#Monel

Explore tagged Tumblr posts

Text

#IYKYK #405LexingtonAvenue #Manhattan #Eagle #Monel

113 notes

·

View notes

Text

Manilaxmi Industrial Announcing New Blog Site

Our blog provides Insights, industry updates, and in-depth information on industrial products, including pipes, fittings, and flanges, tailored to help businesses stay informed and succeed.

#Blog#Blogging#ManilaxmiIndustrial#IndustrialProducts#IndustrialSupplies#IndustrialEquipment#PipesAndFittings#PipeFittings#Flanges#SteelProducts#MetalProducts#AlloySteel#ForgedFittings#StainlessSteel#NickelAlloys#Hastelloy#Monel#Inconel#DuplexSteel#PipeManufacturers#SteelSuppliers#IndustrialManufacturers#Manufacturing#Engineering#Fabrication#SteelIndustry#FAQ#FrequentlyAskedQuestions#ProductFAQs#TechnicalSupport

3 notes

·

View notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Monel K500: Properties, Applications, Composition & More

Introduction to Monel K500

Monel K500 is a nickel-copper alloy that provides the excellent corrosion resistance of Monel 400 with added superior strength and greater hardness. This increased performance is attained by adding small percentages of aluminum and titanium to the base alloy and by using a process known as age hardening (also precipitation hardening). The final material is very desirable for high-demand industrial uses where strength, toughness, and corrosion resistance are paramount.

Monel K500 not only resists corrosion in a wide range of environments including seawater, chemicals, and industrial atmospheres but it also retains its mechanical properties across a broad range of temperatures, from sub-zero to high temperatures.

Key Characteristics of Monel K500

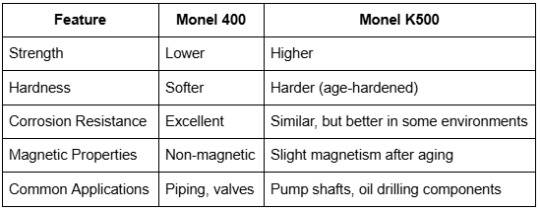

Outstanding Strength: Exceptional Strength: Nearly twice the tensile strength and triple the yield strength of Monel 400.

Enhanced Corrosion Resistance: Excellent protection against saltwater, marine environments, chemicals, and acidic conditions.

Excellent Toughness: Maintains mechanical integrity from cryogenic to elevated temperatures (~480°C / 900°F).

Non-Magnetic Nature: Monel K500 remains generally non-magnetic in its annealed state. However, slight magnetism may develop after age-hardening.

Spark Resistant: Safe for use in explosive environments.

Chemical Composition of Monel K500

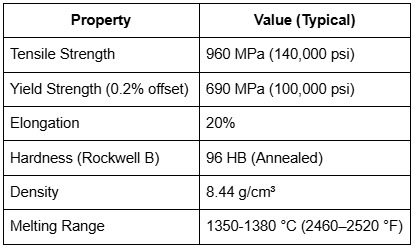

Mechanical Properties of Monel K500

Monel K500 vs Monel 400

Applications of Monel K500

Monel K500 is applied in various industries that require high strength and outstanding corrosion resistance.

Some of the major applications include:

Marine Engineering: Used for propeller shafts, pump shafts, and valves that are subject to seawater.

Oil and Gas Industry: Applied in drill collars, non-magnetic housings, and oil-well tools.

Chemical Processing Equipment: Pumps, valves, and heat exchangers.

Medical Equipment: Specialized surgical instruments and implants.

Defense and Military: Components requiring resistance to corrosive and explosive environments.

Heat Treatment and Hardening

Monel K500 attains its remarkable strength through age-hardening, a process also referred to as precipitation hardening. The typical heat treatment process involves:

Solution Annealing: Heating to about 980°C (1800°F) and rapid cooling.

Aging: Holding the alloy at a lower temperature (~590°C / 1100°F) for several hours to precipitate Ni₃(Al, Ti) particles, which strengthen the matrix.

Proper heat treatment is critical for achieving the best combination of mechanical properties and corrosion resistance.

Corrosion Resistance of Monel K500

Monel K500 offers excellent resistance to:

Seawater: Outstanding for marine applications.

