#valve instruments

Explore tagged Tumblr posts

Text

Band of 107th U.S. Colored Infantry at Fort Corcoran, Arlington, Va. holding saxhorn brass valve instruments. These saxhorns were the type of instruments played at the funeral of African Civil War hero and Captain Andre Cailloux. Many of the instruments were played over the shoulder to play to the army following the band. Instruments today face forward and bands can be in the middle or back of a procession.

Library of Congress

Smith, William Morris, photographer

Created / Published

1865

#african#afrakan#kemetic dreams#africans#brownskin#brown skin#afrakans#library of congress#william morris#1865#fort corocran#arlington#va#saxhorn brass#valve instruments#civil war heros#photographers#photographer

16 notes

·

View notes

Text

Understanding the Functionality of Valves in Instrumentation Systems |Arcellor controls

The tricky global of instrumentation structures is predicated on a silent orchestra of additives working collectively to exactly control and monitor business strategies. Among these key players are device valves, regularly small but robust in their features. Let's discover the crucial role instrument valves play in making sure the easy operation of diverse commercial packages.

Instrument Valves: Masters of Control

Instrument valves, also called instrumentation valves or gauge valves, are specialized valves designed for specific regulation of float charges, pressures, and course of fluids (liquids, gasses, or slurries) inside instrumentation structures. Unlike their larger cousins in commercial piping, instrument valves usually address smaller glide charges and require an excessive diploma of manipulation.

Key Features of Instrument Valves:

Smaller Size: Ranging from 1/eight inch to one inch in length, device valves are nicely-applicable for tricky managed loops inside instrumentation structures.

High Precision: Their design prioritizes precise management over on/off float or throttling (gradually adjusting) to go with the flow prices and pressures.

Leak-Tight Performance: Tight close-off abilities are essential to save you leakage and keep gadget integrity.

Applications of Instrument Valves:

Instrument valves find software in a huge variety of industries relying on precise process manage:

Chemical Processing: Regulating the float of chemicals in reactors, pipelines, and analytical systems.

Oil and Gas Production: Controlling glide rates and pressures at some point of drilling, refining, and transportation.

Power Generation: Maintaining the most reliable glide and stress of fluids in boilers, generators, and cooling structures.

Pharmaceutical Manufacturing: Ensuring sterile and precise go with the flow of fluids in production approaches.

Water Treatment Plants: Regulating glide prices of water and treatment chemicals.

Types of valves instruments:

A diverse variety of tool valves exist, each catering to unique manipulate wishes:

Needle Valves: Offer exceptional-tuned control over float quotes, perfect for low-flow applications.

Ball Valves: Provide short on/off waft management with a rotating ball detail.

Globe Valves: Offer correct throttling capabilities with a forestall-disc design.

Globe Valves: These valves are known for his or her tight close-off abilities and throttling ability.

Check Valves: Allow glide in one direction handiest, preventing backflow.

Butterfly Valves: Offer a fee-powerful alternative for on/off drift management in large traces.

Arcellor Controls: Your Partner in Industrial Control

Arcellor Controls, a globally recognized leader in business automation solutions, knows the crucial position of device valves in manner control. They provide a comprehensive range of amazing tool valves, catering to various industrial programs. Their valves are acknowledged for their:

Durability: Manufactured from high-grade substances to withstand harsh industrial environments.

Reliability: Built to perform consistently and dependably beneath disturbing situations.

Compliance: Adhere to industry requirements and specs for protection and performance.

Conclusion

By understanding the capability of tool valves, we benefit from a deeper appreciation for the problematic workings of instrumentation systems. These silent maestros make sure to manipulate over numerous commercial tactics, keeping them operating effectively and effectively. For dependable and awesome tool valves, Arcellor Controls may depend on associates in reaching the most desirable process manipulation.

