#steel industry

Explore tagged Tumblr posts

Text

hamilton, ontario.

#mine.#photography#photos#black and white#b&w#b&w photography#black and white photography#industrial ontario#steel industry#industrialism#industrial#smoke stacks#smoke stack#b&w edit#b&w picture#black & white

333 notes

·

View notes

Text

HAUT FOURNEAU 4

I adore visiting blast furnaces. They are the most spectacular sights I've ever got to witness. The intricacy of the engineering is quite simply astonishing. This particular specimen in Belgium, which has been under close surveilance since it was shut down in 2008, has been preserved in a remarkably good condition. Almost immediately after the closure, an interest group was established that wanted to preserve the blast furnace as an industrial landmark.

This blast furnace company, which is a defining feature of the city of Charleroi, was founded in 1836, during the heyday of the European steel industry. Like all other steel companies in the region, this blast furnace was also the subject of numerous takeovers and mergers. These mainly took place in the 1960s and 70s. It always remained a flourishing company, competitive on a global scale. However, the takeover by the Duferco group in 2001 heralded the beginning of the end…

The site was then operated under the name Carsid. After a fire in 2007, the furnace was temporarily shut down to carry out the necessary repairs. At the same time, capacity was increased and a number of environmental investments were made. The installation would now be operational for another ten years. Barely a year later, the blast furnace was shut down again, due to “poor prospects”. Due to the economic crisis and the declining demand for steel, the operation of the blast furnace company was no longer deemed profitable.

A “temporary” closure and the search for a buyer should bring relief. After more than three years of uncertainty and economic unemployment, the curtain finally fell for the blast furnace. Since HF4 is one of the best preserved blast furnaces in Europe, the Walloon government is striving to preserve the furnace as industrial heritage. Although a ministerial decree has been published to this effect, the demolition work on the site is progressing steadily…

Unfortunately Charleroi is one of the poorest cities in Belgium. There is no budget for the necessary sanitation and preservation works, which would run in the millions of euros. The futures is looking bleak for this beautiful piece of industrial heritage...

#urban exploration#urbex#abandoned#urban relics#decay#derelict#abandoned places#ue#photography#urbanexploration#HF4#blast furnace#abandoned addiction#industrial heritage#steel industry#urbexpeople#urbexworld#urbexphotography#belgium

322 notes

·

View notes

Text

A quick visit to the abandoned steel- and powerplant in Charleroi

7 notes

·

View notes

Text

George Lauder was born on November 11th 1837 at Dunfermline, Fife.

Lauder is probably a wee bit more well known in his native Dunfermline, or maybe so Americans, I would think this is due to him being a bit overshadowed by a guy described as his "cousin-brother", Andrew Carnegie.

George Lauder was the son of George Lauder, Sr. and Seaton Morrison. His father, a local shop owner on the high street, Dunfermline. Very well read, Lauder Sr. was instrumental in the upbringing of his only son George, as well as his nephew the aforementioned Carnegie.

Lauder Jr. and Carnegie were two years apart in age and best friends as a result of their shared experiences. They affectionately referred to one another as “Dod” and “Naig”, as young children. After Andrew and his family left for America, George stayed in Scotland where he would go on to graduate from Glasgow University with a degree in mechanical engineering while studying under another famous name Lord Kelvin.

Carnegie wrote to Lauder asking him to join him in America as a partner in the Carnegie Steel Corporation. At the time, the major shareholders were Carnegie himself, Carnegie’s brother and two others.

Lauder brought several new developments to the steel business in America, including the process for washing and coking dross from coal mines, which resulted in a significant increase to the overall value of the business.

Lauder would go on to lead the development of the use of steel in armour and armaments. By the turn of the Twentieth Century, Lauder was a director of Carnegie Steel and its second largest shareholder behind his cousin Andrew. Throughout the course of his career, Lauder created a number of patented scientific advancements useful both in the steel industry and beyond.

The sale of Carnegie Steel to JP Morgan in 1901 created U.S Steel where Lauder sat on the board of directors. This became the first corporation in the world with a market capitalization exceeding $1 billion ($43 billion today).

