#greenhydrogen

Explore tagged Tumblr posts

Text

3 notes

·

View notes

Text

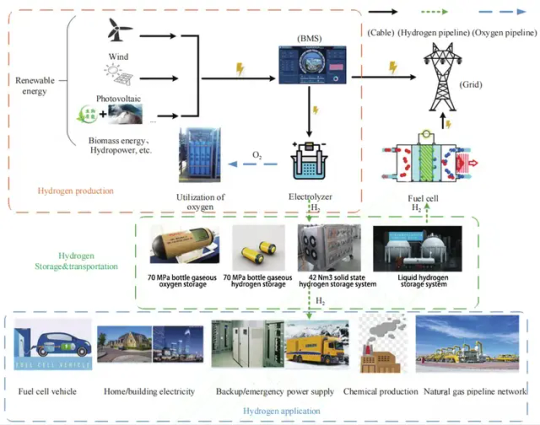

Hydrogen Production Electrolysis: Powering a Greener Future from the Ground Up

In a world racing to reduce carbon emissions and pivot to cleaner energy sources, the spotlight has turned toward hydrogen—specifically, how we can produce it efficiently and sustainably. Among the different methods available, hydrogen production electrolysis stands tall as one of the most promising technologies. It's not just a chemical reaction; it's a gateway to a cleaner, more resilient energy future.

But how does it work? Why is it so important? And more importantly, how does it impact real people, industries, and the planet? Let's take a deep dive, not from a lab bench, but through a lens that connects science, society, and sustainability.

What Is Hydrogen Production Electrolysis?

At its simplest, electrolysis is the process of splitting water (H₂O) into its basic elements—hydrogen (H₂) and oxygen (O₂)—using electricity. This is done through an electrolyzer, a device that passes an electric current through water, breaking the molecular bonds.

When powered by renewable energy sources like solar or wind, the hydrogen produced is referred to as “green hydrogen.” That’s where the magic lies—clean energy in, clean fuel out. No fossil fuels, no carbon emissions, no planetary guilt.

Why Hydrogen? Why Now?

Hydrogen isn’t new. It’s the most abundant element in the universe and has been used industrially for over a century. What’s new is the urgency.

As climate change becomes a defining issue of our time, nations are committing to net-zero goals. Industries that are hard to electrify—like steel production, shipping, aviation, and long-haul transport—are in desperate need of a fuel that’s powerful, portable, and pollution-free.

And that’s where hydrogen production electrolysis comes into play.

A Shift in the Energy Paradigm

Historically, most hydrogen has been produced from natural gas through a process called steam methane reforming (SMR), which emits significant amounts of CO₂. While cheaper, this “grey hydrogen” undermines the environmental promise of hydrogen as a clean fuel.

Now, the paradigm is shifting. With renewable energy prices plummeting and electrolyzer technology becoming more efficient, hydrogen production electrolysis is quickly becoming viable on a global scale. Countries like Germany, Japan, and Australia are investing billions into green hydrogen infrastructure.

Real-World Applications and Impact

Electrolytic hydrogen isn’t just for futuristic pilot projects—it’s already being used across sectors:

Transport: Hydrogen fuel cell vehicles are ideal for long-distance transport and public transit where battery weight and charging times are limiting.

Industry: Green hydrogen is being tested to replace coke in steelmaking, reducing one of the world’s most carbon-intensive processes.

Power Storage: Hydrogen acts as a clean energy storage medium. Excess renewable energy can be used to produce hydrogen during low-demand periods and then reconverted to electricity when needed.

Every one of these applications brings us closer to a circular, clean-energy economy—one that benefits both the climate and the communities that depend on industry.

The Human Side of Electrolysis

Here’s the thing: technology alone isn’t the hero in our climate story. People are.

Whether it's engineers designing more efficient electrolyzers, city planners envisioning hydrogen-fueled bus fleets, or families breathing cleaner air thanks to reduced industrial emissions—hydrogen production electrolysis impacts us all. It represents an alignment between technological progress and social responsibility.

Imagine a town once powered by coal, now hosting a hydrogen plant fueled by the sun. Jobs are not lost—they’re transformed. Children grow up near green facilities instead of smokestacks. This isn't science fiction—it’s beginning to happen.

