#InternalCombustionEngine

Explore tagged Tumblr posts

Text

The Chinese Company "Build Your Dreams (BYD)" just released into Production their new "Super e-Platform" which can charge an Electric Vehicle (EV) with a Range of up to 400 km in just five minutes. In line with this, BYD is releasing two new Models which will be using this Technology next Month of April 2025, the "Han L" and the "Tang L".

The Han L will be able to charge 400 km of Range in just five minutes while the Tang L will be able to charge 370 km of range in the same amount of time. Prices start at Cny 270,000 in China, which is around Php 2.1 million.

BYD plans to 4,000 of the Megawatt Flash Chargers all over China in the next couple of Years.

MY NOTES: So the Technology for EVs to charged as fast as Internal Combustion Engines (ICE) can be refueled is now here, it now is just a question of it being adopted by everyone. If all goes well and there are no serious Issues or Trade Offs with this new Technology, then we will see a massive decline in ICEs in the next Decade and the continued rise of EVs, and China is leading the Way.

The Philippines is being left behind in overall EV Technology even in South East Asia (SEA) only as most of them have wholeheartedly embraced Chinese EV Technology, except the Philippines which still insists on siding with the United States (US) and antagonizing China.

Note that the Php 2.1 million Price for the new BYD Car Models is VERY reasonable as these are Top of the Line and Cutting Edge in Technology. But this Price I think is only good in China, if exported it will likely cost a lot more, probably around twice as much.

Here is the Link to the Article at the “Electric Drive” Website: https://www.electrive.com/2025/03/18/byd-introduces-megawatt-charging-for-electric-cars/

SOURCE: BYD introduces Megawatt charging for Electric Cars {Archived Link}

#buildyourdreams#byd#supereplatform#electricvehicle#ev#hanl#tangl#china#megawattflashchargers#internalcombustionengine#ice#unitedstates#philippines#southeastasia

0 notes

Text

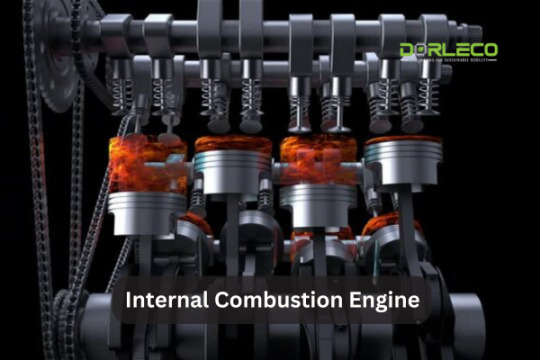

Internal Combustion Engine

Introduction

Internal combustion engine (ICEs), which power around 250 million roadway cars in the US alone, have been the foundation of industrial and transportation uses for more than a century. They are a powerful force in the automotive industry because of their durability, driveability, and compatibility with a wide range of fuels, including ethanol, natural gas, propane, diesel, gasoline, and biodiesel. Additionally, they can be included in plug-in hybrid and hybrid systems to improve range and fuel economy. Internal combustion engines are under increased scrutiny because of environmental concerns and the growing demand for greener alternatives, despite their extensive use and benefits.

Internal Combustion Engine Classification

Continuous combustion engines and intermittent combustion engines are the two main types of internal combustion engines that are distinguished by their combustion mechanisms.

1. Engines with Continuous Combustion

Fuel and oxidizer are continuously injected into these engines, maintaining a constant flame. Two of the best examples of continuous-combustion engines that are frequently used in industrial and aerospace settings are gas turbines and jet engines.

2. Engines with intermittent combustion

Conversely, the air-fuel combination is ignited in cycles by intermittent-combustion engines, commonly referred to as reciprocating engines. This group includes diesel and gasoline piston engines, which produce power by burning fuel in precise order.

The Internal Combustion Engine’s Operating Principles

The basic chemical process of combustion, in which fuel and oxygen combine to create energy, is at the heart of internal combustion engines. ICEs use direct fuel combustion to produce energy inside, as opposed to external combustion engines like steam engines.

