#One Component Epoxy

Explore tagged Tumblr posts

Text

What Is An Epoxy Bonding Adhesive?

In the world of adhesives, few names hold the same weight as epoxy. Kohesi Bond, a leading name among epoxy adhesive manufacturers in India, offers a variety of these versatile bonding solutions. But what exactly is epoxy bonding adhesive, and how does it work?

Understanding Epoxy Bonding Adhesives

Epoxy bonding adhesives are known for their exceptional strength and durability. Unlike standard glues, they consist of two key components: a resin and a hardener. When mixed in the correct proportions (as specified by Kohesi Bond or any other epoxy adhesive manufacturer in India), a chemical reaction occurs. This reaction creates a strong, permanent bond between the adhesive and the materials being joined.

One vs. Two Component Epoxies

Kohesi Bond, like many epoxy adhesive manufacturers in India, offers both one-component and two-component epoxy adhesives. Here's a quick breakdown:

Two Part Epoxy Adhesive: This is the most common type. The resin and hardener come in separate containers, ensuring the uncured adhesive has a long shelf life. When ready for use, you simply mix the two parts according to the instructions and apply.

One Component Epoxy (One Component Epoxy Adhesive): This offers more convenience, as the resin and hardener are pre-mixed within a single tube or cartridge. However, one-component epoxies typically have a shorter shelf life and may not be as strong as their two-component counterparts.

The Advantages of Epoxy Bonding Adhesives

Kohesi Bond's epoxy bonding adhesives offer several advantages over traditional glues:

Superior Strength: Epoxy creates an incredibly strong bond, ideal for adhering a wide range of materials, from wood and metal to ceramics and plastics (refer to the specific product information for compatibility).

Durability: Epoxy bonds are resistant to water, heat, chemicals, and even some solvents, making them perfect for long-lasting applications.

Versatility: Kohesi Bond offers a variety of epoxy formulations designed for specific applications, ensuring you can find the perfect solution for your needs.

Unleashing the Potential of Epoxy Bonding Adhesives

With their exceptional strength and versatility, epoxy bonding adhesives from Kohesi Bond are a valuable tool for a wide range of projects. Whether you're a DIY enthusiast, a professional contractor, or simply someone looking for a reliable bonding solution, Kohesi Bond's epoxies have you covered. Explore their website or visit a trusted retailer to discover the right epoxy adhesive for your next project.

#Two Part Epoxy Adhesive#One part Epoxy Adhesives#One Component Epoxy#Two Component Epoxy#epoxy adhesive manufacturers in india#epoxy adhesive india#epoxy bonding adhesive

1 note

·

View note

Text

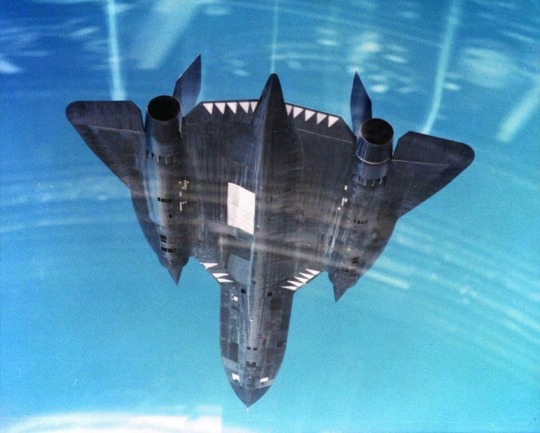

To help reduce the radar cross-section the pie shaped and rectangular shapes were used around the outer edges of the SR 71. This is one of many reasons why they did not allow photographs. The SR -71 was made of 93% aged titanium and 7% composites. The fins and triangle wedges that framed the outer edge of the aircraft were composite constructionsmade from a mixture of asbestos and epoxy. They provided high-temperature radar absorbent characteristics to reduce the aircraft radar cross-section. They found that to attach thin, titanium skin to heavier wing structures, simple standoff clips were developed. These gave structural integrity while providing a heat shield between components with different expansion rates.

According to Wisconsin Metal Tech, the engineers of the SR-71 were among the first people in history to make real use of the material. In that process, they ended up throwing away a lot of material, some through necessity, some through error. At times the engineers were perplexed as to what was causing problems, but thankfully they documented and cataloged everything, which helped find trends in their failures. They discovered that spot welded parts made in the summer were failing very early in their life, but those welded in winter were fine. They eventually tracked the problem to the fact that the Burbank water treatment facility was adding chlorine to the water they used to clean the parts to prevent algae blooms in summer, but took it out in winter. Chlorine reacts with titanium, so they began using distilled water from this point on.

They discovered that their cadmium plated tools were leaving trace amounts of cadmium on bolts, which would cause galvanic corrosion and cause the bolts to fail. This discovery led to all cadmium tools to be removed from the workshop.

Linda Sheffield

@Habubrats71 via X

53 notes

·

View notes

Note

hi! i hope you dont mind me asking a question about the pin manufacturing process as i know you are not personally involved in the actual physical production of your pins, but i was wondering if you knew why rainbow plated pins are always (or at the very least near always) soft enamel? is there something in the iodizing process that renders them incompatible with the way hard enamel is put in the pin frame? what makes epoxy different that allows it to be used? no worries at all if you can't answer, i was just curious :]

Hi there Anon, no worries, I love talking about pin stuff and I'd be happy to explain.

Pin manufacturing basically has two major components: enamel fill and metal plating. The order in which these take place is different depending on the type of enamel: hard or soft.

All pins start out as metal "pin blanks" or "embryos", without enamel or plating.

In hard enamel pins, the pins are overfilled with enamel and then polished down to a smooth surface. Below is an example of an in-progress hard enamel pin, notice how the enamel is spilling over in some places. After the enamel is polished the pin is plated, only certain plating options are available that would not affect the enamel.

In soft enamel pins, the plating comes first and then the enamel fill. Soft enamel pins are never polished so more plating options are available, such as anodized and dyed metal. Dyed metal is actually just paint that is sprayed onto the metal pin blanks: so you can imagine it would come off if the pin was polished, and could not be applied after the enamel is filled in.

The tradeoff is, because the enamel is never polished, soft enamel pins do not have a smooth surface. In the below image, the first two pins are hard enamel, and the third pin is soft enamel with rainbow (anodized) plating.

