#cañada real

Explore tagged Tumblr posts

Text

The banner hanging over the busy road that runs through Europe’s largest shantytown carries a desperate plea that has now remained unanswered for four years. “Luz para Cañada,” it reads – “Light for Cañada”. On 2 October 2020, the lights went out in two sectors of the Cañada Real, the sprawling informal settlement that lies half an hour’s drive from the centre of Madrid. The loss of power – which the energy provider Naturgy attributes to illegal and intensive use that overloaded the system, triggering emergency shutdowns – affected about 4,000 people, including 1,800 children. Two months after the power went, UN experts warned that the lack of electricity violated the children’s right to adequate housing and was having “a very serious effect on their rights to health, food, water, sanitation and education”. Almost two years after that, Spain’s public ombudsman described life in parts of the Cañada Real, where most people are of north African or Roma descent, as “an unsustainable humanitarian emergency situation”. But despite all the outrage, the warnings and the protests, little has changed for those in the Cañada who remain, literally and metaphorically, powerless. Among them are the Fernández family, who sit outside their homes in sector six, soaking up as much daylight as they can. The fuel for the generators they have had to buy costs €15 to €20 a day, which rules out lighting their dark rooms by day. Come midnight, the generators are switched off and brought inside to prevent them being stolen. “There are days when we don’t have enough money to buy fuel to run the generators, which we’ve had to do for four years,” says 30-year-old Quinito Fernández, who supports his family by collecting and selling scrap. In the summer, when temperatures around the Spanish capital can climb past 40C (104F), he cools off his children with a hose. In winter, when the mercury can drop well below zero, the children wake in the dark and wash their faces in freezing water. The lack of electricity also means that a fridge is a costly luxury, so most of their food is tinned or bought every two days to stop it going off.

continue reading

21st century Europe.

#spain#cañada real#shanty town#4 years without power#migrants and roma#childrens rights#discrimination#racism

6 notes

·

View notes

Text

El Marqués realiza campaña de esterilización delegacionales

Con el objetivo de mejorar las condiciones de vida de los caninos y felinos en la demarcación, el municipio de El Marqués, a través del Centro de Atención Municipal (CAAM), puso en marcha las campañas de esterilización delegacionales, las cuales se llevarán a cabo durante septiembre, en seis distintas localidades. Cabe destacar que en dicha campaña, el costo por esterilización será de 89 pesos…

0 notes

Text

RUTA CAÑADA REAL CONQUENSE 2024.

( Esta reseña y su descripción son obra de Juanjo y Pilar, quienes han puesto todos los medios a su alcance para que la ruta fuese un éxito, tal cual ha sido). vamos a recordar aquellos desplazamientos tratando, con la imaginación no cabe otra cosa, de emular cómo sería esa vida ambulante, aprovechando que algunos recorridos pasan cercanos a nuestras localidades y otros por el mismo centro de nuestras poblaciones. Con el café tomado subiremos al autobús el cual nos dejará en el paraje conocido como ERVIAS y allí iniciaremos nuestro andar. Es un terreno prácticamente llano de una escasa vegetación, salpicado de tomillos, romeros, carrascas y algunas retamas. Los cultivos, una vez casi desaparecida la vid, se limitan a monte bajo, algunas parcelas de almendros, olivos y poco mas. Efectuaremos un pequeño alto en el camino para desayunar reponiendo fuerzas y el fin de ruta será en la localidad de Ruidera, donde está previsto llegar a la hora de la comida. Cada participante libremente optará hacerlo en cualquiera de los bares y restaurantes o de mochila según mejor vea. Distancia 20 Km de DIFICULTAD física y técnica BAJA-MEDIA por la distancia.

1 note

·

View note

Text

El 8 de marzo de 1933, Federico García Lorca estrenó "Bodas de sangre" en el teatro Beatriz de Madrid, la historia de una novia que rechaza un matrimonio impuesto y decide fugarse con la persona que amaba.

La historia se basaba en un suceso real ocurrido en Almería en 1928, cuando Francisca Cañadas huyó el día de su boda con su primo Francisco Montes. Él fue asesinado la misma noche de su fuga, y ella vivió en soledad el resto de su vida.

