printing#3d printing services#sls#slm

2 notes

·

View notes

Text

Jay Steel Corporation: Leading Nickel fastener Manufacturers in India Jay Steel Corporation is a trusted and reputable manufacturer of nickel fasteners to cater to various industrial applications. Their extensive inventory includes grades like 200, 201 and many more, allowing customers to find the right material for their specific needs.

0 notes

Text

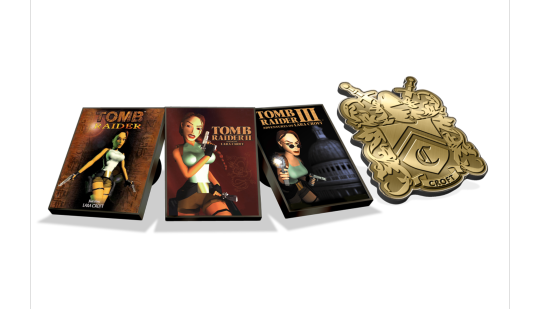

Idea Planet Launch Tomb Raider Collector Bundle - Lara Croft's Backpack

ITEM NEEDS CROWD FUNDING

First proposed in 2023 through fan surveys, this bundle features Lara Croft’s Backpack, Lara’s Journal and some Tomb Raider game covers pin badge collection. The bundle itself will not go into production unless it can get the support of 2500 people to back the project. Pre-orders began at 08:00 a.m. EST on February 14, 2024, and run until 11:59 p.m. EST on March 31, 2024. The bundle will cost $119.

The backpack itself measures approximately W13" x H10.5" x D5", with space to fit a tablet, chargers, a journal, and more! It is made from authentically-aged and distressed top-quality vegan leather and will have a fully lined interior. The main compartment features two smaller compartments and for ease, the backpack will be fastened by snap closures although it has brass buckles for extra detailing. Just like Lara's backpack as seen in the classic games, this backpack also has the two outside side pockets and one front pocket. Every backpack will be individually numbered.

The journal measures W5.3" x L8.5" x and 0.75" thick, and is very reminiscent to the journals seen in the Rise of the Tomb Raider collector's Edition. Just like the backpack, it will be made of authentically aged and distressed top-quality vegan leather and features the the debossed Croft family crest on the front. It contains 85 blank pages, weathered, 150 gsm acid free paper and the whole thing can be fastened by an adjustable leather strap closure.

The pins that feature the cover art from the first three Tomb Raider games measure in at H1.83" x W1.43", made from die-cast zinc alloy with rubber stopper. The family crest pin is a little bigger, measuring at H2" x W1.6", also made from die-cast zinc alloy, but finished with antique nickel with metallic gold and black wash. It also has a rubber stopper.

To preorder or see more images, click HERE!

9 notes

·

View notes

Text

Buy SS 304 Blind Flange | Lowest Price in India

SS 304 Blind Flanges are a vital component for industrial piping systems, known for their durability, corrosion resistance, and strength. These flanges, made from stainless steel grade 304, are designed to seal the ends of pipes or valves, making them ideal for industries such as oil and gas, chemical processing, water treatment, and more. For businesses in India, finding SS 304 Blind Flanges at the lowest price is essential for minimizing operational costs while ensuring high-quality performance. With a wide range of suppliers offering competitive pricing, it's easier than ever to source these flanges at the best rates.

What is SS 304 Blind Flange?

SS 304 Blind Flanges are flat, circular components used to close off the ends of pipelines, valves, or pressure vessels. Unlike other flanges, the blind flange does not have a central bore, meaning it completely blocks the flow of liquid or gas through the pipe. This makes it useful for isolating sections of a piping system for maintenance, testing, or system shutdowns.

The material used in these flanges—stainless steel grade 304—is an austenitic alloy with high chromium (18%) and nickel (8%) content. This composition gives SS 304 its excellent corrosion resistance, making it a perfect choice for harsh industrial environments where chemicals, moisture, and high temperatures are present.

