#cold forging

Explore tagged Tumblr posts

Text

What is the forging process?

Forging is the working of metal into a useful shape by using localized compressive forces. These forces are applied through various tools such as hammers or presses. This process is integral to producing high-strength components for various industries, including automotive, aerospace, and construction.

Most forging operations are carried out hot, although certain metals may be cold forged. Two major classes of equipment are used for forging operations: the forging hammer, or drop hammer, which delivers rapid impact blows to the surface of the metal, and the forging press, which subjects the metal to a slow speed compressive force.

#science#materials science#engineering#materials science and engineering#materials#metals#alloys#mechanical properties#mechanical properties of materials#metal forging#cold forging#hot forging#forging tools#forging

15 notes

·

View notes

Text

Gostaria de comprar aço DIN 1.2714, DIN 1.2343, DIN 1.2344 na Europa, Portugal e Espanha para a sua indústria siderúrgica de trabalho a quente?

Entre em contato conosco hoje para colocar sua exigência!

Aço para trabalho a quente reconhecido por sua alta resistência ao desgaste, condutividade térmica, dureza e resistência a altas temperaturas. Esses aços apresentam melhores características de desgaste devido ao menor teor de enxofre.

Aplicações adequadas de AÇO PARA FERRAMENTAS DE TRABALHO A QUENTE … https://moldsteel.eu/steel-products/hot-work-steel/

Se você estiver interessado em seus produtos ou tiver alguma dúvida específica, é recomendável entrar em contato diretamente com a EDELSTAHL VIRAT IBERICA para obter mais informações e discutir suas necessidades.

Consulte nossa equipe que irá auxiliá-lo na negociação de materiais de aço DIN 1.2714, DIN 2343 e DIN 2344.

https://moldsteel.eu/steel-products/hot-work-steel/

Chat WhatsApp: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#din2344#din2714#din2343#hot work steel#metal forging#open die forging#metal#forging bonds#cold forging#hot forging

2 notes

·

View notes

Text

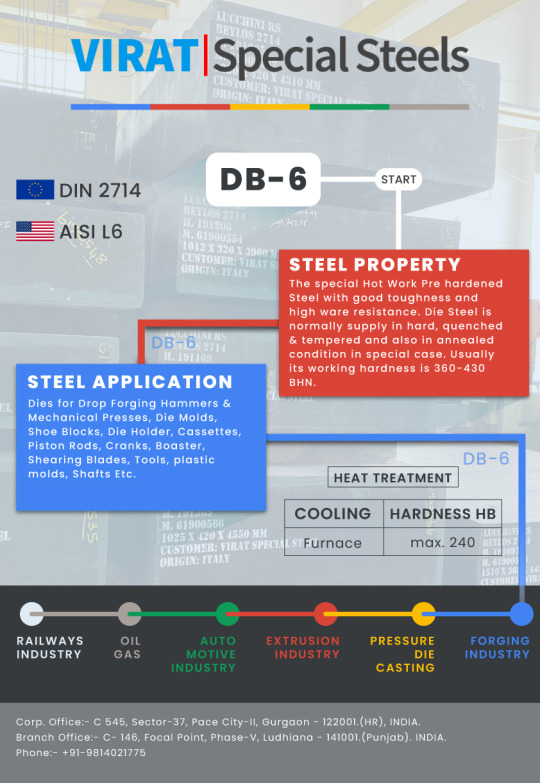

Are you looking for Die Steel blocks DB6 in India? Die steel blocks DB6 could be a great choice for your close die forging applications!

Discover Quality Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED , INDIA.

Virat Special Steels indeed offers a variety of tool steels, including Die Steel Blocks DB6 Steel. We are known for being one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Die steel blocks DB6, also known as DIN 1.2714, is a hot work tool steel with high toughness and wear resistance, which is achieved through a specific composition of chromium, nickel, molybdenum, and vanadium. This grade of steel is characterized by its high tempering resistance and good through-hardening properties, making it particularly impact-resistant and suitable for large hammer and press dies.

Applications: It’s commonly supplied in a pre-hardened condition and has a typical working hardness range of 360 to 430 BHN (Brinell hardness number). DB6/ DIN 1.2714 steel is used for various applications, including forging dies, die molds, shoe blocks, die holders, piston rods, bolster, cranks, cassettes, plastic molds, shearing blades, tools, and more.

DB6 / DIN 1.2714 steel is also known for its good thermal conductivity and coefficient of thermal expansion, which are critical properties for materials used in high-temperature environments.