Challenges on the Path

Of course, no revolution comes without resistance. Hydrogen production electrolysis faces hurdles:

Cost: Electrolyzers and green electricity still come at a premium, although economies of scale are rapidly improving this.

Infrastructure: We need hydrogen pipelines, storage facilities, and distribution networks, which require time and investment.

Public Awareness: Hydrogen safety, efficiency, and viability are still misunderstood by the general public, slowing adoption.

But these challenges are surmountable. With international collaboration, policy support, and public-private partnerships, the groundwork for a global hydrogen economy is already being laid.

Innovations Driving Change

Technology is evolving fast. Advances in solid oxide and proton exchange membrane (PEM) electrolyzers are improving efficiency and lowering costs. Meanwhile, AI-driven energy management systems are optimizing the timing and scale of hydrogen production.

Startups are experimenting with modular electrolyzer units, which could make hydrogen viable even in rural areas. And researchers are exploring seawater electrolysis, expanding the range of water sources that can be used.

All these innovations are making hydrogen production electrolysis not only more affordable but more adaptable to different regions and use cases.

Why You Should Care

Whether you’re an investor, a business owner, a policymaker, or just someone who wants a healthier planet for your kids—the rise of hydrogen matters to you. This isn’t just about switching fuels. It’s about rethinking how we power our world and who benefits from that transition.

When we support green hydrogen, we’re saying yes to cleaner skies, more resilient economies, and energy independence. We’re saying no to pollution, to climate instability, and to leaving future generations with a mess we could’ve prevented.

Looking Forward

The world is on the brink of an energy transformation. As we build new power systems, hydrogen will be one of the pillars. And at the core of this is hydrogen production electrolysis—a process that is simple in theory, but profound in its potential.

By investing in this technology, by educating ourselves, and by supporting clean-energy policies, we can ensure that the next generation inherits not just better technology—but a better world.

0 notes

Text

Industrial Gases: Trends, Growth, and Key Players

Industrial gases might not be the first thing that comes to mind when you think about global industries, but they play a crucial role in keeping everything running—from the oxygen in hospitals to the hydrogen fueling clean energy initiatives. These invisible powerhouses are the backbone of manufacturing, healthcare, electronics, food production, and more.

With the market projected to grow from $105.6 billion in 2023 to $137.9 billion by 2028, industrial gases are set to become even more vital in our daily lives. Let’s dive into what’s driving this growth and how these gases are shaping the future.

Why Are Industrial Gases So Important?

Imagine a world without industrial gases—factories would halt, hospitals would struggle, and food wouldn’t stay fresh as long. These gases touch almost every aspect of our lives:

Manufacturing & Welding: Oxygen and acetylene are used in welding, while nitrogen is crucial in preventing oxidation during production.

Healthcare: Oxygen therapy saves countless lives, and nitrogen helps preserve biological samples.

Electronics: Ultra-pure gases ensure the flawless production of semiconductors and displays.

Food & Beverages: Carbon dioxide is used to carbonate drinks and extend the shelf life of packaged food.

What’s Driving the Growth of Industrial Gases?

1. The Shift Towards Sustainability

As industries push for lower carbon footprints, green hydrogen is emerging as a game-changer. Produced using renewable energy, it is key to decarbonizing industries like steel, transportation, and power generation.

2. Technological Advancements

From advanced air separation technologies to real-time monitoring systems, technology is making industrial gases more efficient and sustainable. Companies are adopting automation and AI to optimize gas usage, reducing costs and environmental impact.

3. Expanding Healthcare Needs

The pandemic reminded the world of just how critical medical gases are. As healthcare systems expand, the demand for oxygen and other medical gases continues to rise, ensuring hospitals are prepared for any situation.

4. Industrial and Infrastructure Boom

Countries like China and India are experiencing rapid industrialization. More factories, more infrastructure projects, and more energy production mean a higher demand for industrial gases.

The Biggest Players in the Market

A global industrial gases companies dominate the industrial gases market, each bringing innovations and sustainability commitments:

Air Liquide (France): Leading the way in green hydrogen and gas solutions across 80+ countries.

Linde (UK): A pioneer in industrial gases, with a focus on clean energy technologies.

Air Products (USA): Investing heavily in hydrogen infrastructure for a sustainable future.

Messer (Germany): Specializing in industrial and medical gases with a customer-first approach.