Hydrofluoric Acid: One of the rare alloys that exhibit resistance to hydrofluoric acid.

Alkalis: Strong resistance to caustic solutions.

Salts and Brines: Resistant to various chloride and bromide salts.

Organic and Inorganic Acids: Sulfuric, hydrochloric, and nitric acids in moderate concentrations.

However, it can suffer from stress-corrosion cracking in some conditions, especially in the presence of high concentrations of chlorides.

Forms Available in Monel K500

Monel K500 is available in several product forms, including:

Sheets and Plates

Bars and Rods

Pipes and Tubes

Wires

Forgings

Fittings and Flanges

Fasteners (bolts, nuts, washers)

Conclusion

Monel K500 is the preferred material for applications that demand both high strength and outstanding corrosion resistance. Its unique properties make it indispensable in demanding environments such as marine, chemical processing, aerospace, and oil & gas industries. Though it is more expensive compared to many standard stainless steels, its performance benefits often outweigh the cost in critical applications.

Choosing Monel K500 ensures long-term reliability, fewer maintenance concerns, and superior mechanical performance even under the harshest operating conditions.

FAQs About Monel K500

Q1. Is Monel K500 magnetic?

Monel K500 is non-magnetic in the annealed condition, although it can develop slight magnetism after age-hardening.

Q2. Can Monel K500 be welded?

Yes, but special care must be taken. Welding should ideally be performed using Monel filler metal and proper post-weld heat treatment to prevent cracking.

Q3. What is the maximum temperature Monel K500 can withstand?

Monel K500 can perform reliably at temperatures as high as 480°C (900°F).

Q4. Is Monel K500 expensive?

Yes, Monel K500 is considered a premium material due to its nickel content and specialized manufacturing processes.

Q5. What differentiates Monel K500 from Monel 400?

Monel K500 has higher strength and hardness compared to Monel 400 due to its age-hardening capabilities, while both offer similar corrosion resistance.

#monel#monelfasteners#fasteners#monelk500#monel400#ananka#anankafasteners#articles#blog#fastenersmanuafcturer#manufacturer#supplier#mumbai#tumblr blog#tumblr

0 notes

Photo

PRIMA PAGINA The Jerusalem Post di Oggi lunedì, 17 febbraio 2025

#PrimaPagina#thejerusalempost quotidiano#giornale#primepagine#frontpage#nazionali#internazionali#news#inedicola#oggi blat#days#matan#gali#ariel#engel#meny#hadar#gadi#horn#idan#abra#monel#yair#pinta#avina#weiss#nadar#offa#otra#pong

0 notes

Text

Monel Prices, News, Trend, Graph, Chart, Forecast and Historical

Monel a versatile nickel-copper alloy known for its corrosion resistance and strength, has consistently garnered attention in various industries, including marine, aerospace, and chemical processing. The market for Monel prices is influenced by numerous factors, ranging from raw material availability and production costs to global demand trends and economic conditions. A deeper understanding of the Monel market reveals the complex interplay of these factors, which can lead to fluctuations in pricing and availability.

The primary driver of Monel prices is the cost of its constituent metals—nickel and copper. Nickel prices, in particular, play a significant role in determining the cost of Monel, as the alloy typically contains a higher proportion of nickel. Global nickel prices are influenced by supply-demand dynamics, geopolitical events, mining output, and regulatory changes. For instance, disruptions in major nickel-producing countries such as Indonesia and the Philippines can cause supply shortages, leading to higher prices. Similarly, copper prices are subject to changes in mining activities and demand from key sectors like construction and electronics. The combined effect of these metal price fluctuations directly impacts the overall cost of Monel, making it sensitive to changes in the broader commodity markets.

Get Real time Prices for Monel : https://www.chemanalyst.com/Pricing-data/monel-1364

Another critical factor influencing Monel prices is production costs, including energy, labor, and technology used in manufacturing. The alloy's production involves sophisticated processes requiring significant energy inputs, which makes it vulnerable to shifts in energy prices. Moreover, technological advancements that improve manufacturing efficiency can help reduce costs, while labor expenses in different regions can also affect pricing. For example, producers in regions with lower labor costs may offer more competitive prices, influencing the global market dynamics of Monel.

