#Plastic Raw Material Testing

Explore tagged Tumblr posts

Text

Raw Material Testing Lab Mumbai, Pune, Nashik, Chennai, Hyderabad, India

#Plastic Raw Material Testing#Rubber Raw Material Testing Lab#Composite Raw Material Testing Lab#Chemical Raw Material testing Lab#Metallic raw material

0 notes

Text

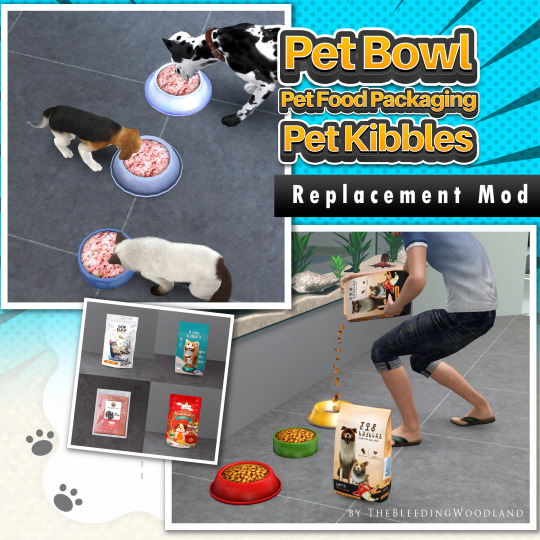

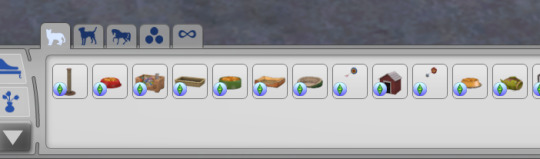

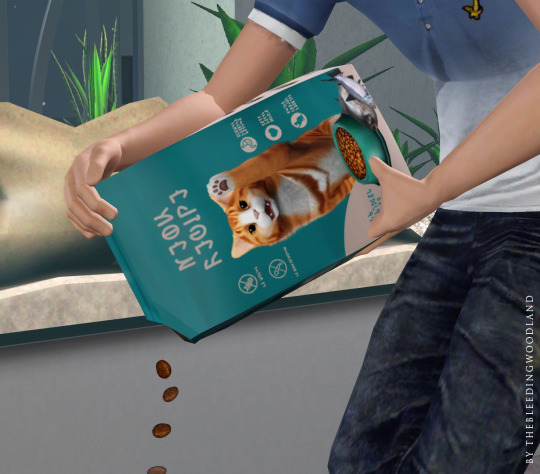

TS3 - Pet Bowl, Pet Food Packaging, Pet Kibbles Replacement Mod

D E F A U L T R E P L A C E M E N T & F U N C T I O N A L P E T B O W L WITH GeoStates (Full, Half, Empty)

-----------------------------------

Remember those EA tacky pet bowls and purple pixelated pet food packaging....

Not just pixelated... I made these default replacement mods for the sake of realism. It's because in real life there is no such thing as Pet food kibbles made by commercial pet food industry for both Cats & Dogs. Cat food and Dog food are separated due to different ingredients and nutrition formulated for Cats and Dogs.

Food suitable for both Cats and Dogs are raw food, usually made by small business company or handmade.

-----------------------------------

5 styles you can only choose one :

Dog Food

Cat Food

Cat & Dog Raw Food

Dog Biscuit Chinese New Year Edition

Cat Biscuit Balinese Edition

These Mods will replace:

Pet Bowls (Cheap, Moderate, Luxury) & Pet Kibbles

Each Pet Bowl has 3 Presets and recolourable.

‣ Cheap Pet Bowl using EA's Moderate pet bowl mesh, because plastic pet bowl with round shape is much more common in real life rather than rounded square shape.

‣ Moderate Pet Bowl: Removed the EA stencil on Moderate Pet Bowl because of tacky, pixelated and the "For Dog" design (depicted with bones) cannot be changed to "For Cat" version of design.

‣ Luxury Pet Bowl using "My First Pet Bowl" mesh by myself because it much more realistic for expensive pet bowl with shiny aluminum material. EA's Luxury Pet Bowl with carving and feet are too tacky, complicated and does not exist in real life.

Pet Bowls have title name and price same as EA's.

With thumbnail :

Pet Food Packaging (Decoration)

Pet Food Packaging title name is Simina Pet Chow Price: § 75 You can find on Decoration > Miscellaneous Decor. (Same as EA's)

With thumbnail:

Pet Food Packaging (Pouring)

Requirement: Pets Expansion Pack

⚠️ Disclaimer: These Mods are changing appearance of mesh and texture only, no script Mod. Dogs still can eat Cat food and Cats can eat Dog food following EA code in the game.

⚠️ This package will be replacing the default EA, so you have to choose one. Installing more than one default replacement will cause conflict. ⚠️

As usual, install one of these packages on Package folder. You can safely delete the package if you no longer want to use the default replacement.

[ Download Dog Food Default Replacement Pack ]

[ Download Cat Food Default Replacement Pack ]

[ Download Cat & Dog Raw Food Default Replacement Pack ]

[ Download Dog Biscuit Chinese New Year Edition Default Replacement Pack ]

[ Download Cat Biscuit Balinese Default Replacement Pack ]

These Mods are fully tested in the game. The pet bowls are working with GeoStates (Full, Half, Empty) and recolour in Create-A-Style mode.

Click Read More to see

#the sims 3#ts3#ts3 mod#ts3 default replacement#ts3 pets#ts3 pet bowl#ts3 pet food packaging#ts3 pet kibbles#ts3 dogs#ts3 cats#ts3cc#ts3cc download#thebleedingwoodland#ts3 maxis match#ts3 simlish

379 notes

·

View notes

Text

there's this cruel irony of imperialism -- obviously many of them -- and there's a good chance somebody is going to call me either shortsighted, highfalutin, ungrounded, or reaching for saying this, but i've been thinking about the networked effects of extracted resources. first it was spice colonialism, then the spices all turned out to be too aphrodisiac and this eventually led to the industrialization of cornflakes

they used to construct elaborate fictions for conflict minerals, this item is unbelievably valuable and the only appropriate use for it is to commemorate a lifelong, monogamous and reproductive relationship (diamonds). now the conflict mineral (lithium) is an unnecessary substitute for an herb (tobacco) and it has become disposable

the nature and progression of imperialism requires continual growth and this means the conflict minerals can't maintain their value, they turn from precious heirloom jewelry to litter, simply because litter is less rare and so more profitable. first they had to mine the raw metals to build out an electrical grid, and then the materials to build roads and cars, and now that the grid requires baseload batteries parked in your garage we're throwing lithium on the ground. plastics have an irrevocable hold on the market simply because they're petroleum byproducts

cities could never have become as large as they did without the development of firefighting and now the baseload batteries are inextinguishable. progress of ever-smaller fragmentation for profit leads to contradiction. the city cannot move forward without the conflict mineral battery, but it can't put the fire out and it can't stop throwing them away, ostensibly to suppress use of an herb, once medicinal, now an adulterated vice. because adulterating it not only increases the rate of cancer but attributes it to personal choice, which is necessary, because otherwise it would be more attributable to the materials that keep the system running (uranium). it's incredible

the state with the lowest rate of cancer is downwind of the test site, because it's populated by yet another extremist christian wing of imperial progress, so extreme that they don't smoke or drink, because these personal choices have an outsized influence in comparison to the global contamination that the development of the bomb caused. a bit of the money made from the extraction of resources is put towards repayment for citizens of the imperial core, for exposure to the product that created their way of life, but the program expires and nobody cares because they seem to think it didn't affect them

anyway somebody threw a whole clock radio in my garden. i took the battery and now i can't do anything with it unless i want to figure out where to take it to be recycled. holding this blue plastic-wrapped cylinder of fire risk conflict mineral in my little hand and ruminating on it. do you think it traveled further than i have to get to me? i should never have left it sitting next to my keys i've been glancing at it in passing every day for weeks. of course you're not supposed to throw them on the ground, but i've already criticized the abdication of responsibility by corporations for the waste their products become. makes it into another issue of personal choice when they wouldn't have existed if they hadn't been industrialized

32 notes

·

View notes

Text

At the core of Repolywise’s Atomic Scissors technology is a highly advanced hydrocracking process that breaks down waste plastics at the atomic level.

Unlike traditional recycling methods, Atomic Scissors selectively degrade plastics like polyethene (PE) and polypropylene (PP) into valuable raw materials.

This innovative catalyst, developed through years of research at Oxford, has already proven its efficiency and high yield in lab-scale tests.

The Atomic Scissors process transforms plastic waste into propane in a single step, which is then sold to the petrochemical industry.