Benefits of SS 304 Blind Flange

1. Outstanding Corrosion Resistance: The SS 304 Blind Flange’s high chromium content allows it to form a passive layer of chromium oxide on its surface, which prevents rust and corrosion. This makes it ideal for use in chemical processing, oil refineries, water treatment plants, and other industries that deal with corrosive environments.

2. High Strength and Durability: SS 304 Blind Flanges are designed to withstand extreme pressures and temperatures. This makes them suitable for high-pressure applications, including oil and gas pipelines, steam systems, and heavy-duty processing plants. Their durability ensures long-term performance without frequent replacements, reducing maintenance costs.

3. Low Maintenance: Due to its superior resistance to corrosion and wear, SS 304 Blind Flanges require minimal maintenance compared to other materials. This makes them a cost-effective choice for industries where reliable performance and low upkeep are critical.

4. Versatile Applications: SS 304 Blind Flanges are used across a wide range of industries. They are suitable for temporarily sealing off pipelines during repairs or permanently closing off systems. Their versatility makes them valuable in oil and gas, petrochemical, marine, pharmaceutical, food processing, and water treatment industries.

Why Buy SS 304 Blind Flanges in India?

India is home to a vast array of suppliers and manufacturers offering SS 304 Blind Flanges at competitive prices. Buying locally ensures that you have access to high-quality products that meet Indian and international standards, such as ASTM or ASME certifications. Here are a few reasons why purchasing SS 304 Blind Flanges in India makes sense:

1. Cost-Effective Pricing: Indian suppliers offer some of the most competitive prices in the global market for SS 304 Blind Flanges. Whether you're looking to buy in small quantities or bulk, Indian manufacturers provide quality products at reasonable rates, often with the option to negotiate prices for large orders.

2. Fast Delivery and Local Availability: When you buy from Indian suppliers, you benefit from faster delivery times and lower shipping costs, especially for domestic orders. Many suppliers have stock readily available, ensuring that you can meet your project deadlines without delays.

3. Industry-Standard Certifications: SS 304 Blind Flanges manufactured in India often adhere to industry standards such as ASTM, ASME, or DIN. These certifications guarantee that the flanges meet the required quality and performance specifications, ensuring safety and reliability in industrial applications.

4. Bulk Discounts: Many suppliers in India offer discounts on bulk orders, making it more affordable for businesses that need large quantities of SS 304 Blind Flanges. Bulk purchasing not only reduces the unit price but can also lead to savings on transportation and logistics.

Applications of SS 304 Blind Flange

SS 304 Blind Flanges are used in various industrial settings due to their robust and corrosion-resistant properties. Common applications include:

Oil and Gas Industry: SS 304 Blind Flanges are used to close off pipeline sections during repairs or testing, especially in environments where corrosion is a concern.

Chemical Processing: In chemical plants, these flanges are used to block pipes that carry corrosive fluids, ensuring the system remains secure and sealed.

Water Treatment Plants: SS 304 Blind Flanges help in sealing off sections of water pipelines, providing a rust-resistant solution for water treatment facilities.

Marine Applications: Due to their resistance to seawater corrosion, SS 304 Blind Flanges are used in marine environments, including shipbuilding and offshore drilling operations.

Pharmaceutical and Food Industry: The non-reactive and hygienic properties of SS 304 make it an excellent choice for industries that require clean and sterile processing, such as pharmaceuticals and food manufacturing.

Tips for Finding SS 304 Blind Flanges at the Lowest Price in India

1. Compare Multiple Suppliers: When purchasing SS 304 Blind Flanges in India, it’s important to compare prices from several suppliers. This will allow you to find the most competitive pricing while ensuring the quality of the product.

2. Look for Bulk Discounts: If your project requires a large quantity of flanges, ask suppliers about bulk pricing. Many manufacturers offer substantial discounts for large orders, helping you reduce the cost per unit.

3. Check for Certifications: Make sure the supplier offers SS 304 Blind Flanges that meet industry standards like ASTM, ASME, or DIN. Certified products provide assurance that the flange will perform under the required conditions.