Get in touch with us today to place your requirement ! The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels…

Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Contact us today to buy the best quality DB6 / DIN 2714 steel for your tooling needs! https://www.viratsteels.com/db6.html

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📩[email protected] 📲+91-98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#db6 steel#din 2714#hot work steel#AISI L6#SteelSupply#MetalTraders#MetalIndustry#open die forging#forging#metal forging#cold forging#hot forging

2 notes

·

View notes

Text

I was bored at work today so in between customers I got a fork and a pair of pliers and set about using the latter to turn the former into a bracelet. So far I’m like 80% of the way there except the … bowl of the fork? The wide part? Just will not allow itself to be bent. I suspect I need something to act as an anvil, or possibly something to apply heat. Or both? Advice from veteran forksmiths would be appreciated.

I may end up bending two spoons and interlocking them to form one bracelet, because the single spoon is too short to go all the way around my wrist. But first I need to figure out the bending-the-flat-part problem.

Image ID: a fork rests on a wooden table. Its tines have been bent into curlicues and the handle of the fork has been bent into a half circle. The widest part of the fork is towards the camera, stubbornly unbending. End image ID.

#fork#jewelry#crafting#metalsmithing#cold forging#steel#crafts#kitsch#how do I encourage this bloody fork to bend

2 notes

·

View notes

Text

Oh lawd we hammering.

2 notes

·

View notes

Text

The world's top ten mold types ranking - Forging die

For previous reading, please refer to The world’s top ten mold types ranking-Plastic mold, Stamping die.A die that forms a metal blank into a blank or a product under pressure, including hammer forging die, mechanical press forging die, screw press forging die, hydraulic press forging die, flat forging die, etc. 1. Upper die seat 2. Upper die core 3. Upper ejector 4. Lower die seat 5. Lower die…

View On WordPress

#cold forging#cold forging dies#die design#Die forging process#die forgings#Forging die#forging process#hot forging die#hot forging dies#precise forging process

0 notes

Text

With August coming up I thought I'd share a picture of this cute little peridot (Augusts birthstone) wire wrapped, cold forged mushroom in silver filled wire.

Also available in copper. 💚🍄

#Peridot pendant necklace#Wire wrapped jewellery#cold forging#gemstone jewellery#August birthstone#mushroom pendant#cottagecore

0 notes

Text

Explore $153.9 billion metal forging market: Get exclusive insights on key market trends, segments, geographical analysis, & competitive analysis!

#Metal Forging Market#Forging#Metal Forging#Cold Forging#Warm Forging#Hot Forging#Open Die Forging#Closed Die Forging#Roll Forging

0 notes

Text

viktor visits jayce in the forge. jayce gets distracted

#enthyrea art#idk i had a vision of forge jayce and viktor and i spat this out after blacking out for three hours#i just wanted to draw dom viktor because you can tear hc that out my cold head hands#arcane#arcane jayvik#jayvik#vikjayce#jayvik fanart#jayce talis#arcane jayce#jayce x viktor#arcane viktor#viktor arcane#viktor x jayce#arcane fanart#arcane art#viktor nation#jayvik nation#arcane s2#jayce arcane#jayvik arcane

2K notes

·

View notes

Text

Know about the CNC Turning Service | Protoindus

CNC Turning is a manufacturing process that involves the use of a computer-controlled lathe to create precise and intricate parts from a variety of materials. The lathe is equipped with a cutting tool that is programmed to move along the surface of a spinning workpiece, removing material to achieve the desired shape and dimensions.

0 notes

Text

my @secretsolenoid-revived gift for @forged-cold ! sentinel is enjoying some gifts from his adoring public 💕 happy holidays!!

#secret solenoid#transformers#maccadam#transformers one#sentinel prime#bone arts#2024#illustration#fanart#☆#forged-cold#i tried experimenting with softer shading on this one and i think it turned out nice!!

745 notes

·

View notes

Text

need-to-know basis

when chromedome backed up brainstorm's lie about being forged was he being a true bestie or did he genuinely not know. this haunts me

#transformers#maccadam#brainstorm#nautica#mtmte#it's way funnier if he genuinely did not freaking know#additionally the fact that he lied about it in the first place is INCREDIBLY loaded. the entire series pretty much nobody is cagey about it#except for him and megatron. like even the other MTOs discuss their experiences openly. who hurt you brainstorm#the kind of... prejudice? i guess? against cold constructed transformers in idw is interesting because#tyrest aside it happens JUST often enough for you to be like hmmm what is wrong with these people#it's ratchet outright saying that forged hands are better. it's whirl bragging about being forged. it's starscream's constant frame changes#I THINK ABOUT THIS CONSTANTLY