This propane is cracked into olefins, a key ingredient in producing new plastics like polyethene and polypropylene.

This process addresses one of the most significant challenges in plastic recycling, which is turning waste back into high-quality raw materials and closing the loop in the plastic lifecycle.

This innovation is particularly significant for polyolefin plastics, which represent nearly half of the 330 billion kilograms of plastic produced annually.

Traditional recycling methods often lead to ‘downcycling,’ where plastic is repurposed into lower-quality products. In contrast, Atomic Scissors enables these materials to be recycled into high-quality polypropylene, supporting sustainable production.

20 notes

·

View notes

Text

Scientist romance

parings: fr! Wally x reader

Ww:gore

---

Here is the new fan fiction I wrote for you. I hope you like it.😊

---

You have always admired Wally Darling. He was your boss, your mentor, and your friend. He was also the most brilliant scientist you have ever met. He had a vision of creating a new color, a color that would revolutionize the world of art and science. He had dedicated his life to this project, working tirelessly in the Rainbow Factory.

The Rainbow Factory was a secret facility hidden in yhe groaned, where people were captured and turned into rainbows. The rainbows were then used as raw materials for Wally's experiments. You knew it was wrong, you knew it was cruel, but you also knew it was necessary. Wally had explained to you that there was no other way to achieve his goal. He had tried everything else, but nothing worked. He needed the rainbows, he needed the colors.

You were his assistant, his right hand, his confidant. You helped him with his research, his calculations, his tests. You also helped him with his personal problems, his emotions, his pain. You respected him, you trusted him, you cared for him.

But you did not love him.

Not yet.

That changed on the day of the accident.

It was supposed to be a routine test. Wally had created a new color by mixing different types of rainbows, and he wanted to see how it would react with other substances. He had asked you to assist him in the lab, as usual.

You followed him to the lab, wearing your protective gear and carrying your equipment. You entered the lab and saw a large glass container filled with a swirling liquid that glowed with an indescribable hue. It was beautiful, mesmerizing, hypnotic.

Wally smiled at you and gestured to the container.

"Behold, my dear assistant," he said proudly. "This is my masterpiece. This is the new color."

You gasped in awe and admiration.

"It's amazing, Wally," you said sincerely. "How did you do it?"

He chuckled and winked at you.

"That's my little secret," he said playfully. "But I'll tell you this much: it took me years of hard work and countless failures to achieve this result. And it was all worth it."

He walked over to a control panel and pressed some buttons.

"Now, let's see how it behaves with other elements," he said excitedly. "I have prepared some samples of different materials here: metal, wood, plastic, paper, etc. I'm going to inject them into the container and observe the reactions."

He picked up a syringe filled with a metal solution and inserted it into a small hole in the container.

"Ready?" he asked you.

You nodded and moved closer to him.

"Ready," you said.

He pushed the plunger and released the metal solution into the container.

Nothing happened at first.

Then, suddenly, there was a loud bang.

The container exploded.

Glass shards flew everywhere.

The liquid splashed all over the lab.

You screamed and ducked behind a table.

Wally shouted and fell to the floor.

You looked up and saw him lying on his back, clutching his right arm.

His arm was gone.

Blood spurted from the stump where his arm used to be.

He looked at you with pain and fear in his eyes.

"Help me," he whispered.

You felt a surge of panic and adrenaline.

You ran to him and grabbed a towel from a nearby rack.

You wrapped it around his wound and applied pressure.

You tried to stop the bleeding.

You tried to save him.

You tried not to cry.

"Stay with me, Wally," you said urgently. "Stay with me."

He groaned and squeezed your hand.

"I'm sorry," he said weakly. "I'm so sorry."

You shook your head and fought back tears.

"Don't be sorry," you said softly. "It's not your fault."

"It is," he said bitterly. "It's all my fault."

He coughed and spat blood.

"I messed up," he said hoarsely. "I messed up everything."

"No, you didn't," you said firmly. "You're amazing, Wally. You're brilliant."

He smiled faintly and looked at you with gratitude and affection.

"You're amazing too," he said sincerely. "You're wonderful."

He paused and took a deep breath.

"You're beautiful," he said softly.

You felt a blush rise to your cheeks.

You felt a warmth in your chest.

You felt a flutter in your stomach.

You felt something you had never felt before.

You felt love.

You looked into his eyes and saw love.

You leaned down and kissed him.

He kissed you back.

You kissed him with passion and tenderness.

You kissed him with fear and hope.

You kissed him with everything you had.

You kissed him like it was the last time.

It wasn't.

---

This is the end of the first chapter of the new fan fiction I wrote for you guys. Do you want me to continue?😊

#rf!wally#rf!wally x reader#rainbow factory#wally x reader#wally x y/n#wally darling x reader#welcome home arg#wally darling#welcome home

316 notes

·

View notes

Text

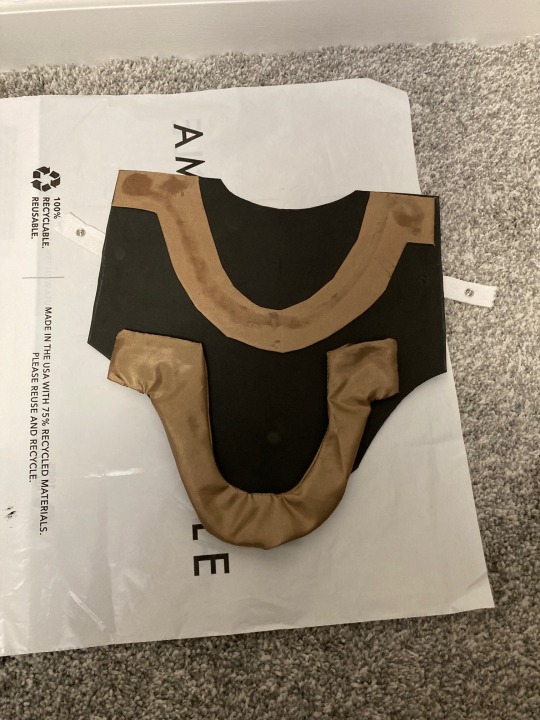

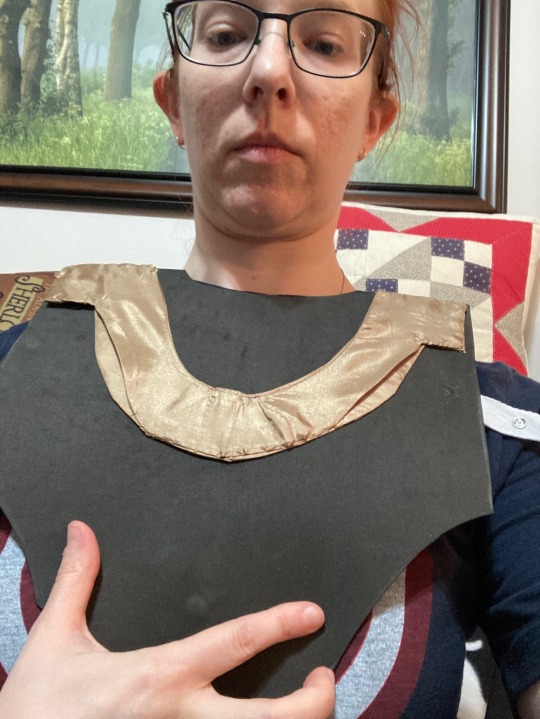

Loki Cosplay Part 8

Previously on Loki Cosplay: https://www.tumblr.com/dailyshowchica/761376032329777152/loki-cosplay-part-7?source=share

So with Halloween rapidly approaching, I have been working on the detail work for Loki's trousers, tunic, and coat. I am not done yet, but I am making progress.

First, the trousers. These were the easiest to do, since all I had to do was cut out a bunch of small rectangles out of metallic silver craft foam.

One of these I used E6000, and the other, I used a hot glue gun. The E6000 discolored some of the squares. Since E6000 doesn't dry right away, I covered my work with a plastic bag and weighted it down with a few large books overnight. In pulling away the plastic, I lost some silver.

I also used a lot more adhesive than I thought I would, so for the other leg, I used hot glue. That dries almost instantly, but I'm not sure it's as secure. It'll be fine for pictures, but if I were to wear this to a con, I might want to use E6000 just be to sure it stays together. It worked perfectly for my sister's dance costumes, after all.

Next up, the tunic. That is two pieces that I'll snap on, a chest piece, and a stomach/skirt piece.

