#titanium alloy products

Explore tagged Tumblr posts

Text

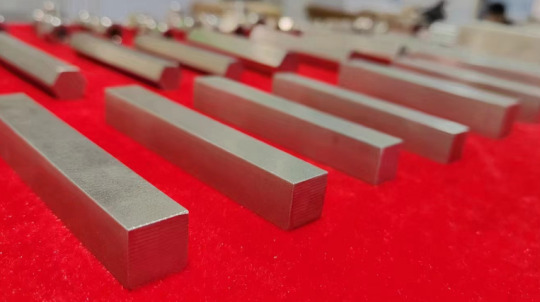

Different Types of Titanium Sheets & Plates: Grades, Characteristics, & Usage

Titanium Alloys are a versatile material that reveals giant use across numerous industries because of its top notch properties. Titanium sheets and plates, particularly, function indispensable additives in aerospace, car, medical, commercial programs, and so forth. At Jay Stel Corporations, we delight ourselves on being the foremost Titanium Alloy Sheets Manufacturer & Titanium Alloy Plates Exporter of top class satisfactory, providing a complete variety of titanium sheets and plates in a couple of Titanium grade alternatives Gr. 2, Gr, 5, Gr. 7, Gr.12 to cater to diverse business desires.

In this insightful guide, we'll delve into the numerous sorts of titanium sheets and plates, highlighting their grades, precise traits, and good sized programs.

Different Types of Titanium Sheets and Plates

Hot Rolled Sheets: Hot-rolled titanium sheets are produced at high temperatures, resulting in a scaled surface finish and progressed mechanical houses appropriate for forming and shaping packages.

Cold Rolled Sheets: Cold rolled titanium sheets go through a process of bloodless reduction, yielding smoother surfaces, tighter thickness tolerances, and more advantageous floor finishes, making them perfect for precision engineering and aesthetic applications.

Plates: Titanium plates are usually thicker than sheets and are produced thru warm-rolling or cold-rolling tactics, imparting superior power and sturdiness for structural packages inclusive of aerospace additives, commercial equipment, and marine vessels.

Sheets: Titanium sheets are thin, flat pieces of titanium cloth to be had in various thicknesses, imparting versatility in programs ranging from architectural cladding to clinical device production, where light-weight, corrosion resistance, and formability are paramount.

Exploring Titanium Sheets & Plates Grades

As a famous Titanium Alloy Sheets Manufacturer & Titanium Alloy Plates Exporter, we provide an array of grades to satisfy the stringent requirements of different industries: Titanium sheets and plates come in quite a few grades, every engineered to satisfy particular necessities primarily based on their alloy composition and residences. The most usually used grades include:

Grade 2 Titanium Sheets & Plates:

Commercially pure titanium is famend for its incredible corrosion resistance and formability. Ideal for applications requiring moderate energy and weldability, including structure and scientific devices.

Grade 5 Titanium (Ti-6Al-4V):

Alloyed with aluminum and vanadium for better energy and heat resistance. Widely utilized in aerospace components, sports system, and automotive parts because of its super overall performance.

Grade 7 Titanium Sheets & Plates:

Alloyed with palladium for superior corrosion resistance in reducing environments.

Well-applicable for chemical processing device, seawater applications, and offshore structures.

Grade 12 Titanium Sheets & Plates:

Alloyed with molybdenum and nickel for advanced strength and creep resistance.

Ideal for high-pressure vessels, heat exchangers, and commercial equipment.

Characteristics of Titanium Sheets & Plates:

Titanium sheets and plates offer numerous different characteristics that make them surprisingly sought-after in various industries:

Lightweight: Titanium boasts a low density, making it significantly lighter than metallic even as maintaining similar strength, best for weight-touchy packages like aerospace engineering.

Corrosion Resistance: Titanium well-knownshows superb corrosion resistance, even in harsh environments including seawater and chemical processing vegetation, ensuring durability and reliability in corrosive atmospheres.

High Strength-to-Weight Ratio: Despite its light-weight nature, titanium possesses terrific energy, bearing in mind the layout of strong systems without adding excessive weight, crucial in industries where both power and weight are crucial factors.

Biocompatibility: Certain titanium grades, such as Grade five, are biocompatible, that means they're properly-tolerated by the human body and regularly utilized in scientific implants, dental prosthetics, and surgical devices.

Temperature Resistance: Titanium keeps its mechanical properties at multiplied temperatures, making it appropriate for packages uncovered to intense warmness, which include exhaust systems in automotive and aerospace packages.

Titanium Sheets & Plates Usage Across Industries:

Titanium sheets and plates discover sizable utilization throughout various industries, inclusive of but no longer restricted to:

Aerospace: Titanium alloys are appreciably used in aircraft systems, engine additives, and spacecraft because of their lightweight nature, high energy, and warmth resistance.

