#copper manufacturer

Text

Copper's Contribution to India's Infrastructure Development

Steel and concrete are probably the materials that come to mind when you consider the materials that power modern civilisation. However, the durable and adaptable metal copper has been quietly influencing infrastructural development not only globally but also considerably in India. Let's examine copper's crucial contribution to India's infrastructure development and why we can't afford to ignore it.

The Many Uses of Copper: A Versatile Commodity

If you've ever wondered why copper is so common, a deeper look at its many uses should put your mind at ease. Excellent corrosion resistance, malleability, and electrical conductivity are all features of the metal. It is unavoidable due to these three qualities alone in a variety of industries:

Copper wiring is the industry standard (pun intended) for electrical circuits, according to the electrical infrastructure. Its conductivity guarantees effective power transfer, minimizing energy loss.

Communication: Copper's function is more important than ever in the age of 5G and the Internet of Things (IoT). It is a top choice for telecommunications infrastructure because of its efficiency in transmitting both electrical and data signals.

Construction: Copper pipes are the best choice for plumbing, heating, and cooling systems due to their durability. Their durability results in fewer replacements being necessary over time, conserving resources.

Automotive Industry: As the use of electric vehicles increases, it is anticipated that the need for copper for batteries, wiring, and motors would skyrocket.

The Supply-Demand Equation: A Look at Economics

It is not necessary to be an economist to understand that the copper sector is governed by the rules of supply and demand. The demand for copper has increased as a result of the boom in infrastructural projects across India.

The demand for copper is rising as a result of urbanization and industrialization. The applications range widely from fundamental utilities to cutting-edge technologies.

Limited Supply: Copper ore, regrettably, has a limited supply. The risks of an excessive reliance on imports include unstable global market circumstances. The discrepancy between supply and demand highlights the significance of domestic Cuprous chloride manufacturers in India and Cuprous chloride suppliers in advancing society.

Benefits for the Environment: A Sustainable Option

Copper stands out for its environmental advantages in a time when sustainability is more than just a buzzword:

Copper is recyclable and may be used again without losing any of its quality. When compared to mining fresh ore, this not only conserves the resource but also uses less energy.

Energy Efficiency: since of copper's high conductivity, electrical systems have a smaller carbon footprint since less energy is lost as waste heat.

Benefits to health: Copper surfaces are less likely to support bacterial and virus growth due to its inherent anti-microbial qualities, which helps to create healthier living conditions.

Sectors of Infrastructure Most Affected by Copper

When we discuss infrastructure development, we don't just mean building buildings and motorways.

Energy Sector: Copper is a critical component for the efficient operation of renewable energy systems, particularly solar panels and wind turbines. The systems are more sustainable since copper's conductivity guarantees that energy loss is kept to a minimum.

Transport: Copper plays a huge part in the infrastructure of today's transportation systems, especially with the popularity of electric cars (EVs). Electric motors, efficient, lightweight batteries, and the charging infrastructure for EVs are all made with copper.

Healthcare: Copper is essential for both hospital infrastructure and medical equipment. since of its antibacterial qualities, it is the perfect material for surfaces in healthcare facilities since it helps stop the spread of illnesses.

Economic Independence: By supporting domestic Cuprous chloride producers in India, we lessen dependency on imports, which is essential for maintaining the stability of the country's economy. Local manufacturing contributes to national skill development and job generation.

Global Supply Chain Vulnerabilities: The COVID-19 outbreak has exposed the flaws in global supply chains. A layer of security is added by concentrating on domestic production, ensuring that important infrastructure projects are not impeded by changes in the global economy or geopolitical tensions.

Local production frequently enables more stringent quality standards. Local copper providers might follow certain area requirements, guaranteeing a consistent and high-quality final product.

Sustainability: Locally sourced materials require less transportation, which reduces their carbon footprint.

Contribution of Copper to Indian Infrastructure

One cannot overestimate copper's impact on India's expanding infrastructure. Its applications are as varied as they are numerous, ranging from supplying power to your homes to supporting intricate industrial processes.