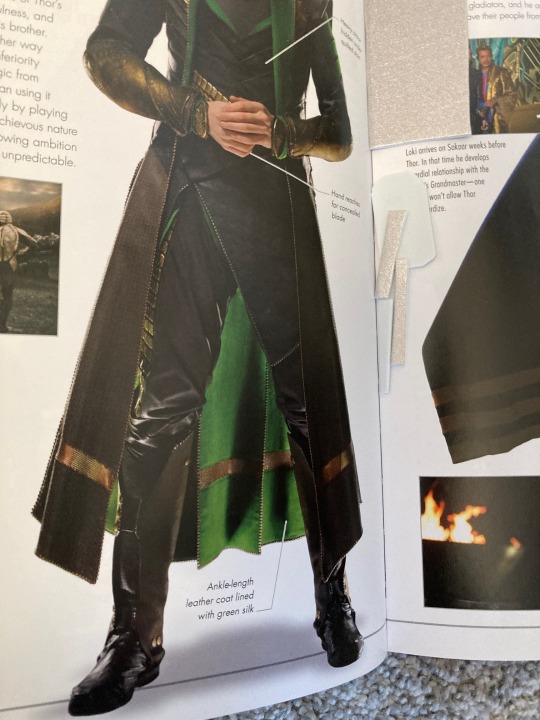

I had to think for awhile about how to make the chest piece. In the end, I went with craft foam, and the gold lining fabric I had gotten for the skirt jacket. I cut out the fabric and glued it to a heavy paper template. But as you can see, the E6000 bled through. So, I made another necklet out of fabric. This was double-layered and treated like a ribbon, or waist tie, with finished edges. This fabric frays like crazy, so the edges had to be sewn. Then I sewed the all-fabric necklet in place. I lost more than I expected to in seam allowance, so it's not a perfect match. But it covers the glue stains, and looks pretty good. And Pretty Good is Good Enough. Time to move on.

This is where the scrap pieces of the black vinyl/faux leather came in handy. I looked at pictures of Loki and copied the shapes as best as I could. The vinyl doesn't fray, but I've tried to finish these edges anyway, if only for a bit more security. Plus, the skirt part of the tunic has matching trim to the coat. While the original may have metal trim, I'm just using gold ribbon in a decorative stitch at the edge.

The coat trim is the most work by volume, and work that has to be done by hand. From the Marvel Studios Visual Dictionary, I was able to see the metallic trim on the inside and outside of Loki's coat. And I luckily had SOME of that material handy- it was also thee scarf/tie Crowley used in his Heavenly disguise in Good Omens Season 2. But I don't have a lot of it. Also, this stuff can snag on other fabrics if you're not careful, so I decided it was only going on the outside. The inside trim was a gold-colored fabric remnant I found at Joann fabrics.

Using legal paper, I determined the positioning of the trim stripes. And as I was working, Ruthie cat came to supervise. She loves a good tent, and the coat, hanging on a tall chair with the skirt panels spread out, makes a pretty good tent.

I made the inner trim by cutting the strips maybe half an inch wider than needed, ironed nonwoven fusible interfacing to the back, and rolled back the edges. As I said above, this fabric frays like crazy, so I was very careful yo make sure there were no raw edges.

I have a bracelet of that same chainmail material in blue, so I used that and a scrap of the vinyl fabric to test sewing the mail in place. It works, but given how small the holes in the mail are, I have to move the needle straight up and down, which means there's going to be visible stitching on the inside. Not too big a problem, but it does mean the outer trim has to go on first. Then I can cover the stitching with the inner trim.

I also can't really pin the outer trim in place. Luckily for me, my mom worked for a magnet company for a few years, and I have lots of small, very strong magnets. Those work very well to hold the mail in place as I sew.

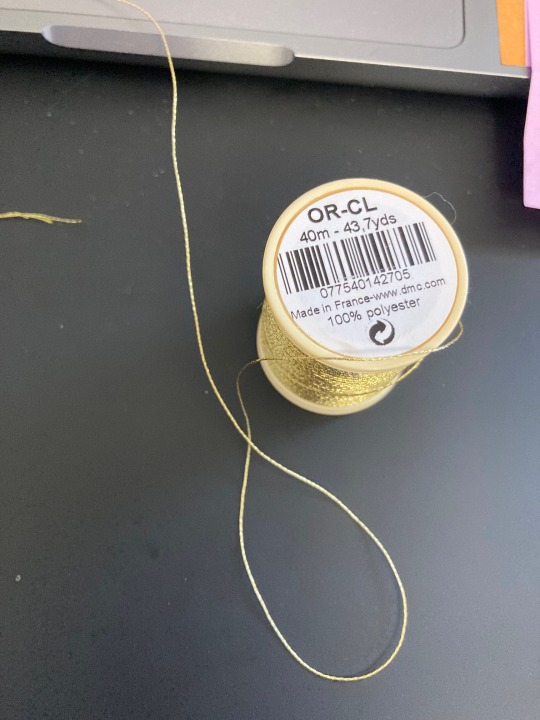

The gold embroidery thread was something I bought for my God of Stories costume, but it's too fine for what I had planned. So, to use it up, I'm using it to sew the inner trim in place- it's too thick/prone to snagging to be used on the outer trim.

I opted to sew in a zigzag pattern when attaching the trim. That way it's secure along the whole length and at the edges without me needing to go all the way around, as I will need to with the inner trim. But I can use invisible hem stitching on the inner hem, so it all evens out.

But then Ruthie decided I had worked long enough. But I've got the path mapped out, and sooner or later, I'll get it finished.

See ya next time!

#halloween#cosplay#marvel#the avengers#loki (avengers)#sewing#crafting#just making it up as i go#tom hiddleston#black cat

8 notes

·

View notes

Text

3D Printing: Saving weight and space at launch

Additive manufacturing, also known as 3D printing, is regularly used on the ground to quickly produce a variety of devices. Adapting this process for space could let crew members create tools and parts for maintenance and repair of equipment on the spot, rather than trying to bring along every item that might be needed.

The ability to manufacture things in space is especially important in planning for missions to the moon and Mars because additional supplies cannot quickly be sent from Earth and cargo capacity is limited.

Research on the International Space Station is helping to develop the capability to address multiple needs using 3D printing.

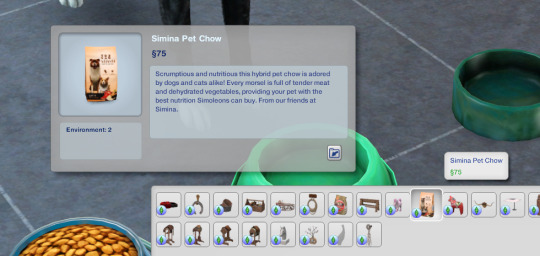

Metal 3D Printer, a current investigation from ESA (European Space Agency), tests 3D printing of small metal parts in microgravity. Results could improve understanding of the function, performance, and operations of 3D printing in space with metal, as well as the quality, strength, and characteristics of printed parts. This work also could benefit applications on Earth that use metal, such as the automotive, aeronautical, and maritime industries.

3D Printing in Zero-G sent the first 3D printer, developed by NASA's Marshall Space Flight Center and Redwire (formerly Made in Space), to the space station in 2014. The printer used a process that feeds a continuous thread of plastic through a heated extruder and onto a tray layer by layer to create an object. The investigation produced more than a dozen parts, including a ratchet wrench, showing that researchers could send a design from the ground to the system on the station more than 200 miles above.

Comparing the parts made in space with those made on the ground showed that microgravity had no significant effect on the process.

Redwire then developed the Additive Manufacturing Facility (AMF), sent to the station in 2015. Researchers evaluated its mechanical performance and found improvements in tension strength and flexibility compared to the earlier demonstration, helping to further the technology for this type of manufacturing on Earth and in space.

In 2015 and 2016, Portable On Board 3D Printer tested an automated printer developed by the Italian Space Agency to produce plastic objects in space. The investigation provided insight into how the material behaves in microgravity, which could support development of European additive manufacturing technology for use in space.

Printing with other materials

Another approach is recycling plastic—for example, turning a used 3D-printed wrench into a spoon and creating items from the plastic bags and packing foam needed to send supplies to space. This technology could help reduce the amount of raw material at launch and cut down on the volume of waste that must be disposed of on long journeys.

The Refabricator, a machine created by Tethers Unlimited Inc, tested this approach and successfully manufactured its first object. Some issues occurred in the bonding process, likely caused by microgravity, but assessment of the material could help determine whether there are limits to how many times plastic can be re-used. Ultimately, researchers plan to create a database of parts that can be manufactured using the space station's capabilities.

Redwire Regolith Print (RRP) tested another kind of feedstock for 3D manufacturing in orbit, a simulated version of regolith, the dust present on the surface of the moon and other planetary bodies. Results could lead to development of technology for using regolith to construct habitats and other structures rather than bringing raw materials from Earth.

The space station also has hosted studies of a form of 3D printing called biological printing or bioprinting. This process uses living cells, proteins, and nutrients as raw materials to potentially produce human tissues for treating injury and disease, which could benefit future crews and patients on Earth.