An ICE is made up of a moving piston and a stationary cylinder. The crankshaft is turned by the piston’s movement, which is pushed by expanding combustion gases. The powertrain then uses this mechanical energy to drive the wheels of the vehicle.

Currently, there are two main categories of ICEs in production:

Spark-Ignition Gasoline Engines: These engines use a spark plug to ignite a mixture of gasoline and air before compression.

Diesel engines that use compression ignition only compress air before injecting high-pressure fuel, which ignites on its own because of the heat generated during compression.

The four-stroke cycle used by the majority of ICEs consists of four crucial stages:

The Cycle with Four Strikes

Stroke of Intake: The piston is close to the top dead center (TDC) at the start of the intake stroke. The piston descends as the intake valve opens, bringing in fuel and air (or just air in diesel engines). For the combustion chamber to receive a new charge, this stroke is necessary.

An engine cycle needs two full crankshaft revolutions (720°), and only one power stroke produces torque; the other strokes use energy.

Internal Combustion Engine Components

Important elements of an ICE consist of:

Cylinder Head: The camshaft, valves, valve buckets, return springs, spark plugs for gasoline engines, and fuel injectors for direct injection engines are all housed in the cylinder head. Additionally, it has engine coolant tubes.

Engine Block: The crankshaft, connecting rods, pistons, and cylinders make up the engine block. To regulate temperature, it also makes coolant flow easier.

Combustion Chamber: The combustion chamber is the area between the piston, cylinder head, and engine block where air-fuel combustion takes place.

Internal Combustion Engine Benefits

Compact Size: Internal combustion engines (ICEs) are substantially smaller than external combustion engines.

High Power-to-Weight Ratio: They are appropriate for transport applications due to their high power-to-weight ratio.

Portability: the ability to fit a variety of vehicles and allow for easier carrying.

Fast Start Time: Internal combustion engines (ICEs) may start nearly instantly, in contrast to steam engines.

More Efficiency: Compared to external combustion engines, it offers higher efficiency.

Reduced Maintenance: Needs comparatively less care.

Lower Lubricant Consumption: Lubrication is more effective than in external combustion engines.

Moderate Operating Temperature: In contrast to steam engines, internal combustion engines’ maximum temperatures only last a brief period.

Internal Combustion Engine Drawbacks

ICEs have significant disadvantages despite their benefits:

Limited Fuel Options: Rely on premium gaseous or liquid fuels.

High Fuel Costs: When compared to alternative energy sources, gasoline and diesel are more costly.

Environmental Issues: Compared to external combustion engines, internal combustion engines emit more pollutants.

Noise pollution: reciprocal engines produce a lot of noise during burning.

Power Restrictions: Not recommended for applications requiring a lot of power.

Internal Combustion Engine Applications

Many industries make extensive use of ICEs.

Gasoline Engines: Automobiles, boats, and airplanes all use gasoline engines.

Industries use gas engines to generate electricity.

Diesel engines power large machinery, trucks, ships, and railroads.

Industrial, maritime, and aviation settings employ gas turbines.

Internal Combustion Engines’ Future

Cleaner alternatives are becoming more and more necessary as environmental concerns and resource depletion become more urgent issues. Even with notable improvements in ICE efficiency and emissions management, their dependence on fossil fuels continues to be a major drawback.

To overcome these obstacles, research and development initiatives concentrate on:

Alternative Fuels: Sustainable substitutes include hydrogen, biofuels, and synthetic fuels.

Electrification: hybrid and plug-in hybrid technologies integrate electric motors to lower pollution and fuel consumption.

Advanced Engine Management Systems: Control systems powered by AI increase productivity.

Lightweight Materials: Better materials contribute to a lighter engine, which improves fuel economy.

Aerodynamic Enhancements: Improving a car’s aerodynamics helps it use less fuel.

Conclusion

Internal combustion engines have greatly aided modern industries and transportation. They are essential because of their success, reliability, and adaptability. However, ICEs need to change to be relevant as the world moves toward greener energy alternatives.