Medical: Titanium implants, surgical units, and scientific gadgets leverage the biocompatibility and corrosion resistance of titanium, making sure secure and lengthy-lasting overall performance inside the human frame.

Chemical Processing: Titanium's corrosion resistance makes it precious in chemical processing system, reactors, and storage tanks, where exposure to corrosive materials is usual.

Marine Industry: Titanium's resistance to seawater corrosion makes it a perfect choice for marine hardware, offshore systems, and desalination plants, ensuring durability in maritime environments.

Industrial: From warmth exchangers and pressure vessels to warmth shields and industrial equipment, titanium sheets and plates play a important function in various business programs, wherein sturdiness and overall performance are paramount.

Apart from those, our titanium sheets and plates also are utilized in Sporting Goods, Energy Industry, Electronics, Automotive and plenty of more.

Final Words!

The diverse range of titanium sheets and plates is obtainable by using Jay Stel Corporation, a outstanding producer of titanium alloy sheets and plates exporter. As a depended on Titanium Alloy GR 2 Sheets Stockist, we make certain spark off availability to satisfy your requirements. Additionally, we excel as a Titanium Alloy GR 5 Plates Supplier, handing over great products tailor-made in your specifications. For those in search of titanium alloy GR 7 sheets, depend on us as your selected titanium alloy GR 7 sheets Exporter, presenting precision-engineered solutions throughout industries. Whether you are in need of a Titanium Alloy Sheets Manufacture or in search of a Titanium Alloy Plates Exporter, Jay Stel Corporation stands geared up to exceed your expectations.

Resourch Link: https://jaysteelcorporation.co.in/blog/different-types-of-titanium-sheets-plates-grades-characteristics-usage/

0 notes

Note

.

Is spider silk being as strong as steel another lie from childhood? Bc you're able to break it pretty easily on accident. Genuinely asking.

spider silk IS actually significantly stronger pound-for-pound than the same amount of steel, but only in one direction! and coincidentally, it's the same exact direction that got a bunch of people killed in a submersible last month.

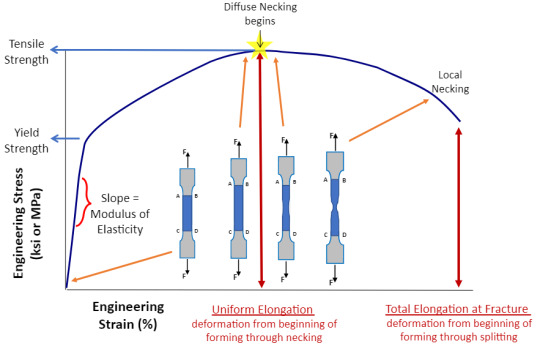

see, when people talk about the "strength" of spider silk versus steel, they're specifically talking about tensile strength:

which is specifically the measure of the strength of a material when two forces are pulling at it from the ends, like when a steel cable is holding up a bridge support, or crane cargo:

or like when a strand of silk is supporting the entire spider.

that's tensile strength, baby!

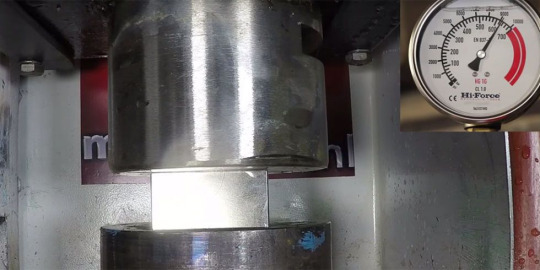

but there's another type of strength that's very important to take into consideration when you're actually building things like bridges and submersibles, and spider silk and similar materials like carbon fiber are absolutely garbage at it! and that's compressive strength.

this is basically the inverse of tensile strength, where instead of being yanked at from both ends, the forces are crushing inwards at the material from both directions instead.

you can expect to see these kinds of forces involved in road surfaces, vehicle engines, and again, submersibles.

now steel and its more competent cousin titanium are fucking GREAT at compressive strength! the harder the outside forces are compressing them, the stronger the metals get.

NOT TODAY, FUCKERS

but strand-based materials like spider silk and, again, carbon fiber, are fucking garbage at this. they can take a certain amount of pressure, but each round with compressive forces snaps some of the strands that makes up the material! and those don't grow back, so basically you're just gradually reducing your poor overstressed carbon-fiber hull into a completely useless shell of shattered thread fragments over time as the strands of fiber that actually give it strength die off one by one.

and eventually, something's gotta give! and then people die about it.

this is why, even though spider silk IS stronger than steel in one specific way, we're never going to stop using steel in industrial applications and switch over to spider silk or carbon fiber full time. these materials all have their areas of use, and steel just covers a wider base of applications.

and don't even get me started on shear strength. we'll be here all damn day.

