#Plastic Extrusion Guide

Explore tagged Tumblr posts

Text

Know About The Potential of Plastic Extrusion Process

A manufacturing technique called plastic extrusion is used to make products with a predetermined cross-sectional profile. To form molten plastic into a continuous profile that can be cut to specified lengths, it is pushed through a die. Numerous items may be produced with this technique, ranging from straightforward pipes and tubes to intricate profiles utilized in packaging, automotive, construction, and other industries.

Flexibility in Utilization

Building: Plastic extrusion plays a key role in the building sector by creating pipes, profiles, and other parts that go into drainage systems, windows, doors, roofing, and plumbing. For example, extrusion is frequently used in the manufacturing of PVC and HDPE pipes because of its robustness and resistance to corrosion.

Consumer Products: The production of toys, furniture, and home appliances has benefited from the usage of the Plastic Extrusion Process. Custom profiles and complex designs may be produced with this technology, meeting the practical and aesthetic needs of many items.

Medical: Tubing, catheters, and other medical equipment are produced in the medical industry via plastic extrusion. The capacity to produce accurate, sterile parts guarantees adherence to strict legal requirements while satisfying the needs of medical practitioners and patients.

Benefits of Plastic Extrusion:

Cost-Effectiveness: Plastic extrusion provides affordable options for producing a variety of goods. Compared to alternative approaches, the process lowers material waste and needs less expensive tooling, making it a financially feasible option for large-scale manufacturing.

Design Flexibility: Manufacturers may design unique profiles and forms using plastic extrusion to satisfy certain specifications. In markets with intense competition, this flexibility promotes innovation and product differentiation.

Efficiency: The production of consistent profiles in continuous lengths with little downtime is possible through the very efficient process of plastic extrusion. This efficacy adds to overall operational effectiveness by translating into increased production and quicker turnaround times.

Material Versatility: PVC, HDPE, LDPE, PP, and ABS are just a few of the thermoplastic materials that may be used with plastic extrusion. Because of its adaptability, plastic extrusion manufacturer may choose the material that best suits their needs by weighing characteristics like strength, flexibility, and chemical resistance.

2 notes

·

View notes

Text

How High-Performance Stretch Film Transforms Shipping in Vietnam

Efficient shipping is becoming increasingly vital in Vietnam's booming economy. From bustling markets to high-tech industrial zones, the need for effective transportation and secure packaging has never been greater. Enter high-performance stretch film—a game-changer that's transforming the way Vietnamese businesses handle shipping. This guide will show you how high-performance stretch film can enhance your shipping processes, reduce costs, and improve overall efficiency.

The Basics of Stretch Film

What is Stretch Film?

Stretch film is a highly stretchable plastic film used to wrap products on pallets, ensuring they remain secure during transit. Its primary purpose is to hold loads tightly together, preventing them from shifting, tipping, or getting damaged. This makes it an essential tool in the shipping and logistics industry.

Types of Stretch Film

There are two main types of stretch film—cast and blown. Cast stretch film is produced using a continuous process called casting, which results in a clear, glossy film. It offers excellent clarity, making it easier to identify wrapped products. On the other hand, blown stretch film is manufactured using a blown extrusion process, resulting in a more robust and tear-resistant film with a matte finish. Each type has its own strengths and is suitable for different applications.

Key Attributes of High-Performance Stretch Film

High-performance stretch film boasts several key attributes that set it apart from standard films. These include superior stretchability, puncture resistance, and load retention capabilities. These features ensure that high-performance stretch film provides better protection and stability for your shipments, making it an invaluable asset in the shipping process.

Selecting the Right Stretch Film for Your Needs

Factors to Consider

Choosing the right stretch film involves considering several factors, including the size and weight of your load, as well as the shipping conditions. Heavier loads may require a thicker, more robust film, while lighter loads can be secured with a thinner film. Additionally, consider the shipping environment—will your products be exposed to extreme temperatures or rough handling? These factors will help determine the most suitable stretch film for your needs.

Environmental Considerations

In today's environmentally conscious world, opting for sustainable and eco-friendly stretch films can make a significant difference. Look for films made from recyclable materials or those that use less plastic without compromising on strength and durability. This not only helps reduce your carbon footprint but also aligns your business with global sustainability initiatives.

Cost-Effectiveness

Balancing quality with budget constraints is crucial when selecting stretch film. While high-performance stretch film may come at a higher initial cost, its enhanced durability and efficiency can lead to long-term savings. Invest in quality stretch film to minimize material usage and reduce the risk of product damage during transit, ultimately lowering your overall shipping costs.

Benefits of Using High-Performance Stretch Film

Enhanced Load Stability and Protection

One of the primary benefits of high-performance stretch film is its ability to provide enhanced load stability and protection. The superior stretchability and load retention capabilities ensure that your products remain securely wrapped throughout the shipping process, reducing the risk of damage or loss.

Reduction in Material Usage and Cost Savings

High-performance stretch film is designed to maximize efficiency, requiring less material to achieve the same level of protection as standard films. This reduction in material usage translates to cost savings, making it a cost-effective solution for businesses of all sizes.

Increased Efficiency in Packing and Handling

Using high-performance stretch film can significantly improve the efficiency of your packing and handling processes. Its superior stretchability and puncture resistance mean fewer breaks and interruptions, allowing for smoother and faster wrapping. This increased efficiency can lead to faster turnaround times and improved overall productivity.

Compliance with Vietnamese Regulatory Standards

Adhering to regulatory standards is essential for businesses operating in Vietnam. High-performance stretch film complies with Vietnamese regulatory standards and best practices, ensuring that your shipments meet all necessary requirements. This compliance helps build trust with customers and partners, reinforcing your commitment to quality and reliability.

2 notes

·

View notes

Text

Advanced Vacuum Solutions: Exploring Screw Pumps, Helium Detection & Recovery Systems

In industries where precision and cleanliness are non-negotiable—semiconductors, pharmaceuticals, space tech, and metallurgy—vacuum technology forms the backbone of safe, reliable operations. Whether it’s leak testing in aerospace, drying in chemical labs, or vacuum packaging in food production, having the right pump or detection system is critical.

This guide explores five key technologies shaping modern vacuum solutions: the dry screw vacuum pump, helium leak detector, screw vacuum pump, helium recovery system, and the rotary vane pump—and how they are transforming productivity, efficiency, and sustainability across sectors.

1. Dry Screw Vacuum Pump – Oil-Free Precision, Built for Clean Environments

The dry screw vacuum pump has become a gold standard in cleanroom and contamination-sensitive processes. Unlike traditional pumps that use oil to create a seal, dry screw pumps operate without internal lubricants—making them ideal for industries like food, pharma, and electronics.

Key Features:

Oil-free operation means zero contamination risk

Handles aggressive gases and vapors

High pumping speeds at low pressures

Minimal maintenance and long service life

Dry screw pumps are often used in solvent recovery, vacuum drying, freeze-drying, and even in vacuum furnaces. Their corrosion-resistant coatings and compact design make them suitable for continuous industrial duty.

2. Helium Leak Detector – Detecting What You Can’t See

Leaks in vacuum systems or sealed components can compromise product safety, performance, and reliability. Enter the helium leak detector—a highly sensitive instrument that uses helium as a tracer gas to detect minute leaks with incredible accuracy.

How it works:

A component is filled with helium or exposed to a helium-rich environment

The detector measures the presence of helium escaping from leaks

Pinpoints leak locations down to microliters per second

Industries that rely on helium leak detection:

Aerospace (fuel systems, satellite components)

Medical (pacemakers, surgical devices)

Automotive (airbags, fuel lines)

HVAC & refrigeration (compressor and valve testing)

Portable, bench-top, and fully automated helium leak detectors are now widely used in manufacturing and quality control labs worldwide.

