#3-D printing

Explore tagged Tumblr posts

Text

being an anthropology major in university means you’re a little TOO aware of the current trends in academia since you’re conditioned to look for them.

for example: i had three podcast assignments last semester and now have at least two 3-D printing assignments… i’m not sure if i’m impressed or horrified

35 notes

·

View notes

Text

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

New Post has been published on https://thedigitalinsider.com/interactive-mouthpiece-opens-new-opportunities-for-health-data-assistive-technology-and-hands-free-interactions/

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

When you think about hands-free devices, you might picture Alexa and other voice-activated in-home assistants, Bluetooth earpieces, or asking Siri to make a phone call in your car. You might not imagine using your mouth to communicate with other devices like a computer or a phone remotely.

Thinking outside the box, MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) and Aarhus University researchers have now engineered “MouthIO,” a dental brace that can be fabricated with sensors and feedback components to capture in-mouth interactions and data. This interactive wearable could eventually assist dentists and other doctors with collecting health data and help motor-impaired individuals interact with a phone, computer, or fitness tracker using their mouths.

Resembling an electronic retainer, MouthIO is a see-through brace that fits the specifications of your upper or lower set of teeth from a scan. The researchers created a plugin for the modeling software Blender to help users tailor the device to fit a dental scan, where you can then 3D print your design in dental resin. This computer-aided design tool allows users to digitally customize a panel (called PCB housing) on the side to integrate electronic components like batteries, sensors (including detectors for temperature and acceleration, as well as tongue-touch sensors), and actuators (like vibration motors and LEDs for feedback). You can also place small electronics outside of the PCB housing on individual teeth.

Play video

MouthIO: Fabricating Customizable Oral User Interfaces with Integrated Sensing and Actuation Video: MIT CSAIL

The active mouth

“The mouth is a really interesting place for an interactive wearable and can open up many opportunities, but has remained largely unexplored due to its complexity,” says senior author Michael Wessely, a former CSAIL postdoc and senior author on a paper about MouthIO who is now an assistant professor at Aarhus University. “This compact, humid environment has elaborate geometries, making it hard to build a wearable interface to place inside. With MouthIO, though, we’ve developed a new kind of device that’s comfortable, safe, and almost invisible to others. Dentists and other doctors are eager about MouthIO for its potential to provide new health insights, tracking things like teeth grinding and potentially bacteria in your saliva.”

The excitement for MouthIO’s potential in health monitoring stems from initial experiments. The team found that their device could track bruxism (the habit of grinding teeth) by embedding an accelerometer within the brace to track jaw movements. When attached to the lower set of teeth, MouthIO detected when users grind and bite, with the data charted to show how often users did each.

Wessely and his colleagues’ customizable brace could one day help users with motor impairments, too. The team connected small touchpads to MouthIO, helping detect when a user’s tongue taps their teeth. These interactions could be sent via Bluetooth to scroll across a webpage, for example, allowing the tongue to act as a “third hand” to open up a new avenue for hands-free interaction.

“MouthIO is a great example how miniature electronics now allow us to integrate sensing into a broad range of everyday interactions,” says study co-author Stefanie Mueller, the TIBCO Career Development Associate Professor in the MIT departments of Electrical Engineering and Computer Science and Mechanical Engineering and leader of the HCI Engineering Group at CSAIL. “I’m especially excited about the potential to help improve accessibility and track potential health issues among users.”

Molding and making MouthIO

To get a 3D model of your teeth, you can first create a physical impression and fill it with plaster. You can then scan your mold with a mobile app like Polycam and upload that to Blender. Using the researchers’ plugin within this program, you can clean up your dental scan to outline a precise brace design. Finally, you 3D print your digital creation in clear dental resin, where the electronic components can then be soldered on. Users can create a standard brace that covers their teeth, or opt for an “open-bite” design within their Blender plugin. The latter fits more like open-finger gloves, exposing the tips of your teeth, which helps users avoid lisping and talk naturally.

This “do it yourself” method costs roughly $15 to produce and takes two hours to be 3D-printed. MouthIO can also be fabricated with a more expensive, professional-level teeth scanner similar to what dentists and orthodontists use, which is faster and less labor-intensive.