Meghmani, a significant figure in the copper chemistry sector, is aware of the crucial function that copper, particularly cuprous chloride, plays in contemporary life.

Contact us right now if you're interested in finding out more about how Meghmani can help your infrastructure needs. One of the top Copper manufacturers in India, we stand out because of our dedication to quality and sustainability.

0 notes

Text

expansion of copper tubing

#my posts#gif#hydraulic machine#factory machinery#metal pipe#copper pipe#manufacturing#suggestive#objectophilia#objectum

440 notes

·

View notes

Text

What's your favourite *drumroll*...

Also which one do you pledge right now to include in some way in your next faneork that includes Sam. I hope it's gators.

#these are all in the text of Supernatural#spn poll#pollsnatural#I SHOULD be hearing about Sam's love of his old coin collection at the same rate that I hear about Dean's love of pie.#(he is able to identify unusual elements of a coin via niche coin manufacturing knowlege by just looking at it for a few seconds)#(I know he's a copperhead. that's a name I just made up for people who are really into coins do you like it)#(it's because the uk 1 2 and 10 pence pieces are made of copper)#I just feel the need to spread the word about Sam's interests they don't get a huge amount of narrative focus

78 notes

·

View notes

Text

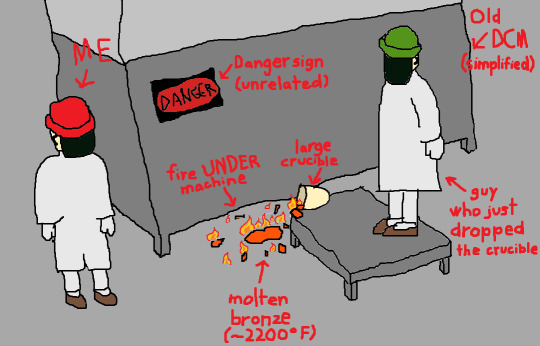

Bit of an issue.

#all the castings came out super good though!#my stuff#art#casting#bronze#manufacturing#paint#this took me a while#I used the mousepad so that might be why#this happened RIGHT AFTER the other guy finished explaining to me the dangers of copper and bronze#in that it will stick to you instead of bouncing off#and you will get severely burned#no one was injured this time though!

108 notes

·

View notes

Text

A novel surgical implant developed by Washington State University researchers was able to kill 87% of the bacteria that cause staph infections in laboratory tests, while remaining strong and compatible with surrounding tissue like current implants.

The work, reported in the International Journal of Extreme Manufacturing, could someday lead to better infection control in many common surgeries, such as hip and knee replacements, that are performed daily around the world. Bacterial colonization of the implants is one of the leading causes of their failure and bad outcomes after surgery.

"Infection is a problem for which we do not have a solution," said Amit Bandyopadhyay, corresponding author on the paper and Boeing Distinguished Professor in WSU's School of Mechanical and Materials Engineering. "In most cases, the implant has no defensive power from the infection. We need to find something where the device material itself offers some inherent resistance -- more than just providing drug-based infection control. Here we're saying, why not change the material itself and have inherent antibacterial response from the material itself?"

Read more.

#Materials Science#Science#Medical technology#Anitbacterial#Titanium#Tantalum#Copper#3D printing#Washington State University#Additive Manufacturing

8 notes

·

View notes

Text

China Alloy Steel, Alloy Steel, wholesale Alloy Steel, Alloy Steel manufacturers stainless steel manufacturers, stainless steel suppliers, stainless steel factory, China stainless steel price, Chinese suppliers https://superbmaterials.com/

#630 stainless steel#631 stainless steel#stainless steel forging#stainless steel alloys#alloy steel china#carbon steel china#nickel alloys china#stainless steel china#copper producers china#heat resistant alloys#china#united states#Shanghai#Pudong#suppliers#stainless#Alloy Steel#Alloy#Steel#Chinese#factory#manufacturers#kitchen

2 notes

·

View notes

Text

looking at humidifier reviews is honestly an enlightening experience. who knew there were so many people in the world stuck believing that mold growing in standing water is some kind of design flaw on the part of the vessel.