Nippon Sanso (Japan): A key player in Asia, serving industries from electronics to healthcare.

What’s Next for Industrial Gases?

🔹 Green Hydrogen Revolution: Hydrogen-powered vehicles, factories, and even homes will become more common. 🔹 Digitalization & Smart Gas Solutions: AI-driven monitoring and automation will make gas distribution more efficient. 🔹 Stronger Regulations & Sustainability Goals: Companies will continue innovating to meet strict environmental standards. 🔹 New Industry Applications: From space exploration to biotechnology, industrial gases will unlock new possibilities.

Final Thoughts

Industrial gases may be invisible, but their impact is everywhere. Whether you’re breathing oxygen in a hospital, using a smartphone, or sipping a carbonated drink, these gases play a role in your daily life. As industries evolve and sustainability becomes a priority, the demand for industrial gases will only grow—bringing new innovations, cleaner energy, and more efficient production methods.

Get detailed insights by downloading the PDF brochure.

The next time you see a welding spark, a soda bubble, or even a hydrogen-powered car, take a moment to appreciate the invisible force that keeps our world moving.

#IndustrialGases#Sustainability#GreenHydrogen#Innovation#Manufacturing#Healthcare#Technology#IndustryTrends#CleanEnergy

0 notes

Text

Supply Chain Dynamics in the Green Ammonia Market

Green Ammonia Market: Trends, Growth Factors, and Future Outlook

The Green Ammonia Market is expected to grow at a compound annual growth rate (CAGR) of 70% from 2024 to 2033, from a projected value of USD 290 million in 2023 to USD 20.18 billion by 2033. Demand from producers of green chemicals and the electricity generation sector is propelling the market. In a similar vein, the worldwide drive for low-carbon and sustainable solutions will fuel market expansion.

Green Ammonia Market Trends and Analysis

Rising Adoption of Renewable Energy: With increased investment in wind and solar power, green ammonia production is becoming more viable and cost-effective.

Government Policies and Incentives: Various governments worldwide are supporting green ammonia projects with subsidies and incentives to promote sustainability.

Technological Advancements: Emerging technologies, such as electrolysis-based ammonia production, are expected to enhance efficiency and reduce production costs.

Expansion in Agriculture and Maritime Sectors: Green ammonia is being explored as a sustainable alternative for fertilizers and marine fuel, driving its market growth.

Decarbonization of Industry: Heavy industries, including steel and chemical production, are integrating green ammonia to reduce carbon emissions.

Request Sample PDF Copy:https://wemarketresearch.com/reports/request-free-sample-pdf/green-ammonia-market/1359

Green Ammonia Market Growth Factors

Increased Environmental Regulations: Stricter regulations on carbon emissions are compelling industries to adopt green ammonia.

Growing Hydrogen Economy: The development of the hydrogen economy positively impacts green ammonia production.

R&D Investments: Companies are investing heavily in research and development to optimize ammonia production and storage methods.

Strategic Partnerships: Collaborations between governments, research institutes, and private players are accelerating market growth.

Market Segments

Market, By Production

Electrolysis

Haber-Bosch Process with Carbon Capture and Utilization (CCU)

Biomass Gasification

Hydrothermal Gasification

Other Sustainable Production Methods

Market, By Application

Agriculture

Chemicals

Power Generation

Transportation

Refrigeration

Others

Market, By Product Form

Anhydrous Ammonia

Aqueous Ammonia Solution

Key Points of the Green Ammonia Market

The Green Ammonia Market Size is projected to expand significantly due to increasing demand for sustainable solutions.

The Green Ammonia Market Share is expected to be dominated by regions investing in renewable energy infrastructure.

The Green Ammonia Market Price may fluctuate based on production costs and technological advancements.

The Green Ammonia Market Forecast indicates robust growth, with industries focusing on carbon neutrality.

Benefits of Green Ammonia Market Report

Comprehensive Market Analysis: Detailed insights into market trends, drivers, and challenges.

Competitive Landscape: Information on key players and their strategies.

Investment Opportunities: Identification of profitable areas within the industry.

Strategic Recommendations: Guidance for stakeholders to make informed business decisions.

Challenges in the Green Ammonia Market

High Initial Investment: The cost of setting up green ammonia production plants remains a barrier.