276 notes

·

View notes

Text

Frigid Steel, Boiling Wraith

Thinking about how pale ore is eerily chill to the touch

about how PV's spells, likely learnt from its father, take on the same shape as nails made out of an ore allegedly related to its parents

about how those spells are pretty much a solid state of soul for a few moments about how solid state of matter is often the most "cold" state, generally speaking

about how cold it's often associated with lack of emotion and corpses

Also thinking about how the knight's spells, learned from the snails, is more raw, more volatile

stated and shown to literally burn opponents, more of a hot blast than a proper solid mass

shaped and named after haunting ghosts, spectres that do not lay to rest, despite soul itself being present in the whole environment and not necesarily directly linked to sentient beings

about how it is strong emotions what fuels their transformation into their more powerful state through the usage of void, a volatile yet maleable substance, and the opposite of light

if you want to, you can get this drawing in full quality and ready to be a phone wallpaper at my kofi page completely free of charge (although i wont be mad if you leave a lil tip)

#makes me think if the pale king himself or the wyrm were also cold to the touch#or if his presence brought a chill to the place as opposed to radiance's burning presence#the 'snow' in kingdom's edge is actually ashes from a rotting corpse (so marine snow without the marine)#except maybe it is still quite cold actually?#theres also stuff that can be said about the forging of a pure nail and the readiness/fitness of a vessel#but that shall be left for another time#hollow knight#mebi's art#hollow knight art#hollow knight fanart#hk the hollow knight#the hollow knight#pure vessel#hk pure vessel#hk the knight#the knight hollow knight#the knight#digital art#krita#fanart#artist on kofi#artist on tumblr

1K notes

·

View notes

Text

Late night tender moments - Secondo Emeritus:

The warm feeling of his kitchen, as he prepares a meal. The smell of the boiling pasta, simmering tomato sauce, and spices fill the air. Banter and little quips come and go between the two of you, as he guides you through his cooking process. As he puts the finishing touches on the two dishes, you sit on the countertop while your eyes take him in. You have never loved him as much as you did right in this moment.

A warm kiss exchanged in the garden late at night. Nature is quiet, and the ministry is asleep. The only sound you hear now is his voice, his breath. He firmly yet gently holds your waist, before tenderly placing a kiss on your lips. As you process the heat that now comes alive within you; the cool, calm wind of the night envelopes you. A contradiction that only happens in his presence.

The soft sound of the running sink awakens you, before you are welcomed by his scent. The silky bed sheets felt nice against your figure, but someone was missing. You sluggishly get off the bed, dragging your feet as you approached his restroom. You find him shaving his stubble, carefully grooming himself before he shoots a glance in your direction. Then a smile. Memories of your shared intimacy come flooding in. In the reflection of his mirror, you faintly see the marks on your neck that he left last night.

A flickering candlelight dances around in his room late at night, while he reads a book. You turn around in an attempt to conceal sleep, but give up as you look at him. "È tardi, piccolina" he adds distractedly, while he turns the page. "You are one to talk". He lets out a soft, rumbling chuckle at your little observation, before holding you closer to him. "Cattiva, cattiva..." His voice soothes you. His embrace ends up doing the trick, and you quickly fall asleep in his arms.

A slow dance shared in the privacy of his chambers. His piercing eyes adoringly look into yours, while you softly sway from side to side to the rhythm of the music that comes from his record player. You smile brightly, your eyes never leaving his. Not many words are exchanged, only glances that reveal shared longing. You rest your head against his chest, and as he continues guiding you through his dance, your senses focus on his heartbeat. You feel your body relax and all tensions dissipate, carried away by his touch.

#the band ghost#ghost the band#Papa Emeritus II#Papa Emeritus Secondo#Secondo#II#Secondo x reader#Papa Emeritus II x reader#i don't know what this is i just feel kinda sentimental tonight#like.. do you ever miss a fictional character? yeah#like that#Secondo to me feels warm and cold at the same time.. i just ;;; tobias forge#thank you for your OCs#ghuleh writes

179 notes

·

View notes

Text

The big one's name is Toe Crusher.

1 note

·

View note

Text

Character, book, and author names under the cut

Victor Vale- Vicious by VE Schwab

August Landry- One Last Stop by Casey McQuiston

Daja Kisubo- The Circle of Magic series by Tamora Pierce

Neil Josten- All for the Game by Nora Sakavic

#Victor Vale#Vicious#Vengeful#Villains#VE Schwab#August Landry#One Last Stop#OLS#McQuistonverse#Casey McQuiston#Daja Kisubo#The Circle of Magic series#The Circle Opens series#The Will of the Empress#Daja’s Book#The Fire in the Forging#Cold Fire#Emelan#Tamora Pierce#Neil Josten#aftg#the foxhole court#tfc#the kings men#the raven king#all for the game#Nora Sakavic#lgbt books#polls#queer book character tournament 2.0

255 notes

·

View notes