Global demand trends play a pivotal role in shaping the Monel market. The alloy's exceptional corrosion resistance makes it a preferred choice in marine applications, such as shipbuilding and offshore oil and gas production. Additionally, Monel is widely used in the aerospace industry for manufacturing components exposed to high temperatures and corrosive environments. Demand from these sectors significantly impacts prices, particularly when large-scale projects or investments drive the need for Monel-based products. For example, increasing investments in renewable energy and offshore wind farms are expected to boost the demand for Monel in the coming years, potentially pushing prices upward.

Economic conditions and geopolitical events also influence Monel prices. Economic growth in emerging markets often leads to increased infrastructure development and industrial activities, driving demand for high-performance materials like Monel. Conversely, economic slowdowns or recessions can reduce demand, leading to price stabilization or declines. Geopolitical tensions, trade policies, and tariffs can further affect the global trade of Monel and its raw materials. For instance, restrictions on nickel or copper exports from key producing countries could tighten supply and elevate prices, while favorable trade agreements might enhance market access and stabilize costs.

Environmental regulations and sustainability initiatives are increasingly shaping the Monel market. As industries adopt more stringent environmental standards, there is a growing emphasis on sustainable and eco-friendly production practices. Recycling and the use of secondary raw materials are becoming crucial in the Monel production process, potentially reducing dependency on primary nickel and copper. This shift could influence prices by lowering production costs while meeting environmental compliance requirements. Furthermore, companies investing in greener technologies may experience initial cost increases, which could reflect in higher Monel prices in the short term.

The competitive landscape among Monel producers also impacts pricing trends. Key players in the market continually strive to optimize production, improve product quality, and enhance distribution networks to maintain a competitive edge. Price competition among manufacturers, especially in regions with lower production costs, can result in variations in Monel prices across different markets. Additionally, mergers, acquisitions, and strategic partnerships within the industry may influence supply dynamics and pricing, as consolidated entities often have greater control over production and distribution.

Currency exchange rates are another factor affecting Monel prices, particularly in the context of international trade. Since Monel is traded globally, fluctuations in currency values can impact its cost for buyers and sellers in different regions. A weaker local currency may lead to higher import costs, while a stronger currency can make exports more competitive. This dynamic is particularly relevant for countries heavily reliant on imports for their Monel requirements.

Market trends and forecasts indicate that the demand for Monel is likely to grow in the foreseeable future, driven by advancements in technology and increased adoption in critical industries. Emerging applications in areas such as hydrogen storage, fuel cells, and advanced chemical processing are expected to further bolster the market. However, uncertainties in raw material availability, geopolitical developments, and environmental regulations may continue to pose challenges to price stability.

In conclusion, the Monel market is characterized by a complex web of factors influencing pricing dynamics. The interplay between raw material costs, production expenses, global demand, economic conditions, and environmental considerations creates a highly dynamic pricing environment. As industries continue to innovate and expand, the demand for Monel is poised to grow, presenting both opportunities and challenges for market participants. Monitoring these trends closely and adopting adaptive strategies will be essential for stakeholders to navigate the evolving landscape of Monel prices effectively.

Get Real time Prices for Monel : https://www.chemanalyst.com/Pricing-data/monel-1364

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Monel#Monel Price#Monel Prices#Monel Pricing#Monel News#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

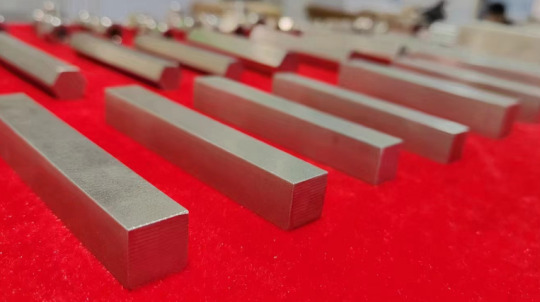

CNC Machined Monel: Where Precision Meets Durability

Monel alloys are a favorite in industries like marine, chemical, and aerospace for their incredible strength and corrosion resistance. But when you add CNC machining into the mix? You get custom-crafted parts that stand up to the toughest conditions.