I prefer a smooth finish on my pins, I think it makes them feel more high quality. So what is a pin maker to do? Well after the enamel and plating is done, we can add a layer of epoxy over the surface of the soft enamel pin to give it that smooth finish.

In the below image, the gray pin is hard enamel and the indigo pin is soft enamel with epoxy.

So basically: hard enamel pins get enamel, polishing, then plating. While soft enamel pins get plating, enamel, and then optionally epoxy.

One last important difference I'll mention is cost, for anyone who is looking into making pins. Hard enamel pins are more expensive to make because of the polishing step. Soft enamel pins without epoxy are cheaper, but if you add epoxy the cost can be about the same as hard enamel because of the additional work needed.

Anodized plating can easily triple the cost of a pin because the materials are expensive, and they have a higher plating flaw rate, requiring the factory to make extras.

If you let me I'll easily continue talking about pin manufacturing, but I'll stop here for now ahahaha - hope that answers your question Anon!

For more details and videos, you can find a great article by WizardPins.

192 notes

·

View notes

Text

Claybridge - (pre-) Fuzzmaster

"... indeed a PRE-Fuzzmaster, Claybridge Sound Systems Fuzz Box! Everything was matching up: the two controls, the 15ft lead (or output cable), the sticker on the side that read the earliest name of the company; it was all there. ...

two major details jumped out as being definitive proof of its validity: A. The small white knobs used on this "prototype" were also found on a legitimate v1 Fuzzmaster, in addition to appearing on the original Fuzzmaster ads! B. The same label-maker seemed to be used on the MKIV Fuzzmasters!

... the circuit is completely encapsulated in an opaque epoxy resin. This is not unlike the infamous "brick" inside of an Ampeg Scrambler, and also not any less of a kick in the stomach for pedal nerds like myself. That initial disappointment aside, what is notable about the guts is that the enclosure seems entirely too small to hold a true Fuzzmaster circuit (which is essentially a 2 transistor fuzz that's smashing a treble booster). So even though this pedal matches most of the details described in the May 16th ad, I can't see how it would be possible to fit both the "improved" fuzz circuit and the "inbuilt treble boost" into such a tiny space. The other thing to note are the components we can see, like the two resistors and that big yellow cap hiding below the wires. Including the pots, jack and switch, everything matches up pretty well with a 1966 release. So, let's see how it sounds. ... [long fuzzologic description of the pedals sound, read here] ... No joke, and hyperbole aside, this is one of the best fuzz pedals I have ever heard. "

cred: tonemachinesblog.com

30 notes

·

View notes

Text

Recently seen another wave of people getting into resin casting hobbies and it stresses me the hell out so this is going to be a PSA

IF YOU ARE USING RESIN YOU NEED PROPER PPE

Resin is nasty stuff and just because it's sold in hobby kits now doesn't mean it's safe. Unfortunately a lot of resins marketed to casting craft hobbies will be marked as "non-toxic/low VOC/safe to use at home" however this can mean anything from 'fairly harmless' to 'slightly less toxic than some other resins'. Don't let anyone tell you you don't need PPE while using resin.

So lets talk about resin allergies

The components in resin and it's hardeners and dilutants are all powerful irritants and sensitisers. This means obviously they can irritate your skin and airways if you come into contact with them or breathe in the fumes, but this also means that you can build up a sensitivity over time. Because of this you can develop a severe reaction over time, you might have your first reaction to resin on the first day you use it, or you might develop an allergy after several years of using it. The more you use resin the more likely you are to develop an allergy.

The reaction is most often a form of dermatitis which could present as redness, ichiness, irritation, swelling, or even skin blisters. Fumes can also cause breathing difficulties and other complications, and with some resins these may be present in significant quantities up to a week after the resin has cured.

In the absolute worst case if you develop a severe epoxy allergy (or allergy to other related compounds) you may be restricted from using a significant percentage of glues and paints, you will need to tell your dentist before you have any work done, you may even be unable to use things like vinyl or plastic handbags. And that's not even the half of it.

So what can you do about it?

The best way to protect yourself from a resin allergy is the proper PPE. Always read any safety materials that come with the resin (these should be inclued with the resin, but you may have to check the manufactureres or sellers website).

Only use resin in a well ventilated space, preferably outdoors, DO NOT DO THIS IN YOUR BEDROOM or any other room you are spending a lot of time in, just because you cannot smell fumes doesn't mean they're not there. If you don't have a suitable space you will need to build a fumes tent: instructions here.

Use NITRILE gloves (latex gloves won't cut it)

USE A RESPIRATOR! You will need either a half face respirator and safety glasses or a full face respirator, and it will need to be able to filter organic gasses and vapors. Make sure your mask fits correctly and air isn't getting in through the sides, and check how often you need to change your filters. (note - you should also have one of these for things like spray painting)

Make sure you're wearing long sleeves/as much skin is covered as possible. If you get resin on your clothing it will ruin them so having dedicated old clothing for working with resin is a good idea.

keep your workspace clean and have materials to mop us spillages on hand so you can minimise the risk of cross contamination.

If you do get resin on your skin wash it off with soap and water immedaitely (you can also get special soaps that are more effective for washing it off of skin)

Finally just do your own research, this sounds silly but it's your own health (and possibly the health of anyone else or any pets living with you) that's at risk here, so make sure you understand the safety implication of the materials you're using.

Please don't take this post as the be all and end all, I've almost definitely forgotten something and this is just intended to be a starting point

#resin#epoxy#epoxy resin#casting#resin casting#dice making#dice maker#epoxy art#resin art#look i know this sounds all doom and gloom and i don't mean this to be patronising#but i'm aware a lot of people just don't know how dangerous resin is because a lot of craft type places that sell it downplay it a lot#also i feel like this could be applicable to a lot of things but#just because other people aren't wearing ppe doesn't mean it's not neccesary#this has been my bi-yearly health and safety rant#i've re-written this post like 5 times so this will just have to be good enough

