#Instrument Valves

Explore tagged Tumblr posts

Text

Understanding Instrument Valves and Their Importance in Industrial Applications

In industrial systems, precision and reliability are paramount, especially in processes involving the measurement and control of fluids. Instrument valves, a critical component of these systems, ensure safe and efficient operation. At Avlok, we take pride in manufacturing high-quality instrument valves designed to meet the rigorous demands of modern industries. In this blog, we will explore the types, functions, and applications of instrument valves, highlighting their significance in various sectors.

What Are Instrument Valves?

Instrumentation valves are specialized valves used in fluid control systems to regulate, isolate, or vent fluids. These valves are integral to instrumentation systems, ensuring accurate measurement and control in processes like oil and gas extraction, chemical processing, pharmaceuticals, and more. They are designed for precision, often employed in systems that demand high pressure and temperature handling capabilities.

At Avlok, we specialize in manufacturing robust instrument valves that meet international standards, providing reliability and performance in diverse applications.

Types of Instrument Valves

There are several instrument valve types, each serving a unique purpose. Here are the most common types:

1. Ball Valves

Ball valves are widely used for their simplicity and effectiveness. They feature a rotating ball with a hole that allows or blocks fluid flow when turned. These valves are ideal for quick shut-off applications and offer high durability and reliability. We are a leading ball valve manufacturers.

2. Needle Valves

Needle valves provide precise control of fluid flow. They are commonly used in systems where minute adjustments are required, such as in laboratory or instrumentation setups. We are a leading needle valves manufacturers.

3. Manifold Valves

Manifold valves combine multiple valve functions into a single unit, reducing the need for separate valves. They are used in pressure and differential pressure instruments for isolation, equalization, and venting purposes.

4. Check Valves

Check valves allow fluid to flow in one direction only, preventing backflow and protecting sensitive equipment. These valves are essential in maintaining system integrity and efficiency. We are a leading check valve manufacturers.

5. Gauge Valves

Gauge valves are used to isolate pressure gauges from the main process, ensuring accurate readings and protecting the gauges from damage.

Key Applications of Instrument Valves

Instrument valves play a vital role in various industries, including:

1. Oil and Gas

In the oil and gas sector, instrument valves are used in exploration, production, and refining processes to control and monitor fluid flow under extreme conditions.

Avlok's valves are trusted by industry leaders for their durability and performance.

2. Chemical and Petrochemical

Chemical plants rely on instrument valves for precise control of corrosive and high-temperature fluids.

Our corrosion-resistant valves ensure safe and efficient operations in such challenging environments.

3. Pharmaceuticals

Precision is critical in the pharmaceutical industry, where instrument valves are used in processes like filtration, mixing, and sterilization.

Avlok's valves meet stringent hygiene and precision standards, making them ideal for pharmaceutical applications.

4. Power Generation

Power plants utilize instrument valves to regulate steam, water, and other fluids in high-pressure systems.

Our valves are designed to handle the rigorous demands of power generation systems.

Why Choose Avlok for Instrument Valves?

As a leading, Avlok combines innovation, quality, and expertise to deliver products that exceed industry standards. Here are some reasons to choose Avlok:

Unmatched Quality: Our valves are made from premium materials and undergo rigorous testing to ensure reliability and durability.

Customization: We offer tailored solutions to meet specific customer requirements, ensuring seamless integration into your systems.

Global Standards: Avlok's products comply with international quality standards, giving you peace of mind.

Expert Support: Our team of experts provides guidance and support to help you select the right valves for your application.

Conclusion

Instrument valves are indispensable in industrial applications, providing precision, safety, and efficiency. At Avlok, we are committed to delivering top-notch instrument valves that meet the highest standards of quality and performance. Whether you are in the oil and gas industry, pharmaceuticals, or any other sector, our valves are designed to cater to your specific needs.

For more information about our range of instrument valves, feel free to contact us or visit our website. Trust Avlok for all your instrument valve requirements and experience unparalleled quality and service.