From precision valve components to high-strength marine hardware, CNC-machined Monel delivers the performance you can count on. Ready to harness the power of Monel? Let’s make it happen! 🌊

0 notes

Text

Nickel 201 vs. Other Alloys: What Sets It Apart in Forged Fittings

In industries where durability, reliability, and resistance to extreme conditions are most important forged fittings play a critical role. Among the all materials available for manufacturing these essential components, Nickel 201 stands out as a superior choice. But what makes Nickel 201 unique compared to other alloys commonly used for forged fittings? In this blog, we’ll dive into its properties, advantages, and why it’s often the preferred material in demanding applications.

Comparing Nickel 201 with Other Alloys

1. Nickel 201 vs. Stainless Steel

Corrosion Resistance: While stainless steel is a popular choice for forged fittings, it can struggle in environments with high levels of halides, such as chlorides. Nickel 201 offers exceptional resistance to a wide range of corrosive chemicals, including strong acids and alkalis, making it ideal for chemical processing plants.

Thermal Stability: Nickel 201 outperforms stainless steel in high-temperature environments. Its resistance to oxidation and thermal cracking makes it the go-to material for applications requiring prolonged exposure to extreme heat.

2. Nickel 201 vs. Inconel (Nickel-Chromium Alloys)

Chemical Purity: Inconel alloys, while robust, are designed for specific high-stress environments like jet engines or nuclear reactors. Nickel 201, on the other hand, offers the advantage of higher chemical purity, making it more suitable for processes requiring inert and contamination-free materials.

Cost-Effectiveness: Nickel 201 is often more cost-effective than Inconel for applications where pure nickel properties are sufficient, such as in caustic soda production or food-grade equipment.

3. Nickel 201 vs. Brass and Copper Alloys

Durability: While brass and copper alloys are known for their conductivity, they lack the mechanical strength and durability of Nickel 201. In industrial settings with high mechanical stress, Nickel 201 forged fittings excel due to their superior tensile strength.

Corrosion in Alkaline Environments: Brass and copper alloys are prone to dezincification and corrosion in alkaline conditions. Nickel 201’s exceptional resistance to strong alkalis ensures a longer lifespan in such applications.

4. Nickel 201 vs. Titanium Alloys

Chemical Compatibility: Titanium alloys are lightweight and highly corrosion-resistant but can be cost-prohibitive. In cases where extreme lightweight properties are not necessary, Nickel 201 provides an equally corrosion-resistant but more economical solution, especially in highly acidic or caustic environments.

Ease of Fabrication: Nickel 201 is easier to forge and weld compared to titanium, reducing manufacturing complexity and costs for custom fittings.

Conclusion

Nickel 201 forged fittings are a testament to how advanced materials engineering can solve industrial challenges. When compared to other alloys, its combination of durability, thermal stability, and chemical resistance makes it an unmatched choice for applications requiring reliable and long-lasting performance.

If your project demands materials that can withstand the toughest conditions, Nickel 201 should undoubtedly be at the top of your list.

0 notes

Text

Premier Monel Manufacturer

Unmatched corrosion resistance and strength of Monel with Ashapura Steel! As a leading manufacturer, we provide high-quality Monel products for marine, chemical, and industrial applications. 💪

🌟 Why Choose Monel?

Superior Corrosion Resistance

High Strength and Durability

Versatile Applications

🚢 Applications:

Marine

Chemical Processing

Oil and Gas

Trust Ashapura Steel for all your Monel needs. Contact us today to learn more!

0 notes

Text

Pipe Grades and Properties:

Stainless Steel: Corrosion-resistant, durable, used in chemical and food industries.

Mild Steel: Ductile, weldable, used in construction and automotive industries.

Carbon Steel: Strong, cost-effective, used in pipelines and structural applications.

Hastelloy: Corrosion-resistant, high strength, used in chemical processing.

Monel: Nickel-copper alloy, corrosion-resistant, used in marine applications.

Inconel: High temperature and corrosion resistance, used in aerospace and turbines.

Titanium: Lightweight, high strength, corrosion-resistant, used in aerospace and medical devices.

Tantalum: Excellent corrosion resistance, used in electronics and medical implants.