#huh. i was going to take issue with the 'more competent cousin' statement#but titanium alloys have come a long way since my undergrad days#it seems they've resolved the fatigue limit issues and now the main barrier is cost#though i wonder if the hcp structure is as friendly to production techniques like knurling#machining is still a splosion hazard i think

5K notes

·

View notes

Text

Nowadays, we have access to more manufacturing capability than ever before. Weirdos working in their basements can quickly order professional-looking products. A single drunken whim can activate a factory half a world away, to pump out something that would have been impossible for even the hardest-working hobbyist even twenty years ago. Sometimes you can do it at home.

Obviously, this is great. All your strange little joke projects can be near-instantly materialized into reality. You can add to the world's surplus of shit that nobody needs for mere pennies. Total nirvana, right? Wrong: the next thing you want is more capability. It's incredible what you can already do, sure, sure, but now I want to be able to laser cut aerospace-grade titanium in my living room.

This sort of tension between can-do spirit and can't-do reality is what has gotten us this far, however. Even now, there are sleep-deprived hobbyists working hard on making sure that I can fill my entire house with noxious gases and fine mineral particulate. They want to help me construct a toaster entirely out of an alloy that we once had to trick the Soviet Union into letting us buy to turn into stealth bombers.

This is what real progress is, not that false thing that happens outside my house, at the place called "work." Here, no manager is going to stand over me and tell me that an inert nitrogen-purged atmosphere is probably not the same thing as a shag carpet for the purposes of welding. Thank you, hard-working weirdos.

154 notes

·

View notes

Text

WERE DOING SPECBIO STUFF AGAIN BABY. Feels fucking good to get back to my roots (i get to close 50 tabs worth of research now. Delightful)

Terminators are made of a Titanium Alloy (Im going with ferrotitanium which is a mix of iron and titanium. They never specify in the movie what the titanium is mixed with so fuck it we ball baby)) skeleton contains limited amounts of Mimetic Polyalloy (fake material used for the terminator in terminator two). Mimetic polyalloy can be hard or flexible and will be used to create new structures that the iron collected from food will later fully establish. This will allow his metal endoskeleton to mimic standard growth that a regular skeleton would have growing up.

When first introduced to the foster system (medical checkups are required once entering the foster system. The police probably do some checkups on Robbie also just to make sure hes okay when they find him), medical tests show that he has anemia, so it’s recommended he be put on iron supplements. My reasoning is any iron in his blood is almost instantly sent to work on growing his endoskeleton. That means the actual amount of iron left in his blood is pretty low (the opposite of this is hemochromatosis which is when there's too much iron in your blood). I could see him probably trying to stop iron supplements but I think there would be some side effects to convince him to start taking them again. His joints might ache or I could see child terminator Robbie saying some mildly concerning shit like ‘my bones feel hungry’. I also think he might crave foods that are high in iron. Like beef/chicken liver, canned tuna, and seafood. Idk how frequently he could AFFORD these things but yk. The endoskeleton hungers eternal ¯\_(ツ)_/¯

Nanobots are used to repair wiring for his nervous system, synthetic muscular system, acts as his immune system and sometimes accelerates healing for his organic systems (organic parts of his muscular system, skin, and nerves). For the most part his organic systems heal on their own at about the same pace as a normal human person. Nanomachines/nanoparticles are fueled by glucose (if Robbie needs work done by the nanobots he might need to eat or crave sugar both before and afterwards).

He probably has a fairly (?) normal digestive system and circulatory system. The spread of his circulatory system is just more limited because some parts of him don't really need blood. . The primary job of the nanomachines when they aren't busy healing or growing his body is to harvest as much heme iron from the food/supplements he consumes as possible so that it can be repurposed later. His immune system is taken care of by the nanobots so all he has to worry about is red blood cell and plasma production. Similar to adults, most of this takes place in his spine, ribs, skull and breastbone. The red bone marrow is stored inside these metal parts and the red blood cells are then released into his bloodstream. Plasma is created in the liver and also in bone marrow so most of that stays the same

Another fun bit about the endoskeleton:

Bones close to his skin that are in danger of being exposed (knuckles, kneecaps, cheekbones) have a very thin enamel coating to preserve the illusion that they are bones. But underneath it’s all just the same Ferrotitanium.

onto the muscular system

Muscles are laced with a Shape Memory Alloy called Nitinol. A flexible (SURPRISINGLY durable godamn) metal material made of nickel and titanium that reacts to electrical and thermal impulses. It’s already used in the medical field (I can not fucking BELIVE that this is real thats so so so SO fucking cool). Superficial muscles are more organic (80% muscle 20% nitinol) but as the muscles go deeper they become more and more synthetic (20% muscle 40% nitinol 40% titanium wiring for durability). Superficial muscles are more muscle for stealth purposes. If injuries go deeper than anticipated he will still be able to fly mostly under the radar, assuming no wires have been significantly dislodged. If he’s been injured into the deeper layers then there’s no use in trying to lay low anymore. He’s clearly in a combat situation and stealth protocols no longer matter.