#federico garcía lorca#mevuelveslorca#frases#pensamientos#escritos#fragmentos#literatura#escritores#libros#literatura universal

10 notes

·

View notes

Text

Fustiñana, Spain. A herd of sheep is driven by Angel Mari Sanz, 62, along La Cañada Real de los Roncaleses (the Path of the Roncaleses), an ancient transhumance route. Photograph: Álvaro Barrientos/AP / Guardian #spanish #sheep

3 notes

·

View notes

Text

📌La Fiscalía pide 10 años de inhabilitación a dos altos cargos de Almeida y Ayuso por un derribo en la Cañada Real 📌Ecoembes miente: se debe implantar la devolución de los envases de un solo uso en dos años 📌Ayuso invertirá un 34% menos para luchar contra la violencia machista en 2025 📌La Plataforma Salvemos Eugenia Montijo se moviliza 📌… Y MÁS …. https://carabanchel.net

#Carabanchel#Madrid#cárceldeCarabanchel#memoriahistorica#laAntigua#obras#PlataformaSalvemosEugeniaMontijo#CañadaReal#demolicion#desalojo#Fiscalía#inhabilitacion#AlmeidaDimisión#Ayusoaprisión#ecoembes#envases#residuosplásticos#Retorno#SDDR#sistemadedepósito#faltaderecursos#informeCCOO#violenciacontralasmujeres

0 notes

Text

La XXXIV edición de la C. P. Cañada Real Soriana se la adjudican Cristóbal Ortigosa y Lisa Esquivel

0 notes

Text

Terrenos en venta en Desarrollo Residencial en Huixquilucan EDOMÉX.

#agenciainmobiliaria#bienesraices#queremoslomejorparati#ciudades de caracter#inversionistas#familias

0 notes

Text

Siruela y Tamurejo vuelven a reivindicar la trashumancia

Los municipios pacenses de Siruela y Tamurejo volverán a poner en valor la trashumancia, el uso de las cañadas reales y la ganadería tradicional mediante la decimotercera edición de la Fiesta de la Transterminancia. Consistirá en un recorrido a través de los nueve kilómetros que separan ambas poblaciones a través de la Cañada Real de las Merinas, un ramal de la antigua cañada segoviana. El…

0 notes

Text

MIT team takes a major step toward fully 3D-printed active electronics

New Post has been published on https://sunalei.org/news/mit-team-takes-a-major-step-toward-fully-3d-printed-active-electronics/

MIT team takes a major step toward fully 3D-printed active electronics

Active electronics — components that can control electrical signals — usually contain semiconductor devices that receive, store, and process information. These components, which must be made in a clean room, require advanced fabrication technology that is not widely available outside a few specialized manufacturing centers.

During the Covid-19 pandemic, the lack of widespread semiconductor fabrication facilities was one cause of a worldwide electronics shortage, which drove up costs for consumers and had implications in everything from economic growth to national defense. The ability to 3D print an entire, active electronic device without the need for semiconductors could bring electronics fabrication to businesses, labs, and homes across the globe.

While this idea is still far off, MIT researchers have taken an important step in that direction by demonstrating fully 3D-printed resettable fuses, which are key components of active electronics that usually require semiconductors.

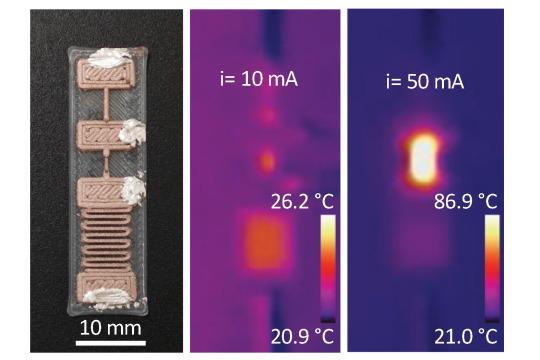

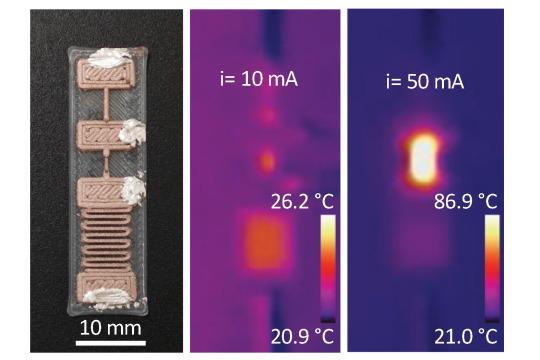

The researchers’ semiconductor-free devices, which they produced using standard 3D printing hardware and an inexpensive, biodegradable material, can perform the same switching functions as the semiconductor-based transistors used for processing operations in active electronics.