Compared to its closed counterpart, which fully covers your teeth, the researchers view the open-bite design as a more comfortable option. The team preferred to use it for beverage monitoring experiments, where they fabricated a brace capable of alerting users when a drink was too hot. This iteration of MouthIO had a temperature sensor and a monitor embedded within the PCB housing that vibrated when a drink exceeded 65 degrees Celsius (or 149 degrees Fahrenheit). This could help individuals with mouth numbness better understand what they’re consuming.

In a user study, participants also preferred the open-bite version of MouthIO. “We found that our device could be suitable for everyday use in the future,” says study lead author and Aarhus University PhD student Yijing Jiang. “Since the tongue can touch the front teeth in our open-bite design, users don’t have a lisp. This made users feel more comfortable wearing the device during extended periods with breaks, similar to how people use retainers.”

The team’s initial findings indicate that MouthIO is a cost-effective, accessible, and customizable interface, and the team is working on a more long-term study to evaluate its viability further. They’re looking to improve its design, including experimenting with more flexible materials, and placing it in other parts of the mouth, like the cheek and the palate. Among these ideas, the researchers have already prototyped two new designs for MouthIO: a single-sided brace for even higher comfort when wearing MouthIO while also being fully invisible to others, and another fully capable of wireless charging and communication.

Jiang, Mueller, and Wessely’s co-authors include PhD student Julia Kleinau, master’s student Till Max Eckroth, and associate professor Eve Hoggan, all of Aarhus University. Their work was supported by a Novo Nordisk Foundation grant and was presented at ACM’s Symposium on User Interface Software and Technology.

#3-D printing#3d#3D model#Accessibility#alexa#app#artificial#Artificial Intelligence#Assistive technology#author#Bacteria#batteries#bluetooth#box#Capture#career#career development#communication#complexity#computer#Computer Science#Computer Science and Artificial Intelligence Laboratory (CSAIL)#Computer science and technology#data#dental#Design#development#devices#do it yourself#Electrical engineering and computer science (EECS)

2 notes

·

View notes

Text

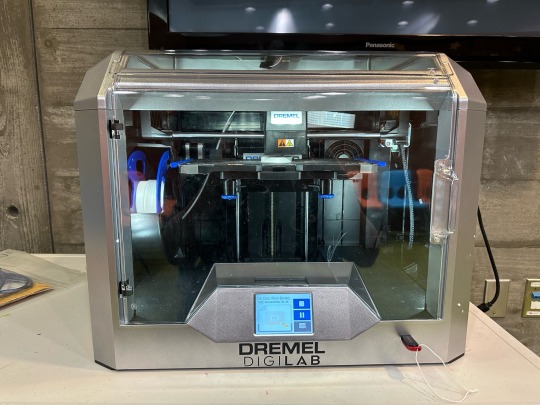

Here’s a sneak peek at the 3-D printer that we’ve been using for our children’s STEAM programs! Each printout takes several hours, so in between programs, we’re printing out the kids’ designs.

Here’s what it looks like in action:

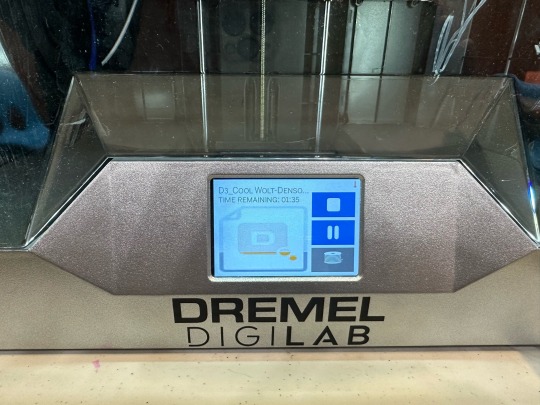

And then … VOILA … a new design emerges!

We still have this printer for a few more months. Visit our website to see when we’ll be giving our next 3-D printing program for kids!