Lauder’s oldest daughter, Harriet married Dr. James C. Greenway combining the Lauder and Greenway families into what is now known as the Lauder Greenway Family, their influence in American political and economic affairs dates from the 1640s through the contemporary era. Their primary contributions have been in the sciences, government, and intelligence. His son George Lauder III, was a high-profile sailor who set the record in 1900 (held until 1905) for the fastest trans-Atlantic crossing with his yacht, Endymion,

In 1905 Harriet bought, what has become known as The Lauder-Greenway Estate a 50-acre property in Greenwich, Connecticut, where George lived out the last eleven years of his life passing away on August 24th, 1924.

The Estate, for a time, was the most expensive private residence in the United States in 2014 when it sold for an eye watering $120 million.

Pics are of George Lauder, the second is Andrew Carnegie, George Lauder, and Thomas Miller in 1862 taken in Glasgow, it is one of very few pics of Carnegie without a beard, Thomas Miller is said to be the man who started Carnegie in the steel business.

6 notes

·

View notes

Text

As a native of Gary, Indiana, and a former "summer employee" at U.S. Steel (to pay for my college education), I'm obviously invested in what happens to the Gary Works of U.S. Steel. This story answers several of my questions, and puts me on the "no" side of this proposal. Excerpt from this story from Grist:

U.S. Steel, once the world’s largest company of any kind, can take substantial credit for the growth of American industrial power in the 20th century. But in recent decades, it’s been shuttering mills and shedding workers. Now, the iconic Pittsburgh-based manufacturer is set to be acquired by a Japanese steelmaker, Nippon Steel — if the federal government allows the deal to proceed.

Earlier this month, reports emerged that the Biden administration is preparing to block the nearly $15 billion merger on the grounds that it presents a threat to America’s national security interests. The United Steelworkers union opposes it, fearing future layoffs and weaker labor protections under new ownership. So do both major candidates for president, who are vying for votes in the Rust Belt. Supporters of the deal, like the Washington Post editorial board and the nonpartisan think tank The Atlantic Council, have cast the politicians’ opposition as election-season pandering, and argued that the national security rationale on which Biden may block it is flimsy. But one area, in which the question of whether the merger goes through could be particularly consequential, has gone largely unremarked upon in the conversation: what it means for the climate.

Some environmentalists say the deal could slow the crucial progress that the steel industry must make in order to decarbonize. Their argument stems from the fact that both U.S. Steel and Nippon Steel have been slow, compared to industry peers, to adopt the most impactful decarbonization technologies, even with federal funding available in the U.S. to do so.

The most common process by which primary steel is produced is massively carbon-intensive. The reasons for this lie in chemistry. Steel is made from iron, but the form in which iron ore occurs in the Earth’s crust is mostly iron oxide (similar to rust). In order to get usable iron from it, one needs to remove the oxygen. For centuries, iron-makers have accomplished this by using coke, a fuel made from coal, which is heated alongside iron ore in a blast furnace at such high temperatures that the iron melts into a liquid while the oxygen bonds with the carbon in the coke and produces carbon dioxide.

Blast furnaces are responsible for the lion’s share of carbon emissions from steelmaking, and the inextricability of carbon emissions from the ironmaking process is a large part of the reason why, overall, steelmaking is responsible for 7 percent of global carbon emissions, and a quarter of industrial carbon emissions. These percentages will likely grow as other sectors of the economy are decarbonized. In the U.S., demand for steel is also expected to grow dramatically over the next decade to provide the raw material of the industrial growth sparked by the Inflation Reduction Act and the planned buildout of clean energy infrastructure and transmission lines. For these reasons, the task of decarbonizing steel is as urgent as it is difficult and expensive.