3. Screw Vacuum Pump – Robust and Energy Efficient

Often confused with the dry variant, the screw vacuum pump refers to the broader category of screw-based pumping systems—some oil-sealed, others dry. These pumps use two intermeshing screw rotors that compress gas along the length of the screw chamber.

Advantages:

Smooth, pulsation-free flow

High vapor and particulate tolerance

Energy-efficient at mid- to high-pressure ranges

Ideal for continuous 24/7 operation

Screw pumps are preferred in chemical processing, vacuum distillation, plastic extrusion, and metallurgy. They offer strong suction capabilities, handle condensables well, and reduce operational costs through better efficiency.

4. Helium Recovery System – Sustainability Meets Technology

As helium becomes more expensive and its availability more limited, industries using it for leak testing, welding, or cryogenics are investing in helium recovery systems. These systems capture, purify, and reuse helium—lowering operational costs and reducing environmental impact.

System Components Typically Include:

Collection tanks for helium from test chambers

Compression units to store the recovered gas

Filtration and purification modules

Automated control systems for pressure and purity

Benefits:

Reduces helium costs by up to 90%

Protects against supply disruptions

Helps companies meet sustainability goals

Payback period as short as 1–2 years depending on usage

Industries like healthcare (MRI systems), research labs, aerospace, and automotive rely on helium recovery not only to lower costs but to future-proof their operations.

5. Rotary Vane Pump – A Workhorse of the Vacuum World

Simple, robust, and cost-effective, the rotary vane pump is one of the oldest and most reliable vacuum pump designs. It’s widely used in general vacuum applications that don’t require extreme cleanliness or dryness.

How it works:

A rotor with sliding vanes rotates inside a cavity

As the volume expands, gas is drawn in; as it contracts, gas is compressed and expelled

Where it’s used:

Refrigeration servicing

Vacuum packaging

Lab vacuum systems

Printing and paper handling

Modern rotary vane pumps are quieter, more energy-efficient, and available in oil-sealed and dry versions. They remain a go-to choice for many small- and medium-scale vacuum applications.

Comparing the Technologies

Pump/SystemBest Use CaseAdvantagesDry Screw Vacuum PumpPharma, chemicals, semiconductorsOil-free, low maintenance, clean processHelium Leak DetectorLeak detection in critical systemsExtremely accurate, fast, non-destructiveScrew Vacuum PumpHeavy-duty industrial useHandles vapor, continuous operationHelium Recovery SystemHelium conservation, sustainabilityRecovers and recycles costly heliumRotary Vane PumpLabs, food, printingAffordable, durable, easy to maintain

Choosing the Right Vacuum Technology

The right equipment depends on your application, volume needs, and sensitivity to contamination. For cleanroom environments or solvent handling, dry screw vacuum pumps offer a perfect fit. If you're in R&D or quality control, a helium leak detector is essential.

Meanwhile, screw vacuum pumps are ideal for 24/7 production environments requiring higher flow rates. For companies with significant helium use, a helium recovery system is not just an option—it’s a strategic investment. And for everyday vacuum needs in packaging or labs, the reliable rotary vane pump still holds strong.

Final Thoughts

Vacuum systems and gas handling technologies are evolving fast—and they’re more critical than ever. Whether you’re streamlining manufacturing, testing for leaks, or recovering valuable resources, investing in the right equipment ensures efficiency, reliability, and long-term savings.

From the precision of the helium leak detector to the clean performance of the dry screw vacuum pump, these innovations help industries maintain the highest standards in safety, sustainability, and productivity.

#Dry Screw Vacuum Pump#Helium Leak Detector#Screw Vacuum Pump#Helium Recovery System#Rotary Vane Pump

0 notes

Text

Industrial Plastic Recycling: A Smart, Sustainable Solution for a Greener Tomorrow

Introduction to Industrial Plastic Recycling

Industrial plastic recycling is more than just a waste management strategy, it's a necessity in today’s manufacturing world. As industries expand, so does the volume of plastic waste generated. Fortunately, eco-conscious businesses now prioritize recycling to reduce environmental impact and embrace sustainable growth.

This guide dives into practical, local, and cost-effective plastic waste recycling solutions designed to help manufacturing industries reduce plastic waste, comply with regulations, and cut disposal costs.

Why Industrial Plastic Recycling Matters

Industrial plastic recycling plays a key role in combating pollution, lowering production costs, and supporting a circular economy. Manufacturers generate massive amounts of scrap plastic from packaging, production errors, and obsolete products.

Key Benefits:

Reduces landfill usage and environmental degradation

Turns waste into valuable reusable material

Cuts raw material and disposal costs

Enhances corporate sustainability and compliance

Types of Plastic Waste in Industrial Settings

Understanding the types of plastic waste generated in factories helps develop effective recycling systems. Here are common sources:

Post-industrial plastic: Production offcuts, trimmings, and scraps

Obsolete products: Outdated or defective inventory

Packaging waste: Pallet wrap, plastic films, and containers

Mixed plastic waste: Contaminated or multi-resin plastics

Plastic Waste Recycling Solutions for Industries

Modern recycling companies offer tailored solutions based on plastic type and business size:

Bulk plastic waste pickup

On-site baling and shredding services

Granulation and pelletizing

Chemical recycling and reprocessing

Plastic-to-energy conversion for non-recyclables

Plastic Recycling Services Offered

Reliable recycling services help industries offload the logistical burden of managing plastic waste.

Common Services:

Scheduled pickup of industrial plastic scrap

Waste audits and compliance checks

Plastic sorting and segregation

Granulation, extrusion, and reprocessing

Nationwide logistics support

Sustainable Plastic Waste Management Practices

Industries can adopt a range of sustainable strategies to minimize waste:

Reduce: Streamline operations to avoid overproduction

Reuse: Repurpose plastic containers and dunnage

Recycle: Implement closed-loop recycling

Educate: Train staff on proper sorting and handling

Eco-Friendly Plastic Recycling Techniques

Adopting eco-conscious methods ensures minimal environmental impact:

Mechanical Recycling: Cleaning, shredding, and melting plastics

Chemical Recycling: Breaking down plastic into raw chemicals

Energy Recovery: Converting plastic waste into electricity or fuel

How to Recycle Industrial Plastic Waste

Step-by-Step Guide:

Conduct a waste audit

Segregate plastic by type and resin code

Partner with a certified recycling service

Schedule regular pickups

Implement staff training and signage

Cost-Effective Plastic Recycling for Manufacturers

Plastic recycling doesn’t have to break the bank. With the right systems in place, it can save you money.

Money-Saving Tips:

Recycle on-site with compactors or shredders

Sell scrap plastic to local recyclers

Apply for green tax credits and sustainability grants

Optimize packaging design to use less plastic

Industrial Plastic Scrap Collection and Recycling

Recyclers offer collection services that include:

Drop trailers for large factories

Totes and bins for smaller facilities

GPS-tracked pickup scheduling

Digital reporting and weight tracking

Best Practices in Industrial Plastic Recycling

For Long-Term Success:

Use balers to compress plastic waste

Keep recyclables clean and dry

Choose recycling partners with transparent practices

Monitor progress with sustainability KPIs

Plastic Baling and Shredding Services

Efficient baling and shredding make storage and transportation easier and cheaper.

Benefits:

Reduces volume by up to 80%

Easier handling for bulk pickup

Prevents contamination

Boosts recycling value per ton

Advanced Technologies in Plastic Reprocessing

New innovations make recycling faster and more versatile:

AI-powered sorting systems

Infrared identification for mixed plastics

Bio-degradable additives for packaging

Mobile granulation and shredding units

Closed-Loop Recycling and the Circular Economy

Closed-loop systems return recycled plastic into the production cycle, creating:

Zero-waste facilities

Self-sustaining material streams

Lower production costs

Improved ESG ratings

Industrial Plastic Recycling in Virginia, North Carolina, and the East Coast

Regional Benefits:

Fast and reliable recycling services

Locally tailored compliance solutions

Cost-efficient logistics

Support from regional sustainability experts

Green Initiatives and the Future of Plastic Waste Management

Manufacturers are committing to:

Net-zero waste goals

Carbon footprint reduction

Eco-friendly packaging design

Supplier sustainability audits

FAQs

1. What types of plastic can be recycled?

Ans: Most post-industrial plastics, including HDPE, LDPE, PP, and PET, can be recycled.