As ICE technology advances, attention is turning to more environmentally conscious options. Electric powertrains, hybridization, and advanced fuels are shaping the future of transportation. The long-term sustainability of internal combustion engines will depend on how well we balance environmental responsibility and energy efficiency. The secret to guaranteeing a sustainable and effective future in industry and mobility is to embrace innovation.

#Internalcombustionengine#AutonomousVehicle#sensors#Actuators#Dorleco#CANKeypads#CANDisplays#VCUs#Vehiclecontrolunit#EVSoftwareServices#E/Earchitectures

0 notes

Text

#electriccars#FY25#Tata Motors#InternalCombustionEngine#vehicles#electricvehiclesnews#evnews#evtimes#autoevtimes#evbusiness

0 notes

Text

002 INTRODUCTION TO FUEL INJECTION

download notes

#AutomotiveDiagnostics#AutomotiveEngineering#AutomotiveFuelSystems#EFI#ElectronicFuelInjection#EngineFuelInjection#EnginePerformance#FuelDeliverySystems#FuelInjectionBasics#FuelInjectionComponents#FuelInjectionSystems#FuelInjectionTechnology#FuelInjectionTypes#FuelManagement#InternalCombustionEngines#IntroToFuelInjection#VehicleFuelSystems

0 notes

Video

youtube

"Avadi MA-250: The Future of Lightweight and Fuel-Efficient Engines"

#youtube#AvadiMA250 EngineInnovation InternalCombustionEngine TechRevolution LightweightEngine FuelEfficiency MechanicalEngineering AutomotiveTech In

0 notes

Text

House Vote on EV Rule: Setback for Biden's Climate Change Plan Sparks Ongoing Debate #Automakers #BidenAdministration #carbondioxideemissions #climatechange #congress #cost #democrats #electricvehicles #EnvironmentalProtectionAgency #EVs #executiveaction #executivepower #fuelcosts #greenhousegasemissions #internalcombustionengines #legislation #ongoingdebate #partylines #phaseout #policy #presidentbiden #Republicans #rule #setback #technology #transportation #UnionofConcernedScientists #Veto

#Politics#Automakers#BidenAdministration#carbondioxideemissions#climatechange#congress#cost#democrats#electricvehicles#EnvironmentalProtectionAgency#EVs#executiveaction#executivepower#fuelcosts#greenhousegasemissions#internalcombustionengines#legislation#ongoingdebate#partylines#phaseout#policy#presidentbiden#Republicans#rule#setback#technology#transportation#UnionofConcernedScientists#Veto

0 notes

Text

🔩 Valve Seat Inserts are quietly thriving — Growing from $3.5B to $6.0B by 2034 (5.5% CAGR, smooth and steady).

Valve Seat Inserts play a critical role in internal combustion engines by providing a hard-wearing surface for the intake and exhaust valves to seal against. These components ensure optimal compression, efficient combustion, and extended engine life. Made from high-strength alloys, valve seat inserts are designed to withstand extreme temperatures, high pressures, and constant mechanical stress. They are especially vital in modern engines that operate under more demanding conditions, including those powered by alternative fuels.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS22776 &utm_source=SnehaPatil&utm_medium=Article

With the rise of turbocharged engines and stricter emission regulations, the quality and performance of valve seat inserts have become increasingly important. Precision-engineered for a perfect fit, these inserts reduce valve wear, prevent leakage, and improve fuel efficiency. In high-performance and heavy-duty applications, advanced materials like powdered metal and bimetallic alloys are used to enhance durability and thermal conductivity. Whether in passenger vehicles, motorcycles, or industrial engines, valve seat inserts are key to maintaining engine reliability and performance. As engine technologies evolve, so too does the design and functionality of valve seat inserts, making them a vital innovation in automotive and mechanical engineering.