#Instrument Valves#Instrumentation valves#ball valve manufacturers#needle valves manufacturers#Manifold valves#check valve manufacturers

1 note

·

View note

Text

Arcellor Controls: Top Supplier of Instrument Valves

At Arcellor Controls, we take satisfaction in being the pinnacle supplier of device valves inside the industry. With our determination to exceptional and reliability, we offer a extensive variety of precision-engineered instrument valves designed to fulfill the various wishes of our clients. Whether you require valves for drift manipulate, strain regulation, or isolation, our products are constructed to deliver incredible overall performance in diverse programs. Backed by way of years of revel in and a commitment to excellence, Arcellor Controls guarantees that our device valves adhere to the highest standards of craftsmanship and sturdiness. Trust us to offer you with the solutions you want in your instrumentation structures, making sure easy operations and best overall performance. Choose Arcellor Controls as your chosen instrument valves supplier and revel in unmatched quality and carrier.

0 notes

Text

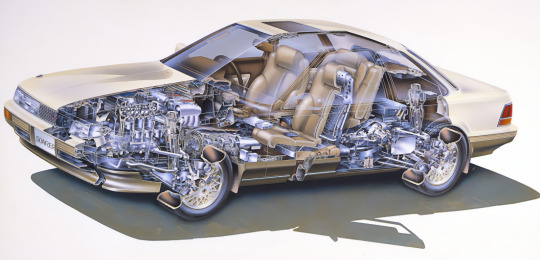

Toyota Soarer 3.0 GT-Limited, 1986. The second generation Z20 Soarer shared its platform with the A70 series Supra. It introduced the Electro Multi Vision digital vehicle information display. The 3.0 GT was powered by a DOHC 24 valve turbocharged straight 6

#Toyota#Toyota Soarer#Toyota Soarer Z20#1986#sports coupé#straight 6#24 valve#DOHC#digital instrumentation

311 notes

·

View notes

Text

Still Alive (Radio Mix) // Portal (2007)

#portal#portal (game)#still alive#playstation 3#xbox 360#PC#valve#game#instrumental#2007#oktaviaslabyrinth