2. How much does industrial plastic recycling cost?

Ans: Costs vary but are offset by reduced landfill fees, tax credits, and resale value of processed plastic.

3. Can mixed plastic waste be recycled?

Ans: Yes, with advanced sorting and processing technologies.

4. What industries benefit the most from recycling?

Ans: Manufacturing, packaging, automotive, electronics, and logistics.

5. Is plastic-to-energy a sustainable option?

Ans: It is a secondary solution best used for non-recyclable plastics.

Conclusion

Industrial plastic recycling is not just a compliance measure, it’s a smart business strategy that drives savings, improves public image, and helps build a better planet. Whether you’re a small manufacturer in Danville or a large-scale factory in North Carolina, the future lies in sustainable plastic waste management.

Take the leap today and become part of the growing network of eco-conscious industries embracing smarter, greener solutions.

0 notes

Text

Comprehensive Guide to HDPE Sheets for Sourcing

HDPE sheet is a type of thermoplastic polymer made from high-density polyethylene resin. It is characterized as possessing a superior strength-to-density ratio and therefore is a highly strong and versatile product. HDPE sheets are manufactured using processes of extrusion or compression molding and result in flat, smooth, uniform sheets which are easy to manipulate and cut to order. The plastic comes in a variety of different thicknesses and colors, although natural white or black are most usual.

0 notes

Text

A Beginner’s Guide to Plastic Manufacturing Techniques and Technologies

Plastic manufacturing is a foundational part of modern industry, contributing to countless products we use daily from packaging and furniture to automotive parts and electronics. For beginners looking to understand how plastic products are made, it’s essential to get familiar with the various techniques and technologies that drive this vast and evolving industry.

This guide provides an overview of the most commonly used plastic manufacturing methods, how they work, and the technologies behind them.

Injection Molding

Injection molding is one of the most widely used techniques in plastic manufacturing. It involves melting plastic pellets and injecting the molten material into a metal mold under high pressure. Once the plastic cools and solidifies, the mold opens to release the finished part.

Common Applications: Bottle caps, containers, automotive parts, and electronic housings.

Advantages: High production speed, repeatable precision, and low scrap rates.

Technologies Used: CNC-machined molds, hydraulic or electric presses, and automated robotics for part removal.

Blow Molding

Blow molding is used to create hollow plastic products. In this process, a heated plastic tube (called a parison) is placed into a mold and then inflated with air, forcing the plastic to conform to the mold’s shape.

Common Applications: Bottles, drums, and fuel tanks.

Advantages: Efficient for mass production of uniform hollow items.

Technologies Used: Extrusion blow molding machines, injection blow molding systems, and air compressors.

Extrusion

Plastic extrusion involves melting plastic resin and forcing it through a die to create continuous shapes like pipes, sheets, or films. The extruded plastic is then cooled and cut to the desired length.

Common Applications: Plastic pipes, tubing, window frames, and packaging film.

Advantages: High-volume production, consistent cross-sections, and cost-effectiveness.

Technologies Used: Extruders, cooling systems, and precision dies.

Thermoforming

Thermoforming involves heating a plastic sheet until it's soft, then stretching it over a mold and vacuuming or pressing it into shape. Once cooled, the formed part is trimmed.

Common Applications: Clamshell packaging, trays, disposable cups, and automotive panels.

Advantages: Ideal for large parts with lower tooling costs.

Technologies Used: Vacuum formers, pressure formers, and CNC trimming machines.

Rotational Molding (Rotomolding)

In rotational molding, powdered plastic is placed inside a mold, which is then heated and rotated on multiple axes. The plastic melts and coats the interior of the mold evenly. After cooling, the mold opens to release the part.

Common Applications: Large hollow items like storage tanks, playground equipment, and traffic cones.

Advantages: Uniform wall thickness, low-cost tooling, and minimal material waste.

Technologies Used: Rotational molding ovens, cooling chambers, and biaxial rotation systems.

3D Printing (Additive Manufacturing)

3D printing is a newer method that creates plastic products layer by layer from digital designs. It’s especially useful for prototyping and custom parts.

Common Applications: Prototypes, medical models, small production runs, and customized components.

Advantages: Design flexibility, low setup cost, and rapid prototyping.

Technologies Used: Fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Key Considerations When Choosing a Technique

When selecting a manufacturing method, businesses must consider several factors:

Volume Requirements: Injection molding suits high-volume runs, while 3D printing is best for small batches or prototypes.

Part Complexity: Detailed or intricate shapes may require specific molding or printing techniques.

Material Type: Some methods work better with certain plastics (e.g., thermoplastics vs. thermosets).

Tooling Costs: Processes like injection molding have high upfront tooling costs, while methods like thermoforming and 3D printing have lower barriers to entry.

Understanding the different plastic manufacturing techniques and technologies is the first step toward navigating this essential industry. Each method offers unique benefits, and the right choice depends on the desired product, budget, and production goals.

As sustainability and innovation continue to drive change, new materials and advanced technologies are being integrated into traditional plastic manufacturing. For beginners, staying informed about these evolving practices can open doors to better product design, efficiency, and business opportunities in a rapidly growing global market.

0 notes

Text

Industrial performance starts with the right raw materials — and calcium stearate in PVC manufacturing is one of the most reliable additives in the industry. Whether used in plastics, paints, or lubricants, calcium stearate delivers consistency, smooth processing, and cost efficiency.

What is Calcium Stearate?

Calcium Stearate is a fine white powder used in various industrial processes. It works as a:

Heat stabilizer

Processing lubricant

Anti-caking agent

Water repellent

Pigment disperser

Key Uses in PVC Manufacturing

Calcium Stearate in PVC Manufacturing helps industries produce smoother, more durable PVC products by:

Enhancing flow during extrusion

Preventing material from sticking to machinery

Improving surface finish

Increasing thermal stability

Common products: Pipes, cables, profiles, sheets, and films.

Uses in Paint Industry

Calcium Stearate in Paint Industry is known for:

Reducing gloss levels (flatting agent)

Improving pigment dispersion

Preventing hard settling

Adding water resistance to coatings

Perfect for decorative paints, industrial finishes, and architectural coatings.

Used as Lubricant in Manufacturing

Calcium stearate used for lubricant applications provides:

Improved mold release in plastic and rubber molding

Reduced friction in powder metallurgy

Smooth tablet pressing in pharmaceuticals

Better flow in thermoplastic and rubber blends

Explore the full guide here: 🔗 https://sukhmaniimpex.com/calcium-stearate-in-pvc-manufacturing/

Industrial-grade solutions supplied by Sukhmani Impex

0 notes

Text

China PVC Profiles: Your Guide to Smarter Building Materials

Meta Description: Discover why China PVC profiles are transforming construction. Learn about benefits, uses, and how to find reliable suppliers. Save costs and build smarter.

Have you ever wanted to point out the fact that building materials are too dear, that they are so much maintenance and you think they are simply too soft? That’s where China PVC profiles come in. Think of them as the strong, silent backbone of modern windows, doors, and much more. They are based on sturdy plastic (PVC) and by the way, they are transforming construction. Whether it is a large or a small project that you are planning on taking up then these profiles should help you think smarter.

Why Builders Love PVC Profiles

So, what’s the big deal? Here’s why China PVC profiles are so popular:

Tough as Nails: Rain, sun or even irritating termites? No problem. PVC will not rot or corrode like wood or metal and will not be consumed. It only endures.

Energy Saver: The hollow parts in the profiles? They are like a thermos that traps air inside, storing heat in winter and storing it outside in summer. This will cut down your heating and cooling bills by a huge margin.