#valveseatinserts #enginecomponents #engineperformance #automotiveengineering #internalcombustionengine #valvetrain #engineefficiency #cylinderhead #valveseats #highperformanceengines #valvetechnology #engineparts #automotiveparts #mechanicalengineering #powderedmetal #heavyengineparts #engineinnovation #enginecooling #fuelcombustion #precisionengineering #valveprotection #thermalresistance #engineupgrade #highpressureengines #valvesealing #engineoptimization #vehiclerepair #motortech #autoindustry #alternativfuelengines #metalalloys #enginebuilding #enginewearprotection #valvedesign #engineassembly #automotivetechnology

Research Scope:

· Estimates and forecast the overall market size for the total market, across type, application, and region

· Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

· Identify factors influencing market growth and challenges, opportunities, drivers, and restraints

· Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

· Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

"Powering Progress: The Legacy and Future of Internal Combustion Engines 🚗⛽️"

The internal combustion engine (ICE) has been the driving force behind transportation for over a century, propelling vehicles of all shapes and sizes with the power of controlled explosions.

From the iconic rumble of classic muscle cars to the quiet hum of modern hybrids, ICEs have evolved alongside automotive technology, continually improving in efficiency, power, and environmental impact. While electric vehicles are gaining traction, ICEs remain dominant due to their affordability, reliability, and infrastructure compatibility. With advancements in fuel injection, turbocharging, and variable valve timing, today's ICEs achieve unprecedented levels of performance while meeting increasingly stringent emissions standards. As the automotive industry faces pressure to reduce carbon emissions and embrace sustainable alternatives, hashtags like #InternalCombustionEngine, #ICE, #FuelEfficiency, #AutomotiveInnovation, #EngineTechnology, #FutureOfTransportation, #CleanerEngines, #HybridPower, #GasolineEngines, #DieselEngines, #SustainableMobility, #DrivingExperience, #InnovationInEngineering, #EfficientPower, and #EngineEvolution reflect the ongoing dialogue surrounding the role of ICEs in shaping the future of mobility. With continued research into alternative fuels and hybrid powertrains, the legacy of the internal combustion engine will endure, driving progress towards a greener, more efficient automotive landscape. 🌿🔧

0 notes

Photo

F1 CEO vows there will never be an electric car on the grid - Autoblog F1 CEO Stefano Domenicali said the sport is pursuing sustainable fuels instead of electric powertrains for its next major rules change in 2026. https://www.autoblog.com/2023/03/01/f1-will-never-have-electric-cars-ceo-says/ #internalcombustionengine #internalcombustion #newengines #newengine #engines #engine #renewablefuels #renewablefuel #renewablepetrol #diesel #petrol #syntheticfuels #synthfuels #synthfuel #syntheticfuel #sustainablefuel #sustainablefuels #efuel #epetrol #petroleum #egas #dieselhead #dieselheads #petrolhead #petrolheads #hydrogen #hydrogencombustion #greenhydrogen #transport #transportation https://www.instagram.com/p/CpQoh1Itn6M/?igshid=NGJjMDIxMWI=

#internalcombustionengine#internalcombustion#newengines#newengine#engines#engine#renewablefuels#renewablefuel#renewablepetrol#diesel#petrol#syntheticfuels#synthfuels#synthfuel#syntheticfuel#sustainablefuel#sustainablefuels#efuel#epetrol#petroleum#egas#dieselhead#dieselheads#petrolhead#petrolheads#hydrogen#hydrogencombustion#greenhydrogen#transport#transportation

2 notes

·

View notes

Photo

Germany has successfully watered down a planned EU ban on the sale of combustion-engine cars European Union members formally approved a ban on the sale of new carbon dioxide (CO2)-emitting cars by 2035. What was meant to be a milestone legislation towards the decarbonization of the European car industry was watered down by Germany to provide an exemption for cars running on e-fuels.Read more... https://qz.com/eu-ban-combustion-engine-cars-electric-vehicles-germany-1850273664