81 notes

·

View notes

Text

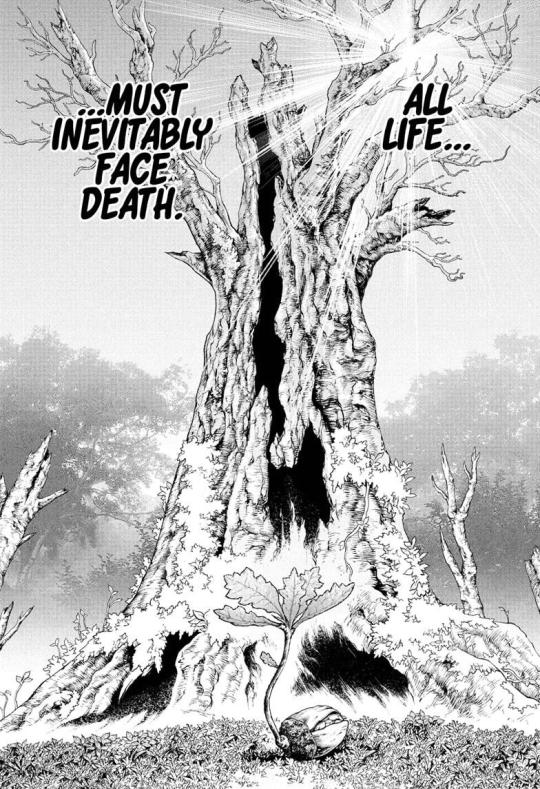

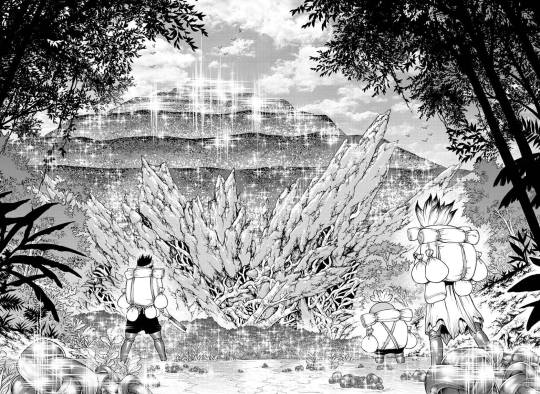

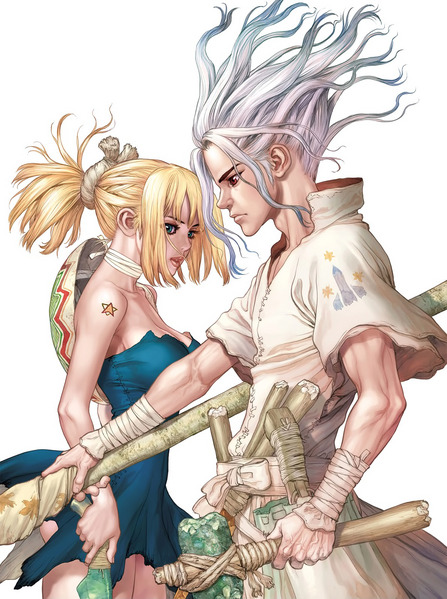

Chapter 230 Trivia

We've had 3 chapters of nothing but Medusa backstory and content and I am living for it.

Oak trees are symbols of strength, endurance and heritage, and bring the idea of mighty growth from tiny, humble beginnings in the West. But in Japan, this relation doesn't seem to exist. If anything, Japanese oak would make you think of bokken (wooden practice swords).

Oxygen rusts the devices' components, which is why the pile in Manaus was full of duds that didn't work, even with a new battery.

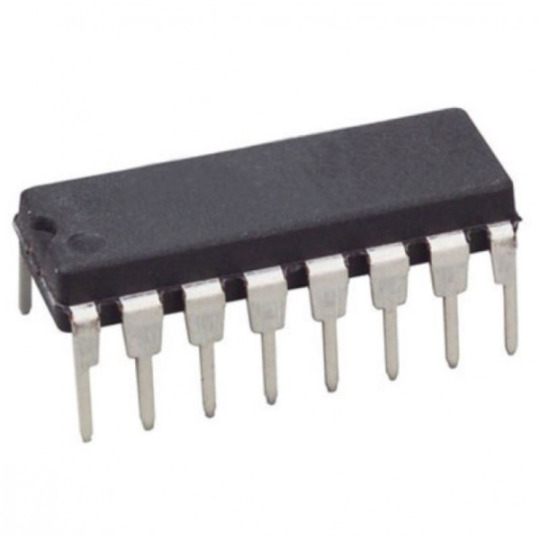

Modern components are stored in plastic/epoxy, ceramics, or even glass. Glass can last for thousands of years… Problem solved?

(If the solution ends up being to put the Medusas in glass bubbles (~chapter 29) that hold a vacuum (~chapter 53/58 depending on which vacuum pump they use), the fact the devices wanted a technologically advanced civilization in order to live forever will be pretty funny…)

New angle for the pyramid! This time we don't see any of the "petrified trees" or whatever they were, unless we only see the tops of the "trees" and not the "roots"?

This cover page is reminiscent of one of the illustrations from way back in volume 3.

This is another example of the Medusas on the moon having no idea what's happening on Earth: they believe that by copying what Senku did (what they'd heard over the radio), they'd activate a device. What they didn't realize was that the signal was getting converted to sound.

The oxygen does more than decay the devices' components: it prevents them moving. Whether or not they can still think in this state is unknown, but it makes you wonder if they understand the fear of being petrified…

The Medusas make it sound like they're familiar with other species that are much more mentally developed than humans, but I wonder how much quicker they were expecting humanity to wake up because of that. A hundred years? Ten? Only a few months?

There was no hesitation in the Medusas' actions here, and it makes me wonder about Senku's goals: are we going to have to wait chapters to find out what Senku wants to do, like we did with Xeno's blinking (Araxá) or what Gen asked Francois to tell Whyman (we still don't know)?

Doing this may also have cost him the trust of everyone on Earth: this is objectively a very concerning move to make when the fate of every living human is in your hands, and most of them don't know you very well.

Stanley aiming his tiny grenade net launcher at the huge swarming mass of Medusas is pretty silly looking, but I can appreciate the effort.

The Medusas made a living Faraday cage to block all of the radio waves, but because of the apparent density of the ball, I'm not sure there's any light getting in there either.

I thought this chapter was clearer than the other chapters so I didn't include as much explanation.

If you are confused, I highly recommend rereading and focusing on Gen's simplifications.

8 notes

·

View notes

Text

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

Unique FAQs

Are synthetic resin adhesives suitable for outdoor applications?

How do synthetic resin adhesives compare to traditional adhesives?

What safety precautions should be taken when using synthetic resin adhesives?

Can synthetic resin adhesives be used underwater?

Are there eco-friendly alternatives to synthetic resin adhesives?