Easy Life: No more sanding and painting in every 2-3 years. Most of the time all that is necessary is a wipe of soapy water. Simple!

Friendly to the planet: Although Good PVC profiles need to be recycled, a large number of producers in China are also introducing recycling content.

More Than Just Windows and Doors

Sure, China PVC window profiles are everywhere, but these versatile materials do way more:

Building Skins (Curtain Walls): Creating sleek, modern facades for tall buildings.

Kitchens & Bathrooms: Perfect for cabinets and frames where water splashes – no swelling or damage.

Greenhouses: They stand up to sun and weather year after year.

Why China is the Go-To Source

It’s no secret most of the world's PVC profiles come from China. Why?

They Know Their Stuff: Years of experience mean factories have the extrusion tech down pat, ensuring consistent quality.

Great Value: Large-scale production makes China PVC profiles very cost-effective without cutting corners on quality.

Need Something Special? Many suppliers can customize profiles for unique projects – curved designs, extra soundproofing, you name it.

Finding the Right Partner: Don't Skip This Step!

Choosing the right PVC profile manufacturer in China is crucial. Look out for:

Proof of Quality: Certifications like ISO 9001 are a good sign.

Good Material: Ask if they use virgin uPVC (unplasticized PVC) – it’s stronger and lasts longer.

Responsible Practices: More buyers care about sustainability and ethical production.

Companies like East Building have built strong reputations by focusing on exactly these things – quality control, clear communication, and solutions that work for builders globally. It’s worth finding partners who make the process smooth.

Real Talk: Saving Money with PVC

Let’s be practical. Imagine building an apartment block. Cheaper aluminum frames might look good upfront. But over 10 or 15 years? China PVC profiles often win hands-down. One project manager told me they saved nearly 40% on energy and maintenance compared to aluminum. That’s serious cash back in your pocket.

The Future Looks PVC

As we all focus more on greener building, PVC’s recyclability is a big plus. New innovations are making profiles even stronger and more versatile, opening doors (literally!) for cooler designs.

Wrapping It Up

China PVC profiles offer a fantastic blend of durability, energy savings, low upkeep, and smart value. They are worth consideration whether you are renewing your house or undertaking a big construction project. The major aspect in getting an optimal outcome is to liaise with competent and credible suppliers. Study, read, question and create something awesome.

0 notes

Text

Thermoplastic Elastomer (TPE): The Ultimate Guide to Thermoplastics

Thermoplastic elastomers (TPEs) are a remarkable class of materials that combine the elasticity of rubber with the processability of plastics. These polymers have revolutionized manufacturing by offering the best of both worlds—durability, flexibility, and recyclability—without the need for complex vulcanization processes.

You may not realize it, but TPEs are everywhere. From the soft grips on your toothbrush to the seals in your car’s dashboard, these materials play a crucial role in everyday products. While consumers rarely think about what makes TPEs unique, industries ranging from automotive to medical rely on them for their versatility, cost-efficiency, and performance.

So, what exactly are thermoplastic elastomers, how do they work, and why are they so widely adopted? Let’s dive into their structure, properties, and applications to understand why they’ve become indispensable in modern manufacturing.

What is a Thermoplastic Elastomer (TPE)?

A Thermoplastic Elastomer (TPE) is a unique class of polymer that combines the properties of both thermoplastics and elastomers. These materials exhibit the elasticity and flexibility of traditional rubbers while maintaining the ease of processing associated with thermoplastics. Structurally, TPEs are composed of hard crystalline segments and soft amorphous segments. This blend allows them to be easily molded, reshaped, or recycled using standard thermoplastic processing techniques, such as injection molding, extrusion, or blow molding. The ability to recover their original shape after deformation makes TPEs an essential material in a variety of industrial and consumer applications.

View Jieya TPE Compounding Extruders for more details.

Difference Between TPE and Traditional Rubber

The primary distinction between TPEs and traditional rubber lies in their processing and recycling capabilities. Traditional rubber, also known as thermoset rubber, undergoes a curing process called vulcanization, which creates permanent cross-links between molecules. Once vulcanized, traditional rubber cannot be reshaped or recycled. Conversely, TPEs are thermoplastics and do not rely on vulcanization. Instead, their molecular structure permits repeated melting, reshaping, and reprocessing. This recyclability, coupled with TPEs' excellent mechanical properties and resistance to wear, makes them a more sustainable and versatile alternative in many applications.

Common Applications of TPE Materials

TPEs are widely used across industries, thanks to their adaptability and performance. Some of the most common applications include:

· Automotive Industry: TPEs are utilized in weather seals, gaskets, and interior components due to their durability and resistance to extreme temperatures.

· Consumer Goods: This includes items like soft-grip handles, footwear, and household appliances, where comfort, grip, and wear resistance are critical factors.

· Medical Devices: TPEs are ideal for tubing, seals, and catheters due to their biocompatibility and ease of sterilization.

· Electronics: TPEs are used in wire and cable insulation, connectors, and flexible enclosures, offering excellent electrical insulation properties.

· Packaging: Their pliable yet resilient nature makes TPEs suitable for caps, seals, and closures in food and beverage applications.

The versatility and eco-friendly nature of TPE make it a go-to material for modern manufacturing, balancing performance, sustainability, and cost-effectiveness.

What are the Properties of TPE?

Thermoplastic elastomers (TPEs) have a unique combination of properties that make them valuable across diverse industries. Their ability to combine the elasticity of rubber with the processability of plastics allows for significant versatility. Below, we explore the key properties that define TPEs and contribute to their widespread use.

Elastomeric Properties of Thermoplastic Elastomers

One of the defining characteristics of TPEs is their exceptional elastomeric behavior. TPEs can be stretched to considerable lengths and return to their original shape upon release, demonstrating high elasticity and flexibility. This property is essential for applications such as gaskets, seals, and flexible tubing, where durability and the ability to withstand repeated deformation are crucial. The elastomeric properties of TPEs also make them suitable for applications requiring comfort, such as grips and cushioning materials.

Mechanical Properties and Performance of TPE

TPEs exhibit strong mechanical performance, combining tensile strength, impact resistance, and excellent dimensional stability. They are capable of maintaining their structural integrity across a broad temperature range, which enhances their usefulness in various environments. Additionally, TPEs demonstrate high fatigue resistance, making them ideal for dynamic applications like vibration dampers and moving mechanical parts. Their ability to blend hardness with softness also allows for customization depending on specific requirements.

Chemical Resistance in TPE Materials

Chemical resistance is a major advantage of TPEs, enabling them to perform well in harsh environments. TPE materials can resist exposure to oils, greases, solvents, and various chemicals without degrading or losing performance. This property ensures their longevity in applications like automotive components, industrial hoses, and medical equipment. Furthermore, their resistance to moisture and the ability to be compounded for enhanced chemical compatibility make TPEs a reliable choice in demanding industries.

Types of Thermoplastic Elastomers (TPEs)

Thermoplastic elastomers (TPEs) represent a versatile class of materials that combine the elastic properties of rubbers with the processing advantages of plastics. These materials are classified into various families based on their molecular structure and unique characteristics. Understanding these types and their applications is crucial for selecting the most suitable TPE for a given application.

Overview of TPE Families

TPEs are broadly categorized into six major families, each distinguished by their composition and performance characteristics:

1. Styrenic Block Copolymers (TPE-S): These are among the most commonly used TPEs, offering high elasticity, excellent surface finish, and easy processability. They are widely used in consumer goods, sealing applications, and grip components.

2. Thermoplastic Olefins (TPE-O): These are blends of elastomers and polypropylene, valued for their toughness and heat stability. They are commonly utilized in automotive interiors and exterior trim.

3. Thermoplastic Vulcanizates (TPE-V): Comprising cross-linked rubber and thermoplastic phases, TPE-Vs deliver superior heat and chemical resistance, making them ideal for seals, hoses, and gaskets.