2 notes

·

View notes

Photo

This book is essential reading for researchers and practitioners in computer science, technical managers and software specialists This book provides a comprehensive treatment of the subject of sculptured surface machining in terms of user needs, CAM software solutions and theoretical research results and issues. State-of-the-art capabilities of the best commercial CAM systems are compared to user needs, and advanced academic research is presented. Among the topics covered are the following: Generative NC for dies and molds; 5-axis machining of impellers; Cutting simulation and NC verification; Virtual machining; CAPP for die and mold machining; NURBS-based CNC interpolators

Cutting Molds/Dies from Scan data

Experiences from a Quantum Leap Improvement in Turbine Manufacturing

A Generative Approach for Die Pattern Machining

Geometric Contributions to 3-Axis Milling of Sculptured Surfaces

Efficiency of Multi-Axis NC Machining of Sculptured Part Surfaces

Best-Fit of Sculptured Surfaces

Point-based Geometric Modelling

Virtual Machining and the Manufacturing Model

Virtual CNC with Performance Error Modeling

Fast Simulation of Sculptured Surface Milling with 3-Axis NC Machine

Simulation of Ball-nose End Milling Operations — Selection of Geometric Resolution Parameters

Machining Process Modeling for Intelligent Rough Machining of Sculptured Parts

Bridging the Gap Between Tool Path Generation for Sculptured Surface Machining and Computer Aided Process Modelling Techniques

Automatic Five-Axis CNC Feedrate Selection via Discrete Mechanistic, Geometric, and Machine Model Integration

Milling Simulation with an adaptive Strategy

Deformed Swept Volume Analysis to NC Machining Simulation with Cutter Deflection

Segmentation and Surface Fitting in Reverse Engineering

Surface Reconstruction from Point Clouds

Reverse Engineering Employing a Wrap-Around SurfaceTriangle Set

Manufacturability of Reverse Engineered CAD-models : a case study

https://archive.org/details/springer_10.1007-978-0-387-35392-0

3 notes

·

View notes

Text

Additive manufacturing applicable to every day life

0 notes

Text

Maybe in Your Lifetime, People Will Live on the Moon and Then Mars

Through partnerships and 3-D printing, NASA is plotting how to build houses on the moon by 2040.

By Debra Kamin

Reporting from NASA’s Marshall Space Flight Center in Huntsville, Alabama.

The New York Times - October 1, 2023

#Science#Astronomy#Space science#Earth & Moon & Mars#Space exploration research & development#Interplanetary travel & settlement#NASA#Spacecraft#Robotics systems#AI#ICON technology & construction#SEArch+ (Space Exploration Architecture)#Lavacrete#Bjarke Ingels Group#3-D printing#International cooperation#Artemis Accords

1 note

·

View note

Text

youtube

Ukrainians are ingenious. By necessity they are using their own resources to improve on existing military technology.

We've already seen the success of their upgraded drones (both air and sea) and the R-360 Neptun missile.

Their 3-D printed anti-mine boots are an example of developing defensive military technology. Not only are they more effective, but they are cheaper than Western imports.

#invasion of ukraine#landmines#3-d printing#anti-mine boots#ukrainian technology#ihor yefimenko#kyrylo sirenko#vadym vovchenko#russia's war of aggression#vladimir putin#putin is a war criminal#агрессивная война россии#владимир путин#военные преступления#путин хуйло#это ВОЙНА а не 'спецоперация'#союз постсоветских клептократических ватников#руки прочь от украины!#геть з україни#вторгнення оркостану в україну#україна переможе#деокупація#наземні міни#вадим вовченко#ігор єфименко#кирило сіренко#україна – круто!#слава україні!#героям слава!#Youtube

1 note

·

View note

Text

Design For Additive Manufacturing (DFAM) - Wipro 3D

Wipro 3D design for Additive Manufacturing (DfAM) can transform your metal 3D printing process.Our DFAM expertise enables you to optimize product design, reduce production time, and achieve greater accuracy.