Although still far from achieving the performance of semiconductor transistors, the 3D-printed devices could be used for basic control operations like regulating the speed of an electric motor.

“This technology has real legs. While we cannot compete with silicon as a semiconductor, our idea is not to necessarily replace what is existing, but to push 3D printing technology into uncharted territory. In a nutshell, this is really about democratizing technology. This could allow anyone to create smart hardware far from traditional manufacturing centers,” says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the devices, which appears in Virtual and Physical Prototyping.

He is joined on the paper by lead author Jorge Cañada, an electrical engineering and computer science graduate student.

An unexpected project

Semiconductors, including silicon, are materials with electrical properties that can be tailored by adding certain impurities. A silicon device can have conductive and insulating regions, depending on how it is engineered. These properties make silicon ideal for producing transistors, which are a basic building block of modern electronics.

However, the researchers didn’t set out to 3D-print semiconductor-free devices that could behave like silicon-based transistors.

This project grew out of another in which they were fabricating magnetic coils using extrusion printing, a process where the printer melts filament and squirts material through a nozzle, fabricating an object layer-by-layer.

They saw an interesting phenomenon in the material they were using, a polymer filament doped with copper nanoparticles.

If they passed a large amount of electric current into the material, it would exhibit a huge spike in resistance but would return to its original level shortly after the current flow stopped.

This property enables engineers to make transistors that can operate as switches, something that is typically only associated with silicon and other semiconductors. Transistors, which switch on and off to process binary data, are used to form logic gates which perform computation.

“We saw that this was something that could help take 3D printing hardware to the next level. It offers a clear way to provide some degree of ‘smart’ to an electronic device,” Velásquez-García says.

The researchers tried to replicate the same phenomenon with other 3D printing filaments, testing polymers doped with carbon, carbon nanotubes, and graphene. In the end, they could not find another printable material that could function as a resettable fuse.

They hypothesize that the copper particles in the material spread out when it is heated by the electric current, which causes a spike in resistance that comes back down when the material cools and the copper particles move closer together. They also think the polymer base of the material changes from crystalline to amorphous when heated, then returns to crystalline when cooled down — a phenomenon known as the polymeric positive temperature coefficient.

“For now, that is our best explanation, but that is not the full answer because that doesn’t explain why it only happened in this combination of materials. We need to do more research, but there is no doubt that this phenomenon is real,” he says.

3D-printing active electronics

The team leveraged the phenomenon to print switches in a single step that could be used to form semiconductor-free logic gates.

The devices are made from thin, 3D-printed traces of the copper-doped polymer. They contain intersecting conductive regions that enable the researchers to regulate the resistance by controlling the voltage fed into the switch.

While the devices did not perform as well as silicon-based transistors, they could be used for simpler control and processing functions, such as turning a motor on and off. Their experiments showed that, even after 4,000 cycles of switching, the devices showed no signs of deterioration.

But there are limits to how small the researchers can make the switches, based on the physics of extrusion printing and the properties of the material. They could print devices that were a few hundred microns, but transistors in state-of-the-art electronics are only few nanometers in diameter.

“The reality is that there are many engineering situations that don’t require the best chips. At the end of the day, all you care about is whether your device can do the task. This technology is able to satisfy a constraint like that,” he says.

However, unlike semiconductor fabrication, their technique uses a biodegradable material and the process uses less energy and produces less waste. The polymer filament could also be doped with other materials, like magnetic microparticles that could enable additional functionalities.

In the future, the researchers want to use this technology to print fully functional electronics. They are striving to fabricate a working magnetic motor using only extrusion 3D printing. They also want to finetune the process so they could build more complex circuits and see how far they can push the performance of these devices.

“This paper demonstrates that active electronic devices can be made using extruded polymeric conductive materials. This technology enables electronics to be built into 3D printed structures. An intriguing application is on-demand 3D printing of mechatronics on board spacecraft,” says Roger Howe, the William E. Ayer Professor of Engineering, Emeritus, at Stanford University, who was not involved with this work.

This work is funded, in part, by Empiriko Corporation.