Other manufacturing techniques tested on the orbiting lab include producing optical fibers and growing crystals for synthesizing pharmaceuticals and fabricating semiconductors.

TOP IMAGE: The first metal part 3D printed in space. Credit: ESA

CENTRE IMAGE: NASA Astronaut Butch Wilmore holds a ratchet wrench created with the 3D Printing in Zero-G printer. Credit: NASA

LOWER IMAGE: The Redwire Regolith Print facility before launch to the space station. Credit: Redwire Space

3 notes

·

View notes

Link

4 Min Read 3D Printing: Saving Weight and Space at Launch The first metal part 3D printed in space. Credits: ESA Science in Space March 2025 Additive manufacturing, also known as 3D printing, is regularly used on the ground to quickly produce a variety of devices. Adapting this process for space could let crew members create tools and parts for maintenance and repair of equipment on the spot, rather than trying to bring along every item that might be needed. The ability to manufacture things in space is especially important in planning for missions to the Moon and Mars because additional supplies cannot quickly be sent from Earth and cargo capacity is limited. Research on the International Space Station is helping to develop the capability to address multiple needs using 3D printing. NASA astronaut Jeanette Epps configures the Metal 3D Printer to produce experimental samples from stainless steel.NASA Metal 3D Printer, a current investigation from ESA (European Space Agency), tests 3D printing of small metal parts in microgravity. Results could improve understanding of the function, performance, and operations of 3D printing in space with metal, as well as the quality, strength, and characteristics of printed parts. This work also could benefit applications on Earth that use metal, such as the automotive, aeronautical, and maritime industries. Printing with plastic NASA Astronaut Butch Wilmore holds a ratchet wrench created with the 3D Printing in Zero-G printer.NASA 3D Printing in Zero-G sent the first 3D printer, developed by NASA’s Marshall Space Flight Center and Redwire (formerly Made in Space), to the space station in 2014. The printer used a process that feeds a continuous thread of plastic through a heated extruder and onto a tray layer by layer to create an object. The investigation produced more than a dozen parts, including a ratchet wrench, showing that researchers could send a design from the ground to the system on the station more than 200 miles above. Comparing the parts made in space with those made on the ground showed that microgravity had no significant effect on the process. Redwire then developed the Additive Manufacturing Facility (AMF), sent to the station in 2015. Researchers evaluated its mechanical performance and found improvements in tension strength and flexibility compared to the earlier demonstration, helping to further the technology for this type of manufacturing on Earth and in space. In 2015 and 2016, Portable On Board 3D Printer tested an automated printer developed by the Italian Space Agency to produce plastic objects in space. The investigation provided insight into how the material behaves in microgravity, which could support development of European additive manufacturing technology for use in space. Printing with other materials NASA astronaut Anne McClain installs the Refabricator in Feb. 2019.NASA Another approach is recycling plastic – for example, turning a used 3D-printed wrench into a spoon and creating items from the plastic bags and packing foam needed to send supplies to space. This technology could help reduce the amount of raw material at launch and cut down on the volume of waste that must be disposed of on long journeys. The Refabricator, a machine created by Tethers Unlimited Inc, tested this approach and successfully manufactured its first object. Some issues occurred in the bonding process, likely caused by microgravity, but assessment of the material could help determine whether there are limits to how many times plastic can be re-used. Ultimately, researchers plan to create a database of parts that can be manufactured using the space station’s capabilities. The Redwire Regolith Print facility before launch to the space station.Redwire Space Redwire Regolith Print (RRP) tested another kind of feedstock for 3D manufacturing in orbit, a simulated version of regolith, the dust present on the surface of the Moon and other planetary bodies. Results could lead to development of technology for using regolith to construct habitats and other structures rather than bringing raw materials from Earth. The space station also has hosted studies of a form of 3D printing called biological printing or bioprinting. This process uses living cells, proteins, and nutrients as raw materials to potentially produce human tissues for treating injury and disease, which could benefit future crews and patients on Earth. Other manufacturing techniques tested on the orbiting lab include producing optical fibers and growing crystals for synthesizing pharmaceuticals and fabricating semiconductors.

2 notes

·

View notes

Text

INTERVIEW: The next big thing? - Exclusive F1 interview with Ferrari's rising star (Motorsport.com, 2017)

source: motorsport.com published: july 2017 series: f2, 2017

Excerpts:

How come your family was in Monaco?

Well my father has always been there. My mum then married my father and became Monegasque also.

Your grandparents were as well?

Yeah. They had, well my grandfather had quite a big plastic industry and then my father had some little industries for himself but to be honest, he was more following me on the races than anything.

So is it a rich family?

No. My parents aren't particularly rich, my grandparents were a little bit, so they were helping us pay for the hotels and all that but they never wanted to invest in anything in racing.

How far did your dad's career go?

He went into Formula 3 then he tested in Formula 1 once or twice, but he never had the budget. It was like 10 years before I was born, so that's why I don't know much about it

Was he always keen for you to race? Did he push you into it?

No, I don't think he was. Actually, on the way back after I did my first laps, which I asked for on the karting, I said to my father 'I want to do that when I'm older'. And from then on we were going very, very often to Jules' track, probably every weekend to drive because I was really asking for it, and obviously my father was more than happy that I was driving because it was his passion, but he has never pushed me. I mean I always wanted to go there so it wasn't necessary for him to push me.

Charles Leclerc is a name that you will be hearing a lot in the next few months.

He is dominating the FIA F2 championship this season (the re-branded GP2) and at Silverstone this weekend he took his fifth victory of his rookie season to open up an 87 point lead in the table.

In two weeks his attention will turn to F1 testing with Ferrari after the Hungarian Grand Prix. Leclerc will drive for the Scuderia on one of the two days of testing before the summer shutdown and it is likely that from there attention on him will grow as the market for F1 seats for 2018 begins in earnest.

The Ferrari Academy driver is a hot property, so JA on F1 took the opportunity - before the stampede - to visit the F2 paddock to get some exclusive time with the next big thing to find out more about the man behind the name.

Leclerc is from Monaco, his father used to race F3 cars not terribly succesfully, but he was mentored by Jules Bianchi, who passed away after a serious accident in the 2014 Japanese Grand Prix.

Leclerc has lost two people close to him recently, as his father died shortly before the Baku weekend. Leclerc went out and won that race, demonstrating a strong mentality.

Apart from his speed, what catches the eye about Leclerc in the car is his calmness and racing brain. He makes few mistakes and is capable of overtakes like a Hamilton and a Verstappen, but more driven by calculation than aggression. He is not the finished article, of course, but the raw materials are there for a different kind of driver.

So, let's go back a little bit to the origins, how did you start racing?.

Yeah my dad used to race in F3 but his best friend was also the father of Jules. So every time we had free time we were going to the track so that's how I actually started when we were going there. The first time I went there I was probably three-and-a-half and I didn't want to go to school, so I told my dad I was sick and he brought me to Phillippe's track and there Jules' dad was driving, obviously, and I did my first lap behind Phillippe with a rope attaching his go-kart to my go-kart, to be sure that I knew the basis before. Then I did half a lap and he took off the rope and that's how I started.

How come your family was in Monaco?

Well my father has always been there. My mum then married my father and became Monegasque also.

Your grandparents were as well?

Yeah. They had, well my grandfather had quite a big plastic industry and then my father had some little industries for himself but to be honest, he was more following me on the races than anything.

So is it a rich family?

No. My parents aren't particularly rich, my grandparents were a little bit, so they were helping us pay for the hotels and all that but they never wanted to invest in anything in racing,

How far did your dad's career go?

He went into Formula 3 then he tested in Formula 1 once or twice, but he never had the budget. It was like 10 years before I was born, so that's why I don't know much about it

Was he always keen for you to race? Did he push you into it?

No I don't think he was. Actually, on the way back after I did my first laps, which I asked for on the karting, I said to my father 'I want to do that when I'm older'. And from then on we were going very, very often to Jules' track, probably every weekend to drive because I was really asking for it, and obviously my father was more than happy that I was driving because it was his passion, but he has never pushed me. I mean I always wanted to go there so it wasn't necessary for him to push me.

What were the turning points along the way? If you had to identify moments where things really turned.

Hm. Well obviously, my first race I did, Jules was my mechanic, so obviously there he taught me a lot from the beginning which helped me to work maybe a bit quicker than others. Then I would say 2011 when Nicolas [Todt, Leclerc's manager] took me, obviously it was a big moment in my career because at the end of that year I would have stopped, because my sponsor couldn't have afforded the other budgets.