#what exactly is a manufacturer supposed to do to prevent that i'd like to know!#any antifungals in the water make it unfit to be breathing in!#maybe if the reservoir was made of copper.....

10 notes

·

View notes

Text

Copper Nickel Alloy 70/30 Flanges Suppliers

Being a prominent name, Technolloy Inc. has the massive experience of having given the Copper Nickel 70/30 Forged fittings starting with one side of the planet and then onto the next for a sweeping stretch. We made a pleasant picture-saving watch for giving the best quality CuNi 70/30 Fashioned Fittings and various other things. We believe in giving the best to our clients.

#Copper Nickel 70/30 Forged Fittings Manufacturers in Mumbai#Copper Nickel 70/30 Forged Fittings Suppliers in Mumbai

9 notes

·

View notes

Text

Heavy Copper PCB

Heavy copper pcb manufacturering up to 26 OZ

Hitech is a professional heavy copper pcb, thick copper pcb board manufacturer, PCB power supplier from China, we have been associated with heavy copper pcb plating since 2000 and we have won good reputation in this industry. If you have customized heavy copper pcb needs, please don’t heisitate to conatct [email protected] .

Demand for heavy copper PCB in Electric automotive, Power charge, voltage transformer, Charging station, industrial controls, and military is growing very fast. More than 80% of the existing printed wiring board manufacturing is limited or not capable of producing reliable heavy copper printed circuit boards.

Hitech thick copper board technology offers the possibility to implement complex switches in limited space in combination with circuitry for high current levels. Multi-layer PCB has reliable processes to produce copper layer thicknesses up to 26 Oz .

Hitech heavy copper PCB normally used for high power rectifiers, Power charge, Transformaer, Charging station, computer, military, electric vehicle charging, power grid switching system, etc

What is heavy copper PCB board

Heavy copper PCB boards ( also being called thick copper board, power board etc ) are usually bonded with a layer of copper foil on a glass epoxy substrate. The thickness of copper foil is usually 18μm, 35μm, 55μm and 70μm. The most commonly used copper foil thickness is 35μm. The thickness of copper foil used in China is generally 35-50μm, and there are also thinner ones such as 10μm and 18μm; and thicker ones such as 70μm. The thickness of the composite copper foil on a substrate with a thickness of 1-3mm is about 35μm; the thickness of the composite copper foil on a substrate with a thickness of less than 1mm is about 18μm, and the thickness of a composite copper foil on a substrate with a thickness of more than 5mm is about 55μm. If the thickness of the copper foil on the PCB is 35μm and the printed line width is 1mm, then for every 10mm length, its resistance value is about 5mΩ, and its inductance is about 4nH. When the di/dt of the digital integrated circuit chip on the PCB is 6mA/ns and the working current is 30mA, the resistance and inductance contained in each 10mm printed line are used to estimate the noise voltage generated by each part of the circuit to be 0.15. mV and 24mV.

Advantages of heavy copper PCB board

Heavy copper plate has the characteristics of carrying large current, reducing thermal strain, and good heat dissipation.

1. The heavy copper circuit board can carry large current

In the case of a certain line width, increasing the copper thickness is equivalent to increasing the cross-sectional area of the circuit, which can carry a larger current, so it has the characteristic of carrying a large current.

2. Heavy copper circuit boards reduce thermal strain

Copper foil has a small electrical conductivity (also called electrical resistivity ), the temperature rise is small when a large current is passed, so it can reduce the amount of heat and thereby reduce the thermal strain.

Metal “conductors” are divided into: ” silver→copper→gold→aluminum→tungsten→nickel→iron ” according to conductivity.