#combustion#low carboneconomy#energy#robertametsola#volvo#sustainabletechnologies#macron#articles#ferrari#renewableenergyeconomy#environment#nature#internalcombustionengine#electricvehicle#fuel#syntheticfuel#franstimmermans#teresaribera#fordmotors#energyeconomics#Diego Lasarte#Quartz

0 notes

Photo

#urbandecay #abandoned #chennaidiaries #chennaistreet #chennai #fujifilmxseries #morningscenes #streetphotography #streetsofchennai #streetphotographer #engineblock #internalcombustionengine #ice (at Border Thottam) https://www.instagram.com/p/CbPLhNAPI1x/?utm_medium=tumblr

#urbandecay#abandoned#chennaidiaries#chennaistreet#chennai#fujifilmxseries#morningscenes#streetphotography#streetsofchennai#streetphotographer#engineblock#internalcombustionengine#ice

0 notes

Text

Internal Combustion Engine

March 5, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

In the United States, internal combustion engines power almost 250 million highway vehicles due to their exceptional longevity and drivability. They can run on renewable or alternative fuels in addition to gasoline or diesel (e.g., natural gas, propane, biodiesel, or ethanol). Additionally, they can be paired with plug-in hybrid electric systems to increase the range of hybrid electric vehicles or with hybrid electric powertrains to improve fuel efficiency.

Internal combustion engines are divided into two groups:

Continuous combustion:

Engines with both intermittent and continuous combustion. Fuel and oxidizer enter the engine steadily, which is the hallmark of a continuous-combustion engine. An engine (such as a jet engine) maintains a steady flame.

Intermittent-combustion engines:

The air and fuel in an intermittent combustion engine ignite periodically, giving rise to the term “reciprocating engine.” A cycle is used to process discrete amounts of fuel and air. Examples of this second type are diesel engines and gasoline piston engines.

A sequence of thermodynamic events can be used to describe internal combustion engines. Thermodynamic processes take place concurrently in a continuous-combustion engine as the fuel, oxidizer, and combustion products move through the engine in a steady flow.

In contrast, all of the events in an intermittent combustion engine happen one after the other and are repeated throughout each cycle.

Internal combustion engines consume air, compress it, and either introduce fuel into the air or compress the air-fuel combination. Rockets are an exception to this rule, as they use both liquid-propellant and solid rocket motors.

The air-fuel mixture is then burned, work is obtained from the expansion of the hot gaseous combustion products, and finally, the combustion products are discharged through the exhaust system, as is the case with all internal combustion engines.

Their functioning can be compared to that of external combustion engines (such as steam engines), where energy is obtained exclusively by heat transfer to the working fluid via a heat exchanger and no chemical reaction occurs in the working fluid.

The four-stroke, gasoline-powered, homogeneous-charge, spark-ignition engine is the most widely used internal combustion engine. This might be attributed to its exceptional performance as a leading player in the ground transportation sector.

The aeronautics industry uses spark-ignition engines as well, but because of its focus on range, speed, and passenger comfort, aircraft gas turbines have emerged as the industry’s main players.

Exotic systems including advanced rocket engines and motors, like those found on U.S. space shuttles and other spacecraft, and supersonic combustion ramjet engines (scramjets), like those envisioned for hypersonic aircraft, are also included in the category of internal combustion engines.

How Does An Internal Combustion Engine Work?

The fundamental chemical process of releasing energy from a fuel and air mixture is called combustion, or burning. The process of fuel ignition and combustion in an internal combustion engine (ICE) takes place inside the engine. After that, the engine uses a portion of the energy produced by combustion to power itself. A stationary cylinder and a moving piston make up the engine. The crankshaft rotates as a result of the piston being pushed by the expanding combustion gasses. In the end, this action turns the wheels of the car through a set of gears in the powertrain.

The spark-ignition gasoline engine and the compression-ignition diesel engine are the two types of internal combustion engines that are currently in production. The majority of these are four-stroke engines, which require four piston strokes to complete a cycle. The intake, compression, combustion, power stroke, and exhaust are the four independent operations that make up the cycle.