Infrastructure Limitations: Lack of widespread infrastructure for ammonia storage and transportation.

Energy Intensity: High energy consumption during electrolysis poses a challenge.

Market Competition: Competition with traditional ammonia and alternative fuels.

Key Companies

Siemens Energy

Thyssenkrupp AG

MAN Energy Solutions

Nelasa

ITM Power

Mcphy Energy SA

Enapter Srl

Green Hydrogen Systems

Stamicarbon

Hygenco

Market Analysis By Region

North America is starting to embrace green ammonia as a sustainable agricultural nitrogen source. Green ammonia fits in with the area's goal of lessening the negative effects of agriculture on the environment, as there is an increasing emphasis on ecologically friendly and sustainable farming methods. State and federal regulations are beginning to provide incentives and assistance for the production of green ammonia. Green ammonia's ability to lower emissions and aid in the shift to a cleaner, more sustainable energy and agriculture sector is being acknowledged by governments.

FAQs

Q1: What is driving the growth of the Green Ammonia Market?

Q2: What industries benefit from green ammonia?

Q3: How does green ammonia contribute to sustainability?

Q4: What are the key challenges in the Green Ammonia Market?

Q5: What is the future outlook for the Green Ammonia Market?

Explore More Report:

Antimicrobial-Coatings-Market

https://medium.com/@priteshwemarketresearch/antimicrobial-coatings-market-analysis-type-size-trends-key-players-and-forecast-2024-to-2034-f644d5e8f094

Heat-Transfer-Fluids-Market

Global-Nanocomposites-Market

https://medium.com/@priteshwemarketresearch/global-nanocomposites-market-latest-trends-and-analysis-future-growth-study-by-2034-374bc36be5d6

Global-Green-Solvent-Market

https://medium.com/@priteshwemarketresearch/global-green-solvent-market-growth-trends-analysis-and-dynamic-demand-forecast-2024-to-2034-6cf30e39c8de

Industrial Lubricants Market:

https://wemarketresearch.com/reports/industrial-lubricants-market/1356

3D Printing Materials Market:

https://wemarketresearch.com/reports/3d-printing-materials-market/1338

Conclusion

The Green Ammonia Market is poised for significant growth, driven by the global shift toward sustainability. Despite challenges, ongoing Ammonia Market Investments in technology and infrastructure are expected to boost its adoption, making it a key player in the transition to a greener future.

About We Market Research:

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep-rooted market studies and insightful analysis of different markets.

Our strategic market analysis and capability to comprehend deep cultural, conceptual and social aspects of various tangled markets has helped us make a mark for ourselves in the industry. WE MARKET RESEARCH is a frontrunner in helping numerous companies; both regional and international to successfully achieve their business goals based on our in-depth market analysis. Moreover, we are also capable of devising market strategies that ensure guaranteed customer bases for our clients.

Contact Us:

Mr. Robbin Joseph

Corporate Sales, USA

We Market Research

USA: +1-724-618-3925

Websites: https://wemarketresearch.com/

Email: [email protected]

#GreenAmmonia#SustainableFertilizers#RenewableEnergy#GreenHydrogen#CleanTechnology#Decarbonization#AmmoniaProduction#CarbonFreeFuel#RenewableEnergySolutions

0 notes

Text

Can Sunlight Solve Our Energy Crisis ! This Japan's Reactor Says.... | @researchatory

Japan's groundbreaking solar-powered water-splitting reactor paves the way for a hydrogen-fueled future! This futuristic reactor harnesses the power of the sun to split water into hydrogen fuel, a major step towards a sustainable energy future. #GreenHydrogen #CleanEnergy #Innovation #RenewableEnergy #HydrogenFuel #SolarEnergy #Sustainability #GreenHydrogen #ClimateAction #Innovation #TechNews #FutureOfEnergy #Science #Research

In essence, the research in Japan represents a promising step towards a cleaner and more sustainable energy future.