#synthetic resin adhesives#construction adhesives#acrylic adhesive#industrial adhesives#flooring installation#adhesive properties#durability#polyurethane adhesive

2 notes

·

View notes

Text

Innovative Applications of Customised Insulators in Modern Engineering

In the rapidly evolving field of modern engineering, the demand for high-performance materials and components is ever-growing. One such critical component is the insulator, which plays a pivotal role in ensuring the efficiency and safety of electrical systems. This article delves into the innovative applications of customized insulators, focusing on the contributions of leading manufacturers in India.

The Importance of Customized Insulators in Engineering

Insulators are essential for preventing electrical failures and ensuring the safe operation of electrical systems. In modern engineering, the customization of insulators has become crucial to meet the specific requirements of various applications. Customized insulator manufacturers in India are at the forefront of this innovation, offering tailored solutions that cater to diverse industrial needs.

Epoxy Insulator: A Game-Changer in Electrical Engineering

Epoxy insulators have emerged as a preferred choice for many electrical engineering applications due to their exceptional properties. These insulators offer superior mechanical strength, excellent electrical insulation, and high resistance to environmental factors. As a result, they are widely used in applications ranging from power distribution to advanced electronic systems.

Leading Customized Insulator Manufacturers in India

India has become a hub for the production of high-quality insulators, with manufacturers focusing on customization to meet global standards. These manufacturers provide a wide range of insulators designed to cater to specific industrial requirements, ensuring optimal performance and reliability.

Applications of Medium Voltage Support Insulators

Medium voltage support insulators are critical components in power transmission and distribution systems. These insulators are designed to withstand medium voltage levels while providing robust mechanical support. Medium voltage support insulator manufacturers in India are known for their innovative designs and high-quality materials, making them a trusted choice for electrical infrastructure projects.

Innovative Applications of Customized Insulators

Power Transmission and Distribution:

Customized insulators, such as epoxy insulators and medium voltage support insulators, are extensively used in power transmission and distribution networks. Their ability to withstand high mechanical stress and environmental conditions ensures reliable operation and minimal maintenance.

Renewable Energy Systems:

In renewable energy systems, such as solar and wind power installations, customized insulators play a crucial role in enhancing efficiency and safety. Manufacturers in India are developing insulators specifically designed to meet the unique requirements of renewable energy applications, ensuring long-term performance and sustainability.

Advanced Electronic Devices:

The miniaturization and complexity of modern electronic devices necessitate the use of specialized insulators. Epoxy insulators, with their excellent electrical insulation properties and versatility, are widely used in advanced electronics to ensure optimal performance and protection.

Automotive and Aerospace Industries:

Customized insulators are also making significant strides in the automotive and aerospace sectors. These insulators are designed to meet the stringent requirements of high-performance vehicles and aircraft, providing reliable electrical insulation and mechanical support under extreme conditions.

Conclusion

The innovative applications of customized insulators are transforming the landscape of modern engineering. With the expertise of customized insulator manufacturers in India, industries can access tailored solutions that enhance efficiency, reliability, and safety. Whether it's for power transmission, renewable energy, advanced electronics, or high-performance vehicles, customized insulators are essential components driving progress in engineering.

As the demand for high-performance insulators continues to grow, the role of Indian manufacturers in providing cutting-edge solutions will remain pivotal. Their commitment to innovation and quality ensures that customized insulators will continue to meet the evolving needs of modern engineering, paving the way for a more efficient and sustainable future.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India

4 notes

·

View notes

Text

Ethylenediamine is usually one component in the two-component epoxy resin kits (figure 26.18) that you can buy in hardware or craft stores (it is often wrongly called 'catalyst' on the packaging); it is also the reagent with the acrid smell.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#ethylenediamine#epoxy resin#hardware store#craft store#catalyst#reagent#acrid

2 notes

·

View notes

Text

Dear Sephiroth: (a letter to a fictional character, because why not) #142

Today was another relatively blurry day for reasons I don't fully understand. It started out relatively normally, with tea and everything. This time, it was the biscuit tea, with honey, molasses, and cream:

I didn't get to fly the kite yet, because the weather has not been sufficiently breezy. However, today I did order one of the components I will need in order to modify it, though I had to toodle off to several places in order to find exactly what I was looking for. In the end, I did find a place that had the services I needed, and the item will be ready by 5pm tomorrow! I will need to make a few minor adjustments to it once I have it, but that should be super easy. I'm looking forward to seeing the results, and I'm looking forward to showing them to you!

...I thought I would have the gumption to sing the song today so that I could send it along to my guitarist friend and my pianist friend, but... I dunno. I guess I felt more than a little self-conscious about it. M and J were both at home, and... I suppose I get more than a little bashful about singing when there are people around. It doesn't help that it was my mind that filled in some of the holes in the lyrics.

...What if I do the thing and the folks I'm sending it along to think that the words I wrote are stupid and silly garbage words? What if they think my voice sucks? What if they hate it and say to me, "I don't want anything to do with this cheesy corny song, and also I don't want anything to do with you either by proxy!"

...Those are all just silly weird worries that come about as a result of being mocked a lot for creating things in the past. I don't hang out with folks like that anymore, and my guitarist and pianist friends are amazingly kind people. Suppose the only thing for it is to just be brave and get it over with. Maybe I'll ask M and J to go hang out somewhere out of the house so I can make my voice do the things; it gets all tense when I get self-conscious, and then it doesn't work right...

I did a few other odds and ends today. I used some epoxy glue to fix my laptop hinge, and now I don't have to worry about it coming undone, even if it does look a little weird! That's all right though; appearances don't matter as long as it does the job!