3. The heavy copper circuit board has good heat dissipation

Copper foil has high thermal conductivity (thermal conductivity 401W/mK), which can play an important role in improving heat dissipation performance, so it has good heat dissipation;

Thermal conductivity refers to the heat transfer through an area of 1 square meter within 1H for a 1 meter thick material with a temperature difference of 1°C on both sides under stable heat transfer conditions, measured by W/m·K.

Heavy copper plate has the characteristics of carrying large current, reducing thermal strain, and good heat dissipation.

Disadvantages of heavy copper PCB board

The outer copper-clad plane must be separated by the surface components and signal lines. If there is a poorly grounded copper foil (especially the thin and long copper), it will become an antenna and cause EMI problems.

If the pins of electronic components are fully connected with copper, it will cause the heat to dissipate too fast, and it will be difficult to desolder and rework soldering. The copper-clad plane of the outer layer must be well grounded, and more vias need to be punched to connect to the main ground plane. If more vias are punched, it will inevitably affect the wiring channels, unless buried blind vias are used.

Applications of heavy copper PCB board

The application field and demand for thick copper plates have been rapidly expanded in recent years, and it has become a “hot” PCB variety with good market development prospects.

The vast majority of heavy copper PCBs are high-current substrates (current x voltage = power). The main application areas of high-current PCBs are two major areas: power modules and automotive electronic components. Some of its main terminal electronic product fields are the same as conventional PCBs (such as portable electronic products, network products, base station equipment, etc.), and some are different from conventional PCB fields, such as automobiles, industrial controls, and power modules.

High-current PCBs are different from conventional PCBs in terms of efficacy. The main function of a conventional PCB is to form a wire for transmitting information. The high-current PCB has a large current through it, and the main function of the substrate carrying the power device is to protect the current carrying capacity and stabilize the power supply. The development trend of such high-current PCB is to carry larger currents, and the heat emitted by larger devices needs to be dissipated. Therefore, the large currents passing through them are getting larger and larger, and the thickness of all the copper foils of the PCBs is getting thicker and thicker. The 6 oz copper thickness of the high-current PCBs manufactured now has become normal;

The application areas of heavy copper circuit boards include: mobile phones, microwaves, aerospace, satellite communications, network base stations, hybrid integrated circuits, power supply high-power circuits and other high-tech fields.

#heavy copper pcb#pcb#pcb assembly#pcb designer#pcb layout#pcb manufacturing#pcb production#pcb supplier

4 notes

·

View notes

Text

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

4 notes

·

View notes

Text

Copper Nickel 70/30 Sheets And Plates Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. industry has sorted out some way to acquire a recognizable market in collecting, conveying and giving broad assortment of Copper Nickel 70/30 Sheets and Plates. We give the client an obliging method for managing satisfy the requirements of our clients to satisfy their necessities.

Copper Nickel 70/30 Sheets and plates are made using premium quality copper. These sheets and plates come in various shapes, sizes, length and thickness. Further, they can similarly be framed by the prerequisites and solicitations of the clients. They come in different designs like rolls, circles, foils, ring (flange), penetrated sheets, checkered plates, shim sheets and plain sheets. They have different lengths like twofold erratic, single sporadic and cut length. They furthermore shift in finishing as a couple of sheets and plates have hot moved finishing, some have cold rotted finishing, etc. They in similar manner come in different hardness types like sensitive, hard, half hard, quarter hard, spring hard, etc.

The sheets are used in condensers, power plants, and seawater directing and exchanger shells. The plates are used in versatile metal hose, weld wire, pot parts and welding backing rings. These sheets and plates are furthermore used in various endeavors like substance organizations, drugs, power industry, sugar production lines, crush and paper industry, and substantial industry.

Due to their high disintegration impediment, incredible versatility and flexibility, the Copper Nickel 70/30 Sheets and Plates are significantly famous. These sheets and plates moreover have properties like adversaries of damaging, high warm and electrical conductivity. They, moreover, have extraordinary mechanical and appealing properties. The sheets are unyielding in nature and besides have plausibility.

They have extraordinary solidness, astounding surface culmination, and harsh turn of events, and can persevere in high temperature locales and in significant weights, heavenly layered precision. The sheets and plates, moreover, have the limit of oxidation.