4. Thermoplastic Polyurethanes (TPE-U): Known for their abrasion resistance and flexibility, TPE-Us are suitable for footwear, medical tubing, and wire coatings.

5. Thermoplastic Copolyester (TPE-E): These provide excellent resilience, thermal resistance, and long-term fatigue performance, often applied in industrial belts and pumps.

6. Thermoplastic Polyamides (TPE-A): These materials are highly durable and resistant to chemicals, commonly used in automotive fuel lines and advanced engineering applications.

Block Copolymers vs. Conventional Thermoplastics

The fundamental difference between block copolymers (a key type of TPE) and conventional thermoplastics lies in their molecular architecture. Block copolymers consist of alternating hard and soft segments, giving them enhanced elasticity and flexibility compared to purely rigid thermoplastics. This unique structure allows TPEs to achieve elastomer-like properties while maintaining the ability to be melted and reformed, which cannot be achieved by traditional thermoplastics or fully cross-linked rubbers.

Applications of Different Types of TPE

Each type of TPE serves distinct purposes across industries:

· TPE-S is ideal for creating non-slip grips, soft-touch surfaces, and household products due to its excellent tactile properties.

· TPE-O finds applications in automotive dashboards, bumpers, and under-the-hood components owing to its impact resistance and low-temperature performance.

· TPE-V is preferred for weather seals in construction and automotive sectors because of its resistance to extreme temperatures and harsh environments.

· TPE-U is widely employed in sports equipment, industrial cables, and medical devices, given its flexibility and strength.

· TPE-E is used in gears, dampers, and suspension systems for its resilience and dimensional stability under stress.

· TPE-A supports high-performance requirements in fuel systems and electronic components due to its durability and chemical resistance.

By understanding the unique properties and applications of these TPE types, engineers and designers can optimize material selection to enhance product durability, functionality, and cost-effectiveness.

How is TPE Processed?

Thermoplastic elastomers (TPEs) are processed using standard thermoplastic manufacturing methods, which combine efficiency with high-quality results. Their unique ability to be repeatedly melted, shaped, and solidified makes them ideal for diverse industrial applications. Below are the most common techniques used in TPE production and the factors influencing optimal processing outcomes.

Common Thermoplastic Processing Methods

TPEs can be processed using various techniques, with injection molding and extrusion being among the most widely utilized methods. These techniques enable the creation of precise components for automotive, medical, consumer goods, and industrial applications. Other methods, such as blow molding, thermoforming, and compression molding, can also be employed depending on the specific design and application requirements.

Injection Molding vs. Extrusion of TPE

Injection molding is a popular process for manufacturing complex TPE components with high precision. It involves heating the material until it becomes fluid, injecting it into a mold cavity, and allowing it to cool. This technique is ideal for producing products with intricate shapes, such as seals, grips, and gaskets.

Extrusion, on the other hand, is used to create continuous profiles of TPE materials, such as tubing, wire coatings, or strips. The process involves forcing the molten TPE through a specific die, resulting in consistent shapes suitable for longer, linear applications. While injection molding focuses on discrete parts, extrusion excels at producing uniform, continuous lengths.

Factors Influencing TPE Processing

Several factors impact the quality and efficiency of TPE processing:

· Material Properties: The specific grade and chemical composition of TPE dictate its melting point, flow characteristics, and cooling behavior.

· Temperature Control: Precise temperature management during melting and cooling is critical to prevent defects such as warping or stress marks.

· Tooling and Machine Settings: Well-designed molds, dies, and optimized equipment settings ensure consistent and accurate output.

· Additives and Modifiers: Additives like UV stabilizers, colorants, or fillers can enhance specific properties but also affect processing behavior.

Understanding these factors allows manufacturers to fine-tune processes, minimize waste, and achieve the desired performance for their end products.

What are the Advantages of Using Thermoplastic Elastomers?

Thermoplastic elastomers (TPEs) are versatile materials that combine the elasticity of rubber with the processability of plastics. Their unique characteristics make them a preferred choice across various industries, including automotive, medical, consumer goods, and electronics. The following sections highlight key advantages of using TPEs, focusing on their recyclability, comparison with other elastomeric materials, and cost-effectiveness in manufacturing.

Benefits of Recyclability in TPE Products

One of the standout features of TPEs is their inherent recyclability, which significantly reduces environmental impact. Unlike traditional thermoset rubbers that cannot be reprocessed once cured, TPEs can be melted, reshaped, and reused multiple times without substantial degradation in properties. This makes them ideal for sustainable manufacturing practices, contributing to reduced waste and more efficient material use. Furthermore, recycling TPE products lowers raw material costs and supports compliance with increasingly stringent environmental regulations, giving manufacturers a competitive edge.

Comparison of TPE with Other Elastomeric Materials

TPEs outperform traditional elastomeric materials in several critical areas. While thermoset rubbers require complex curing processes and offer limited design flexibility, TPEs benefit from simpler processing methods like injection molding and extrusion. Additionally, TPEs exhibit excellent resistance to chemicals, UV, and weathering, making them suitable for demanding applications. Unlike vulcanized rubbers, which are non-recyclable, TPEs allow for reusability, enabling manufacturers to meet sustainability goals. These advantages, combined with superior surface finish and compatibility with overmolding, position TPEs as a more advanced alternative in various applications.

Cost-Effectiveness of TPE in Manufacturing

Using TPEs in manufacturing significantly reduces production costs without compromising performance or quality. Their processability allows for faster cycle times, lower energy consumption, and reduced labor expenses compared to traditional elastomeric materials. Furthermore, the ability to reuse waste material during production minimizes material costs and enhances overall efficiency. TPEs also support multi-functional product designs, such as combining rigid and soft components in a single molding step, which further reduces assembly costs. These attributes make TPEs an economically viable solution for industries seeking to optimize costs while maintaining high-quality output.

What are the Challenges in Using TPE?

While thermoplastic elastomers (TPEs) offer significant advantages, they are not without their challenges. Understanding these limitations ensures better material selection and application efficiency.

Limitations of Thermoplastic Elastomeric Materials

TPEs, despite their versatility, can exhibit reduced mechanical strength compared to traditional thermoset elastomers. This limitation may hinder their suitability in applications requiring high durability or extreme stress resistance. Additionally, TPEs often display lower thermal resistance, making them less ideal for applications exposed to prolonged high temperatures. Over time, UV or chemical exposure can also degrade certain TPE grades, which may require additional stabilizers or coatings to maintain performance.

Understanding the Hardness and Elastic Properties

The hardness and elastic behavior of TPEs depend heavily on their formulation and intended use. Achieving the right balance between hardness and flexibility can be a complex process, as it often involves trade-offs between performance and functionality. For example, overly rigid TPEs may lack sufficient elasticity for dynamic applications, while softer grades may fail to provide adequate structural integrity. Engineers must carefully analyze the specific requirements of their applications to fine-tune these properties.

Addressing the Issues of Material Selection

Selecting the most appropriate TPE grade can be challenging due to the vast range of formulations available. Variations in performance across grades, including resistance to chemicals, temperature, and mechanical stresses, necessitate thorough testing in intended operating environments. Cost considerations further complicate material selection, as specialized TPE grades with enhanced properties may increase expenses. Proper collaboration between designers, engineers, and material suppliers is crucial to ensure the chosen TPE aligns with application-specific demands.

Frequently Asked Questions

Q: What are TPEs and how do they differ from traditional plastics?

A: TPEs, or thermoplastic elastomers, are materials that combine the properties of rubber with those of thermoplastics. Unlike traditional plastics, TPEs exhibit both thermoplastic and elastomeric properties, allowing them to be molded and reshaped upon heating while maintaining flexibility and elasticity at room temperature.

Q: What is the significance of the soft phase in TPEs?

A: The soft phase in TPEs refers to the elastomeric component that provides flexibility and rubber-like properties. This soft phase is critical in determining the properties of rubber, such as elasticity and tensile strength, which are essential for applications requiring durability and resilience.