#instrument valve#instrumentation valves#valves instruments#valve instruments#valves and instruments#valves in instrumentation

0 notes

Text

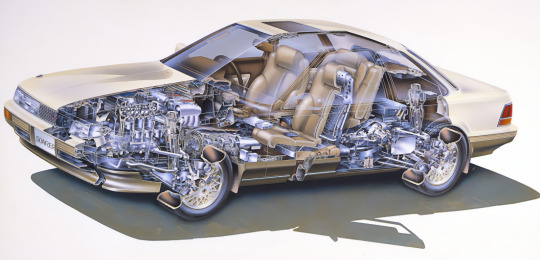

Toyota Soarer 3.0 GT-Limited, 1986. The second generation Z20 Soarer shared its platform with the A70 series Supra. It introduced the Electro Multi Vision digital vehicle information display. The 3.0 GT was powered by a DOHC 24 valve turbocharged straight 6

#Toyota#Toyota Soarer#Toyota Soarer Z20#1986#sports coupé#straight 6#24 valve#DOHC#digital instrumentation

311 notes

·

View notes

Text

Still Alive (Radio Mix) // Portal (2007)

#portal#portal (game)#still alive#playstation 3#xbox 360#PC#valve#game#instrumental#2007#oktaviaslabyrinth

36 notes

·

View notes

Text

They need to add more stupid attachment thingies to instruments. Instruments need to get scrunklier.

#-Loki#instruments#trombone#F trigger trombone#trumpet#euphonium#compensating valve euphonium#french horn#double french horn#triple french horn#Music

9 notes

·

View notes

Text

Understanding the meaning, applications, and advantages of control valves.

Control valves are devices that play an essential role in controlling and regulating the flow, pressure, and temperature in industrial processes and control systems. It is installed in the field-level area of the automation pyramid and connected to the control system and PLC through the PLC’s hardware. The global control valve consists of the body, actuator, Positioner, Valve trim, stem, and bonnet to prevent leakage. There are also the Gaskets and seals that are used when connecting the valve with other mechanical parts.

Control valves have many advantages such as Accurate Control of Process Parameters, Easy Automation Compatibility by integrating these items with the main Control systems (DCS and PLC), Energy saving and energy efficiency by optimizing the process condition and minimizing waste, maintaining safe operating conditions and increase process safety factors, Improve Process Efficiency and Increase Product Quality.

Control valves are used in many applications such as the Automotive Industry, Cement and steel, and Oil and Gas Industry, especially in gas valve trains, Renewable Energy, and HVAC Systems.

For full article check the following link:

For more articles about Renewable, Automation and Instrumentation, check the following link:

www.ecaico.com

#automation#instrumentation#renewable#control system#plc#sensors#pressure#gas valve#industrial valves

2 notes

·

View notes

Text

AHHHH THE SPIT. THE SPIT GOT ON ME.

hee...heugh...heeeughh...

#i HATE this instrument#i love tjis instrument :)#the spit valve...finger in the wrong spot...#AHHHHHH#trombone#band!!!!

5 notes

·

View notes

Text

Wait fuck I’m learning a wind instrument. The band kids fucking won.

#chit chat#DAMN it#all throughout high school the marching band kids wanted me to become one of them#and i said I’d never take up mouth instruments because they were gross#and now...#sigh#i do admit that i do find the harmonica a little gross and i do have to try and wipe it down after every exercise#but i don’t have to deal with spit valves or reeds or whatever the flutes do#so there is that#harmonica adventures

6 notes

·

View notes

Text

Shitty soldering job, right?

WRONG

That, my friends, is epoxy.

This one got filed under "haha NOPE" because the cost of the repair would not have been worth it. Epoxy does not melt and wipe off the way solder does; I would have had to basically chisel it off, and who knows how long that would have taken me.