Before Copper Nickel 70/30 Sheets and Plates are full and conveyed to the clients, they go through various testing cycles to satisfy the quality and rules of the thing. A part of the tests integrates pitting impediment test and hardness test. Huge scope/little test, intergranular utilization test, positive material conspicuous evidence tests, praising test substance and mechanical test.

Cupro Nickel Sheets and Plates Specification : ASTM B151 / ASME SB151

Dimension Standard : JIS, AISI, ASTM, GB, DIN, EN, etc

Width : 1000mm, 1219mm, 1500mm, 1800mm, 70 / 300mm, 2500mm, 3000mm, 3500mm, etc

Length : 70 / 300mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 120 mm

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

For more information :

Visit our website : https://www.merakimetals.ae

Contact us : +971-523973687, +971-48801107, +971-48240333

Email : [email protected]

#Copper Nickel 70/30 Sheets And Plates Manufacturers in UAE#Copper Nickel 70/30 Sheets And Plates Suppliers in UAE#Copper Nickel 70/30 Sheets And Plates Stcokists in UAE#Copper Nickel 70/30 Sheets And Plates Exporters in UAE

4 notes

·

View notes

Text

Copper carbonate exporters

Copper carbonate, a chemical compound with a greenish-blue hue, finds use in a range of industries due to its unique properties. It is a versatile substance known for its applications in manufacturing, agriculture, and more.

Applications of Copper Carbonate

Copper carbonate has diverse applications:

Agriculture: It's used as a fungicide to protect plants from various diseases.

Pigments: The compound's distinctive color makes it valuable in creating vibrant blue and green pigments for art and industry.

Chemical Reactions: It serves as a reactant in various chemical processes, contributing to the production of other compounds.

The Role of Copper Carbonate Exporters

Copper carbonate exporters act as bridges between producers and consumers. They ensure a seamless flow of the compound across international borders, catering to different industries' demands.

Ensuring Quality and Standards

Reliable exporters prioritize quality control and adherence to international standards. They play a crucial role in maintaining the compound's integrity during transportation and storage.

Global Impact and Sustainability

Exporters of copper carbonate contribute to the global economy by facilitating the trade of this essential compound. Sustainability practices, such as eco-friendly packaging and efficient logistics, further reduce the environmental impact of the trade.

Choosing the Right Export Partner

Selecting a reputable copper carbonate exporter is essential. Factors like experience, industry reputation, shipping capabilities, and customer service should be considered when choosing an export partner.

Future Trends in Copper Carbonate Export

As industries evolve and environmental concerns grow, future trends may include a focus on sustainable practices, digital integration for smoother transactions, and advanced packaging solutions.

Conclusion

Copper carbonate exporters play a vital role in ensuring the availability and accessibility of this essential compound across diverse industries. Their expertise, commitment to quality, and role in global trade make them indispensable in the modern business landscape.

0 notes

Text

Copper Flat Bars are accessible in manufactured or hot/cool moved complete in various measurements. These precisions completed level bars are accessible on finch conditions, including hard, half-hard and delicate alternatives, in this way giving best end utilization to electrical purposes. We can likewise convey compound and mechanical attributes of copper bars as per European gauges.

#Copper Flat Bars Manufacturers in Mumbai#Copper Flat Bars Suppliers in Mumbai#Copper Flat Bars Exporters in Mumbai#Copper Flat Bars Importers in Mumbai#Copper Flat Bars Manufacturers in India#Copper Flat Bars Suppliers in India#Copper Flat Bars Exporters in India#Copper Flat Bars Importers in India

2 notes

·

View notes

Text

Business Names in the 1800s: Primary Flour, Just Cement, Worldwide Copper, The Only Gasoline You Should Be Allowed To Buy

Business Names in the 1900s: Axiom, Artemis Manufacturing, Pinnacle Hygienics, Olympian Glue, Divine Yogurt, The Coolest Car Manufacturer With The Largest Hog In Town

Business Names in the 2000s: Gubi, Turna, Clooper, Jumbli, Dongr, Shnet, Pungu, Pooble, Weeeu

58K notes

·

View notes

Text

Top 3 Applications of Pipe Fittings

What are Pipe Fittings?