Jules has helped me massively to make contact with Nicolas, explaining to him the situation of my career, that I will have stopped at the end of the year. And luckily Nicolas helped me, and since then he has helped me hugely. Then in 2014, when I went up to cars, that has been quite a big moment also and 2016 which was my first year as a Ferrari Academy driver.

And you won championships along the way, which has not been easy – some big fights. But you seem as you've gotten older you've gotten more – not dominant, too strong a word – much stronger as you progressed up the category?

Yeah well I believe, yeah. As I said I think, I had a really good godfather, that was Jules, and that helped me massively to grow up as a driver especially as I made my step up to cars. Well, his crash arrived quite early in my car career, but he has helped me hugely to get into this world and then my father - even though he hasn't been to a very high motorsport level - his advice was always very good and I think circumstances I've been in in the last two years, losing two very close people, have made me a lot stronger as a person.

Obviously it was a big shock for all of us what happened with Jules, but did that hit you very hard? Did that take a while to get over? You were very young as well.

Yeah I mean; Jules, it was a bit like the family, my brother was his best friend. So, yeah it has been very hard at the beginning. It still is obviously but I need to do well for them up there. It has been a shock. Once I knew, I remember I was in Jerez for the last round of the championship and my father wouldn't tell me what happened and I learned eventually and obviously it was quite hard.

What happened in the race? Do you remember what you were thinking? Or did you forget about it and drive the car?

Well I had to. Obviously it's quite hard in these types of circumstances but that's how – I've seen it the way that I had to do the best job I could in the car. Obviously in that moment I didn't really know all about his real state because we didn't have any news in Jerez, yet but I knew the accident was quite bad but I told myself that I knew that Jules - and my father, in Baku - would be happy for me to do well and not to think about it and not do a bad race. So that's the only thing I was thinking about; trying to do the best I could for them.

In the Formula 1 paddock people were really impressed with that; impressed that you turned up for the next race and won in Baku. That really made an impression in the Formula 1 paddock And obviously the way you drive, I've worked with Senna and Schumacher, you have a calmness as a driver. I mean, when you need to get on with it you do and you make the passes, but you don't make the passes in a very aggressive way, and it seems to me that you make them in a thoughtful way. Is that right?

Yes. I think I've definitely improved in this since I was younger. I was very very emotional when I was younger. I could get quite angry very quickly and I knew that was my weakness and I've worked on it quite a lot.

How?

With Formula Medicine [an organisation run by Dr Cecharelli], who are helping (mentally) the drivers to just stay as calm as possible. I have actually been doing that for nine years now; to mentally work on myself, which I think is very very important and now for two years I'm working with the mental trainers of Ferrari which are amazing also. And that's helped me a lot to improve in this manner, to stay calm in these difficult times, that was quite difficult from me in the beginning.

And one of the things I've noticed working with champions over the years is that when they've had a big setback, they first seekto understand it, and then they throw it away like a piece of rubbish and move on and never think about it again otherwise it drags you down, doesn't it?

Right, exactly. I think, in sport the last part of the season in F3 was hugely difficult and to come back from that in GP3 has been quite hard. And as I said I think until I was 11 years old I would have never thought the mental aspect of a driver is that important and once I started to actually work on it and see the improvements I actually think that a driver cannot be good if his mental aspect is not right.

The other thing I'm fascinated with is that we all see the talented guys coming through from the juniors, like you, Lewis or Verstappen. But now there is a real debate about how long it should take to arrive in F1. Verstappen went straight in from F3, Lewis took a few more steps. You're doing it more like him, F3, GP3, F2, you're not straight from F3 into F1. I can't help but feel that these extra couple of steps are a good idea.

Yes. It depends on the driver; I think some people adapt very quickly, not not all of them.

It depends also on how you look at things. With my manager, Nicolas, we think that if one day I want to go into F1, I want to be 200% ready and that's what we hare aiming for. That's why we did so many steps in the junior categories. I did one year in more or less every category that was useful to arrive in F1. And looking back at it I think we did well. This year I feel more ready than I've ever been, a lot of experience. So yeah, looking back at things I wouldn't change anything. I'm very happy with how we solved things and how we managed my career until now.

Last year you got a taste of F1, driving Friday FP1 for Haas at several races. But to get a taste of F1 before F2 is good because you know where you're aiming for, where the next step looks like?

Definitely. But I also thought there's a positive part and a negative part to that situation I was in. Doing an FP1 at the same weekend as a GP3 weekend for me wasn't the best thing we could've done,b ecause F1 and GP3 are two completely different cars and to be honest to go from F1 to GP3 in the same weekend has been very, very hard to manage last year.

But working with an F1 team and working with people, drivers like Romain [Grosjean] who has huge experience has been very helpful for me. To see how they work, to see the little details that maybe you don't put much importance on when you're younger actually seeing the F1 drivers mentioning it and taking a long time to analyse it in the briefings helped me usually to check every little detail and to try to improve absolutely everything. That has helped me massively.

But the plus is that it must have made you more adaptable, whcih is a really important quality in F1. The top F1 drivers all need to be adaptable.

Right. I think it also made me a bit weaker in the middle part of the GP3 season when I did that because going from F1 to GP3 I struggled to come back from F1 to GP3. I think I could have done better.

That's interesting; were you honest with yourself while it was going on and telling those around 'I'm struggling with this transition?'

Oh yeah completely, I said to the team in GP3 that I wasn't taking 100% of the car and I still believe that I didn't, in this middle part, I didn't show the best of myself and it's a shame. But I think we have learned from it and yeah, this year if we have the possibility to do some FP1s at the middle of this year I wouldn't take it. I'm very happy to be in this position I'm in now.

I bet you are. Just 100% focused on winning the championship.

Exactly, and I'm very happy about this to have managed to have a fully focused season middle of the season, for now here in F2 and don't think about anything else apart from F2.

How would you describe this championship that you're in? There's some pretty good drivers around, there's a few that have been here for a few years. Not that many rookies apart from you, how would you describe driving in this championship?

I think obviously the drivers in F2 are very talented I mean drivers like Oliver Rowland or Alex Albon are very talented and in F2, (formerly GP2) I think we are seeing many times that experienced drivers are taking a bit the upper hand off the talented drivers in this category because obviously with the tyres, it's quite difficult to understand them.

Pirelli is quite a huge step compared to every Formula we've had before and yeah to a driver it's quite hard to learn all of this very quickly. Luckily I have a great team this year who are helping me to learn the car very quickly and yeah, to be honest it wasn't my weakest point of adapting to cars quickly. I've always been quite OK with [Adapting to the tyres].

In Bahrain I remember you'd learned a lot in the first race about how to manage the tyres as you had not quite got it right and since then you've really got it right pretty much every time

I'm still learning right now but the first two weeks I've learned a huge amount.

For the degradation, in Bahrain it was the worst track of the season for the tyre degradation, so to start for this one as the first race was very hard. But I think we managed quite well with the third place and then a nice strategy in the sprint race to win.

It's definitely part of the learning programme of this year and we knew it would be so.

Obviously quite a few drivers have been in your position, won the final step of the ladder and not got further. You got on the radar with a lot of people in F1, the Ferrari driver academy and the right manager. Do you worry a little bit about whether the journey continues or do you feel like you do the best you do on the track and leave the rest of it to the people around you to make it happen?

I think I'm in a lucky place and I'm lucky enough to have very good surroundings that are taking care of my career. Ferrari obviously are amazing and are supporting me and trying to find solutions for me next year and I have an amazing manager that is Nicolas, helping me since 2011 and I'm giving my- I never know this word in English – confiance.

Faith.

Yes, exactly. I'm giving my total faith to them for them to find me a place, which is very good because I just have to focus on driving and I feel very lucky to be in this position because I believe not many drivers are in this position to be able to fully have faith in their surroundings.

Would you say from your experience, your journey, you're looking at people coming up behind you that F2 is an important step. Lance Stroll and Max Verstappen have jumped it, quite a few people have, but is this an important step for you?

Yeah definitely, I think the F2 cars are definitely the closest to F1, the drivers are a lot more experienced as I said and you can always learn anyway but obviously I think in this category it's one of the categories I've learned the most. Especially with the degradation of the tyre you don't have anything similar before it and yeah I think the biggest aspect is the degradation of the tyre that is very helpful for the future because in F1 it is a big factor and to learn and to make experience with this car, this year, is very important.

Finally, I've noticed that you don't make very many mistakes. I didn't watch all of your races earlier on, is that something you've always had or something you've had to work on as you've gotten higher up in the category

I think that came a little bit with the mentality, to stay calm in the difficult situations, to avoid stupid errors in the difficult situations, that helped me to be a bit stronger and obviously during the last two years I became a lot more strong mentally and that helped me to avoid making stupid mistakes as I was doing before.