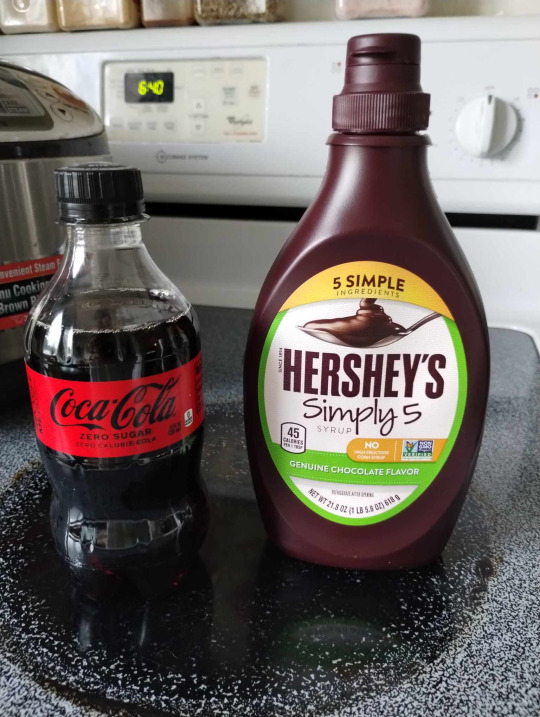

Oh!!! I almost forgot!! Some super awesome anonymous person from the internet had an amazing suggestion for me! They had read the letter I wrote to you in which I wished that chocolate cola existed so I could try it! And!!! They suggested to just put some chocolate syrup in it!! So J and I went to the grocery, and I got the necessary things to do that!!

Hey, Sephiroth? Do you like chocolate? Have you had chocolate syrup? Lots of folks here like to put chocolate syrup in milk and stir it around, and that's pretty good stuff! I wonder if you've had anyone make you any chocolate milk before. If you haven't tried it yet, you can pop by my house and I'll make some for you, easy peasy!

Anyway, so I put the chocolate syrup into the cola a little bit at a time; cola is kinda funky in that sometimes if you mix things with it , it gets all weird and bubbly (Mentos, for example, is a kind of candy here that is infamous for making cola explode), so it's best to test things only a little bit at a time. Doing as such was a very good call; cola seems to react just a little weirdly to chocolate syrup, but not enough to cause any problems as long as it's added gradually:

From here, I swirled it around gently until the chocolate syrup dissolved! The resulting cola was maybe a little flatter than I'd like, but my anonymous friend was quite right; the flavor combination is VERY delightful!! 😄💖 I wonder if they'd have suggestions for me, regarding how much syrup I should use, and best practices for mixing them together without losing too much carbonation...

...Today managed to be both very full of stuff and very uneventful at the same time. And I'm not really sure how that can be, but I guess at least for today, it is what it is. I wonder if you ever get days like that. I wonder if you feel just as blurry and disoriented in response to them. Hm...

Suppose I'll end today's letter for now. J is out and about, M is on the TV playing a game called Animal Well, and I... maybe I'll do some other writing.

I love you. Please stay safe out there. I'll write again tomorrow.

Your friend, Lumine

#sephiroth#ThankYouFFVIIDevs#ThankYouFF7Devs#ThankYouSephiroth#final fantasy vii#final fantasy 7#ff7#ffvii#final fantasy vii crisis core#final fantasy 7 crisis core#final fantasy crisis core#ffvii crisis core#ff7 crisis core#crisis core#ff7r#final fantasy vii remake#final fantasy 7 remake#ffvii remake#ff7 remake#final fantasy vii rebirth#final fantasy 7 rebirth#ffvii rebirth#ff7 rebirth#final fantasy 7 ever crisis#ffvii ever crisis#ff7 ever crisis#ffvii first soldier#chocolate cola#repairs and modifications#wholesome

3 notes

·

View notes

Text

How Synthetic Resin Adhesives Are Revolutionizing the Construction Industry

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

4 notes

·

View notes

Text

True one component epoxy systems are gaining increasing acceptance as compared to popular two component epoxy systems.

1 note

·

View note

Text

To help reduce the radar cross-section the pie shaped and rectangular shapes were used around the outer edges of the SR 71. This is one of many reasons why they did not allow photographs. The SR -71 was made of 93% aged titanium and 7% composites. The fins and triangle wedges that framed the outer edge of the aircraft were composite constructionsmade from a mixture of asbestos and epoxy. They provided high-temperature radar absorbent characteristics to reduce the aircraft radar cross-section. They found that to attach thin, titanium skin to heavier wing structures, simple standoff clips were developed. These gave structural integrity while providing a heat shield between components with different expansion rates.

According to Wisconsin Metal Tech, the engineers of the SR-71 were among the first people in history to make real use of the material. In that process, they ended up throwing away a lot of material, some through necessity, some through error. At times the engineers were perplexed as to what was causing problems, but thankfully they documented and cataloged everything, which helped find trends in their failures. They discovered that spot welded parts made in the summer were failing very early in their life, but those welded in winter were fine. They eventually tracked the problem to the fact that the Burbank water treatment facility was adding chlorine to the water they used to clean the parts to prevent algae blooms in summer, but took it out in winter. Chlorine reacts with titanium, so they began using distilled water from this point on.

They discovered that their cadmium plated tools were leaving trace amounts of cadmium on bolts, which would cause galvanic corrosion and cause the bolts to fail. This discovery led to all cadmium tools to be removed from the workshop.

Linda Sheffield

@Habubrats71 via X

5 notes

·

View notes

Text

Heavy Copper PCB

Heavy copper pcb manufacturering up to 26 OZ

Hitech is a professional heavy copper pcb, thick copper pcb board manufacturer, PCB power supplier from China, we have been associated with heavy copper pcb plating since 2000 and we have won good reputation in this industry. If you have customized heavy copper pcb needs, please don’t heisitate to conatct [email protected] .

Demand for heavy copper PCB in Electric automotive, Power charge, voltage transformer, Charging station, industrial controls, and military is growing very fast. More than 80% of the existing printed wiring board manufacturing is limited or not capable of producing reliable heavy copper printed circuit boards.

Hitech thick copper board technology offers the possibility to implement complex switches in limited space in combination with circuitry for high current levels. Multi-layer PCB has reliable processes to produce copper layer thicknesses up to 26 Oz .

Hitech heavy copper PCB normally used for high power rectifiers, Power charge, Transformaer, Charging station, computer, military, electric vehicle charging, power grid switching system, etc

What is heavy copper PCB board

Heavy copper PCB boards ( also being called thick copper board, power board etc ) are usually bonded with a layer of copper foil on a glass epoxy substrate. The thickness of copper foil is usually 18μm, 35μm, 55μm and 70μm. The most commonly used copper foil thickness is 35μm. The thickness of copper foil used in China is generally 35-50μm, and there are also thinner ones such as 10μm and 18μm; and thicker ones such as 70μm. The thickness of the composite copper foil on a substrate with a thickness of 1-3mm is about 35μm; the thickness of the composite copper foil on a substrate with a thickness of less than 1mm is about 18μm, and the thickness of a composite copper foil on a substrate with a thickness of more than 5mm is about 55μm. If the thickness of the copper foil on the PCB is 35μm and the printed line width is 1mm, then for every 10mm length, its resistance value is about 5mΩ, and its inductance is about 4nH. When the di/dt of the digital integrated circuit chip on the PCB is 6mA/ns and the working current is 30mA, the resistance and inductance contained in each 10mm printed line are used to estimate the noise voltage generated by each part of the circuit to be 0.15. mV and 24mV.