#musical instrument repair#music#brass instrument#brasswind#musical instrument#cornet#epoxy#this is what we in the industry often refer to as a “dad fix”#because 9/10 times it is a kid's dad that does stuff like this#moms do it too but in less destructive ways#like telling the kid who forgot to bring valve oil to just use vegetable oil on the valves because oil is oil#less damaging but still a pain#it is well-intentioned but please just don't#or do since then I get paid to fix the problem

2 notes

·

View notes

Text

Whoever pioneered making a valve this shape should be shot

#euphonium#baritone#tuba#low brass#brass#brass instrument#valves#brass valves#valve instrument#2nd valve

4 notes

·

View notes

Text

I started renting a valve trombone from my school a few days ago and I can say, with full confidence, that it is now one of my favorite instruments. It’s like a trumpet, but bigger and lower and 1000 times cooler. The only thing cooler than it is the tuba, because nothing can compare to the tuba.

4 notes

·

View notes

Text

From my experience with the more cursed instruments I gotta say they all would make really great spell focuses for bards and even better magic wands adjacent things. The three most cursed instruments might have to be the Bassoon, Sarrusophone, and valved Trombone, each something that feels magical all differently...

#Sarrusophone#bassoon#wizard#wizard posting#band#valved Trombone#bard#musical instruments#having tried playing them all the Bassoon is the only one that i ended up buying

5 notes

·

View notes

Text

The Ultimate Guide to Different Types of Valves for Instruments |Arcellor controls

Presenting the final compendium on instrument valves, courtesy of Arcellor Controls India – your esteemed companion in precision engineering answers. As the most reliable producer, dealer, and exporter of instrumentation valves, we concentrate on offering a wide variety of valves instruments tailored to suit the needs of numerous industries and programs. Whether you're on the lookout for instrument valves, instrumentation valves, valves instruments, valve instruments, or valves and instruments, look no similarly than our comprehensive services.

Understanding Instrumentation Valves:

Instrumentation valves play a vital position in controlling the waft of beverages and gases inside commercial processes. They are designed to face up to excessive strain, extreme temperatures, and corrosive environments, making them indispensable additives across a huge range of industries consisting of oil and fuel, petrochemical, prescription drugs, and more.

Types of Instrumentation Valves we offer:

Needle Valves:

Needle valves are precision-engineered valves with a slender, tapered needle-like stem that permits for particular manage of flow costs.

Ideal for packages requiring quality modifications and throttling, needle valves are normally used in instrumentation systems and manner manage packages.

Ball Valves:

Ball valves characteristic a spherical disc (the "ball") with a hole thru the center that may be circled to control the glide of fluid.

Known for his or her reliability, sturdiness, and brief quarter-flip operation, ball valves are appropriate for both on/off and throttling programs.

Gate Valves:

Gate valves utilize a sliding gate or wedge mechanism to alter flow. When completely open, the gate creates a instantly-thru passage for maximum waft.

These valves are properly-desirable for packages requiring minimal restriction and low strain drop, along with in pipelines and isolation offerings.

Globe Valves:

Globe valves feature a disc that moves perpendicular to the drift to modify fluid control. The design offers precise throttling capabilities and first rate close-off characteristics.

Commonly used in applications requiring precise manage and mild pressure drops, inclusive of in steam structures and water remedy flora.

Manifold Valves:

Manifold valves combine multiple valves into a unmarried compact unit, making an allowance for the simultaneous manipulate of multiple procedure lines.

These valves streamline installation, lessen potential leak factors, and enhance gadget performance, making them perfect for device isolation and calibration packages.

Check Valves:

Check valves, also known as non-return valves, permit fluid to waft in a single path whilst preventing reverse glide.

Essential for preventing backflow and protecting gadget, take a look at valves find packages in pumps, compressors, and piping structures.

Monoflange Valves:

Monoflange valves integrate isolation and venting capabilities into a unmarried compact unit, disposing of the need for separate valves and fittings.

These valves reduce capability leak factors, keep space, and simplify set up and maintenance, making them best for instrument mounting and gauge isolation.

Choosing the Right Valve inside the Instrument

Selecting the right instrumentation valve to your challenge requires cautious attention of numerous elements, along with:

Operating situations (stress, temperature, media)

Flow necessities

Material compatibility

Size and connection specs

Environmental and protection rules

At Arcellor Controls India, we provide a comprehensive range of instrumentation valves designed to meet the highest industry standards and specs. Our valves are to be had in numerous sizes, materials, and configurations to match diverse utility requirements. Whether you want precision control with needle valves, dependable close-off with ball valves, or flexible overall performance with manifold valves, we've got the solution for you.