19 notes

·

View notes

Text

Guaranteed low price Dx51d Dx52d Dx66d galvanized steel coil

Galvanized steel coil is a specially treated steel product whose production process includes a number of fine steps. First, the raw material is all-hard board, which requires a pickling process to remove surface impurities and oxide layers, and then a rolling process to achieve the desired thickness and smoothness. The sheets are then fed into a zinc pan, where they are coated with a uniform and continuous zinc film. This layer of zinc film can not only effectively isolate the direct contact between the air and the substrate, thus greatly enhancing the corrosion resistance of the material; At the same time, because the zinc itself has good plasticity and ductility, the galvanized steel plate also has better processing and forming ability and good coating adhesion.

Hot-dip galvanizing technology is one of the most widely used methods for surface protection of steel products, which takes advantage of the unique electrochemical properties of zinc - when zinc is used as a sacrificial anode, it can be preferentially corroded by oxidation over iron, thereby protecting the internal base metal from damage. This method is especially suitable for those components or equipment that need to be exposed to the outside environment for a long time, such as building structures, Bridges, highway guardrails, etc.

According to the requirements of different application scenarios, the manufacturer can also adjust the specific thickness range of the galvanized layer, which can usually reach a maximum of about 120 grams per square meter. In addition, in cases where the appearance quality of the final product is required to be high, additional polishing treatment can also be selected to obtain a smoother and more delicate surface effect. According to whether such a follow-up processing process is carried out, the common galvanized steel coil on the market can be divided into two categories: zero spot type (that is, no additional treatment is done) and ultra-smooth type.

Our advantage

01. Advanced equipment: We have three production lines, all equipped with the most advanced production equipment in China. These devices not only improve production efficiency, but also ensure the quality and consistency of the product. Our factory covers an area of 30,000 square meters, and spacious production workshops provide ample space for large-scale production.

02. High-quality raw materials: We always adhere to the selection of high-quality raw materials, from the source to ensure the quality of products. We have established long-term and stable cooperation with many well-known suppliers to ensure that the quality of raw materials is reliable and meets international standards.

03. Strict quality inspection: We implement strict quality inspection standards, and strictly monitor and test every production link. Our products comply with ISO and SGS international standards, ensuring that every product can meet 100% of customer requirements.

04. Fast delivery: We use advanced production management processes, from order receipt to production arrangement to product delivery, the entire process is efficient and fast. Our goal is to complete customers' orders in the shortest possible time to ensure that customers receive satisfactory products in a timely manner.

05. Professional Sales services: We have a professional sales team who are fluent in Spanish, Portuguese, French, Arabic and Russian. This enables us to better communicate and cooperate with customers in different countries and regions, and provide customers with more intimate and professional services.

2 notes

·

View notes

Text

Why Virat Special Steels?

At Virat Special Steels, we are more than just a steel supplier – we are your trusted partner in quality and reliability. With a strong foothold in the industry, we are known as a preferred dealer, wholesaler, and supplier of top-notch Steel Blocks.

Our comprehensive range includes Flats, Squares, and Bars, all manufactured using quality-tested raw materials sourced from reliable vendors in the market.

What sets VIRAT SPECIAL STEELS PVT. LIMITED , INDIA apart is our commitment to excellence. We import Tools & Die Steels from the world's top manufacturing companies, including M/s. Schmiedewerke Groditz Thyssen and Deutsche Edelstahlwerke from Germany, and M/s. Thyssen Krupp from France. This ensures that our customers receive only the best quality products that meet international standards.

We supply steel bars to forging companies across #Ludhiana, #Faridabad, #Bhiwadi, #Sonipat, #Rohtak, #Haryana, #Punjab, #Jamshedpur, #Trichy, #Aurangabad, #Pune, #Gurgaon, #Noida, #Ghaziabad, #Indore, and all locations in India.

Our goal is to support the tool and steel products industry by providing high-quality materials that enable our customers to excel in their businesses.

Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Product List

DIE STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us : 🌐https://viratsteels.com 📨 [email protected] 📞 +91 098140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#db6 steel#h13diesteel#h13toolsteels#h11steel#din2714#din 2344#din2343#p20steels#din2738#Jamshedpur#gaziabad#manesar

2 notes

·

View notes

Text

The Vital Role of Quality Aspect in Plastic Extrusion

In the Plastic Extrusion Process, raw plastic material is melted and then forced through a die to form a continuous profile. The efficiency, affordability, and consistency of the produced complicated forms make this method a popular choice across a wide range of sectors.

Quality Control Is Crucial for Plastic Extrusion

Plastic extrusion quality control is a complex process that aims to guarantee that the final product fulfills strict quality requirements. The following salient features underscore the significance of quality control in this production process:

Content Management

The key to a successful extrusion process is the quality of the raw plastic material. The first step in quality control is to thoroughly examine and analyze the incoming raw materials to ensure that they are pure, consistent, and meet all required criteria. This contributes to fault prevention and extrusion process stability.

Procedure Observation

It is essential to continuously monitor the plastic extrusion China in order to spot and fix any deviations from the intended specifications. In order to monitor temperature, pressure, and speed in real time and make sure the process stays within the ideal range, automated systems and sensors are essential.

Control in Dimensions

In plastic extrusion, accuracy is crucial, particularly when creating goods with precise dimensional specifications. Regular measurements of the extruded goods' dimensions are one of the quality control procedures that make sure they adhere to the required tolerances.

Examining and Verifying

Strict processes for testing and inspection are followed during the whole extrusion process. To ensure that the extruded goods fulfill the necessary quality requirements, this may entail non-destructive testing techniques, visual inspections, and performance testing. Evaluations of mechanical qualities, color consistency, and other pertinent features may be part of the testing process.

Advantages of Strict Quality Control

Cut Costs: Early fault detection and resolution eliminates waste, lowers rework expenses, and boosts overall operational effectiveness.

Compliance and Reputation: Upholding quality standards guarantees adherence to industry rules, boosting the manufacturer's reputation and inspiring trust in clients.

Improved Quality of Product: Product quality is continuously good, meeting both customer and industry expectations and industry standards thanks to strict quality control procedures in Plastic Injection.

#plastic extrusion China#Plastic Extrusion Companies#plastic extrusion supplier#Plastic Extrusion Process#Plastic Extrusion Guide

2 notes

·

View notes

Text

Decoding the Essence: What Are Display Racks Made Of?

In the intricate world of retail, the backbone of showcasing products lies in the choice of materials for display racks. Retail Display Rack Manufacturers play a pivotal role in shaping these structures, and understanding what goes into crafting them can provide valuable insights.

The Core Foundations: Wood, Metal, or Plastic?

Wooden Wonders

Wood has long been a classic choice for display racks, offering a timeless aesthetic that effortlessly blends with various retail environments. Crafted with precision, wooden display racks not only exude warmth but also provide durability. Retail Display Rack Manufacturers often favor hardwoods for their sturdiness, ensuring these racks withstand the test of time.

Metallic Marvels

For a modern and sleek look, metal display racks take center stage. Stainless steel, aluminum, or wrought iron offer a contemporary touch that resonates with cutting-edge retail spaces. Retail Display Rack Manufacturers leverage the strength of metal to create open and airy designs, perfect for showcasing a diverse range of products.

Plastic Perfection

In the quest for versatility and cost-effectiveness, plastic display racks emerge as a viable option. Retail Display Rack Manufacturers appreciate the lightweight nature of plastic, making these racks easy to move and rearrange. Additionally, plastic allows for vibrant color options, adding a playful element to the overall visual appeal.

Crafting Excellence: Techniques Employed by Retail Display Rack Manufacturers

Precision Engineering

The artistry of Retail Display Rack Manufacturers lies in their commitment to precision engineering. Each component is meticulously designed and crafted, ensuring that the display rack not only looks captivating but also functions seamlessly. Precision is the cornerstone that transforms raw materials into a functional work of art.

Innovative Design Solutions

To stand out in a competitive retail landscape, innovative design solutions are a must. Retail Display Rack Manufacturers continuously push boundaries, experimenting with shapes, angles, and modular designs. This not only enhances the visual appeal but also maximizes the functionality of the display racks.

Why Does Material Matter?

Aesthetic Harmony

The material of a display rack significantly contributes to the overall aesthetic harmony of a retail space. Whether aiming for a rustic charm or a futuristic vibe, Retail Display Rack Manufacturers carefully select materials that align with the brand identity and store ambiance.

Durability and Longevity

Investing in quality materials ensures that display racks remain resilient against wear and tear. Retail Display Rack Manufacturers prioritize durability, understanding that a long-lasting display solution is a smart investment for both retailers and consumers.