Advantages of heavy copper PCB board

Heavy copper plate has the characteristics of carrying large current, reducing thermal strain, and good heat dissipation.

1. The heavy copper circuit board can carry large current

In the case of a certain line width, increasing the copper thickness is equivalent to increasing the cross-sectional area of the circuit, which can carry a larger current, so it has the characteristic of carrying a large current.

2. Heavy copper circuit boards reduce thermal strain

Copper foil has a small electrical conductivity (also called electrical resistivity ), the temperature rise is small when a large current is passed, so it can reduce the amount of heat and thereby reduce the thermal strain.

Metal “conductors” are divided into: ” silver→copper→gold→aluminum→tungsten→nickel→iron ” according to conductivity.

3. The heavy copper circuit board has good heat dissipation

Copper foil has high thermal conductivity (thermal conductivity 401W/mK), which can play an important role in improving heat dissipation performance, so it has good heat dissipation;

Thermal conductivity refers to the heat transfer through an area of 1 square meter within 1H for a 1 meter thick material with a temperature difference of 1°C on both sides under stable heat transfer conditions, measured by W/m·K.

Heavy copper plate has the characteristics of carrying large current, reducing thermal strain, and good heat dissipation.

Disadvantages of heavy copper PCB board

The outer copper-clad plane must be separated by the surface components and signal lines. If there is a poorly grounded copper foil (especially the thin and long copper), it will become an antenna and cause EMI problems.

If the pins of electronic components are fully connected with copper, it will cause the heat to dissipate too fast, and it will be difficult to desolder and rework soldering. The copper-clad plane of the outer layer must be well grounded, and more vias need to be punched to connect to the main ground plane. If more vias are punched, it will inevitably affect the wiring channels, unless buried blind vias are used.

Applications of heavy copper PCB board

The application field and demand for thick copper plates have been rapidly expanded in recent years, and it has become a “hot” PCB variety with good market development prospects.

The vast majority of heavy copper PCBs are high-current substrates (current x voltage = power). The main application areas of high-current PCBs are two major areas: power modules and automotive electronic components. Some of its main terminal electronic product fields are the same as conventional PCBs (such as portable electronic products, network products, base station equipment, etc.), and some are different from conventional PCB fields, such as automobiles, industrial controls, and power modules.

High-current PCBs are different from conventional PCBs in terms of efficacy. The main function of a conventional PCB is to form a wire for transmitting information. The high-current PCB has a large current through it, and the main function of the substrate carrying the power device is to protect the current carrying capacity and stabilize the power supply. The development trend of such high-current PCB is to carry larger currents, and the heat emitted by larger devices needs to be dissipated. Therefore, the large currents passing through them are getting larger and larger, and the thickness of all the copper foils of the PCBs is getting thicker and thicker. The 6 oz copper thickness of the high-current PCBs manufactured now has become normal;

The application areas of heavy copper circuit boards include: mobile phones, microwaves, aerospace, satellite communications, network base stations, hybrid integrated circuits, power supply high-power circuits and other high-tech fields.

#heavy copper pcb#pcb#pcb assembly#pcb designer#pcb layout#pcb manufacturing#pcb production#pcb supplier

4 notes

·

View notes

Text

My first attempt at fake* kintsugi! Thank you @nayvi for advice + golden mica powder!! Detailed process + reel under the cut.

*fake 'cause it's not actual gold, it's epoxy with gold pigment

The vase was made by Edith Merle in 1985 and I inherited it already broken and glued together with superglue. She is a sculptor known primarily for her ceramic "birds", and happened to be a friend of the family, so we have quite a few of her lovely birds, this one, Jonas II, being the largest.

I used acetone to unglue it and to carefully (with q-tips) remove all glue residue. Then I mixed some 2-component epoxy resin with golden mica powder and used that to carefully stick the pieces together. That took 3 sessions (attach 1 piece, wait for it to cure until tomorrow, etc)

Of course, I worked with gloves and the window open, while handling epoxy. At all times I had warm water + q-tips that I used to remove excess epoxy while it was still soft. I wasn't able to attach the pieces very precisely, and I had to sandpaper the last one quite a lot to fit it.

Then I had 2 sessions of filling in the bigger gaps and editing smaller details with a fine brush. The final session was to sandpaper away small mistakes and stains of epoxy. I didn't remove 100% of the stray droplets and drips, because I liked some of them.

Finished, with its lid! Unfortunately, the lid doesn't fit very well after these repairs :/ But alas. Still better than it was with superglue, and not bad for a first attempt. Then again, as sparkly as the golden epoxy is, it cannot measure with the texture and shine of real kintsugi. I wonder how difficult it would be to do it the traditional way, hmmmmm.... Anyway, to finish here is an accursed reel I made for IG

6 notes

·

View notes

Text

Garage Epoxy Floor - the ultimate guide!

What Exactly is it?

Garage epoxy floor uses materials that will coat over the garage slab, bonding to it and creating an exceptionally strong coating. To put into perspective, as per Nevada Ready Mix, the compressive strength of concrete tends to be around 2,500 to 4,000 psi, meanwhile an epoxy coating hovers at around 8,000 psi to 11,000 psi. Thus, making it anywhere from twice to three times stronger than the concrete in place.

Some of the most common materials used for a garage epoxy floor are 100% solids epoxy, polyaspartic polyurea and polyurea base coat. We’ll dig a little deeper into each material down in the styles section. And probably the most used, and most well-known setup is the RapidCast system; or simply put, the flake floor. When installed correctly (which of course, by us, it is), it serves more than just something pretty to look at.

Two things to remember when doing epoxy over your existing concrete garage floor; it is ONLY as good as the concrete it is bonding to AND the preparation done beforehand. These two cardinal rules must always be kept in mind.

Process

In just about everything that you do, there is a process to ensure that your task is successful. Garage epoxy floor is no different. There may be more than one correct and effective way to do a task, your garage floor included, but this is how we go about it. Here’s a brief overview.