Fortunately, there is a solution on offer that has recently become viable due to new technological advances — and one that the Biden administration has sought to heavily subsidize: replacing blast furnaces with a process called direct reduction, and using hydrogen as a reducing agent in place of carbon, ultimately discharging water rather than carbon dioxide. “The chemistry is sound, it’s being built, it’s been piloted and demonstrated,” said Yong Kwon, a senior advisor with the Sierra Club’s Industrial Transformation Campaign. “The question is now: Will industries adopt it?”

There are eight operating steel mills in the United States that make “primary” steel (newly created steel, rather than the generally lower-quality “secondary” steel produced from scrap metal). Three are owned by U.S. Steel. Cleveland-Cliffs, the owner of the other five, has also made an offer to buy U.S. Steel and has been much more proactive in making the shift to greener production. “The Department of Energy has made available a great deal of money to do partnerships with industry to demonstrate the value of decarbonized projects,” said Todd Tucker, director of the industrial policy and trade program at the Roosevelt Institute. Both Cleveland-Cliffs and U.S. Steel have availed themselves of such funding to embark on decarbonization programs. U.S. Steel has partnered with the Department of Energy on carbon capture projects at several of their steel mills, and funded research and development of hydrogen-based ironmaking technology. The company also plans to install a carbon capture program at a blast furnace at its steel mill in Gary, Indiana, which it says will turn up to 50,000 metric tons of carbon dioxide annually into limestone — a tiny fraction of that facility’s overall emissions. But critics note that U.S. Steel has yet to take a step as ambitious as its rival by actually replacing one of its blast furnaces with direct reduction of iron.

The stakes of the potential U.S. Steel-Nippon Steel merger are perhaps best illustrated in the city of Gary, Indiana, which was built in 1906 by U.S. Steel to house workers at its Gary Works steel mill. That mill is home to the country’s largest and most carbon-emitting blast furnace — and it’s nearing the end of its lifespan. This situation hypothetically presents the furnace’s owner with an ideal opportunity to switch to a cleaner technology, with federal funding on the table to do so. But in August, Nippon Steel announced its prospective plans for Gary Works, which include a $300 million investment in relining the furnace to extend its lifespan for another 20 years. With this announcement, Kwon said, “Not only have they back in Japan not pursued solutions that we feel are responsible; they’ve now explicitly come out and said that they’re not going to pursue the solution that is on the table for reducing the climate change and public health harms that are currently produced by the iron-making process.”

7 notes

·

View notes

Text

7 notes

·

View notes

Text

Inconel Material: Properties, Composition, and Grades

When thinking of materials for high performance in demanding applications, the name Inconel material automatically comes to mind. As the Inconel material is very expensive, the use is of a limited nature. Because of this Inconel material is generally less familiar as compared to Steel or Aluminum. In this article, we will explore some basics of this Inconel Material.

What is Inconel Material?

Inconel is a nickel-chromium-based super alloy that's known for its high strength, corrosion resistance, and ability to withstand extreme temperatures, pressure, or mechanical loads. Inconel Material alloys are oxidation- and corrosion-resistant. When heated, Inconel material forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range and is attractive for high-temperature applications where aluminum and steel would come to creep as a result of thermally induced crystal vacancies. Inconel Material's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy

Inconel Material Properties

Inconel is a nickel-chromium-based super alloy that's known for its high strength, corrosion resistance, and ability to withstand extreme temperatures, pressure, or mechanical loads. Inconel Material alloys are oxidation- and corrosion-resistant. When heated, Inconel material forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range and is attractive for high-temperature applications where aluminum and steel would come to creep as a result of thermally induced crystal vacancies. Inconel Material's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy

In addition to high-temperature performance, Inconel material has excellent strength properties at room temperature. The high amounts of chromium also give it superb corrosion resistance at room temperatures as well. The other alloys mentioned above in the composition section provide additional properties such as toughness and hardness. Several Inconel alloys, such as Inconel 718, are precipitated and hardened to increase strength even further.