For more Information Visit: https://platinexpiping.com/

#StainlessSteel#MildSteel#CarbonSteel#Hastelloy#Monel#Inconel#Titanium#Tantalum#Piping#Materials#Engineering#Manufacturing#Industrial#Construction#Aerospace#ChemicalProcessing#MarineEngineering

#StainlessSteel#MildSteel#CarbonSteel#Hastelloy#Monel#Inconel#Titanium#Tantalum#Piping#Materials#Engineering#Manufacturing#Industrial#Construction#Aerospace#ChemicalProcessing#MarineEngineering

0 notes

Text

What is Monel and what is it used for?

Discovering Monel: The Sturdy Nickel-Copper Alloy

Monel is a robust alloy made primarily of nickel and copper, with small amounts of other elements like iron, manganese, carbon, and silicon. It’s known for its incredible strength and resistance to corrosion, making it suitable for many demanding environments.

Where Is Monel Used?

Marine Environments: Monel’s resistance to seawater makes it perfect for ship parts, underwater pipes, and marine equipment.

Chemical Plants: Its ability to withstand strong acids and chemicals is essential for chemical processing equipment.

Oil Fields: Monel is used in drilling tools, valves, and pipelines that must endure rough and corrosive conditions.

Aerospace: The alloy’s strength and durability make it ideal for parts in spacecraft and aircraft that face extreme temperatures and pressures.

Musical Instruments: Monel is chosen for its reliable sound quality and durability in musical instruments.

Monel’s combination of strength and corrosion resistance makes it a valuable material in many high-stress applications. Whether in the depths of the ocean or the heights of the sky, Monel continues to be a reliable choice for engineers and designers.

0 notes

Text

High-Quality Monel Fasteners Manufacturer and Supplier - Fasteners LLP

Fasteners LLP offers a wide range of high-quality Monel fasteners for various industrial applications. Our Monel fasteners are made from premium-grade materials and are known for their strength, corrosion resistance, and durability. Contact us for all your Monel fastener needs.

0 notes

Text

What is the ASTM grade of Monel 400?

In the realm of metallic materials, Monel 400 holds a distinct position as a nickel-copper alloy with exceptional corrosion resistance and high strength. Therefore, understanding the ASTM grade of Monel 400 is very important for its application in various industries, especially those involving harsh environmental conditions.

What is the ASTM grade of Monel 400?

Monel 400, also known by its UNS number N04400, is a nickel-copper alloy primarily composed of approximately 63% to 70% nickel and 28% to 34% copper, with minor additions of iron, sulfur, carbon, silicon, and manganese. This composition gives it remarkable resistance to corrosion in a wide range of environments, including seawater, hydrogen fluoride, fluorine, sulfuric acid, and alkaline media.

The ASTM grade of Monel 400 is specified in several ASTM standards, including ASTM B127, ASTM B163, ASTM B164, and ASTM B165. These standards define the chemical composition, mechanical properties, and other characteristics of the alloy, ensuring its consistent performance across different applications.

The chemical composition specified in these ASTM standards ensures that Monel 400 maintains its corrosion resistance and mechanical properties. The high nickel content, in particular, confers immunity to chloride-induced stress corrosion cracking, a common failure mode in many other alloys. Additionally, the alloy’s ductility and toughness allow it to be easily formed and processed into various shapes and sizes.

Mechanically, Monel 400 exhibits high strength and toughness over a broad temperature range. Its yield strength and tensile strength, as defined by the ASTM standards, are sufficient to withstand significant loads and stresses in demanding applications. Furthermore, its ductility enables it to absorb deformation without fracturing, enhancing its reliability and durability.

Physically, Monel 400 has a density of approximately 8.80 grams per cubic centimeter and a melting range of 1300-1350 degrees Celsius. Its thermal conductivity and specific heat capacity are also within the range specified by the ASTM standards, ensuring consistent thermal performance.

The processing characteristics of Monel 400 are also addressed in the ASTM standards. It can be easily processed using traditional machining operations, making it suitable for a wide range of manufacturing processes. Its soft nature allows for hot forming into almost any shape, while cold working is typically performed on annealed material to optimize its mechanical properties.

Conclusion

In conclusion, the ASTM grade of Monel 400 is defined by a set of standards that ensure its consistent chemical composition, mechanical properties, and processing characteristics. These standards are the foundation for its widespread use in various industries, where its corrosion resistance and high strength are paramount.