4. Negotiate for Better Pricing: Negotiation is common in the industrial supply market. If you’re placing a large order or planning a long-term partnership, don’t hesitate to ask for better terms or discounts.

5. Look for Seasonal or Promotional Offers: Some suppliers may offer seasonal discounts or promotional deals on SS 304 Blind Flanges. Stay on the lookout for such opportunities to get the best value for your money.

#SS304BlindFlange#BuySS304Flange#StainlessSteelFlange#IndustrialFlange#CorrosionResistantFlange#LowestPriceInIndia#PipelineSolutions#OilAndGasFlange#MarineFlange#WaterTreatmentFlange#BuyNow#IndiaFlangeDeals

5 notes

·

View notes

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Monel K500 Pipe Fittings Manufacturers in India

-Manilaxmi Industrial

Monel K500 Pipe Fittings are a great option. Because of their increased strength and longevity, the nickel-copper alloy used to make these fittings makes them perfect for a range of demanding applications.

Manilaxmi Industrial is one of the leading exporters of Monel K500 pipe fittings. Customers all over the world are drawn to our products because of their outstanding quality and functionality.

#PipeFittings#IndustrialFittings#PlumbingSupplies#PipingSolutions#PipeConnections#PipeInstallation#PipeAccessories#IndustrialPipes#PlumbingFittings#Pipework#PipeFabrication#PipeSystems#PipeParts#PipeManufacturing#PipingIndustry

2 notes

·

View notes

Text

when a safety pin has that atomic age pre-mass-production-of-shitty-nickel-alloy vintage ironsteel strenghtfeel and you know you can fully let that strong stiff armpin keep your garments in place.... the pleasure is almost sexual

11 notes

·

View notes

Text

Cobalt Nickel 188 Sheet

Alloy 188 is a cobalt-nickel-chromium-tungsten super alloy that is sold under different brand names including: Nickel Alloy 188, Haynes® 188, Udimet 188®. Due to its high level of chromium mixed with small amounts of lanthanum, Alloy 188 can be used to create products that are incredibly tough and corrosion resistant.

Alloy 188 provides an excellent high-temperature strength, suflidation resistance, and good oxidation resistance up to 2000 °F (1095°C). Fabrication is not difficult with Alloy 188, and it can be cold and hot worked, and offers users outstanding ductility and metallurgical stability.

For More Information: Visit Our Website: https://www.aluminiumwala.com/ Contact No: +91 916 734 7029 E-Mail ID: [email protected]

6 notes

·

View notes

Text

Apollo (Brooch)

I have been meaning to post more of my artwork here, so here's one:

July, 2020 Gibeon meteorite, sterling silver, stainless steel wire 54mm x 48mm x 5mm (HxWxD | Measured at the thickest point.)

Iron meteorites are hunks of metal which amble through space for billions of years. Sometimes, against all odds, these extraterrestrial objects will find their way to our small planet, where they will sit for millions of years until one of our own discovers them through chance.

If you cut one of these meteorites in half you will reveal an intricate lattice-work structure of two different nickel-like alloys. They call these “Widmanstätten Patterns”, and they are unique to every meteorite. (Meteorites are sort of like deadly cosmic snowflakes if you think about it.) These patterns are the product of phenomenal cosmic forces acting upon the metal as it aimlessly drifts through space for a truly unimaginable amount of time.

This brooch features a fraction of one such meteorite in the center of it that I cut, shaped, polished, and then etched to reveal its unique pattern. The formal aspect of this brooch was heavily inspired by the Voyager 2 space probe, as well as fictional interstellar objects depicted in retro-futuristic illustrations from the 1970s and 80s. The silhouette was designed to direct attention to the extraterrestrial centerpiece and signify space exploration through iconic design elements.

In the end, everything is made of stardust; some of it is just a long way from home.

#metalsmithing#jewelry#metalsmith#handmade#metalwork#meteorite#gibeon#space#nasa#brooch#art jewelry#wmvmetals

13 notes

·

View notes