Want to know more about Inconel material prices? Contact us today, and we'll provide you with competitive pricing and expert guidance. Inconel Material Grades

Inconel material has a variety of grades varying in composition and properties developed for specific applications. The common Inconel grades are as follows:

1. Inconel 600: Inconel material is the original alloy. It is heat- and corrosion-resistant, noted for elevated temperature corrosion/oxidation resistance, good hot and cold processing characteristics, good low-temperature strength, and both hot/cold fatigue properties. Inconel material has high strength under 650 °C, and it’s suitable for chemical-plant components.

2. Inconel 601: Inconel material has excellent oxidation resistance at elevated temperatures and high resistance to carburization. It is good for high-temperature organic-chemical plants. It resists oxidation from sulfur atmospheres and has good mechanical properties at room temperature and high temperature. It also has great stress corrosion crack resistance because of the low carbon content and fine grain structure. It has particularly good creep strength at elevated temperatures (above 500 °C, at which other alloys can fail). 601GC is the alloy's grain-controlled version, offering some properties enhancement over 601.

3. Inconel 625: Inconel material offers better corrosion resistance than 600 and 601. It has better performance in retaining strength and resisting creep from low temperatures up to a maximum service temperature of 980 °C

4. Inconel 718: Inconel material is suited to precipitation hardening. It offers good strength and toughness up to 650 °C and good general corrosion/oxidation resistance at all service temperatures. It is formulated for solution treatment or precipitation hardening.

5. Inconel X-750: Inconel material offers elevated corrosion resistance and oxidation resistance, as well as good strength below 980 °C. In addition, Inconel X-750 has good low-temperature performance and molding performance. It is mainly used for aerospace and industrial gas turbine components.

6. Inconel 690: Inconel material offers greater resistance to chloride corrosion (e.g., salt water), high temperature/pressure water stress corrosion, strong oxidation environments, and fluorinated atmosphere attack. It is mainly applied in nitric acid environments, steam generators, and nuclear waste treatment plants.

Read More - Density of Inconel

2 notes

·

View notes

Text

#Chinese overcapacity is crushing the global steel industry

“The vast scale of its output—around 1bn tonnes a year—is obscured by the fact that most of it stays in the country. Lately, however, China’s exports of the metal have surged, reaching 90m tonnes in 2023, up by 35% on the previous year (see chart 1). That may be a fraction of China’s total production, but it is more than what #America or #Japan make in a year. And it is enough to build a thousand Golden Gate bridges.”

Governments are stepping in to protect local producers

https://www.economist.com/business/2024/09/17/chinese-overcapacity-is-crushing-the-global-steel-industry #SOE #tradewar #china #India #GarbageTime #Philadelphia @IBEW98 @steelworkers @PACarpenters @PhillyAFLCIO

2 notes

·

View notes

Text

#mine.#photography#photos#black and white#contrast#do ya see the little bird flying??? :)#factory#industrial ontario#industrialism#industrial#steel industry#canadian photography

129 notes

·

View notes

Text

POWERPLANT F

Every blast furnace company also has a power station. The gases generated during the blast furnace's smelting process were converted into electricity here, which was then used to power the rest of the company.

This power station was part of a blast furnace that was demolished back in 2016. Despite years of inactivity, the power plant has been beautifully preserved. This is probably due to the fact that all possible entrances on the ground floor were firmly closed. Getting in here required some climbing. Since the rest of the site has mostly been demolished, it will only be a matter of time before this beautiful piece of industrial heritage will undergo the same destiny.

#urban exploration#urbex#abandoned#abandoned places#ue#urbexworld#urbexpeople#photography#belgium#urban relics#industrial#steel industry#urbanexploration#urbanexploringphotography

161 notes

·

View notes

Text

How to to control nitrogen levels ?

Why is it important to control nitrogen levels during the steelmaking process?