Prepare the surface. The concrete needs to be prepped in order for the epoxy to adhere to your garage floor. Have you ever tried to stick tape to a dirty surface? No good, right? This is no different. That’s why this is probably the most important step.

Vapor Barrier. As far as we’re concern, this step is just as crucial. The purpose of the vapor barrier is to help mitigate moisture. Industrial grade garage epoxy floor materials are not breathable, thus, overtime, water issues may arise. We don’t like issues; I’m assuming you don’t either. Thus, why we consider this step exceptionally important.

Lay down the base coat. Once the surface is prepped, vapor barrier installed, and ready to go, time to go to work! Time to lay down the epoxy material on your garage floor as per agreement. Then, flakes over it.

Flakes Base coat is on, Sweet! Now on to with flakes! Let’s make it happen!

Topcoat Once that is all done and good to go, time to put on a topcoat. Once the right topcoat is put on, job is done!

***** There’s a lot more to it, do not get me wrong, but this is just so you get the gist of it.

Systems

Now that you have an overview of our garage epoxy floor process, here are a few different systems that can be used. Aesthetically speaking, they will all look the same. The process remains virtually the same; prep, vapor barrier, base coat, flake, topcoat. With said, we will not push to sale you something that you do not need (unless you want it, of course). Therefore, your needs/wants will dictate which system we believe is best suited for you and why that is.

System #1 – 100% solids epoxy

This garage epoxy floor system is probably the most well-known, the most searched online, and the most mixed up as far as information goes. It was started back in the 1970s when contractors started laying this stuff down in garages. Word got around of its benefits, and boom, the demand grew; along with misinformation and some deception. More on that later.

This garage epoxy system is a 2-component, 100% solids epoxy system. 100% solids mean that nothing will be evaporated, it will maintain its thickness throughout its curing process. This would be used as a base coat. Flakes will go into it, then topcoat with either another coat of epoxy OR a coat of polyaspartic polyurea. Job is done.

System #2 – Polyaspartic Polyurea

Most of you probably know this one as the famous “1 day install” or “transform your garage floor in one day!” or “4x stronger than epoxy” or blah blah blah.

Polyaspartic (a type of polyurea) was invented back in the 90s by Bayer MaterialScience LLC, as a protective steel coating for bridges. Its purpose was to prevent corrosion and protect it against harsh chemicals. Well, if it can handle outside well, it can handle inside your garage, no?

This system will use polyaspartic polyurea for a base coat, then flake, then another coat of polyaspartic polyurea. Job done.

System #3 – Polyurea base

This garage epoxy floor system is new to us. We actually had a long conversation with a manufacture about it. From our conversation with them, this is the “improved” 1-day install. Without getting too deep into it, the way that it is chemically made, it makes for a much better product to bond to the concrete than the original “1 day install”; thus, the improved version. Either way, it is available for those that want the 1-day install, but a better version of it. We have not tested this out, therefore, we will not comment on how good it actually is.

Benefits

There are plenty of benefits to getting a garage epoxy floor, regardless of which system you (or we) deem best suited for your needs. Here’s to list a few:

Benefit #1 – Strength

Most concrete slabs will cure at somewhere around 2,500 to 4,000 psi. And as stated up top, most industrial grade epoxies will cure at around 8,000 psi to 11,000 psi. Depending on each mix scenario, that could be a fourfold increase in strength. Realistically though, you’re probably looking at somewhere around two, may three time stronger. Either way, your new garage floor will be much stronger than the garage concrete that you stare at every time you open your garage to go to work.

Benefit #2 – Chemical, scratch, slip resistant

There is a zero chance that your garage floor is chemical, scratch and slip resistant. Have you ever changed the oil in your car inside the garage and accidentally spilled some over? Concrete is exceptionally porous, so it absorbs everything.

The more things it absorbs, the higher the chance to shorten the life of your concrete. If only you had something to protect the concrete from foreign substances…. Yeah…. Oh yeah! Our garage epoxy floor coating system!

Benefit #3 – Longevity

We all want the things we buy to last, right? Protecting them is usually the best way to go about it. Since our garage floor epoxy coating can be made to be chemical, scratch and slip resistant, the less foreign objects getting into the concrete, the longer it’ll last.

Benefit #4 – Low maintenance

Most people are busy, period. We as humans like things that are easy and low maintenance. Nothing wrong with that. Quick sweep and mop, done. Next task!

Benefit #5 – Beauty

This one is kind of goes without saying, but hey, we’ll state it anyways. Not only do we all want our things to last, but we also want them to be pretty and aesthetically pleasing. Concrete is a material that is used to build foundations of buildings, sidewalks, driveways, etc., not because it’s pretty, but because overall, it is the best bang for the buck. With that said, it is not very pretty to look at.

Concrete tends to be gray, dull and dead looking; and when dirty, exceptionally ugly as well. Dirt just so happens to show really well on dead concrete. Our floors most definitely change that. I mean, take a look at our work, it speaks for itself.

Great! Where can I get this done?

Good question! And the answer to that is kind is everywhere, but kind of just inside. Confusing, we know. We’ll explain.

If you gave us a blank check and that came with a “I want this here, make it happen!” kind of attitude, then, absolutely! We will make it happen; and it’ll last.

If you asked us “Hey guys, does it make sense to put this stuff on my patio?” we will probably turn around and say “how about a decorative concrete instead?”

I’m going to keep this really short and really sweet. None of these materials used for garage floor epoxy coatings are breathable. What does that essentially mean? There’s a good chance that your outside concrete (driveway, sidewalk, pool patio, etc.) does NOT have a vapor barrier. If we put a nonbreathable material over a concrete slab with no vapor barrier, moisture could potentially build up. Once enough moisture builds up, it’ll pop through the coating. You’ll have these “bubble” looking spots.

Have you ever heard of a time where mankind has EVER won against mother nature? Yeah, neither have we. This is no different.

NOW, that is NOT to say it CANNOT be done. This is where the whole blank check and “I want this here, make it happen!” attitude comes in! It’s not that we cannot or will not do it; we could, and we would. Money talks though.

Everything sounds great! Now, how much is it going to cost me?

Another great question! This one is much easier to answer than the decorative concrete cost one. Why? Because there is really one option (flake) and a 2-car garage tends to be roughly the same size.