36 notes

·

View notes

Text

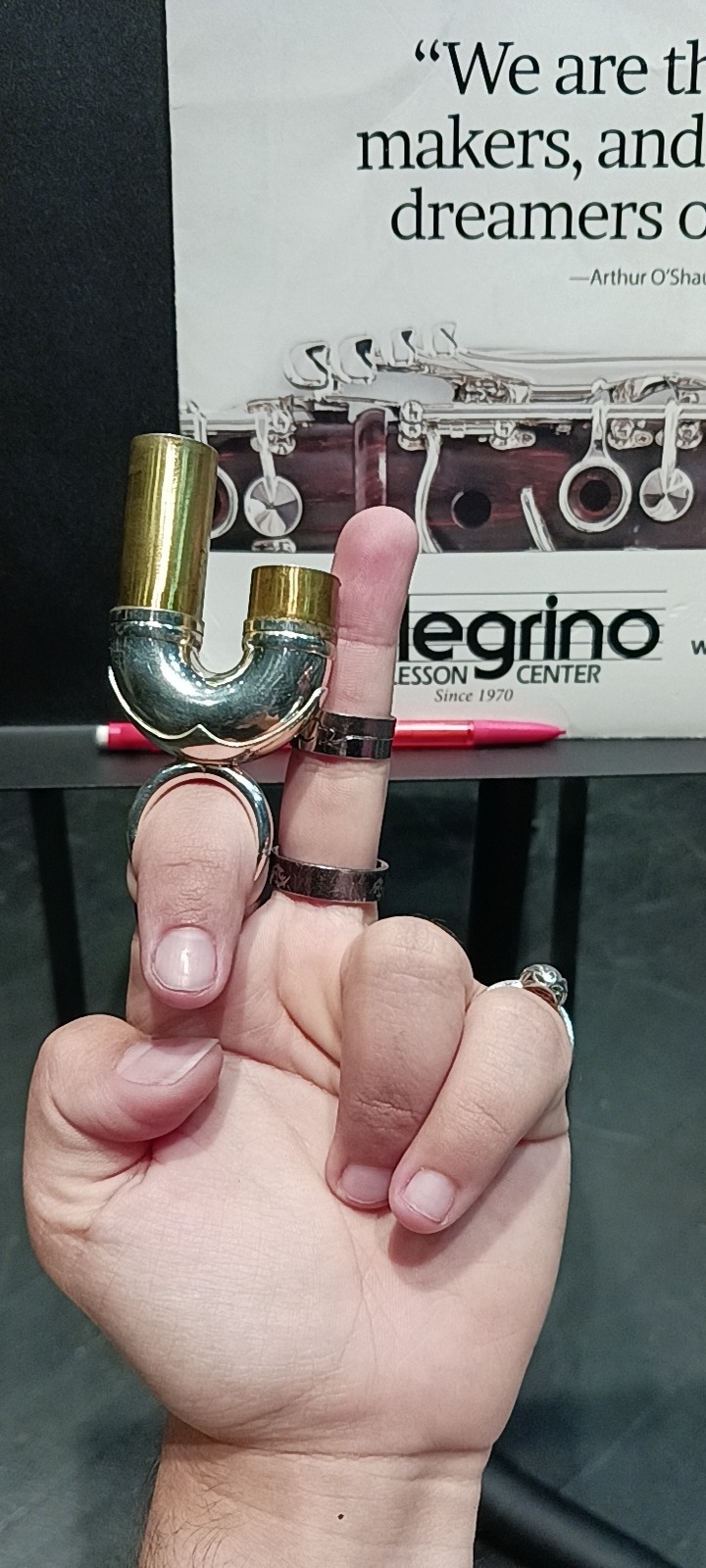

They need to add more stupid attachment thingies to instruments. Instruments need to get scrunklier.

#-Loki#instruments#trombone#F trigger trombone#trumpet#euphonium#compensating valve euphonium#french horn#double french horn#triple french horn#Music

9 notes

·

View notes

Text

Understanding the meaning, applications, and advantages of control valves.

Control valves are devices that play an essential role in controlling and regulating the flow, pressure, and temperature in industrial processes and control systems. It is installed in the field-level area of the automation pyramid and connected to the control system and PLC through the PLC’s hardware. The global control valve consists of the body, actuator, Positioner, Valve trim, stem, and bonnet to prevent leakage. There are also the Gaskets and seals that are used when connecting the valve with other mechanical parts.

Control valves have many advantages such as Accurate Control of Process Parameters, Easy Automation Compatibility by integrating these items with the main Control systems (DCS and PLC), Energy saving and energy efficiency by optimizing the process condition and minimizing waste, maintaining safe operating conditions and increase process safety factors, Improve Process Efficiency and Increase Product Quality.

Control valves are used in many applications such as the Automotive Industry, Cement and steel, and Oil and Gas Industry, especially in gas valve trains, Renewable Energy, and HVAC Systems.

For full article check the following link:

For more articles about Renewable, Automation and Instrumentation, check the following link:

www.ecaico.com

#automation#instrumentation#renewable#control system#plc#sensors#pressure#gas valve#industrial valves

2 notes

·

View notes

Text

AHHHH THE SPIT. THE SPIT GOT ON ME.

hee...heugh...heeeughh...

#i HATE this instrument#i love tjis instrument :)#the spit valve...finger in the wrong spot...#AHHHHHH#trombone#band!!!!

5 notes

·

View notes

Text

Wait fuck I’m learning a wind instrument. The band kids fucking won.

#chit chat#DAMN it#all throughout high school the marching band kids wanted me to become one of them#and i said I’d never take up mouth instruments because they were gross#and now...#sigh#i do admit that i do find the harmonica a little gross and i do have to try and wipe it down after every exercise#but i don’t have to deal with spit valves or reeds or whatever the flutes do#so there is that#harmonica adventures

6 notes

·

View notes

Text

Shitty soldering job, right?

WRONG

That, my friends, is epoxy.

This one got filed under "haha NOPE" because the cost of the repair would not have been worth it. Epoxy does not melt and wipe off the way solder does; I would have had to basically chisel it off, and who knows how long that would have taken me.