ALSO I did some math to try and figure out how heavy Robbie would be with all this metal in his system. Heres the logic for my equation:

CONTENT WARNING. MATH.

About 12 - 15% of your body mass is bone. A person weighing 155 lbs will have about 22lbs of bones. One Cubic centimeter of bones will weigh about 1.85 grams.

Ferrotitanium alloy is 4.5 grams per cubic centimeter.

The equation 1.85/4.5 = 22/x in which x is his new bodyweight. Multiply 1.85 by 2.43 to get 4.5. Because the equation must be symmetrical you then multiply 22 by 2.43 to get 53.5 lbs.

With all of the extra metal in his system, I think it would be reasonable to assume that he LOOKS like he should be about 155 lbs but his actual weight is around 250 lbs. I have. NO idea how doctors are going to deal with this.

Had some VERY FUN hypotheticals from @moosemonstrous (thank you for proofreading my insanity once again <3) about his body shedding as much water as possible and like. shriveling his organs to drop as much weight as possible before doctors appointments. But given that he is a cyborg and not an android I do think that might kill him so Im thinking??? Maybe people just assume the scale is broken.... every single time he's in.

IDK man if they have access to his wack ass file then his breaking the conservation of mass is the least weird thing in there.

OKAY YAYYYYY NOW THAT I HAVE HIS INTERWORKINGS LAID OUT I CAN DO FUN CYBORG GORE!!!!! <33

63 notes

·

View notes

Text

The SR 71 was at least 60 years ahead of its time.

The question was …is the SR 71 a product of its time? (Time frame would be late 1950s to 1966.)

Former U-2 technician Damien Leimback wrote; the following *In my opinion, this man is brilliant.*

He Disagrees with the question that the SR 71 was a product of its time.

I disagree because of the technologies that had to be invented or perfected in order for the plane to work that did not exist before the types (I include the A-12 here) introduction.

Here are some examples……

Using titanium in such massive amounts was unheard of in an aircraft; most of it is sourced from the Soviet Union through shell companies. New fabrication methods and new titanium alloys had to be created to build the plane.

Corrugated panels that expanded without changing shape were used in a novel way, as well as new types of glass for the windscreen and new ways of fusing it to the frame without the use of glue (that would melt under high temps) were used.

The fuel was routed through the leading edges of the wings to keep them cool and also to preheat the fuel for a better burn, novel approaches used for the first time on this plane.

The fuel itself was a custom blend and had a radioactive isotope added to it that allowed the ionization to scatter Radar waves in the high atmosphere. C-50 was used to secure the contract for the CIA. it was also called panther pi%s

Oils and lubricants had to be custom blended for the aircraft in order to function at the high and low temp extremes the plane would encounter.

The David Clark company built a pressure suit for the pilots, as the one the U-2 pilots wore was insufficient. The U-2 pilots later adopted the same suit.

The tires had aluminum mixed with latex in order to withstand the temps that would be encountered in the wheel wells during flight.

The J-58 engine was a hybrid of the turbo jet and ramjet, and MOST EFFICIENT at Mach 3.2, unheard of anywhere before or since.

And this is just a small sampling of the technologies that had to be invented or perfected in order for this plane to work. No one else was capable of flying anything like it in the 1960’s and its performance has yet to be matched today, almost 60 years later. If that's not ahead of its time, I don't know what is.

Posted by Linda Sheffield

@Habubrats71 via X

#sr 71 blackbird#aircraft#usaf#aviation#lockheed aviation#mach3+#habu#reconnaissance#cold war aircraft

42 notes

·

View notes

Text

I have reached the breaking point, the point of no return, it’s very clear to see a fool like me will never, ever learn. I have reached the breaking point, I hear the drums of doom, I’m gonna flip my wig in one great big atomic boom! —“The Breaking Point,” Bobby Darin (1966)

It Keeps Right On a-Hurtin’ #27 - Ring-a-Ding-Ding VI

Collaborative Issue! Guest Artist: @sas-afras

Archive Links

«« First | « Previous || Next » | Last »»

Read IKROAH on Archive of Our Own

Notes / Transcript:

Notes

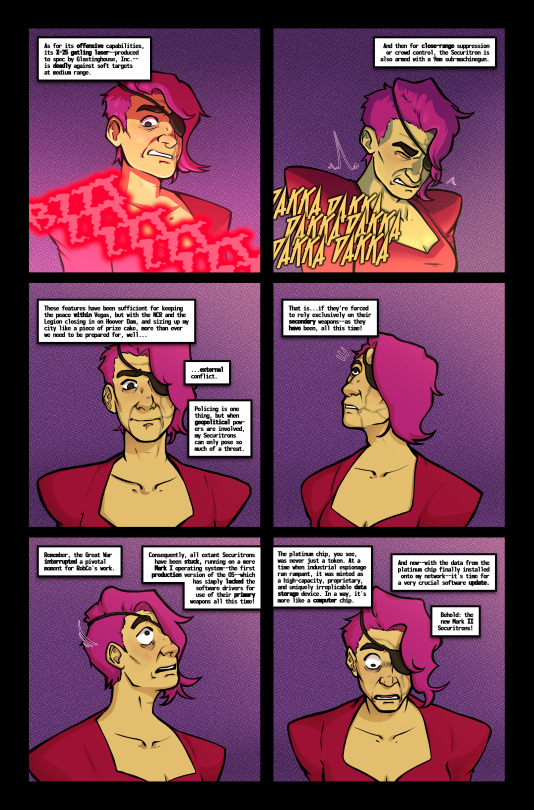

Huge thanks to Monty over at @sas-afras for getting this one done! I handled the original layout and lettering, but the rest was all them. Layouts like this can seem simple and easy because of how straight-forward and repetitive they are, but when all you've got are a dozen and one reaction shots, every single one of those reaction shots needs to be as perfect as you can get them. And Monty did a hell of a job. Especially on the coloring! Monty, if you're reading this, you're a hell of a good colorist (on top of everything else). Thanks again!

Another note about this issue is that it, along with the previous one, were some of the most difficult to write in this whole damn comic so far. I really hate repeating in-game dialogue verbatim without good reason, but there's really not much else I could do here. It's a very necessary part of the story that is also literally a part in the game where your character is fixed in place listening to a monologue. I took some liberties, did some punch-up, not just for its own sake but to really drive home what I find most interesting and vital here about Mr. House as a character.

Anyway, Agnes is in trouble. And there's only one issue left in Volume 2! The next one closes out this arc of the story, at long last. Stay tuned.

Transcript

INT. LUCKY 38 BASEMENT. From an observation deck of sorts, AGNES SANDS watches several SECURITRON robots position themselves in a testing area, containing several sandbags, dummies, and makeshift fortifications. A voice booms from an unseen speaker.

MR. HOUSE: You're well familiar with my Securitron police force. But have you ever wondered: what exactly makes them the marquee option in perimeter security and pacification?

AGNES glances in the direction of the voice, uncomfortable.

MR. HOUSE: Well to start, the reinforced titanium alloy housing of each unit, which protects its electronic core, easily deflects small arms and shrapnel.

MR. HOUSE: As for its offensive capabilities, its X-25 gatling laser—produced to spec by Glastinghouse, Inc.—is deadly against soft targets at medium range.

SFX: BZZTZZTZZTZZTZZT

AGNES recoils as a red glow washes over her from the testing area.

MR. HOUSE: And then for close-range suppression or crowd control, the Securitron is also armed with a 9mm sub-machinegun.

SFX: DAKKA DAKKA DAKKA DAKKA DAKKA DAKKA

AGNES shuts her eyes, wincing from the crack of gunfire.

MR. HOUSE: These features have been sufficient for keeping the peace within Vegas, but with the NCR and Legion closing in on Hoover Dam, and sizing up my city like a piece of prize cake, more than ever we need to be prepared for, well...external conflict. Policing is one thing, but when geopolitical powers are involved, my Securitrons can only pose so much of a threat.

MR. HOUSE: That is...if they're forced to rely exclusively on their secondary weapons--as they have been, all this time!

AGNES looks upward, surprised.

MR. HOUSE: Remember, the Great War interrupted a pivotal moment for RobCo's work. Consequently, all extant Securitrons have been stuck, running on a mere Mark I operating system—the first production version of the OS—which has simply lacked the software drivers for the use of their primary weapons all this time!

AGNES looks around, as if HOUSE were in the room somewhere and she could find him, in a panic.

MR. HOUSE: The platinum chip, you see, was never just a token. At a time when industrial espionage ran rampant, it was minted as a high capacity, proprietary, and uniquely irreplicable data storage device. In a way, it's more like a computer chip. And now—with the data from the platinum chip finally installed onto my nextwork—it's time for a very crucial software update. Behold: the new Mark II Securitrons!

AGNES gawks downward at the testing area, eyes wide. Oh no.

MR. HOUSE: Their newly accessible M-235 Missile Launcher gives them the ability to engage ground and air targets at significantly longer ranges...

SFX: PSSSSSHHH KTHOOM THOOM THOOM THOOM

AGNES flinches, covering her face for protecting, and screams as explosions rip apart the testing area below.

MR. HOUSE: ...and their rapid-fire G-28 grenade launching system, another part of the Mark II, makes them much more powerful in close-range engagements as well.

SFX: THMP THMP THMP KRRSSH KRAKTK KABOOM

AGNES, nearly frozen, watches the bombardment with horror.