Pipe fittings are essential in many industries and systems where the handling of fluids-one form or other-is involved. Pipe Fittings are used for connecting, changing the direction of, controlling, and stopping the flow of a liquid, gas, or slurry inside a piping system. Their versatility and functionality make them indispensable across several fields. Some common applications and usages of pipe fittings are discussed below. Pearl Pipe Fittings is the leading Pipe Fittings Manufacturer in India and Flange Manufacturer in India.

Top 3 Applications of Pipe Fittings

1. Plumbing Systems

Probably the most common plumbing pipe fitting used serves to connect various sections of pipe in residential, commercial, and industrial buildings for water distribution and sewage systems. Standard elbows, tees, and couplers allow the flow of water to divert around obstructions or corners, while reducers change pipe sizes to comprehend any variation in pressure. We are also the best Carbon Steel Pipe Fittings Manufacturer in India and CS Flanges Manufacturers in India

2. Oil and Gas Industry

The oil and gas industry-operated pipe fittings are highly important to guarantee that crude oil, natural gas, or refined products are being moved around safely. Applications involving fittings under high-pressure conditions and requirements for corrosion resistance call for materials to be manufactured from carbon steel, stainless steel, or alloy for this purpose. Such fittings play an indispensable role in the process of connecting pipelines, flow rate control, and leak-proof applications at the stage of extraction, refining, and distribution.

3. Chemical and Pharmaceutical Industry

The chemical and pharmaceutical industries are one of the prime concerns in terms of precision with safety. The pipe fitting deployed within this industry needs to be resistant to corrosion and thereby not chemically reactive. Thus, this is used for transporting liquids, gases, and powders so that the substance being conveyed retains its integrity. Flanged connections, valves, and special fittings such as fittings for sanitary appliances ensure the process remains clean and free from contamination.

You may also like: Copper Nickel Flange Manufacturer in India

Product Source: Stainless Steel Flanges Manufacturer in India and SS Pipe Fittings Manufacturers in India

#Pipe Fittings Manufacturer in India#Flange Manufacturer in India#Carbon Steel Pipe Fittings Manufacturer in India#CS Flanges Manufacturers in India#Copper Nickel Flange Manufacturer in India#Stainless Steel Flanges Manufacturer in India#SS Pipe Fittings Manufacturers in India

0 notes

Text

How Koprex Became a Leading Copper Anodes Manufacturer in the Industry

In industries like electroplating, electronics, and energy, the demand for high-quality, reliable copper anodes has grown significantly. Copper anodes are essential for these applications, and the market requires a manufacturer that delivers not just consistent quality but also innovation and sustainability. Koprex, a well-known copper anodes manufacturer, has risen to the forefront by addressing these demands, becoming a trusted name for many industrial sectors. Here’s a closer look at how Koprex became an industry leader and what sets it apart from the competition.

A Commitment to Quality

One of the key factors behind Koprex’s success as a copper anode manufacturer is its unwavering commitment to quality. In industries that rely on copper anodes, such as electroplating and power generation, the purity and performance of the material are critical. Even the smallest impurities in copper can lead to inefficiencies or malfunctions in these sensitive processes.

Koprex addresses this by implementing strict quality control measures at every step of the manufacturing process. From sourcing raw materials to the final production, the company ensures that its copper anodes meet the highest standards. By doing so, Koprex provides its customers with reliable, high-performance anodes that contribute to the overall efficiency of their operations.

Advanced Manufacturing Technology

The production of copper anodes requires advanced technology to ensure precision and purity. Koprex has invested in state-of-the-art manufacturing facilities that utilize cutting-edge equipment to produce copper anodes with superior conductivity and corrosion resistance. These anodes are made with precision, ensuring they meet the exact specifications needed for a variety of industrial applications.