By @imaakashkhurana For more details join our medium page. (https://medium.com/@researchatory)

#GreenHydrogen#CleanEnergy#Innovation#RenewableEnergy#HydrogenFuel#SolarEnergy#Sustainability#ClimateAction#TechNews#FutureOfEnergy#Science#Research

1 note

·

View note

Text

#UnionBudget2025#economictransformation#AI#cleantechnology#cybersecurity#semiconductor#automation#Cleanenergy#greenhydrogen#renewables#electricvehiclesnews#evtimes#autoevtimes#evbusines

0 notes

Text

At Autometers Energitec Ltd, we are dedicated to delivering energy-efficient solutions that help our partners meet their goals while minimizing their carbon footprint. From innovative oil & gas solutions to green hydrogen and custom-built systems, our proven expertise ensures efficient and sustainable energy processes worldwide.

Explore how our advanced process skids and cutting-edge technology can transform your operations.

To learn more about how we can support your energy needs, visit our website https://lnkd.in/dJ77VqDJ or reach out to us at [email protected]

#energyefficiency#oilandgas#greenhydrogen#sustainableenergy#custodymetering#gasfiltration#modularskids#autometersenergitec#branding#economy#marketing

1 note

·

View note

Text

Hydrogen Fuel Cell Market — Forecast(2025–2031)

𝐓𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐂𝐥𝐞𝐚𝐧 𝐄𝐧𝐞𝐫𝐠𝐲: 𝐄𝐱𝐩𝐥𝐨𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐇𝐲𝐝𝐫𝐨𝐠𝐞𝐧 𝐅𝐮𝐞𝐥 𝐂𝐞𝐥𝐥 𝐌𝐚𝐫𝐤𝐞𝐭 | IndustryARC™

The global hydrogen fuel cell market size was valued at $2.7 billion in 2021, and is projected to reach $5.7 billion by 2031, growing at a CAGR of 8.1% from 2022 to 2031.

👉𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕

🔹The hydrogen fuel cell market refers to the industry focused on the production, development, and deployment of #hydrogen_fuel_cell technology, which generates #electricity through a chemical reaction between hydrogen and #oxygen, with water as the primary byproduct. This technology is seen as a #clean_energy solution, offering an alternative to traditional fossil fuels and helping reduce greenhouse gas emissions.

🔹A hydrogen fuel cell is a device that converts hydrogen and oxygen into water while simultaneously generating electricity. In a hydrogen fuel cell device, chemicals are continuously pumped into the cells, preventing the battery from running out. The market for hydrogen fuel cells is being driven by the increase in demand for electric vehicles.

🔹The Accelerating Clean Hydrogen initiative has over 200 members from 60 organizations, including public and private stakeholders dedicated to accelerating the development of the clean hydrogen economy. The initiative leverages its network of global organizations to collaborate on hydrogen.

📊 𝐆𝐞𝐭 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭

✅𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐯𝐞 𝐭𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐞𝐬 𝐟𝐨𝐫 𝐭𝐡𝐞 𝐇𝐲𝐝𝐫𝐨𝐠𝐞𝐧 𝐅𝐮𝐞𝐥 𝐂𝐞𝐥𝐥 𝐌𝐚𝐫𝐤𝐞𝐭

∘Solid-State Hydrogen Storage

∘Electrolyzer Advancements

∘Fuel Cell Efficiency

∘Fuel Cell Vehicles (FCVs)

∘Hydrogen as a Grid Storage Solution

∘Hydrogen Infrastructure Development

∘Hydrogen-Integrated Industrial Applications

Get this Report on discount of $1000 on purchase of Credit Card

✅ 𝗞𝗲𝘆 𝗖𝗼𝗺𝗽𝗮𝗻𝗶𝗲𝘀 𝗣𝗿𝗼𝗳𝗶𝗹𝗲𝘀 𝗚𝗶𝘃𝗲𝗻 𝗶𝗻 𝘁𝗵𝗶𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗥𝗲𝗽𝗼𝗿𝘁: Bloom Energy | Intelligent Energy | FuelCell Energy | FuelCell Energy Solutions GmbH | Ballard Power Systems | Plug Power | Plug In Power Solutions | Ceres | AFC Energy | Doosan Fuel Cell | Nedstack Fuel Cell Technology | SFC Energy AG | Schaeffler | ACT Expo / ACT News | Gore Alternative Energy & Storage | Hyundai Commercial Vehicle and Hydrogen Business | Freudenberg Sealing Technologies | Cummins Europe | Lead Intelligent Equipment | Transportation | Parker Hannifin | Zero Emission Ports North Sea — ZEM Ports NS | 美锦能源股份有限公司 |