Final Words!

Comprehending the diverse categories of instrumentation valves and their respective applications is paramount to ensuring top overall performance and dependability in commercial operations. With our tremendous collection of pinnacle-tier instrument valves and profound proficiency in precision engineering, Arcellor Controls India emerges as your pass-to ally for all your valve instruments necessities. Reach out to us nowadays to explore how our complete variety of valves and instruments can empower you to gain extraordinary overall performance and performance for your endeavors.

#instrument valve#instrumentation valves#valves instruments#valve instruments#valves and instruments

0 notes

Text

Trunnion ball valve suppliers & manufacturers in Dubai, UAE | Instruments Fittings

Dubai, the thriving business hub of the UAE, is home to a wide variety of industries requiring awesome components to maintain their operations. Among the critical components for diverse commercial applications are trunnion ball valves. These valves are designed for durability, performance, and reliability, making them vital in industries that include oil and gas, petrochemicals, water treatment, and production. This blog explores the leading trunnion ball valve providers, sellers, and manufacturers in Dubai-UAE, losing mild on why these valves are a favored preference for crucial operations.

What Are Trunnion Ball Valves?

Trunnion ball valves are specialized forms of ball valves that characterize a pivot or trunnion to aid the ball inside the valve. Unlike preferred ball valves, in which the ball is free to move, trunnion ball valves have a mechanical anchoring device that enhances their operational performance. This design is specifically useful for managing high-stress systems as it guarantees higher sealing, reduced put-on, and longer provider lifestyles.

The versatility and robust design of trunnion ball valves lead them to be perfect for traumatic programs in industries wherein reliability is non-negotiable. Whether it’s coping with the drift of oil and fuel or coping with corrosive chemicals inside the petrochemical area, trunnion ball valves providers in Dubai offer products that supply top-notch performance.

Leading Trunnion Ball Valve Manufacturers in Dubai-UAE

Dubai’s commercial landscape is exceedingly competitive, and corporations rely upon quality products to preserve their aspect. Trusted trunnion ball valve producers inside the region make certain their valves meet the very best standards of durability and overall performance. Here are a few key motives why deciding on local manufacturers advantages businesses:

Customised Solutions: Manufacturers in Dubai apprehend the precise demands of the location’s industries and provide tailored trunnion ball valves to meet precise desires.

High-Quality Standards: With a dedication to excellence, Dubai-primarily based trunnion ball valve manufacturers ensure their products adhere to global satisfactory standards.

Faster Turnaround: Choosing neighborhood manufacturers reduces delivery instances, making sure that organizations face minimal downtime.

Technical Support: Manufacturers in Dubai offer sturdy technical assistance, providing steerage on valve choice and renovation.

At Instrument Fittings, our aim is to offer pinnacle-notch additives, together with trunnion ball valves, that set new benchmarks for quality and sustainability within the fittings and fasteners industry.

Reliable Trunnion Ball Valve Suppliers in Dubai-UAE

For industries working in excessive stress and high-temperature environments, the reliability of their additives is important. This is where the position of trunnion ball valve suppliers in Dubai turns fundamental. Suppliers act as the bridge between manufacturers and cease-users, making sure seamless get-right of entry to first-rate products.

Key attributes of top trunnion ball valve providers include:

Wide Range of Products: Suppliers in Dubai offer an intensive stock, catering to numerous business packages.

Expertise and Knowledge: They are ready with in-depth know-how approximately trunnion ball valves, assisting clients pick the right valve for his or her wishes.

After-Sales Support: Leading suppliers provide splendid after-income offerings, ensuring the valves characteristically over time.

Competitive Pricing: Dubai’s trunnion ball valve sellers make sure that remarkable valves are to be had at competitive charges, making them available to agencies of all sizes.