2 notes

·

View notes

Text

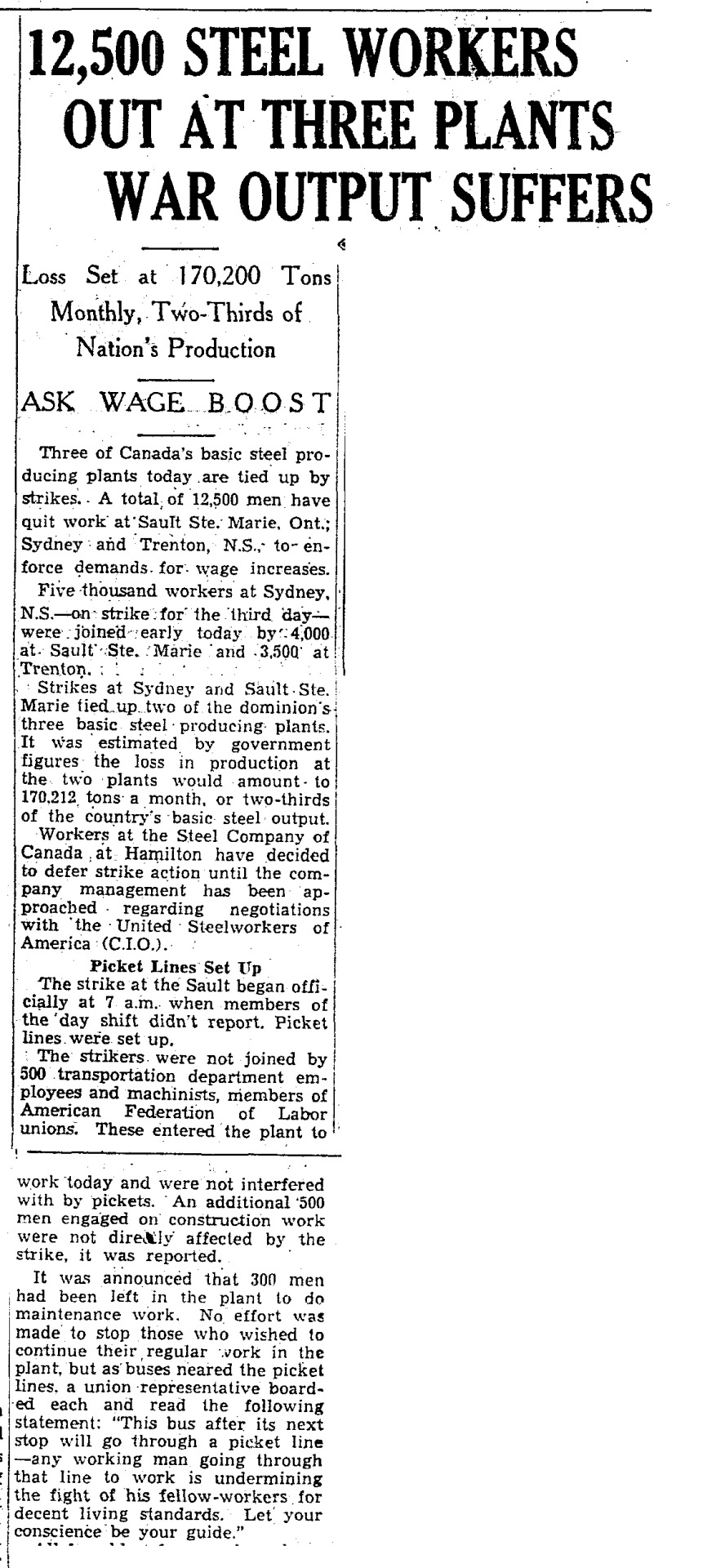

"12,500 STEEL WORKERS OUT AT THREE PLANTS; WAR OUTPUT SUFFERS," Toronto Star. January 14, 1943. Page 1. ---- Loss Set at 170,200 Tons Monthly, Two-Thirds of Nation's Production ---- ASK WAGE BOOST ---- Three of Canada's basic steel producing plants today are tied up by strikes. A total of 12,500 men have quit work at Sault Ste. Marie, Ont.; Sydney and Trenton, N.S., to enforce demands for wage increases.

Five thousand workers at Sydney, N.S. - on strike for the third day - were joined early today by 4,000 at Sault Ste. Marie and 3,500 at Trenton.