Q: Can you explain the different types of TPEs available?

A: There are several types of TPEs, including thermoplastic vulcanizates (TPVs), thermoplastic polyurethane (TPU), and styrenic block copolymers. Each type offers unique characteristics, making them suitable for various applications ranging from automotive components to medical tubing.

Q: How do TPEs compare to thermosets in terms of recycling?

A: TPEs are generally more recyclable than thermosets. While thermosets cannot be reprocessed once cured, TPEs can be melted and remolded, allowing them to retain their thermoplastic properties and be recycled into new products, which is beneficial for sustainability in material science.

Q: What are some common applications of TPEs in the automotive industry?

A: In the automotive industry, TPEs are widely used for gaskets, seals, and soft-touch components due to their excellent weather resistance, flexibility, and durability. Their thermoplastic properties make them ideal for parts that require both strength and elastic performance.

Q: What role does the polymer chain play in the properties of TPEs?

A: The polymer chain in TPEs is essential for defining their mechanical properties. The arrangement and interaction of the polymer chains determine the material's flexibility, tensile strength, and overall performance. A well-designed polymer chain can enhance the physical mix of polymers to achieve desired characteristics.

Q: Are TPEs suitable for medical applications?

A: Yes, TPEs are often used in medical products, such as tubing and connectors, due to their biocompatibility, chemical resistance, and ability to be sterilized. Their soft elastomer properties make them ideal for applications requiring comfort and flexibility.

Q: How do TPEs maintain their original shape after deformation?

A: TPEs maintain their original shape after deformation due to their unique combination of thermoplastic and elastomeric properties. When stretched or compressed, the polymer chains can return to their initial configuration upon removal of the applied force, similar to natural rubber.

Q: What are the advantages of using TPEs over traditional rubber?

A: TPEs offer several advantages over traditional rubber, including easier processing, lower production costs, and better recyclability. Additionally, TPEs can be engineered to provide specific performance characteristics, such as improved weather resistance and enhanced durability, making them versatile for a range of applications.

The Bottom Line

Thermoplastic elastomers are transforming industries by offering a perfect balance of flexibility, durability, and processability. Whether it’s improving the comfort of shoe soles, enhancing the safety of medical devices, or reducing the weight of automotive components, TPEs provide solutions that traditional materials cannot match.

For manufacturers, selecting the right TPE—whether it’s a soft TPU for medical applications or a robust TPV for automotive seals—can significantly impact product performance and cost efficiency. As material science advances, we can expect even more innovative TPE formulations to emerge, further expanding their role in modern engineering.

At the end of the day, TPEs prove that sometimes, the best solutions come from blending the best of two worlds—rubber’s elasticity and plastic’s versatility.

1 note

·

View note

Text

PVC Extruders: A Comprehensive Guide to Technology and Applications

Polyvinyl chloride (PVC) is one of the most versatile thermoplastics, used in everything from construction materials to medical devices. At the heart of PVC manufacturing lies the PVC extruder, a machine that melts, shapes, and forms PVC into profiles, sheets, pipes, and more. While consumers interact with PVC products daily—whether in plumbing pipes, window frames, or packaging—few understand the precision engineering behind their production.

Industries ranging from construction to automotive rely on PVC extrusion for its efficiency, durability, and customization capabilities. The right extruder can mean the difference between a high-performance product and one that fails under stress.

This guide explores how PVC extruders work, the different types available, key components, and their industrial applications. Whether you're a manufacturer selecting equipment or an engineer optimizing processes, understanding PVC extrusion is critical for quality production.

View Jieya PVC extrusion more to get into the details

What is the Extrusion Process for PVC?

The extrusion process for PVC is a controlled method used to produce high-quality, durable plastic components with consistent shapes and profiles. It involves feeding raw PVC material—usually in the form of pellets or powder—into an extrusion machine, where it undergoes heating, melting, and shaping. This process is widely utilized in industrial and commercial sectors to create products such as pipes, window frames, and electrical conduits.

How does the extrusion process work with PVC?

The PVC extrusion process begins with feeding raw material into the machine's hopper. The material is driven through a heated barrel by a rotating screw, where the friction and heaters gradually melt the PVC. Once melted, the material is pushed through a precisely shaped die, which determines the final profile of the product. Upon exiting the die, the extruded material is cooled using water or air to solidify its form. Additional processes, such as cutting or coiling, may follow depending on the product specifications.

PVC extrusion involves melting PVC resin (either rigid or flexible) and forcing it through a die to create continuous shapes. The process consists of several stages:

1. Feeding & Melting

1. PVC resin, often mixed with stabilizers, plasticizers, and fillers, is fed into the extruder’s hopper.

2. The material moves through the barrel, where heating elements and shear forces from the screw gradually melt it into a viscous fluid .

3. Compression & Homogenization

1. The screw design (typically conical or parallel twin-screw) compresses the material, ensuring uniform melting and eliminating air pockets.

2. For rigid PVC, low-shear screws prevent degradation, while flexible PVC may use higher shear for better mixing .

5. Extrusion Through the Die

1. The molten PVC is pushed through a shaped die, forming profiles, sheets, or pipes.

2. Temperature control is critical—too hot, and PVC degrades; too cold, and flow becomes uneven .

7. Cooling & Sizing

1. The extruded product passes through cooling tanks or calibrators to solidify its shape.

2. For foam PVC, controlled cooling ensures a stable cell structure .

Critical Components of a PVC Extruder

1. The Screw

· Design: Varies by material—gradient screws for rigid PVC, short compression zones for flexible PVC .

· Compression Ratio: Typically 2.5–4.0 for rigid PVC; higher for foam applications .

· L/D Ratio: A 25:1 ratio is common for uniform melting .

2. Barrel & Heating Zones

· Divided into feed, compression, and metering zones, each with precise temperature control.

· Overheating risks degradation (PVC breaks down at ~200°C) .

3. Die & Calibration

· Determines final product shape (e.g., pipe dies, sheet dies).

· Post-extrusion sizing ensures dimensional accuracy .

4. Downstream Equipment

· Cooling tanks, pullers, cutters – Essential for maintaining product integrity.

· Foam PVC lines require precise calibrators to stabilize cell structure .

Find more info now

What are the benefits of plastic extrusion?

Plastic extrusion offers several key benefits, including high efficiency, cost-effectiveness, and versatility. It allows for the production of continuous profiles, minimizing material waste and ensuring consistent output. Additionally, the process can accommodate complex shapes and provide flexibility in using different additives to enhance material properties such as UV resistance or impact strength. This makes plastic extrusion a preferred method for creating durable and customized products.

What materials can be extruded?

While PVC is one of the most commonly extruded materials due to its durability and versatility, a wide range of other materials can also undergo extrusion. These include polyethylene (PE), polypropylene (PP), polystyrene (PS), and thermoplastic elastomers (TPE). Each material offers unique properties, making extrusion adaptable to various applications, from industrial components to household items.

What Types of Extruders are Used in PVC Pipe Extrusion?

Extruders play a critical role in the PVC pipe extrusion process by shaping the raw material into desired profiles effectively and consistently. The two main types of extruders utilized in this application are single screw extruders and twin screw extruders. Each type has specific strengths, making them suitable for different processing requirements and production goals.

Types of PVC Extruders

Different extrusion processes require specialized machines. The main types include:

Extruder Type

Key Features

Applications

Single-Screw

Simple design, cost-effective, suitable for rigid PVC

Pipes, profiles, basic sheet extrusion

Twin-Screw (Parallel)

High mixing efficiency, better for compounding

PVC blends, foam sheets, complex profiles

Twin-Screw (Conical)

Gradual compression, lower shear stress

High-precision rigid PVC products

Co-Extrusion

Multiple layers for enhanced properties

Barrier films, multi-layer sheets

Specialized Extruders:

· Foam PVC Extruders – Use chemical blowing agents (e.g., AC/Na₂CO₃) to create lightweight, insulating panels .