1 note

·

View note

Text

im playing my favorite dating sim again 💌

#stardew valley#sdv#alex#abigail#elliott#emily#harvey#haley#leah#sebastian#maru#shane#penny#my art#new print for april tour !!!!#and my online store soon hopefully :D#it was designed to be a3 but the thought of shipping a3s is scary i have to figure that out lmAO#so i will print it in a4 as well for online and for ppl who dont have a3 space <3#BUT YA hope to see u at melbnova/goldnova/auckland overload/dreamhack etc etc#hopefully this month doesnt beat my ass LMAO

3K notes

·

View notes

Text

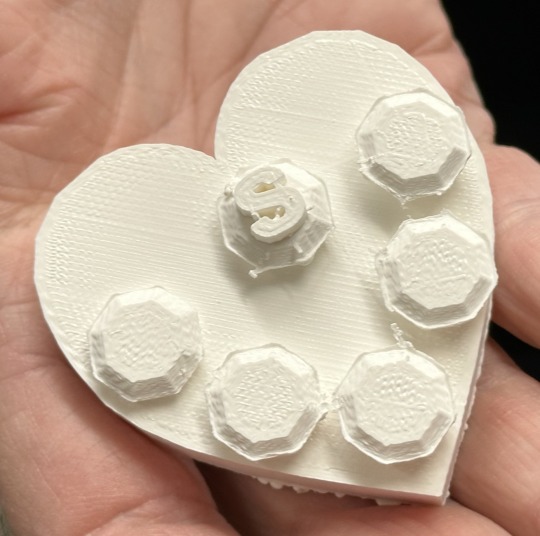

It looks amazing!!!!!

⚡️⚡️⚡️ IT WORKED ⚡️⚡️⚡️

it workedddddddd

I can't believe it! It's SO WEIRD to hold in your hand the thing you saw on the screen.

Holding it in my hand!!!!

And the quality! Holy shit we are living in the future!!!

Though here is the back side where I placed all the supports and was too rambunctious cracking them off and scratched everything up. The raised oval seems to be where I put too many supports close together and they melded together into a lump. I Am Learning Thing!

I am mentally running around with my pants on fire now. Which of the huge queue of things to print next 🔥🫨🔥

149 notes

·

View notes

Text

Knock knock!

Who’s there?

ORANGE you glad to see our MakerBot 3-D printer in action???

0 notes

Text

Finally finished this portrait of Minthara :D

#minthara#minthara baenre#bg3#baldurs gate 3#art#digital art#artwork#fanart#portrait#bloodiedflora art#prints coming soon I think :D

820 notes

·

View notes

Text

I'll be your mirror, reflect what you are, in case you don't know

(I'll Be Your Mirror by Nico and The Velvet Underground)

#sat in a graphic printing class with the opportunity to make another linocut and thought to myself 'i NEED to make a trigun piece'#and thus: vashwood to the song I'll Be Your Mirror. because music is my biggest inspiration and this was all my brain had in it that day#i found this song through trigun fanart but i don't remember the artists username... ill look it up later and reblog it again#this can technically stand as an unrelated piece but im still tagging it as trigun because that's the inspiration#also ignore how Vash's shoulder is. nonsensical. maybe he just has shoulder pads okay its too late to fix it now#he wears a shoulder pad with his undersuit in vol. 2 of trigun. imagine its that#i also imagined wolfwood in his trimax vol. 3 outfit with the sweater because. idk it has a warm energy and i was aiming for that#trigun#trigun fanart#vash the stampede#nicholas d. wolfwood#vashwood#my art#linocut#linoprint

752 notes

·

View notes

Text

freak of nature

#low poly kunikidog complete :3#kunikida doppo#bsd#bungou stray dogs#kite draws#kite watches bsd#I haven't touched blender in years ugh#might make a version I can 3-d print.. we will see LOL

426 notes

·

View notes

Text

Commission for Yukari's VA Heather Gonzalez!

Getting paid to draw my girl ship by one of the voice actors was definitely a moment. :D

#I met heather a few weeks ago and she was super nice :D#It was surreal to see her signing my prints!#yukamitsu#yukari takeba#mitsuru kirijo#persona 3#p3#persona 3 reload#illustration#art#fanart#digital art#artist#my art#anime

703 notes

·

View notes

Text

Im screaming

More detailed one below

#I actually wanted to put color to the line art#but I pressed “fusion all layers” jskajsjs cries#it was too late to come back bc I realized only when I saved the whole drawing lol#so yeah black lines#anyways LOOK HOW HANDSOME HE IS#This is the best digital art Ive made#I love him so much#and all the tiny details#it took me years to make but it was worth it#silmarillion#silm art#tolkien#tolkien art#my art#fav art#<3#gona print it and put it my wall!!!! >:D#not really#😭💅#wish I could#fingon#findekano

111 notes

·

View notes