Why Choose Trunnion Ball Valves?

Trunnion ball valves are the favored desire for industries requiring sturdy and dependable drift control answers. Here’s why:

Enhanced Sealing: The trunnion design guarantees better sealing even under high strain, making these valves ideal for essential programs.

Durability: Made from corrosion-resistant materials, trunnion ball valves are constructed to face up to harsh environments.

Ease of Operation: These valves provide easy operation, lowering put-on and tear over time.

Low Maintenance: With fewer moving parts and enhanced sealing, trunnion ball valves require minimal preservation, ensuring cost and financial savings.

The trunnion ball valve manufacturers and providers in Dubai always meet the stringent needs of various industries, presenting products that ensure safety, efficiency, and reliability.

Instrument Fitting New Standards

Instrument Fittings is dedicated to revolutionising the fittings and furnishings area with the aid of providing products that combine high-quality with sustainability. As a relied-on provider of trunnion ball valves, we ensure our products meet global standards, catering to the various wishes of our customers.

Our understanding lies in delivering fittings that assure seamless connections, making sure your operations run smoothly. By setting new benchmarks within the industry, we intend to create lasting relationships with our customers while specializing in a sustainable future.

Choosing the Right Trunnion Ball Valve Dealer

Selecting the proper trunnion ball valve dealers is vital for making sure the achievement of your industrial operations. Here are some elements to bear in mind whilst choosing a supplier in Dubai:

Product Range: Ensure the supplier gives a huge range of trunnion ball valves to satisfy your unique desires.

Reputation: Opt for sellers with a strong popularity for delivering tremendous products and first-rate customer service.

Certifications: Check if the provider’s products are licensed to fulfill international standards.

Experience: Look for dealers with years of experience in offering trunnion ball valves to diverse industries.

The Future of Trunnion Ball Valves in Dubai-UAE

As industries in Dubai continue to expand, the call for dependable components like trunnion ball valves is about to grow. Manufacturers and suppliers in the place are constantly innovating to meet this call for, specializing in sustainable and efficient solutions.

Trunnion ball valve producers, providers, and sellers in Dubai are well-placed to cater to the evolving needs of industries, supplying products that make certain operational efficiency and safety.

Conclusion

Trunnion ball valves are a cornerstone of business operations, imparting reliable glide-managed solutions for a variety of packages. Dubai’s trunnion ball valve manufacturers, providers, and dealers have mounted themselves as dependent on companions for industries throughout the UAE, making sure of great performance in every product.

Whether you’re in oil and gas, petrochemicals, or water treatment, deciding on the proper provider or manufacturer is important for seamless operations. With Instrument Fittings, you may rest assured that you’re getting the quality-in-elegance additives designed to decorate your approaches even as focusing on sustainability and innovation.

trunnion ball valve manufacturers

#Trunnion ball valve suppliers#Trunnion ball valves dealers#Trunnion ball valves manufacturers#Instruments Fittings#trunnion ball valves

0 notes

Text

6000 Psi ss Instrument needle valves manufacturer in India

Needle Valves Manufacturer - 6000 Psi instrument Needle Valve, SS Needle Valves in India. Padlock is an Exporter and Supplier of types of Needle Valves in Mumbai, Chennai, Ahmedabad, Vadodara, Gujarat, Rajasthan, Bangalore, Delhi and Ghaziabad in India. The precision is achieved through the fine movement of the shaft. We provide you with quality needle valves that are of high-quality international standards.

0 notes

Text

BAXCELL Instrument Valves & Fittings

BAXCELL Instrument Valves & Fittings Pvt. Ltd. is an ISO 9001:2008 certified privately held share holding company engaged in Design/Development, Manufacture & Exports of Instrumentation Valves, Valve Manifolds, Compression Tube Fittings, Pipe Fittings & Instrumentation related accessories. BAXCELL Compression Tube Fittings are completely interchangeable with similar fittings of other manufacturers like Parker, Swagelok, Hoke, Hylok, Hamlet etc.

1 note

·

View note