Thank you for reading our article and we hope it can help you to have a better understanding of the ASTM grade of Monel 400. If you are looking for Monel Alloy suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel Alloy products from Shanghai China, Huaxiao Alloy offers customers high-quality Monel alloy products such as Monel 400 and Monel K500 at a very competitive price.

0 notes

Text

High Nickel Fasteners: Properties, Applications, and Benefits

Introduction to High Nickel Fasteners

High nickel fasteners are specially engineered fastening components made from alloys containing a significant amount of nickel. These fasteners are widely recognized for their exceptional corrosion resistance, high-temperature strength, and durability in extreme environments. Industries such as marine, chemical processing, power generation, aerospace, and oil & gas heavily rely on these fasteners to ensure safety, performance, and longevity of their systems.

Nickel’s inherent ability to resist corrosion and oxidation makes high nickel alloys ideal for applications exposed to harsh conditions. When formed into bolts, nuts, washers, and screws, these alloys deliver unmatched performance that typical stainless steels or carbon steels cannot achieve.

Common Types of High Nickel Alloys Used in Fasteners

High nickel fasteners are manufactured from a variety of nickel-based alloys, each selected for its unique combination of strength, corrosion resistance, and temperature performance. Here are some of the most widely used nickel alloys in fastener production:

1. Inconel Alloys (e.g., 600, 625, 718)

Renowned for outstanding resistance to corrosion and oxidation

Maintains strength at elevated temperatures

Ideal for aerospace, heat treatment, and chemical processing environments

2. Monel Alloys (e.g., 400, K500)

Excellent resistance to seawater and corrosive chemicals

High mechanical strength

Commonly used in marine, oil & gas, and chemical sectors

3. Hastelloy Alloys (e.g., C22, C276)

Offers outstanding protection against highly corrosive and acidic media

Ideal for use in chemical processing equipment, including reactors and pressure vessels

4. Nickel 200 / Nickel 201

Commercially pure nickel with good ductility and corrosion resistance

Performs well in caustic and high-temperature environments

Used in electronics, food processing, and synthetic fiber production

5. Alloy 20

A nickel-chromium-molybdenum alloy with added copper

Excellent resistance to sulfuric acid and stress corrosion cracking

Preferred in chemical, food, and pharmaceutical applications

These alloys provide the foundation for high-performance fasteners that meet the demands of the most challenging environments.

Types of High Nickel Fasteners

High nickel fasteners come in a variety of forms and sizes to meet specific engineering requirements:

Bolts (Hex Bolts, Heavy Hex, Socket Cap, Stud Bolts)

Nuts (Hex Nuts, Lock Nuts, Dome Nuts)

Washers (Plain, Spring, Fender, Flat Washers)

Screws (Machine Screws, Self-tapping Screws, Set Screws)

Threaded Rods and Bars

Key Properties of High Nickel Fasteners

1. Corrosion Resistance

High nickel content provides strong resistance to a wide range of corrosive media, including:

Acidic environments (sulfuric, hydrochloric, hydrofluoric acids)

Seawater and brine

High moisture or oxidizing agents

2. Heat Resistance

High nickel fasteners retain their strength and integrity even at extreme temperatures. Ideal for high-heat applications such as:

Turbines

Reactors

Heat exchangers

3. Mechanical Strength

These fasteners offer superior tensile, yield, and fatigue strength, ensuring high load-bearing capabilities under stress.

4. Magnetic and Electrical Properties

Nickel alloys offer precise magnetic permeability and superior electrical conductivity, making them highly suitable for use in electronic and nuclear applications.

5. Fabrication and Machinability

Despite their strength, high nickel fasteners can be machined, welded, and fabricated using conventional methods with skilled handling.

Applications of High Nickel Fasteners

High nickel fasteners are indispensable in environments where ordinary fasteners would fail. Common application sectors include:

Aerospace Industry

Used in jet engines, exhaust systems, and aircraft structures where high temperature and stress are factors.

Marine and Offshore

Ideal for saltwater environments, these fasteners are used in shipbuilding, submarines, and oil rigs.

Chemical Processing

Used in piping systems, reactors, and tanks where aggressive chemicals are handled.