The methods used by compression ignition diesel engines and spark ignition gasoline engines to feed and ignite fuel are different. During the intake phase in a spark ignition engine, fuel and air are combined and then forced into the cylinder. The fuel-air mixture is compressed by the piston and then ignited by the spark, leading to combustion. During the power stroke, the piston is pushed by the combustion gasses’ expansion. Only air is introduced and subsequently compressed into an engine in a diesel. The fuel then ignites when diesel engines spray it into the hot compressed air at a proper, controlled rate.

In essence, an internal combustion engine converts the air-fuel mixture’s heat energy into mechanical energy. The reason it is named Four Strokes is that a full combustion cycle in the piston requires four strokes to complete. An internal combustion engine, sometimes known as an ICE (internal combustion engine), is a four-stroke piston engine that powers a passenger car.

Let’s now investigate which constitutes an ICE’s principal parts.

The camshaft(s), valves, valve buckets, valve return springs, spark/glow plugs, and injectors (for direct injection engines) are typically located in the cylinder head. The engine’s cooling liquid passes via the cylinder head.

We can locate the piston, connecting rod, and crankshaft inside the engine block. Regarding the cylinder head, coolant passes through the engine block to assist in regulating the engine’s temperature.

From BDC to TDC, the piston travels inside the cylinder. When the piston is near TDC, a volume is formed between the cylinder head, engine block, and piston. This space is known as the combustion chamber.

An ICE with four strokes has the following phases (strokes) in a complete engine cycle:

Intake power (expansion) exhaust compression intake The piston’s movement between the bottom and top dead centers is referred to as a stroke.

Now that we are aware of an ICE’s constituent parts, we can investigate the actions that take place throughout each engine cycle stroke. The position of the piston at the start of each stroke and the specifics of what happens inside the cylinder are displayed in the table below.

Stroke 1 – INTAKE

Stroke 2 – COMPRESSION

After the intake stroke is complete, the piston begins the compression stroke at BDC. The intake and exhaust valves close during the compression stroke, and the piston travels toward TDC. The air/mixture is compressed when both valves are closed, and when the piston approaches TDC, the pressure reaches its maximum. During the compression stroke, just before the piston reaches TDC (but not quite there),

Stroke 3 – POWER

Stroke 4 – EXHAUST

After the power stroke is over, the exhaust stroke begins with the piston at the BDC. There is an open exhaust valve during this stroke. Most of the exhaust gasses are forced out of the cylinder and into the exhaust pipes by the piston’s movement from the BDC to the TDC. The engine uses energy during the exhaust stroke because the components’ inertia causes the crankshaft to rotate.

As you can see, the piston needs to make four strokes to complete a combustion (engine) cycle. This indicates that two full crankshaft revolutions (720°) are required for one engine cycle.

Advantages of internal combustion engines

Engine size is extremely small in comparison to external combustion engines.

The power-to-weight ratio is elevated.

Excellent for applications with low power requirements

Typically, more transportable than external combustion engines of the same kind

safer to use with a much shorter start time

Higher efficiency compared to an external combustion engine

There is no possibility of working fluid leaks minimal upkeep is necessary

Compared to external combustion engines, there is a reduction in lubricant use.

Because the peak temperature is only achieved briefly (during the fuel’s explosion), the overall working temperature in the case of reciprocating internal combustion is modest.

Disadvantages of internal combustion engines

The range of fuels available for utilization is restricted to extremely high-quality gaseous and liquid fuels.

Fuel utilized, such as gasoline or diesel, is quite expensive.

In general, engine emissions are higher than those of an external combustion engine.

Unsuitable for producing significant amounts of power When there is reciprocating internal combustion, fuel detonation produces noise.

Types and applications of internal combustion engine:

Gasoline engines are utilized in automobiles, boats, and airplanes.

Gas engines are employed to provide industrial power.

Diesel engines are utilized in the automotive, railroad, power, and marine industries.

Gas turbines: They are employed in the maritime, industrial, and aircraft industries.