#HydrogenEnergy#FuelCellTechnology#GreenHydrogen#RenewableEnergy#SustainableTech#CleanEnergy#Innovation#ClimateAction#HydrogenFuelCells#FutureOfEnergy#EcoFriendly#ZeroEmissions#EnergyStorage#HydrogenEconomy#ElectricVehicles#TechInnovation#Renewables#GreenTech#CleanTech#FutureOfTransport#EnergyTransition

0 notes

Text

Green Hydrogen

Green Hydrogen Massive green hydrogen capacity around Tuticorin: More on what is going on There are plans for a massive green energy hub in Tuticorin Here are the plans By 2027: 508,080 metric tons of Green Hydrogen capacity By 2028: 508,080 metric tons of Green Hydrogen (cumulative, same as 2027 since demand remains constant) By 2029: 989,004 metric tons of Green Hydrogen capacity By 2030: 1,229,028 metric tons of Green Hydrogen capacity Find out what kind of background work is going on

0 notes

Text

"𝐏𝐨𝐰𝐞𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞: 𝐒𝐚𝐟𝐞, 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐭, 𝐚𝐧𝐝 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐥𝐞 𝐇𝐲𝐝𝐫𝐨𝐠𝐞𝐧 𝐒𝐭𝐨𝐫𝐚𝐠𝐞 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬" | IndustryARC™

The Hydrogen Storage market size is forecast to reach US$7.2 billion by 2030, after growing at a CAGR of 19.7% during 2024-2030.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐚𝐠𝐞𝐬 𝐍𝐨𝐰

Hydrogen storage plays a pivotal role in the growing hydrogen economy, enabling the safe and efficient storage of hydrogen for diverse applications. It is essential for the transportation, industrial, and energy sectors, facilitating the use of hydrogen as a clean fuel and energy source.

In the transportation sector, hydrogen is stored for use in fuel cell electric vehicles (FCEVs), offering a zero-emission alternative to conventional fossil fuel-powered vehicles. Hydrogen storage systems, such as compressed hydrogen tanks and liquid hydrogen storage, enable long driving ranges and quick refueling times.

Industrially, hydrogen is used in refining, ammonia production, and as a feedstock in various chemical processes. Storage systems allow for a stable and continuous supply of hydrogen to meet production demands, even during peak periods.

For renewable energy integration, hydrogen acts as an energy carrier and storage medium. Excess renewable energy (e.g., from solar or wind) can be used to produce hydrogen via electrolysis, which is then stored and later converted back into electricity or used for heating when demand exceeds production.

With growing emphasis on reducing carbon emissions, hydrogen storage technologies are crucial for advancing clean energy solutions, offering the potential for a more sustainable, flexible, and resilient energy system.

#HydrogenEconomy#SustainableEnergy#CleanEnergySolutions#HydrogenInnovation#EnergyTransition#HydrogenStorageTech#GreenHydrogen#FutureEnergy#HydrogenPower#NetZeroGoals

0 notes

Text

🌱 Green Hydrogen: The Future of Clean Energy 💡

Green hydrogen is making waves as a clean, sustainable alternative to fossil fuels, but what makes it so promising, and how can it transform our energy systems?

💰 Current production costs: $3–$6/kg globally. 📉 Future outlook: By 2030, costs could drop to $1–$2/kg, making green hydrogen as affordable as traditional fuels. 🌞 What’s driving the shift?

Falling renewable energy prices.

Advances in electrolyzer technology.

Strong global policies and investments.

🚧 The challenges?

High initial costs for production infrastructure.

Efficiency hurdles in energy conversion.

Supply chain issues for critical components.

Despite these obstacles, green hydrogen is set to revolutionize industries, decarbonize transportation, and support renewable energy grids.

🌍 Want to dive deeper? Check out our latest blog: 👉 The Economics of Green Hydrogen: Cost Trends and Future Projections

Let’s reimagine the future of clean energy together. 🌟

0 notes

Text

Hydrogen Power Plant: The Quiet Revolution in Clean Energy

As the world turns a critical eye toward climate change and carbon emissions, a quiet but powerful transformation is happening in the energy sector—ushered in by the hydrogen power plant. While solar and wind often steal the spotlight, hydrogen is emerging as a reliable, scalable, and clean energy source with the potential to reshape our future.