0 notes

Text

MIT team takes a major step toward fully 3D-printed active electronics

New Post has been published on https://thedigitalinsider.com/mit-team-takes-a-major-step-toward-fully-3d-printed-active-electronics/

MIT team takes a major step toward fully 3D-printed active electronics

Active electronics — components that can control electrical signals — usually contain semiconductor devices that receive, store, and process information. These components, which must be made in a clean room, require advanced fabrication technology that is not widely available outside a few specialized manufacturing centers.

During the Covid-19 pandemic, the lack of widespread semiconductor fabrication facilities was one cause of a worldwide electronics shortage, which drove up costs for consumers and had implications in everything from economic growth to national defense. The ability to 3D print an entire, active electronic device without the need for semiconductors could bring electronics fabrication to businesses, labs, and homes across the globe.

While this idea is still far off, MIT researchers have taken an important step in that direction by demonstrating fully 3D-printed resettable fuses, which are key components of active electronics that usually require semiconductors.

The researchers’ semiconductor-free devices, which they produced using standard 3D printing hardware and an inexpensive, biodegradable material, can perform the same switching functions as the semiconductor-based transistors used for processing operations in active electronics.

Although still far from achieving the performance of semiconductor transistors, the 3D-printed devices could be used for basic control operations like regulating the speed of an electric motor.

“This technology has real legs. While we cannot compete with silicon as a semiconductor, our idea is not to necessarily replace what is existing, but to push 3D printing technology into uncharted territory. In a nutshell, this is really about democratizing technology. This could allow anyone to create smart hardware far from traditional manufacturing centers,” says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the devices, which appears in Virtual and Physical Prototyping.

He is joined on the paper by lead author Jorge Cañada, an electrical engineering and computer science graduate student.

An unexpected project

Semiconductors, including silicon, are materials with electrical properties that can be tailored by adding certain impurities. A silicon device can have conductive and insulating regions, depending on how it is engineered. These properties make silicon ideal for producing transistors, which are a basic building block of modern electronics.

However, the researchers didn’t set out to 3D-print semiconductor-free devices that could behave like silicon-based transistors.

This project grew out of another in which they were fabricating magnetic coils using extrusion printing, a process where the printer melts filament and squirts material through a nozzle, fabricating an object layer-by-layer.

They saw an interesting phenomenon in the material they were using, a polymer filament doped with copper nanoparticles.

If they passed a large amount of electric current into the material, it would exhibit a huge spike in resistance but would return to its original level shortly after the current flow stopped.

This property enables engineers to make transistors that can operate as switches, something that is typically only associated with silicon and other semiconductors. Transistors, which switch on and off to process binary data, are used to form logic gates which perform computation.

“We saw that this was something that could help take 3D printing hardware to the next level. It offers a clear way to provide some degree of ‘smart’ to an electronic device,” Velásquez-García says.

The researchers tried to replicate the same phenomenon with other 3D printing filaments, testing polymers doped with carbon, carbon nanotubes, and graphene. In the end, they could not find another printable material that could function as a resettable fuse.

They hypothesize that the copper particles in the material spread out when it is heated by the electric current, which causes a spike in resistance that comes back down when the material cools and the copper particles move closer together. They also think the polymer base of the material changes from crystalline to amorphous when heated, then returns to crystalline when cooled down — a phenomenon known as the polymeric positive temperature coefficient.

“For now, that is our best explanation, but that is not the full answer because that doesn’t explain why it only happened in this combination of materials. We need to do more research, but there is no doubt that this phenomenon is real,” he says.

3D-printing active electronics

The team leveraged the phenomenon to print switches in a single step that could be used to form semiconductor-free logic gates.

The devices are made from thin, 3D-printed traces of the copper-doped polymer. They contain intersecting conductive regions that enable the researchers to regulate the resistance by controlling the voltage fed into the switch.

While the devices did not perform as well as silicon-based transistors, they could be used for simpler control and processing functions, such as turning a motor on and off. Their experiments showed that, even after 4,000 cycles of switching, the devices showed no signs of deterioration.

But there are limits to how small the researchers can make the switches, based on the physics of extrusion printing and the properties of the material. They could print devices that were a few hundred microns, but transistors in state-of-the-art electronics are only few nanometers in diameter.

“The reality is that there are many engineering situations that don’t require the best chips. At the end of the day, all you care about is whether your device can do the task. This technology is able to satisfy a constraint like that,” he says.

However, unlike semiconductor fabrication, their technique uses a biodegradable material and the process uses less energy and produces less waste. The polymer filament could also be doped with other materials, like magnetic microparticles that could enable additional functionalities.