In Conclusion: Elevating Retail Spaces with Display Rack Mastery

In the realm of retail design, the choice of materials for display racks is an art form. Retail Display Rack Manufacturers, armed with creativity and technical prowess, weave together wood, metal, or plastic to create functional masterpieces that elevate the visual appeal of products. Understanding the thought process behind these choices adds a layer of appreciation for the craft that goes into every retail display. Star Interiors Private Limited, among the Hypermarket Rack Manufacturers, contributes to this artistic endeavor, showcasing their expertise in crafting displays that seamlessly blend aesthetics and functionality.

#Departmental Store Rack Manufacturers#Retail Store Rack Manufacturers#Retail Display Rack Manufacturers#Hypermarket Rack Manufacturers#Display Rack Manufacturers#racks#supermarket rack manufacturers

2 notes

·

View notes

Text

Fight for Brazil chemicals group Braskem draws in foreign bidders — and Lula government

Latin America’s largest petrochemicals producer has attracted bids from Apollo and Abu Dhabi state-run oil company

A contest is under way for control of Latin America’s largest petrochemicals producer, Braskem, with big-name bidders including US private equity giant Apollo, a Gulf petrostate and one of Brazil’s most prominent business families.

On the block is a majority stake in a $3.7bn-valued enterprise that runs factories across its homeland as well as Mexico, the US and Germany, supplying the raw materials for everything from plastics to paints.

Alongside Apollo, the sale has drawn in Abu Dhabi’s state-run oil company, the dynasty behind top beef processor JBS, fellow Brazilian chemical manufacturer Unipar Carbocloro — and even Brazil’s government.

The future of São Paulo-headquartered Braskem is considered of strategic national importance by the administration of president Luiz Inácio Lula da Silva, which could exert a major sway on the outcome.

In the eyes of some in Brazil’s corporate world, it is set to be a litmus test for how far the leftwing leader is prepared to expand the reach of the state into the economy.

Continue reading.

3 notes

·

View notes

Text

Take Chances, Make Mistakes, Get Messy

Following the example of Miss Frizzle from the Magic School Bus, let's make the most of the Interim opportunity by embracing surprise, wonder, and discovery in the liturgical year that has just begun. This sermon was delivered to The Unitarian Society in East Brunswick on October 1, 2023, by the Rev. Lyn Cox.

September was a month of opening up, welcoming new experiences and new sensations and new friendships. We got a great start to the liturgical year here, and some exciting new ideas are brewing among us. I feel a spirit of hope and joy in the congregation, and I am glad to be partnering with you as we grow in that spirit.

In my family, September is also when we started a new school year. We homeschool our eighth-grade twins. The subject I manage at home is science, and we are studying the physics of motion right now. We have a curriculum and an online community for the class and some video lectures from a teacher, and we also have lots of room to try things out on our own. Which is how we ended up climbing to the top of a ladder with a raw egg last week. Let me back up.

One of the concepts in our lesson last week was inertia, the tendency of objects at rest to remain at rest, and of objects in motion to remain in motion in a straight line at a constant velocity, unless acted upon by an outside force. We also learned about gravity as a force, and how different objects with different masses tend to fall at the same rate unless there are factors like wind resistance at play. And so one of the lab assignments the teens had was to create a structure that would keep a raw egg from cracking when dropped from a height. The curriculum had very few rules other than that the egg must be a raw chicken egg and that we should submit photos or videos to the learning community by the following Sunday.

I sent the teens on a scavenger hunt around the house to find suitable materials for an egg protection and descent unit. (In case you were worried, I got permission from the teens to mention them in this sermon.) There was cackling and running, and very soon the kitchen table was full of potential engineering assets. It was kind of a mess, but a temporary mess. I had this idea that we were going to have an orderly design process and they would sketch their ideas on paper and create a whole plan before moving ahead. That is not what happened, and what did happen was a better way to start the year.

The two of them brainstormed together and came up with a concept, then divided the labor so that one student worked on the restraint system and the other student worked on creating air resistance. I supplied a box of round objects like ping-pong balls and bouncy balls so that we could have a few trials with crash test dummies.

In the first trial, they surrounded the crash test subject with cotton balls, plastic wrap, duct tape, and a sandwich bag, placed that in a plastic container full of water, and taped packing material to the sides and bottom of the box. They taped one corner of a pillowcase to the top of the box as a kind of kite tail. Test subject one landed with a loud thump that suggested the box was heavier than they expected, and they did not achieve the air resistance they had hoped for.

In the second trial, they replaced the water in the container surrounding the padded non-egg test subject with poly-fill from the craft closet, the kind of filling I would normally put inside stuffed animals. The pillowcase was attached on two edges to try to create more of a cape effect. This time, the thump was less loud, but still pretty thumpy, and the apparatus landed upside-down.

The student working on wind resistance tried a few more ideas using a different container. The final design was a parachute attached to strings at each of the four corners, each string duct-taped to a corner of the box containing the egg. The student working on the restraint system added even more padding, especially to the top of the box. Then we were ready for the live trial with a real, raw chicken egg from the fridge. The parachute deployed, the box landed with an audible but cushioned thump, and the egg was extracted from the apparatus unharmed. Then I made celebratory omelets for lunch.

We learned about trying different things and making improvements each time. We learned that wind resistance makes a difference on something that’s being pulled by gravity. And we caught some of the wonder and excitement that is possible in science and engineering. It was a good day.

One of my science education role models is Ms. Frizzle from the book and TV series of the 1990’s, The Magic School Bus. The books were written by Joanna Cole and Bruce Degan, and the animated Ms. Valerie Frizzle was voiced by Lily Tomlin. There was also a reboot on Netflix from 2018-2020 with Valerie’s sister, Fiona Frizzle, voiced by Kate McKinnon, becoming the new teacher. If you don’t know about The Magic School Bus, ask your nearest children’s librarian.

In every book or episode, the students in Ms. Frizzle’s class complete research projects about something like magnetism, the solar system, dinosaurs, or the human digestive system. When the students run into a question they can’t answer, Ms. Frizzle proposes a surprise field trip. “To the bus! Seatbelts, everyone!” The bus mysteriously becomes big or small, or travels through time or outer space, or withstands the conditions of a volcano or a waterfall so that the students are able to make observations and answer their scientific questions. Ms. Frizzle always says, “Take chances! Make mistakes! Get messy!” These three instructions are key for the ability of the class to learn new things and to have fun while learning.

Take chances. Make mistakes. Get messy. You will hear me say these three things again, because they also speak to a congregation’s opportunities during the Interim Ministry period.

In our engineering experiment, we took a chance with an egg. We actually had plenty of eggs in the fridge, so losing one was fairly low-stakes. But the thing that was harder to risk was failure. Sometimes people make mistakes (we’ll cover that in a minute), and sometimes things just don’t work out. Trying new things always risks the theoretical ideal of what could be so that we can live into the complexity of what actually happens. Starting off our school year with an experience with an iterative process really helped open us up to the awe and wonder of science. We could try different things because there would be lots of tries.

We take chances. Not everything turns out the way we hope. Our inability to control the universe does not mean we are bad or lazy or incomplete. Living life to the fullest, learning and growing, requires a certain degree of risk.

In spiritual community, especially during the golden opportunity of an Interim year, we take chances together. We experiment with new ways of understanding the world, with different spiritual practices, and ways of doing church. Right now, as I speak, we are experimenting with a hybrid ministry that makes it possible for us to work together and gives us a training ground for hearing a broader diversity of voices in the pulpit in the future. We can take the risk of letting go of things that do not serve the mission of the congregation. We may take chances with different ways of sharing leadership, or new traditions. We take the risk of speaking the truth with love. Take chances.

Make mistakes. Ms. Frizzle reminds us that the scientific method involves making a hypothesis and testing it. If we guess right every time, science doesn’t advance as quickly. We have to be willing to be wrong sometimes, and to admit we were wrong so that we can get to the juicy, exciting part of the learning process. We are human beings and we are fallible.

Perfectionism is a poison that gets in the way of relationships, innovation, and the health of our bodies and souls. Perfectionism is one of the traps that leads to defensiveness and gets in the way of our journey toward an anti-racist, beloved community. Our tendency as humans to make mistakes does not and should not cut us off from community or from the traditions of spiritual growth or from the disciplines of science and craftsmanship. Humans are welcome in community, broken and whole, flawed and fabulous.

Getting better at anything, from engineering to teaching to cooking omelets to being human, means we have to start out not being very good at it. Fail spectacularly. Fail with gusto. Fail better, and keep learning.

In teaching science to middle schoolers, there are times when precision is important and times when it isn’t. When we get to chemistry at the end of the semester, precision will be more important. I thought careful planning and lab reports were the correct way to start, but the curriculum designer knew that generating and harnessing excitement is the right way to start. We start getting into lab reports and data sheets in the second week, after the students have already gotten excited by the science. I was wrong and I had to take a minute to adjust to that realization. When I remembered that it’s OK to make mistakes, I was able to celebrate the learning process and get caught up in the excitement rather than dwell on my miscalculation. Make mistakes.