#musical instrument repair#music#brass instrument#brasswind#musical instrument#cornet#epoxy#this is what we in the industry often refer to as a “dad fix”#because 9/10 times it is a kid's dad that does stuff like this#moms do it too but in less destructive ways#like telling the kid who forgot to bring valve oil to just use vegetable oil on the valves because oil is oil#less damaging but still a pain#it is well-intentioned but please just don't#or do since then I get paid to fix the problem

2 notes

·

View notes

Text

Band of 107th U.S. Colored Infantry at Fort Corcoran, Arlington, Va. holding saxhorn brass valve instruments. These saxhorns were the type of instruments played at the funeral of African Civil War hero and Captain Andre Cailloux. Many of the instruments were played over the shoulder to play to the army following the band. Instruments today face forward and bands can be in the middle or back of a procession.

Library of Congress

Smith, William Morris, photographer

Created / Published

1865

#african#afrakan#kemetic dreams#africans#brownskin#brown skin#afrakans#library of congress#william morris#1865#fort corocran#arlington#va#saxhorn brass#valve instruments#civil war heros#photographers#photographer

16 notes

·

View notes

Text

Whoever pioneered making a valve this shape should be shot

#euphonium#baritone#tuba#low brass#brass#brass instrument#valves#brass valves#valve instrument#2nd valve

4 notes

·

View notes

Text

I started renting a valve trombone from my school a few days ago and I can say, with full confidence, that it is now one of my favorite instruments. It’s like a trumpet, but bigger and lower and 1000 times cooler. The only thing cooler than it is the tuba, because nothing can compare to the tuba.

4 notes

·

View notes

Text

What to Consider When Selecting Instrumentation Valves? - Arcellor Controls India

Instrumentation valves play a crucial role in the performance and efficiency of various industrial processes. They are designed to control the flow of liquids and gases in various systems, ensuring that the desired levels of pressure, temperature, and flow rate are maintained. With the wide range of instrumentation valves available in the market, selecting the right one for your specific needs can be overwhelming.

At Arcellor Controls India, we are committed to providing our customers with high-quality instrumentation valves that meet their specific requirements. As the leading supplier, stockiest, exporter, and manufacturer of instrumentation valves, we have a wealth of experience in this field. In this blog post, we will guide you through what you should consider when selecting the right instrumentation valves for your needs.

Instrumentation Valves:

Instrumentation valves are used in process control systems to regulate the flow of fluids, gases, and other materials. These valves are designed to provide precise control over flow rates, pressures, and temperatures, making them an integral part of many industrial processes.

Instrumentation valves are different from other types of valves in that they are designed to provide accurate and repeatable flow control in high-pressure, high-temperature, and corrosive environments. They are often made from materials such as stainless steel, brass, and exotic alloys, which are resistant to corrosion and erosion.

Types of Valves in Instrumentation

With us, at Arcellor Controls (India) we offer several types of valves used in instrumentation, including:

Ball Valves:

These are valves that use a rotating ball to control the flow of fluids. They are ideal for use in high-pressure applications and are known for their durability and reliability.

Needle Valves:

These are valves that use a small, tapered needle to control the flow of fluids. They are ideal for use in low-flow applications and are known for their precision and accuracy.

Globe Valves:

These are valves that use a disc to control the flow of fluids. They are ideal for use in applications where precise flow control is required.

Manifold Valves:

Manifold valves are designed to combine multiple valves into a single unit to simplify installation and maintenance. They are commonly used in applications where space is limited or where multiple valves need to be installed in close proximity to each other.

At Arcellor Controls India, we offer a range of manifold valves, including 2-way, 3-way, and 5-way valves, in various sizes and materials to suit different applications.

Check Valves:

Check valves, also known as non-return valves, are designed to allow fluid flow in one direction and prevent backflow in the opposite direction. They are commonly used in applications where backflow can cause damage to the system or where flow reversal is not desirable.

We offer a range of check valves, including ball check valves, swing check valves, and piston check valves, in various sizes and materials to suit different applications.

Monoflange Valves:

Monoflange valves are compact, single-unit valves designed to replace traditional multi-valve systems. They are commonly used in applications where space is limited or where weight reduction is desired.

At Arcellor Controls India, we offer a range of mono flange valves, including block and bleed valves, Block and Bleed Valve 3, Block and Bleed Valve 7, and Block and Bleed Valve 11 in various sizes and materials to suit different applications.