Nuclear and Power Plants

Essential for high radiation, pressure, and heat resistance in nuclear reactors and turbines.

Pharmaceutical and Food Industry

Chosen for their non-contaminating nature and ability to withstand cleaning and sterilization procedures.

Advantages of Using High Nickel Fasteners

Excellent resistance to corrosion and oxidation

High strength-to-weight ratio

Extended lifespan, minimizing the need for frequent maintenance and replacements

Reliability in extreme and hazardous conditions

Compatibility with harsh chemicals and high temperatures

High Nickel Fasteners Manufacturer – Ananka Group

At Ananka Group, we are a leading manufacturer, supplier, and exporter of high nickel fasteners in India and across the globe. With state-of-the-art facilities and a commitment to quality, we provide a wide range of nickel alloy fasteners tailored to your specifications.

Why Choose Ananka Group?

In-house manufacturing & testing

ISO-certified processes

Custom sizes & coatings available

Export-ready with global logistics support

Compliance with ASTM, ASME, DIN, and ISO standards

Whether you're in aerospace, petrochemical, or marine sectors, our high nickel fasteners offer durability and reliability you can trust.

Conclusion

High nickel fasteners are a critical component in numerous high-performance applications. Their ability to withstand extreme conditions chemical, thermal, or mechanical makes them indispensable for modern engineering. With the right material selection and manufacturing partner like Ananka Group, industries can enhance safety, longevity, and efficiency in their operations.

Frequently Asked Questions (FAQ)

What is the difference between Inconel and Monel fasteners?

Inconel offers better performance at high temperatures, while Monel is more corrosion-resistant in marine environments.

Are high nickel fasteners expensive?

Yes, due to the cost of nickel and complex manufacturing, they are more expensive but offer superior longevity and performance.

Can high nickel fasteners be used in seawater?

Absolutely. Alloys like Monel and Inconel are ideal for long-term exposure to seawater.

Do high nickel fasteners need special considerations during installation?

They may require torque adjustments due to their strength, and care must be taken to avoid galling or seizing.

#ananka#anankafasteners#highnickel#nickelfasteners#articles#blog#nickelfastenersmanufacturer#inconel#monel#grade#gradematerial#manufacturer#fasteners#supplier#tumblr#blog tumblr

0 notes

Text

Precision Forging

More short videos on 👉YouTube and photos on 👉Pinterest.

Every nut, bolt, and screw - Forgings for harsh environments.

KB Schmiedetechnik GmbH expertly manages all processes in-house, including CAD design, engineering, material flow and forging simulation, CAM tool manufacturing, forging, heat treatment and quenching, destructive testing and surface crack detection in own laboratory, CNC machining, and dimensional inspection.

Key Applications Across Critical Areas

Valve bodies and yokes for cryogenic, nuclear, and hydrogen applications; pipe fittings and specialty flanges for shipbuilding and boiler fabrication; pinion and gear blanks; forged supports, chain links and hooks; as well as applications in the agricultural, maritime, and defense applications.

Development of a forged valve body.

As a leader in the small-batch production of high-quality forgings in Germany, KB Schmiedetechnik GmbH serves a broad range of industries.

Closed-Die Forgings for Extreme Conditions

The company works with a variety of materials, including virtually all steel grades—carbon steels, high- and low-alloy steels, including AISI 316 and duplex stainless steels, as well as nickel-based superalloys such as Monel®, Incoloy®, Inconel®, and Hastelloy®, along with titanium.

Securing the drop-forge.com domain supports the company’s strategic vision to expand its global reach and underscores its dedication to quality and innovation.

For environmental aspects, please click on "ALT" in the image:

Eyebolts, Eyelets, Eye Nuts - For Your Trust!

Examples

Example: a socket for a tram wagon

Examples: forged hydraulic component, support and a forged eyelet.

Examples (l.t.r.): forged chain links, a forged support, and a forged hydraulic component.