In the future, the researchers want to use this technology to print fully functional electronics. They are striving to fabricate a working magnetic motor using only extrusion 3D printing. They also want to finetune the process so they could build more complex circuits and see how far they can push the performance of these devices.

“This paper demonstrates that active electronic devices can be made using extruded polymeric conductive materials. This technology enables electronics to be built into 3D printed structures. An intriguing application is on-demand 3D printing of mechatronics on board spacecraft,” says Roger Howe, the William E. Ayer Professor of Engineering, Emeritus, at Stanford University, who was not involved with this work.

This work is funded, in part, by Empiriko Corporation.

#000#3-D printing#3d#3D printing#additive manufacturing#Art#author#binary#biodegradable#board#Building#carbon#Carbon materials#carbon nanotubes#chips#computation#computer#Computer Science#consumers#covid#crystalline#data#defense#devices#direction#economic#Electrical engineering and computer science (EECS)#electronic#electronic devices#Electronics

1 note

·

View note

Text

Te leemos las noticias aquí Imágenes de las tres nuevas especies de rosas. /CSIC Los ejemplares descubiertos muestran una combinación de características que no se encuentran en ninguna rosa salvaje ni de Europa ni del resto de las poblaciones del archipiélago. El estudio se ha publicado en Flora Montiberica. Un equipo del Consejo Superior de Investigaciones Científicas (CSIC) ha descubierto tres nuevas especies de rosas silvestres en tres de los volcanes más altos y antiguos de las islas Canarias. Las tres nuevas rosas, según apuntan los científicos, muestran una combinación de características que no se encuentran en ninguna rosa silvestre ni de Europa ni del resto de las poblaciones de Canarias. El estudio se ha publicado en Flora Montiberica. El estudio está liderado por los investigadores Pablo Vargas (Real Jardín Botánico, RJB-CSIC), Manuel Nogales (Instituto de Productos Naturales y Agrobiología IPNA-CSIC) y Modesto Luceño (Universidad Pablo de Olavide de Sevilla), que se encontraban en Canarias desarrollando un estudio taxonómico cuando descubrieron estas rosas silvestres no descritas ni catalogadas hasta la fecha. “Proponemos tres especies nuevas para la ciencia encontradas en los volcanes más altos y antiguos de las islas Canarias: en el Roque de los Muchachos de La Palma (R. roque-muchachensis), en las cañadas de El Teide (R. cannadas-teydensis), y en la caldera de Tejeda en Gran Canaria (R. gran-canariae)”, indica Vargas. Las rosas cultivadas proceden de la domesticación de las silvestres. En concreto, el género Rosa, con unas 150 especies precursoras de los rosales cultivados, ha sido estudiado y manipulado desde hace siglos en Europa, América y Asia. La necesidad de una clasificación de rosas canarias La escasez de poblaciones y la complejidad taxonómica de las rosas canarias solo ha permitido un estudio somero, de tal manera que hay numerosos registros confusos desde principios del siglo XX. Sin embargo, a pesar del interés del género Rosa en Europa, no hay ninguna clasificación actualizada para todo el archipiélago canario. Por ello, los investigadores comenzaron un estudio taxonómico de las rosas presentes en el archipiélago canario. “Sobre la base del tratamiento taxonómico actual adoptado para las rosas europeas en las últimas seis décadas, proponemos un mínimo de seis especies de rosas caninas (sección Caninae) para el archipiélago canario, de las cuales solo dos ya han sido citadas: Rosa micrantha y R. rubiginosa”, señala Pablo Vargas. “Algunos caracteres clave encontrados en otras poblaciones distribuidas en Gran Canaria y La Gomera encajan en el concepto de una tercera especie ya conocida en Europa: R. nitidula Besser”. Vargas, Nogales y Luceño han analizado en detalle diecinueve caracteres clave para el estudio del género Rosa en Canarias. Interpretan que no se conocen bien las especies de rosas canarias porque sus colonizadoras europeas y africanas son de difícil identificación por diversas causas: “una gran confusión respecto a los nombres correctos de las especies por falta de ejemplares tipo para muchos tipas vaciedades europeas; sólo publicadas breves descripciones originales; una hibridación generalizada entre especies que dificulta distinguir entre híbridos recientes o estabilizados; y el estudio de un género muy atractivo para los jardineros y botánicos que ha producido la publicación de un elevadísimo número de sinónimos de difícil asignación”, subrayan los investigadores Enclaves recónditos Para desarrollar este trabajo, Vargas y Nogales han recolectado ejemplares de rosas silvestres y han estudiado un total de 75 ejemplares en los herbarios de la Universidad de La Laguna (TFC), del Jardín de Aclimatación de la Orotava (ORT) y en el herbario del Real Jardín Botánico-CSIC de Madrid (MA). En concreto, han visitado enclaves recónditos del archipiélago canario gracias a los biólogos de los cabildos y parques nacionales que trabajan en todas las islas: La Palma (F. Manuel Med...