MR. HOUSE: It also includes rewritten drivers for the Securitrons' auto-repair systems—although always sophisticated, the new optimizations render them inexhaustible in even the most protracted and attritious of engagements. Altogether, the Mark II upgrade confers a 235% total increase in combat effectiveness per unit—and it's all because of you!

AGNES lowers her arm slowly, jaw slack, mortified.

MR. HOUSE: Vegas finally has an army—worthy to protect not just the city itself, but the best interests of all of mankind, at home and abroad. Which is to say: this simple display of might remains a mere teaser for what I can, and what I will, accomplish, in an illustrious new epoch.

AGNES sinks further into a paralytic terror.

MR. HOUSE: What we will accomplish, Agnes—should you accept my offer, of employment. Ah—but I digress. I'm certain that you've had a long day. You can rejoin Miss Cassidy in the presidential suite for the night, if you'd like to, as they say, "sleep on it."

MR. In fact...say for as long as you'd like. However long you may need, to think everything over. And you'll be very well provided for in the meantime, consider it a taste of what could be...should you make the right choice before you.

MR. HOUSE: That reminds me���I've already sent Victor to collect your belongings from the Vault 22 Hotel, so no need to exhaust yourself further by making that trip on your own, hm? There's much about your future to consider, Agnes—and I would like you to think of it as our future.

AGNES stares straight ahead with a deadened expression.

The testing area in the basement has been reduced to smithereens. Fires rage on the rubble of obliterated structures, gnarled steel, and collapsed walkways. The dummies have been dismembered entirely.

MR. HOUSE: ...Goodness, what a mass. With friends like these, I sure wouldn't envy my enemies.

MR. HOUSE: Wouldn't you agree?

#fallout#fallout new vegas#fnv#mr. house#courier six#agnes sands#it keeps right on a hurtin#ikroah archive#volume 02#27

136 notes

·

View notes

Text

William Justin Kroll (24 November 1889 – 30 March 1973)

A Luxembourgish metallurgist, William Justin Kroll (born Guillaume Justin Kroll) moved to Berlin after graduating high school, where he completed his doctoral thesis. He then worked in Germany, followed by Austria, for a number of years before returning to Luxembourg where he would eventually turn his focus to titanium. In 1940, aware of the threat of the Nazi party in Germany to his home country, Kroll emigrated to America only months before Luxembourg was invaded and subsequently occupied.

Kroll is most well known for the titanium processing method, still the mostly widely used process today, that bears his name. His method enabled the production of high-purity titanium and increased the applications and usage of the element and its alloys. Over his lifetime he worked on many other metals and alloys, including lead, aluminum, steel, and eventually zirconium.

Sources/Further Reading: (Image source - Edubilla) (Duke) (Abrams) (Wikipedia)

17 notes

·

View notes

Text

Scientists in China have unearthed a never-before-seen type of ore that contains a rare earth element sought after for its superconductive properties. The ore, dubbed niobobaotite, is made of niobium, barium, titanium, iron and chloride, the South China Morning Post reported. It's the niobium that is causing excitement: This light-gray metal is currently used mostly in the production of steel, which it strengthens without adding significant weight. Niobium is also used in making other alloys (materials made of mixes of metals) and can be found in particle accelerators and other advanced scientific equipment because it is a superconductor at low temperatures, according to the Royal Society of Chemistry. The deposit was found in the Bayan Obo ore deposit in the city of Baotou in Inner Mongolia on Oct. 3. The brownish-black ore is the 17th new type found in the deposit and one of 150 new minerals found in the region, according to the China National Nuclear Corporation (CNNC).

Continue Reading.

133 notes

·

View notes

Text

The Mitsubishi Galant AMG: A Unique Blend of Japanese and German Engineering

The late 1980s and early 1990s were a time of significant innovation in the automotive world, with manufacturers pushing the boundaries of performance and design. One of the most intriguing collaborations of this era was between Mitsubishi and AMG, resulting in the creation of the Mitsubishi Galant AMG. This vehicle remains a fascinating piece of automotive history, representing a blend of Japanese engineering and German tuning expertise.

The Mitsubishi Galant AMG was produced from 1989 to 1991. At a time when AMG was primarily known for its work with Mercedes-Benz, this collaboration with Mitsubishi was unconventional but visionary. The project aimed to infuse the Galant with performance enhancements that would set it apart from its peers.

The Galant AMG's modifications included high compression pistons, titanium valve springs, and a special intake manifold in a 4G63 engine. These upgrades significantly boosted its performance, making it a competitive vehicle in its class.

Aesthetically, the Galant AMG featured a distinctive body kit, AMG badges, and unique alloy wheels. The interior boasted real wood trim and special upholstery, emphasizing its luxury status.

The limited production of approximately 500 units adds to the Galant AMG's allure as a collector's item. Its blend of Japanese reliability and German performance tuning continues to captivate car enthusiasts.

Though some purists criticized the collaboration, many appreciated the innovative spirit and the performance enhancements AMG brought to the Galant. This unique partnership demonstrated the potential of cross-cultural engineering collaboration.