Valve Accessories:

Valve accessories are components that are designed to enhance the performance of valves or to provide additional functionality. They include items such as valve positioners, limit switches, and solenoid valves.

At Arcellor Controls India, we offer a range of valve accessories to suit different types of instrumentation valves, including 3 Way Gauge Cock Valves, 2 Way Gauge Cock Valves, Pulsation Dampener/Snubber, Bleed Vent Valves, and Gauge Saver (Pressure Overload Protectors).

Materials Available with Instrumentation Valves

With Arcellor Controls India, we manufacture instrumentation Valves in Various materials including;

Stainless Steel

Carbon Steel Alloys

Duplex & Super Duplex

Hastelloy

Monel

Inconel

Factors to Consider When Selecting Instrumentation Valves

Selecting the right instrumentation valve requires careful consideration of various factors, including:

Operating Conditions:

The operating conditions of your system play a crucial role in determining the type of valve you need. Consider the following factors:

Temperature: The temperature of the media affects the material of construction of the valve. High-temperature applications require valves made of materials that can withstand high temperatures.

Pressure: The pressure of the media determines the pressure rating of the valve. Ensure that the valve you select can withstand the pressure of your system.

Flow rate: The flow rate of the media determines the size of the valve. Ensure that the valve you select can handle the required flow rate.

Medium: The type of media being transported affects the material of construction of the valve. Ensure that the valve you select is compatible with the media.

Material of Construction:

The material of the construction of the valve affects its durability and resistance to corrosion. Consider the following factors:

Compatibility with the medium: The material of construction of the valve must be compatible with the medium being transported.

Resistance to corrosion: Valves used in corrosive environments must be made of materials that can withstand corrosion.

Temperature resistance: High-temperature applications require valves made of materials that can withstand high temperatures.

Pressure resistance: Valves used in high-pressure applications must be made of materials that can withstand high pressures.

End Connections:

The end connections of the valve determine how it connects to the system. Consider the following types of end connections:

Threaded: Threaded-end connections are easy to install and remove.

Flanged: Flanged end connections provide a secure and leak-proof connection.

Welded: Welded end connections are permanent and provide a leak-proof connection.

Compression: Compression end connections are commonly used in low-pressure applications.

Control Mechanism:

The control mechanism of the valve determines how it is operated. Consider the following types of control mechanisms:

Manual valves: Manual valves are operated manually and require human intervention to regulate the flow.

Pneumatic valves: Pneumatic valves use compressed air to regulate the flow. These valves offer fast and precise control and are commonly used in automated systems.

Electric valves: Electric valves use an electric signal to regulate the flow. These valves offer precise control and can be integrated with other electrical components in the system.

Hydraulic valves: Hydraulic valves use hydraulic fluid to regulate the flow. These valves are commonly used in high-pressure applications.

Valve Features

In addition to the above factors, you should also consider the following valve features when selecting instrumentation valves:

Shutoff capabilities: Valves with good shutoff capabilities ensure that there is no media leakage when the valve is closed.

Flow control capabilities: Valves with good flow control capabilities ensure that the media flow can be precisely regulated.

Maintenance requirements: Valves that require frequent maintenance can result in downtime and increased costs. Consider selecting valves that require minimal maintenance.

Size: The size of the valve should be suitable for the space available in the system.

Why Choose Arcellor Controls (India) for Instrumentation Valves Needs?

When selecting instrumentation valves, it's essential to choose a reliable manufacturer, supplier, stockiest, and exporter who can provide you with high-quality valves at competitive prices. At Arcellor Controls India, we have years of experience in designing and manufacturing high-performance valves for various applications.

We have a wide range of instrumentation valves, including Needle Valves, Ball Valves, Gate Valves, Globe Valves, Manifold Valves, Check Valves, Monoflange Valves, and Valves Accessories. We use high-quality materials and advanced manufacturing processes to ensure that our valves meet the highest standards of quality and performance.

We also have a vast network of suppliers and stockiest, which allows us to offer our customers quick and efficient delivery of valves, regardless of their location. We are also well-known exporters of instrumentation valves to various countries, including Oman, Qatar, USA, Germany, UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia, at the most competitive prices.