View On WordPress

0 notes

Text

The Importance of Professional Stump Grinding Services: Why Your Yard Needs It

Tree removal doesn’t always mean your yard is completely cleared. Often, you’re left with a stubborn stump that, while easy to ignore at first, can turn into a long-term problem if not dealt with properly. So, what’s the solution? Stump grinding services. Let’s break down why removing stumps is essential and how professional stump grinding can make a real difference in your yard’s appearance and safety.

Why You Shouldn’t Ignore That Stump After a tree is removed, the stump left behind can quickly become an eyesore or, worse, a hazard. Many property owners make the mistake of thinking they can live with the stump, but over time, the issues can stack up. Here’s why stump removal, specifically through grinding, is an important part of tree care:

1. Pest Magnet Old tree stumps are a prime spot for pests like termites, ants, beetles, and even rodents. These pests won’t just hang out in the stump—they could eventually move on to your home or other parts of your yard. Grinding the stump eliminates this nesting ground, protecting your property from unwanted invaders.

2. Hazardous Obstacles Stumps may seem harmless, but they can be dangerous. Children playing in the yard or even adults walking around can trip over them, leading to potential injuries. Plus, if you’re mowing your lawn, you’ve now got an obstacle to dodge. Grinding the stump down to below ground level solves these problems once and for all.

3. Regrowth and Lawn Interference Many stumps will try to regenerate if left alone. Sprouts can start to grow, meaning you’ll have to deal with an unwanted tree trying to make a comeback. Additionally, stumps and their root systems can interfere with new plantings or your lawn’s overall health, sucking up nutrients that could go to other parts of your garden.

What Exactly Is Stump Grinding? Now, you might be wondering—what’s the difference between removing a stump and stump grinding? The main distinction is in how the process works. When a tree is cut down, the stump can either be pulled out, roots and all, or ground down.

Stump grinding uses a specialized machine to shred the stump into mulch-like pieces, grinding it down several inches below ground level. This method is more efficient, less disruptive to your yard, and prevents regrowth. After grinding, the remaining wood chips can be used as mulch or removed entirely, leaving the ground ready for fresh landscaping.

The Benefits of Professional Stump Grinding Services While some might think they can handle stump grinding on their own, this job is best left to professionals. Here’s why hiring a team like Cañada Tree Care for your stump grinding services makes all the difference:

1. Safety First Stump grinding machinery is heavy and requires precision. Without proper training, there’s a risk of serious injury or damage to nearby structures. Our professional team has the expertise and equipment needed to grind stumps safely, without posing risks to your home, garden, or yourself.

2. Preserve Your Landscaping Grinding a stump without damaging the surrounding landscape is a delicate process. At Cañada Tree Care, we use state-of-the-art machinery that allows us to target the stump while minimizing any impact on your lawn or garden. You won’t have to worry about torn-up grass or damage to nearby plants.

3. Complete Removal of Unsightly Stumps A stump left in the yard can be an eyesore, taking away from the overall beauty of your property. Stump grinding doesn’t just make the area look cleaner; it opens up space for new possibilities. Whether you want to plant new trees, start a garden, or even pave over the area, stump grinding ensures you have a fresh slate to work with.

4. Prevent Future Problems Tree stumps can be more than just an aesthetic issue—they can also lead to underground complications. The remaining root systems may decay and attract fungi, or worse, sprout new shoots. Professional stump grinding eliminates these risks by completely breaking down the stump, leaving no chance for regrowth or root interference.

The Stump Grinding Process: What to Expect So, what’s the process like when you hire Cañada Tree Care for stump grinding services?

Initial Consultation We start with a free consultation, where one of our specialists visits your property to assess the stump and discuss your needs. This allows us to determine the best equipment for the job and give you an accurate quote. Preparation and Safety Measures Before we begin, we take safety precautions, ensuring there are no underground utilities or obstacles in the way. This step is crucial to prevent damage to plumbing, wiring, or irrigation systems.