Conclusion:

To sum up, for more than a century, internal combustion engines have been essential in powering a variety of industry and transportation options. They are essential to contemporary industrialization and mobility because of their effectiveness, dependability, and flexibility. However, the desire to switch to greener, more sustainable options is growing as worries about the effects on the environment and the depletion of resources increase.

Internal combustion engines’ dependence on fossil fuels is still a severe disadvantage, despite notable improvements in efficiency and emissions reduction. Research and development efforts are being directed toward alternative fuels like biofuels and hydrogen, as well as electrification technologies like electric and hybrid powertrains, in an attempt to address these problems.

Moreover, the use of sophisticated engine management systems, lightweight materials, and enhanced aerodynamics keeps improving internal combustion engine performance and fuel efficiency. To combat climate change and lessen reliance on limited resources, a thorough transition to greener transportation options is required.

In conclusion, even though internal combustion engines have proved essential to contemporary transportation and industry, there are growing concerns about their long-term viability. The key to the future is adopting cutting-edge technologies that balance environmental protection with the changing demands of society for dependable and efficient power sources.

Also Read: Things to know about Hybrid Powertrains

#InternalCombustionEngine#VCU#Powertrains#EVEMS#EVCharging#Dorleco#ADAS#Electricmotor#EVs#Hybridelectricvehicles#Electrigenerator

0 notes

Text

001 ELECTRONIC PETROL INJECTION SYSTEMS

download notes

#AutomotiveDiagnostics#AutomotiveElectronics#AutomotiveEngineering#AutomotiveMaintenance#AutomotiveTechnology#CBET#CDAC#ElectronicControlUnit#ElectronicPetrolInjectionSystems#EngineManagementSystems#EnginePerformance#FuelInjectionSystems#FuelManagementSystems#FuelSystemsDiagnostics#InternalCombustionEngines#MotorVehicleTechnology#PetrolInjectionTechnology#tvet#VehicleFuelSystems#VehicleSystems

0 notes

Photo

"Вечная любовь!" Она такая разная... ☝️😉📸 (интересно, а ключ тоже в воду выбросили?🤔) #love #eternallove #eternal #bridge #tradional #technics #cars #undyinglove #engine #internalcombustionengine #crazy #crazylove #lockdown #lock #padlock #key #nokeys #wrench #BorBorich67 #instalove #любовь #вечнаялюбовь #замок #ключ #традиция #техника #автомобили #двс #сумашедшаялюбовь #мост https://www.instagram.com/p/CBk9bPfKFAO/?igshid=1k331upllcrfs

#love#eternallove#eternal#bridge#tradional#technics#cars#undyinglove#engine#internalcombustionengine#crazy#crazylove#lockdown#lock#padlock#key#nokeys#wrench#borborich67#instalove#любовь#вечнаялюбовь#замок#ключ#традиция#техника#автомобили#двс#сумашедшаялюбовь#мост

0 notes

Photo

#Tesla #TeslaModelS #SuperCar #EV #electricvehicle meets #ICE #911 #Porsche #Porsche911 @ #Porsche_Zentrum_Hofheim #Zentrum #Hofheim #Taunus #Hessen #Deutschland #Germany #internalcombustionengine #havefun #joy #car . . . [3.6.2019] (hier: Porsche Zentrum Hofheim) https://www.instagram.com/p/ByfsRfOIsBd/?igshid=rq0ug8oj1hf1

#tesla#teslamodels#supercar#ev#electricvehicle#ice#911#porsche#porsche911#porsche_zentrum_hofheim#zentrum#hofheim#taunus#hessen#deutschland#germany#internalcombustionengine#havefun#joy#car

0 notes

Text

GSMC Car Podcast Episode 25: Engine Cylinder Configurations - Your I Engine ISN'T a V Engine!

#automotivenews#cylinderconfigurations#gsmccarpodcast#gsmcpodcastnetwork#inlineengines#internalcombustionengines#vengine#wengines

0 notes