· Desktop & Lab-Scale Extruders – For R&D or small-batch production (e.g., XH-432 series, 5 kg/h output) .

What is the Difference Between Single Screw and Twin Screw Extruders?

Single screw extruders are simpler in design, featuring a single helical screw that transports and melts PVC material within the barrel. They are cost-efficient, making them ideal for applications requiring straightforward processing with moderate output and less material mixing. Conversely, twin screw extruders consist of two intermeshing screws, which can rotate in the same or opposite directions, allowing for improved control over material mixing, feeding, and output. Twin screw extruders handle high-performance applications and complex formulations more effectively than single screw systems.

What are Twin-Screw Extruders and Their Advantages?

Twin-screw extruders are highly specialized machines designed to enhance the processing of PVC and other polymers through superior mixing, melting, and material homogenization. Their design enables better shear and temperature control, which is essential for processing rigid or highly filled PVC compounds. Advantages of twin screw extruders include enhanced efficiency in compounding, improved material consistency, and a higher throughput capacity. Additionally, these extruders excel at handling materials with additives, such as stabilizers or fillers, making them the go-to choice for demanding industrial pipe production.

How Does Screw Design Affect Extrusion Capabilities?

Screw design is a critical factor determining the performance, efficiency, and output quality of an extruder. Key design aspects, such as screw diameter, length-to-diameter ratio (L/D ratio), and flight geometry, impact the screw’s ability to feed, compress, melt, and discharge material effectively. For PVC extrusion, screws are often tailored to optimize shear stress and ensure uniform melting without degrading the polymer. For example, twin screw designs allow for customizable configurations, enabling precise control over mixing intensity and temperature distribution. Selecting the right screw design ensures consistent product quality, minimal material waste, and reliable production at an industrial scale.

Key Components of an Extrusion Machine

Extrusion machines are complex systems comprising various components that work together to process raw materials into finished products efficiently. Each part of the machine plays a specific role in ensuring optimal performance, precision, and reliability during the extrusion process.

What Roles Do the Hopper and Barrel Play in Plastic Extrusion?

The hopper and barrel are fundamental to the operation of an extrusion machine. The hopper serves as the entry point for the raw material, typically in the form of pellets, granules, or powder. It is designed to regulate the consistent feeding of material into the barrel, preventing issues such as uneven flow or material blockages.

The barrel, which encases the screw, is the primary component responsible for processing the material. It provides a controlled heating environment that enables the material to soften, melt, and reach the desired viscosity for shaping. The heating zones along the barrel can be precisely adjusted to meet the requirements of specific polymer types, ensuring uniform temperature and avoiding degradation.

How Does Energy Consumption Factor Into Extrusion Machinery?

Energy efficiency is a critical consideration in extrusion processes, as these machines require substantial power to operate. Modern extrusion systems incorporate advanced designs such as energy-efficient motors, insulated barrels, and optimized screw geometries to reduce energy loss. Additionally, smart controls and software can monitor energy usage in real time, allowing operators to identify inefficiencies and make necessary adjustments. Reducing energy consumption not only lowers operational costs but also minimizes the environmental impact of industrial production.

What Safety Features Are Included in Modern Extrusion Machines?

Safety is paramount in the operation of extrusion machinery due to the high temperatures, pressures, and moving parts involved. Modern extrusion machines are equipped with features such as emergency stop systems, safety guards, and interlock mechanisms to protect operators. Temperature sensors and pressure monitors help ensure the machinery operates within safe limits, reducing the risk of thermal runaway or mechanical failure. Furthermore, automated shutdown systems can activate if deviations from preset parameters occur, safeguarding both the equipment and personnel. These advancements reflect the industry’s commitment to creating safer and more efficient production environments.

Applications of PVC Pipe Extrusion

Polyvinyl chloride (PVC) pipe extrusion is widely utilized in various industries due to its versatility, durability, and cost-effectiveness. The extrusion process enables the production of pipes with consistent dimensions, tailored properties, and high performance, making PVC pipes suitable for numerous applications in construction, agriculture, and industrial sectors.

Where is PVC pipe commonly used?

PVC pipes are extensively used in water distribution systems, including both residential and municipal pipelines, due to their ability to resist corrosion and chemical degradation. Additionally, they play a key role in agricultural irrigation systems, ensuring reliable water supply to crops. Apart from water management, PVC pipes are employed in drainage systems, conduit installations for electrical wiring, and industrial fluid handling, illustrating their adaptability across varied environments.

What are the advantages of using rigid PVC in pipe production?

Rigid PVC offers several advantages for pipe production. It has high tensile strength and impact resistance, making it well-suited to withstand external pressures and mechanical stress. Its excellent thermal stability allows the pipes to maintain performance under varying temperature conditions, while the inherent chemical resistance ensures performance in contact with a variety of substances. Furthermore, rigid PVC is lightweight, simplifying transportation and installation, which can significantly reduce labor costs.

How does plastic processing impact the quality of PVC pipes?

The quality of PVC pipes is strongly influenced by the precision and control during the plastic processing phase. Consistent extrusion parameters such as temperature, pressure, and speed are essential to ensure uniform wall thickness and dimensionally accurate pipes. Additive selection during processing—such as stabilizers, lubricants, and UV inhibitors—affects the final product's mechanical properties, longevity, and resistance to environmental factors. Advanced processing technologies, such as computer-controlled extrusion, further enhance quality by minimizing defects and ensuring repeatable production results.

How to Choose the Right Extrusion Manufacturer?

Choosing the right extrusion manufacturer is critical to ensuring the quality, consistency, and performance of your finished products. A thorough evaluation of potential partners can help you identify a manufacturer that meets your technical requirements and provides reliable solutions.

What Should You Consider When Selecting an Extrusion Manufacturer?

When selecting an extrusion manufacturer, start by assessing their experience and expertise in your specific industry. Look for a company with a proven track record of delivering high-quality results, particularly for projects similar to yours. Additionally, evaluate their production capacity and equipment capabilities to ensure they can meet your volume and technical specifications. Other key factors include lead times, cost efficiency, and their ability to collaborate on custom solutions tailored to your design needs.

How Can You Evaluate the Extrusion Capabilities of a Manufacturer?

To accurately evaluate a manufacturer’s extrusion capabilities, request detailed information about their production processes, materials expertise, and quality control systems. The manufacturer should be able to handle a wide range of materials and offer advanced technologies, such as multi-layer extrusion, co-extrusion, or specialized profiles. Visiting their facility or reviewing samples of their work can also provide valuable insight into their technical proficiency and attention to detail.

What Certifications Should a Reputable Extrusion Manufacturer Have?

A reputable extrusion manufacturer should hold relevant industry certifications that demonstrate their commitment to quality and compliance. Look for certifications such as ISO 9001 for quality management systems, ISO 14001 for environmental management, and any application-specific certifications relevant to your industry (e.g., NSF for food and beverage applications or UL for safety compliance). These credentials indicate that the manufacturer adheres to stringent standards and consistently delivers high-quality, safe, and reliable products.

What Innovations are Changing the Plastic Extrusion Industry?

The plastic extrusion industry is undergoing significant transformation driven by technological advancements and a growing focus on sustainability. These innovations are not only improving production efficiency but also addressing environmental concerns and enabling greater customization to meet evolving market demands.

How is Custom Plastic Extrusion Evolving?

Custom plastic extrusion is evolving through the integration of advanced machinery and digital technologies. The use of computer-aided design (CAD) and simulation software allows manufacturers to create highly accurate and intricate profiles tailored to specific client needs. Additionally, advancements in materials science have introduced new polymer blends and composites that enhance performance characteristics such as heat resistance, UV stability, and mechanical strength. Automation, including real-time monitoring systems, is also enabling manufacturers to reduce waste, improve precision, and accelerate production timelines.