Final Words!..

Selecting the right instrumentation valve for your industrial needs is crucial to the success of your processes and equipment. By considering factors such as pressure rating, temperature range, flow control, size, material, and end connections, you can choose the valve that best suits your needs. Arcellor Controls India is a trusted supplier of instrumentation valves, providing high-quality products, customization options, competitive pricing, timely delivery, and excellent customer support.

Choosing Arcellor Controls India as your supplier can help ensure that your industrial processes and equipment run smoothly and efficiently.

#instrument valves#instrument valve#instrumentation valves#valves instruments#valve instruments#valves and instruments#valves in instrumentation#instrumentation valves manufacturer#valves for instrumentation#types of valves in instrumentation#instrument valves supplier#instrumentation valves supplier in india#needle valves#BallValves#HighPressureValves#ValveDurability#ReliableValves#NeedleValves#LowFlowValves#PreciseFlowControl#GlobeValves#FlowControlSolutions#ManifoldValves#SpaceSavingValves#InstallationAndMaintenance#CheckValves#NonReturnValves#BackflowPrevention#MonoflangeValves#CompactValves

0 notes

Text

From my experience with the more cursed instruments I gotta say they all would make really great spell focuses for bards and even better magic wands adjacent things. The three most cursed instruments might have to be the Bassoon, Sarrusophone, and valved Trombone, each something that feels magical all differently...

#Sarrusophone#bassoon#wizard#wizard posting#band#valved Trombone#bard#musical instruments#having tried playing them all the Bassoon is the only one that i ended up buying

5 notes

·

View notes

Text

Trunnion ball valve suppliers & manufacturers in Dubai, UAE | Instruments Fittings

Dubai, the thriving business hub of the UAE, is home to a wide variety of industries requiring awesome components to maintain their operations. Among the critical components for diverse commercial applications are trunnion ball valves. These valves are designed for durability, performance, and reliability, making them vital in industries that include oil and gas, petrochemicals, water treatment, and production. This blog explores the leading trunnion ball valve providers, sellers, and manufacturers in Dubai-UAE, losing mild on why these valves are a favored preference for crucial operations.

What Are Trunnion Ball Valves?

Trunnion ball valves are specialized forms of ball valves that characterize a pivot or trunnion to aid the ball inside the valve. Unlike preferred ball valves, in which the ball is free to move, trunnion ball valves have a mechanical anchoring device that enhances their operational performance. This design is specifically useful for managing high-stress systems as it guarantees higher sealing, reduced put-on, and longer provider lifestyles.

The versatility and robust design of trunnion ball valves lead them to be perfect for traumatic programs in industries wherein reliability is non-negotiable. Whether it’s coping with the drift of oil and fuel or coping with corrosive chemicals inside the petrochemical area, trunnion ball valves providers in Dubai offer products that supply top-notch performance.

Leading Trunnion Ball Valve Manufacturers in Dubai-UAE

Dubai’s commercial landscape is exceedingly competitive, and corporations rely upon quality products to preserve their aspect. Trusted trunnion ball valve producers inside the region make certain their valves meet the very best standards of durability and overall performance. Here are a few key motives why deciding on local manufacturers advantages businesses:

Customised Solutions: Manufacturers in Dubai apprehend the precise demands of the location’s industries and provide tailored trunnion ball valves to meet precise desires.

High-Quality Standards: With a dedication to excellence, Dubai-primarily based trunnion ball valve manufacturers ensure their products adhere to global satisfactory standards.

Faster Turnaround: Choosing neighborhood manufacturers reduces delivery instances, making sure that organizations face minimal downtime.

Technical Support: Manufacturers in Dubai offer sturdy technical assistance, providing steerage on valve choice and renovation.

At Instrument Fittings, our aim is to offer pinnacle-notch additives, together with trunnion ball valves, that set new benchmarks for quality and sustainability within the fittings and fasteners industry.

Reliable Trunnion Ball Valve Suppliers in Dubai-UAE

For industries working in excessive stress and high-temperature environments, the reliability of their additives is important. This is where the position of trunnion ball valve suppliers in Dubai turns fundamental. Suppliers act as the bridge between manufacturers and cease-users, making sure seamless get-right of entry to first-rate products.