Example: some forged pinion blanks (machined)

Example: threaded support hooks (forged)

YouTube channel with a few videos (mostly in German):

#DropForging#ClosedDie#ValveBodies#nuclear#hydrogen#boilers#Monel#Inconel#Incoloy#Hastelloy#AISI316#DuplexSteel

0 notes

Text

Monel Price | Prices | Pricing | News | Database | Chart

North America

In Q2 2024, the Monel market in North America saw a significant decline in prices, primarily due to major shifts in supply and demand dynamics. Prices faced considerable downward pressure this quarter as a result of high inventory levels and fluctuating raw material costs, worsened by geopolitical tensions and operational disruptions in key regions that produce raw materials. Additionally, shipping costs rose sharply because of extended transit times and increased spot rates for sea freight, contributing to overall market volatility. Although production levels remained steady, the market grappled with oversupply, fostering a bearish sentiment.

In the USA, the most dramatic price fluctuations occurred. A combination of rising inventory, lower-than-expected demand from critical industrial sectors, and persistent supply chain bottlenecks significantly influenced the pricing landscape. Seasonal trends and shifting consumer preferences in the automotive industry further exacerbated the situation, resulting in a continuous decline in Monel prices. The overall price trend exhibited a consistent downturn, with a decrease from the previous quarter and an additional drop in the latter half of the quarter.

By the end of the quarter, the price for Alloy 400 Sheet DEL Florida reached USD 46,080/MT, underscoring the negative pricing environment throughout Q2 2024. Disruptions in the Red Sea and Panama Canal also played a notable role in affecting market stability. Overall, the quarter was characterized by adverse market conditions, reflecting ongoing challenges in aligning supply with demand in the Monel sector.

Get Real Time Prices for Monel : https://www.chemanalyst.com/Pricing-data/monel-1364

Asia-Pacific

In Q2 2024, the Monel market in the Asia-Pacific region followed a declining trend, primarily influenced by global supply chain disruptions and fluctuating demand dynamics. Several critical factors impacted Monel prices this quarter, including geopolitical tensions, changes in nickel mining operations, and volatile shipping costs. A decline in nickel production in key regions and the suspension of operations at significant plants, such as Eramet SA in New Caledonia, greatly constrained supply and exacerbated the pricing environment.

Japan experienced the most notable price changes within the region, with the Monel market exhibiting a bearish trend. Prices have steadily declined, driven by elevated inventory levels and subdued demand, especially within the automotive sector. Seasonal factors intensified the downturn, with a pronounced dip in market activity linked to fiscal year-end adjustments. Compared to the same quarter last year, the market has weakened significantly, highlighting ongoing economic challenges.

At the close of the quarter, the price of Alloy 400 Sheet Ex Osaka in Japan settled at USD 44,409/MT, reflecting a persistently negative pricing environment. This decrease underscores broader market struggles and the diminishing momentum in the region's Monel market. Overall, Q2 2024 was marked by negative pricing sentiment, highlighting the urgent need for strategic responses to stabilize the market.

Europe

In Q2 2024, Monel prices in Europe faced a notable downturn, primarily driven by a combination of factors. The quarter was characterized by weak demand across various industries, compounded by ongoing geopolitical tensions and supply chain disruptions. The construction sector, a significant consumer of Monel, experienced a marked decline in activity and new orders due to high costs and economic uncertainty. The automotive industry also saw a drop in new registrations, further reducing demand for Monel. These industry-specific challenges were amplified by rising inventory levels and a surplus of refined nickel, leading to an overall bearish market sentiment.

Germany witnessed the most significant price fluctuations within Europe. The market demonstrated a clear downward trend, influenced by seasonality and structural issues within key consuming sectors. The correlation between decreased construction activity and challenges in the automotive sector was evident, resulting in a continuous decline in Monel prices. Prices decreased compared to the previous quarter, with a more significant drop noted between the first and second halves of the quarter, emphasizing the unfavorable pricing environment.

Despite some stabilization efforts in the industry, the overall sentiment remained negative. The quarter ended with Monel Alloy 400 priced at USD 40,172/MT Ex Werdohl in Germany, reflecting the cumulative impact of these adverse factors. The market's trajectory underscored ongoing challenges and highlighted the need for strategic adjustments to navigate persistent downward pressures.

Get Real Time Prices for Monel : https://www.chemanalyst.com/Pricing-data/monel-1364

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Monel#Monel Price#Monel Prices#Monel Pricing#Monel News#Monel Price Monitor#Monel Database#Monel Price Chart#Monel Price Trend#Monel Market Price

0 notes