By leveraging advanced manufacturing processes, Koprex can deliver copper anodes that offer enhanced durability and longer operational life, reducing the need for frequent replacements and lowering costs for its customers. This has made Koprex a preferred copper anode manufacturer for businesses that prioritize performance and longevity.

Focus on Innovation

One of the reasons Koprex has been able to maintain its position as a leading copper anode manufacturer is its focus on innovation. The company is continually researching and developing new ways to improve the performance of its products. Whether it’s enhancing the conductivity of the copper or finding new ways to minimize impurities, Koprex is always looking for innovative solutions that provide added value to its customers.

This focus on innovation has allowed Koprex to stay ahead of industry trends and consistently offer products that meet the evolving needs of modern businesses. The company’s ability to adapt and improve its manufacturing processes has been a significant driver of its growth and success.

Custom Solutions for Industry Needs

Another aspect that sets Koprex apart as a copper anode manufacturer is its ability to offer custom solutions for its clients. The industries that rely on copper anodes often require products that are tailored to their specific needs. Whether it's adjusting the size, shape, or composition of the anode, Koprex works closely with its clients to ensure they receive products that perfectly match their requirements.

This customer-focused approach has helped Koprex build strong, long-term relationships with its clients. Businesses know they can rely on Koprex not just for high-quality copper anodes but also for personalized solutions that enhance their operations.

Sustainability at the Core

In today’s industrial landscape, sustainability is no longer just an option—it’s a necessity. Koprex understands this and has made environmental responsibility a key part of its business model. The company is committed to using eco-friendly manufacturing processes that minimize waste and energy consumption, ensuring that its products have a lower environmental impact.

Koprex’s dedication to sustainability not only makes it a responsible choice for businesses but also aligns with the increasing demand for environmentally friendly products in the marketplace. By choosing Koprex as their copper anode manufacturer, businesses can rest assured that they are partnering with a company that takes both quality and sustainability seriously.

Meeting Global Standards

As a global copper anodes manufacturer, Koprex adheres to strict international standards in its production processes. This ensures that its copper anodes meet the highest levels of purity, performance, and durability. The company’s adherence to these standards is a reflection of its commitment to delivering superior products to customers worldwide.

By maintaining these global standards, Koprex has been able to expand its market reach, serving clients not just in its home country but across various international markets. This global presence further solidifies Koprex’s position as a trusted name in the industry.

Industry Applications of Koprex Copper Anodes

Koprex’s copper anodes are widely used in several industries:

Electroplating: The high purity of Koprex’s copper anodes ensures that the plating process delivers a consistent and high-quality finish, critical for manufacturing industries.

Electronics: In the electronics industry, the conductivity of copper is essential for the performance of various components, and Koprex’s anodes provide the reliability required in this sector.

Energy: Power generation and transmission systems also benefit from the high conductivity and corrosion resistance of Koprex’s copper anodes, making them an integral part of energy infrastructure.

Strong Customer Relationships

Koprex’s success as a copper anode manufacturer is also driven by its strong commitment to customer satisfaction. The company takes pride in understanding the unique needs of its customers and delivering solutions that meet those needs. Whether it’s providing technical support, offering customization options, or ensuring timely delivery, Koprex goes above and beyond to ensure its clients receive the best service possible.

This customer-centric approach has helped Koprex build a loyal client base that continues to rely on its products for its critical applications.

Conclusion

Koprex’s rise to becoming a leading copper anodes manufacturer is a result of its dedication to quality, innovation, and customer satisfaction. By producing high-performance copper anodes that meet the stringent requirements of various industries, Koprex has established itself as a trusted partner for businesses around the world. With a focus on sustainability and custom solutions, Koprex continues to lead the way in delivering reliable, top-tier products that support the success of its clients.

This Blog Was Originally Published At: https://koprexmti.blogspot.com/2024/09/how-koprex-became-leading-copper-anodes.html

0 notes