Key attributes of top trunnion ball valve providers include:

Wide Range of Products: Suppliers in Dubai offer an intensive stock, catering to numerous business packages.

Expertise and Knowledge: They are ready with in-depth know-how approximately trunnion ball valves, assisting clients pick the right valve for his or her wishes.

After-Sales Support: Leading suppliers provide splendid after-income offerings, ensuring the valves characteristically over time.

Competitive Pricing: Dubai’s trunnion ball valve sellers make sure that remarkable valves are to be had at competitive charges, making them available to agencies of all sizes.

Why Choose Trunnion Ball Valves?

Trunnion ball valves are the favored desire for industries requiring sturdy and dependable drift control answers. Here’s why:

Enhanced Sealing: The trunnion design guarantees better sealing even under high strain, making these valves ideal for essential programs.

Durability: Made from corrosion-resistant materials, trunnion ball valves are constructed to face up to harsh environments.

Ease of Operation: These valves provide easy operation, lowering put-on and tear over time.

Low Maintenance: With fewer moving parts and enhanced sealing, trunnion ball valves require minimal preservation, ensuring cost and financial savings.

The trunnion ball valve manufacturers and providers in Dubai always meet the stringent needs of various industries, presenting products that ensure safety, efficiency, and reliability.

Instrument Fitting New Standards

Instrument Fittings is dedicated to revolutionising the fittings and furnishings area with the aid of providing products that combine high-quality with sustainability. As a relied-on provider of trunnion ball valves, we ensure our products meet global standards, catering to the various wishes of our customers.

Our understanding lies in delivering fittings that assure seamless connections, making sure your operations run smoothly. By setting new benchmarks within the industry, we intend to create lasting relationships with our customers while specializing in a sustainable future.

Choosing the Right Trunnion Ball Valve Dealer

Selecting the proper trunnion ball valve dealers is vital for making sure the achievement of your industrial operations. Here are some elements to bear in mind whilst choosing a supplier in Dubai:

Product Range: Ensure the supplier gives a huge range of trunnion ball valves to satisfy your unique desires.

Reputation: Opt for sellers with a strong popularity for delivering tremendous products and first-rate customer service.

Certifications: Check if the provider’s products are licensed to fulfill international standards.

Experience: Look for dealers with years of experience in offering trunnion ball valves to diverse industries.

The Future of Trunnion Ball Valves in Dubai-UAE

As industries in Dubai continue to expand, the call for dependable components like trunnion ball valves is about to grow. Manufacturers and suppliers in the place are constantly innovating to meet this call for, specializing in sustainable and efficient solutions.

Trunnion ball valve producers, providers, and sellers in Dubai are well-placed to cater to the evolving needs of industries, supplying products that make certain operational efficiency and safety.

Conclusion

Trunnion ball valves are a cornerstone of business operations, imparting reliable glide-managed solutions for a variety of packages. Dubai’s trunnion ball valve manufacturers, providers, and dealers have mounted themselves as dependent on companions for industries throughout the UAE, making sure of great performance in every product.

Whether you’re in oil and gas, petrochemicals, or water treatment, deciding on the proper provider or manufacturer is important for seamless operations. With Instrument Fittings, you may rest assured that you’re getting the quality-in-elegance additives designed to decorate your approaches even as focusing on sustainability and innovation.

trunnion ball valve manufacturers

#Trunnion ball valve suppliers#Trunnion ball valves dealers#Trunnion ball valves manufacturers#Instruments Fittings#trunnion ball valves

0 notes

Text

6000 Psi ss Instrument needle valves manufacturer in India

Needle Valves Manufacturer - 6000 Psi instrument Needle Valve, SS Needle Valves in India. Padlock is an Exporter and Supplier of types of Needle Valves in Mumbai, Chennai, Ahmedabad, Vadodara, Gujarat, Rajasthan, Bangalore, Delhi and Ghaziabad in India. The precision is achieved through the fine movement of the shaft. We provide you with quality needle valves that are of high-quality international standards.

0 notes