Grinding the Stump Our team uses professional stump grinders to safely and efficiently reduce the stump to below ground level. This method minimizes any disruption to your landscaping while thoroughly removing the stump. Clean-Up and Final Touches After the stump is ground down, we either leave the wood chips for you to use as mulch or remove them entirely—your choice! We make sure the area is clean and ready for whatever you have planned next. When Should You Consider Stump Grinding Services? Not sure if it’s time to deal with that stump? Here are a few telltale signs:

Old tree stumps left after removal: If you’ve had a tree taken down but the stump remains, it’s best to remove it before it becomes a bigger problem. Stump attracting pests: Notice more insects or critters hanging around the stump? This is a sure sign it needs to go. Lawn care issues: If the stump is in the way of your mowing or landscaping efforts, grinding it down can restore the full use of your yard. Planning new landscaping projects: Stumps can interfere with future gardening, construction, or even patio expansions. Grinding clears the way for these projects. FAQs About Stump Grinding Q: How deep does stump grinding go? A: Typically, stump grinding goes about 6-12 inches below ground level. However, deeper grinding is possible if you plan to build or plant something on the spot.

Q: Will the tree grow back after stump grinding? A: No, once a stump is ground down, it eliminates the tree’s ability to regrow.

Q: Is stump grinding environmentally friendly? A: Yes! The wood chips left behind from stump grinding can be used as natural mulch, and the process itself doesn’t involve harmful chemicals.

Wrapping Things Up Getting rid of stumps is about more than just making your yard look nicer. It’s a key step in keeping your property safe, healthy, and ready for future landscaping projects. With Cañada Tree Care’s stump grinding services, you can ensure the job is done right, without risking injury or damage to your yard. From safety to efficiency, we’ve got your back.

Don’t let that stump stick around—contact Cañada Tree Care today for expert stump grinding services in La Cañada!

0 notes

Text

La cara b de los informes que hacen los relatores de la ONU: movilizan a la opinión pública pero no a los Estados... El caso de la Cañada Real en Madrid es un ejemplo... Olivier de Schutter, relator de la ONU para la extrema pobreza, pidió a España que tomase las medidas necesarias para mejorar la situación de los residentes, pero a día de hoy se superan las 1.340 jornadas consecutivas sin luz... varios relatores de la ONU también pidieron a España que tomase medidas contra las leyes de Concordia de PP y Vox y tampoco hubo una respuesta... también sufren ataques los relatores a raíz de sus investigaciones... los expertos que abordaron la situación de los territorios palestinos ocupados por Israel afrontaron ataques y acusaciones. Las amenazas a familiares fueron algo recurrente a lo que tuvieron que hacer frente los relatores, buscando intimidar sus acciones, siendo sometidos a una gran presión para no denunciar los hechos

0 notes

Text

"Aunque es de noche". Premio Goya al mejor cortometraje

"Aunque es de noche". Premio Goya al mejor cortometraje,

La obra ‘Aunque es de noche’ (16 minutos), dirigida por Guillermo García López y que aborda la situación de los vecinos de la Cañada Real, ha conseguido el Premio Goya 2024 al Mejor Cortometraje de Ficción. “Aquí arriba con nosotros está la Cañada Real, donde hoy más de 4.000 personas, de las cuales la mitad son niños y niñas, viven sin suministro eléctrico desde hace tres años”, revindicó el…

View On WordPress

0 notes

Text

📌Cañada Real: cuatro años, 1.460 días y noches, de oscuridad 📌El documental ‘7291’ sobre las muertes en residencias se estrenará en cines de Madrid, con sus primeras sesiones llenas 📌13-O, hacia la huelga de alquileres 📌La manifestación de hoy en defensa de la Atención Primaria en Carabanchel cambia de recorrido 📌… Y MÁS …. https://carabanchel.net

#Carabanchel#Madrid#AtencionPrimaria#BarriosPorLaSanidadPública#JuevesPorLaSanidad @CSAbrantes#manifestacion#13OCTUBRE#huelgaalquileres#leydevivienda#7291VICTIMAS#documental7291#protocolosdelamuerte#residencias#CañadaRealGaliana#ComunidaddeMadrid#sinluz#suministroelectrico

0 notes