Strikes at Sydney and Sault Ste. Marie tied up two of the dominion's three basic steel producing plants. It was estimated by government figures the loss in production at the two plants would amount to; 170,212 tons a month, or two-thirds of the country's basic steel output.

Workers at the Steel Company of Canada at Hamilton have decided to defer strike action until the company management has been approached regarding negotiations with the United Steelworkers of America (C.I.O.).

Picket Lines Set Up The strike at the Sault began officially at 7 a.m. when members of the day shift didn't report. Picket lines were set up.

The strikers were not joined by 500 transportation department employees and machinists, members of American Federation of Labor unions. These entered the plant to work today and were not interfered with by pickets. An additional 500 men engaged on construction work were not direly affected by the strike, it was reported.

It was announced that 300 men had been left in the plant to do maintenance work. No effort was made to stop those who wished to continue their regular work in the plant, but as buses neared the picket lines, a union representative boarded each and read the following statement: "This bus after its next stop will go through a picket line - any working man going through that line to work is undermining the fight of his fellow-workers for decent living standards. Let your conscience be your guide."

#sault ste. marie#sydney nova scotia#trenton#strike#picket line#picketing#steel workers#steel plant#steel industry#algoma steel#dominion steel#united steel workers of america#central industrial organization#hamilton#wage demands#wage increase#wage freeze#price controls#canada during world war 2#working class struggle

9 notes

·

View notes

Text

I was born and raised in Gary, Indiana, so this story resonates deeply with me. Way too many of my high school friends died young from heart and lung diseases easily traceable to the crud in the air we all breathed for years.

Excerpt from this story from the Chicago Tribune:

The “Dirty Steel, Dangerous Air” report details the national and local health and economic costs of steel industry pollution. Industrious Labs released the report on Monday.

Industrious Labs is an environmental organization focused on cleaning up industries through network and capacity building, research and analysis, and data-driven campaigns, according to its website.

The 44-page report found that coal-based steelmaking contributes to an estimated $13.2 billion in health costs, 892 premature deaths and almost 100,000 lost school and work days annually, according to a news release from the organization.

“Steel communities have been sounding the alarm on harmful air pollution for years, and this report quantifies just how devastating and far-reaching the consequences are,” Hilary Lewis, steel director at Industrious Labs, said in the news release. “The EPA has consistently failed to safeguard the health of these communities from the dangers of coal-based steelmaking. It’s time for stronger regulations that recognize the opportunity of cleaner steelmaking technologies and tougher enforcement of penalties on polluters to truly protect public health.”

The report focuses on 17 facilities nationwide, including four plants in Northwest Indiana, each of which are owned by U.S. Steel or Cleveland-Cliffs.

In addition to steelmaking, the report looks at the harmful effects of coke, a processed form of coal used in steelmaking.

The steel industry accounts for more than 90% of the market demand for coke, according to the report, which called coke a “very dirty fossil fuel.”

The product is made by mixing coal with oil or water and heating it at 2,000 degrees for many hours. Coke requires dozens of large ovens to be made as well, according to the report.

Industrious Labs’ report also found that most residents in Gary are in the top 10% of U.S. residents most at risk for developing asthma and at risk of low life expectancy.

The city is home to U.S. Steel’s Gary Works facility, which could potentially receive $300 million for its blast furnace if a deal between the company and Nippon Steel is approved.

The $300 million investment will allow for higher steel production and reduced emissions, Gary Mayor Eddie Melton said in a statement. The furnace should have its life extended by up to 20 years.

Some residents, including those who are members of Gary Advocates for Responsible Development, have concerns about the investment.

Carolyn McCrady, member of GARD, said the only way for the steel industry to grow in “a healthy way” is to get rid of blast furnaces. McCrady believes in the use of direct reduction furnaces, which she calls more environmentally and economically friendly.

Direct reduction furnaces could reduce carbon dioxide emissions by half and produce about 20% of steel nationwide, McCrady said.

5 notes

·

View notes

Text

1952..when steel was still hot in the US..before the silicon chips

4 notes

·

View notes