Unlike conventional power plants, a hydrogen power plant doesn't rely on fossil fuels to generate electricity. Instead, it uses hydrogen—a simple element with extraordinary energy potential. Through a process known as fuel cell technology, hydrogen is combined with oxygen to produce electricity, and the only by-product? Water vapor. Imagine that: power with zero emissions.

But it's not just about being green. The real power of hydrogen lies in its flexibility. A hydrogen power plant can serve as a backup for solar and wind, storing excess renewable energy and delivering it when the sun isn’t shining or the wind isn’t blowing. That makes it a key player in solving the intermittency problem of renewables—a challenge that has long held back the full-scale shift to clean energy.

From powering entire cities to fueling heavy industries and even airplanes, the potential applications are vast. Countries like Japan, Germany, and Australia are already investing billions into hydrogen infrastructure, seeing it as a cornerstone of their net-zero strategies.

Let’s face it, the transition to a greener planet isn’t just about the tech—it’s about us. It’s about the air we breathe, the jobs we create, and the legacy we leave behind. By supporting innovations like the hydrogen power plant, we’re not just adopting new energy—we’re embracing a cleaner, smarter, and more sustainable way of life.

0 notes

Text

⚡️ Harnessing the Power of Hydrogen to Fuel a Cleaner, Greener Future 🌍💧 #HydrogenEnergy #CleanEnergy #SustainableFuture #GreenHydrogen #RenewableEnergy #EnergyTransition #HydrogenPower #Decarbonize #FutureOfEnergy

#HydrogenEnergy#CleanEnergy#SustainableFuture#GreenHydrogen#RenewableEnergy#EnergyTransition#HydrogenPower#Decarbonize#FutureOfEnergy

0 notes

Text

The Future of Shipping: Hydrogen Fuel Cells and Maritime Transport

Shipping has always been the backbone of global trade, but it comes with a huge environmental cost. The ships we rely on to carry goods across the oceans burn fossil fuels that release harmful emissions like carbon dioxide (CO2) and sulfur oxides (SOx). However, a cleaner, greener future for maritime transport is on the horizon – thanks to hydrogen fuel cells.

Hydrogen fuel cells offer a zero-emission solution that could revolutionize the shipping industry. Instead of burning oil, these fuel cells use hydrogen to produce electricity, with water vapor as the only byproduct. This means no harmful emissions, no pollution, and a much smaller carbon footprint.

More details: https://www.xinrenresearch.com/reports/global-hydrogen-fuel-cells-for-maritime-transport-market/

Here’s why hydrogen fuel cells could be the future of shipping:

Zero Emissions: Hydrogen fuel cells produce only water and heat, making them one of the cleanest technologies available.

Efficiency: These fuel cells are highly efficient and can power even the largest ships.

Sustainability: Hydrogen can be produced from renewable energy sources like wind and solar, making it a truly green fuel option.

Flexibility: From small ferries to massive cargo ships, hydrogen fuel cells can be scaled for a variety of ship types.

However, there are still challenges to overcome, such as the cost of producing green hydrogen and the lack of infrastructure for refueling hydrogen-powered ships. But with advancements in technology and growing global support for sustainable solutions, it’s only a matter of time before hydrogen fuel cells become a key player in maritime transport.

The shipping industry is at a crossroads, and hydrogen fuel cells offer a clear path to a cleaner, more sustainable future. 🌍⚓️

More reports: https://www.xinrenresearch.com

#hydrogenfuelcells#maritimetransport#sustainableshipping#cleanenergy#greenhydrogen#climatechange#futuristicshipping#hydrogenpower#oceantransport#zerocarbon#cleanfuture#sustainabletechnology#shippingindustry#greenfuture#renewableenergy#eco-friendlyshipping

0 notes

Text

Hydrogen Plants: Driving the Transition to Green Energy More Info:https://www.transparencymarketresearch.com/hydrogen-plants-market.html

The Hydrogen Plants Market is experiencing significant growth as global demand for clean and renewable energy sources rises. Hydrogen, a key component in the transition to carbon-neutral energy systems, is being increasingly produced in specialized plants. These plants leverage various technologies, including electrolysis and natural gas reforming, to generate hydrogen with minimal environmental impact. With governments and industries investing heavily in green hydrogen projects, the market is set to play a pivotal role in the future of energy production.

0 notes

Link

0 notes