We were once told this a long time ago; “Good, fast and cheap. You only get to pick two.” And I tend to agree; “Good work ain’t cheap, cheap work ain’t good”, am I right? As with any project that uses good materials and done right, it is not cheap.

For your standard 2 car garage WITHOUT vapor barrier, you are looking at around 7 dollars a square foot. For your standard 2 car garage WITH vapor barrier, you are looking at around 9 dollars a square foot. – Keep this in mind; bigger surface = lower per square foot price. Why? Volume. – Keep this in mind; the more prep = the higher the cost.

Frequently Asked Questions (FAQ)

Question #1 – My concrete is badly damaged. Will epoxy fix it? – No! It most definitely will not! If the concrete is failing, has sunken, clear signs of being that badly degraded, your best bet is to rip out and replace. All things have an expiration date, and such said concrete has most definitely reached it.

Question #2 – If I do have to replace the concrete, will you do it? – No, I will not. I do not pour concrete.

Question #3 – My concrete is cracked. Once filled and epoxy applied, will it crack again? – In short, maybe. We fill the cracks with the best materials we can get our hands on. With that said, due to so many variables, those cracks may come back or, they may be formed in a different area (I want someone to tell me when has mankind ever won a fight against mother nature. This is no different.

Question #4 – How long will this garage epoxy floor last? – This one is hard to say as there are various factors to it, but with that said, as far as your garage goes, under normal conditions (You’re not running bulldozers through your garage. You are parking your car, changing your oil, storing your pedal bikes, maybe cutting some 2×4) should last a decade or more. IF well maintained, of course.

Question #5 – “Well maintained?” What exactly do I need to do? – Just clean it; sweep and mop. Take care of it as you would with anything else. If you change your oil and spill some on it, don’t let it sit there for a week and expect it last as long as some would keep the garage floor clean.

Question #6 – Vapor barrier, in your professional experience, luxury or required? In short; both. We’re writing an article about it to better explain this. Check back soon. Do not worry though if you don’t see the article here. We will MOST DEFINITELY, IN DETAIL, explain this part of the process when giving you your estimate.

Question #7 – I’ve seen other companies do “lifetime warranties.” Why do you not? – Simple, because we don’t believe in gimmicks. That sounds like a sales pitch from the get-go! You really think someone is going to come out and fix something, anything, for you 30 years from now? Who knows, they might; we’re just not holding my breath.

Also, “lifetime”, lifetime of what exactly? Your lifetime? the company’s? the material’s? the floor’s? the ceiling’s? Nothing has to be shown to us, mainly because we do not worry about how others do their jobs and/or conduct themselves, but with that said, if anyone offers you guys a lifetime warranty on a garage floor, ask them for their warranty paperwork; see what they really cover.

Question #8 – One day garages, do you recommend them or do you not? It truly depends on what your needs are, and most importantly, time frame AND time of the year (temperature).

Concrete is exceptionally porous. Even at a lower viscosity, polyaspartic sets very fast. There is not a lot of time to work with it once it is on the floor. Epoxy on the other hand, even though it has a higher viscosity, it takes much longer to set up. You have more time to work with it once it is on the floor. Less rushing = less chances of making a mistake.

Let’s be very clear about this; YOU CAN DO A ONE DAY INSTALL. We want that to be crystal clear. There ARE scenarios where we would recommend them. With that said, we just do not believe your garage floor is one of them.

Question #9 – Then why do companies offer them? – That’s simple; profit. The company installing can save a lot of time (thus, money on labor) if they are in and out in one day. If they take 2 days to do your garage, that cuts into profits. Also, one of the reasons we particularly do not like it is, since time working with polyaspartic on the floor is so short, any little mistake and we would have to repair your garage for free.

THAT IS NOT TO SAY YOU CANNOT DO IT. WE WANT THAT TO BE CRYSTAL CLEAR. WE DO NOT WANT YOU TO THINK AT ALL THAT ONE DAY INSTALLS HAVE NO PURPOSE AND ARE BAD FLOORS. WE WANT TO BE CRYSTAL CLEAR ABOUT IT. CRYSTAL CLEAR.

There ARE scenarios and locations where a one-day install IS needed, make no mistake, no questions about it. PERIOD. We just cannot picture your garage being one of them.

Question #10 – Can I get your materials at Home Depot or Lowes? – ABSOLUTELY NOT. The materials we use to do your garage floor is NOT some DIY garage floor epoxy you purchase at your local box store for a couple to a few hundred dollars; not even close. We use industrial grade materials in order to ensure the longevity of your investment.

Question #11 – We have seen the “X times stronger than epoxy” or “X times harder than epoxy”. Why use epoxy then? – Here is what we want you do to. Go on google right now and search the following. – “100% solids epoxy data sheet” (no need to include the brackets, that’s just what we want you to search) – “polyaspartic data sheet” – “polyurea data sheet”

Don’t take our word for it; look it up. Want to take our word for it? Here is what we got; OUR findings (YOURS MAY BE DIFFERENT, and if it is, let us know) was that the compressive, tensile, flexural strength, adhesion and hardness of the polyaspartic and polyurea were NOT twice, or three times, or four times, or whatever, stronger than the epoxy’s. We’re not 100% sure exactly what parameters were used when making such claims. We used compressive, tensile, flexural strength, adhesion and hardness because they made sense.

We are not saying anyone is lying by any means. We use commercial grade materials that are readily available to companies that install epoxy and polyaspartic. Some companies may have their own chemists that do make their own mix and thus, can tweak it in order to make such claims; we are not one of them. Therefore, we cannot (nor would we ever) make such claims because well, the materials and parameters we use does not make such statement true.

If you as the client were told that and want to make sure, just ask them for THEIR data sheet in order to prove it. And if they refuse? Well, we’re NOT telling you what to do, but would you believe someone that says something that they refuse to prove it?

Question #12 – And the cool epoxy floor with the waves and swirls? You mean a metallic epoxy floor? In short, if you keep your garage close 99% of the time OR due to where your garage is facing, it gets virtually no sunlight, then sure, it’s a good option. Otherwise, stick with the flakes. More on that later (writing article for exactly that; epoxy floor.)

Did we miss anything? Let us know at Rossi Decorative Concrete & Epoxy if you have any additional questions, comments, or concerns. Please don’t forget, follow us on Facebook and Instagram! Drop a like and share our work!

2 notes

·

View notes