The Mitsubishi Galant AMG stands as a testament to the possibilities that arise when different automotive philosophies unite.

#JDM#Euro Tuned#EUDM#Galant#Mitsubishi#Mitsubishi Galant#Mitsubishi Galant AMG#AMG#AMG Engineering#AMG Tuning#Tuning#brochure#catalog#4G63#MMC#rally#race car#sedan#rare cars#vintage#retro#Legends of the 90's#rare gems#Car History#三菱ギャランAMG#ギャラン#三菱#クラシックカ#日本車#希少車

9 notes

·

View notes

Text

FAA Investigating How Titanium Parts With Falsified Records Wound Up In Boeing And Airbus Planes – Detroit Michigan reporting

It will be up to regulators including the Federal Aviation Administration to decide whether any work needs to be done to planes that are already carrying passengers.

The FAA said it is “investigating the scope and impact of the issue.” The agency said Boeing reported the problem covering material from a distributor “who may have falsified or provided incorrect records.” The FAA did not name the distributor.

Boeing and Airbus declined to say how many planes were flying with parts made from the undocumented titanium.

Spirit AeroSystems, which makes fuselages for Boeing planes and wings for Airbus jets, reported the falsified documents.

“This titanium that has entered the supply system via documents that have been counterfeited,” Spirit spokesperson Joe Buccino said. “When this was identified, all suspect parts were quarantined and removed from Spirit production.”

Buccino said more than 1,000 tests have been conducted on the material “to ensure continued airworthiness.”

The New York Times first reported THE FAA INVESTIGATION. THE NEWSPAPER SAID A PARTS SUPPLIER FOUND SMALL HOLES IN THE MATERIAL FROM CORROSION.

Titanium alloys have been used for decades in aircraft production because of their light weight, strength and RESISTANCE TO CORROSION and high temperatures. They are used in airframes, landing gear and other parts.

Boeing said it was removing affected parts on planes before delivering them to airlines. “Our analysis shows the in-service fleet can continue to fly safely,” the company said. It did not say which of its aircraft models were affected.

3 notes

·

View notes

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Benefits of Titanium Alloy Products in Industrial Applications

In the area of business applications, the quest for materials that embody strength, sturdiness, and flexibility is endless. Enter Jay Steel Corporation, your maximum superb Titanium Alloy Product Supplier, that specialize in Titanium Alloy Round Bars, Plates, Sheets, and Fittings. We take satisfaction in revolutionizing several sectors with our first-rate products, tailor-made to fulfill numerous undertaking requirements. Whether you are in want of Titanium Alloy Plates or looking for a Titanium Alloy Fittings Exporter, we have were given you protection. Join us as we unveil the myriad blessings that titanium alloys supply to business endeavors.

Unmatched Strength-to-Weight Ratio: Titanium alloys are famend for his or her fantastic electricity-to-weight ratio, surpassing even that of metallic. This function makes them a skip-to preference for industries wherein light-weight however robust substances are imperative, such as aerospace, car, and scientific devices. With our sizeable variety of titanium alloy merchandise, ranging in sizes, grades, and specifications, clients can effortlessly discover the precise healthy for their particular utility, ensuring most suitable usual performance without compromising on electricity.

Exceptional Corrosion Resistance: Corrosion can wreak havoc on business system, main to luxurious renovation and downtimes. Titanium alloys, however, show off splendid corrosion resistance, even within the maximum stressful environments. Whether it's exposure to harsh chemical materials, saltwater, or extreme temperatures, our titanium alloy merchandise stand the test of time, ensuring durability and reliability in numerous Applications, from marine engineering to chemical processing vegetation.

Superior Biocompatibility: In the medical location, biocompatibility is paramount, specifically for implants and surgical units. Titanium alloys boast awesome biocompatibility, making them the cloth of desire for clinical implants, prosthetics, and surgical tools. With Jay Steel Corporation's sizeable range of titanium alloy products, health workers can rely upon advanced quality substances that seamlessly combine with the human frame, promoting recuperation and minimizing the risk of unfavourable reactions.

High Temperature Stability: Industries operating in excessive-temperature environments name for substances that may resist severe warm temperature with out compromising usual performance. Titanium alloys excel on this regard, displaying tremendous heat resistance and thermal stability. From aerospace components subjected to severe warmth in the course of flight to business furnaces and energy generation mills, our titanium alloy products ensure reliable operation even within the most harsh situations, contributing to advanced overall performance and safety.

Cost-Effective Long-Term Solution: While the preliminary investment in titanium alloy merchandise can be higher in assessment to conventional substances, their lengthy-term benefits a long way outweigh the prices. Thanks to their extraordinary sturdiness and resistance to corrosion and fatigue, titanium alloys provide a fee-powerful solution in the long run, minimizing renovation costs and prolonging equipment lifespan. At Jay Steel Corporation, we provide competitive pricing on our titanium alloy merchandise, making sure that our clients get keep of splendid cost for their funding.