What is the Impact of Plastic Waste on Extrusion Processes?

Plastic waste has become a critical factor influencing extrusion processes as industries aim to adopt more sustainable practices. Recycling initiatives are integrating post-consumer and industrial plastic waste into extrusion feedstock to minimize the reliance on virgin materials. However, dealing with contaminated or inconsistent recycled materials presents challenges such as equipment wear, processing inefficiencies, and quality issues. Innovations such as filtration systems and advanced sorting technologies are being utilized to ensure higher-quality input materials, allowing for more reliable and eco-friendly extrusion outputs.

What Future Trends are Expected in Plastic Extrusion Technology?

The future of plastic extrusion technology lies in sustainability, automation, and smart manufacturing. Developments in biodegradable and compostable polymers are expected to open new opportunities for environmentally friendly product applications. Industry 4.0 technologies, including IoT-enabled machinery, predictive maintenance, and AI-driven analytics, are poised to optimize production lines and reduce downtime. Additionally, energy-efficient extrusion systems and renewable power integration will further align the industry with global sustainability goals. The push for lightweight, durable, and multifunctional materials will continue to drive innovation in design and production capabilities.

Frequently Asked Questions

Q: What is PVC extrusion and how does it work?

A: PVC extrusion is a manufacturing process that involves melting polyvinyl chloride (PVC) plastic and shaping it into specific profiles using plastic extruders. The molten plastic is forced through a die to create continuous shapes, which can then be cooled and cut to length.

Q: What are the common extrusion materials used in PVC extrusion?

A: Common extrusion materials for PVC extrusion include polyvinyl chloride (PVC) itself, as well as other thermoplastics such as polyethylene (hdpe) and polypropylene. These materials are selected based on the desired properties of the final product.

Q: What types of plastic extruders are used in the PVC extrusion process?

A: There are several types of plastic extruders used in PVC extrusion, including single screw extruders and parallel twin screw extruders. The parallel twin configuration is particularly effective for processing PVC due to its ability to mix and homogenize the material efficiently.

Q: How does the torque of the extruder affect the PVC extrusion process?

A: The torque of the extruder is crucial for ensuring that the molten plastic is adequately mixed and processed. Higher torque levels typically allow for better handling of high-viscosity materials and can enhance the efficiency of the extrusion process.

Q: What are the benefits of using modular extrusion lines for PVC profiles?

A: Modular extrusion lines offer flexibility and scalability, allowing manufacturers to easily adjust production setups for different PVC profiles. This adaptability can lead to improved efficiency and reduced downtime in the plastics industry.

Q: Can PVC extrusion be used for both standard and custom applications?

A: Yes, PVC extrusion can be tailored for both standard and custom applications. Manufacturers can create a wide range of PVC profiles and shapes to meet specific customer requirements, ensuring versatility in the production process.

Q: What role does the temperature of the barrel play in the PVC extrusion process?

A: The temperature of the barrel is critical during the PVC extrusion process as it affects the melting and flow characteristics of the polymer. Maintaining optimal temperature levels ensures consistent processing and high-quality output of PVC plastic products.

Q: What is the significance of high-volume manufacturing in PVC extrusion?

A: High-volume manufacturing in PVC extrusion allows for the production of large quantities of plastic profiles efficiently. This is essential for meeting market demands and maximizing cost-effectiveness in the production of PVC products.

Q: How can the extrusion process affect the thickness of PVC profiles?

A: The extrusion process can be finely tuned to achieve varying thicknesses of PVC profiles by adjusting the die and the extrusion speed. Precise control over these parameters is crucial for producing consistent and high-quality PVC products.

The Bottom Line

PVC extruders are the backbone of countless industries, transforming raw resin into functional products through precision engineering. From high-output twin-screw systems for construction materials to compact lab extruders for prototyping, the right machine ensures efficiency and quality.

For manufacturers, selecting the ideal extruder—whether for rigid pipes, foam panels, or multi-layer films—requires balancing material properties, screw design, and thermal control. Partnering with experienced suppliers ensures optimal performance, whether you’re mass-producing or innovating with new formulations.

Choose wisely, and your PVC extrusion process will deliver durable, high-performance products that meet the demands of modern industry.

References:

· [1] Study on extrusion technology of rigid low-foamed PVC sheet

· [4] Battenfeld-Cincinnati PVC sheet extrusion lines

· [5] Conical twin-screw extruder specifications

· [6] PVC extruder heating zones explained

· [7] Single vs. twin-screw extruders for PVC pipes

· [8][10] Desktop PVC extruders (XH-432 series)

1 note

·

View note

Text

The Vital Role of Quality Aspect in Plastic Extrusion

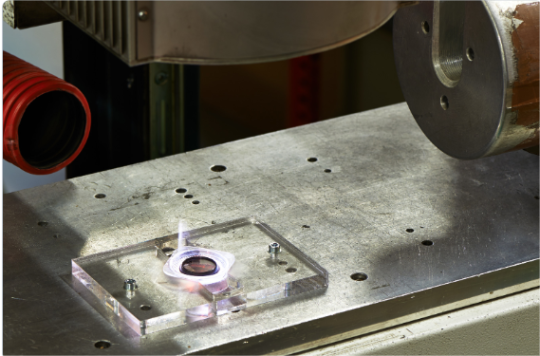

In the Plastic Extrusion Process, raw plastic material is melted and then forced through a die to form a continuous profile. The efficiency, affordability, and consistency of the produced complicated forms make this method a popular choice across a wide range of sectors.

Quality Control Is Crucial for Plastic Extrusion

Plastic extrusion quality control is a complex process that aims to guarantee that the final product fulfills strict quality requirements. The following salient features underscore the significance of quality control in this production process:

Content Management

The key to a successful extrusion process is the quality of the raw plastic material. The first step in quality control is to thoroughly examine and analyze the incoming raw materials to ensure that they are pure, consistent, and meet all required criteria. This contributes to fault prevention and extrusion process stability.

Procedure Observation

It is essential to continuously monitor the plastic extrusion China in order to spot and fix any deviations from the intended specifications. In order to monitor temperature, pressure, and speed in real time and make sure the process stays within the ideal range, automated systems and sensors are essential.

Control in Dimensions

In plastic extrusion, accuracy is crucial, particularly when creating goods with precise dimensional specifications. Regular measurements of the extruded goods' dimensions are one of the quality control procedures that make sure they adhere to the required tolerances.

Examining and Verifying

Strict processes for testing and inspection are followed during the whole extrusion process. To ensure that the extruded goods fulfill the necessary quality requirements, this may entail non-destructive testing techniques, visual inspections, and performance testing. Evaluations of mechanical qualities, color consistency, and other pertinent features may be part of the testing process.

Advantages of Strict Quality Control

Cut Costs: Early fault detection and resolution eliminates waste, lowers rework expenses, and boosts overall operational effectiveness.

Compliance and Reputation: Upholding quality standards guarantees adherence to industry rules, boosting the manufacturer's reputation and inspiring trust in clients.

Improved Quality of Product: Product quality is continuously good, meeting both customer and industry expectations and industry standards thanks to strict quality control procedures in Plastic Injection.

#plastic extrusion China#Plastic Extrusion Companies#plastic extrusion supplier#Plastic Extrusion Process#Plastic Extrusion Guide

2 notes

·

View notes

Text

PET Bottle Market Trends in Europe: CAGR of 2.7% Forecast Through 2031

Astute Analytica's Europe PET Bottle Market Report 2024 provides an in-depth strategic analysis, offering valuable insights into the evolving landscape of the Europe PET Bottle market. This detailed report covers key market dimensions, including current valuation, projected growth, emerging trends, and competitive dynamics. It equips stakeholders with the critical intelligence needed to navigate the increasingly competitive digital marketing ecosystem. By focusing on market structure and future potential, this report serves as an essential guide for businesses looking to excel in the dynamic world of digital marketing.

Market Size and Growth Forecast