Get messy! Science education can lead to all kinds of messes, from vinegar and baking soda reactions to rock collections discovered in odd places around the house to close observations of living things. I have to admit that I was a little overwhelmed when I saw all of the potential engineering materials spread out on the kitchen table. The mess was part of the process.

Mess can mean different things to different people. For some of us, mess is about a loss of the illusion of control. Most of us aren’t as in control as we think we are, and so perhaps mess can sometimes be a teacher. Letting go of the illusion of control can help us to open ourselves up to collaboration and learning. Getting messy can lift our senses to discovery. In the story, “A List” (from Frog and Toad Together by Arnold Lobel), Toad has a hard time letting go of control of his day when the list blows away. We can all hope for a friend or a partner like Frog, who will stick with us and help us to find our way back to inner peace at the end of the day. Maybe sometimes we can be that friend.

For some of us, mess is stressful if we worry about what other people will think. If those other people have power over our employment or housing or health care, that is scary. If we are going to create communities and learning experiences following the wisdom of Ms. Frizzle, we also need to create safe places for people to be human, including secure housing and other human rights. Within our communities of love and care like congregations, part of our spiritual work is to be compassionate toward ourselves and each other for a little bit of the mess of trying new things.

For some of us, mess feels threatening if we feel isolated and responsible for cleaning it up. When we can count on each other to keep each other safe and healthy, to restore things to the places where people who need them can get them, getting temporarily messy is more fun. And if you have ever reorganized a closet, you know that we have to get temporarily messy in order to get to the part where we have everything in the place where we want it.

In the middle of the lively jumble of being in community, let’s pay more attention to what we are doing together than on looking neat and pristine or on creating the illusion of having everything together. In a spiritual community, we get messy by being vulnerable and by accepting the range of wisdom and experience and emotion that our companions bring into the circle. An inclusive community welcomes all people, but not all behaviors. Figuring out how to be together, setting boundaries to help the congregation to be a place of courage and growth, is not easy. This is the art of covenant. Communities where people are authentic are complicated and difficult and heartbreaking and annoying and surprisingly joyful. Get messy.

Let us give thanks. Let us remember the risks and acknowledge the losses, yet let us focus on gratitude and abundance. Fail better, and increase tries. Let us celebrate the skills within us and among us, and let us commit to the love and artistry of living in community. As we bring in the first fruits of this new congregational year together, let us commit to a path of spiritual growth, lifelong learning, diverse and welcoming community, justice, and compassion. To stay on that path, let us take chances, make mistakes, and get messy.

So be it. Blessed Be. Amen.

5 notes

·

View notes

Text

Lyocell, milk fibre and pineapple leather: New textile fibres advertise sustainability. Few can keep their promises

Initiatives are many, the textile industry is in a frenetic state

Polyester causes microplastics, and the natural fibre cotton also has environmental damage in its luggage. No wonder some manufacturers are looking for alternatives. But they can at best be part of the solution.

When someone buries his/her underpants in the garden, it's not necessarily a sign of outlandish or disturbing preferences. It can also be just a slightly more entertaining test of soil quality, which the University of Zurich has even used scientifically. However, most of our clothes would probably emerge from the earth relatively unchanged after a few months, even if the soil in question contains enough beneficial organisms. Because most of our clothes are not biodegradable in the environment - often not even those made of supposedly more sustainable fibres.

“First of all, you have to differentiate between natural fibres that grow on bushes, stalks or trees and are already in fibre form, and man-made fibres,” says Anett Matthäi, who works on sustainable textiles at the engineering faculty of the Hof University of Applied Sciences[1] in Bavaria.

Up until the turn of the 19th and 20th centuries, clothing was always made of natural fibres, cotton, linen, wool or silk. Then, at the beginning of the 20th century, the first synthetic fibre was commercially manufactured: wood became viscose. In 1940, nylon was the first completely synthetic fibre to appear on the market. In the 1950s, the first items of clothing made of polyester were found in stores. Today, polyester is by far the most common material for clothing, accounting for 52 percent of global fibre production[2].

Polyester, cotton and viscose are harmful to the environment

Polyester[3], nylon[4], and other man-made fibres like polyamide[5], acrylic[6], and elastane[7] have advantages—they're cheap, and they use relatively little water to make. But their starting material is the finite raw material petroleum. And they contribute to plastic and microplastic pollution when they enter the environment.

And they do that on a significant scale: clothing loses fibres, during manufacture, during wear and during washing; In Switzerland, 650 tons of microplastics from textiles end up in the environment every year. And in countries like Chile or Ghana[8], old clothes collected abroad rot in huge landfills; some of them are washed into the sea. They will not rot in the ground or in salt water. Instead, like other plastic waste, they break down into smaller and smaller particles over time.

The second most important fibre on the market does not have this problem: cotton[9] is a natural fibre and biodegradable. But growing them requires a lot of fertilizer, pesticides and water. An estimated 3,700 or 4,700 litres of water are needed to produce one pair of jeans.

And viscose[10], which is made from renewable raw materials, also has its pitfalls. The cellulose from the wood of beech or eucalyptus is dissolved and the resulting so-called dope is pressed through nozzles to create the fibre. "You can imagine the process as making spaghetti from dough," says Matthäi, "only much finer, and the 'spaghetti' doesn't tear as quickly."

In this process, however, large amounts of toxic carbon disulfide and caustic soda are sometimes used. The same applies to modal, which is also made from cellulose. Bamboo viscose has therefore also fallen into disrepute. At first it was considered particularly sustainable because of the fast and pesticide-free growing raw material.

The production of lyocell does not require any toxic chemicals

Because neither viscose nor polyester nor cotton are really sustainable, manufacturers are looking for alternative fibres. And so there are now clothes made of materials with names like Lyocell[11] or PLA[12], bamboo viscose or soy silk, pineapple leather or milk fibre.[13] A lot of it sounds like nature. But the raw material alone does not make a fibre sustainable.

Lyocell is considered to be comparatively environmentally friendly, and the label often includes the brand name Tencel. It is also a so-called regenerated fiber that is chemically synthesized from renewable raw materials. But unlike classic viscose, the solvent used in lyocell is not toxic.

And lyocell is – just like classic viscose – biodegradable, i.e. it is broken down by microorganisms into CO2, water and minerals. A recently published study showed that this not only works in the garden, but also in the sea.

"Compostable" does not mean "biodegradable"

Scientists hung samples of different textiles in the sea for more than a year. The cotton samples then dissolved – no surprise, even from the cotton underpants buried in the garden only the seams and the elastic band are left after two months if the soil is healthy. The lyocell had also disappeared after months in the sea.

The sample made of PLA, a bioplastic that is also processed into textiles, was almost unchanged. PLA is the abbreviation of Polylactic Acid. It is made from fermented starch from sugar beets or corn, advertised as particularly sustainable and is officially compostable. But that does not mean that it is degraded in the environment.

Because in order to be able to call itself "compostable", the material only has to decompose within three months in an industrial composting plant. In this, however, there are completely different conditions of temperature, humidity and oxygen supply than in the garden - and even more so than in the sea.

“You cannot draw any direct conclusions from results on the compostability of a material as to whether it can also be decomposed by microorganisms in a different environment,” says Matthäi. "The conditions and the composition of the microorganisms are completely different." The study shows that bioplastics also contribute to the littering of the oceans with plastic.[14]

Soy silk, milk fibre and pineapple leather: new fibres have their pitfalls

It might be different with soy silk.[15] According to Matthäi, it is in principle biodegradable, but like viscose, manufacturing processes and chemical additives could impair its degradability. The material is often featured in reports on sustainable clothing, but only a few raw fabrics and yarns are available to knit yourself. According to the information provided, they are made from waste from tofu production in a closed cycle.

While soy silk[16] does not seem to play a role on the market so far, an Austrian underwear manufacturer has released the first models with another new material this spring: milk fibre[17]. It should be very comfortable to wear. How good it is for the environment depends on whether only dairy waste that is no longer suitable for consumption is processed. And it depends on which additives are needed to spin a fibre from the milk protein. However, the underwear manufacturer does not provide this information – and does not provide it later on request either.

Pineapple leather[18] is just one particularly exotic-sounding example of a non-animal and therefore supposedly sustainable alternative to leather. Other manufacturers use cork, mushrooms[19], apples[20], coffee, grapes, cacti or bananas as raw materials. But the naturalness usually doesn't go any further than that. Plastic is always involved, as a carrier material, adhesive or coating, and then often polyurethane[21].

Not all fibres can be recycled