Final Words!

The plain advantages of titanium alloy products in industrial Applications span at some point of severa sectors, from aerospace and car to clinical and marine industries. The versatility and top notch performance of titanium alloys constantly redefine excellence necessities. Jay Steel Corporation stands as your committed Titanium Alloy Product Supplier, offering a comprehensive range which includes Titanium Alloy Round Bars, Plates, Sheets, and Fittings. We are devoted to empowering industries with many of the satisfactory solutions, fostering innovation and development. Trust Jay Steel Corporation to be your reliable associate in turning in top charge titanium alloy merchandise, using fulfillment in tough environments. Experience the distinction in recent times.

0 notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

☝️ good heat absorber; it was also a good heat emitter.” Ben said to Kelly Johnson, “Think of how much easier it will be to build the airplane using a softer titanium, which we can do if we lower the heat friction temperature on the surface.”

The black paint would actually radiate away more heat than it would absorb through fiction. I calculated that at the color would lower the temperature by 35°, which would make it possible to use the more pliable soft titanium. Titanium is so hard that in the right thickness, it is bulletproof. When you add alloys with the titanium ( making it softer) and lower the heat on the skin of the SR 71 by adding black paint, this is a win-win solution. The heat generated by the high friction of flying Mach 3.3 causes a 3.6 Celsius or 600 Fahrenheit surface heat on the SR 71.

The early days at the Skunk Works. Fortunately, they documented, and catalog everything. Through the documentation, it was discovered that spot-welding parts made in the summer were failing, but those welding in the winner were just fine. Why? The water supply used chlorine during the summer. They discovered cadmium tools were causing corrosion, which caused the bolts to fail. All Cadmium tools were replaced, and distilled water was used instead of the local water supply.

The people that worked at the Skunk Works were geniuses that worked together to overcome the problems that occurred during production. This, along with the work ethic maintained by the Skunk Works, was how they were able to make the Blackbirds on schedule years before technology caught up with their methods . Written by Linda Sheffield Miller

211 notes

·

View notes

Text

Ford TuringKa Concept (1998) - A Bigger Ka(r)

[ALT: The logotype design for the Ford TuringKa concept car. At the background is a retro globe in yellow. In front are the words "Turing" in white and "Ka" in grey.] (image source: me)

Ah yes, the funny shitbox that is the first-generation Ford Ka. Many British teens in the 2000's probably had it as their first car. Many Gran Turismo fans regard it as a meme icon purely for the looks. I'm neither a British teen in the 2000's nor a (hardcore) Gran Turismo fan, but I appreciate this car nonetheless.

Now the Ka wasn't large in any stretch - in fact, it was the smallest of Ford's lineup. But what if it was bigger? What would a grown-up Ka look like? This was Ghia's answer: the TuringKa.

[ALT: A 3/4 left shot, back shot and interior shot of the Ford TuringKa concept car. More details below.] (image source: wheelsage.org)

Immediately, one would notice the addition of 2 doors at the back. Turned out the Italians had elongated the Ka into the size of a more conventionally-sized hatchback (some may classify it as a wagon too), which doesn't look too shabby. On top of that, they also designed it to have titanium grey bumpers contrasting the bright yellow body and wider wheel arches to accommodate the 17-inch cast alloy wheels. The other body panels remained the same as the ones found in the production model.

The interior was covered with leather from the seats to even the luggage compartment and completed with yellow accents. This style was similar to the interior of the 1992 Ford Focus concept by the same design house.

The production-model Ka's puny 60hp engine was replaced by a 1.7L Zetec inline-4 engine sourced from the Ford Puma, which provided double the horsepower to mitigate the weight gains from having 2 extra doors. Disc brakes on all 4 wheels completed the car's performance-oriented look.

While the TuringKa only remained a concept, it seems to be in good hands. As of 2019, it is currently kept in a private collection in Florida, making appearances in special events on occasion.

4 notes

·

View notes

Text

First 3D visualization of an aluminum nanocomposite for the auto industry

Manufacturing cars with strong, lightweight aluminum alloys rather than steel could improve fuel efficiency and extend electric vehicle range, but the material's instability at high temperatures has held the alloys back from widespread adoption. Creating tiny, reinforcing particles of titanium carbide (TiC) directly inside of molten aluminum results in a stronger, more temperature resistant aluminum-based material called a metal matrix nanocomposite. Up to this point, researchers have not understood how these nanoparticles form, or how they interact with other features in the microstructure, hindering production of the material on an industrial scale.

Read more.

#Materials Science#Science#Aluminum#Composites#Nanotechnology#Cars#Titanium carbide#Titanium#Carbides#Materials characterization#Intermetallics#University of Michigan

12 notes

·

View notes